Study on Hydrodynamic Coefficients of a Submarine Piggyback Pipeline under the Action of Waves and Current

Abstract

:1. Introduction

2. Experimental Section

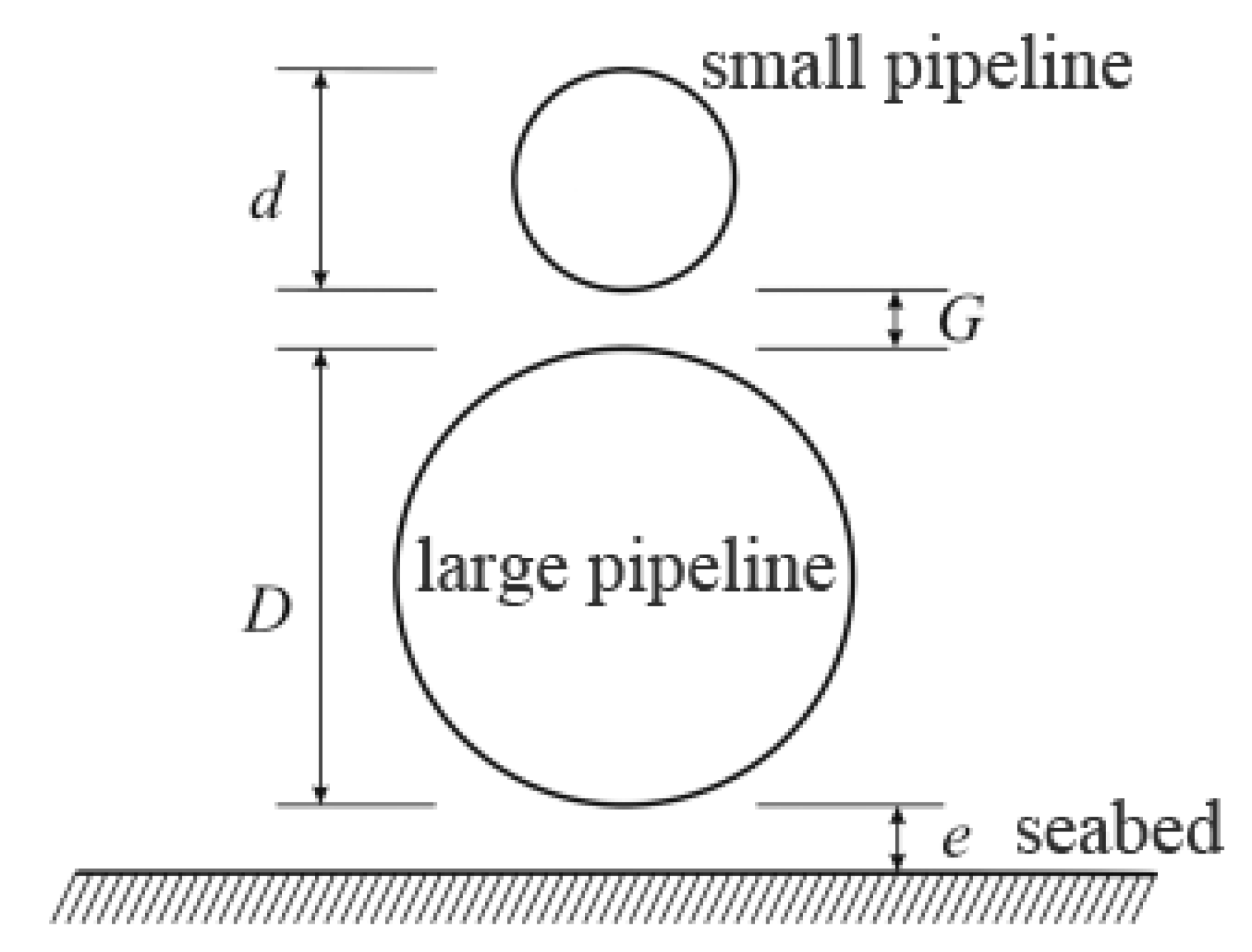

2.1. Experimental Arrangement

2.2. Experimental Wave and Current Parameters

2.3. Data Processing Methods

2.3.1. Velocity and Acceleration of Water Paricles in Wave–Current Coexisting Field

2.3.2. Hydrodynamic Coefficient Analysis Method

3. Experimental Model Verification

4. Experimental Results and Analysis

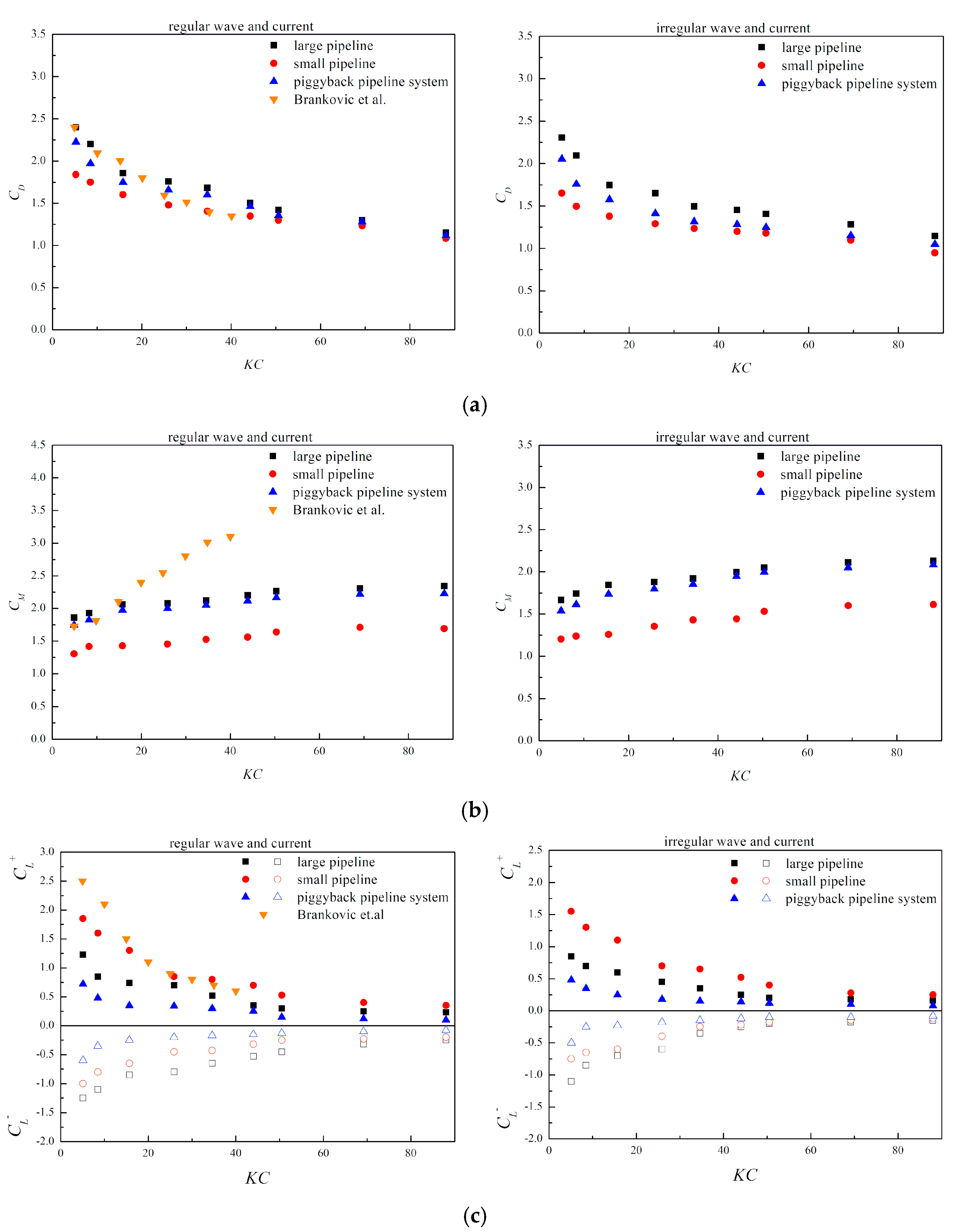

4.1. Effect of the KC Number

4.2. Effect of the Velocity Ratio

