A Novel Strength Model for Cement Marine Clay Based on the Mechanical-Chemical Coupling Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

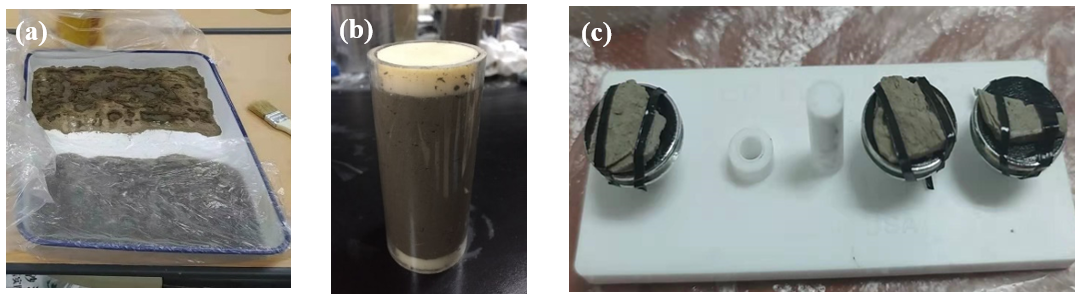

2.2. Preparation of Samples

2.2.1. Samples for Strength Test

2.2.2. Samples for the SEM Observation

2.3. Method and Tests

2.3.1. UCS Test

2.3.2. SEM Observation

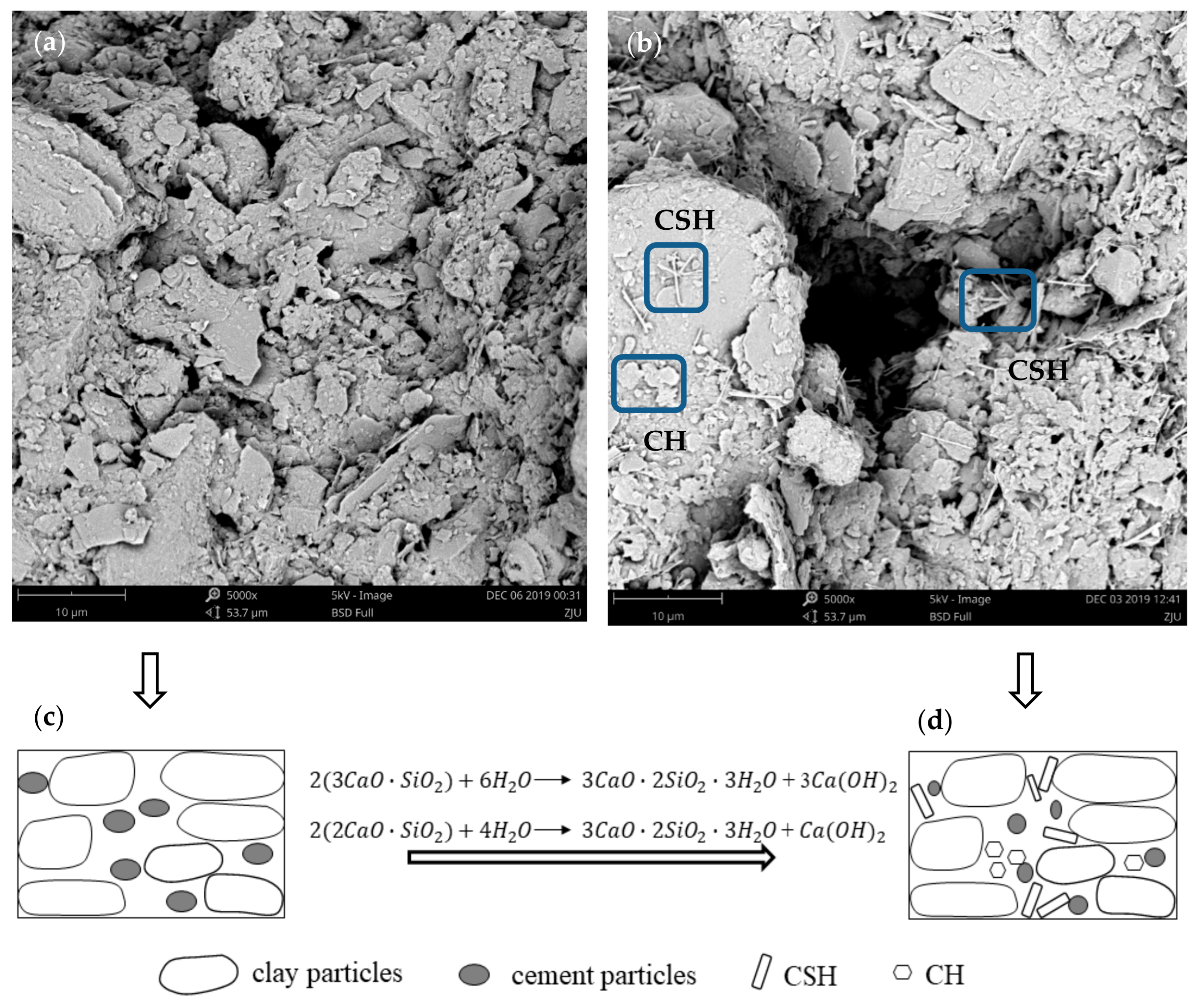

2.4. The Mechanisms of Mechanical-Chemical Coupling during the Cement Hydration Process

2.5. The MC Model

2.5.1. Elastic Behavior

2.5.2. The Yield Function

2.6. The Simulation of the UCS Test via COMSOL

3. Results

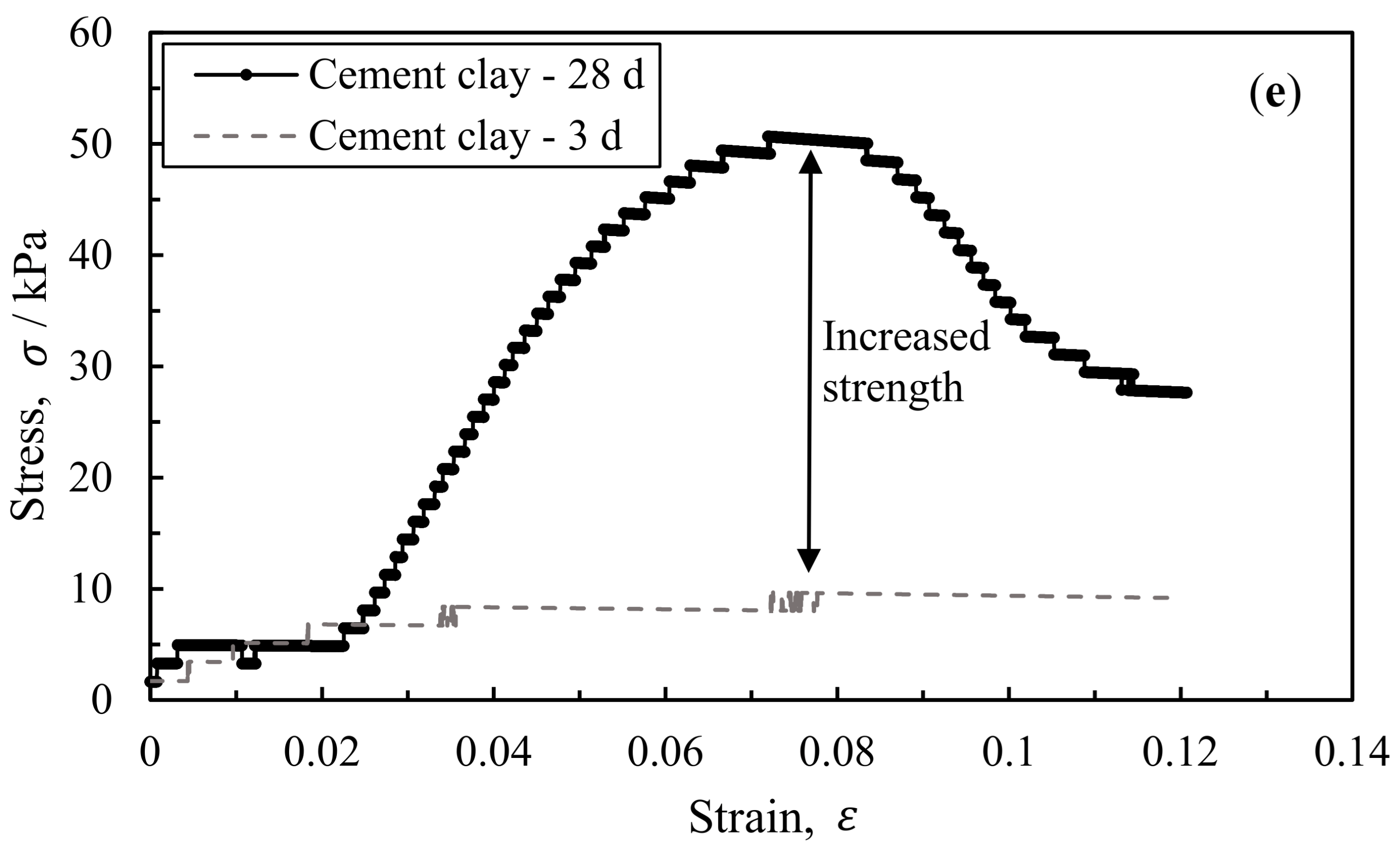

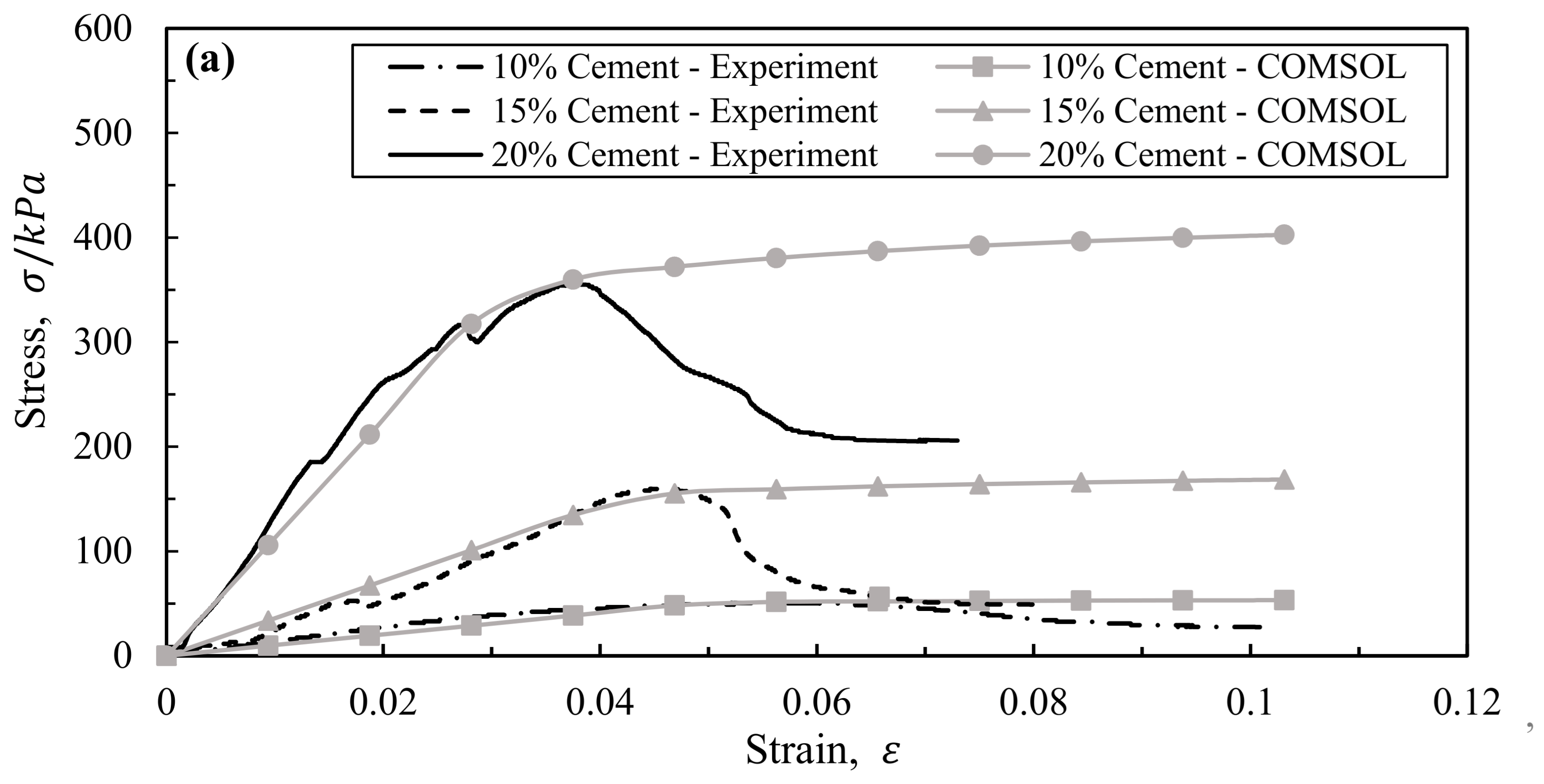

