Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility

Abstract

:1. Introduction

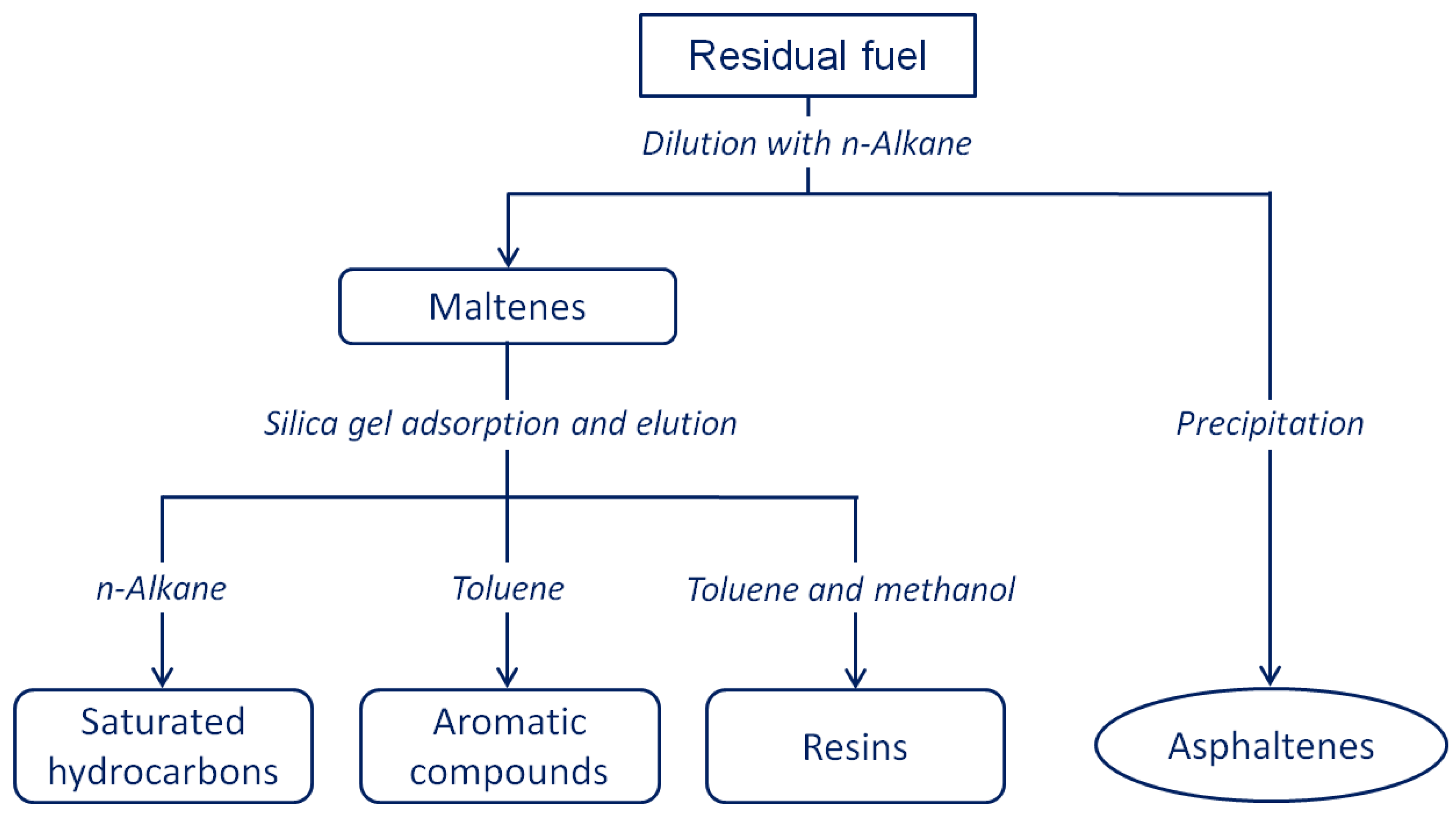

2. Materials and Methods

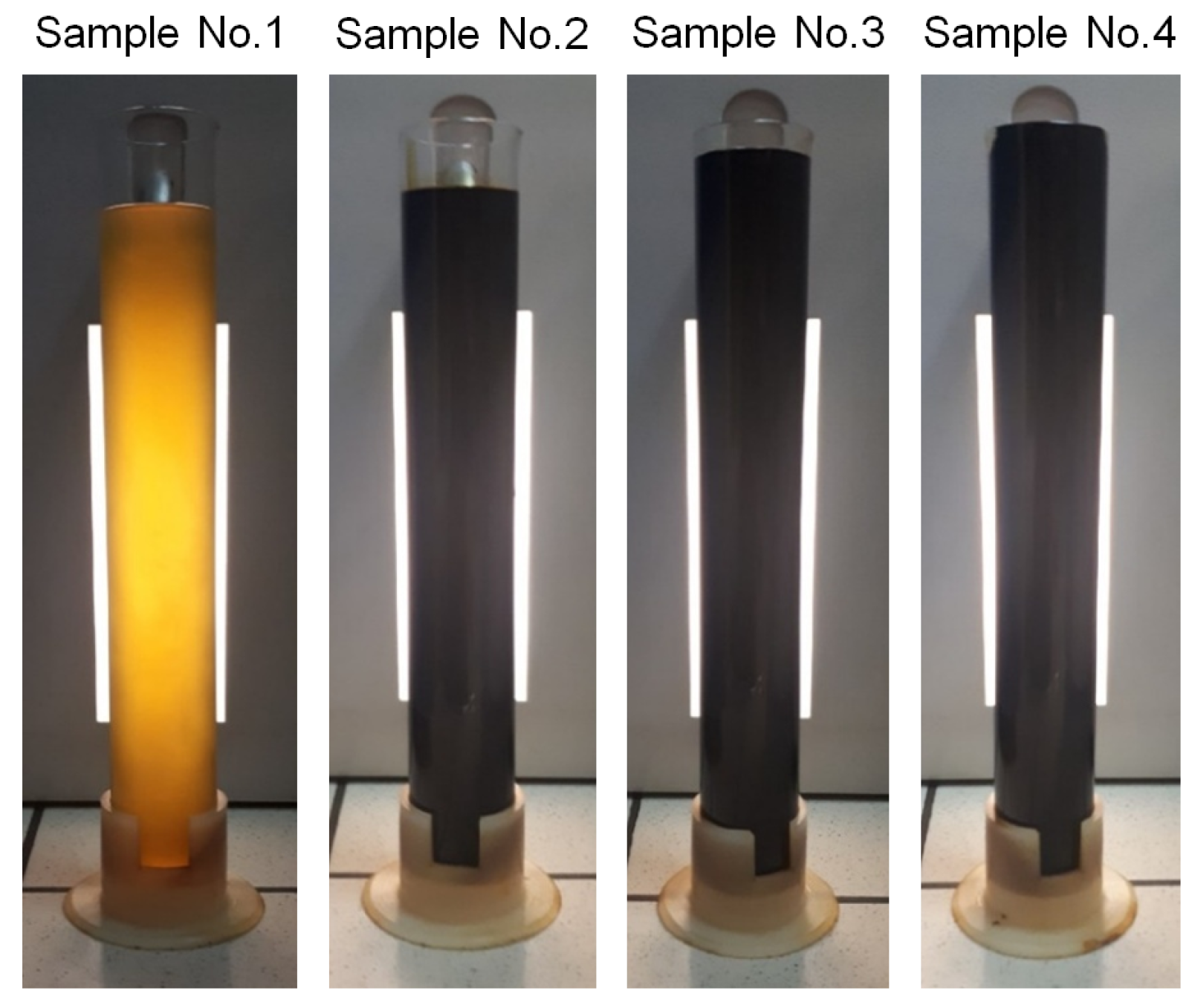

- Sample No.1—Compound oils grade A type 1 (KMC);

- Sample No.2—Fuel for TSU-80 marine installations (RMD-80);

- Sample No.3—Fuel for TSU-380 marine installations (RMG-380);

- Sample No.4—Residual oil fuel M-100, low ash (RK-700).

