Inversion of the Thickness of Crude Oil Film Based on an OG-CNN Model

Abstract

:1. Introduction

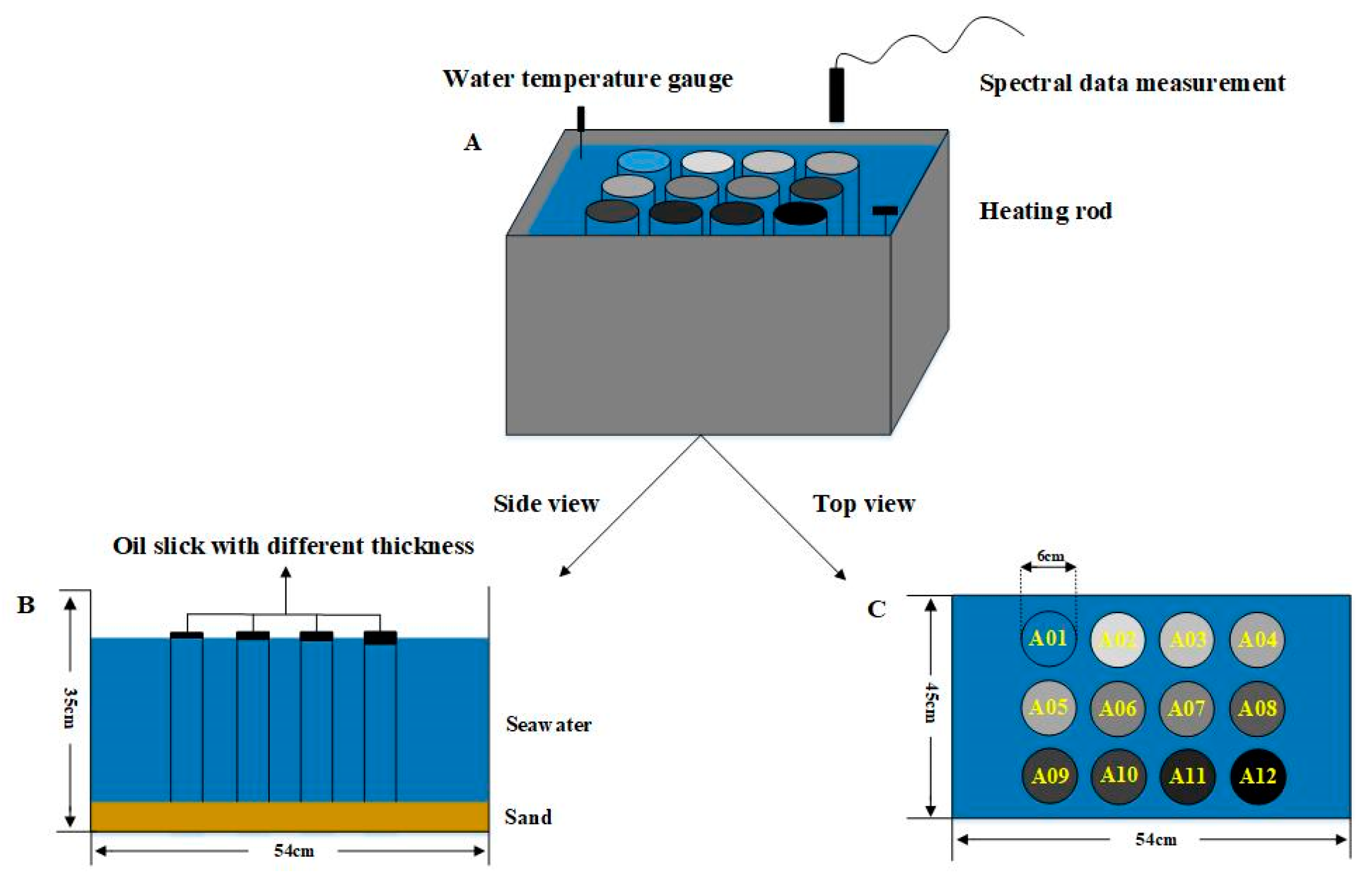

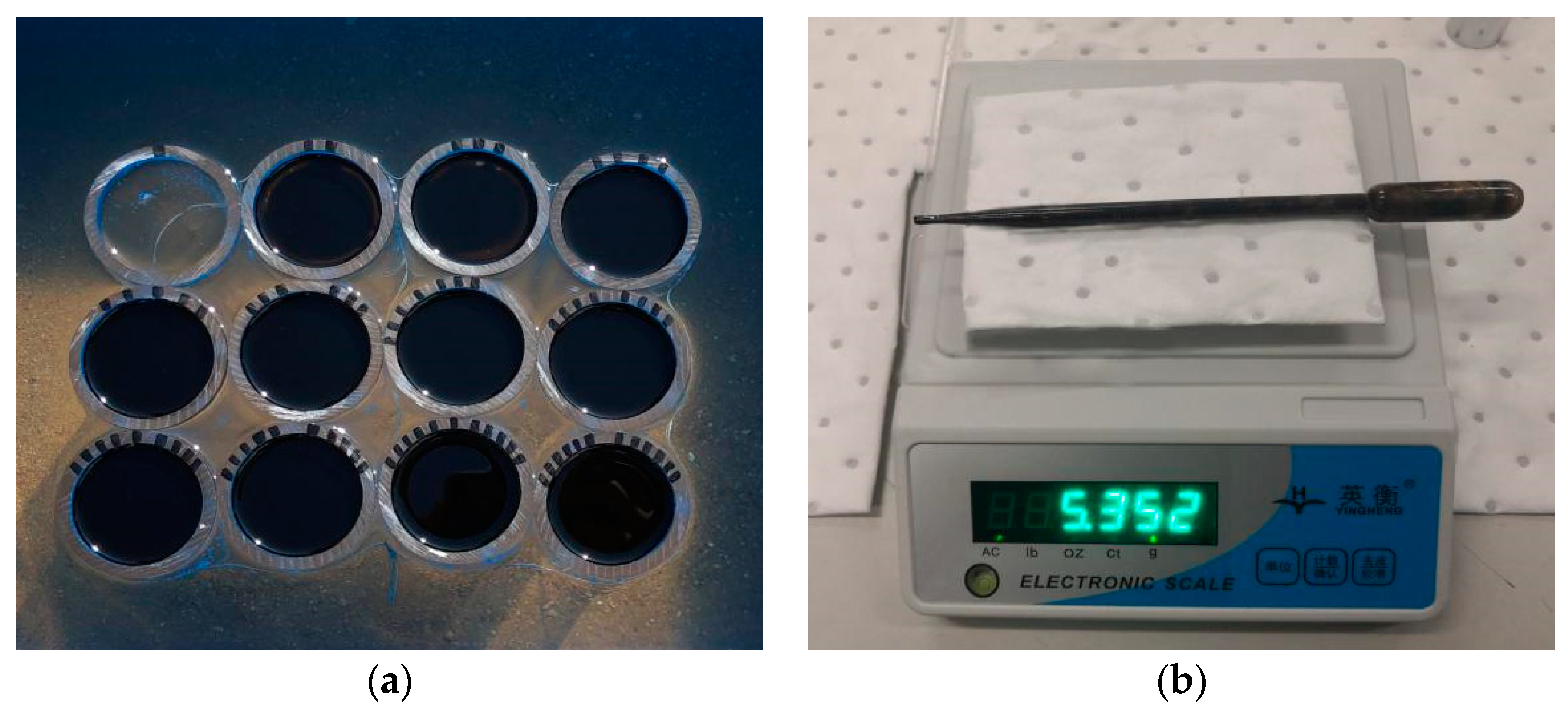

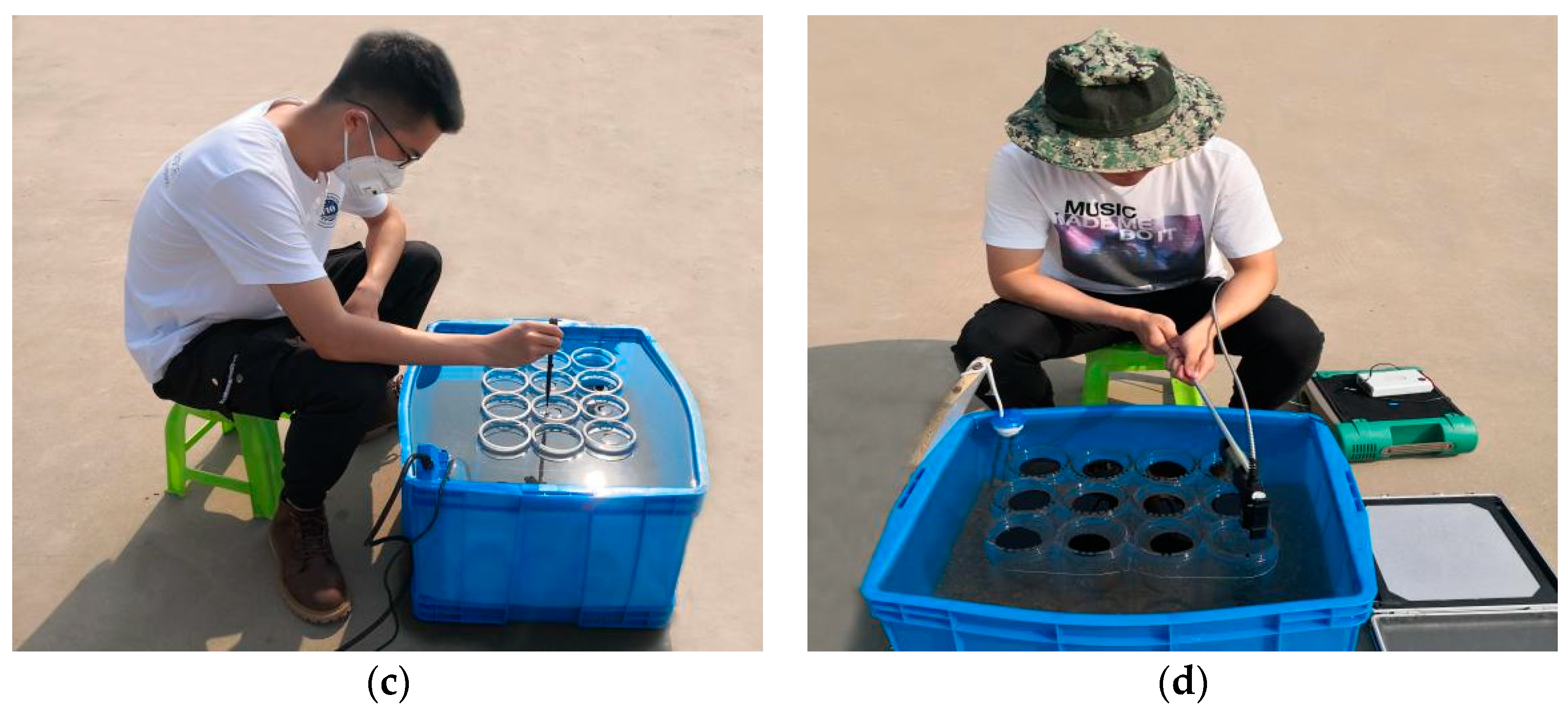

2. Data Collection and Processing

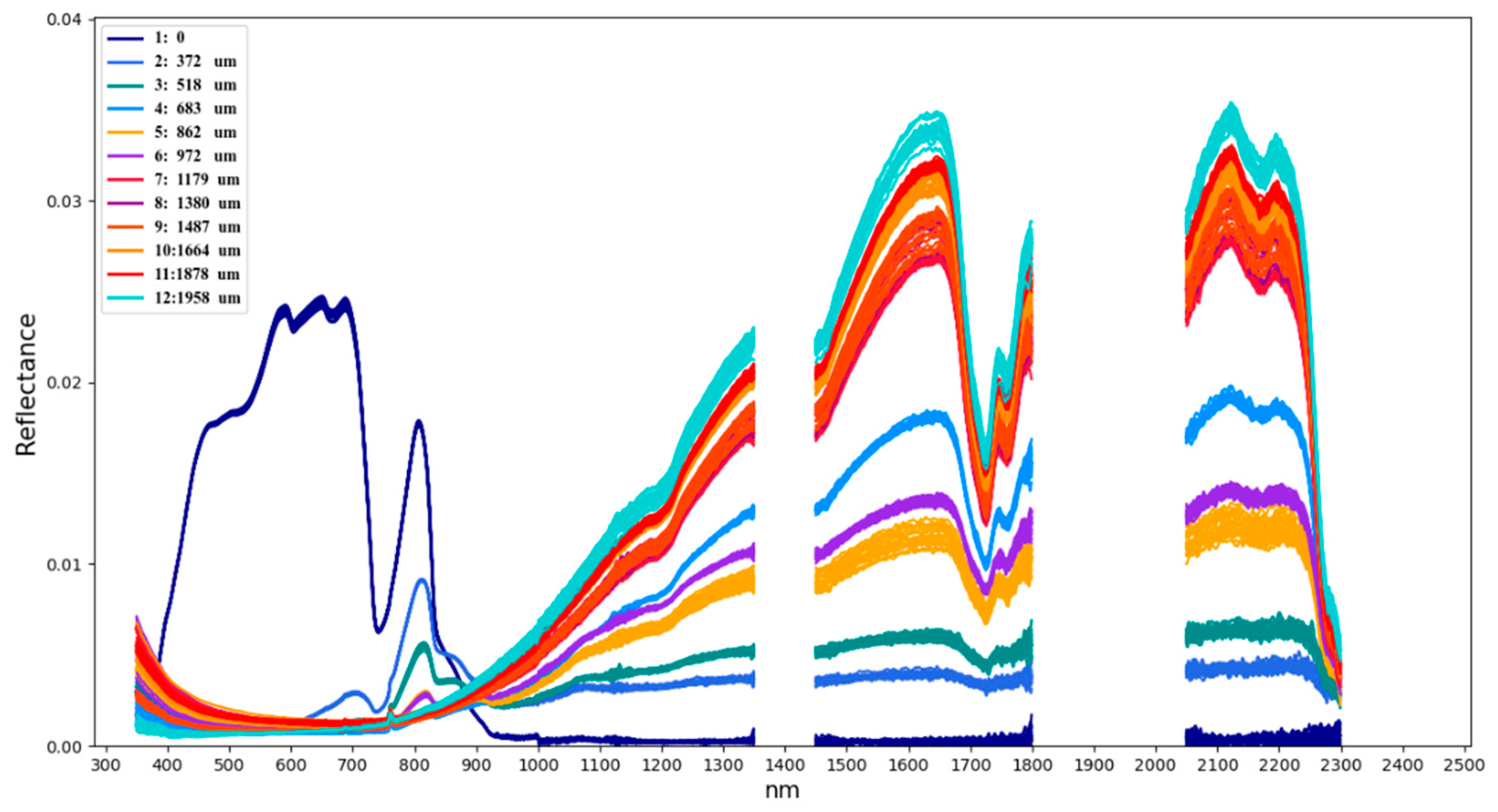

2.1. Data Acquisition

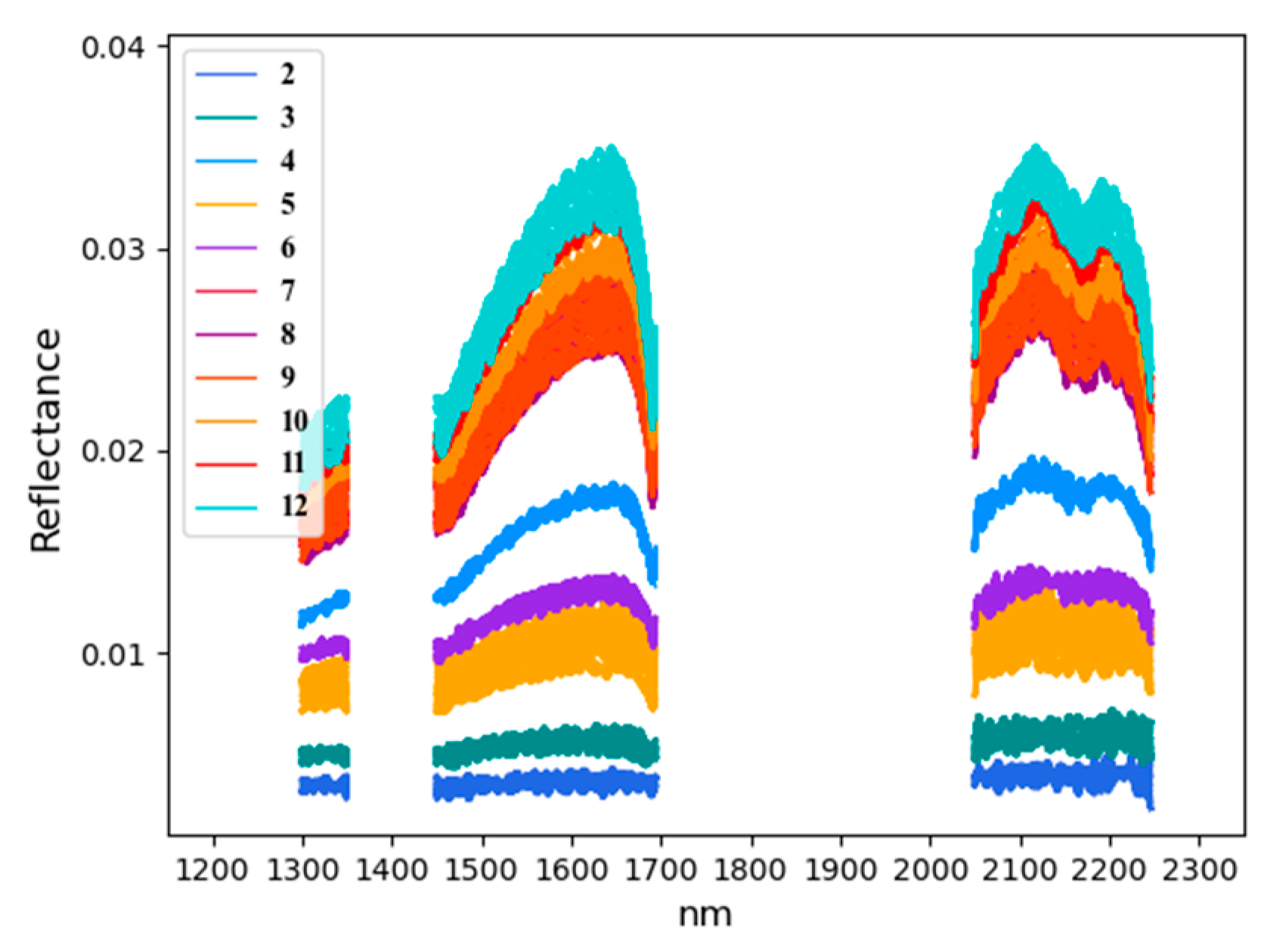

2.2. Spectral Data Processing

3. Model and Method

