1. Introduction

Fluid interaction with thin perforated structures is of interest in a range of contexts. Applications in marine engineering include current and wave interaction with aquaculture containers [

1,

2] and breakwaters [

3,

4]. Another more general application is in tuned liquid dampers with baffles for building motion attenuation [

5,

6,

7]. Thus, there is significant interest in the challenge of simulating the effect of these thin porous structures using computational fluid dynamics (CFD). Full geometric resolution of the porous microstructure [

8,

9] is unlikely to be computationally feasible for large scale structures. When large-scale effects such as global forces and the overall fluid-flow behaviour are of the main interest, it is useful to represent a perforated structure by its macro-scale effects. Instead of resolving the microstructural geometry explicitly, the effect of the structure on the fluid can be applied as a porous pressure-drop and momentum source term respectively. This approach is less computationally demanding than microstructural CFD modelling [

4,

10,

11], which requires a large number of mesh cells and also makes less restrictive assumptions compared to models based on potential-flow theory [

12,

13,

14].

This paper presents an assessment of different macro-scale methods for the representation of thin perforated structures exposed to regular waves. The investigated options are the implementation as a two-dimensional (2D) surface with zero thickness and as volumetric three-dimensional (3D) porous media. The porous-media approach can accommodate isotropic or anisotropic material characteristics, where we can distinguish orthotropic characteristics (in which the porosity has separate values in three perpendicular rotationally symmetric axes) as a sub-category of the latter.

Figure 1 outlines the main types of porosity representation in CFD modelling investigated here. While the porous-media approach can be used for both thin and volumetric structures, the porous surface or baffle implementation is only valid for thin structures.

Figure 2 shows schematics of the main types of macro-scale porosity representation investigated. In the sketches, the arrows outline velocity vectors close to the porous barrier and the bold lines along the cell faces indicate the components of the velocity that are subject to a pressure-drop.

The representation as a porous surface, often referred to as a porous baffle, uses a pressure-jump condition where a resistance source is applied to the Navier–Stokes momentum equation at the cell faces of a geometrically defined surface. The resistance source and pressure-jump respectively are commonly specified as a function of the velocity component normal to the surface. This approach is commonly used for structures where the thickness can be assumed to be negligibly small, such as membranes, fans, actuator disks, perforated baffles or fish nets. Examples of its use to represent membranes include studies on separation processes by Li and Cheng [

15] or examinations of the flow field through perforated tiles in data centers by Arghode and Joshi [

16]. For fans, the baffle-implementation has been used by Chacko et al. [

17] to improve radiator efficiency by air flow optimization, by van der Spuy and von Backström [

18] and Sumara and Šochman [

19] to represent fans in air-cooled condensers. In the form of a perforated baffle, it has been used to simulate contact tanks for water treatment by Kizilaslan et al. [

20] or in refrigeration cabinets by Wang et al. [

21]. The same pressure-jump principle has also been used in the form of actuator disks for wind turbine rotors [

22], tidal turbines [

23], ship propellers [

24] and helicopter rotors [

25,

26]. As a marine engineering application similar to the present case, Shim et al. [

2] have used a porous baffle to model current flow through and around a cylindrical fish net cage. Most of the existing research described here has been performed for steady-state conditions and in single phase flow. Bakica et al. [

24] investigated ship resistance with two phases, but the actuator-disk that represents the ship propeller was fully submerged in the water. Apart from applications to actuator disks [

22,

25,

26] and for water treatment [

20], steady-state solutions have been calculated in most previous examples.

Porosity representation as a volumetric porous zone, often referred to as porous media, is implemented as momentum resistance applied to the cell centres (in a cell-centered finite-volume framework) of a volumetrically defined geometric region. The porous media can be implemented with either isotropic or anisotropic characteristics and the resistance-source terms can be formulated by means of either scalar or tensor values respectively. It can furthermore be used with or without consideration of the reduced amount of fluid inside the volume as a result of the geometric blockage of the porous structure. Typically, for large volumetric structures such as dams or breakwaters, the reduced amount of fluid needs to be taken into account and the volume-averaged Navier–Stokes equations or volume-averaged Reynolds-averaged Navier–Stokes (VARANS) equations are used, which are formulated for the intrinsic velocity inside the porous structure. Higuera et al. [