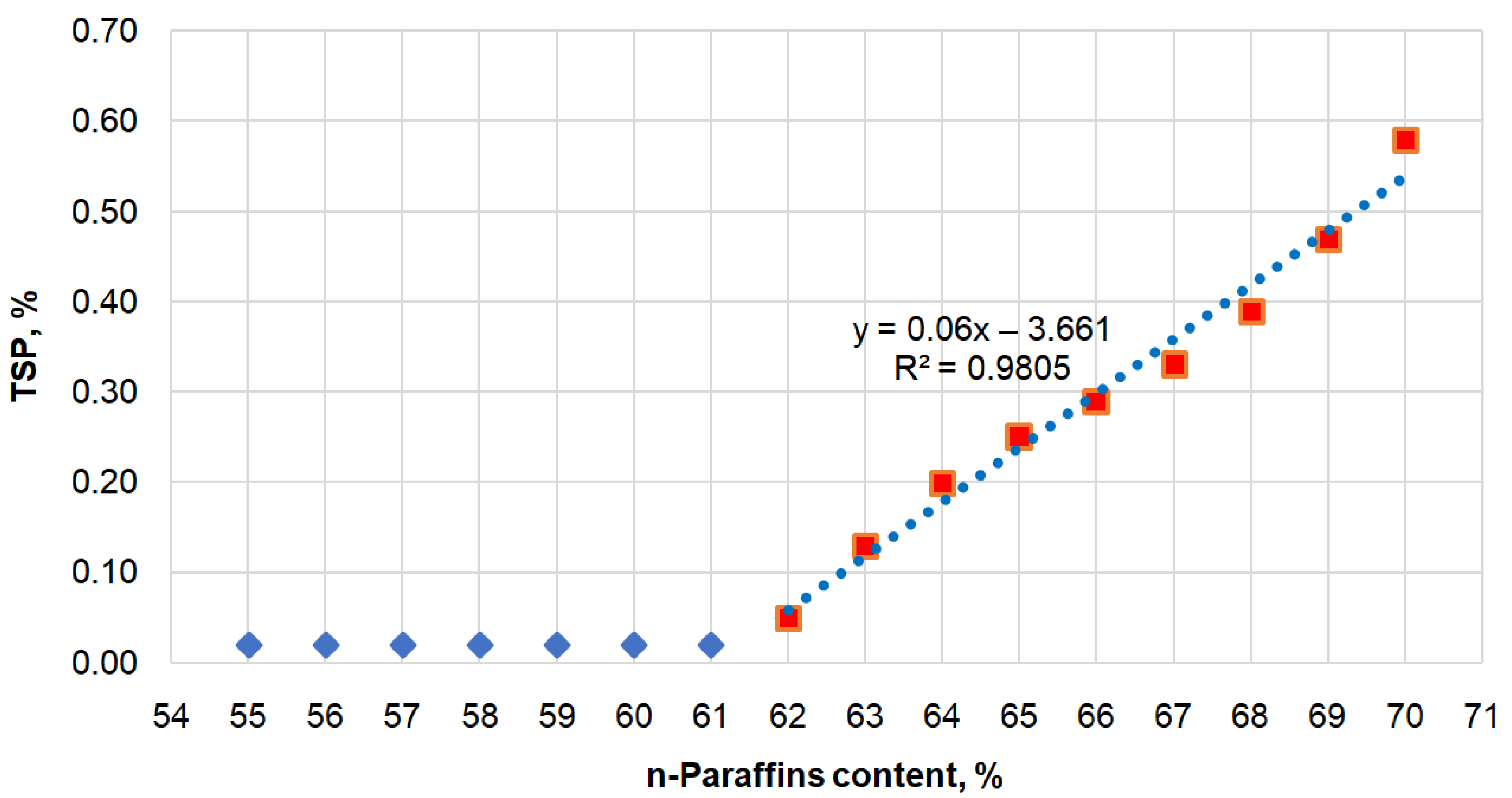

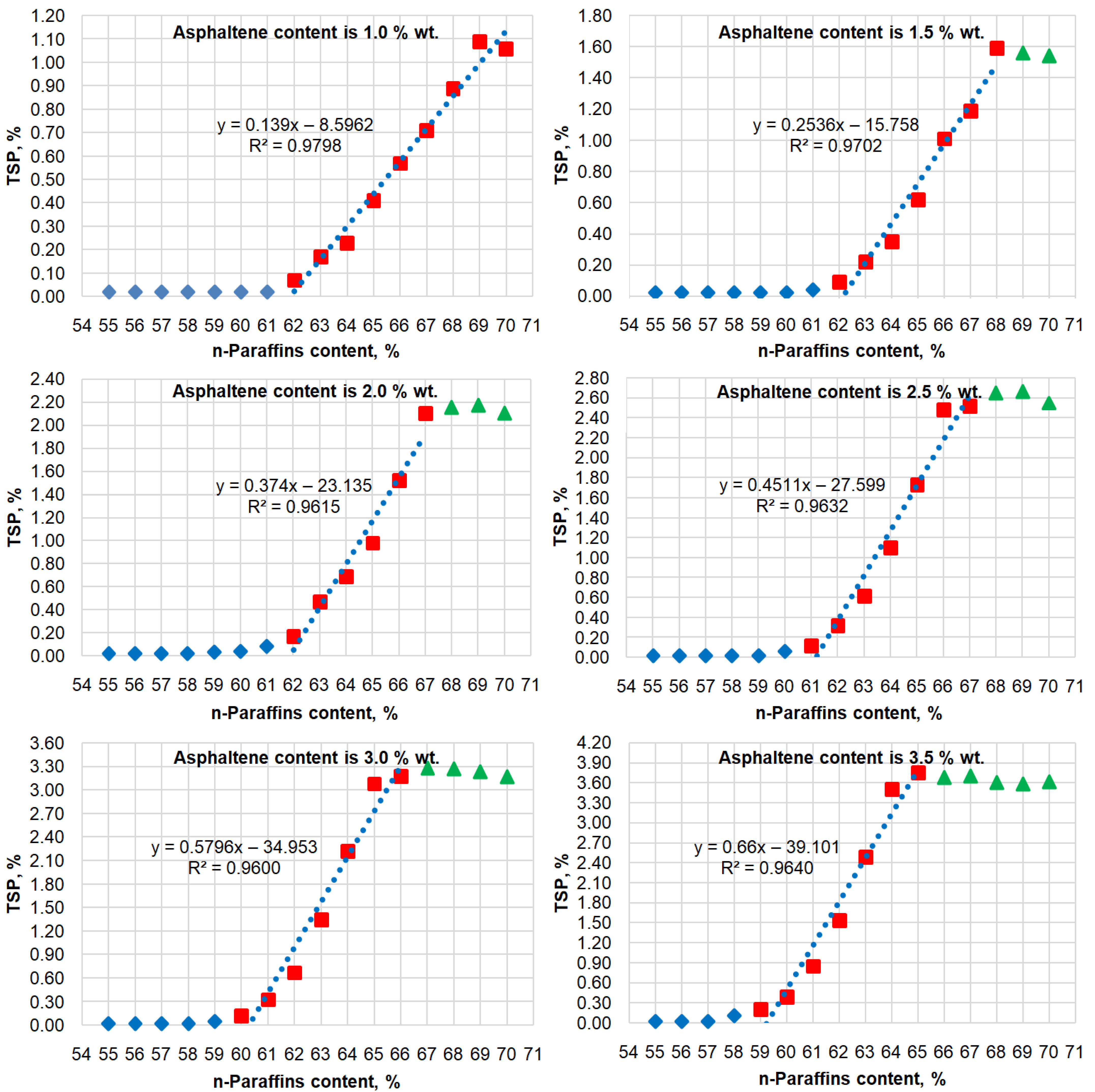

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GOST | Russian government standard |

| CI | Compatibility index |

| ISO | International organization for standardization |

| SARA | Saturate, aromatic, resin, and asphaltene |

| TSA | Total sediment accelerated |

| TSP | Total sediment potential |

References

- Stratiev, D.; Dinkov, R.; Shishkova, I.; Yordanov, D. Can we manage the process of asphaltene precipitation during the production of IMO 2020 fuel oil? Erdoel Erdgas Kohle/EKEP 2020, 12, 32–39. [Google Scholar]

- Litvinenko, V.S.; Tsvetkov, P.S.; Molodtsov, K.V. The social and market mechanism of sustainable development of public companies in the mineral resource sector. Eurasian Min. 2020, 2020, 36–41. [Google Scholar] [CrossRef]

- Litvinenko, V.S. Digital economy as a factor in the technological development of the mineral sector. Nat. Resour. Res. 2020, 29, 1521–1541. [Google Scholar] [CrossRef]

- Filatova, I.; Nikolaichuk, L.; Zakaev, D.; Ilin, I. Public-private partnership as a tool of sustainable development in the oil-refining sector: Russian case. Sustainability 2021, 13, 5153. [Google Scholar] [CrossRef]

- Dubovoy, E.S.; Shmatkov, A.A.; Shtonda, N.V.; Lyapin, A.Y. On the approach to performance evaluation oil blending stations. Sci. Technol. Oil Oil Prod. Pipeline Transp. 2018, 8, 540–546. [Google Scholar] [CrossRef]

- Demidova, N.P.; Marchenko, A.A.; Onishchenko, O.A. Evaluation of the compatibility of marine heavy fuels. Bull. Kamchatka State Tech. Univ. 2016, 35, 15–20. [Google Scholar] [CrossRef]

- Stratiev, D.; Russell, C.; Sharpe, R.; Shishkova, I.; Dinkov, R.; Marinov, I.; Petkova, N.; Mitkova, M.; Botev, T.; Obryvalina, A.; et al. Investigation on sediment formation in residue thermal conversion based processes. Fuel Process. Technol. 2014, 128, 509–518. [Google Scholar] [CrossRef]