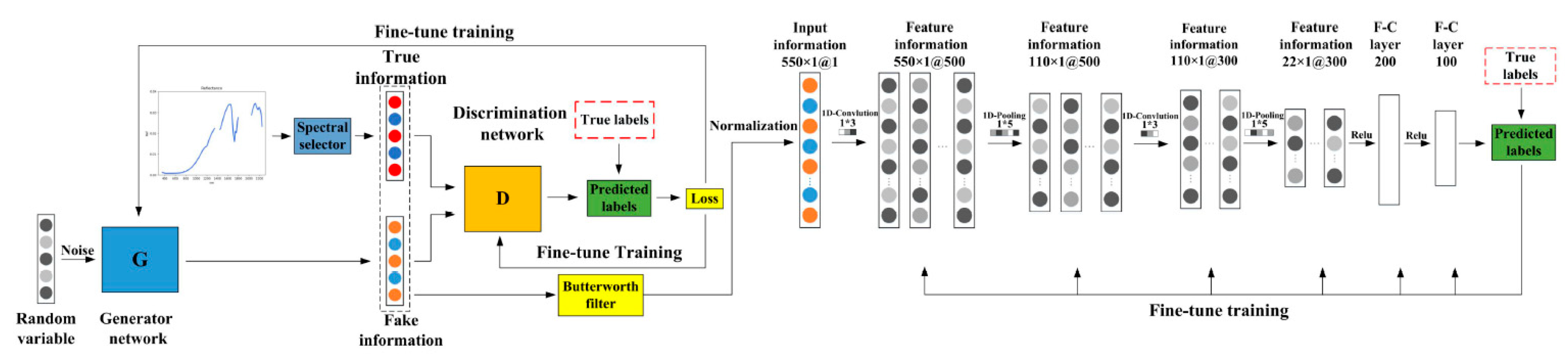

3.1. Crude Oil Film Spectral Feature Data Self-Expanding Module

3.2. Crude Oil Film Absolute Thickness Inversion Module

4. Results and Discussion

4.1. Accuracy Evaluation Indices

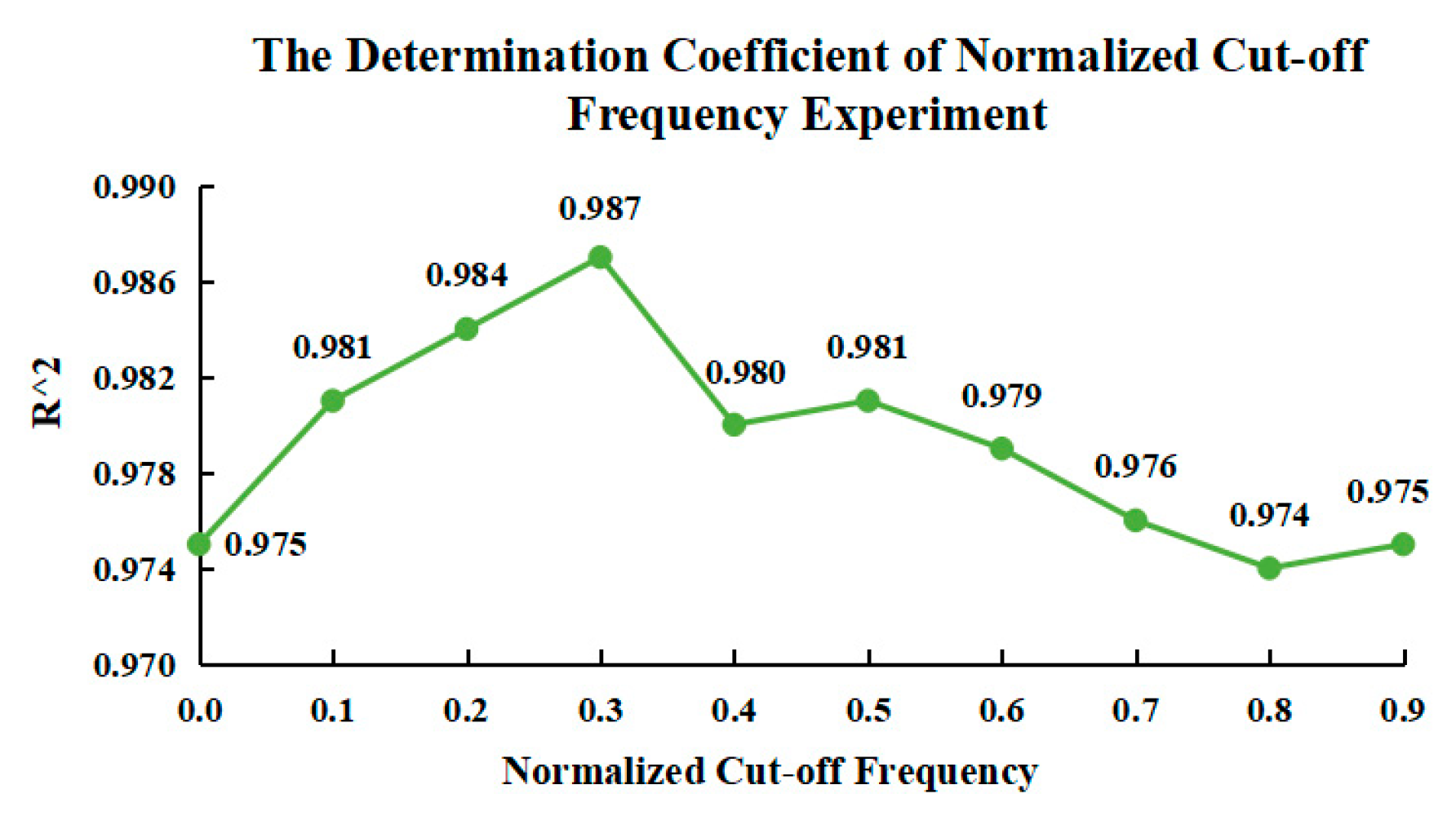

4.2. Spectral Feature Filter Experiment

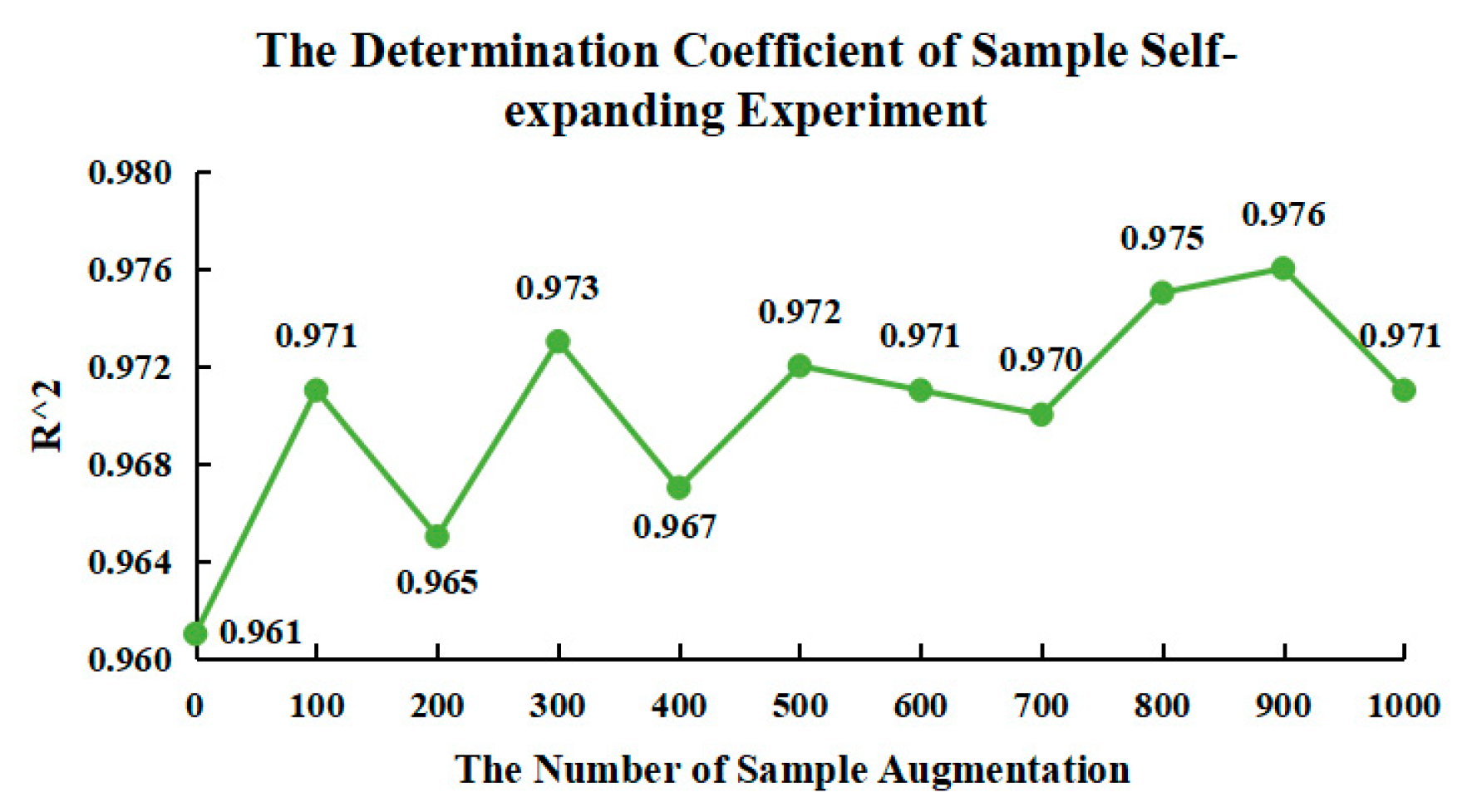

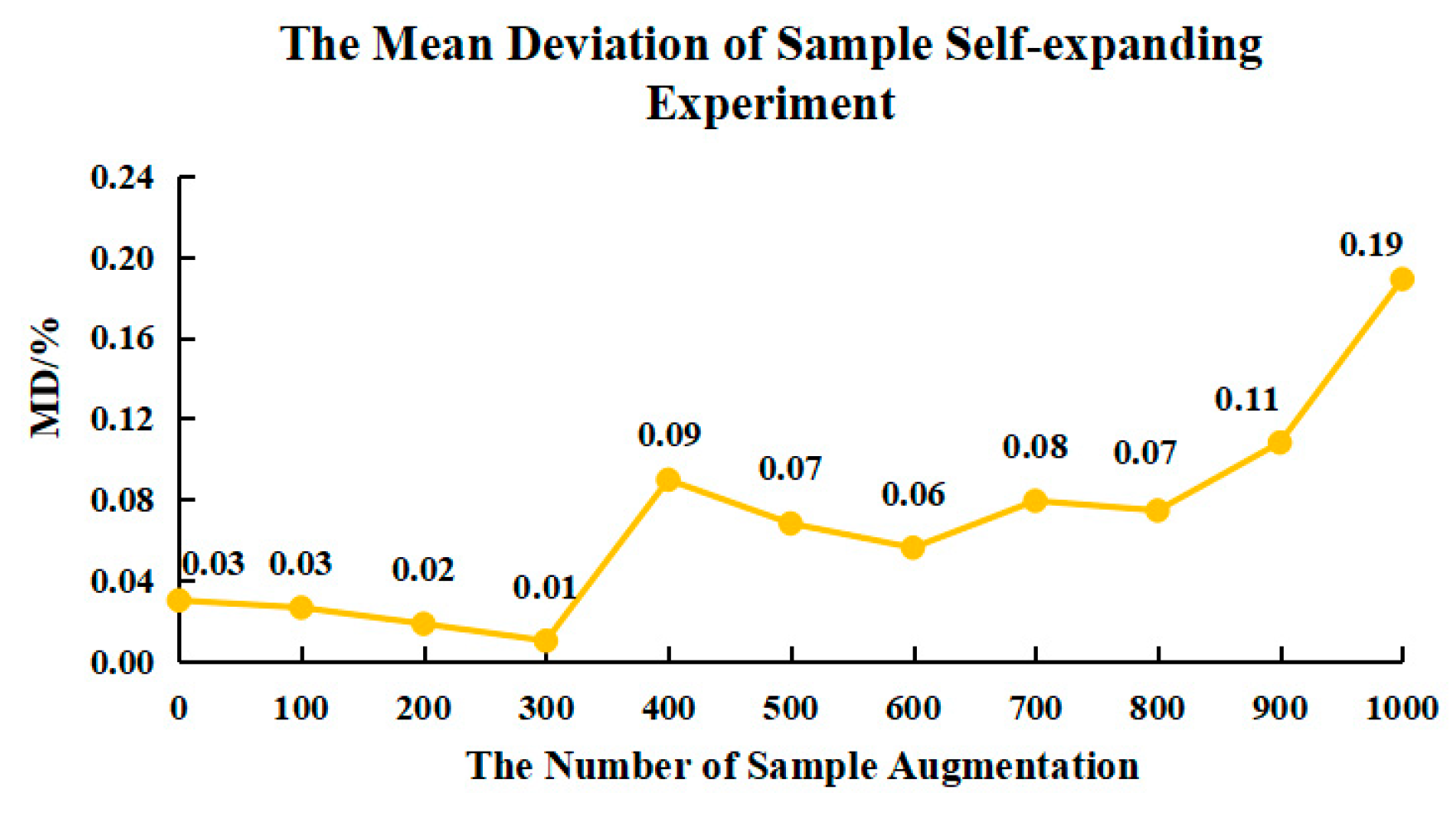

4.3. Sample Data Self-Expanding Experiment

