Structural Safety Analysis for an Oscillating Water Column Wave Power Conversion System Installed in Caisson Structure

Abstract

:1. Introduction

1.1. Development of an Oscillating Water Column (OWC) Wave Energy Converter

1.2. Objectives of the Study

2. Analytical Model and Environmental Forces

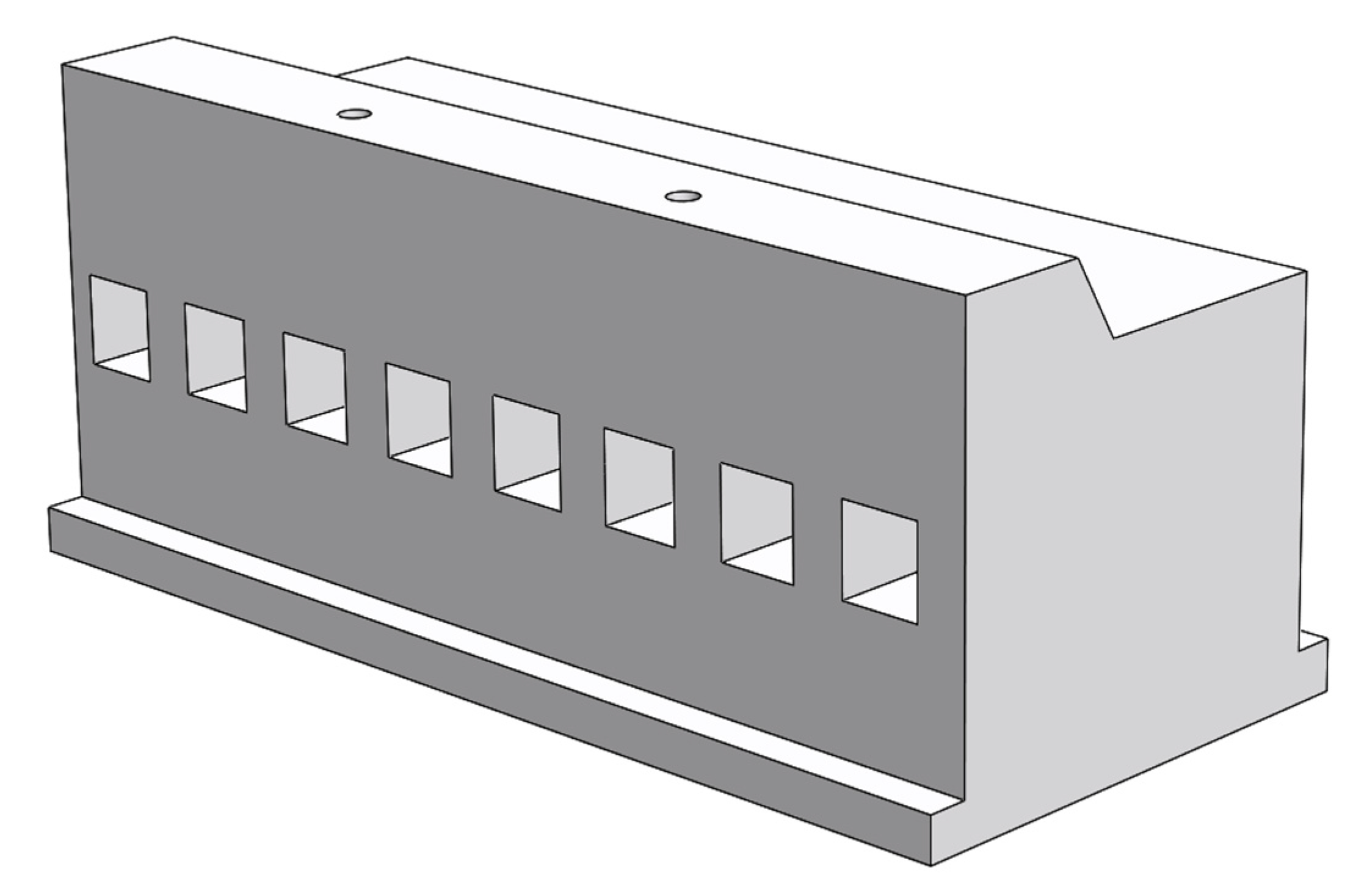

2.1. Analytical Model of the Structure

2.2. Environmental Forces

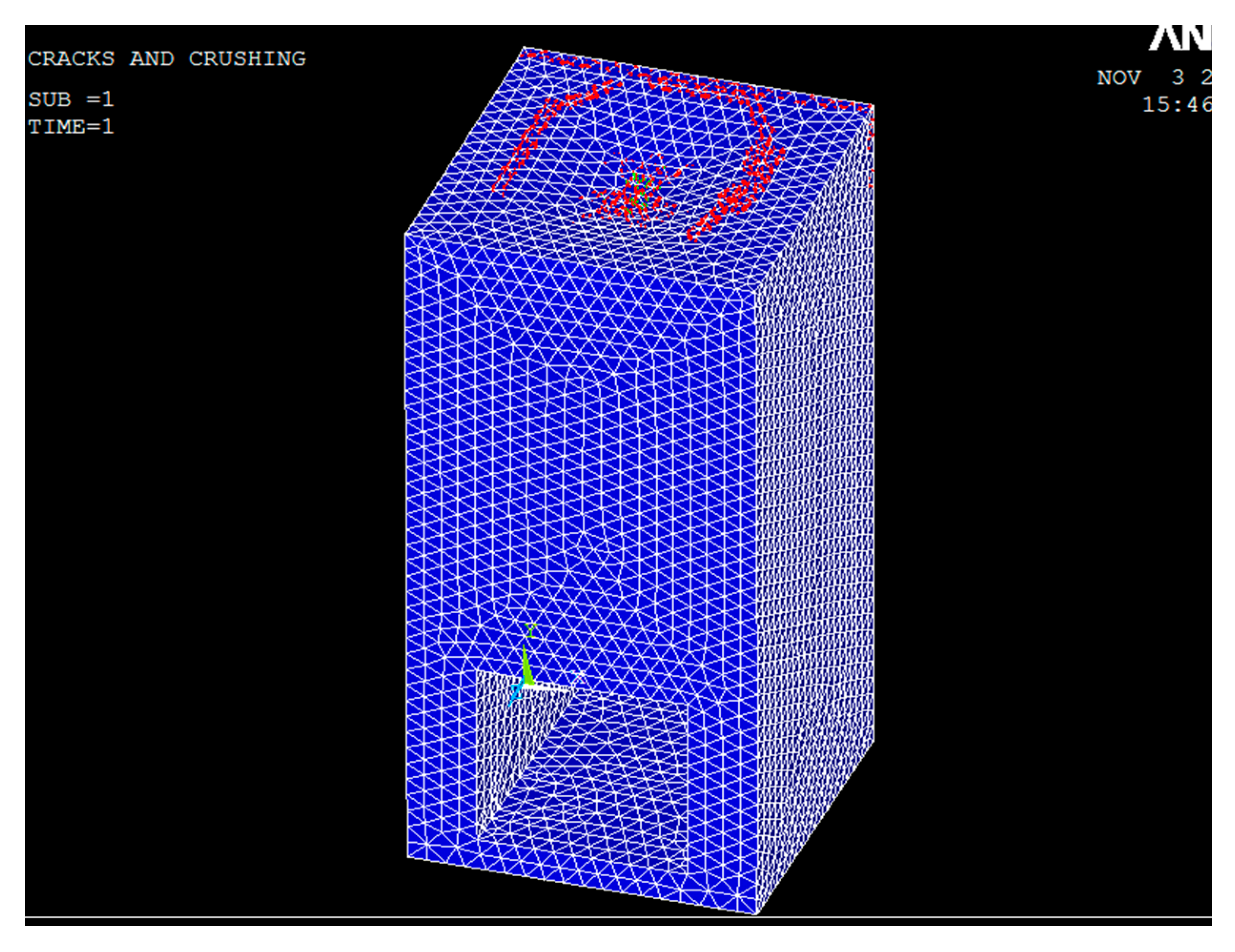

3. Mechanic Analysis of Structural Safety

3.1. Global Structural Analysis

3.2. Structural Analysis for the Chamber of OWC Converter

3.2.1. Transverse Deformation for the front Curtain-Wall

3.2.2. Transverse Deformation for the Top Ceiling-Slab

3.2.3. Transverse Deformation for the Side-Wall

3.2.4. Discussions on the Deformation of Chamber Members

4. Evaluation of Air-pressure in the Chamber during the Operation of Wave Energy Conversion

4.1. Theorem of Fluid Mechanics Applied in the Study

4.2. Analysis of Wave-Induced Air Pressure in the Chamber

5. Conclusions

- (1)

