Static Characteristics and Leakage Rates of Smooth Annular Seals Based on a New Solution Method for Gas-Liquid Two-Phase Conditions

Abstract

:1. Introduction

2. Model and Numerical Method

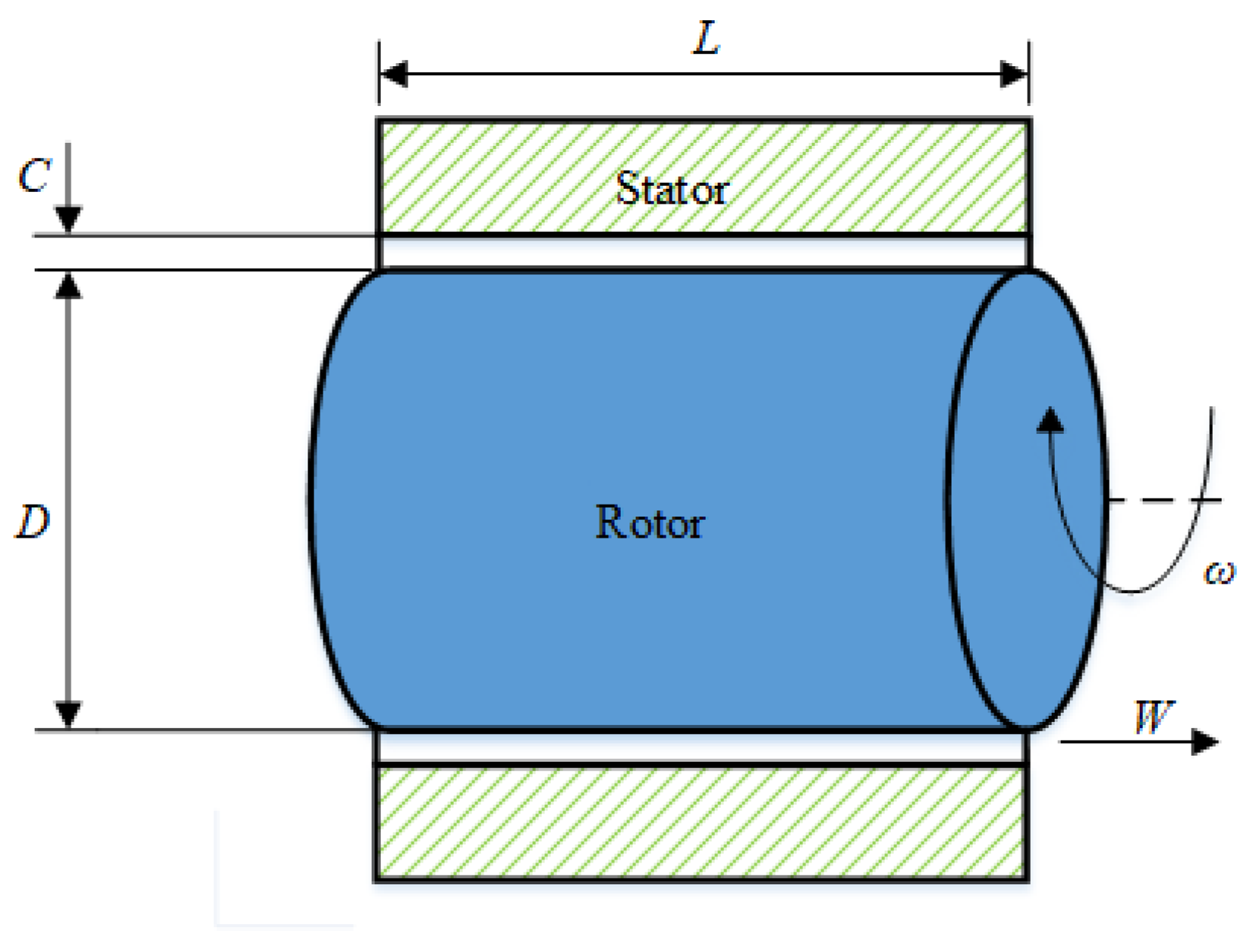

2.1. Geometric Model and Basic Equations Based on the Bulk-Flow Model

2.2. Mixture Properties

2.3. Rayleigh–Plesset Equation

2.4. Static Characteristics and Leakage Solution

- (a)

