Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals

Abstract

:1. Introduction

2. Climate Change and the Shipping Industry

2.1. Climate Change

Size of Shipping Industry in Terms of Emissions

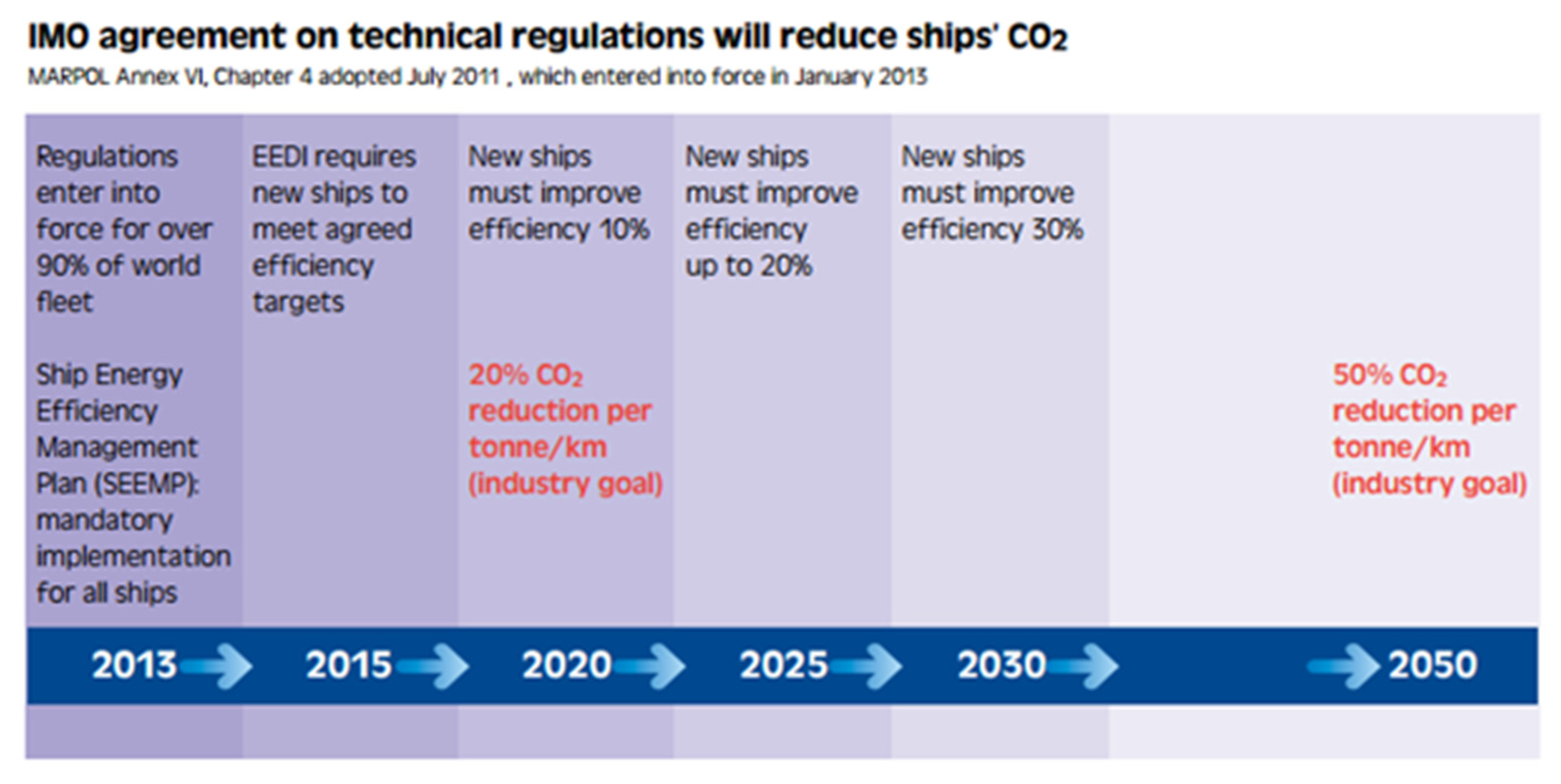

2.2. Current Legislation and Incentives to Meet 2050 Emission Targets Set by the International Maritime Organization (IMO)

- To reduce the carbon intensity of international shipping, compared to 2008 levels, by 40% by 2030.

- To increase that reduction to 70% by 2050.

- To reduce the GHG emissions from international shipping, again compared to 2008 levels, by at least 50%, by 2050.

- To achieve zero GHG emissions as soon as possible within this century, i.e., by 2100.

- Hull design,

- Economy of scale,

- Power and propulsion (including energy-saving devices),

- Speed,

- Fuels and alternative energy sources, and

- Weather routing and scheduling

2.2.1. Ship Energy Efficiency Management Plan (SEEMP)

2.2.2. Energy Efficiency Design Index (EEDI)

2.2.3. Energy Efficiency Operational Index (EEOI)

2.2.4. New Short-Term Measures (2018–2023)

2.2.5. Energy Efficiency Existing Ship Index (EEXI)

2.2.6. Carbon Intensity Index (CII)

2.2.7. Medium- (2023–2030) and Long-Term Measures (Beyond 2030)

2.2.8. Market-Based Measures (MBM)

- Economic incentives for the maritime sector to reduce its fuel consumption by investing in more fuel-efficient ships, technologies and operating ships in a more energy efficient way.

- Offsetting in other sectors with growing emissions related to the shipping industry.

2.3. European Green Deal

2.4. International Maritime Research and Development Board (IMRB)

2.5. Existing Pilot Projects

- Safety,

- Environmental impact,

- Economic costs, and

- Generation of knowledge and experience that can be used to further improve technologies. In this way, the overall cost will reduce, a key prerequisite for disseminating and scaling these technologies.

- Hydrogen-fueled ship (C—ZERO Japan H2).

- Super-efficient LNG-fueled ship (C—ZERO Japan LNG and Wind).

- Ammonia-fueled ship (C—ZERO Japan NH3).

- Onboard CO2-capturing ships (C—ZERO Japan Capture).

3. Alternative Fuels for Shipping

- LNG, methanol and LPG are competitive in terms of energy costs, while HVO is significantly more expensive.

- Hydrogen and ammonia are also far more expensive.

- The large cost range indicates a significant uncertainty in terms of pricing.

3.1. Hydrogen

3.1.1. Hydrogen Storage Technologies

- Compressed hydrogen,

- Liquid hydrogen (cooling hydrogen to −252.9 °C),

- Chemical storage

- Ammonia, nitrogen-based storage (via the Haber-Bosch reaction, ammonia can serve as storage medium and a fuel itself),

- CO2-based storage (via carbon capture and storage, producing synthetic fuels such as synthetic diesel, synthetic liquefied synthetic methane—LSM, methanol and formic acid),

- Aromatic Liquid Organic Hydrogen Carriers (LOHCs) (use of aromatic LOHCs and a catalyst to store hydrogen)

- Metal hybrides (store hydrogen within materials).

3.1.2. Hydrogen Safety

3.1.3. Green Hydrogen

3.1.4. Other “Colors” for Hydrogen (Brown, Grey, Yellow, Blue)

3.1.5. Liquid Hydrogen (LH2)

3.2. Ammonia

3.3. Methanol

3.4. Liquefied Natural Gas (LNG)

- Lean-burn spark ignition,

- Low-pressure dual fuel (4- and 2-stroke),

- High-pressure dual fuel and

- Gas turbine.

4. Renewable Energy Sources

4.1. Wind

- Soft-sail,

- Fixed-sail,

- Flettner rotor,

- Kite-sail, and

- Turbine technologies.

4.1.1. Soft-Sails

4.1.2. Fixed-Sails

4.1.3. Flettner Rotors

4.1.4. Kite Sails

4.1.5. Wind Turbines

4.2. Solar

Solar-Hybrid Systems

4.3. Biofuels

- First Generation: “The source of carbon for the biofuel is sugar, lipid or starch directly extracted from a plant. The crop is actually or potentially considered to be in competition with food.”

- Second Generation: “The biofuel carbon is derived from cellulose, hemicellulose, lignin or pectin. For example, this may include agricultural, forestry wastes or residues, or purpose-grown non-food feedstocks (e.g., Short Rotation Coppice, Energy Grasses).”

- Third Generation: “The biofuel carbon is derived from aquatic autotrophic organisms (e.g., algae). Light, carbon dioxide and nutrients are used to produce the feedstock, “extending” the carbon resource available for biofuel production.”