- Abramova, E.A.; Shuvalov, G.V.; Yasyrova, O.A. Development of a method for assessing the stability and compatibility of marine fuels. Geo-Sibir. 2011, 5, 206–209. [Google Scholar]

- Bykova, M.V.; Pashkevich, M.A.; Matveeva, V.A.; Sverchkov, I.P. Assessment and abatement of the soil oil-contamination level in industrial areas. In Proceedings of the International Forum-Contest of Young Researchers: Topical Issues of Rational Use of Natural Resources, St. Petersburg, Russia, 18–20 April 2018; pp. 347–359. [Google Scholar]

- Karimov, R.M.; Mastobaev, B.N. Effect of paraffins, resins and asphaltenes on commodity quality of oil. Bashkir Chem. J. 2012, 19, 97–102. [Google Scholar]

- Sergeenko, S.R. High Molecular Weight Compounds; Chemistry Press: Moscow, Russia, 1959. [Google Scholar]

- Petrovich, N.I.; Ostroukhov, N.N.; Vasilyev, V.V.; Salamatova, E.V.; Strakhov, V.M. Comparison of light fuel-oil fractions produced by semicoking of kukersite shale in a gas generator and in a solid-fuel system. Coke Chem. 2019, 62, 249–257. [Google Scholar] [CrossRef]

- Hemmingsen, T.; Hinnaland, D.; Saasen, A. The co-effect of asphaltene on wax precipitation and crystallisation temperature. In Proceedings of the 9th International Oil Field Chemical Symposium, Norway, Geilo, 22–25 March 1998; pp. 1–6. [Google Scholar]

- Method for Determining Secondary Residual Products of Oil Refining in Mixed Fuels. Available online: https://new.fips.ru/Archive/PAT/2011FULL/2011.08.10/DOC/RUNWC1/000/000/002/426/116/DOCUMENT.PDF (accessed on 25 July 2021).

- Method for Determining Stability Factor of Fuel Compositions Containing Residual Products of Oil Processing. Available online: https://new.fips.ru/Archive/PAT/2007FULL/2007.09.10/DOC/RUNWC1/000/000/002/305/836/DOCUMENT.PDF (accessed on 25 July 2021).