- At the inlet of the annular seal (z = 0), the gas volume fraction, supply pressure, and bubble radius are given according to the initial boundary conditions, i.e.,

- (b)

- At the outlet of the annular seal (z = L), the fluid pressure equals to the given outlet pressure, i.e.,

- (c)

- Due to the inertial effect of the fluid, there will be a sudden pressure drop at the seal inlet, and the inlet pressure is a function of axial flow velocity and the empirical entrance loss coefficient ξ [11]:

3. Results and Discussion

3.1. Numerical Method Validation

3.2. Effects of Operating Conditions on the Leakage Flow Rate

3.3. Effects of Bubble Radius on the Leakage Flow Rate

3.4. Effects of Seal Clearance on the Leakage Flow Rate

4. Conclusions

- (a)

- Seal leakage decreased with the increasing inlet GVF but increased with the pressure difference. Both the mixture density and viscosity decreased with the increasing inlet GVF and pressure difference.

- (b)

- Axial pressure drop was large around the seal outlet, which led to a rather large GVF expansion. With the same inlet GVF, the outlet GVF will increase intensely under a larger pressure difference.

- (c)

- Bubble radius had little effect on the leakage rates, GVF distribution, pressure characteristics, mixture density, and viscosity, while the leakage decreased slightly with the increase of the bubble radius.

- (d)

- Leakage rates of the model seals with bigger clearance are more sensitive to the inlet GVF changes. The smaller the seal clearance is, the more dramatically the density and viscosity around the seal exit decrease.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | dimensionless coefficient defined in Equation (21) |

| C | nominal seal radial clearance (m) |

| D | seal diameter (m) |

| f | friction factor |

| fr | friction factor relative to the rotor |

| fs | friction factor relative to the stator |

| H | seal radial clearance (m) |

| k | heat process factor |

| L | seal length (m) |

| n, m | coefficients for friction factors |

| P | fluid pressure (pa) |

| ΔP | pressure difference (pa) |

| PB | pressure inside the bubble (pa) |

| Pe | exit pressure (pa) |

| PG | pressure provided by the gas part of the bubble (pa) |

| PS | supply pressure (pa) |

| PV | vapor pressure (pa) |

| Q | seal leakage (kg/s) |

| R | seal radius (m) |

| RB | bubble radius (m) |

| RG | gas constant |

| R0 | bubble radius at the inlet (m) |

| S | surface tension (N) |

| t | time (s) |

| T | supply temperature (℃) |

| U | circumferential velocity (m/s) |

| W | axial velocity (m/s) |

| um | mean flow velocity relative to the wall (m/s) |

| Z | dimensionless axial seal position |

| ZC | gas compressibility factor |

| Greek symbols | |

| α | gas volume fraction |

| α0 | inlet gas volume fraction |

| θ | circumferential angle (rad) |

| μ | fluid viscosity (N.s/m2) |

| μG, μL | gas and liquid viscosity (N.s/m2) |

| μe | liquid equivalent viscosity (N.s/m2) |

| νe | liquid equivalent kinematic viscosity (m2/s) |

| ξ | inlet pressure loss coefficient |

| ρ | fluid density (kg/m3) |

| ρG, ρL | gas and liquid density (kg/m3) |

| σ | dimensionless coefficient defined in Equation (20) |

| τ | wall shear stress (pa) |

| τx, τz | circumferential and axial wall shear stresses (pa) |

| ω | rotor speed (rad/s) |

| ωn | bubble natural frequency |

References

- Black, H.F. Effects of Hydraulic Forces in Annular Pressure Seals on the Vibrations of Centrifugal Pump Rotors. J. Mech. Eng. Sci. 1969, 11, 206–213. [Google Scholar] [CrossRef]

- Black, H.F.; Jessen, D.N. Dynamics hybrid properties of annular pressure seals. Proc. J. Mech. Eng. 1970, 184, 92–100. [Google Scholar]

- Black, H.F.; Jessen, D.N. Effects of high-pressure ring seals on pump rotor vibrations. ASME Pap. 1971, 71, 38–46. [Google Scholar]