27], Lara et al. [

28] and del Jesus et al. [

29] have used porous-media VARANS-formulations with isotropic material characteristics for studies on fluid interaction with dams, cubical porous barriers and Brito et al. [

30] and Hadadpour et al. [

31] have used it for fluid interaction with vegetation. Chen and Christensen [

1] used a volume-averaged Navier–Stokes formulation with anisotropic material characteristics for plane and circular fish nets. Using 2D models, they investigated current flow across a truncated plane with various angles of attack, wave interaction with bottom-fixed vertical sheets, whilst in a 3D model, they looked at current flow across a truncated fully submerged cylinder.

In previous work, we have used a volume-averaged Navier–Stokes formulation with isotropic material assumptions to model wave interaction with thin perforated sheets and cylinders in [

32,

33]. Qiao et al. [

34] have used an identical method and achieved good agreement between CFD results and the same experimental results of wave interaction with vertical sheets. For other cases of thin porous structures, the Navier–Stokes or Reynolds-averaged Navier–Stokes (RANS) equations have previously been used inside and outside the porous structure neglecting the effects of a reduced fluid amount in the openings. This was done so with anisotropic material assumptions by Kyte [

35] for the representation of a filter as part of a domestic ventilation waste heat recovery system and by Zhao et al. [

36,

37] for rigid plane fish nets. The anisotropic approach can also be used to direct the fluid flow in a certain way, as demonstrated for instance by Hafsteinsson [

38] to model flow through a conical diffuser.

For all these implementations, the formulation of the pressure-drop resistance and its corresponding porosity coefficients are of key importance. For fluid flow across thin perforated structures, the flow regime is typically turbulent with high Reynolds numbers (

); where turbulent drag forces dominate, transient losses have a minor effect on the flow and viscous forces can be considered to be negligible. In the context of fluid interaction with fish net cages, Shim et al. [

2] used a drag force with a porosity coefficient obtained from experiments in combination with a baffle implementation. Zhao et al. [

36,

37] have used both a viscous force and drag force with coefficients based on empirical formulations within a porous-media RANS implementation. With a porous-media VARANS-approach, Chen and Christensen [

1] have applied both a drag and a transient resistance term. The drag coefficient was obtained from a Morison-type load-model that assumes a fish net being composed of cylindrical twines without knots. The transient coefficient was arguably set to 0.43 without further investigations and declared to be an inherited parameter from work on large volumetric dams by Jensen et al. [

39].

The present work on thin structures with numerous circular perforations omits the viscous and transient pressure-drop terms and uses a drag term with a drag coefficient as a function of porosity. The use of this assumption in previous work demonstrated good agreement between CFD, potential-flow and experimental results for wave interaction with vertical sheets and cylinders [

33]. The methodology is further explained in

Section 3.1. This theoretical pressure-drop formulation avoids calibration procedures, in contrast to the approaches by Shim et al. [

2] and Chen and Christensen [

1]. The focus of the current work is the assessment of the different pressure-drop implementation approaches, as outlined in

Figure 1. As part of the assessment, this work explores the use of a porous baffle for transient two-phase wave-structure interaction as a new application. It furthermore uses a porous-media approach with orthotropic material properties for two-phase wave interaction with a bottom-fixed cylinder. A 2D model of a thin perforated bottom-fixed sheet and a 3D model with a thin perforated bottom-fixed cylinder exposed to regular waves are simulated. The aim is to compare the different types of porosity implementations by means of flow visualizations, water velocity profiles, the mean flow behaviour in terms of wave gauge signals and the horizontal force on the structures. The outcome of this work can serve as a guide for CFD model setup for similar applications in a marine engineering context.

This paper is structured as follows. Firstly, a brief outline of the experiments conducted for model validation is given in

Section 2. Then, the numerical method is explained in

Section 3 and the specific model setup in

Section 4. The results are presented in

Section 5, showing the comparison between the investigated types of macro-scale porosity implementations. This is followed by a discussion in

Section 6 and conclusions in

Section 7.

2. Wave Flume Experiments

This work focuses on the comparison between CFD models with different types of porosity implementations, but experimental results are included for reference. For detailed information and photos of the experiments, we refer to [

33,

40,

41], but relevant aspects of the setup are outlined in the following.

