Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure

Abstract

1. Introduction

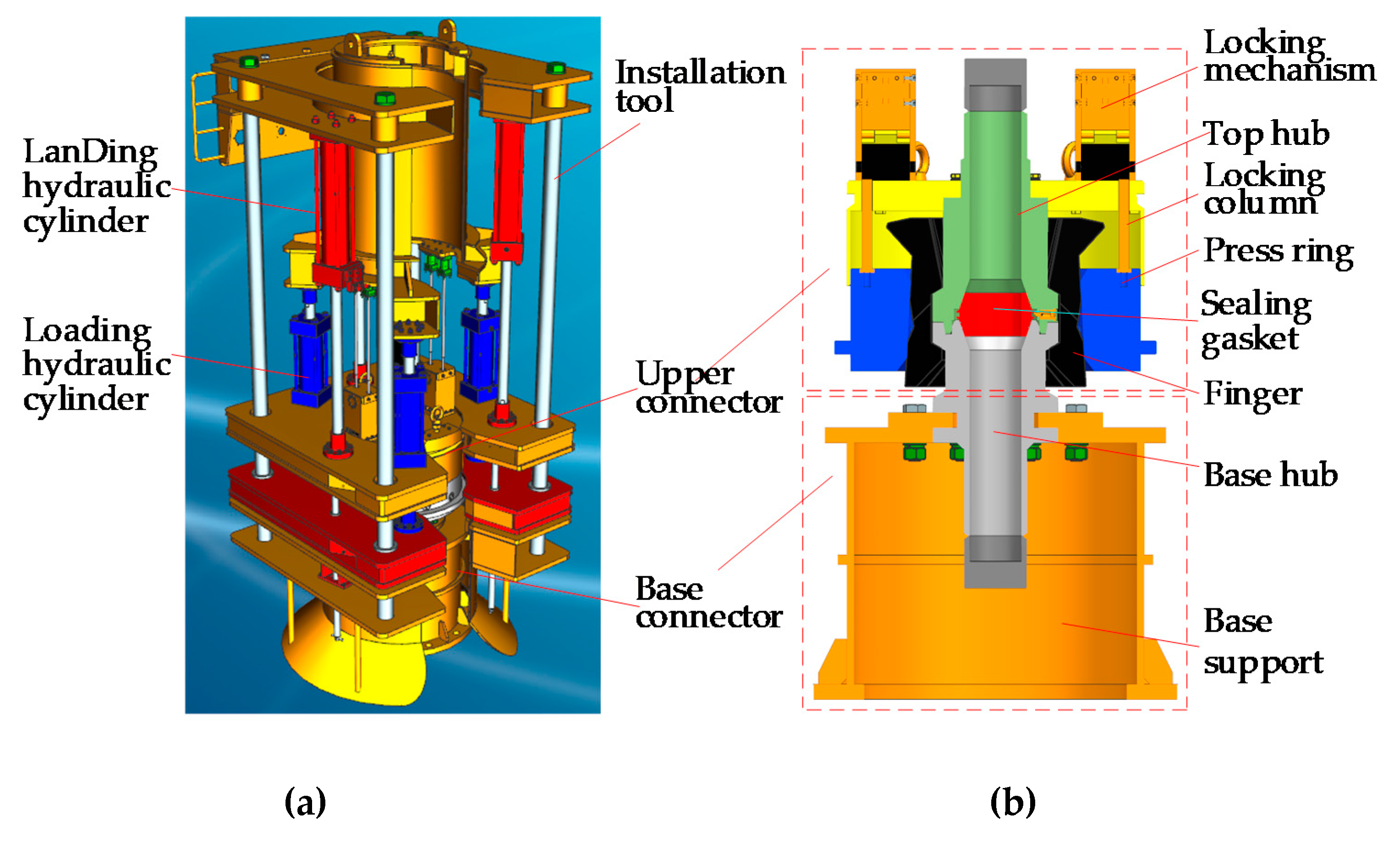

2. Subsea Collet Connector Structure

3. Mechanical Study on Lens-Type Sealing Structure of Subsea Collet Connector

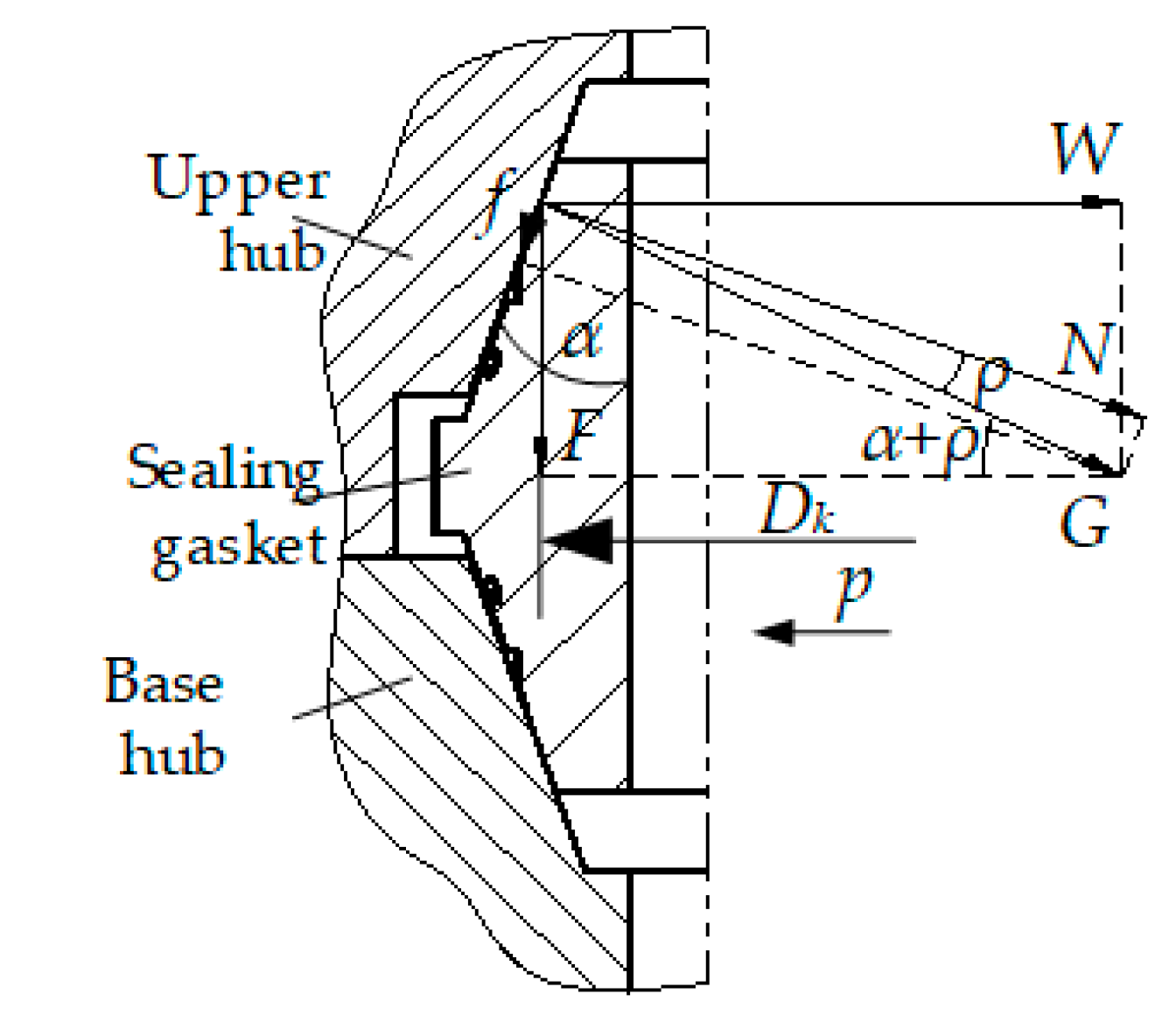

3.1. Analysis of Axial Preload of Sealing Structure

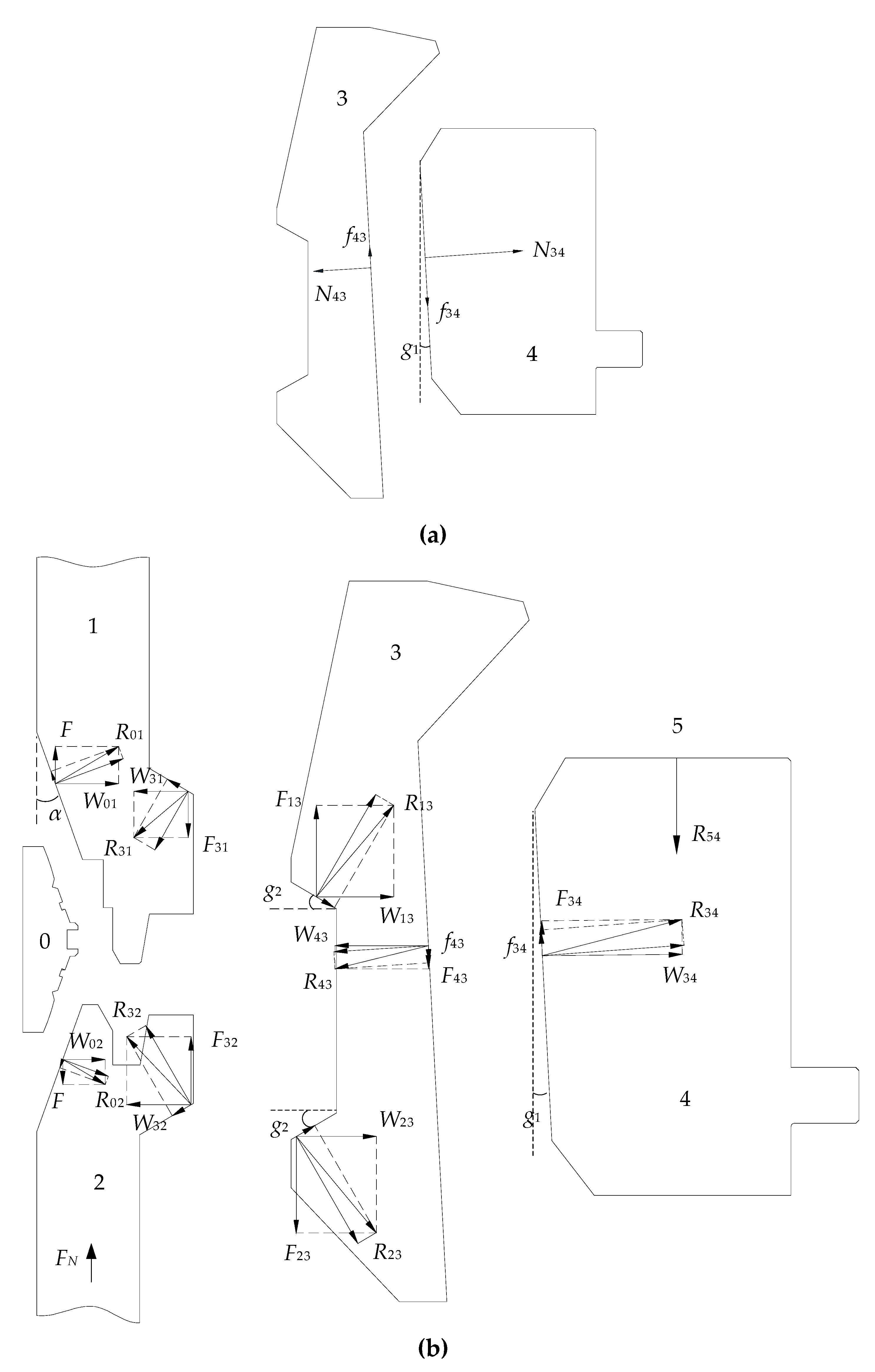

3.2. Analysis of Self-Locking Ability of the Subsea Collet Connector