4.4. Spectral Feature Filter Experiment

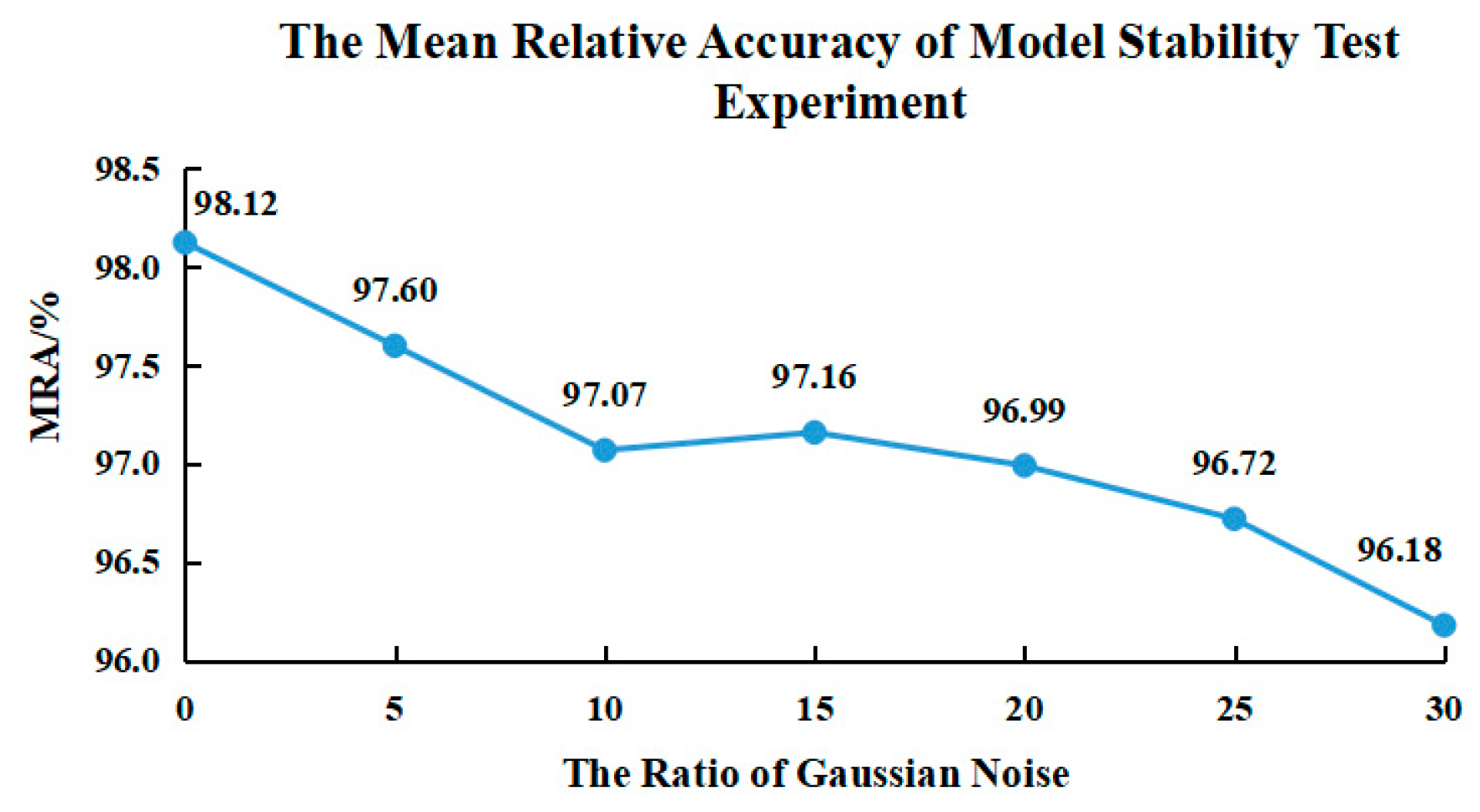

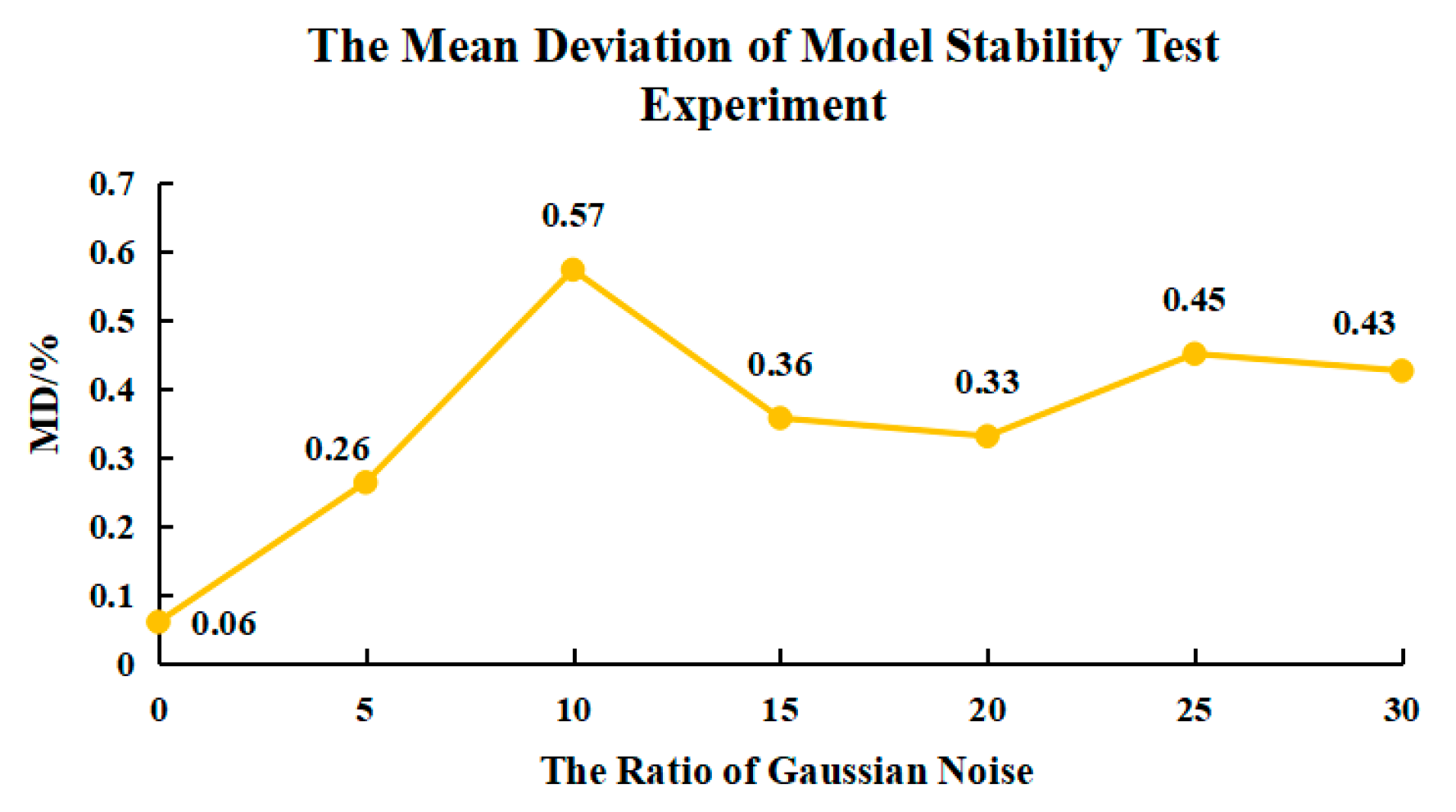

4.5. Model Stability Evaluation

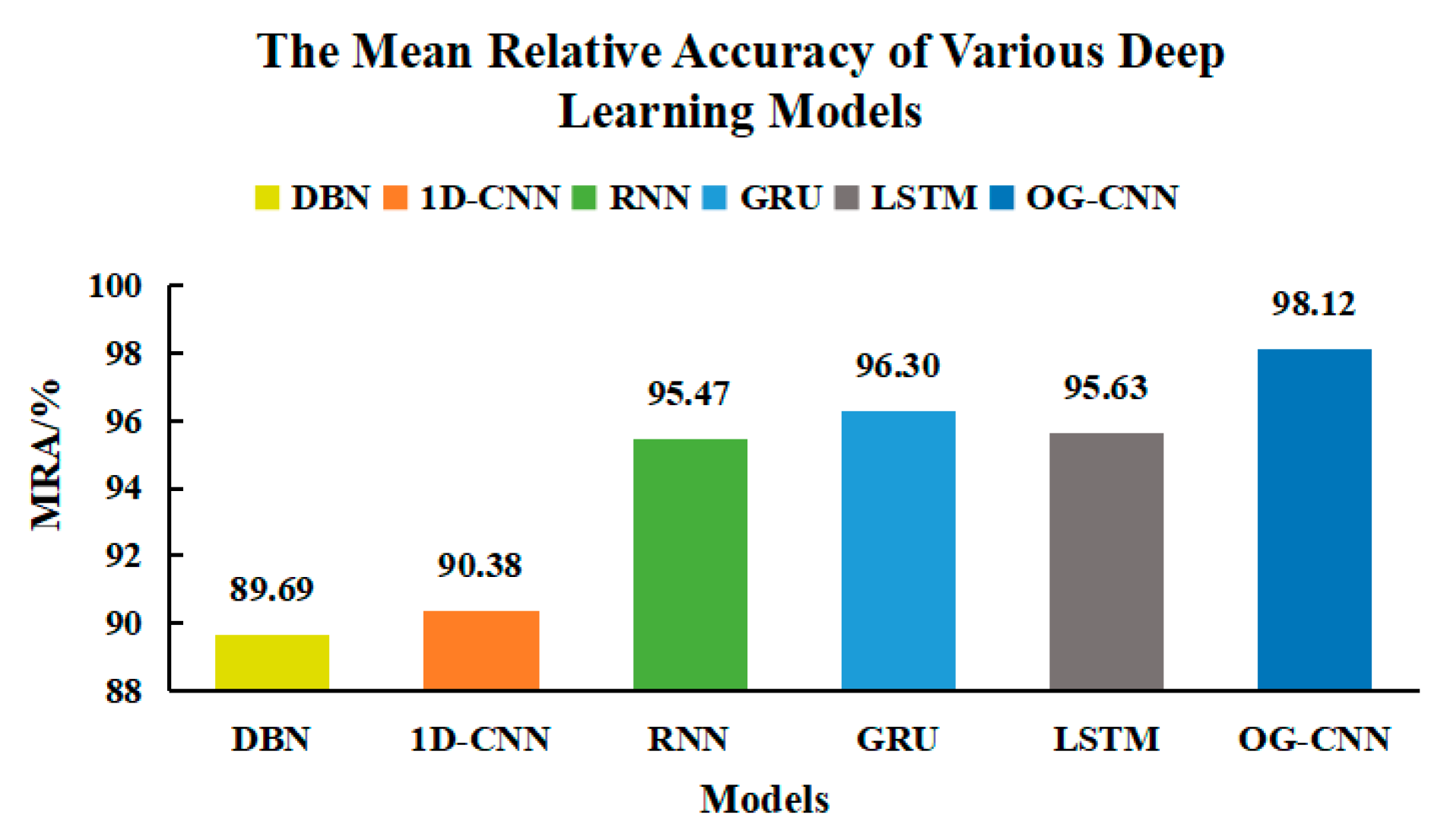

4.6. Comparison with Various Deep Learning Models

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leifer, I.; William, J.L.; Simecek-Beatty, D.; Bradley, E.; Clark, R.; Dennison, P.; Hu, Y.; Matheson, S.; Jones, C.E.; Holt, B.; et