- Method of Determining Compatibility of Components of Fuel Mixture. Available online: https://new.fips.ru/Archive/PAT/2012FULL/2012.02.27/DOC/RUNWC1/000/000/002/444/005/DOCUMENT.PDF (accessed on 25 July 2021).

- Fuel Compatibility and Stability Analyzer. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2018185520 (accessed on 25 July 2021).

- Pelenitsyna, O.A.; Litvinenko, N.A.; Gaile, A.A. Development of optimal formulations of ship low-viscosity and residual fuels on the basis of commodity oil products. Bull. SPBSIT 2018, 45, 30–36. [Google Scholar]

- Martin, C.W.G. The stability and compatibility of fuel oils. In Proceedings of the 3rd World Petroleum Congress, The Hague, The Netherlands, 28 May 1951; pp. 66–75. [Google Scholar]

- Holmes, J.W.; Bullin, J.A. Fuel oil compatibility probed. Hydrocarb. Process. 1983, 62, 101–103. [Google Scholar]

- Murzakov, R.M.; Sabanenkov, S.A.; Syunyaev, Z.I. Influence of petroleum resins on colloidal stability of asphaltene-containing disperse systems. Chem. Technol. Fuels Oils 1980, 16, 674–677. [Google Scholar] [CrossRef]

- Kassinger, R. Fuel blending—How to minimize risk of incompatibility. In Proceedings of the SPE 6th International Conference on Stability and Handling of Liquid Fuels, Vancouver, BC, Canada, 13–17 October 1997; pp. 489–502. [Google Scholar]

- Evdokimov, I.N. Problems of Incompatibility of Oils When They are Mixed; National University of Oil and Gas “Gubkin University” Press: Moscow, Russia, 2008. [Google Scholar]

- Mitusova, T.N.; Kondrasheva, N.K.; Lobashova, M.M.; Ershov, M.A.; Rudko, V.A. Influence of dispersing additives and blend composition on stability of marine high-viscosity fuels. J. Min. Inst. 2017, 228, 722–725. [Google Scholar]

- Gulvaeva, L.A.; Khavkin, V.A.; Shmel’kova, O.I.; Mitusova, T.N.; Ershov, M.A.; Lobashova, M.M.; Nikul’shin, P.A. Production technology for low-sulfur high-viscosity marine fuels. Chem. Technol. Fuels Oils 2019, 54, 759–765. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Rudko, V.A.; Nazarenko, M.Y.; Gabdulkhakov, R.R. Influence of parameters of delayed asphalt coking process on yield and quality of liquid and solid-phase products. J. Min. Inst. 2020, 241, 97–104. [Google Scholar] [CrossRef]

- Wiehe, I.A.; Kennedy, R.J. The oil compatibility model and crude oil incompatibility. Energy Fuels 2000, 14, 56–59. [Google Scholar] [CrossRef]

- Wiehe, I.A.; Yarranton, H.W.; Akbarzadeh, K.; Rahimi, P.M.; Teclemariam, A. The paradox of asphaltene precipitation with normal paraffins. Energy Fuels 2005, 19, 1261–1267. [Google Scholar] [CrossRef]

- Kopteva, A.V.; Koptev, V.Y. Automated monitoring system for asphaltene-resin-paraffin deposits in main oil pipelines. Int. J. Appl. Eng. Res. 2016, 11, 2191–2198. [Google Scholar]

- Cheremisina, O.V.; Ponomareva, M.A.; Sagdiev, V.N. Thermodynamic characteristics of sorption extraction and chromatographic separation of anionic complexes of erbium and cerium with Trilon B on weakly basic anionite. Russ. J. Phys. Chem. 2016, 90, 664–670. [Google Scholar] [CrossRef]

- Cheremisina, O.; Kulagin, V.; El-Saleem, S.; Nikulchev, E. Multisensory gas analysis system based on reconstruction attractors. Symmetry 2020, 12, 964. [Google Scholar] [CrossRef]

- Korshunov, G.I.; Eremeeva, A.M.; Drebenstedt, C. Justification of the use of a vegetal additive to diesel fuel as a method of protecting underground personnel of coal mines from the impact of harmful emissions of diesel-hydraulic locomotives. J. Min. Inst. 2021, 247, 39–47. [Google Scholar] [CrossRef]

- Prakoso, A.; Punase, A.; Klock, K.; Rogel, E.; Ovalles, C.; Hascakir, B. Determination of the stability of asphaltenes through physicochemical characterization of asphaltenes. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23 May 2016; pp. 1–20. [Google Scholar]

- Povarov, V.G.; Lopatnikov, A.I. A simple multisensor detector based on tin dioxide in capillary gas chromatography. J. Anal. Chem. 2016, 71, 901–906. [Google Scholar] [CrossRef]

- Method of Determining Compatibility and Stability of Fuel Mixture Components. Available online: https://new.fips.ru/ofpstorage/Doc/IZPM/RUNWC1/000/000/002/733/748/%D0%98%D0%97-02733748-00001/document.pdf (accessed on 25 July 2021).