4.3. Effect of the Gap Ratio

4.4. Effect of the Spacing Ratio

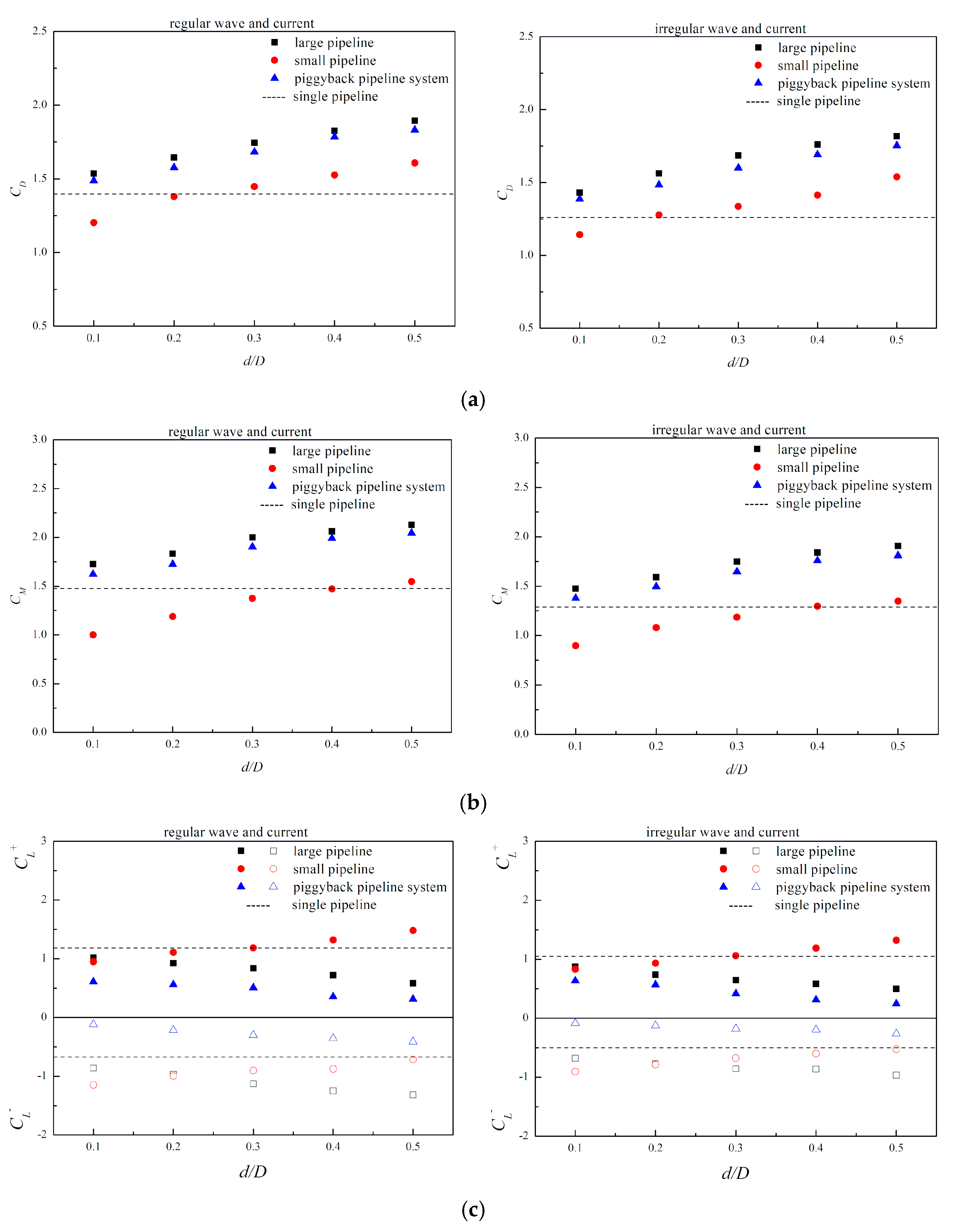

4.5. Effect of the Diameter Ratio

5. Conclusions

- (1)

- No matter whether they are under the action of regular wave and current or irregular wave and current, the hydrodynamic coefficients of the submarine piggyback pipeline change with KC in the same way. With the increase in KC, , and decrease gradually, but increases slowly. In terms of magnitude, of the small pipeline is smaller than that of the large one and the pipeline system, and the difference decreases with the increase in KC, of the small pipeline is about 70% of that of the large one or the pipeline system, and the lift coefficient difference between the large, small pipeline and pipeline system gradually decreases as KC increases.

- (2)

- Relative to the pure wave field, the existence of steady flow will lead to a decrease in the hydrodynamic coefficients. Under the action of waves and current, the hydrodynamic coefficients of the large, small pipeline and piggyback pipeline system have the same variation trend with , , , and all decreasing as increases, and the variation amplitude gradually tends to flatten out.