3.3. Analysis of Loading Force of The Connector Sealing Structure

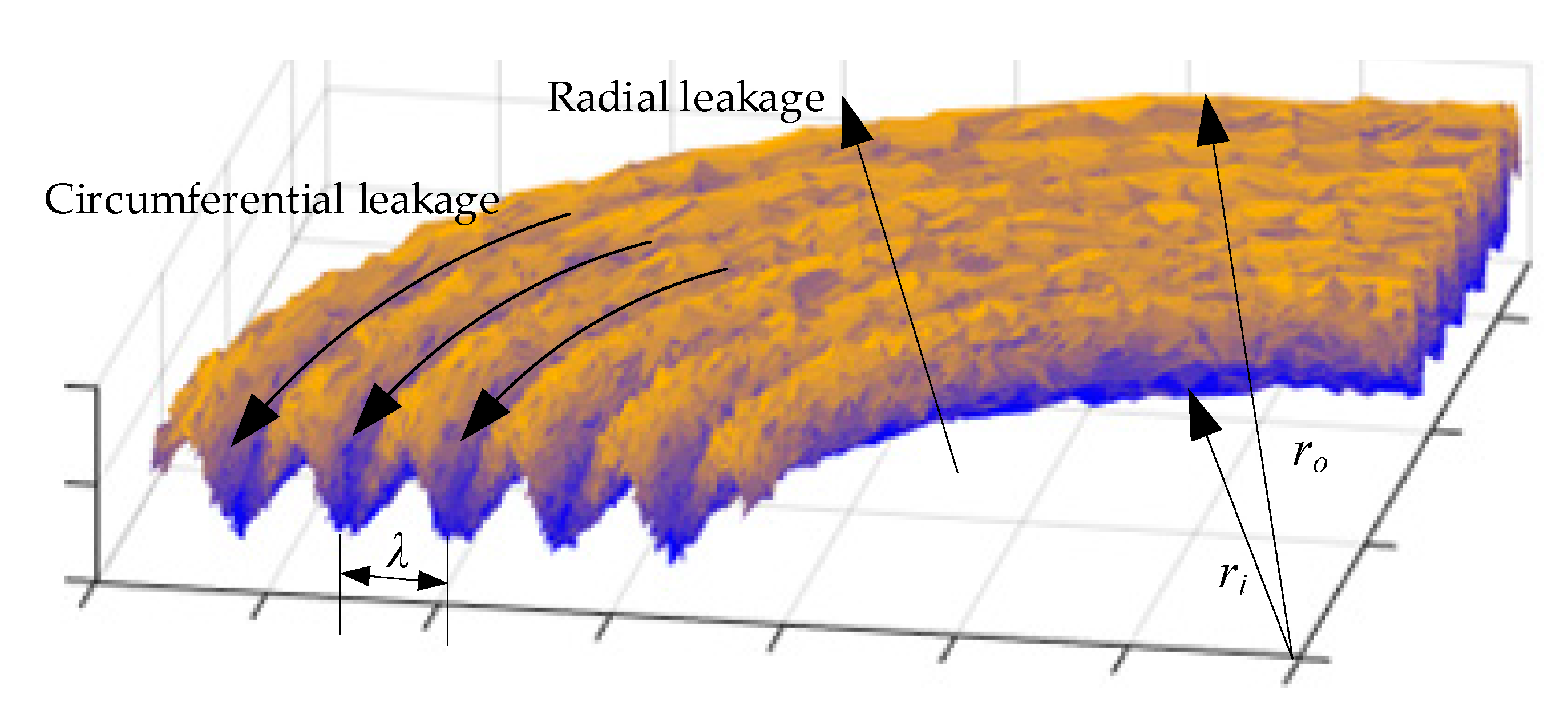

4. Analysis of Leakage Characteristics of Connector Lens-Type Sealing Gasket

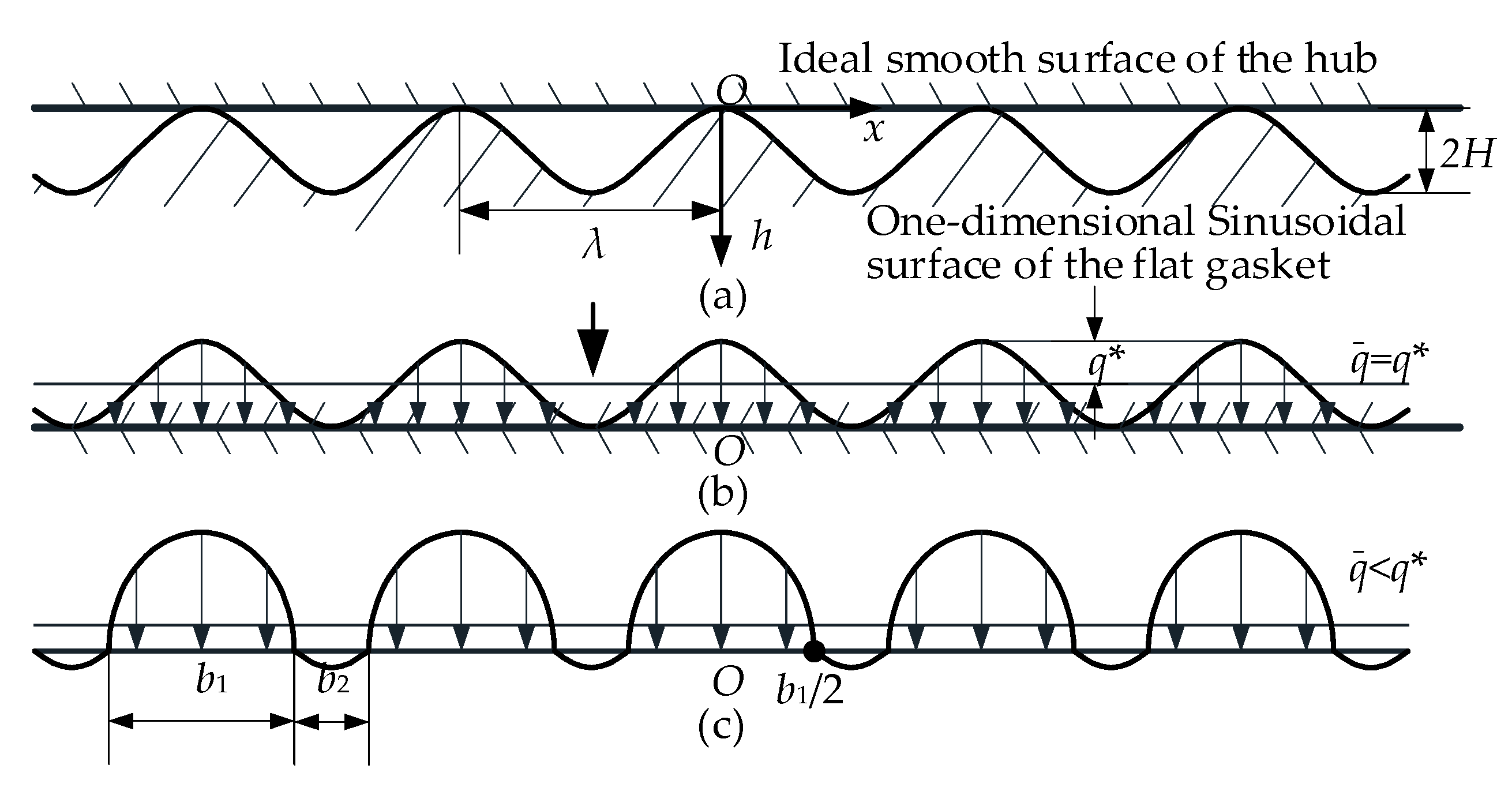

4.1. Microscopic Sealing Contact Process of Turning Surface

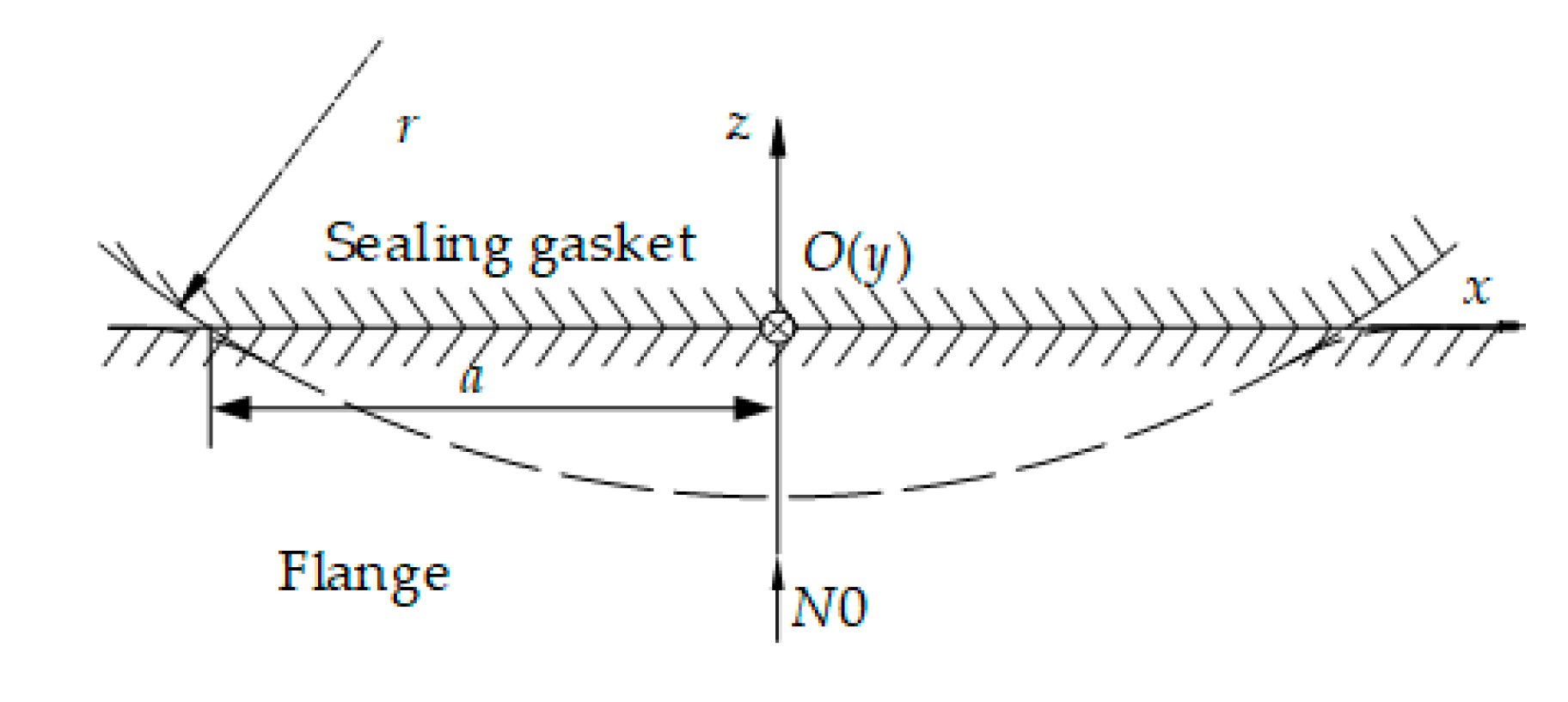

4.2. Microscopic Contact Analysis of Metal Flat Gasket

4.3. Micro-Contact Analysis of Lens-Type Sealing Gasket

4.4. Sealing Leakage Rate Analysis

4.4.1. Leakage Analysis of Metal Flat Gasket