- Program for Calculating Kinematic Viscosity, Density, Sulfur and Water Content for a Mixture of Crude Oil and Petroleum Products. Available online: https://new.fips.ru/ofpstorage/Doc/PrEVM/RUNWPR/000/002/020/613/357/2020613357-00001/document.pdf (accessed on 25 July 2021).

| No. | Indicator Name | Unit of Measurement | Regulation of the Test Method | Result | |||

|---|---|---|---|---|---|---|---|

| Sample No.1 | Sample No.2 | Sample No.3 | Sample No.4 | ||||

| 1 | Density at 15 °C | kg/m3 | ISO 12185 | 833.5 | 901.0 | 956.0 | 976.0 |

| 2 | Kinematic viscosity at 50 °C | mm2/s | GOST 33 ISO 3104 | 12.1 | 34.5 | 321.5 | 680.1 |

| 3 | Flashpoint PMCC | °C | GOSTREN ISO 2719 | 181.0 | 110.0 | 98.0 | 110.0 |

| 4 | Sulfur mass fraction | % | GOST R 51947 ISO 8754 | 0.004 | 0.046 | 1.276 | 2.668 |

| 5 | Pourpoint | °C | ASTM D 6749 | 26.0 | 10.0 | 16.0 | 20.0 |

| 6 | Mass fraction of water | % | GOST R 51946 ISO 3733 | – | – | 0.05 | 0.1 |

| 7 | Total sediment accelerated (TSA) | % | GOST R 50837.6 ISO 10307-2 | 0.01 | 0.01 | 0.02 | 0.03 |

| 8 | Total sediment potential (TSP) | % | GOST R 50837.6 ISO 10307-2 | 0.01 | 0.01 | 0.02 | 0.04 |

| Fuel Samples | Asphaltenes, wt. % | n-Alkanes, wt. % | Isoalkane, wt. % | Naphthenes, wt. % | Alkenes, wt. % | Aromatic Hydrocarbons, wt. % | Resins, wt. % |

|---|---|---|---|---|---|---|---|

| No.1 | – | 71.93 | 18.35 | 2.62 | 5.55 | 1.55 | – |

| No.2 | – | 38.68 | 55.09 | 4.95 | – | 1.28 | – |

| No.3 | 2.53 | 54.14 | 22.74 | 5.43 | 0.57 | 14.12 | 0.47 |

| No.4 | 7.15 | 51.15 | 20.71 | 4.37 | 0.41 | 15.70 | 0.51 |

| No. | Asphaltenes, % | n-Paraffins, % | Isoparaffins, % | Aromatic Hydrocarbons, % | Density at 15 °C, kg/m3 | Kinematic Viscosity at 50 °C, mm2/s | Sulfur, % | TSP Values, % |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.5 | 54.91 | 34.05 | 4.00 | 885.7 | 30.74 | 0.29 | 0.02 |