- (3)

- The hydrodynamic coefficients of the large, small pipeline and piggyback pipeline system have the same trend of change with e/D. With the increase in e/D, , and decrease, but increases. When e/D > 0.5, the influence of the seabed on the near wall of the piggyback pipeline gradually weakens or even disappears.

- (4)

- With the increase in G/D, and of the large, small pipeline and piggyback pipeline system all decrease, of the large pipeline increases, decreases, while those of the small pipeline are the opposite. When G/D > 0.6, the influence of G/D on the large pipeline is gradually weakened, and the hydrodynamic coefficients of the large pipeline gradually approach the results of the single pipeline.

- (5)

- With the increase in d/D, and of the piggyback pipeline all increase, of the large pipeline and the pipeline system gradually decreases and gradually increases; on the contrary, of the small pipeline increases and decreases. In terms of magnitude, with the increase in d/D, the lift coefficient difference between the large and small pipelines gradually increases. When d/D = 0.5, the of the small pipeline is about 2–3 times that of the large one, while is about 0.5 times that of the large pipeline.

- (6)

- In practical engineering, the Morrison equation is widely used in hydrodynamic analysis and calculation of submarine pipelines, and the value of hydrodynamic coefficient is the most important one. The stability and safety evaluation of the submarine piggyback pipeline should not only investigate the overall stability of the pipeline system, but also investigate the stability of the large and small pipeline, respectively. Therefore, the above experimental results on hydrodynamic coefficients can be used as an important basis for the safety design of submarine piggyback pipeline.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brockbank, J. Bundled pipes speed offshore laying. Oil Gas J. 1990, 88, 78–84. [Google Scholar]

- Yang, H.; Ni, H.; Zhu, X.H. An applicable replacement bundled pipeline structure for offshore marginal oilfield development. Shipbuild. China 2007, 48, 563–570. [Google Scholar]

- Kalghatgi, S.G.; Sayer, P.G. Hydrodynamic forces on piggyback pipeline configurations. J. Waterw. Port Coast. Ocean Eng. 1997, 123, 16–22. [Google Scholar] [CrossRef]

- Kamarudin, M.H.; Thiagarajan, K.P.; Czajko, A. Analysis of current-induced forces on offshore pipeline bundles. In Proceedings of the 5th International Conference on CFD in the Process Industries, Melbourne, Australia, 13–15 December 2006; Volume 1, pp. 1–6. [Google Scholar]

- Zhao, M.; Cheng, L.; Teng, B. Numerical modeling of flow and hydrodynamic forces around a piggyback pipeline near the seabed. J. Waterw. Port Coast. Ocean Eng. 2007, 133, 286–295. [Google Scholar] [CrossRef]

- Yang, S.P.; Shi, B.; Guo, Y.K.; Yang, L.P. Investigation on scour protection of submarine piggyback pipeline. Ocean. Eng. 2019, 182, 442–450. [Google Scholar] [CrossRef]

- Asrari, S.; Hakimzadeh, H.; Kardan, N. Investigation on the local scour beneath piggyback pipelines under clear-water conditions. China Ocean. Eng. 2021, 35, 422–431. [Google Scholar] [CrossRef]

- Janocha, M.J.; Ong, M.C. Vortex-induced vibrations of piggyback pipelines near the horizontal plane wall in the upper transition regime. Mar. Struct. 2021, 75, 102872. [Google Scholar] [CrossRef]

- Jiang, C.B.; Xu, J.; Qu, K. Numerical investigation on vortex-induced vibration in two-degree-of-freedom piggyback pipeline. J. Harbin Eng. Univ. 2021, 42, 729–737. [Google Scholar]

- Cheng, X.F.; Wang, Y.X.; Wang, G.Y. Hydrodynamic forces on large pipeline and small pipeline in piggyback configuration under wave action. J. Waterw. Port Coast. Ocean Eng. 2012, 138, 394–405. [Google Scholar] [CrossRef]

- Cheng, X.F.; Wang, Y.X.; Wang, G.Y. Influence of proximity of the seabed on hydrodynamic forces on a submarine piggyback pipeline under wave action. J. Offshore Mech. Arct. Eng. 2013, 135, 021701. [Google Scholar] [CrossRef]

- Ma, L.; Wang, J.Y.; Sun, S.S.; Xing, Z.Z. Experimental study of hydrodynamic force loading under the action of wave current on submarine composite pipelines. J. Dalian Univ. 1993, 3, 54–63. [Google Scholar]