4.4.2. Leakage Analysis of Lens-Type Sealing Gasket

Theoretical equation

Leakage rate calculation

5. Hydrostatic Pressure Experiment and Analysis

5.1. Experimental System

- Connect the top connector, sealing gasket, and base connector with the running tool. Adjust the thrust of the loading hydraulic cylinder applied on the press ring by controlling its working pressure. Then record the thrust force of three loaded hydraulic cylinders.

- The loading hydraulic cylinders on the running tool stops loading and returns to the original position.

- Connect the hydraulic pipelines, fill the inner cavity of the connector with water, and exhaust the air from the cavity and the hydraulic pipelines.

- Press into the connector cavity until the pressure is no longer rising and record the pressure gauge value.

- Hold the pressure for 15 min (hold the pressure for 60 min when it is close to 34.5 MPa and 1.5 times of the working pressure, 51.75 MPa), and record the pressure gauge value after holding the pressure.

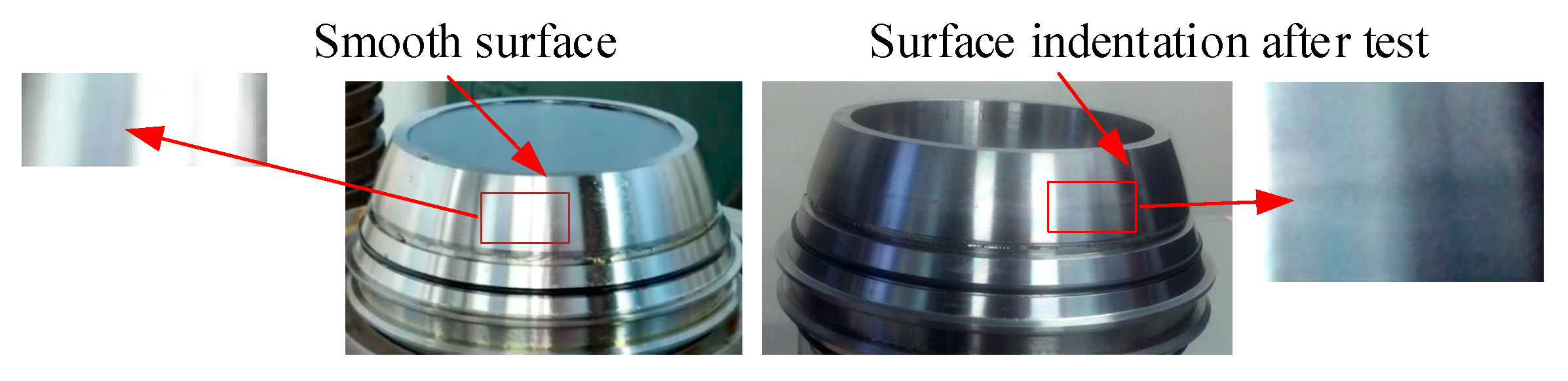

- Use the running tool to open the connector, remove the sealing gasket, use the cursor caliper to measure the sealing width of the sealing sphere, record the value.

- Repeat steps 1–6 until the connector can seal 1.5 times of the working pressure (51.75 MPa).

- Replace the lens-type sealing gasket with a new one, and repeat steps 1–8 twice.