4.3.1. Liquid Biofuels

4.3.2. Biogas

| Engine Type | Manufacturer | Engine Model |

|---|---|---|

| Four-stroke | Anglo Belgian Corporation (Gent, Belgium) | VDZC Series; DL36 Series |

| Akasaka diesels (Tokyo, Japan) | AX 28 Series | |

| Caterpillar Inc (Deerfield, MA, USA) | 3500 Series; 3600 Series | |

| MaK Motoren GmbH and Co. (Peoria, IL, USA) | M601; M20C, M25C, M32C and M43C Series | |

| Daihatsu Motor Co. Ltd. (Ikeda, Japan) | DK-28 Series; DC-17Ae Series | |

| Deutz AG (Cologne, Germany) | TCD 2015 V Series | |

| Doosan Engine Co. Ltd. (Changwon, Korea) | V222TI; L136TI Series | |

| Hanshin Diesel (Kobe City, Japan) | LA 30; LA 34 Series | |

| Hyundai Heavy Industries Co. Ltd. (Ulsan, Korea) | HiMSEN Series H17/28; H21/32; H32/40 | |

| MAN Diesel and Turbo SE (Augsburg, Germany) | L23/30; L16/24; L21/31; L27/38; L32/40; L40/54; L48/60 CR; L58/64; L32/44 CR; D2876 | |

| Mitsui and Co. Ltd. (Tokyo, Japan) | ADD30V | |

| MTU Friedrichschafen GmbH (Friedrichshafen, Germany) | MTU V 4000 | |

| Paxman (Colchester, UK) | VP185 | |

| Rolls-Royce Group Plc (London, UK) | B32:40R; C25:33L | |

| Ruston and Hornsby (Lincoln, UK) | RK 270; RK 280 | |

| Pielstick (Augsburg, Germany) | S.E.M.T. Pielstick series PC2.6B | |

| Sulzer Brothers Ltd. (Winterthur, Switzerland) | Z40; ZA40S | |

| Wärtsilä NSD (Helsinki, Finland) | L20; L/V32C; L/V46C; 64C | |

| Yanmar Co. Ltd. (Osaka, Japan) | 6N21; EY18L; EY26L; AYM | |

| Gas four-stroke | MAN Diesel and Turbo SE (Augsburg, Germany) | V35/44G |

| Mitsubishi Heavy Industries (Tokyo, Japan) | KU30G | |

| Rolls-Royce Bergen (Hordvik, Norway) | C26:33LPG | |

| Gas-diesel dual-fuel four-stroke | MAN Diesel and Turbo SE (Augsburg, Germany) | 35/44DF |

| Caterpillar Inc (Deerfield, MA, USA) | M46DF | |

| Wärtsilä NSD (Helsinki, Finland) | L50DF | |

| Two-stroke ship low-speed crosshead | MAN Diesel and Turbo SE (Augsburg, Germany) | MC, MC-C, ME, ME-C and ME-B series |

| Mitsubishi Heavy Industries (Tokyo, Japan) | UEC LSH-Eso; LSE-Eco | |

| Wärtsilä-Sulzer (Helsinki, Finland) | RTA; RT-Flex Series | |

| WinGD (Winterthur, Switzerland) | W-X Series | |

| Gas diesel two-stroke ship low-speed (low pressure) | WinGD (Winterthur, Switzerland) | X-DF Series |

| Gas diesel two-stroke ship low-speed (high pressure) | MAN Diesel and Turbo SE (Augsburg, Germany) | ME-GI Series |

5. Maturity of Technologies

5.1. Internal Combustion Engines (ICE)

5.1.1. Types of Engines Used in Shipping

Four-Stroke Engines

Two-Stroke Engines

- Fuel (in the gas phase) enters the combustion cylinder after the exhaust valve is closed at the initial stage of the compression stroke under relatively low pressure; hence, such systems are called low-pressure supply systems.

- Fuel (in the gas phase) with the ignition fuel enters the combustion cylinder at the end of the compression stroke which is at high pressure; hence, such systems are called high-pressure supply systems or direct gas injection (GD).

Gas and Gas-Diesel (Dual Fuel) Engines

- (1)

- Convert diesel engines to operate according to the Otto cycle, i.e., mix the air-fuel externally to the combustion cylinder and ignite the air-fuel mixture with electric spark ignition.

- (2)

- Mix the air-fuel externally to the combustion chamber and ignite the air-fuel mixture with electric spark ignition combined with liquid fuel injection into the combustion cylinder: DF engine.

- (3)

- Mix the air-fuel in the combustion chamber and ignite the air-fuel mixture with electric spark ignition combined with liquid fuel injection into the combustion: DF engine.

- Effective lubrication (and the varying degree of sulfur level) because of the use of different fuels. The knocking margin due to alkali and other compounds depositing on the cylinder walls, hence it will be difficult to select a suitable lubricant that satisfies operation in diesel or gas mode.

- Different characteristics of natural gas at different bunkering stations (varying degree of humidity, CO2, etc.) which may cause knocking.

5.1.2. Combustion of Alternative Fuels in ICE

LNG in ICE

Hydrogen in ICE

Ammonia in ICE

- Poor ignition and very slow flame propagation speed compared to other fuels, see Table 4 for minimum ignition energy and laminar flame speed.

- Toxic and corrosive, thus the requirement of sustainable safety and storage solutions.

- Higher NOx emissions, unless controlled either by after-treatment or by optimizing the combustion process.

- Regulations/policies will need to be developed for its use as a marine fuel.

Methanol in ICE

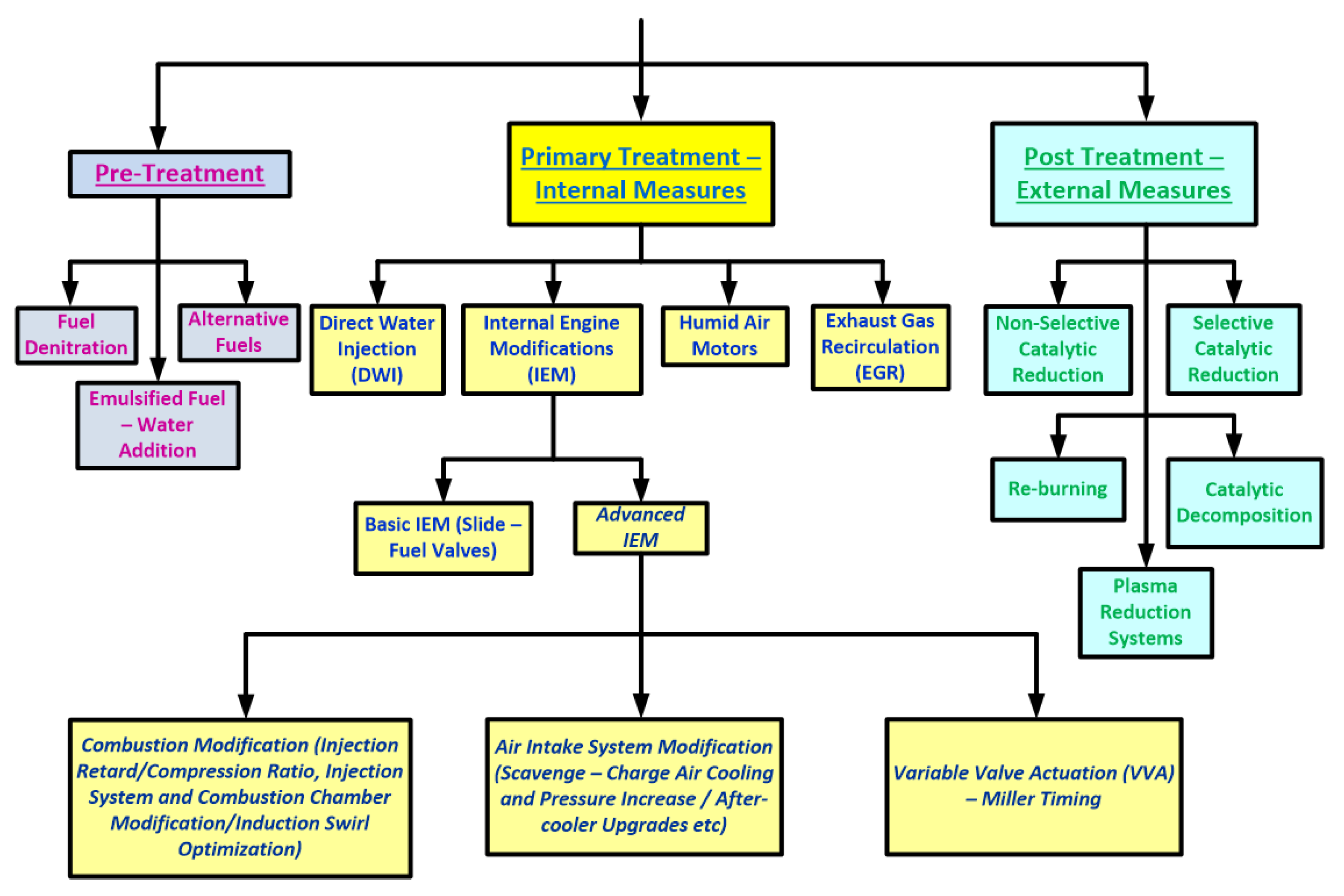

5.1.3. After-Treatment Technologies in ICE

Direct Water Injection (DWI)

Intake Air Humidification

Water-in-Fuel Emulsion

Non-Thermal Plasma (NTP)

Selective Catalytic Reduction (SCR)

- Ammonia SCR after-treatment

- Hydrocarbon SCR after-treatment

- Carbon monoxide SCR after-treatment

- Hydrogen SCR after-treatment

- Alcohol SCR after-treatment

NOx Trap After-Treatment

Exhaust Gas Recirculation (EGR)

Control of Particulate Matter (PM) Emissions

De-SOx After-Treatment Technologies

5.2. Fuel Cells

5.2.1. Fuel Cell Types

- Alkaline fuel cell (AFC),

- Low- and high-temperature polymer electrolyte membrane fuel cell (LT/HT-PEMFC),

- Phosphoric acid fuel cell (PAFC),

- Molten Carbonate fuel cell (MCFC),

- Direct Methanol fuel cell (DMFC) and

- Solid oxide fuel cell (SOFC).