al. State of the art satellite and airborne marine oil spill remote sensing: Application to the BP Deepwater Horizon oil spill. Remote Sens. Environ. 2020, 124, 185–209. [Google Scholar] [CrossRef] [Green Version]

- Fingas, M.; Brown, C. Review of oil spill remote sensing. Mar. Pollut Bull. 2014, 83, 9–23. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.F.; Wan, J.H.; Ma, Y.; Zhang, J.; Hu, Y.B.; Jiang, Z.C. Oil spill hyperspectral remote sensing detection based on DCNN with multi-scale features. J. Coast. Res. 2019, 90, 332–339. [Google Scholar] [CrossRef]

- del Frate, F.; Petrocchi, A.; Lichtenegger, J.; Calabresi, G. Neural networks for oil spill detection using ERS-SAR data. IEEE Trans. Geoence Remote Sens. 1999, 38, 2282–2287. [Google Scholar] [CrossRef] [Green Version]

- Ferraro, G.; Baschek, B.; de Montpellier, G.; Njoten, O.; Perkovic, M.; Vespe, M. On the SAR derived alert in the detection of oil spills according to the analysis of the EGEMP. Mar. Pollut. Bull. 2010, 60, 91–102. [Google Scholar] [CrossRef]

- Solberg, A.S.; Storvik, G.; Solberg, R.; Volden, E. Automatic detection of oil spills in ERS SAR images. Ieee Trans. Geoence Remote Sens. 1999, 37, 1916–1924. [Google Scholar] [CrossRef] [Green Version]