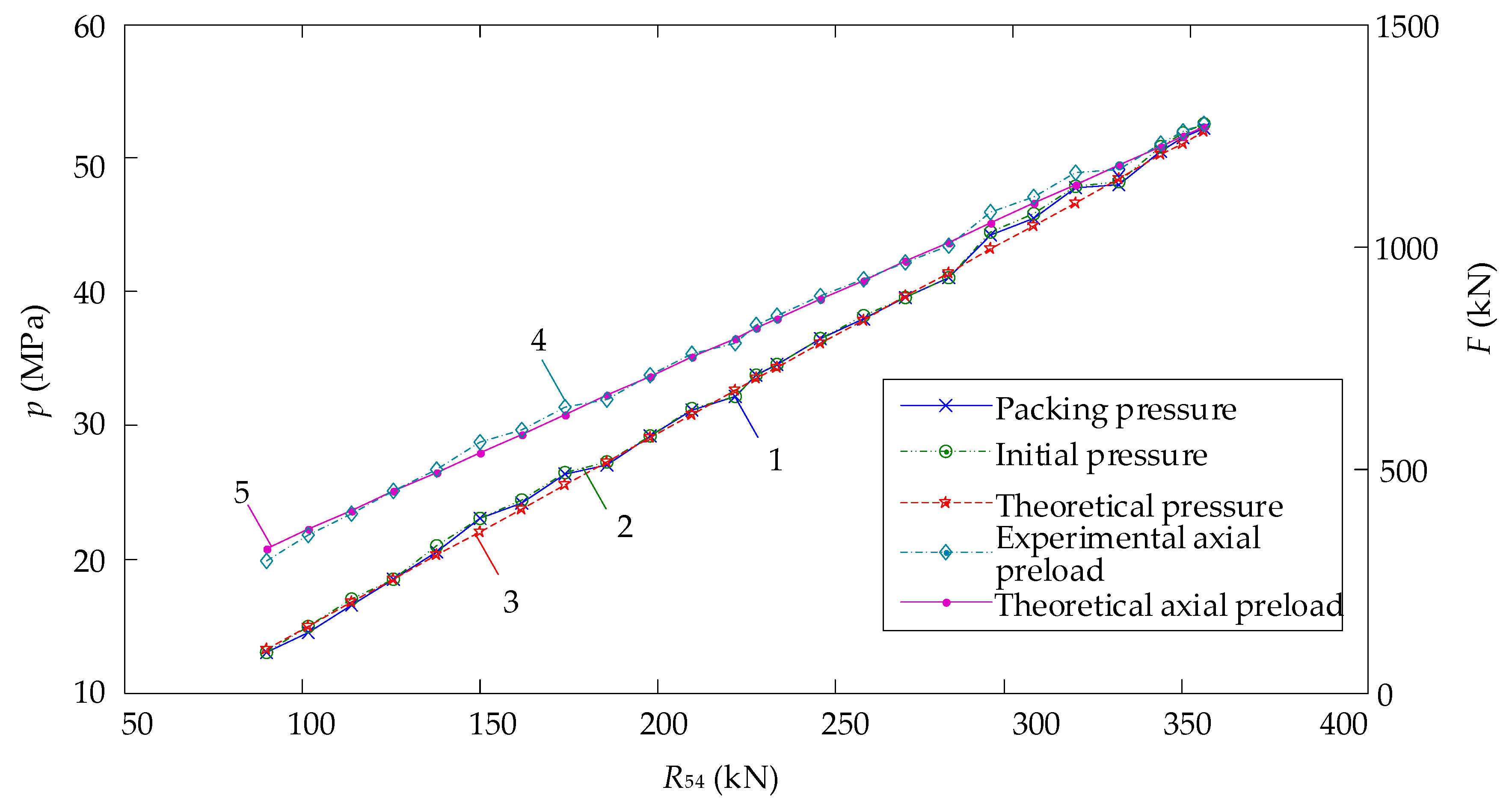

5.2. Experiment Analysis

5.2.1. Experimental results of loading hydraulic cylinder thrust

5.2.2. Experimental results of sealing width

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, Y.; Bai, Q. Subsea Pipelines and Risers, 1st ed.; Elsevier Science Ltd: Kidlington, UK, 2005; pp. 3–19. [Google Scholar]

- Zhang, J.; Gao, J.; Lin, X. Analysis of Connector Contact Failure. IEICE Trans. Electron. 2003, 102, 945–952. [Google Scholar]

- Payne, J.R.; Schneider, R.W. Comparison of proposed ASME rules for bolted flanged joints. In Proceedings of the International Conference on Pressure Vessel Technology, Montreal, QC, Canada, 21–26 July 1996; pp. 147–167. [Google Scholar]

- Feng, X.; Gu, B. Research on Leakage Model of Metallic Gasket Seal. Lubr. Eng. 2006, 31, 83–85. [Google Scholar]

- Feng, X.; Gu, B. Experimental Research on Leakage Model of Metallic Gasket Seals. Lubr. Eng. 2008, 33, 48–50. [Google Scholar]

- Zhao, H.; Chen, R.; Luo, X.; Duan, M.; Lu, Y.; Fu, G.; Tian, H.; Ye, D. Metal Sealing Performance of Subsea X-tree Wellhead Connector Sealer. Chin. J. Mech. Eng. 2015, 649–656. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, L.; Guan, Y.; Yao, S.; Li, S. Static metal sealing mechanism of a subsea pipeline mechanical connector. Adv. Mech. Eng. 2016, 8, 1687814016654821. [Google Scholar] [CrossRef]