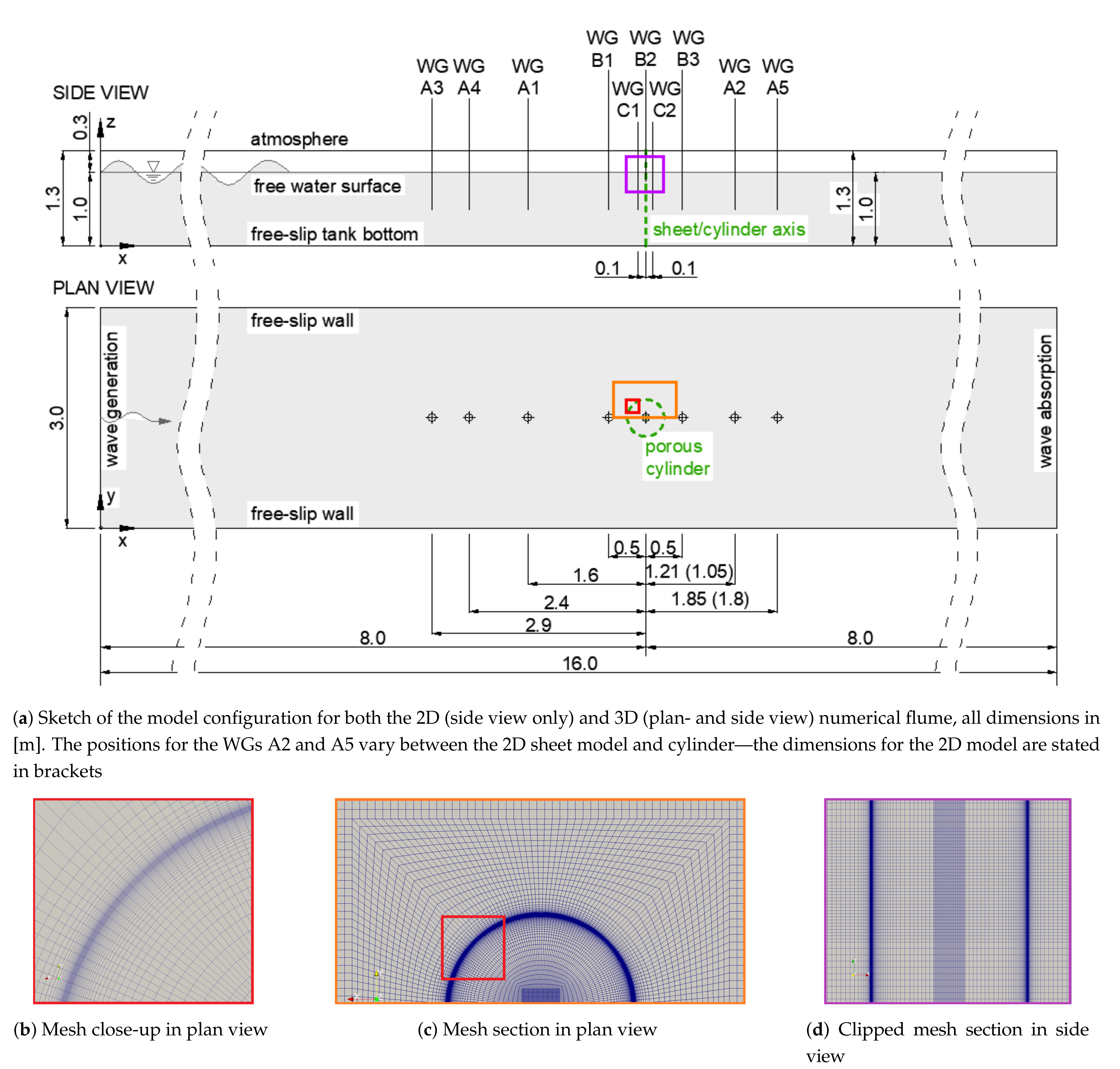

Wave tank tests to investigate wave interaction of thin perforated vertical sheets and cylinders were conducted at Dalian University of Technology, China, where the wave flume has a length of 60 m and is equipped with a piston wavemaker at one end and a sloped beach at the other end. The tests were performed with a water depth of 1.0 m and two separate test-sections; one for a sheet with a width of 1 m and one for a cylinder with a width of 3 m. A range of geometrical parameters such as sheet thicknesses (3 mm 10 mm), hole separation distances (25 mm 100 mm), outer cylinder diameters (0.375 m 0.750 m) and porosities (0.1 0.4) have been tested simultaneously under a range of regular and irregular wave conditions. The porosity, n, is defined as (the ratio of void volume to total volume) for a regular rectangular grid of holes, where the hole centre spacing was kept constant with s = 25 mm and the perforation hole radius, , was varied. On the top and bottom end of both structures, load cells were attached to measure the wave-induced horizontal load.

In this numerical work, only one combination of wave and geometrical parameters per structure has been investigated, since the validity of the theoretical pressure-drop model for other parameters has been demonstrated in previous work, [

33]. All 2D models have been set up with a vertical bottom-fixed sheet with a thickness of

d = 10 mm and all 3D models with a bottom-fixed cylinder with an outer diameter of

D = 0.50 m and a thickness of

d = 5 mm. Both structures had a porosity of

n = 0.2. A single regular wave condition is used for all CFD models. The wave parameters used here are shown in

Table 1, where

T is the wave period,

is the wavelength,

H is the wave height,

is the group velocity,

is the non-dimensional wave number (with

h as the water depth and

k as the wave number) and

is the wave steepness (with

A as the wave amplitude).

5. Results: Comparison of Porosity Implementations

The CFD results obtained from models with the different porosity implementations, as shown in

Figure 2, are compared against the experimental results, but mainly focus on the differences between the CFD results.

Time series signals as well as mean amplitudes have been analyzed for the wave elevation, , and the horizontal force on the structure, . The mean wave elevation amplitude, A, and mean force amplitude, F, have been obtained from the periodically steady signal section (after removing the initial transient section and after cropping it into a whole number of at least 10 periods), calculated with the standard-deviation () of the signals via and respectively.

5.1. Minimum Mesh Requirements 2D Sheet Model

Prior to the comparison of the results obtained from the different implementations, a mesh convergence study was performed separately for each type of porosity implementation. The mean amplitude of the horizontal force on the 2D sheet,