| 2 | 55.92 | 32.93 | 4.01 | 883.6 | 29.63 | 0.29 | 0.02 | |

| 3 | 56.94 | 31.82 | 4.01 | 881.5 | 28.57 | 0.29 | 0.02 | |

| 4 | 57.95 | 30.71 | 4.01 | 879.4 | 27.56 | 0.28 | 0.02 | |

| 5 | 58.95 | 29.61 | 4.01 | 877.3 | 26.60 | 0.28 | 0.02 | |

| 6 | 59.95 | 28.51 | 4.01 | 875.2 | 25.69 | 0.28 | 0.02 | |

| 7 | 60.94 | 27.42 | 4.02 | 873.2 | 24.82 | 0.28 | 0.02 | |

| 8 | 61.93 | 26.33 | 4.02 | 871.1 | 24.00 | 0.27 | 0.05 | |

| 9 | 62.92 | 25.25 | 4.02 | 869.1 | 23.20 | 0.27 | 0.13 | |

| 10 | 64.06 | 24.00 | 4.02 | 866.7 | 22.33 | 0.27 | 0.20 | |

| 11 | 65.04 | 22.93 | 4.02 | 864.7 | 21.61 | 0.26 | 0.25 | |

| 12 | 66.01 | 21.86 | 4.02 | 862.7 | 20.93 | 0.26 | 0.29 | |

| 13 | 66.98 | 20.80 | 4.02 | 860.7 | 20.28 | 0.26 | 0.33 | |

| 14 | 67.94 | 19.74 | 4.02 | 858.7 | 19.65 | 0.25 | 0.39 | |

| 15 | 69.03 | 19.02 | 3.59 | 853.5 | 17.75 | 0.23 | 0.47 | |

| 16 | 70.05 | 18.66 | 2.85 | 846.4 | 15.40 | 0.20 | 0.58 |

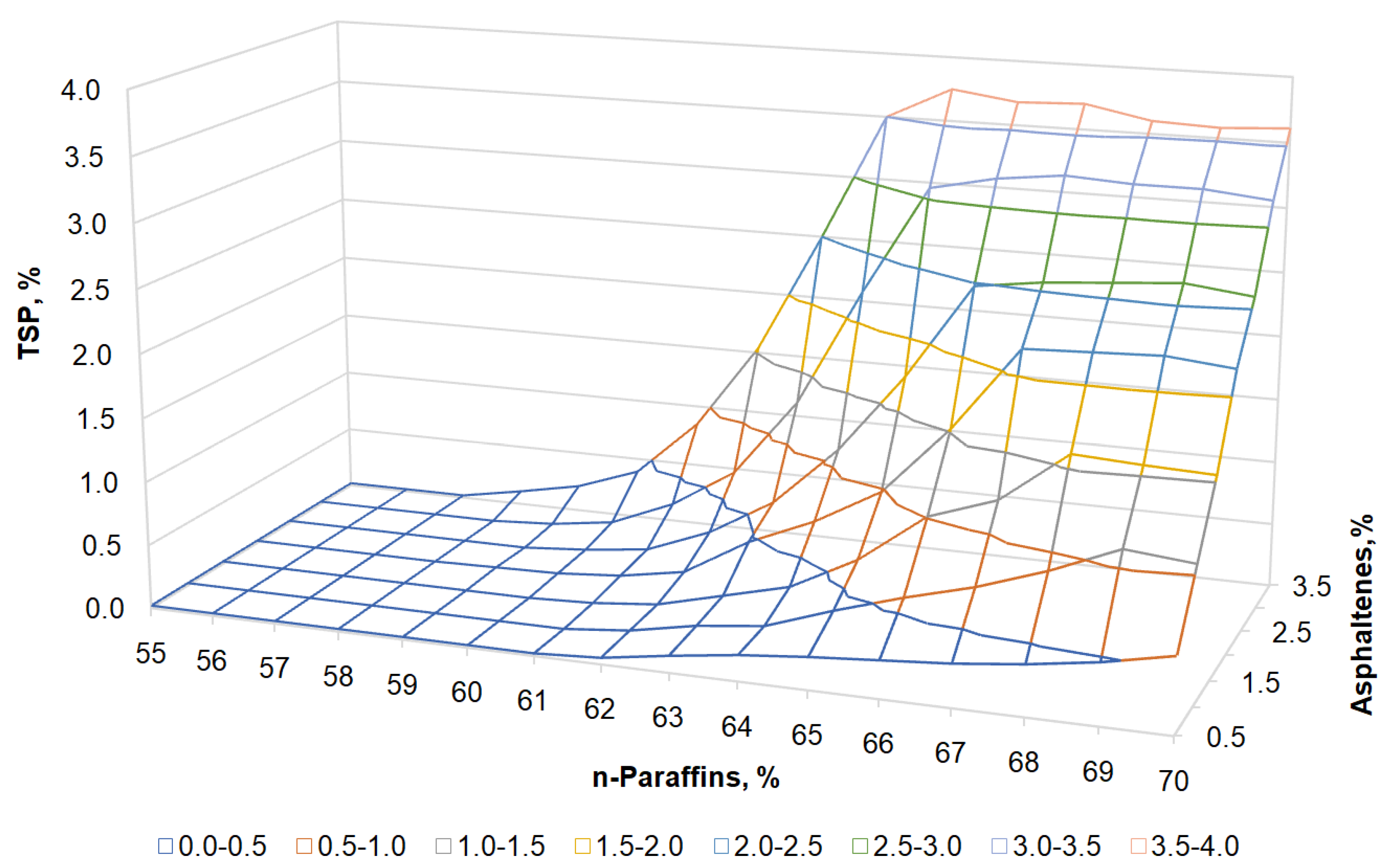

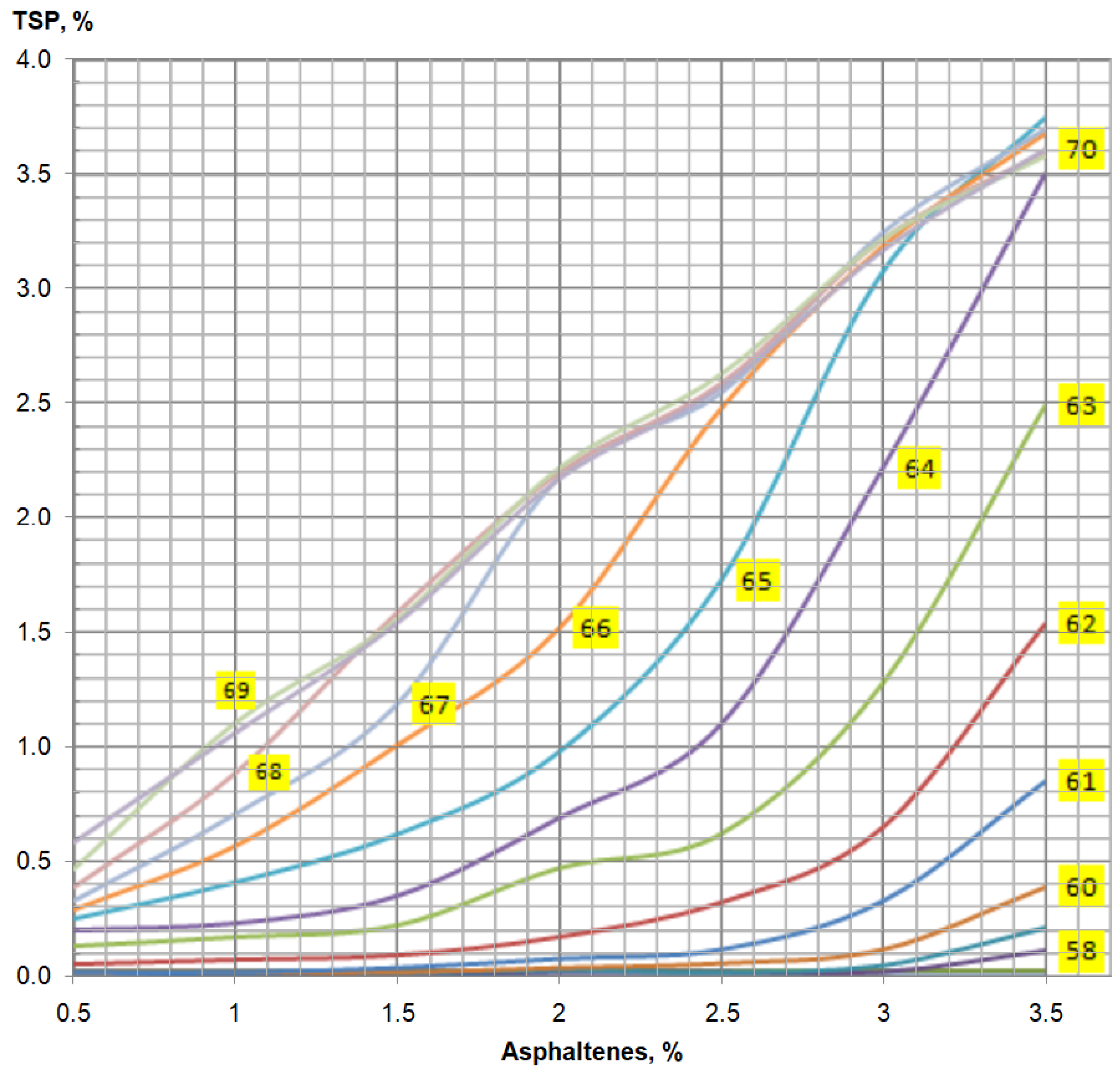

| n-Paraffins, % | Asphaltenes, % | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | |

| 55 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 56 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 57 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 58 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.11 |

| 59 | 0.02 | 0.02 | 0.02 | 0.03 | 0.02 | 0.05 | 0.21 |

| 60 | 0.02 | 0.02 | 0.02 | 0.04 | 0.06 | 0.12 | 0.39 |

| 61 | 0.02 | 0.02 | 0.04 | 0.08 | 0.12 | 0.33 | 0.85 |

| 62 | 0.05 | 0.07 | 0.09 | 0.17 | 0.32 | 0.65 | 1.54 |

| 63 | 0.13 | 0.17 | 0.22 | 0.47 | 0.62 | 1.28 | 2.49 |