- Li, Y.C.; Zhang, N.C.; Sun, Y. The hydrodynamic characteristic of submarine composite pipeline in wave-current coexisting field. J. Hydrodyn. 1994, 9, 51–59. [Google Scholar]

- Branković, M.; Zeitoun, H.; Sutherland, J.; Pearce, A.; Willcocks, J. Physical modelling of hydrodynamic loads on piggyback pipelines in combined wave and current conditions. In Proceedings of the 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; Volume 5, pp. 933–942. [Google Scholar]

- Li, Y.C. Aspect of the normalization of hydrodynamic coefficients in Morison Equation. J. Hydrodyn. 1998, 13, 329–337. [Google Scholar]

- Li, Y.C. Effect of wave-current interaction on the wave parameter. J. Dalian Univ. Technol. 1982, 21, 81–91. [Google Scholar]

- Morison, J.R.; O’Brien, M.P.; Johnson, J.W.; Schaaf, S.A. The force exerted by surface waves on piles. J. Pet. Technol. 1950, 2, 149–154. [Google Scholar] [CrossRef]

- Zhao, D.T. Study on the transverse wave force coefficient CL(n) of submarine horizontal circular pipe. China Offshore Platf. 1993, 8, 137–141. [Google Scholar]

- Sarpkaya, T. Forces on cylinders near a plane boundary in a sinusoidally oscillating fluid. J. Fluids Eng. 1976, 98, 499–503. [Google Scholar] [CrossRef]

- Bryndum, M.B.; Jacobsen, V.; Tsahalis, D.T. Hydrodynamic forces on pipelines: Model tests. J. Offshore Mech. Arct. Eng. 1992, 114, 231–241. [Google Scholar] [CrossRef]

| Pipeline Model | Length (cm) | Outer Diameter (mm) | Wall Thickness (mm) | Material |

|---|---|---|---|---|

| large pipeline | 100 | 20 | 2 | hollow aluminum pipe, filled with water |

| small pipelines | 100 | 2 | 0 | stainless steel bar |

| 100 | 4 | 0 | copper bar | |

| 100 | 6 | 0 | aluminum bar | |

| 100 | 8 | 0 | aluminum bar | |

| 100 | 10 | 0 | aluminum bar |

| Steady Flow | Regular Wave | Irregular Wave | Maximum Horizontal Velocity of the Wave Water Particle uwm () (m/s) | Keulegan–Carpenter Number KC | ||

|---|---|---|---|---|---|---|

| Flow Velocity Uc (m/s) | Wave Height H (m) | Period T (s) | Significant Wave Height (m) | Peak Spectral Period Tp (s) | ||

| 0.04 | 0.04 | 0.8 | 0.04 | 0.8 | 0.05 | 5.1 |

| 0.04 | 0.06 | 1.0 | 0.06 | 1.0 | 0.10 | 8.5 |

| 0.10 | 0.06 | 1.0 | 0.06 | 1.0 | 0.10 | 15.7 |

| 0.15 | 0.09 | 1.1 | 0.09 | 1.1 | 0.14 | 25.9 |

| 0.20 | 0.09 | 1.1 | 0.09 | 1.1 | 0.14 | 34.6 |

| 0.20 | 0.09 | 1.4 | 0.09 | 1.4 | 0.16 | 44.0 |

| 0.20 | 0.09 | 1.6 | 0.09 | 1.6 | 0.18 | 50.5 |

| 0.40 | 0.09 | 1.1 | 0.09 | 1.1 | 0.14 | 69.2 |

| 0.35 | 0.09 | 1.6 | 0.09 | 1.6 | 0.18 | 88.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, X.; Yang, J.; Xu, T.; Xu, Q. Study on Hydrodynamic Coefficients of a Submarine Piggyback Pipeline under the Action of Waves and Current. J. Mar. Sci. Eng. 2021, 9, 1118. https://doi.org/10.3390/jmse9101118

Cheng X, Yang J, Xu T, Xu Q. Study on Hydrodynamic Coefficients of a Submarine Piggyback Pipeline under the Action of Waves and Current. Journal of Marine Science and Engineering. 2021; 9(10):1118. https://doi.org/10.3390/jmse9101118

Chicago/Turabian StyleCheng, Xiaofei, Jun Yang, Tiaojian Xu, and Qianyuan Xu. 2021. "Study on Hydrodynamic Coefficients of a Submarine Piggyback Pipeline under the Action of Waves and Current" Journal of Marine Science and Engineering 9, no. 10: 1118. https://doi.org/10.3390/jmse9101118