F, was compared for a number of meshes. The meshes were generated with a successively increasing number of cells separately for the horizontal

x- and vertical

z-direction, starting off from the cell size in the clear flow region (

= 20 mm). Firstly, the horizontal cell length,

, was decreased successively until a quasi-converged state was reached. Secondly, the vertical cell length

was reduced, while

was kept constant. The averaged force amplitudes obtained from the CFD results,

F, have been scaled to correspond to the experimental sheet width of 1 m.

F has then been normalized over the mean force amplitudes obtained from the experiments,

= 382.63 N.

Figure 5 shows the normalized force amplitude,

, over the mesh refinement levels in terms of number of cells per sheet thickness in

x-direction,

, and number of cells per wave height in

z-direction,

. For the baffle implementation, the refinement level was only investigated in vertical

z-direction as it has zero thickness. No result was obtained for 284

, since the skewness of the cells would have been excessive. For all other models, highly skewed cells have been avoided.

Figure 5a indicates 8 cells per sheet thickness,

, results in a converged force amplitude,

F, for an isotropic implementation. Further horizontal refinement has an insignificant effect on the result. For the orthotropic implementation, convergence can be observed towards 32

. The difference between 16 and 32

is 3% relative to the smaller value. No clear convergence behaviour can be determined from

Figure 5b for the number of cells per wave height in

z-direction,

, for either of the implementations. It is not clear why the value of

F in both porous-media implementations (isotropic and orthotropic) is seen to increase significantly for an increasing number of cells in the vertical direction, but this is suspected to be linked to the smeared nature of the air-water interface of the VOF interface capturing method. Although not presented in the figures here, the comparison of the velocity profiles along the water column for the gauges WG C1 and WG C2, 0.1 m before (

x = 7.90 m) and 0.1 m after (

x = 8.10 m) the sheet, confirm the results above. Based on the number of cells per sheet thickness,

, the profiles of the horizontal component,

, and the profiles of the vertical velocity component,

, require a minimum of 8

for the isotropic and 16

for the orthotropic implementation, to achieve a reasonable converged profile in front of the sheet at WG C1. The vertical mesh size,

, has barely any influence on the velocity profiles,

and

, before and after the sheet for either the volumetric (isotropic and orthotropic) implementation and the baffle implementation. There are no significant differences after the sheet and only small deviations in front of it, where the largest deviations of

are located along the free-surface. Overall, these differences are considered to be insignificant.