5.2.2. Hydrogen as Fuel for Fuel Cells

5.2.3. Ammonia as Fuel for Fuel Cells

5.3. Electric/Hybrid Propulsion

- Batteries,

- Flywheels, and

- Supercapacitors.

5.4. Batteries and Supercapacitors

5.5. Gas Turbines

5.6. Nuclear

5.7. Carbon Capture and Storage (CCS)

6. Reduction of Fuel Consumption via Technical and Operational Measures

6.1. Vessel Speed

- Full speed: 23–25 knots (44 km/h).

- Slow steaming: 20–22 knots (39 km/h).

- Extra slow steaming: 17–19 knots (33 km/h).

- Super slow steaming: 15 knots (28 km/h).

6.2. Reduction of Hull Resistance

6.2.1. Cleaning

6.2.2. Paints and Low-Resistance Coatings

6.2.3. Vessel Design

Reduced Ballast Operation

Lightweight Construction

Optimum Hull Dimensions

Low-Profile Hull Openings

Interceptor Trim Plates

Skeg Shape/Trailing Edge

Bulbous Bow

6.2.4. Propeller Design

- Wing thrusters (<10% improvement),

- Counter rotating propellers (<12% improvement),

- Optimization of propeller–hull interaction (<4% improvement),

- Propeller–rudder interactions (<4%),

- Advanced propeller blade sections (<2%),

- Propeller tip winglets (<4%), propeller nozzle (<5%),

- Constant vs. variable speed operation (<5%),

- Pulling thruster (<10%), and

- Propeller efficiency management (<2%).

6.3. Air Lubrication

- Bubble Drag Reduction (BDR),

- Air Layer Drag Reduction (ALDR), and

- Partial Cavity Drag Reduction (PCDR).

6.3.1. Bubble Drag Reduction

6.3.2. Air Layer Drag Reduction

6.3.3. Partial Cavity Drag Reduction

6.4. Waste Heat Recovery

- Rankine Cycle (RC):

- ○

- Steam/conventional Rankine Cycle

- ○

- Organic Rankine Cycle (ORC)

- ○

- Super-Critical Rankine Cycle

- Kalina Cycle (KC)

- Exhaust gas turbine system:

- ○

- Hybrid turbocharger

- ○

- Mechanical turbo-compound system

- ○

- Hydraulic turbo-compound system

- ○

- Electric turbo-compound system

- Thermoelectric generation (TEG) systems

- There is no optimal WHR solution for maritime applications. One has to consider the trade-offs of costs, working fluid characteristics, size and safety.

- As a rule of thumb:

- Steam RC in combination with a power turbine for marine engines “with power output greater than 25 MW is more likely to be used due to high efficiency and technology maturity”.

- ORC technologies are recommended for relatively small size ships due to high efficiency and flexibility in recovering waste heat from different sources.

- The CO2-based power cycles are “more appealing where the system size is of particular importance”.

- KC has found use in land-based applications (such as geothermal applications) but it is seldom recommended in maritime applications because of the toxicity of the working fluid (ammonia-water mixture).

7. Future Trends, Challenges and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkesa, A.; Staffell, I. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- Energy Transitions Commission. The First Wave. A Blueprint for Commercial-Scale Zero-Emission Shipping Pilots; A Special Report by the Energy Transitions Commission for the Getting to Zero Coalition; Energy Transitions Commission: London, UK, 2020. [Google Scholar]

- Gross domestic product: Total per capita, growth rates, annual. In Proceedings of the United Nations Conference on Trade and Development, New York, NY, USA, 4 September 2019.

- Shell; Deloitte. Decarbonising Shipping: All Hands on Deck; Shell: The Hague, The Netherlands, 2020. [Google Scholar]

- IMO. UN Body Adopts Climate Change Strategy for Shipping IMO, 13 April 2018. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/Pages/06GHGinitialstrategy.aspx (accessed on 19 January 2021).

- Lister, J.; Poulsen, R.T.; Ponte, S. Orchestrating transnational environmental governance in maritime shipping. Glob. Environ. Chang. 2015, 34, 185–195. [Google Scholar] [CrossRef] [Green Version]

- Psaraftis, H.N. Green maritime transportation: Market based measures. In Green Transportation Logistics; Springer International Publishing: Cham, Switzerland, 2016; pp. 267–297. [Google Scholar]

- ITF. Decarbonising Maritime Transport. Pathways to Zero-Carbon Shipping by 2035; International Transport Forum: Paris, France, 2018. [Google Scholar]

- Buhaug, Ø.; Corbett, J.; Endresen, Ø.; Eyring, V.; Faber, J.; Hanayama, S.; Lee, D.S.; Lee, D.; Lindstad, H.; Markowska, A.; et al. Second IMO GHG Study 2009; International Maritime Organization: London, UK, 2009. [Google Scholar]

- CAIT; World Resources Institute. Historical Emissions Data; World Resources Institute: Washington, DC, USA, 2017. [Google Scholar]

- Smith, T.W.P.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO GHG Study; International Maritime Organization: London, UK, 2015; pp. 1–327. [Google Scholar]

- World Bank. World Development Indicators; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Statistica. Flottenkommando Marine. Number of Ships in the World Merchant Fleet between 1 January 2008 and 1 January 2017, by type. 2018. Available online: https://www.statista.com/statistics/264024/number-of-merchant-ships-worldwide-by-type/ (accessed on 20 January 2021).

- IMO. Brief History of IMO. 2017. Available online: https://www.imo.org/en/About/HistoryOfIMO/Pages/Default.aspx (accessed on 20 January 2021).

- Bradley, B.; Hoyland, R. Decarbonisation and Shipping: International Maritime Organization Ambitions and Measures, 4 November 2020. Available online: https://www.hilldickinson.com/insights/articles/decarbonisation-and-shipping-international-maritime-organization-ambitions-and (accessed on 25 January 2021).

- ICS. Environmental Performance: IMO Agreement on Technical Regulations to Reduce Ships’ CO2. 2017. Available online: https://www.ics-shipping.org/shipping-fact/environmental-performance-imo-agreement-on-technical-regulations-to-reduce-ships-co2/ (accessed on 25 January 2021).

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-Art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D 2017, 52, 408–421. [Google Scholar] [CrossRef]

- ICCT. The Energy Efficiency Design Index (EEDI) for New Ships; International Council on Clean Transportation: San Francisco, CA, USA, 2011. [Google Scholar]

- Pariotis, E.G.; Zannis, T.C.; Yfantis, E.A.; Roumeliotis, I.; Katsanis, J.S. Energy saving techniques in ships—Technical and operational measures. In Proceedings of the International Conference Green Transportation, Athens, Greece, 4 June 2016. [Google Scholar]

- Jaques, B. Japanese Zero Emission Ship Concepts Unveiled. 28 May 2020. Available online: https://www.seatrade-maritime.com/environmental/japanese-zero-emission-ship-concepts-unveiled (accessed on 1 February 2021).

- IMO. IMO Working Group Agrees Further Measures to Cut Ship Emissions. 23 October 2020. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/pages/36-ISWG-GHG-7.aspx (accessed on 2 February 2021).

- Wärtsilä; DNV GL. Decarbonising shipping. In Proceedings of the Joint Wärtsilä—DNV GL Webinar, Online, 3 November 2020. [Google Scholar]

- DNV GL. EEXI—Energy Efficiency Existing Ship Index. 2020. Available online: https://www.dnvgl.com/maritime/insights/topics/eexi/index.html (accessed on 2 February 2021).

- Rutherford, D.; Mao, X.; Comer, B. Potential CO2 Reductions under the Energy Efficiency Existing Ship Index. November 2020. Available online: https://theicct.org/publications/marine-eexi-nov2020 (accessed on 2 February 2021).

- IMO. Market-Based Measures. International Maritime Organisation. 2019. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Market-Based-Measures.aspx (accessed on 26 March 2021).