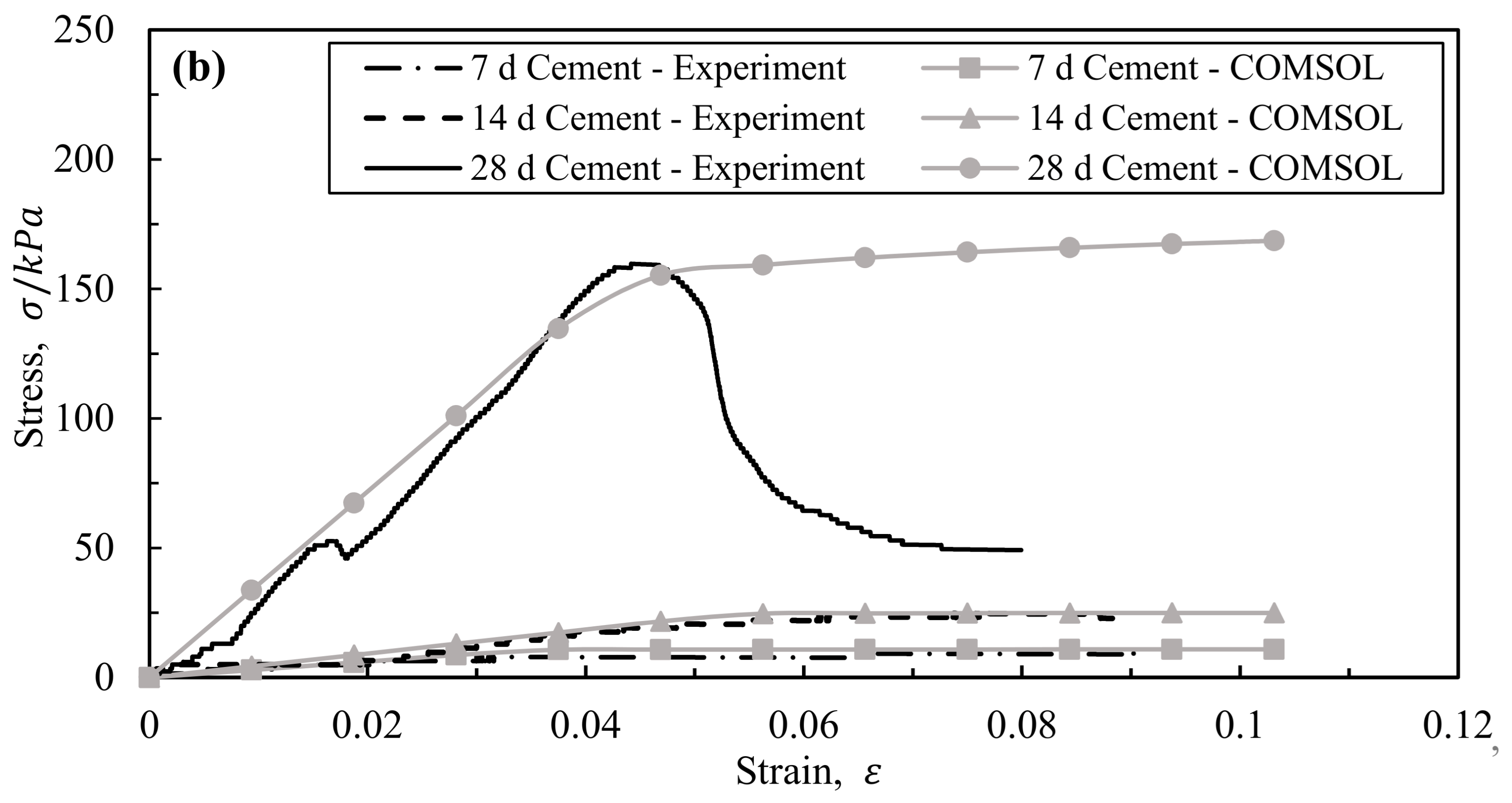

3.1. Comparison between the Experiment and Simulation

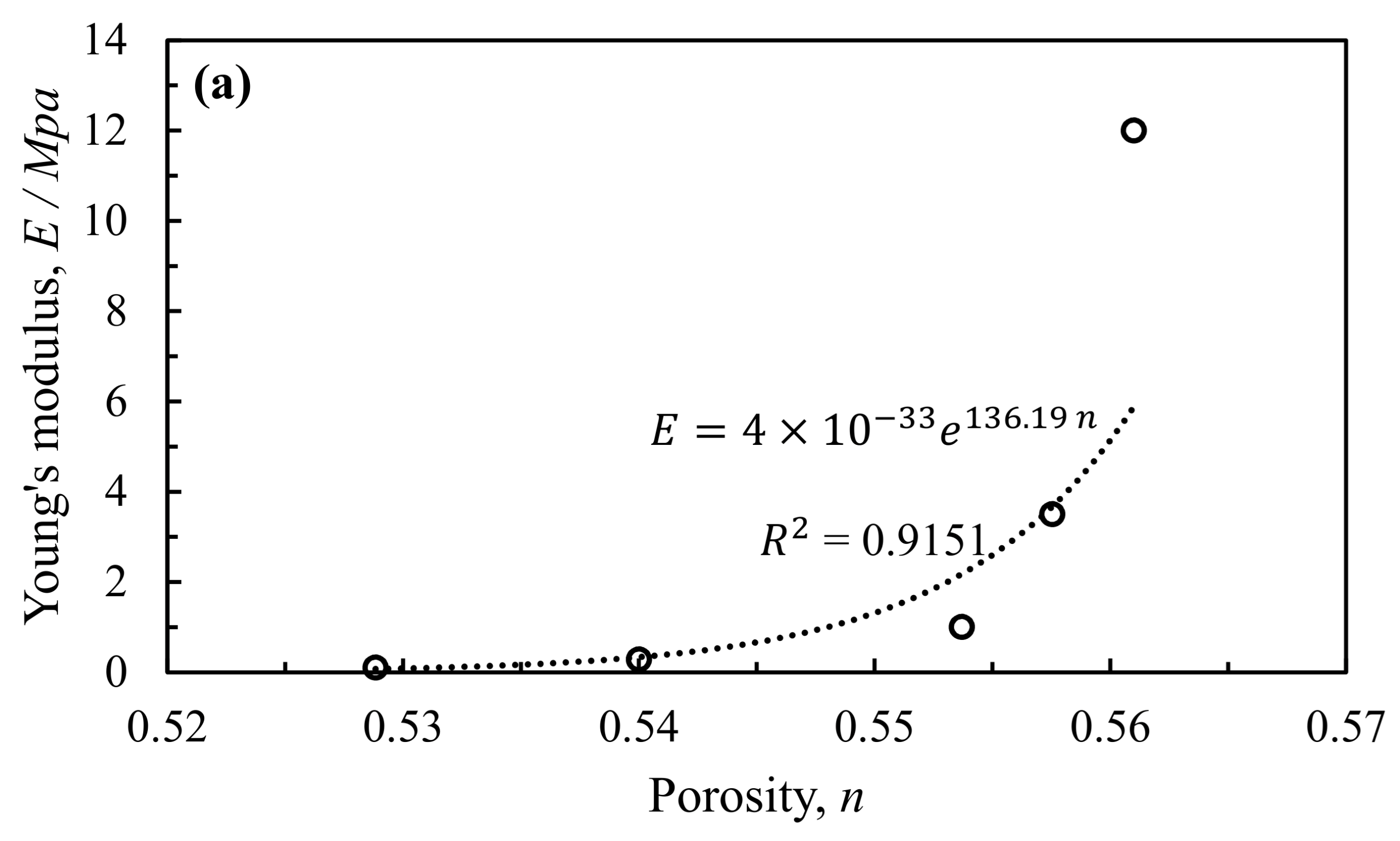

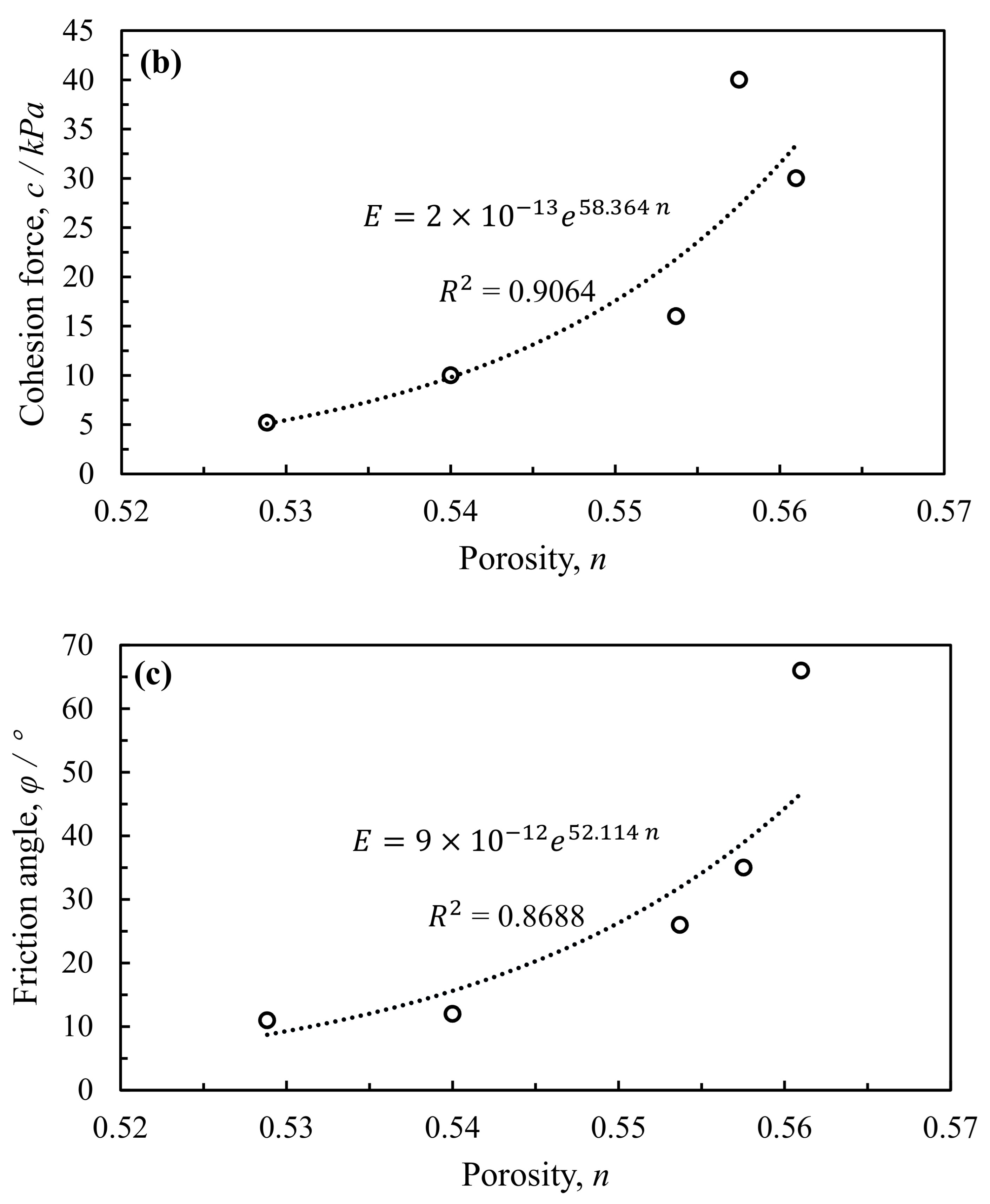

3.2. Results of Mechanical Parameters of the M-C Model

4. Discussion

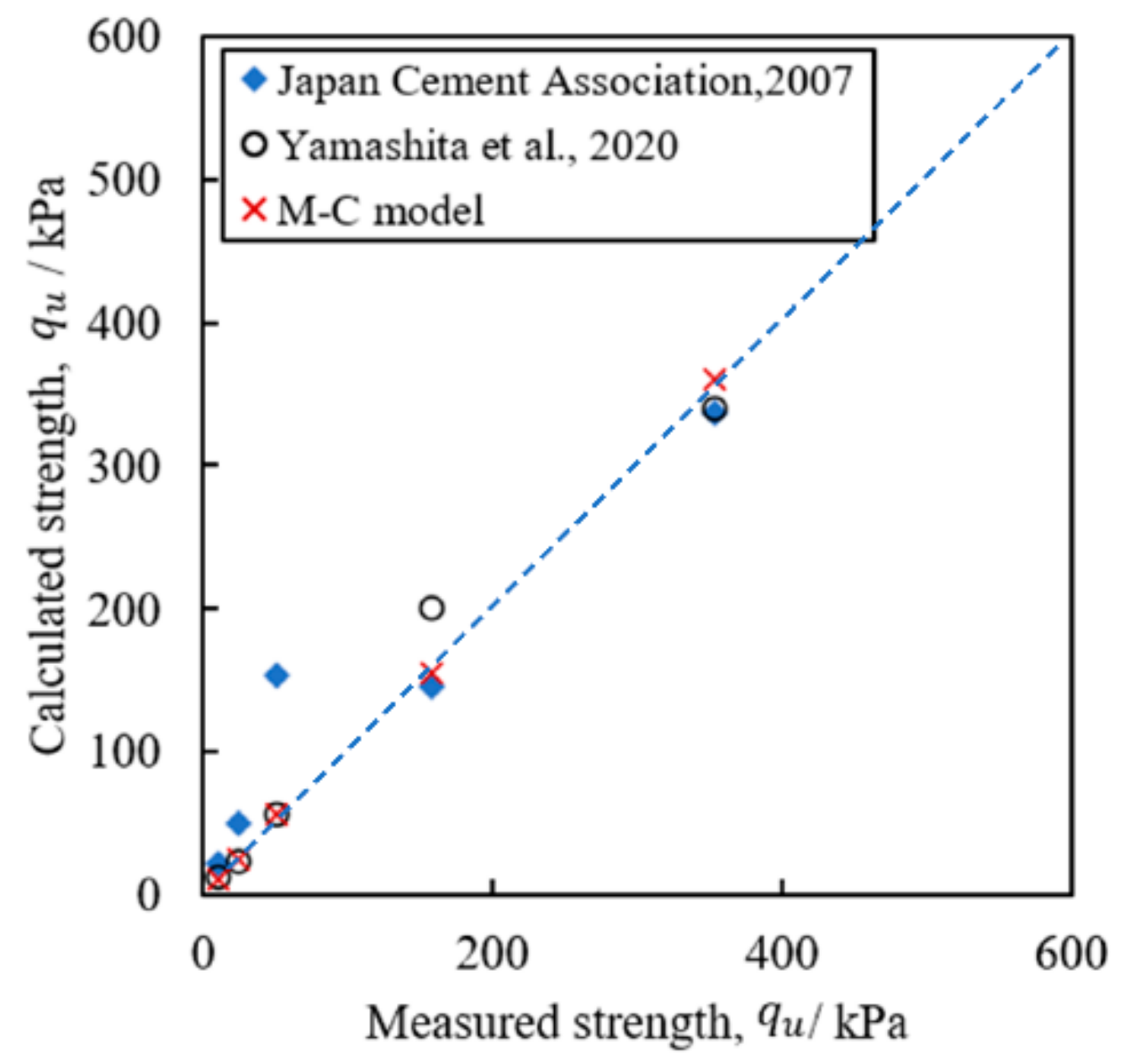

4.1. The Comparison with Existing Strength Models

4.2. The Sensitivity Analysis of Mechanical Parameters

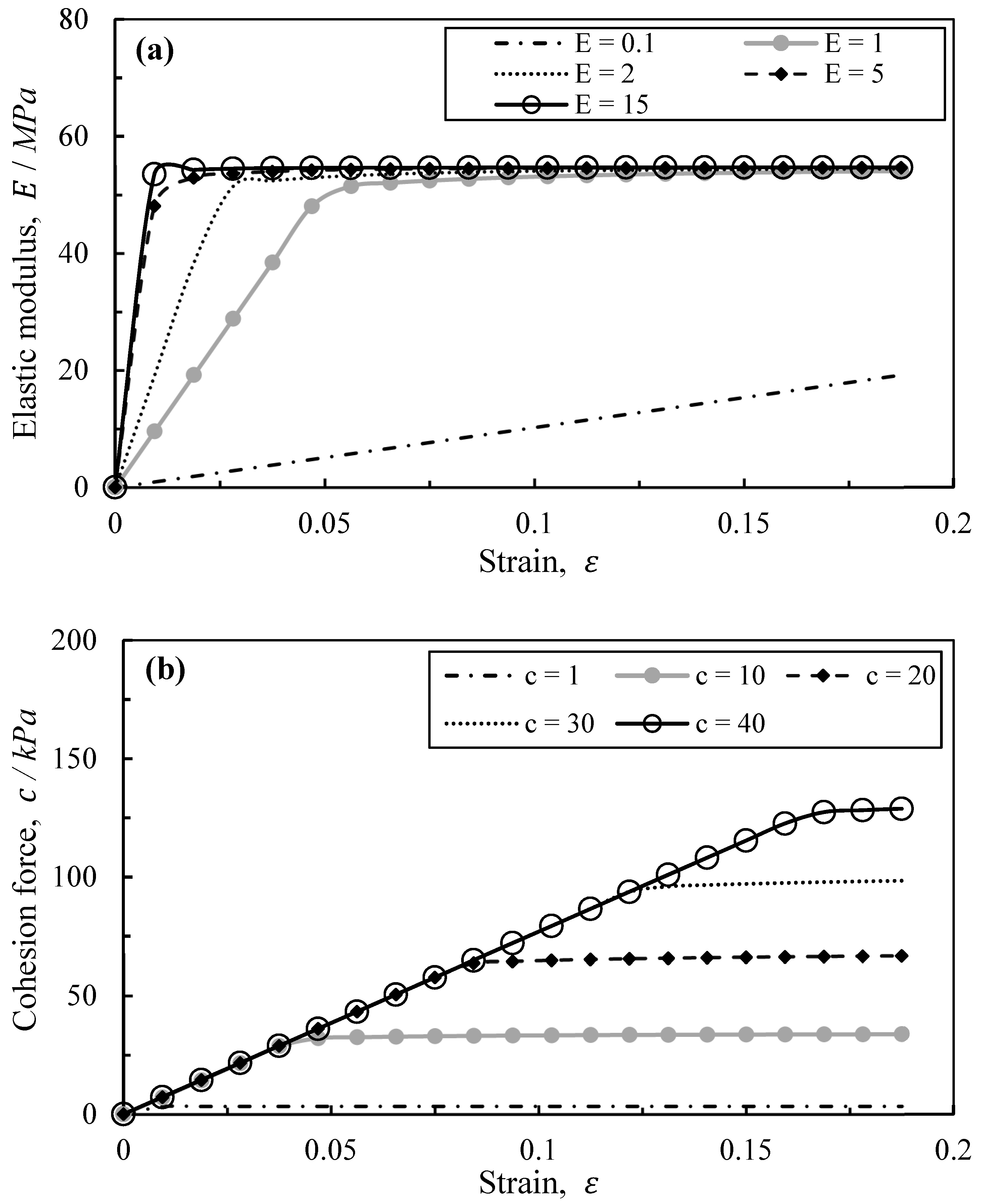

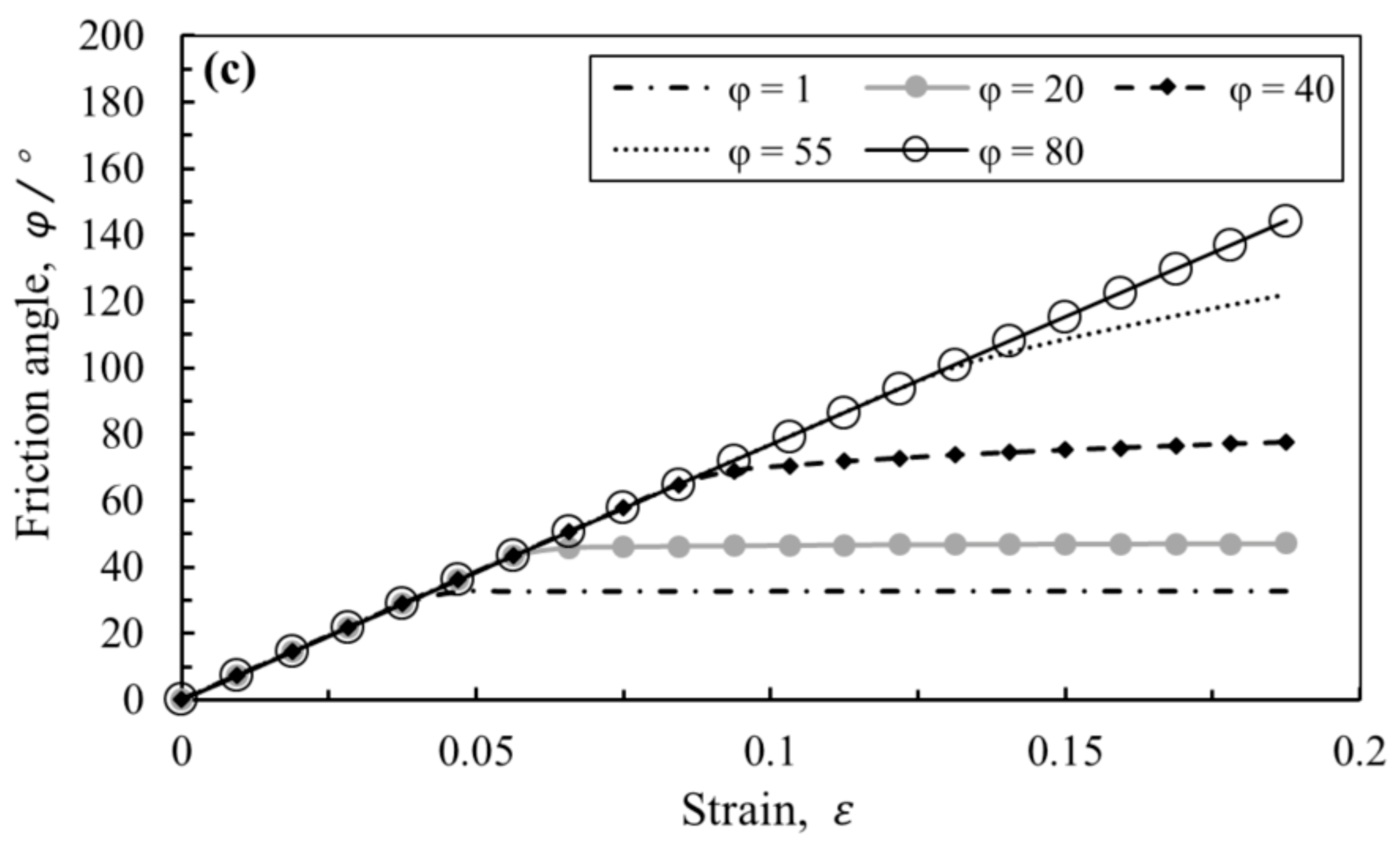

4.3. The Identification of Parameters in the M-C Model

5. Conclusions

- The strength varies during the cement hydration process in the cement marine clay. According to the mechanism analysis of the MCI