For the following models, a mesh resolution corresponding to 16 and 8.875 was used for all volumetric models (both isotropic and orthotropic) and 8.875 has been used for the models with the porous baffle. These values can serve as a guide for similar structures and wave conditions, but the dependence is likely to change for different conditions, in particular for significantly deviating wave conditions.

5.2. Horizontal Force on the Structures

In this section, the time series of the horizontal forces on both the sheet and cylinder are assessed as the main parameters of interest.

5.2.1. Force on the 2D Sheet

As before, the force on the 2D sheet has been scaled to match the width used in the experiments. A comparison between the time series of the horizontal force,

, due to the different types of porosity implementation, is shown in

Figure 6. The vertical line indicates the point in time when the wave has travelled across the tank and back to the center.

All types of porosity implementation are capable of reproducing the shape of the time series, which exhibits a non-sinusoidal shape due to the quadratic pressure-drop. The notable deviations between the CFD and experimental results for the initial transient section of the time series in

Figure 6a are due to differences in the wave ramp-up between the numerical model and the physical wavemaker. The deviations concerning the wave ramp-up have been discussed in previous work, [

33], where the free surface elevation has been validated for a range of regular wave conditions and porosities. The experimental results are slightly contaminated with wave reflections, shown for a section of the time series in

Figure 6b. The numerical results exhibit a clean periodically steady-state after about

t = 24 s. The numerical results agree well among each other, where only minor deviations can be observed at small local sections of the signal, which is outlined for an example in

Figure 6c. The mean force amplitudes,

F, of the CFD results are 391.19 N for the baffle implementation (

= 1.024), 407.84 N for the orthotropic implementation (

= 1.066) and 415.54 N for the isotropic implementation (

= 1.086).

5.2.2. Force on the Cylinder

Next the results of the horizontal force on the cylinder are assessed and the time series,

, are shown in

Figure 7.

For the cylinder model, the initial transient period of the wave ramp-up also differs between the numerical and experimental results, and as before, the experimental results exhibit larger unsteadiness than the numerical results, due to wave reflections. The non-linearity of the force on the cylinder is replicated by all CFD models and all types of porosity implementations. The overall force response is reproduced with reasonably good agreement between the numerical and experimental results, as shown in

Figure 7a. However, the deviations among the numerical results are larger for the cylinder than for the 2D sheet. The baffle implementation and the isotropic porous-media implementation agree well, but the orthotropic porous-media implementation deviates more notably. This can be observed for a section and close-up of the time series in the

Figure 7b,c. The mean force amplitudes,

F, of the CFD results are 218.63 N for the baffle implementation (

= 1.108 where

= 197.36 N), 188.81 N for the orthotropic implementation (

= 0.957) and 205.01 N for the isotropic implementation (

= 1.039).

5.3. Wave Gauges near the Structures

Next, the wave elevation, , at the WGs close to the structures is assessed. Here the whole time series for a physical runtime of 50 s and close-ups of sections of the time series are presented. Again, the vertical lines indicate the point in time when the wave has travelled across the tank and back to the WG.

5.3.1. Wave Gauges near the 2D Sheet

The analysis of the WG results for the 2D model with the sheet focuses on the comparison among the CFD results. The comparison against the experimental results is omitted since the latter are suspected to be unreliable due to a raised section of the floor in the physical tank which was required to submerge the load cells beneath the structures. For more information on this issue, we refer to previous discussions in [

33,

40].

Figure 8 shows the water surface elevation,

, for the WGs C1 and C2, which are placed 0.1 m before and 0.1 m after the sheet respectively, for all types of porosity representations.