- Keramitsoglou, I.; Cartalis, C.; Kiranoudis, C.T. Automatic identification of oil spills on satellite images. Environ. Model. Softw. 2016, 21, 640–652. [Google Scholar] [CrossRef]

- Garcia-Pineda, O.; Macdonald, I.; Hu, C.; Svejkovsky, J.; Hess, M.; Dukhovskoy, D.; Morey, S.L. Detection of floating oil anomalies from the deep water horizon oil spill with synthetic aperture radar. Oceanography 2013, 26, 124–137. [Google Scholar] [CrossRef] [Green Version]

- Topouzelis, K.; Psyllos, A. Oil spill feature selection and classification using decision tree forest on SAR image data. Isprs J. Photogramm. Remote Sens. 2012, 68, 135–143. [Google Scholar] [CrossRef]

- Fingas, M. A literature review of the physics and predictive modelling of oil spill evaporation. J. Hazard. Mater. 1995, 42, 157–175. [Google Scholar]

- FanG, S.A.; Huang, X.X.; Yin, D.Y.; Xu, C.; Feng, X.; Feng, Q. Research on the ultraviolet reflectivity characteristic of simulative targets of oil spill on the ocean. Spectrosc. Spectr. Anal. 2010, 30, 738–742. [Google Scholar]

- Hu, J.C.; Wang, D.F. Monitoring method of ocean oil spilling based on remote sensing. Environ. Prot. Sci. 2014, 40, 68–73. [Google Scholar]

- Ren, G.B.; Guo, J.; Ma, Y.; Luo, X.D. Oil spill detection and slick thickness measurement via UAV hyperspectral imaging. Haiyang Xuebao 2019, 41, 146–158. [Google Scholar]

- Wu, X.D.; Song, J.M.; Li, X.G. Technical methods for marine oil spill quantity capture. Mar. Technol. 2011, 30, 50–54. [Google Scholar]

- Song, S.S.; An, W.; Li, J.W.; Zhao, Y.P.; Jin, W.W. Review on the methods for assessment of marine oil spill volume. Coast. Eng. 2017, 36, 83–88. [Google Scholar]

- Sun, S.; Hu, C.M. The challenges of interpreting oil-water spatial and spectral contrasts for the estimation of oil thickness: Examples from satellite and airborne measurements of the deepwater horizon oil spill. IEEE Trans. Geoence Remote Sens. 2019, 5, 1–16. [Google Scholar] [CrossRef]

- Liu, B.X. Extraction and Analysis of Water Oil Film Based on Hyperspectral Characteristics. Ph.D. Thesis, Dalian Maritime University, Dalian, China, 2013. [Google Scholar]

- Lu, Y.C.; Zhan, W.F.; Hu, C.M. Detecting and quantifying oil slick thickness by thermal remote sensing: A ground-based experiment. Remote Sens. Environ. 2016, 181, 207–217. [Google Scholar] [CrossRef]

- Lu, Y.C.; Tian, Q.J.; Wang, X.Y.; Zheng, G.; Li, X. Determining oil slick thickness using hyperspectral remote sensing in the Bohai Sea of China. Int. J. Digit. Earth 2013, 6, 76–93. [Google Scholar] [CrossRef]

- Jiang, Z.C.; Ma, Y.; Jiang, T.; Chen, C. Research on the extraction of red tide hyperspectral remote sensing based on the deep belief network. J. Ocean. Technol. 2019, 38, 1–7. [Google Scholar]

- Chen, Y.S.; Jiang, H.L.; Li, C.Y.; Jia, X.; Ghamisi, P. Deep feature extraction and classification of hyperspectral images based on convolutional neural networks. IEEE Geosci. Remote Sens. 2016, 54, 6232–6251. [Google Scholar] [CrossRef] [Green Version]

- Hu, F.; Xia, G.S.; Hu, J.W.; Zhang, L. Transferring deep convolutional neural networks for the scene classification of high-resolution remote sensing imagery. Remote Sens. 2015, 7, 14680–14707. [Google Scholar] [CrossRef] [Green Version]

- Ai, B.; Wen, Z.; Wang, Z.; Wang, R.; Su, D.; Li, C.; Yang, F. Convolutional neural network to retrieve water depth in marine shallow water area from remote sensing images. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2020, 13, 2888–2898. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, T.; Li, H.S.; Zhang, S.; Wang, X.; Huang, X.; Metaxas, D.N. StackGAN++: Realistic image synthesis with stacked generative adversarial networks. IEEE Trans. Pattern Anal. Mach. Intell. 2019, 41, 1947–1962. [Google Scholar] [CrossRef] [Green Version]

- Mao, X.; Li, Q.; Xie, H.R.; Lau, R.Y.; Wang, Z.; Smolley, S.P. Least squares generative adversarial networks. IEEE Int. Conf. Comput. Vis. 2016, 2016, 2813–2821. [Google Scholar]

- Jiang, Z.C.; Ma, Y. Accurate extraction of offshore raft aquaculture areas based on a 3D-CNN model. Int. J. Remote Sens. 2020, 41, 5457–5481. [Google Scholar] [CrossRef]

- Zhong, Z.X.; You, F.Q. Oil spill response planning with consideration of physicochemical evolution of the oil slick: A multiobjective optimization approach. Comput. Chem. Eng. 2010, 35, 1614–1630. [Google Scholar] [CrossRef]

- Lu, Y.C.; Tian, Q.J.; Li, X. Overview of optical remote sensing of marine oil spills and hydrocarbon seepage. J. Remote Sens. 2016, 20, 1260–1269. [Google Scholar]

- Lu, Y.; Shi, J.; Wen, Y.; Hu, C.; Zhou, Y.; Sun, S.; Zhang, M.; Mao, Z.; Liu, Y. Optical interpretation of oil emulsions in the ocean-Part I: Laboratory measurements and proof-of-concept with AVIRIS observations. Remote Sens. Environ. 2019, 230, 111183. [Google Scholar] [CrossRef]

- Yang, J.; Wan, J.; Ma, Y.; Zhang, J.; Hu, Y. Characterization analysis and identification of common marine oil spill types using hyperspectral remote sensing. Int. J. Remote Sens. 2020, 41, 7163–7185. [Google Scholar] [CrossRef]

- Sui, B.; Jiang, T.; Zhang, Z.; Pan, X.; Liu, C. A modeling method for automatic extraction of offshore aquaculture zones based on semantic segmentation. Isprs Int. J. Geo. Inf. 2020, 9, 145. [Google Scholar] [CrossRef] [Green Version]

- Ren, G.B.; Zhang, J.; Ma, Y. Spectral discrimination and separable feature lookup table of typical vegetation species in Yellow River Delta wetland. Mar. Environ. Sci. 2015, 34, 420–426. [Google Scholar]