using SEM images, the porosity was employed to describe the influence of the mechanical-chemical coupling, and the MC model was appropriately established.

- Comparisons were made between the predicted results by the MC model, the UCS test, and the existing strength model. The obtained results indicate that the proposed model is suitable for capturing the UCS strength of the cement marine clay. It is a simple model but an effective one with only one parameter (i.e., porosity), which can be readily obtained.

- Regarding the stress–strain curve of the MC model, the elastic stage is controlled by Young’s modulus , and the slope becomes steeper with its growth. Further, the plastic stage is controlled by the cohesion force and friction angle , and the yield stress is enhanced by growing and .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Bared, M.A.M.; Marto, A. A Review on the Geotechnical and Engineering Characteristics of Marine Clay and the Modern Methods of Improvements. Malays. J. Fundam. Appl. Sci. 2017, 13, 825–831. [Google Scholar] [CrossRef] [Green Version]

- Zainuddin, N.; Yunus, N.Z.M.; Al-Bared, M.A.M.; Marto, A.; Harahap, I.S.H.; Rashid, A.S.A. Measuring the Engineering Properties of Marine Clay Treated with Disposed Granite Waste. Measurement 2019, 131, 50–60. [Google Scholar] [CrossRef]

- Saisubramanian, R.; Murugaiyan, V.; Sundararajan, T. Studies on Characteristics, Applications and Strength Improvement of Marine Clay: A Review. J. Geosci. Environ. Prot. 2019, 7, 93–106. [Google Scholar] [CrossRef] [Green Version]

- Shenal Jayawardane, V.; Anggraini, V.; Emmanuel, E.; Yong, L.L.; Mirzababaei, M. Expansive and Compressibility Behavior of Lime Stabilized Fiber-Reinforced Marine Clay. J. Mater. Civ. Eng. 2020, 32, 04020328. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Ma, L.; Yin, Z.Y.; Horpibulsuk, S. Evaluation of the Strength Increase of Marine Clay under Staged Embankment Loading: A Case Study. Mar. Georesour. Geotechnol. 2015, 33, 532–541. [Google Scholar] [CrossRef]

- Al-Bared, M.A.M.; Marto, A. Evaluating the Compaction Behaviour of Soft Marine Clay Stabilized with Two Sizes of Recycled Crushed Tiles. In Proceedings of the Global Civil Engineering Conference, Kuala Lumpur, Malaysia, 25–28 July 2017; Springer: Singapore, 2017; pp. 1273–1284. [Google Scholar]

- Al-Bared, M.A.M.; Marto, A.; Latifi, N.; Horpibulsuk, S. Sustainable Improvement of Marine Clay Using Recycled Blended Tiles. Geotech. Geol. Eng. 2018, 36, 3135–3147. [Google Scholar] [CrossRef]

- Al-Bared, M.A.M.; Marto, A.; Hamonangan, I.S.; Kasim, F. Compaction and Plasticity Comparative Behaviour of Soft Clay Treated with Coarse and Finesizes of Ceramic Tiles. E3S Web Conf. 2018, 34, 01012. [Google Scholar] [CrossRef] [Green Version]