The time series match very well among all CFD results and for all types of porosity implementation. In particular, the close-ups exhibit that the results are nearly identical, both before and after the sheet. At WG C1, 0.1 m before the sheet, the mean wave amplitudes, A, are 0.1189 m for the baffle implementation ( = 1.340 where = 0.08875 m), 0.1200 m for the orthotropic implementation ( = 1.352) and 0.1196 m for the isotropic implementation ( = 1.348). At WG C2, 0.1 m after the sheet, A is 0.0595 m for the baffle implementation ( = 0.6704), 0.0580 m for the orthotropic implementation (=0.6535) and 0.0583 m for the isotropic implementation ( = 0.6565).

5.3.2. Wave Gauges near the Cylinder

For the 3D model with the cylinder, the analysis covers the comparison among the CFD results and against the experimental data.

Figure 9 presents the wave elevation,

, for the WGs shown in

Figure 3a.

Figure 9a shows the WG signals from the numerical results due to all types of porosity implementation and the experimental results further away from the cylinder.

Figure 9b shows the WG results closer to the cylinder where WG B1 is positioned 0.5 m before the cylinder axis, WG B3 0.5m behind the cylinder axis and WG B2 at the cylinder axis and at the center of the cylinder, respectively.

Similar to the time series of the force results, the figures exhibit differences at the initial transient section and wave reflections in the experimental results. Again, the overall agreement between CFD and experimental results is relatively good. The most noticeable differences can be observed between the CFD results for WG A1, positioned 1.6 m before the cylinder (

Figure 9a). The isotropic implementation produces larger amplitudes after the wave has travelled across the tank and back to the centre. For the WG A2, 1.21 m after the cylinder, the results match very well. The time series for the WG B2 in the center of the cylinder exhibits small ripples for all types of porosity implementation. The ripples are suspected to be a result of instabilities in the VOF phase-fraction (

)-field and to be related to the very fine mesh in the cylinder centre due to mesh generation procedures.

Next, the normalized mean wave amplitudes,

, where

= 0.08875 m is the CFD wave amplitude input, are analysed for all WG positions and all types of porosity implementations. The comparison between the mean amplitude results is shown in

Figure 10. For the WGs A1–A5, experimental results are included; for the WGs B1–B3, only CFD results are available.

The qualitative agreement between the experimental and all CFD results is relatively good at all WG positions. The deviations among the CFD results are small and do not exhibit clear patterns. The largest deviation of the mean amplitudes, A, among the CFD results is given at WG B2 in the centre of the tank at an x-position of 8.0 m. There, the largest value of A = 0.0907 m was obtained for the model with orthotropic porosity implementation. This results in a 3.23% larger value than the smallest value of A = 0.0878 m from the model with a porous baffle implementation. The smallest deviation has been obtained for the WG A5, 1.85 m after the cylinder centre at an x-position of 9.85 m, where all values result in a mean amplitude of A = 0.0835 m ( = 0.9408).

5.4. Velocity Profiles near the Structures

The velocity profiles are assessed by means of a comparison between the CFD results from models with different types of porosity implementations. The positions of the velocity profiles correspond to the WG positions around both the sheet and cylinder; see

Figure 3a. A limited number of selected profiles and points in time are presented for one wave trough and one wave crest each. These indicate the overall trend of results.

5.4.1. Velocity Profiles near the 2D Sheet

Figure 11 shows examples of the velocity profiles of the horizontal component,

, and the vertical component,

, with a distance of 0.1 m before (WG C1) and after (WG C2) the sheet. The dashed black horizontal lines indicate the mean water surface level with a water depth of

h = 1.0 m. The continuous coloured horizontal lines represent the instantaneous water level at a specific time step. Both the horizontal and vertical velocity profiles,

and

, cover the whole water column and a section of the air phase above the water level.

It can be observed that the largest differences are present for the horizontal velocities,

, along the air-water interface, with the largest values in the air just above the water surface. Some local high velocities are unphysical and a direct result of the large pressure and density gradients at the phase interface due to the segregated solution algorithm for the pressure-velocity coupling. The occurrence of spurious air velocities is well-known in the context of gravity wave propagation and has previously been reported by [

59,

60,

61,

62,

63,

64,

65] related to the use of

interFoam with its standard (MULES) VOF method.

Excluding the profile section in the air from the analysis, the agreement of the profiles in the water column match with insignificant differences for both the horizontal and vertical component, and . The largest deviations have been obtained for the vertical velocity profile, , 0.1 m after the sheet.