- According to the analysis for the structural safety of this study, for the whole structural safety that included both the caisson breakwater and attached OWC system, the deformations induced from the design-wave, which was based on a storm-wave of 50-year return period, was under the capacity of the concrete material.

- (2)

- The second part analysis of the structural safety, particularly focused on the air-chamber of the OWC converter, where the maximum deformation occurred transversely at the ceiling-slab of the air-chamber for the OWC converter, whereas the front curtain wall subjected to wave-impact directly would also deform greatly, but not so significantly. The developed strains for both the ceiling-slab and the front curtain-wall were well over the strain limit for a concrete material and therefore, when the chamber structure was subjected to a wave close to the designed storm-wave as utilized in the analysis, a major damage may occur on both the ceiling-slab and the front curtain-wall.

- (3)

- According to the study of the air-pressure induced by the heave motion of the waves in the chamber, the pressure was small and would not significantly influence the structural safety of the OWC chamber attached to a caisson structure.

- (4)

- It is concluded that when the OWC is attached to a traditional breakwater structure, the location will be an important factor to decide the performance of energy converting efficiency. To design an OWC structure that may sustain a storm wave of 50-year return period could be expensive. In terms of economic consideration, as long as the damage of the associated structure would not affect the structural safety and operation of the main structure, a design-wave based on a storm of shorter return period should be considered.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Goda, Y.; Nakada, H.; Ohneda, H.; Suzuki, M.; Takahashi, S.; Shikamori, M. Results of field experiment of a wave power extracting caisson breakwater. Proceedings Ocean. Dev. 1991, 7, 143–148. [Google Scholar] [CrossRef] [Green Version]

- Goda, Y.; Shinda, T.; Chiyama, S.; Ohneda, H.; Suzuki, M.; Takahashi, S.; Shikamori, M.; Takaki, Y. Experiment of a wave power extracting caisson breakwater. Proceedings Ocean. Dev. 1989, 5, 1–6. [Google Scholar]

- Spanos, P.D.; Strati, F.M.; Malara, G.; Arena, F. An approach for non-linear stochastic analysis of U-shaped OWC wave energy converters. Probabilistic Eng. Mech. 2018, 54, 44–52. [Google Scholar] [CrossRef]

- Boccotti, P. Comparison between a U-OWC and a conventional OWC. Ocean. Eng. 2005, 34, 799–805. [Google Scholar] [CrossRef]

- Sheng, W. Power performance of BBDB OWC wave energy converter. Renew. Energy 2019, 132, 709–722. [Google Scholar] [CrossRef]

- Ansarifard, N.; Fleming, A.; Henderson, A.; Kianejad, S.S.; Orphin, J. Comparison of inflow and outflow radial air turbines in vented and bidirectional OWC wave energy converters. Energy 2019, 1821, 159–176. [Google Scholar] [CrossRef]

- Elhanafi, A.; Kim, C.J. Experimental and numerical investigation on wave height and power take–off damping effects on the hydrodynamic performance of an offshore–stationary OWC wave energy converter. Renew. Energy 2018, 125, 518–528. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L.; Elsafti, H.; Oumeraci, H. Evaluation of air compressibility effects on the performance of fixed OWC wave energy converters using CFD modelling. Renew. Energy 2018, 119, 741–753. [Google Scholar] [CrossRef]

- Pawitan, K.A.; Dimakopoulos, A.S.; Vicinanza, D.; Allsop, W.; Bruce, T. A loading model for an OWC caisson based upon large-scale measurements. Coast. Eng. 2019, 145, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Viviano, A.; Musumeci, R.E.; Vicinanza, D.; Foti, E. Pressures induced by regular waves on a large scale OWC. Coast. Eng. 2019, 152, 103528. [Google Scholar] [CrossRef]