| 64 | 0.20 | 0.23 | 0.35 | 0.69 | 1.10 | 2.22 | 3.50 |

| 65 | 0.25 | 0.41 | 0.62 | 0.98 | 1.73 | 3.08 | 3.75 |

| 66 | 0.29 | 0.57 | 1.01 | 1.52 | 2.48 | 3.19 | 3.68 |

| 67 | 0.33 | 0.71 | 1.19 | 2.18 | 2.55 | 3.25 | 3.70 |

| 68 | 0.39 | 0.89 | 1.59 | 2.20 | 2.59 | 3.22 | 3.60 |

| 69 | 0.47 | 1.11 | 1.56 | 2.22 | 2.63 | 3.22 | 3.58 |

| 70 | 0.58 | 1.06 | 1.54 | 2.17 | 2.57 | 3.17 | 3.61 |

| Multiple R | 0.999471 |

| R-square | 0.998943 |

| Normalized R-square | 0.998731 |

| Standard error | 0.038477 |

| Significance of F | 1.24E-08 |

| Student t-test | 68.7256 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultanbekov, R.; Islamov, S.; Mardashov, D.; Beloglazov, I.; Hemmingsen, T. Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility. J. Mar. Sci. Eng. 2021, 9, 1067. https://doi.org/10.3390/jmse9101067

Sultanbekov R, Islamov S, Mardashov D, Beloglazov I, Hemmingsen T. Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility. Journal of Marine Science and Engineering. 2021; 9(10):1067. https://doi.org/10.3390/jmse9101067

Chicago/Turabian StyleSultanbekov, Radel, Shamil Islamov, Dmitry Mardashov, Ilia Beloglazov, and Tor Hemmingsen. 2021. "Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility" Journal of Marine Science and Engineering 9, no. 10: 1067. https://doi.org/10.3390/jmse9101067

APA StyleSultanbekov, R., Islamov, S., Mardashov, D., Beloglazov, I., & Hemmingsen, T. (2021). Research of the Influence of Marine Residual Fuel Composition on Sedimentation Due to Incompatibility. Journal of Marine Science and Engineering, 9(10), 1067. https://doi.org/10.3390/jmse9101067