5.4.2. Velocity Profiles near the Cylinder

Figure 12 shows the velocity profiles,

and

, for

t = 36.0 s, where a wave trough passes the cylinder centre.

Figure 13 shows the same for

t = 43.4 s at a wave crest. Again, the dashed black and coloured horizontal lines indicate the initial flat and the instantaneous water level respectively.

Both

Figure 12 and

Figure 13 indicate similar patterns of locally large velocity values close to the air-water interface. The overall differences between the results due to the different porosity implementations are relatively small, both before (WG B1) and after (WG B3) the cylinder. At the cylinder center at WG B2, the profiles exhibit significant scatter for both the horizontal and vertical component,

and

, so no clear trend can be identified from these results.

The differences between the results are the smallest for WG B3 after the cylinder and 0.5 m after the cylinder axis, respectively. At WG B1, 0.5 m in front of the cylinder axis, the profiles obtained from the porous-media models, both isotropic and orthotropic, match with insignificant deviations. The profiles due to the baffle-implementation deviate more notably from both porous-media implementations.

5.5. Flow Visualization near the Cylinder

To assess potential differences between the flow field due to different types of porosity implementations, the velocity vectors have been inspected qualitatively on a horizontal cross section across half of the cylinder. The cross-section is represented by a 50 mm thick horizontal slice of the domain that ranges from

z = 0.75–0.80 m. The initial flat water level was at

= 1.0 m. In

Figure 14, the velocity vectors are shown for all types of investigated porosity implementations for two points in time. On the left, the flow field is presented for

t = 36.0 s, which corresponds to a wave trough at the cylinder centre and on the right for

t = 43.4 s, which corresponds to a wave crest.

Despite the very good agreement between all numerical results in terms of the force response and the flow field further away from the structures, differences are present for the flow field very close to the structure. From a qualitative point of view, the isotropic porosity implementation seems to produce flow patterns that are smoother compared to the orthotropic porous media and porous-baffle methods. In particular, the orthotropic implementation creates a more chaotic flow field and higher local velocities (for exactly the same mesh as the isotropic implementation), see

Figure 14b. This could explain the reason for the requirement of smaller time steps in order to meet the target maximum

number during the automatic time stepping process—which increases the computation time for the orthotropic implementation. The flow patterns agree better between the isotropic porous-media and the baffle implementation, see

Figure 14a,c. This corresponds to a better match of the force results between the isotropic and baffle implementations, see

Figure 7. The orthotropic implementation results in larger deviations for both the force results and the qualitative flow field,

Figure 14b.

5.6. Tabular Summary of the Results

A summary of the main results is given in

Table 2. It shows the results of the mean force amplitudes,

F, and the mean wave amplitudes,

A, at the wave gauges for both the 2D and 3D model and includes the mesh cell number and approximate execution times for each model due to the different porosity implementations.

All models were simulated for 50 s of physical run time on 14-core dual Intel(R) Xeon(R) Gold 5120 CPU @ 2.20 GHz processors. The 2D models with the sheet were run on a single core. For 3D models with the cylinder, 28 CPUs were used.

6. Discussion

The overall results indicate that all types of investigated porosity implementations are capable of reproducing the horizontal force on the structures and the overall flow behaviour around the structures. The differences between the implementations are small for both the force and fluid flow results.

In particular, for the 2D model with the vertical sheet, all results are close to being identical for all types of porosity implementation. Only the vertical velocity profiles,

, exhibit small deviations for the WG C2, 0.1 m after the sheet, see

Figure 11. The results of the model with the cylinder exhibit small deviations. In terms of horizontal force amplitude,

F, the isotropic porous-media and porous-baffle implementation match reasonably well, and the orthotropic porous-media implementation leads to a slightly smaller value, see

Figure 7a. No clear patterns can be determined for the mean flow behaviour in terms of wave elevation signals,

(

Figure 9b), and mean wave amplitude,

A (

Figure 10). The velocity profiles close to the cylinder,

and

, exhibit agreement between all different types of implementation 0.5 m after the cylinder at WG B3, see

Figure 12 and

Figure 13. Moreover, 0.5 m in front of the cylinder axis at WG B1 both porous-media implementations match relatively well, but the baffle implementation results in small deviations, in particular for the horizontal velocity component,

.