- Toshiyuki, S.; Kentaro, T.; Takashi, K.; Ryou, K. Finite Element Method Stress Analysis and Evaluation of the Sealing Performance in Box-Shape Flange Gasketed Connections Subjected to Internal Pressure. J. Press. Vess. Technol. ASME 2017, 139, 051202. [Google Scholar]

- Liu, Y.; Ji, A.; Li, Q.; Zhi, P.; Fan, X.; Xu, C. Finite element analysis on the sealing performance of the casing premium connection. Mach. Des. Manu. Eng. 2017, 46, 21–24. [Google Scholar]

- Yun, F.; Wang, L.; Yao, S.; Liu, J.; Liu, T.; Wang, R. Analytical and experimental study on sealing contact characteristics of subsea collet connectors. Adv. Mech. Eng. 2017, 9, 168781401770170. [Google Scholar] [CrossRef]

- Zhang, K.; Huang, H.; Duan, M.; Hong, Y.; Estefen, S.F. Theoretical investigation of the compression limits of sealing structures in complex load transferring between subsea connector components. J. Nat. Gas Sci. Eng. 2017, 44, 202–213. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Z.; Yao, S.; Guan, Y.; Li, S. Sealing Performance and Optimization of a Subsea Pipeline Mechanical Connector. Chin. J. Mech. Eng. 2018, 31, 18. [Google Scholar] [CrossRef]

- Shao, Y.; Yin, Y.; Du, S.; Xi, L. A Surface Connectivity-Based Approach for Leakage Channel Prediction in Static Sealing Interface. J. Tribol. 2019, 141, 062201. [Google Scholar] [CrossRef]

- Lutkiewicz, P.; Robertson, D.; Pulvino, M. Establishment of Industry Standard Flange Sealing Effectiveness Measure (Leakage Rate Based) Methodology. In Proceedings of the Pressure Vessels and Piping Conference, San Antonio, YX, USA, 14–19 July 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar]

- Wang, S.; Yao, X.; Yang, H. The heat conduction model and leakage characterization of the sealing interface. Int. J. Therm. Sci. 2019, 145, 106027. [Google Scholar] [CrossRef]

- Li, S.; Qian, C.; Li, S.; Li, Q.; Liao, H. Study of sealing mechanism of gas-liquid miscible backflow pumping seal. Tribol. Int. 2020, 142, 105974. [Google Scholar] [CrossRef]

- Wu, H.; Shen, S.; Chen, R.; Zhou, A. Three-dimensional numerical modelling on localised leakage in segmental lining of shield tunnels. Comput. Geotech. 2020, 122, 103549. [Google Scholar] [CrossRef]

- Zhu, H.; Li, D.; Pu, H.; Wang, L.; He, Y.; Bu, Y.; Che, D. Experimental and Numerical Investigations on the Local Direct Leakage Process of Rotary Regenerative Air Preheater. Appl. Sci. 2020, 10, 1523. [Google Scholar] [CrossRef]

- Menga, N. Rough frictional contact of elastic thin layers: The effect of geometrical coupling. Int. J. Solids Struct. 2019, 164, 212–220. [Google Scholar] [CrossRef]

- Menga, N.; Afferrante, L.; Demelio, G.P.; Carbone, G. Rough contact of sliding viscoelastic layers: Numerical calculations and theoretical predictions. Tribol. Int. 2018, 122, 67–75. [Google Scholar] [CrossRef]

- Rajeev, M.; Sheril, M.; Erik, H. Analysis of contact pressure distribution on 3-bolt self-energized connector seals. In Proceedings of the 2009 ASME Pressure Vessels and Piping Conference, Prague, Czech Republic, 26–30 July 2009; pp. 71–79. [Google Scholar]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987; pp. 12–119, 451–481. [Google Scholar]

- Valentin, L.P. Contact Mechanics and Friction: Physical Principles and Applications; Springer: Berlin/Heidelberg, Germany, 2010; pp. 30–74. [Google Scholar]

- Liu, P.; Zhao, H.; Huang, K.; Chen, Q. Research on normal contact stiffness of rough surface considering friction based on fractal theory. Appl. Surf. Sci. 2015, 349, 43–48. [Google Scholar] [CrossRef]

- Pan, W.; Li, X.; Wang, L.; Mu, J.; Yang, Z. A loading fractal prediction model developed for dry-friction rough joint surfaces considering elastic-plastic contact. Acta Mech. 2018, 229, 2149–2162. [Google Scholar] [CrossRef]

- Robbe-Valloire, F.; Prat, M. A model for face-turned surface microgeometry: Application to the analysis of metallic static seals. Wear 2008, 264, 980–989. [Google Scholar] [CrossRef]

- Letalleur, N.; Plouraboué, F.; Prat, M. Average flow model of rough surface lubrication: Flow factors for sinusoidal surfaces. J. Tribol. 2002, 124, 539–546. [Google Scholar] [CrossRef]

- Polycarpou, A.A.; Etsion, I. A model for the static sealing performance of compliant metallic gas seals including surface roughness and rarefaction effects. Tribol. Trans. 2000, 43, 237–244. [Google Scholar] [CrossRef]

- Liao, C.; Xu, X.; Fang, H.; Wang, H.; Man, M. A leakage model of metallic static seals based on micromorphology characteristics of turning flange surface. Ind. Lubr. Tribol. 2015, 67, 572–581. [Google Scholar] [CrossRef]

- Geoffroy, S.; Prat, M. On the leak through a spiral-groove metallic static ring gasket. J. Fluids Eng. 2004, 126, 48–54. [Google Scholar] [CrossRef]