- Hirdaris, S.; Fai, C. Keynote Paper: The role of technology in green ship design. In Proceedings of the 11th International Marine Design Conference, Glasgow, UK, 11–14 June 2012. [Google Scholar]

- Reynolds, G. The history and status of GHG emissions control in international shipping. In Proceedings of the International Conference on Technologies, Operations, Logistics and Modelling for Low Carbon Shipping, Glasgow, UK, 22–24 June 2011. [Google Scholar]

- Tanaka, H.; Okada, A. Effects of market-based measures on a shipping company: Using an optimal control approach for long-term modeling. Res. Transp. Econ. 2019, 73, 63–71. [Google Scholar] [CrossRef]

- Lagouvardou, S.; Psaraftis, H.N.; Zis, T. A Literature Survey on market-based measures for the decarbonization of shipping. Sustainability 2020, 12, 3953. [Google Scholar] [CrossRef]

- Jorgensen, R.N. Shipping Industry Needs to Talk Market-Based Measures. BiMCO. 2 March 2021. Available online: https://www.bimco.org/news/priority-news/20210302-shipping-industry-needs-to-talk-market-based-measures (accessed on 26 March 2021).

- ECSA. Position Paper: A Green Deal for the European Shipping Industry; European Community Shipowners’ Associations: Brussels, Belgium, 2020. [Google Scholar]

- Sogaard, K.; Bingham, C. Mapping of Zero Emission Pilots and Demonstration Projects. 2020. Available online: https://www.globalmaritimeforum.org/news/mapping-of-zero-emission-pilots-and-demonstration-projects/ (accessed on 15 February 2021).

- Hsieh, C.-W.C.; Felby, C. Biofuels for the Marine Shipping Sector; IEA Bioenergy: Paris, France, 2017. [Google Scholar]

- EAFO. Alternative Fuels used for Shipping. 2019. Available online: https://www.eafo.eu/shipping-transport/shipping-overview/af-for-shipping (accessed on 15 February 2021).

- DNV GL. Comparison of Alternative Marine Fuels; DVN GL: Høvik, Norway, 2019. [Google Scholar]

- Lloyd’s Register; UMAS. Techno-Economic Assessment of Zero-Carbon Fuels; Lloyd’s Register: London, UK; UMAS: London, UK, 2020. [Google Scholar]

- Andrews, J.; Shabani, B. Where does hydrogen fit in a sustainable energy economy? Procedia Eng. 2012, 49, 15–25. [Google Scholar] [CrossRef] [Green Version]

- IEA. Hydrogen. 28 August 2020. Available online: https://www.iea.org/fuels-and-technologies/hydrogen (accessed on 16 February 2021).

- Mofor, L.; Nuttall, P.; Newell, A. Renewable Energy Options for Shipping; Technology Brief; IRENA Innovation and Technology Centre: Bonn, Germany, 2015. [Google Scholar]

- IEA. Global Demand for Pure Hydrogen 1975–2018. 2019. Available online: https://www.iea.org/data-and-statistics/charts/global-demand-for-pure-hydrogen-1975-2018 (accessed on 16 February 2021).

- Brooks, A.G. Super Fuel? Can hydrogen fuel live up to its hype? 24 December 2020. Available online: https://www.maritime-executive.com/magazine/super-fuel (accessed on 17 February 2021).

- Lindstad, H.; Asbjornslett, B.; Stromman, A. Reductions in greenhouse gas emissions and cost by shipping at lower speeds. Energy Policy 2011, 39, 3456–3464. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Clean fuel options with hydrogen for sea transportation: A life cycle approach. Int. J. Hydrogen Energy 2018, 42, 1179–1193. [Google Scholar] [CrossRef]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Van Hoecke, L.; Laffineur, L.; Campe, R.; Perreault, P.; Verbruggen, S.W.; Lenaerts, S. Challenges in the use of hydrogen for maritime applications. Energy Environ. Sci. 2021, 14, 815–843. [Google Scholar] [CrossRef]

- Zemships. One Handred Passengers and Zero Emissions: The First Ever Passenger Vessel to Sail Propelled by Fuel Cells; Zemships: Hamburg, Germany, 2008. [Google Scholar]

- Raucci, C. The Potential of Hydrogen to Fuel International Shipping. Ph.D. Thesis, UCL Energy Institute, University College, London, UK, 2017. [Google Scholar]

- Hammerschmidt, A. Fuel cell propulsion of submarines. In Proceedings of the Advanced Naval Propulsion Symposium 2006, Arlington, VA, USA, 30–31 October 2006. [Google Scholar]

- Mokhatab, S.; Valappil, J.; Mak, J.Y.; Wood, D.A. Chapter 9—LNG safety and security aspects. In Handbook of Liquefied Natural Gas; Gulf Professional Publishing: Houston, TX, USA, 2014; pp. 359–435. [Google Scholar]

- BBC. The Fuel that Could Transform Shipping. 30 November 2020. Available online: https://www.bbc.com/future/article/20201127-how-hydrogen-fuel-could-decarbonise-shipping (accessed on 20 February 2021).

- Willuhn, M. Green Hydrogen to Reach Price Parity with Grey Hydrogen in 2030. 16 July 2020. Available online: https://www.pv-magazine.com/2020/07/16/green-hydrogen-to-reach-price-parity-with-grey-hydrogen-in-2030/ (accessed on 20 February 2021).

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Subramanian, S. The Cargo Industry’s Quest to Curb Carbon-Belching Ships. April 2020. Available online: https://www.wired.com/story/cargo-industry-decarbonize-carbon-belching-ships/amp (accessed on 20 February 2021).

- Shell. Decarbonising Shipping: Setting Shell’s Course; Shell: The Hague, The Netherlands, 2020. [Google Scholar]

- Zheng, J.; Chen, L.; Xu, X.; Guo, L.; Zhou, Y.; Wang, J. A novel insulation system based on active cooling without power input for liquid hydrogen storage. Energy 2019, 182, 1–10. [Google Scholar] [CrossRef]

- Kamiya, S.; Nishimura, M.; Harada, E. Study on introduction of CO2 free energy to Japan with liquid hydrogen. Phys. Procedia 2015, 67, 11–19. [Google Scholar] [CrossRef] [Green Version]

- Hansson, J.; Brynolf, S.; Fridell, E.; Lehtveer, M. The potential role of ammonia as marine fuel—Based on energy systems modeling and multi-criteria decision analysis. Sustainability 2020, 12, 3265. [Google Scholar] [CrossRef] [Green Version]

- Brown, T. Yara: Solar Ammonia Pilot Plant, for Start-Up in 2019. Ammoniaindustry. 2017. Available online: https://ammoniaindustry.com/yara-solar-ammonia-pilot-plant-for-start-up-in-2019/ (accessed on 29 March 2021).

- DNV GL. Methanol as a Potential Alternative Fuel for Shipping: A Brief Talk with Chris Chatterton of the Methanol Institute. 2020. Available online: https://www.dnvgl.com/maritime/advisory/afi-update/Methanol-as-a-potential-alternative-fuel-for-shipping-A-brief-talk-with-Chris-Chatterton.html (accessed on 23 January 2020).

- SOTACARBO. Methanol from CO2: Applications and Perspectives. 14 May 2020. Available online: https://www.sotacarbo.it/en/2020/05/metanolo-da-co2-applicazioni-e-prospettive/?fbclid=IwAR2P_f5qhTlLxqUy9pNEhgAU1FklyWvyAPJL99v_qzsfq4X6PGwnrNZI4i4/ (accessed on 22 February 2021).

- Moirangthem, K. Alternative Fuels for Marine and Inland Waterways: An Exploratory Study; JRC Technical, Report; Baxter, D., Ed.; Joint Research Centre: Brussels, Belgium, 2016. [Google Scholar]

- Ellis, J.; Ramne, B.; Falk, T.; Nilsson, M.; Stefenson, P.; Efraimsson, A.; Folić, M.; Kotur, N.; Tanneberger, K.; Freudendahl, U.; et al. SPIRETH—End of Project Report—Activities and Outcomes of the SPIRETH (Alcohol (Spirits) and Ethers as Marine Fuel) Project; Norden Energy and Transport: Calgary, AB, Canada, 2014. [Google Scholar]

- Yfantis, E.A.; Katsanis, J.S.; Pariotis, E.G.; Zannis, T.C. Methanol as a Low-Carbon and Sulphur-Free Alternative Fuel for Shipping: Prospects and Challenges; Hellenic Institute of Marine Technology: Piraeus, Greece, 2018. [Google Scholar]

- Fagerlund, P.; Ramne, B. Effship Project: Summary and conclusions. In Proceedings of the EffShip Seminar, Göteborg, Sweden, 21 March 2013. [Google Scholar]

- Andersson, K.; Salazar, C.M. Methanol as a Marine Fuel; Report; Methanol Institute: Brussels, Belgium, 2015. [Google Scholar]

- Bernatik, A.; Senovsky, P.; Pitt, M. LNG as a potential alternative fuel—Safety and security of storage facilities. J. Loss Prev. Process Ind. 2011, 24, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Sphera. Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel. 10 April 2019. Available online: https://sphera.com/research/life-cycle-ghg-emission-study-on-the-use-of-lng-as-marine-fuel/ (accessed on 22 February 2021).