In contrast to similar work on fish cage structures, [

1,

2,

36,

37], the present work uses and compares three types of implementations in combination with a simpler pressure-drop model and momentum source formulation, respectively. The pressure-drop formulation does not require any calibration procedures or derivations from experimental results. Its validity has been demonstrated in combination with an isotropic porous-media implementation in previous work, [

33], where also the general limitations of a macro-scale representation have been discussed. However, the present formulation has only been validated for thin structures with circular perforations, rather than net structures. Validation of the present method would need further validation for other types of porous barriers.

For the present case of thin perforated structures, we consider all types of implementations as suitable in principle. However, differences in numerical stability and execution times have been observed. While the solution process of all models with porous media-implementations maintained stability with a target maximum

-number of 0.3, the models with the baffle-implementation required very small time steps and a maximum

-number of 0.05 for a stable and unsupervised computation. Since the baffle implementation is usually reported to be more stable than the porous-media implementation in single-phase flow, e.g., by Shim et al. [

2], we suspect that the instabilities are caused by the spurious air velocities at the interface, as already discussed in

Section 5.4 in terms of their effect on the velocity profiles. Excessive velocity spikes at the sheet would directly lead to a spike in the pressure-drop source since it is a function of velocity, Equation (

1), which can cause the solver to diverge and crash. We assume that the spurious velocities impact the baffle implementation significantly, but do not affect the porous-media implementations as much, because the smeared pressure-drop application over a volumetric porous zone possibly helps to avoid excessive pressure spikes. The baffle implementation is considered as disadvantageous for this specific numerical framework, using an algebraic VOF method and a segregated pressure-velocity coupling algorithm, and the present application of two-phase wave-structure interaction. The small time steps increase the computation times significantly. However, this problem could be resolved with a different interface capturing method or a different solver algorithm. Furthermore, the execution time of the isotropic implementation is shorter than the orthotropic porous-media implementation, see

Section 4.2. Despite both models being set up with the identical mesh and same scheme and solver settings, the orthotropic implementation requires smaller time steps to meet the maximum target

number. It is suspected that this is caused by more chaotic flow patterns with higher local velocity values that result from the orthotropic implementation, see

Figure 14b.

While all types of implementations are capable of reproducing the forces and overall flow fields for the specific present conditions, the applicability of each type would need to be assessed for more general cases. It would, in particular, be interesting to assess the threshold of the thickness of the porous barrier at which the current pressure-drop model and the implementations are still valid.

7. Conclusions

This work presents an assessment of possible differences between different types of macro-scale porosity representation of thin perforated structures for CFD modelling of wave-structure interaction. The types of macro-scale representation are implementations as porous surface with a pressure-jump condition and as volumetric porous-media, one with the assumption of isotropic properties and one with orthotropic characteristics.

2D models of regular wave interaction with a vertical bottom-fixed porous sheet and 3D models with a bottom-fixed porous cylinder are simulated. The numerical results are compared against experimental results, but the focus lies on the direct comparison between the CFD results by means of the global force on the structure and the mean flow behaviour close to the structure. The latter is evaluated in terms of the free-surface elevation at wave gauges, velocity profiles along the water column and qualitative fluid flow visualizations.

The present assessment indicates that the differences between all types of investigated porosity implementations are insignificant when global forces and the overall flow behaviour are of interest. All models are capable of accurately reproducing the horizontal force on the structures and the overall fluid flow behaviour.

It was found that the implementation as porous baffle with a pressure-jump condition is numerically the most sensitive within the present numerical framework of a combination of the volume-of-fluid interface capturing method and a segregated pressure-velocity coupling algorithm. Adversely, very small time steps are required to avoid the generation of spurious air velocities above the water surface and their effect of causing pressure-drop spikes and solver divergence.

For the present specific conditions, we consider the isotropic porous-media implementation as the best option due to the following reasons. It is numerically stable and achieved the fastest execution times when it is used with automatic time-stepping. Its implementation is simple and does not require any considerations on directionality in comparison to the orthotropic porous-media implementation. It is capable of reproducing the mean force and fluid flow behaviour and is equally accurate as both the orthotropic porous-media and porous-baffle implementation.

This work can serve as a useful guide for CFD modelling of similar marine engineering problems of current and wave interaction with thin perforated structures.