- Karniadakis, G.; Beskok, A. Micro flows: Fundamentals and simulation. Appl. Mech. Rev. 2002, 55, B76. [Google Scholar] [CrossRef]

- Francois, R.V. Statistical analysis of asperities on a rough surface. Wear 2001, 249, 401–408. [Google Scholar]

- ISO21329. Petroleum and Natural Gas Industries—Pipeline Transportation Systems—Test Procedures for Mechanical Connectors; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- API SPEC 6A. Specification for Wellhead and Tree Equipment; American Petroleum Institute: Washington, DC, USA, 2018. [Google Scholar]

| Loading Times | R54 (kN) | Initial Pressure (MPa) | Packing Pressure (MPa) | Loading Times | R54 (kN) | Initial Pressure (MPa) | Packing Pressure (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 90 | 13.0 | 13.0 | 14 | 234 | 34.6 | 34.6 |

| 2 | 102 | 15.0 | 14.5 | 15 | 246 | 36.5 | 36.5 |

| 3 | 114 | 17.0 | 16.5 | 16 | 258 | 38.2 | 38.0 |

| 4 | 126 | 18.5 | 18.5 | 17 | 270 | 39.5 | 39.5 |

| 5 | 138 | 21.0 | 20.5 | 18 | 282 | 41.0 | 41.0 |

| 6 | 150 | 23.0 | 23.0 | 19 | 294 | 44.5 | 44.2 |

| 7 | 162 | 24.4 | 24.2 | 20 | 306 | 45.8 | 45.5 |

| 8 | 174 | 26.5 | 26.3 | 21 | 318 | 47.9 | 47.8 |

| 9 | 186 | 27.3 | 27.0 | 22 | 330 | 48.2 | 48.0 |

| 10 | 198 | 29.2 | 29.2 | 23 | 342 | 50.8 | 50.5 |

| 11 | 210 | 31.2 | 31.1 | 24 | 348 | 51.8 | 51.5 |

| 12 | 222 | 32.1 | 32.1 | 25 | 354 | 52.5 | 52.2 |

| 13 | 228 | 33.8 | 33.8 |

| Axial Preload (kN) | Pressure (MPa) | Experimental Sealing Width (mm) | Analytical Sealing Width (mm) | Difference (%) |

|---|---|---|---|---|

| 294.00 | 13.0 | 2.74 | 3.30 | 17.09 |

| 354.13 | 14.5 | 3.13 | 3.51 | 10.86 |

| 402.98 | 16.5 | 3.44 | 3.77 | 8.85 |

| 452.00 | 18.5 | 3.78 | 4.02 | 6.09 |

| 500.67 | 20.5 | 3.98 | 4.27 | 6.70 |

| 561.73 | 23.0 | 4.21 | 4.55 | 7.56 |

| 591.04 | 24.2 | 4.39 | 4.69 | 6.38 |

| 642.33 | 26.3 | 4.66 | 4.92 | 5.26 |

| 659.42 | 27.0 | 4.68 | 4.99 | 6.28 |

| 713.15 | 29.2 | 4.96 | 5.23 | 5.08 |

| 759.56 | 31.1 | 5.13 | 5.42 | 5.36 |

| 783.98 | 32.1 | 5.21 | 5.52 | 5.64 |

| 825.50 | 33.8 | 5.33 | 5.69 | 6.33 |

| 845.04 | 34.6 | 5.57 | 5.77 | 3.45 |

| 891.44 | 36.5 | 5.69 | 5.95 | 4.42 |

| 928.08 | 38.0 | 5.84 | 6.1 | 4.21 |

| 964.71 | 39.5 | 6.01 | 6.24 | 3.65 |

| 1001.34 | 41.0 | 6.09 | 6.38 | 4.51 |

| 1079.50 | 44.2 | 6.18 | 6.67 | 7.34 |

| 1111.25 | 45.5 | 6.41 | 6.79 | 5.55 |

| 1167.42 | 47.8 | 6.67 | 6.99 | 4.58 |

| 1172.31 | 48.0 | 6.70 | 7.01 | 4.39 |

| 1233.36 | 50.5 | 6.99 | 7.23 | 3.26 |

| 1257.79 | 51.5 | 7.01 | 7.31 | 4.13 |

| 1274.88 | 52.2 | 7.09 | 7.37 | 3.83 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, F.; Wang, G.; Yan, Z.; Jia, P.; Xu, X.; Wang, L.; Sun, H.; Liu, W. Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure. J. Mar. Sci. Eng. 2020, 8, 444. https://doi.org/10.3390/jmse8060444

Yun F, Wang G, Yan Z, Jia P, Xu X, Wang L, Sun H, Liu W. Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure. Journal of Marine Science and Engineering. 2020; 8(6):444. https://doi.org/10.3390/jmse8060444

Chicago/Turabian StyleYun, Feihong, Gang Wang, Zheping Yan, Peng Jia, Xiujun Xu, Liquan Wang, Haiting Sun, and Weifeng Liu. 2020. "Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure" Journal of Marine Science and Engineering 8, no. 6: 444. https://doi.org/10.3390/jmse8060444

APA StyleYun, F., Wang, G., Yan, Z., Jia, P., Xu, X., Wang, L., Sun, H., & Liu, W. (2020). Analysis of Sealing and Leakage Performance of the Subsea Collet Connector with Lens-Type Sealing Structure. Journal of Marine Science and Engineering, 8(6), 444. https://doi.org/10.3390/jmse8060444