- Garrido, A.J.; Otaola, E.; Garrido, I.; Lekube, J.; Maseda, F.J.; Liria, P.; Mader, J. Mathematical modeling of fluid and structure interaction in ocean engineering. Ocean. Eng. 2015, 2015, 727982. [Google Scholar] [CrossRef] [Green Version]

- Medina-Lopez, E.; Allsop, W.; Dimakopoulos, A.; Bruce, T. Conjectures on the failure of the OWC breakwater at Mutriku. In Proceedings of the Conference Coastal Structures, Boston, MA, USA, 9–11 September 2015. [Google Scholar]

- Benrugeig, P.; Murphy, J. Modelling air compressibility in OWC devices with deformable air chambers. J. Mar. Sci. Eng. 2019, 7, 268. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.-S.; Nam, B.W.; Kim, K.-H.; Park, S.; Shin, S.H.; Hong, K. A numerical study on hydrodynamic performance of an inclined OWC wave energy converter with nonlinear turbine–chamber interaction based on 3D potential flow. J. Mar. Sci. Eng. 2020, 8, 176. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Xu, C.; Huang, S. A CFD simulation of wave loads on a pile-type oscillating-water-column device. J. Hydrodyn. 2019, 31, 41–49. [Google Scholar] [CrossRef]

- Ambühl, S.; Sørensen, J.D. Sensitivity of risk-based maintenance planning of offshore wind turbine farms. Energies 2017, 10, 505. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.H.; Chen, C.-H. Parametric study for an oscillating water column wave energy conversion system installed on a breakwater. Energies 2020, 13, 1926. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.H.; Chiu, Y.-F.; Lin, C.-Y.; Chen, C.-H.; Huang, M.-H. 2016, Parametric study on a caisson based OWC wave energy converting system. World J. Eng. Technol. 2016, 4, 3D. [Google Scholar]

- Goda, Y. Random Seas and Design of Maritime Structures; Tokyo University Press: Tokyo, Japan, 1985. [Google Scholar]

- ACI 357.3R-14. Guide for Design and Construction of Waterfront and Coastal Concrete Marine Structures. ACI Committee 357. 2014. Available online: https://www.concrete.org/Portals/0/Files/PDF/Previews/357_3R_14preview.pdf (accessed on 2 July 2014).

- Sarpkaya, T.; Isaacson, M. Mechanics of Wave forces on Offshore Structures; Van Nostrand Reinhold Company: New York, NY, USA, 1981. [Google Scholar]

- Milne-Thomson, L.M. Theoretical Hydrodynamics; The MacMillan Co.: Toronto, ON, Canada; Macmillan: New York, NY, USA, 1960. [Google Scholar]

- Chiu, Y.-F.; Lee, H.H.; Lin, C.-Y.; Chang, F.-T. Study on a Caisson Based OWC Wave Energy Converting System. 2014. Available online: http://www.hcirp.jornal.wjet (accessed on 27 July 2015).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.H.; Wu, T.-Y.; Lin, C.-Y.; Chiu, Y.-F. Structural Safety Analysis for an Oscillating Water Column Wave Power Conversion System Installed in Caisson Structure. J. Mar. Sci. Eng. 2020, 8, 506. https://doi.org/10.3390/jmse8070506

Lee HH, Wu T-Y, Lin C-Y, Chiu Y-F. Structural Safety Analysis for an Oscillating Water Column Wave Power Conversion System Installed in Caisson Structure. Journal of Marine Science and Engineering. 2020; 8(7):506. https://doi.org/10.3390/jmse8070506

Chicago/Turabian StyleLee, Hsien Hua, Thung-Yeh Wu, Chung-You Lin, and Yung-Fang Chiu. 2020. "Structural Safety Analysis for an Oscillating Water Column Wave Power Conversion System Installed in Caisson Structure" Journal of Marine Science and Engineering 8, no. 7: 506. https://doi.org/10.3390/jmse8070506

APA StyleLee, H. H., Wu, T.-Y., Lin, C.-Y., & Chiu, Y.-F. (2020). Structural Safety Analysis for an Oscillating Water Column Wave Power Conversion System Installed in Caisson Structure. Journal of Marine Science and Engineering, 8(7), 506. https://doi.org/10.3390/jmse8070506