- Al-Bared, M.A.M.; Mustaffa, Z.; Armaghani, D.J.; Marto, A.; Yunus, N.Z.M.; Hasanipanah, M. Application of Hybrid Intelligent Systems in Predicting the Unconfined Compressive Strength of Clay Material Mixed with Recycled Additive. Transp. Geotech. 2021, 30, 100627. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, M.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Leong, M. Evaluation of Fly Ash-and Slag-Based Geopolymers for the Improvement of a Soft Marine Clay by Deep Soil Mixing. Soils Found. 2018, 58, 1358–1370. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Arulrajah, A.; Suksiripattanapong, C.; Udomchai, R. Strength Development in Soft Marine clay Stabilized by Fly Ash and Calcium Carbide Residue Based Geopolymer. Appl. Clay Sci. 2016, 127, 134–142. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Darmawan, S.; Wang, J. Impact of Field Conditions on the Strength Development of a Geopolymer Stabilized Marine Clay. Appl. Clay Sci. 2019, 167, 33–42. [Google Scholar] [CrossRef]

- Dahal, B.K.; Zheng, J.J.; Zhang, R.J.; Song, D.B. Enhancing the Mechanical Properties of Marine Clay Using Cement Solidification. Mar. Georesour. Geotechnol. 2019, 37, 755–764. [Google Scholar] [CrossRef]

- Tan, T.S.; Goh, T.L.; Yong, K.Y. Properties of Singapore Marine Clays Improved by Cement Mixing. Geotech. Test. J. 2002, 25, 422–433. [Google Scholar]

- Ivanov, V.; Chu, J.; Stabnikov, V.; Li, B. Strengthening of Soft Marine Clay Using Bioencapsulation. Mar. Georesour. Geotechnol. 2015, 33, 320–324. [Google Scholar] [CrossRef]

- Latifi, N.; Eisazadeh, A.; Marto, A.; Meehan, C.L. Tropical Residual Soil Stabilization: A Powder Form Material for Increasing Soil Strength. Constr. Build. Mater. 2017, 147, 827–836. [Google Scholar] [CrossRef]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N. Stabilization of Marine Clay Soil Using Polyurethane. MATEC Web Conf. EDP Sci. 2018, 250, 01004. [Google Scholar] [CrossRef]

- Emmanuel, E.; Lau, C.C.; Anggraini, V.; Pasbakhsh, P. Stabilization of a Soft Marine Clay Using Halloysite Nanotubes: A Multiscale Approach. Appl. Clay Sci. 2019, 173, 65–78. [Google Scholar] [CrossRef]

- Wang, W.; Li, Y.; Yao, K.; Li, N.; Zhou, A.; Zhang, C. Strength Properties of Nano-MgO and Cement Stabilized Coastal Silty Clay Subjected to Sulfuric acid Attack. Mar. Georesour. Geotechnol. 2020, 38, 1177–1186. [Google Scholar] [CrossRef]

- Xiao, H.; Shen, W.; Lee, F.H. Engineering Properties of Marine Clay Admixed with Portland Cement and Blended Cement with Siliceous Fly Ash. J. Mater. Civ. Eng. 2017, 29, 04017177. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled Thermo-Hydro-Mechanical–Chemical Behaviour of Cemented Paste Backfill in Column Exper-iments. Part I: Physical, Hydraulic and Thermal Processes and Characteristics. Eng. Geol. 2013, 164, 195–207. [Google Scholar] [CrossRef]

- Loret, B.; Hueckel, T.; Gajo, A. Chemo-Mechanical Coupling in Saturated Porous Media: Elastic–Plastic Behaviour of Homoionic Expansive Clays. Int. J. Solids Struct. 2002, 39, 2773–2806. [Google Scholar] [CrossRef] [Green Version]

- Santamarina, J.C.; Klein, K.A.; Palomino, A.; Guimaraes, M.S. Micro-Scale Aspects of Chemical-Mechanical Coupling Interparticle Forces and Fabric. In Chemo-Mechanical Coupling in Clays; Routledge: London, UK, 2002; Volume 10, p. 2. [Google Scholar]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A Review on Microstructural Study and Compressive Strength of Geopolymer Mortar, Paste and Concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- Lei, H.; Wang, L.; Jia, R.; Jiang, M.; Zhang, W.; Li, C. Effects of Chemical Conditions on the Engineering Properties and Microscopic Characteristics of Tianjin Dredged Fill. Eng. Geol. 2020, 269, 105548. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled Thermo-Hydro-Mechanical–Chemical Behaviour of Cemented Paste Backfill in Column Experiments. Part II: Mechanical, Chemical and Microstructural Processes and Characteristics. Eng. Geol. 2014, 170, 11–23. [Google Scholar] [CrossRef]

- Ekinci, A. Effect of Preparation Methods on Strength and Microstructural Properties of Cemented Marine Clay. Constr. Build. Mater. 2019, 227, 116690. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Sustainable Improvement of Tropical Residual Soil Using an Envi-ronmentally Friendly Additive. Geotech. Geol. Eng. 2017, 35, 2613–2623. [Google Scholar] [CrossRef]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N.; Marto, A. Micro-Level Analysis of Marine Clay Stabilised with Polyurethane. KSCE J. Civ. Eng. 2020, 24, 807–815. [Google Scholar] [CrossRef]

- Ekinci, A.; Hanafi, M.; Aydin, E. Strength, Stiffness, and Microstructure of Wood-Ash Stabilized Marine Clay. Minerals 2020, 10, 796. [Google Scholar] [CrossRef]

- Kou, H.; Jia, H.; Chu, J.; Zheng, P.-G.; Liu, A.-S. Effect of Polymer on Strength and Permeability of Marine Clay. Mar. Georesour. Geotechnol. 2021, 39, 234–240. [Google Scholar] [CrossRef]

- Wu, J.; Deng, Y.; Zheng, X.; Cui, Y.; Zhao, Z.; Chen, Y.; Zha, F. Hydraulic Conductivity and Strength of Foamed Cement-Stabilized Marine Clay. Constr. Build. Mater. 2019, 222, 688–698. [Google Scholar] [CrossRef]

- Kang, G.; Tsuchida, T.; Wakioka, H.; Kim, Y. Strength Mobilization of Cement-Treated Marine Clay with Various Curing Time. Jpn. Geotech. Soc. Spec. Publ. 2016, 2, 2047–2052. [Google Scholar] [CrossRef] [Green Version]

- Ma, T.S.; Chen, P.; Zhang, Q.B.; Zhao, J. A Novel Collapse Pressure Model with Mechanical-Chemical Coupling in Shale Gas Formations with Multi-Weakness Planes. J. Nat. Gas Sci. Eng. 2016, 36, 1151–1177. [Google Scholar] [CrossRef]

- Locat, J.; Bérubé, M.; Choquette, M. Laboratory Investigations on the Lime Stabilization of Sensitive Clays: Shear Strength De-velopment. Can. Geotech. J. 1990, 27, 294–304. [Google Scholar] [CrossRef]