- Jafarzadeh, S.; Paltrinieri, N.; Utne, I.B.; Ellingsen, H. LNG-Fuelled fishing vessels: A systems engineering approach. Transp. Res. Part D 2017, 50, 202–222. [Google Scholar] [CrossRef]

- Schuller, O.; Reuter, B.; Hengstler, J.; Whitehouse, S.; Zeitzen, L. Greenhouse Gas Intensity of Natural Gas; Final Report; Thinkstep AG: Stuttgart, Germany; Natural & Bio Gas Vehicle Association (NGVA) Europe: Brussels, Belgium, 2017. [Google Scholar]

- Lowell, D.; Wang, H.; Lutsey, N. Assessment of the Fuel Cycle Impact of Liquefied Natural Gas as Used in International Shipping; International Council on Clean Transportation: San Francisco, CA, USA, 2013. [Google Scholar]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of full life-cycle air emissions of alternative shipping fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Bengtsson, S.; Andersson, K.; Fridell, E. A comparative life cycle assessment of marine fuels: Liquefied natural gas and three other fossil fuels. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 97–110. [Google Scholar] [CrossRef]

- Stenersen, D.; Thonstad, O. GHG and NOx Emissions from Gas Fuelled Engines—Mapping, Verification, Reduction Technologies; SINTEF Ocean AS: Trondheim, Norway, 2017. [Google Scholar]

- Lindstad, E.; Eskeland, G.S.; Rialland, A.; Valland, A. Decarbonizing maritime transport: The importance of engine technology and regulations for LNG to serve as a transition fuel. Sustainability 2020, 12, 8793. [Google Scholar] [CrossRef]

- ICCT. The Climate Implications of Using LNG as a Marine Fuel; International Council on Clean Transportation: Washington, DC, USA, 2020. [Google Scholar]

- Li, J.; Wu, B.; Mao, G. Research on the performance and emission characteristics of the LNGdiesel marine engine. J. Nat. Gas Sci. Eng. 2015, 27, 945–954. [Google Scholar] [CrossRef]

- DNV GL. Alternative Fuels for Shipping; Position Paper 17-2014; DNV GL: Bærum, Norway, 2014. [Google Scholar]

- Rojon, I.; Dieperink, C. Blowin’ in the wind? Drivers and barriers for the uptake of wind propulsion in international shipping. Energy Policy 2014, 67, 394–402. [Google Scholar] [CrossRef]

- Traut, M.; Gilbert, P.; Walsh, C.; Bows, A.; Filippone, A.; Stansby, P.; Wood, R. Propulsive power contribution of a kite and a Flettner rotor on selected shipping routes. Appl. Energy 2014, 113, 362–372. [Google Scholar] [CrossRef]

- Effship. Work Package 2 Report: Present and Future Maritime Fuels; Effship: Göteborg, Sweden, 2013. [Google Scholar]

- Royal Academy of Engineering. Future Ship Powering Options: Exploring Alternative Methods of Ship Propulsion; Royal Academy of Engineering: London, UK, 2013. [Google Scholar]

- ECOFYS. Potential of Biofuels for Shipping; European Maritime Safety Agency: Utrecht, The Netherlands, 2012. [Google Scholar]

- Oceana. Shipping Solutions: Technological and Operational Methods Available to Reduce CO2; Oceana: Washington, DC, USA, 2010. [Google Scholar]

- Siemens Gamesa; Siemens Energy. Siemens Gamesa and Siemens Energy to Unlock a New Era of Offshore Green Hydrogen Production; Press Release; Siemens Gamesa: Zamudio, Spain; Siemens Energy: Munich, Germany, 2021. [Google Scholar]

- BBC. Kite to Pull Ship Across Atlantic. 22 January 2008. Available online: http://news.bbc.co.uk/2/hi/europe/7201887.stm (accessed on 23 February 2021).

- SkySails Group. 2020. Available online: https://skysails-group.com/index.html (accessed on 23 February 2021).

- Qiu, Y.; Yuan, C.; Sun, Y. Review on the application and research progress of photovoltaics-ship power system. In Proceedings of the 3rd International Conference on Transportation Information and Safety, Wuhan, China, 25–28 June 2015. [Google Scholar]

- OCIUS. 2020. Available online: https://ocius.com.au/ (accessed on 23 February 2021).

- ECO Marine Power. Eco Marine Power. 2020. Available online: https://www.ecomarinepower.com/en/ (accessed on 24 February 2021).

- Vanek, F.M.; Albright, L.D.; Angenent, L.T. Energy Systems Engineering: Evaluation and Implementation, 2nd ed.; Mc Graw Hill: New York, NY, USA, 2012. [Google Scholar]

- Offshore Energy. Maersk. US Navy Test Algae-Based Biofuel on Container Ship Maersk Kalmar. 12 December 2011. Available online: https://www.offshore-energy.biz/maersk-us-navy-tests-algae-based-biofuel-on-container-ship-maersk-kalmar/ (accessed on 24 February 2021).

- BusinessWire. Maersk Tests SoladieselRD® in 6500 Nautical Mile Commercial Voyage. BusinessWire. 23 January 2012. Available online: https://www.businesswire.com/news/home/20120123005469/en/Maersk-Tests-SoladieselRD%C2%AE-in-6500-Nautical-Mile-Commercial-Voyage (accessed on 24 March 2021).

- CE Delft. Availability and Costs of Liquefied Bio-And Synthetic Methane: The Maritime Shipping Perspective; CE Delft: Delft, The Netherlands, 2020. [Google Scholar]

- Bilousov, I.; Bulgakov, M.; Savchuk, V. Modern Marine Internal Combustion Engines: A Technical and Historical Overview; Springer Series on Naval Architecture, Marine Engineering, Shipbuilding and Shipping 8; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Hellenic Shipping News. Why the Internal Combustion Engine is Essential in Shipping’s Decarbonisation Mission. 14 December 2020. Available online: https://www.hellenicshippingnews.com/why-the-internal-combustion-engine-is-essential-in-shippings-decarbonisation-mission/ (accessed on 24 February 2021).

- Kyrtatos, A.; Spahni, M.; Hensel, S.; Züger, R.; Sudwoj, G. The Development of the Modern Low-Speed Two-Stroke Marine Diesel Engine. In Proceedings of the 28th CIMAC World Congress, Helsinki, Finland, 6–10 June 2016. [Google Scholar]

- Weaver, C.S.; Turner, S.H. Dual Fuel Natural Gas/Diesel Engines: Technology, Performance, and Emissions; SAE Technical Paper 940548; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Ohashi, I. Dual-Fuel Marine Engine (Highly Reliable Environmentally Friendly Engine). 27 July 2015. Available online: https://www.yanmar.com/global/about/technology/technical_review/2015/0727_2.html (accessed on 25 February 2021).

- Boretti, A. Advances in diesel-LNG internal combustion engines. Appl. Sci. 2020, 10, 1296. [Google Scholar] [CrossRef] [Green Version]

- Arefin, A.; Nabi, N.; Akram, W.; Islam, M.T.; Chowdhury, W. A review on liquefied natural gas as fuels for dual fuel engines: Opportunities, challenges and responses. Energies 2020, 13, 6127. [Google Scholar] [CrossRef]

- White, C.M.; Steeper, R.R.; Lutz, A.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrogen Energy 2006, 31, 1292–1305. [Google Scholar] [CrossRef]

- Sharma, P.; Dhar, A. Effect of hydrogen supplementation on engine performance and emissions. Int. J. Hydrogen Energy 2018, 43, 7570–7580. [Google Scholar] [CrossRef]

- Mørch, C.; Bjerre, A.; Gøttrup, M.; Sorenson, S.; Schramm, J. Ammonia/hydrogen mixtures in an SI-engine: Engine performance and analysis of a proposed fuel system. Fuel 2011, 90, 854–864. [Google Scholar] [CrossRef]

- Saika, T. Study of an ammonia fueled engine as a clean energy system. Nihon Enerugi Gakkaishi. J. Jpn. Inst. Energy 2000, 79, 530–539. [Google Scholar] [CrossRef] [Green Version]

- Ferguson, C.R.; Kirkpatrick, A.T. Internal Combustion Engines, Applied Thermosciences, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Green, L.J. An ammonia energy vector for the hydrogen economy. Int. J. Hydrogen Energy 1982, 7, 355–359. [Google Scholar] [CrossRef]

- CMB.TECH. Projects—Marine. 2020. Available online: https://cmb.tech/experience/projects-marine/ (accessed on 10 January 2021).

- Reiter, A.J.; Kong, S.-C. Demonstration of compression-ignition engine combustion using ammonia in reducing greenhouse gas emissions. Energy Fuels 2008, 22, 2963–2971. [Google Scholar] [CrossRef]

- Wärtsilä. World’s First Full Scale Ammonia Engine Test—An Important Step Towards Carbon Free Shipping. 30 June 2020. Available online: https://www.wartsila.com/media/news/30-06-2020-world-s-first-full-scale-ammonia-engine-test---an-important-step-towards-carbon-free-shipping-2737809 (accessed on 11 January 2021).