- Black, H.F. Calculation of Forced Whirling and Stability of Centrifugal Pump Rotor Systems. J. Eng. Ind. 1974, 96, 1076–1081. [Google Scholar] [CrossRef]

- Allaire, P.E.; Lee, C.C.; Gunter, E.J. Dynamics of Short Eccentric Plain Seals with High Axial Reynolds Number. J. Spacecr. Rocket. 1979, 15, 341–347. [Google Scholar] [CrossRef]

- Hirs, G.G. Fundamentals of a Bulk-Flow Theory for Turbulent Lubricant Films. Ph.D. Thesis, University of Technology Delft, Delft, The Netherlands, 1970. [Google Scholar]

- Hirs, G.G. A Bulk-Flow Theory for Turbulence in Lubricant Films. J. Lubr. Technol. 1973, 95, 137–145. [Google Scholar] [CrossRef]

- Blasius, H. Das Aehnlichkeitsgesetz bei Reibungsvorgängen in Flüssigkeiten. Mitt. Forsch. Geb. Ing. 1913, 131, 1–41. [Google Scholar] [CrossRef] [Green Version]

- Davies, S.J.; White, C.M. An experimental study of the flow of water in pipes of rectangular section. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1928, 119, 92–107. [Google Scholar] [CrossRef] [Green Version]

- Couette, M.M. Etudes sur le frottement des liquides. Ann. Chem. Phys. 1890, 21, 256–264. [Google Scholar]

- Childs, D.W. Dynamic Analysis of Turbulent Annular Seals Based on Hirs’ Lubrication Equation. J. Lubr. Technol. 1983, 105, 429–436. [Google Scholar] [CrossRef]

- Childs, D.W. Finite-Length Solutions for Rotordynamic Coefficients of Turbulent Annular Seals. J. Lubr. Technol. 1983, 105, 437–444. [Google Scholar] [CrossRef]

- Childs, D.W. Rotordynamic moment coefficients for finite length turbulent seals. Energ. Elettr. 1982, 48, 371–378. [Google Scholar]

- Nelson, C.C. Rotordynamic Coefficients for Compressible Flow in Tapered Annular Seals. J. Tribol. 1985, 107, 318–325. [Google Scholar] [CrossRef]

- Nelson, C.C.; Nguyen, D.T. Comparison of Hirs’ Equation with Moody’s Equation for Determining Rotordynamic Coefficients of Annular Pressure Seals. J. Tribol. 1987, 109, 144–148. [Google Scholar] [CrossRef] [Green Version]

- Beatty, P.A.; Hughes, W.F. Turbulent Two-Phase Flow in Annular Seals. ASLE Trans. 1987, 30, 11–18. [Google Scholar] [CrossRef]

- Arauz, G.L.; Andrés, L.S. Analysis of Two-Phase Flow in Cryogenic Damper Seals—Part I: Theoretical Model. J. Tribol. 1998, 120, 221–227. [Google Scholar] [CrossRef]

- Arauz, G.L.; Andrés, L.S. Analysis of Two-Phase Flow in Cryogenic Damper Seals—Part II: Model Validation and Predictions. J. Tribol. 1998, 120, 228–233. [Google Scholar] [CrossRef]

- Hendricks, R.C. Straight Cylindrical Seal for High-Performance Turbomachines; NASA TP-1850; NASA: Cleveland, OH, USA, 1987.

- Iwatsubo, T.; Nishino, T. An experimental study on the static and dynamic characteristics of pump annular seals. In Proceedings of the 7th Work-Shop on Rotordynamic Instability Problems in High Performance Turbomachinery, College Station, TX, USA, 10–12 May 1993. [Google Scholar]

- Arghir, M.; Zerarka, A.G. Pineau, Rotordynamic analysis of textured annular seals with multiphase (bubbly) flow. INCAS Bull. 2011, 3, 3–13. [Google Scholar]

- Diaz, S.E. The Effect of Air Entrapment on the Performance of Squeeze Film Dampers: Experiments and Analysis. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 1999. [Google Scholar]

- Alehossein, H.; Qin, Z. Numerical analysis of Rayleigh–Plesset equation for cavitating water jets. Int. J. Numer. Methods Eng. 2007, 72, 780–807. [Google Scholar] [CrossRef]