- Bi, J.; Chian, S.C. Modelling of Three-Phase Strength Development of Ordinary Portland Cement- and Portland Blast-Furnace Cement-Stabilised Clay. Géotechnique 2020, 70, 80–89. [Google Scholar] [CrossRef]

- Yamashita, E.; Cikmit, A.A.; Tsuchida, T.; Hashimato, R. Strength Estimation of Cement-Treated Marine Clay with Wide Ranges of Sand and Initial Water Contents. Soils Found. 2020, 60, 1065–1083. [Google Scholar] [CrossRef]

- Yao, K.; Pan, Y.; Jia, L.; Yi, J.T.; Hu, J.; Wu, C. Strength Evaluation of Marine Clay Stabilized by Cementitious Binder. Mar. Georesour. Geotechnol. 2020, 38, 730–743. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Yin, J.H.; Huang, H.W. Rate-Dependent and Long-Term Yield Stress and Strength of Soft Wenzhou Marine Clay: Experiments and Modeling. Mar. Georesour. Geotechnol. 2015, 33, 79–91. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Suddeepong, A. Assessment of strength development in blended cement admixed Bangkok Clay. Constr. Build. Mater. 2011, 25, 1521–1531. [Google Scholar] [CrossRef]

- Ma, C.; Chen, L.Z.; Chen, B. Analysis of Strength Development in Soft Clay Stabilized with Cement-Based Stabilizer. Constr. Build. Mater. 2014, 71, 354–362. [Google Scholar]

- Lorenzo, G.A.; Bergado, D.T. Fundamental Parameters of Cement-Admixed Clay—New Approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Lee, F.-H.; Lee, Y.; Chew, S.-H.; Yong, K.-Y. Strength and Modulus of Marine Clay-Cement Mixes. J. Geotech. Geoenviron. Eng. 2005, 131, 178–186. [Google Scholar] [CrossRef]

- Read, D.; Glasser, F.P.; Ayora, C.; Guardiola, M.T.; Sneyers, A. Mineralogical and Microstructural Changes Accompanying the Interaction of Boom Clay with Ordinary Portland Cement. Adv. Cem. Res. 2001, 13, 175–183. [Google Scholar] [CrossRef]

- Gaucher, E.C.; Blanc, P. Cement/Clay Interactions—A Review: Experiments, Natural Analogues, and Modeling. Waste Manag. 2006, 26, 776–788. [Google Scholar] [CrossRef] [Green Version]

- Chian, S.C.; Nguyen, S.T.; Phoon, K.K. Extended Strength Development Model of Cement-Treated Clay. J. Geotech. Geoenviron. Eng. 2016, 142, 06015014. [Google Scholar] [CrossRef]

- Japan Cement Association. Ground Improvement Manual Using Cement-Based Solidification Material; JCA: Chiyoda-ku, Japan, 2007; Volume 3, pp. 43–44. [Google Scholar]

| Water Content (%) | Unit Weight (kN·m−3) | Specific Gravity | Porosity | Liquid Limit | Plastic Limit |

|---|---|---|---|---|---|

| 59.8% | 17.3 | 2.817 | 0.616 | 51.9 | 24.5 |

| No. | Water Content (%) | Cement Slurry Content (%) | Water Cement Ratio in Cement Slurry | Curing Age (Days) |

|---|---|---|---|---|

| 1 | 40 | 10 | 1:1 | 28 |

| 2 | 40 | 15 | 1:1 | 28 |

| 3 | 40 | 20 | 1:1 | 28 |

| 4 | 40 | 10 | 1:1 | 14 |

| 5 | 40 | 15 | 1:1 | 14 |

| 6 | 40 | 20 | 1:1 | 14 |

| 7 | 40 | 15 | 1:1 | 7 |

| 8 | 40 | 10 | 1:1 | 3 |

| 9 | 40 | 15 | 1:1 | 3 |

| 10 | 40 | 20 | 1:1 | 3 |

| No. | Water Content (%) | Cement Slurry Content (%) | Water–Cement Ratio in Cement Slurry | Curing Age (Days) | UCS Strength (kPa) |

|---|---|---|---|---|---|

| 1 | 40 | 10 | 1:1 | 28 | 50.6 |

| 2 | 40 | 15 | 1:1 | 28 | 158.26 |

| 3 | 40 | 20 | 1:1 | 28 | 354.2 |

| 4 | 40 | 10 | 1:1 | 14 | 12.05 |

| 5 | 40 | 15 | 1:1 | 14 | 24.75 |

| 6 | 40 | 20 | 1:1 | 14 | 122 |

| 7 | 40 | 15 | 1:1 | 7 | 11.33 |

| 8 | 40 | 10 | 1:1 | 3 | 11.31 |

| 9 | 40 | 15 | 1:1 | 3 | 10.21 |

| 10 | 40 | 20 | 1:1 | 3 | 11.2 |

| No. | Curing Age (days) | Cement Content (%) | Porosity before Test | Elastic Modulus (MPa) | Cohesion Force (kPa) | Friction Angle (°) |

|---|---|---|---|---|---|---|

| 1 | 28 | 10 | 0.5537 | 1 | 16 | 26 |

| 2 | 28 | 15 | 0.5575 | 3.5 | 40 | 35 |

| 3 | 28 | 20 | 0.5610 | 12 | 30 | 66 |

| 4 | 14 | 15 | 0.5401 | 0.28 | 10 | 12 |

| 5 | 7 | 15 | 0.5288 | 0.1 | 5.2 | 11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Yan, Z.; Yan, J.; Xu, Q.; Zhu, J.; Xu, R. A Novel Strength Model for Cement Marine Clay Based on the Mechanical-Chemical Coupling Behavior. J. Mar. Sci. Eng. 2021, 9, 1454. https://doi.org/10.3390/jmse9121454

Xu L, Yan Z, Yan J, Xu Q, Zhu J, Xu R. A Novel Strength Model for Cement Marine Clay Based on the Mechanical-Chemical Coupling Behavior. Journal of Marine Science and Engineering. 2021; 9(12):1454. https://doi.org/10.3390/jmse9121454

Chicago/Turabian StyleXu, Liyang, Zihai Yan, Jiajia Yan, Qiliang Xu, Jiancai Zhu, and Riqing Xu. 2021. "A Novel Strength Model for Cement Marine Clay Based on the Mechanical-Chemical Coupling Behavior" Journal of Marine Science and Engineering 9, no. 12: 1454. https://doi.org/10.3390/jmse9121454

APA StyleXu, L., Yan, Z., Yan, J., Xu, Q., Zhu, J., & Xu, R. (2021). A Novel Strength Model for Cement Marine Clay Based on the Mechanical-Chemical Coupling Behavior. Journal of Marine Science and Engineering, 9(12), 1454. https://doi.org/10.3390/jmse9121454