- Wärtsilä. Wärtsilä Advances Future Fuel Capabilities with First Ammonia Tests. 25 March 2020. Available online: https://www.wartsila.com/media/news/25-03-2020-wartsila-advances-future-fuel-capabilities-with-first-ammonia-tests-2670619?utm_source=press-release&utm_medium=org&utm_term=marine&utm_content=1st+Ammonia+test&utm_campaign=Green+Ammonia+engine+tests (accessed on 12 January 2021).

- MAN Energy Solutions. Engineering the Future Two-Stroke Green-Ammonia Engine; MAN Energy Solutions: Copenhagen, Denmark, 2019. [Google Scholar]

- MAN Diesel and Turbo. Using Methanol Fuel in the MAN B&W ME-LGI Series; MAN Diesel and Turbo: Copenhagen, Denmark, 2015. [Google Scholar]

- Tripathi, G.; Dhar, A.; Sadiki, A. Recent advancements in after-treatment technology for internal combustion engines—An Overview. In Advances in Internal Combustion Engine Research. Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 159–179. [Google Scholar]

- Zannis, T.C.; Yfantis, E.A.; Hountalas, D.T.; Papagiannakis, R.G.; Levendis, Y.A. Critical review of the effects of diesel fuel composition and properties on engine performance and pollutant emissions. In Diesel Fuels—Characteristics, Performances and Environmental Impacts; Nova: New York, NY, USA, 2013; pp. 1–59. [Google Scholar]

- Raptotasios, S.I.; Sakellaridis, N.F.; Papagiannakis, R.G.; Hountalas, D.T. Application of a multizone combustion model to investigate the NOx reduction potential of two-stroke marine diesel engines using EGR. Appl. Energy 2015, 157, 814–823. [Google Scholar] [CrossRef]

- Tremuli, P. Development and Perspectives of Marine Engines, Clean Combustion and Greenhouse Gases. In Proceedings of the Wärtsilä EuDA Presentation, Brussels, Belgium, 6 November 2008; Available online: http://www.european-dredging.eu/pdf/WARTSILA_presentation.pdf (accessed on 27 February 2021).

- Zhang, Z.; Kang, Z.; Jiang, L.; Chaoa, Y.; Deng, J.; Hua, Z.; Li, L.; Wu, Z. Effect of direct water injection during compression stroke on thermal efficiency optimization of common rail diesel engine. Energy Procedia 2017, 142, 1251–1258. [Google Scholar] [CrossRef]

- Puchkarev, V.; Kharlov, A.; Gundersen, M.; Roth, G. Application of pulsed corona discharge to diesel exhaust remediation. In Digest of technical papers, Proceedings of the 12th IEEE International Conference on Pulsed Power 1999, Monterey, CA, USA, 27–30 June 1999; IEEE: Minneapolis, MN, USA, 1999. [Google Scholar]

- Talebizadeh, P.; Babaie, M.; Brown, R.; Rahimzadeh, H.; Ristovski, Z.; Arai, M. The role of non-thermal plasma technique in NOx treatment: A review. Renew. Sustain. Energy Rev. 2014, 40, 886–901. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Geng, P.; Chen, Y. NOx emission reduction technology for marine engine based on Tier-III: A review. J. Therm. Sci. 2020, 29, 1242–1268. [Google Scholar] [CrossRef]

- Zannis, T.C.; Yfantis, E.; Katsanis, J.S.; Pariotis, E. Use of Selective Catalytic Reduction (SCR) for NOx Emission Reduction by Marine Engines—Part II: Practical Applications, Performance Characteristics and Financial Data. In Proceedings of the Annual Meeting of Marine Technology, Athens, Greece, 12–13 December 2017. (In Greek). [Google Scholar]

- Notteboom, T.; Delhaye, E.; Vanherle, K. Analysis of the Consequences of Low Sulphur Fuel Requirements; European Community Shipowners’ Associations (ECSA): Brussels, Belgium, 2010. [Google Scholar]

- Guo, M.; Fu, Z.; Ma, D.; Ji, N.; Song, C.; Liu, Q. A short review of treatment methods of marine diesel engine exhaust gases. Procedia Eng. 2015, 121, 938–943. [Google Scholar] [CrossRef] [Green Version]

- Zannis, T.; Pariotis, E.; Yfantis, E.; Katsanis, I. Marine DeSOx systems: A state-of-the-art evaluation. In Proceedings of the 2nd International Conference “Energy in Transportation”, Athens, Greece, 21 October 2017. [Google Scholar]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Warda, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef] [Green Version]

- Van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P.V. A review of fuel cell systems for maritime applications. J. Power Sources 2016, 327, 345–364. [Google Scholar] [CrossRef] [Green Version]

- O’Hayre, R.; Cha, S.-W.; Colella, W.; Prinz, F.B. Fuel Cell Fundamentals, 3rd ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Dodds, P.E.; Ekins, P. A portfolio of powertrains for the UK: An energy systems analysis. Int. J. Hydrogen Energy 2014, 39, 13941–13953. [Google Scholar] [CrossRef] [Green Version]

- Pocard, N. Fuel Cell Price to Drop 70–80% as Production Volume Scales. 30 January 2020. Available online: https://blog.ballard.com/fuel-cell-price-drop (accessed on 17 January 2021).

- Environmental and Energy Study Institute. Fact Sheet—Fuel Cells. 5 November 2015. Available online: https://www.eesi.org/papers/view/fact-sheet-fuel-cells (accessed on 17 January 2021).

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Fuel cell power systems for maritime applications: Progress and perspectives. Sustainability 2021, 12, 1213. [Google Scholar]

- Bischoff, M. Molten carbonate fuel cells: A high temperature fuel cell on the edge to commercialization. J. Power Sources 2006, 160, 842–845. [Google Scholar] [CrossRef]

- Çogenli, M.S.; Mukerjee, S.; Yurtcan, A.B. Membrane electrode assembly with ultra low platinum loading for cathode electrode of PEM fuel cell by using sputter deposition. Fuel Cells 2015, 15, 288–297. [Google Scholar] [CrossRef]

- Dai, W.; Wang, H.; Yuan, X.-Z.; Martin, J.J.; Yang, D.; Qiao, J.; Ma, J. A review on water balance in the membrane electrode assembly of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2009, 34, 9461–9478. [Google Scholar] [CrossRef]

- Baschu, J.J.; Li, X. Carbon monoxide poisoning of proton exchange membrane fuel cells. Int. J. Energy Res. 2001, 25, 695–713. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, Z.; Glass, N.; Zhang, L.; Zhang, J.; Song, D.; Liu, Z.-S.; Wang, H.; Shen, J. A review of PEM hydrogen fuel cell contamination: Impacts, mechanisms, and mitigation. J. Power Sources 2007, 165, 739–756. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, Z.; Zhang, J.; Tang, Y.; Song, C.; Navessin, T.; Shi, Z.; Song, D.; Wang, H.; Wilkinson, D.P.; et al. High temperature PEM fuel cells. J. Power Sources 2006, 160, 872–891. [Google Scholar] [CrossRef]

- Jensen, J.; Li, Q.; Pan, C.; Bjerrum, N.; Rudbeck, H.; Steenberg, T. Ongoing Efforts Addressing Degradation of High Temperature PEMFC; Report Nr; Forschungszentrums Jülich/Energy & Environment: Jülich, Germany, 2010. [Google Scholar]

- Huijsmans, J.; Kraaij, G.; Makkus, R.; Rietveld, G.; Sitters, E.; Reijers, H. An analysis of endurance issues for MCFC. J. Power Sources 2000, 86, 117–121. [Google Scholar] [CrossRef]

- Kulkarni, A.; Giddey, S. Materials issues and recent developments in molten carbonate fuel cells. J. Solid State Electrochem. 2012, 16, 3123–3146. [Google Scholar] [CrossRef]

- Payne, R.; Love, J.; Kah, M. Generating electricity at 60% electrical efficiency from 1–2 kWe SOFC products. ECS Trans. 2009, 25, 231–239. [Google Scholar] [CrossRef]

- Massardo, A.F.; Lubelli, F. Internal reforming solid oxide fuel cell-gas turbine combined cycles (IRSOFC-GT): Part A—Cell model and cycle thermodynamic analysis. J. Eng. Gas Turbines Power 2000, 122, 27–35. [Google Scholar] [CrossRef]

- Leah, R.; Bone, A.; Selcuk, A.; Corcoran, D.; Lankin, M.; Dehaney-Steven, Z.; Selby, M.; Whalen, P. Development of highly robust, volume-manufacturable metal-supported SOFCs for operation below 600 °C. ECS Trans. 2011, 35, 351–367. [Google Scholar] [CrossRef]

- Pellegrino, S.; Lanzini, A.; Leone, P. Techno-Economic and policy requirements for the market-entry of the fuel cell micro-CHP system in the residential sector. Appl. Energy 2015, 143, 370–392. [Google Scholar] [CrossRef]

- Morgan, S. Denmark and Norway Team up to Build World’s Largest Hydrogen Ferry. 7 December 2020. Available online: https://www.euractiv.com/section/shipping/news/denmark-and-norway-team-up-to-build-worlds-largest-hydrogen-ferry/ (accessed on 5 January 2021).