- Schmidt, K.S.; Skidmore, A.K. Exploring spectral discrimination of grass species in African rangelands. Int. J. Remote Sens. 2001, 22, 3421–3434. [Google Scholar] [CrossRef]

| Parameters | Index |

|---|---|

| Spectral range (nm) | 350–2500 |

| Spectral resolution (nm) | 3@350–1000, 7@1001–2500 |

| Spectral sampling interval (nm) | 1.4@350–1000, 1.1@1001–2500 |

| Field angle (°) | 25 |

| Wavelength accuracy (nm) | 0.5 |

| Scanning method | Fixed and moving grating combination spectroscopy |

| Stray light (nm) | 0.02%@350–1000, 0.01%@1001–2500 |

| Wavelength repeatability (nm) | 0.1 |

| No. | Oil Film Area (cm2) | Oil Film Quantity (g) | Oil Film Thickness (μm) |

|---|---|---|---|

| 1 | 0.000 | 0.000 | 0.000 |

| 2 | 19.635 | 0.615 | 372 |

| 3 | 19.635 | 0.856 | 518 |

| 4 | 19.635 | 1.129 | 683 |

| 5 | 19.635 | 1.426 | 862 |

| 6 | 19.635 | 1.608 | 972 |

| 7 | 19.635 | 1.950 | 1179 |

| 8 | 19.635 | 2.282 | 1380 |

| 9 | 19.635 | 2.460 | 1487 |

| 10 | 19.635 | 2.752 | 1664 |

| 11 | 19.635 | 3.106 | 1878 |

| 12 | 19.635 | 3.239 | 1958 |

| Layer | Number | Kernel | Stride |

|---|---|---|---|

| Convolutional layer-1 | 500 | 1 × 3 | 1 |

| Pooling layer-1 | 500 | 1 × 10 | 5 |

| Convolutional layer-2 | 300 | 1 × 3 | 1 |

| Pooling layer-2 | 300 | 1 × 10 | 5 |

| Fully connected layer-1 | 200 | — | — |

| Fully connected layer-2 | 100 | — | — |

| No. | Spectral Feature Intervals (nm) |

|---|---|

| 1 | 350–359 |

| 2 | 1300–1349 |

| 3 | 1450–1694 |

| 4 | 1775–1799 |

| 5 | 2050–2246 |

| Experimental Data | Inversion Results of Oil Film Thickness (%) | Time (s) | ||

|---|---|---|---|---|

| MRA (Single Experiment) | MRA + MD | R2 | ||

| Full band spectral data | 90.45/90.32/90.31/90.44/90.38 | 90.38 ± 0.05 | 0.928 | 290.1 |

| Spectral characteristic data | 94.80/94.74/94.76/94.73/94.82 | 94.77 ± 0.03 | 0.961 | 80.2 |

| Number | Inversion Results of Oil Film Thickness (%) | Time (s) | ||

|---|---|---|---|---|

| MRA (Single Experiment) | MRA + MD | R2 | ||

| 0 | 94.80/94.74/94.76/94.73/94.82 | 94.77 ± 0.03 | 0.961 | 80.2 |

| 100 | 96.10/96.05/96.12/96.13/96.14 | 96.11 ± 0.03 | 0.971 | 95.6 |

| 200 | 95.95/95.96/96.00/95.96/95.99 | 95.97 ± 0.02 | 0.965 | 109.2 |

| 300 | 96.36/96.35/96.34/96.36/96.36 | 96.35 ± 0.01 | 0.973 | 125.5 |

| 400 | 96.28/96.33/96.13/96.05/96.17 | 96.19 ± 0.09 | 0.967 | 141.3 |

| 500 | 96.38/96.56/96.45/96.36/96.35 | 96.42 ± 0.07 | 0.972 | 154.2 |

| 600 | 96.25/96.39/96.46/96.45/96.40 | 96.39 ± 0.06 | 0.971 | 172.7 |

| 700 | 96.49/96.44/96.35/96.35/96.60 | 96.45 ± 0.08 | 0.970 | 187.3 |

| 800 | 96.89/96.75/96.75/96.90/96.72 | 96.80 ± 0.07 | 0.975 | 199.8 |

| 900 | 96.76/96.73/96.80/96.41/96.70 | 96.68 ± 0.11 | 0.976 | 212.4 |

| 1000 | 96.50/96.63/96.14/93.87/96.43 | 96.51 ± 0.19 | 0.971 | 227.9 |

| Parameter | Inversion Results of Oil Film Thickness (%) | Time (s) | ||

|---|---|---|---|---|

| MRA (Single Experiment) | MRA + MD | R2 | ||

| 0 | 96.66/96.75/96.75/96.63/96.72 | 96.80 ± 0.07 | 0.975 | 199.8 |

| 0.1 | 97.43/97.51/97.64/97.44/97.14 | 97.43 ± 0.12 | 0.981 | 199.5 |

| 0.2 | 98.01/98.02/98.07/98.20/98.14 | 98.09 ± 0.07 | 0.984 | 199.2 |

| 0.3 | 98.17/98.01/98.16/98.07/98.18 | 98.12 ± 0.06 | 0.987 | 198.3 |

| 0.4 | 97.54/97.50/97.54/97.49/97.49 | 97.51 ± 0.02 | 0.980 | 198.7 |

| 0.5 | 98.08/97.77/97.82/97.90/98.08 | 97.93 ± 0.12 | 0.981 | 197.9 |

| 0.6 | 97.75/97.74/97.73/97.66/97.82 | 97.74 ± 0.04 | 0.979 | 196.7 |

| 0.7 | 97.71/97.79/97.19/97.05/97.33 | 97.41 ± 0.27 | 0.976 | 197.7 |

| 0.8 | 96.86/96.97/96.95/96.93/96.96 | 96.93 ± 0.03 | 0.974 | 197.5 |

| 0.9 | 97.03/97.08/97.00/96.97/96.98 | 97.01 ± 0.03 | 0.975 | 197.4 |

| Gauss | Inversion Results of Oil Film Thickness (%) | Time (s) | ||

|---|---|---|---|---|

| MRA (Single Experiment) | MRA + MD | R2 | ||

| 0 | 98.17/98.01/98.16/98.07/98.18 | 98.12 ± 0.06 | 0.987 | 198.3 |

| 5 | 97.43/97.87/97.51/97.98/97.19 | 97.60 ± 0.26 | 0.981 | 198.4 |

| 10 | 96.34/97.55/97.36/97.44/97.64 | 97.27 ± 0.57 | 0.979 | 198.4 |

| 15 | 96.29/97.13/97.76/97.24/97.36 | 97.16 ± 0.36 | 0.980 | 198.2 |

| 20 | 96.84/97.14/96.31/97.15/97.50 | 96.99 ± 0.33 | 0.976 | 198.8 |

| 25 | 96.47/95.84/96.83/96.86/97.59 | 96.72 ± 0.45 | 0.975 | 199.2 |

| 30 | 95.53/95.90/96.88/96.04/96.54 | 96.18 ± 0.43 | 0.973 | 199.1 |

| Model | Inversion Results of Oil Film Thickness (%) | Time (s) | ||

|---|---|---|---|---|

| MRA (Single Experiment) | MRA + MD | R2 | ||

| DBN | 89.75/89.78/89.66/89.66/89.61 | 89.69 ± 0.06 | 0.918 | 150.6 |

| 1D-CNN | 90.45/90.32/90.31/90.44/90.38 | 90.38 ± 0.05 | 0.928 | 290.1 |

| RNN | 95.46/95.47/95.81/95.41/95.22 | 95.47 ± 0.13 | 0.967 | 120.6 |

| GRU | 96.52/96.53/95.79/96.37/96.30 | 96.30 ± 0.21 | 0.968 | 123.1 |

| LSTM | 94.91/95.71/95.72/95.71/96.10 | 95.63 ± 0.29 | 0.965 | 124.3 |

| OG-CNN (proposed) | 98.17/98.01/98.16/98.07/98.18 | 98.12 ± 0.06 | 0.987 | 198.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Z.; Ma, Y.; Yang, J. Inversion of the Thickness of Crude Oil Film Based on an OG-CNN Model. J. Mar. Sci. Eng. 2020, 8, 653. https://doi.org/10.3390/jmse8090653

Jiang Z, Ma Y, Yang J. Inversion of the Thickness of Crude Oil Film Based on an OG-CNN Model. Journal of Marine Science and Engineering. 2020; 8(9):653. https://doi.org/10.3390/jmse8090653

Chicago/Turabian StyleJiang, Zongchen, Yi Ma, and Junfang Yang. 2020. "Inversion of the Thickness of Crude Oil Film Based on an OG-CNN Model" Journal of Marine Science and Engineering 8, no. 9: 653. https://doi.org/10.3390/jmse8090653