- Andrés, L.S. Rotordynamic Force Coefficients of Bubbly Mixture Annular Pressure Seals. J. Eng. Gas Turbines Power 2012, 134, 022503. [Google Scholar] [CrossRef]

- Ma, X.; Meng, X.; Wang, Y.; Peng, X. Suction effect of cavitation in the reverse-spiral-grooved mechanical face seals. Tribol. Int. 2019, 132, 142–153. [Google Scholar] [CrossRef]

- Andrés, L.S.; Lu, X.; Liu, Q. Measurements of Flow Rate and Force Coefficients in a Short-Length Annular Seal Supplied with a Liquid/Gas Mixture (Stationary Journal). Tribol. Trans. 2016, 59, 758–767. [Google Scholar] [CrossRef]

- Andrés, L.S.; Lu, X. Leakage, Drag Power, and Rotordynamic Force Coefficients of an Air in Oil (Wet) Annular Seal. J. Eng. Gas Turbines Power 2018, 140, 012505. [Google Scholar] [CrossRef]

- Zhang, M.; Childs, D.W.; Shrestha, H. Experimental study of the leakage and rotordynamic coefficients of a long-smooth seal with two-phase, mainly oil mixtures. ASME J. Tribol. 2019, 141, 042201. [Google Scholar] [CrossRef]

- Awad, M.; Muzychka, Y. Effective property models for homogeneous two-phase flows. Exp. Therm. Fluid Sci. 2008, 33, 106–113. [Google Scholar] [CrossRef]

- Fourar, M.; Bories, S. Experimental study of air-water two-phase flow through a fracture (narrow channel). Int. J. Multiph. Flow 1995, 21, 621–637. [Google Scholar] [CrossRef]

- Brennen, C.E. Cavitation and Bubble Dynamics; Oxford Engineering Series; Oxford University Press: New York, NY, USA, 2013; Volume 44. [Google Scholar]

- Qin, Z. Investigation of the Cavitation Mechanism and Erosion of Submerged High Pressure Water Jets. Ph.D. Thesis, The University of Queensland, Queensland, Australia, 2004. [Google Scholar]

- Wang, Y.-C.; Chen, E. Effects of phase relative motion on critical bubbly flows through a converging–diverging nozzle. Phys. Fluids 2002, 14, 3215–3223. [Google Scholar] [CrossRef]

- Andrés, L.S.; Yang, J.; Lu, X. On the Leakage, Torque, and Dynamic Force Coefficients of Air in Oil (Wet) Annular Seal: A Computational Fluid Dynamics Analysis Anchored to Test Data. J. Eng. Gas Turbines Power 2018, 141, 021008. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Diameter, D | 0.089306 m |

| Length, L/D | 0.65 |

| Clearance, C | 0.188 mm |

| Inlet loss, ξ | 0.25 |

| Supply temperature, T | 39.4 °C |

| Pressure difference, ΔP | 3137.9 bars |

| Exit pressure, Pe | 6.9 bars |

| Rotor speed, ω | 10 krpm |

| Bubble radius, R0 | 10 μm |

| Liquid component | PSF-5cSt |

| Gas component | air |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, C.; Zhai, L.; Guo, J.; Cui, B.; Chen, G. Static Characteristics and Leakage Rates of Smooth Annular Seals Based on a New Solution Method for Gas-Liquid Two-Phase Conditions. J. Mar. Sci. Eng. 2021, 9, 523. https://doi.org/10.3390/jmse9050523

Zhong C, Zhai L, Guo J, Cui B, Chen G. Static Characteristics and Leakage Rates of Smooth Annular Seals Based on a New Solution Method for Gas-Liquid Two-Phase Conditions. Journal of Marine Science and Engineering. 2021; 9(5):523. https://doi.org/10.3390/jmse9050523

Chicago/Turabian StyleZhong, Chao, Lulu Zhai, Jia Guo, Baoling Cui, and Guoyou Chen. 2021. "Static Characteristics and Leakage Rates of Smooth Annular Seals Based on a New Solution Method for Gas-Liquid Two-Phase Conditions" Journal of Marine Science and Engineering 9, no. 5: 523. https://doi.org/10.3390/jmse9050523