- FuelCellWorks. Ammonia Fuel Cells for Deep-Sea Shipping—A Key Piece in the Zero-Emission Puzzle. 29 December 2020. Available online: https://fuelcellsworks.com/news/ammonia-fuel-cells-for-deep-sea-shipping-a-key-piece-in-the-zero-emission-puzzle/ (accessed on 6 January 2021).

- ShipFC. ShipFC project on first maritime fuel cell to run on green ammonia. Fuel Cells Bull. 2020, 2020, 5–6. [Google Scholar]

- Lloyd’s Register; UMAS. Zero-Emission Vessels 2030. How Do We Get There? Lloyd’s Register: London, UK; UMAS: London, UK, 2018. [Google Scholar]

- Newman, N. Hybrid Ships Take to the High Seas. 17 January 2017. Available online: https://eandt.theiet.org/content/articles/2019/01/hybrid-ships-take-to-the-high-seas/ (accessed on 6 January 2021).

- DNV GL. Handbook for Maritime and Offshore Battery Systems, Guidance Paper; DNV GL: Høvik, Norway, 2016. [Google Scholar]

- Bloomberg New Energy Finance. Lithium-Ion Battery Costs and Market: Squeezed Margins Seek Technology Improvements and New Business Models. 5 July 2017. Available online: https://data.bloomberglp.com/bnef/sites/14/2017/07/BNEF-Lithium-ion-battery-costs-and-market.pdf (accessed on 3 February 2021).

- Bloomberg New Energy Finance. Battery Pack Prices Cited Below $100/kWh for the First Time in 2020, While Market Average Sits at $137/kWh. 16 December 2020. Available online: https://about.bnef.com/blog/battery-pack-prices-cited-below-100-kwh-for-the-first-time-in-2020-while-market-average-sits-at-137-kwh/ (accessed on 3 February 2021).

- Lloyd’s Register; UMAS. Zero-Emission Vessels: Transition Pathways; Lloyd’s Register: London, UK, 2019. [Google Scholar]

- Marine Insight. ZeroCat 120—World’s First Electric Ferry Receives Ship of The Year 2014 Award. 16 January 2017. Available online: https://www.marineinsight.com/shipping-news/zerocat-120-worlds-first-electric-ferry-receives-ship-of-the-year-award/ (accessed on 3 February 2021).

- Passenger Ship Technology. Commuter Craft Prototype Creates No Emissions. 2012. Available online: https://www.stirlingdesign.fr/presses/articles/stirling_design_lorient_passenger-ship-technology_10_2012.pdf (accessed on 5 February 2021).

- World Nuclear Association. Nuclear-Powered Ships. November 2020. Available online: https://www.world-nuclear.org/information-library/non-power-nuclear-applications/transport/nuclear-powered-ships.aspx (accessed on 5 February 2021).

- Vergara, J.A.; McKesson, C.B. Nuclear Propulsion in High-Performance Cargo Vessels. Mar. Technol. 2002, 39, 1–11. [Google Scholar]

- IMO. Resolution A.491 (XII), Code of Safety for Nuclear Merchant Ships; International Maritime Organisation: London, UK, 1981. [Google Scholar]

- World Nuclear Association. Hydrogen Production and Uses. November 2020. Available online: https://www.world-nuclear.org/information-library/energy-and-the-environment/hydrogen-production-and-uses.aspx (accessed on 30 January 2021).

- Phys.org. Novel Photocatalyst Effectively Turns Carbon Dioxide into Methane Fuel with Light. 2 February 2021. Available online: https://phys.org/news/2021-02-photocatalyst-effectively-carbon-dioxide-methane.html (accessed on 6 February 2021).

- Exxon Mobil. Searching the Globe for Global Solutions: CCS. 13 August 2020. Available online: https://energyfactor.exxonmobil.eu/science-technology/co2-capture/?gclid=CjwKCAiAsaOBBhA4EiwAo0_AnGo3Nq0ej8p-s6bgrcmlsLLF3fZ-tOfXdqbeRw_37GeYCHz6JNdHQxoC4UgQAvD_BwE (accessed on 20 February 2021).

- Lee, C.-Y.; Lee, H.L.; Zhang, J. The impact of slow ocean steaming on delivery reliability and fuel consumption. Transp. Res. Part E 2015, 76, 176–190. [Google Scholar] [CrossRef]

- Maloni, M.; Paul, J.A.; Gligor, D.M. Slow steaming impacts on ocean carriers and shippers. Marit. Econ. Logist. 2013, 15, 151–171. [Google Scholar] [CrossRef] [Green Version]

- Eide, M.S.; Endresen, Ø.; Skjong, R.; Longva, T.; Alvik, S. Cost-Effectiveness assessment of CO2 reducing measures in shipping. Marit. Policy Manag. 2009, 36, 367–384. [Google Scholar] [CrossRef]

- Rosenthal, E. Cargo skippers cry, “slow speed ahead”. Int. Her. Trib. 2010, 1, 4. [Google Scholar]

- Faber, J.; Nelissen, D.; Hon, G.; Wang, H.; Tsimplis, M. Regulated Slow Steaming in Maritime Transport: An Assessment of Options, Costs and Benefits; CE Delft: Delft, The Netherlands, 2012; pp. 1–117. [Google Scholar]

- IMO. Reduction of GHG Emissions from Ships, Marginal Abatement Costs and Cost Effectiveness of Energy-Efficiency Measures; Institute of Marine Engineering, Science and Technology (IMarEST); IMO: London, UK, 2011. [Google Scholar]

- Yfantis, E.; Pariotis, E.; Zannis, T.; Katsanis, J.; Roumeliotis, I. CO2 Emissions from ships: Reduction methods and technologies. In Proceedings of the International Conference “Energy in Transportation 2016”, Athens, Greece, 12 November 2016. [Google Scholar]

- Willsher, J. The Effect of Biocide Free Foul Release Systems on Vessel Performance; International Paint Ltd.: London, UK, 2008. [Google Scholar]

- Fernandes, J.A.; Santos, L.; Vance, T.; Fileman, T.; Smith, D.; Bishop, J.D.; Viard, F.; Queirós, A.M.; Merino, G.; Buisman, E.; et al. Costs and benefits to European shipping of ballast-water and hull-fouling treatment: Impacts of native and non-indigenous species. Mar. Policy 2016, 64, 148–155. [Google Scholar] [CrossRef] [Green Version]

- IMO. Anti-Fouling Systems; International Maritime Organisation: London, UK, 2003. [Google Scholar]

- Paik, B.-G.; Kim, K.-Y.; Cho, S.-R.; Ahn, J.-W.; Cho, S.-R. Investigation on drag performance of anti-fouling painted flat plates in a cavitation tunnel. Ocean Eng. 2015, 101, 264–274. [Google Scholar] [CrossRef]

- Lu, Y.; Chang, X.; Hu, A.-K. A hydrodynamic optimization design methodology for a ship bulbous bow under multiple operating conditions. Eng. Appl. Comput. Fluid Mech. 2016, 10, 330–345. [Google Scholar] [CrossRef] [Green Version]

- Almeida, R. Part 1: How to Design a More Efficient Ship. 4 January 2012. Available online: https://gcaptain.com/part-design-efficient-ship/#:~:text=Finding%20the%20optimum%20length%20and,negative%20effect%20on%20total%20resistance (accessed on 20 February 2021).

- TheNavalArch. Bulbous Bows—History and Design. 9 May 2020. Available online: https://thenavalarch.com/bulbous-bows-history-and-design/ (accessed on 21 February 2021).

- Babicz, J. Wärtsilä Encyclopedia of Ship Technology, 2nd ed.; Wärtsilä: Helsinki, Finland, 2015. [Google Scholar]

- Fotopoulos, A.G.; Margaris, D.P. Computational analysis of air lubrication system for commercial shipping and impacts on fuel consumption. Computation 2020, 8, 38. [Google Scholar] [CrossRef]

- ABS. Air Lubrication Technology; American Bureau of Shipping: Houston, TX, USA, 2019. [Google Scholar]

- Takahashi, T.; Kakugawa, A.; Nagaya, S.; Yanagihara, T.; Kodama, Y. Mechanisms and Scale Effects of Skin Friction Reduction by Microbubbles. Available online: https://www.nmri.go.jp/oldpages/turbulence/PDF/symposium/FY2000/Takahashi.pdf (accessed on 30 March 2021).

- Kawabuchi, M.; Kawakita, C.; Mizokami, S.; Higasa, S.; Kodan, Y.; Takano, S. CFD predictions of bubbly flow around an energy-saving ship with Mitsubishi air lubrication system. Mitsubishi Heavy Ind. Tech. Rev. 2011, 48, 2011. [Google Scholar]

- Hao, W.U.; Yongpeng, O.; Qing, Y.E. Experimental study of air layer drag reduction on a flat plate and bottom hull of a ship with cavity. Ocean Eng. 2019, 183, 236–248. [Google Scholar] [CrossRef]

- Ceccio, S.L. Friction drag reduction of external flows with bubble and gas injection. Annu. Rev. Fluid Mech. 2010, 42, 183–203. [Google Scholar] [CrossRef] [Green Version]

- Elbing, B.; Mäkiharju, S.; Wiggins, A.; Perlin, M.; Dowling, D.; Ceccio, S. On the scaling of air layer drag reduction. J. Fluid Mech. 2013, 717, 484–513. [Google Scholar] [CrossRef]

- Mäkiharju, S.A.; Perlin, M.; Ceccio, S.L. On the energy economics of air lubrication drag reduction. Int. J. Nav. Archit. Ocean. Eng. 2012, 4, 412–422. [Google Scholar] [CrossRef] [Green Version]

- Senary, K.; Tawfik, A.; Hegazy, E.; Ali, A. Development of a waste heat recovery system onboard LNG carrier to meet IMO regulations. Alex. Eng. J. 2016, 55, 1951–1960. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.; Zhang, K.; Deng, K. A review of waste heat recovery from the marine engine with highly efficient bottoming power cycles. Renew. Sustain. Energy Rev. 2020, 120, 1–17. [Google Scholar] [CrossRef]

- Singh, D.V.; Pedersen, E. A review of waste heat recovery technologies for maritime applications. Energy Convers. Manag. 2016, 111, 315–328. [Google Scholar] [CrossRef]

- MAN Diesel and Turbo. Thermo Efficiency System for Reduction of Fuel Consumption and CO2; MAN Diesel and Turbo: Copenhagen, Denmark, 2014. [Google Scholar]

- Wärtsilä. Boosting Energy Efficiency, Energy Efficiency Catalogue; Wärtsilä: Helsinki, Finland, 2008. [Google Scholar]

- Siemens. SISHIPCIS Boost Hybrid Propulsion with Waste Heat Recovery, Product Sheet: Completely Integrated Solutions for Cargo Vessels; Siemens: Munich, Germany, 2009. [Google Scholar]

- Baldi, F.; Gabrielii, C. A feasibility analysis of waste heat recovery systems for marine applications. Energy 2015, 80, 654–665. [Google Scholar] [CrossRef] [Green Version]

- Sprouse, C.I.; Depcik, C. Review of organic Rankine cycles for internal combustion engine exhaust waste heat recovery. Appl. Therm. Eng. 2013, 51, 711–722. [Google Scholar] [CrossRef]

- Shu, G.; Liang, Y.; Wei, H.; Tian, H.; Zhao, J.; Liu, L. A review of waste heat recovery on two-stroke IC engine aboard ships. Renew. Sustain. Energy Rev. 2013, 19, 385–405. [Google Scholar] [CrossRef]

- Mondejar, M.E.; Andreasen, J.; Pierobon, L.; Larsen, U.; Thern, M.; Haglind, F. A review of the use of organic Rankine cycle power systems for maritime applications. Renew. Sustain. Energy Rev. 2018, 91, 126–151. [Google Scholar] [CrossRef]

- Larsen, U.; Sigthorsson, O.; Haglind, F. A comparison of advanced heat recovery power cycles in a combined cycle for large ships. Energy 2014, 74, 260–268. [Google Scholar] [CrossRef] [Green Version]

- Theotokatos, G.; Livanos, G. Techno-Economical analysis of single pressure exhaust gas waste heat recovery systems in marine propulsion plants. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ 2013, 227, 83–97. [Google Scholar] [CrossRef]

- Livanos, G.A.; Theotokatos, G.; Pagonis, D.-N. Techno-Economic investigation of alternative propulsion plants for ferries and RoRo ships. Energy Convers. Manag. 2014, 79, 640–651. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Yang, D.; Guo, Q. Conceptual design and performance analysis of an exhaust gas waste heat recovery system for a 10000TEU container ship. Pol. Marit. Res. 2012, 19, 31–38. [Google Scholar] [CrossRef] [Green Version]

- A.P. Moller-Maersk. 2018 Sustainability Report; A.P. Moller-Maersk: Copenhagen, Denmark, 2018. [Google Scholar]

| Measures | Possible CO2 Emissions Reductions |

|---|---|

| Advanced biofuels | 25–100% |

| Liquefied Natural Gas (LNG) | 0–20% |

| Hydrogen | 0–100% |

| Ammonia | 0–100% |

| Fuel cells | 2–20% |

| Electricity | 0–100% |

| Wind | 1–32% |

| Solar | 0–12% |

| Nuclear | 0–100% |

| Advantages | Disadvantages |

|---|---|

| No sulfur in its molecular formula, hence no SOx emissions | Slip methane (un-combusted methane leak) enhances GHG gains compared to traditional fuels such as MGO and HFO [74,75] |

| Lower CO2 emissions because of C:H ratio (25% less compared to diesel or bunker fuel), so can help the industry to decarbonize as a transitional fuel [74] | Still an emitter of CO2, hence cannot achieve decarbonization and need to take into account embodied CO2 (well-to-tank analysis) |

| Compared to its gaseous state, takes up 600 times less space for storage and transportation [66] | But special care is required for transportation and storage |

| Compared to hydrogen and ammonia storage, lower implications in terms of toxicity and safety | Safety issues (explosion hazard or cold fracture of hull due to low temperatures) |

| Low NOx emissions if low-pressure dual fuel engine is used [74] | High NOx emissions if high-pressure dual fuel engine is used [74]. Depending on engine conditions, CO and unburnt hydrocarbons may increase [76]. |

| Unit | Ammonia | Hydrogen | |

|---|---|---|---|

| Lower heating value | MJ/kg | 18.8 | 120.0 |

| Flammability limits, gas in air | Vol. % | 15–28 | 4.7–75 |

| Laminar flame speed | m/s | 0.015 | 3.51 |

| Autoignition temperature | °C | 651 | 571 |

| Absolute min. ignition energy | mJ | 8.0 | 0.018 |

| Octane rating, RON | - | >130 | >100 |

| Density, 25 °C, 1 atm | g/L | 0.703 | 0.082 |

| Fuel Cell Type | Project/Vessel Name | Fuel | Capacity |

|---|---|---|---|

| AFC | Hydra | Metal hybride | 6.9 kW |

| Hydrocell Oy | Metal hybride | 30 kW | |

| LT-PEMFC | Elding | H2 | 10 kW |

| ZemShip Alsterwasser | H2 | 96 kW | |

| Nemo H2 | H2 | 60 kW | |

| Hornblower Hybrid | H2 | 32 kW | |

| Hydrogenesis | H2 | 12 kW | |

| SF-BREEZE | H2 | 120 kW | |

| Cobalt 233 Zet | H2 | 50 kW | |

| US SSFC | Diesel * | 500 kW | |

| HT-PEMFC | Pa-X-ell MS Mariella | Methanol | 2 × 30 kW |

| RiverCell | Methanol | 250 kW | |

| MF Vågen | H2 | 12 kW | |

| RiverCell ELEKTRA | H2 | 3 × 100 kW | |

| MCFC | MC WAP | Diesel * | 150/500 kW |

| FelloSHIP Viking Lady | LNG * | 320 kW | |

| US SSFC | Diesel * | 625 kW | |

| SOFC | METHAPU Undine | Methanol | 20 kW |

| SchIBZMS Forester | Diesel * | 100 kW | |

| FELICITAS subproject 2 | LNG * | 250 kW |

| Fuel Cell Type | Operating Temperature (°C) | Fuel | Internal Reforming | Power Capacity | Drawbacks |

|---|---|---|---|---|---|

| AFC | 60–200 | H2 | No | ≤500 kW | CO2 poisoning |

| LT-PEMFC | 65–85 | H2 | No | ≤120 kW | CO + S poisoning |

| HT-PEMFC | 140–220 | H2 | No | ≤500 kW | CO + S poisoning |

| PAFC | 140–200 | H2, LNG and methanol | No | 120–400 kW | CO + S poisoning |

| DMFC | 75–120 | methanol | No | ≤5 kW | Methanol crossover |

| MCFC | 650–700 | H2, CO | Yes | 120 kW–10 MW | S poisoning, cycling effects, long start-up time |

| SOFC | 500–1000 | H2, CO | Yes | ≤10 MW | S poisoning, cycling effects, mechanically fragile, long start-up time |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mallouppas, G.; Yfantis, E.A. Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. J. Mar. Sci. Eng. 2021, 9, 415. https://doi.org/10.3390/jmse9040415

Mallouppas G, Yfantis EA. Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. Journal of Marine Science and Engineering. 2021; 9(4):415. https://doi.org/10.3390/jmse9040415

Chicago/Turabian StyleMallouppas, George, and Elias Ar. Yfantis. 2021. "Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals" Journal of Marine Science and Engineering 9, no. 4: 415. https://doi.org/10.3390/jmse9040415

APA StyleMallouppas, G., & Yfantis, E. A. (2021). Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. Journal of Marine Science and Engineering, 9(4), 415. https://doi.org/10.3390/jmse9040415