1. Introduction

It is important for ship engines to reduce emissions of environmental pollutants, while maintaining performance, efficiency, and stability. The International Maritime Organization (IMO) has implemented regulations to reduce emissions of air pollutants such as CO

2, SOx, and NOx from ships. The energy efficiency design index (EEDI) related to CO

2 emissions requires a minimum energy efficiency level per capacity mile (e.g., tonne mile) for different ship type and size segments. Since the level is to be tightened incrementally every five years, and so the EEDI demands continuous innovation and technical development of all the components influencing the fuel efficiency of a ship from its design phase [

1]. Regulations related to emissions of SOx and NOx have increased the number of ships installing environmental pollutant emissions reduction devices such as scrubbers, exhaust gas recirculation (EGR) [

2], and selective catalytic reduction (SCR) [

3]; alternatively, they use liquefied natural gas (LNG) as fuel [

4]. Since the use of LNG as fuel must be considered during the ship’s construction phase, existing ships are using low sulfur fuel oils (LSFOs) to reduce SOx emission. LSFOs are now replacing the traditional intermediate bunker fuels and heavy fuel oils with ultra-low sulfur fuel oils (ULSFO) (sulfur < 0.1% m/m) for use in the sulfur emission control area (SECA) in Europe and North America from 2015, and a global sulfur cap regulation was implemented from 2020 with very low sulfur oils (VLSFO) (sulfur < 0.5%m/m) [

5]. When the fuel is changed to LSFO, etc., the intake and exhaust gas flows will be different, and the application of an environmental pollutant emission reduction system to a ship’s compression ignition (CI) engine requires analysis of the gas flow in the intake system to predict performance. In CI engines, the gas flow in the intake and exhaust system is pulsating flow with periodic pressure vibrations [

6], and it has the characteristics of a variable wavelength depending on the shape of the manifold and pipe, resulting in pressure waves, reflective waves, overlapping waves, interference, resonance, etc. [

7]. In the intake system, these various characteristics work in combination, so it is necessary to design the shape of the intake pipe and port considering the results of the gas flow analysis.

Experimental studies and numerical analysis studies are being conducted on ways to analyze the performance characteristics of the engine and reduce emissions, and as an experimental method, studies on the fuel system are being conducted. Beatrice et al. evaluated the power density sensitivity to the engine operating parameters by conducting an experimental study on the functional requirements for the diesel engine. The advantage of using a very high fuel injection pressure was confirmed, and a compromise that combines high performance and fuel economy was proposed [

8]. Blasio et al. conducted research on the diesel engine’s CO

2 emission and fuel injection system, and analyzed the effect of the decrease in peak firing pressure on fuel economy, emissions, etc., and confirmed the advantage of using a high injection pressure [

9]. An experimental study on the fuel used in the engine was carried out by Puškár et al., who studied the effect of reducing gaseous emissions by mixing biodiesel with marine diesel engines [

10]. In order to reduce the emission of environmental pollutants as well as experimental studies, parallel numerical analysis is being conducted, and Lamas et al. characterized the pre-injection pattern suitable for Wärtsilä 6L 46, a marine diesel engine, using a computational fluid dynamics (CFD) model verified by the experimental results [

11].

Methods for predicting intake flow using a numerical analysis of intake systems in CI engines and for reducing fuel consumption or improving volume efficiency have been proposed in previous research. Battista et al. studied how to manage intake flow and temperature to reduce fuel consumption and environmental pollutants, and they confirmed the impact of low-temperature intake on internal combustion (IC) engines using EGR and others [

12]. Furthermore, studies by Pelić et al. related to the effect of the intake system of ship engines on NOx emissions and a reduction in fuel consumption found that the fuel consumption and cylinder pressure and temperature are affected by the valve timing of the intake system and pressure in the intake manifold [

13]. Gas flow analysis was also used to study the design, performance, and knocking of natural gas (NG)-fueled engines, and Xiang et al. used the commercial CFD code GT-Power to provide basic parameters and necessary numerical tools and frameworks that affect the knocking behavior of NG fuel engine operations [

14]. To predict the 1D unsteady compressible flow of engine air path systems, Stockar et al. compared two different models and presented a compromise in terms of computational time, accuracy, and stability in simulating the engine in real time [

15].

If 3D modeling and commercial CFD codes are used to simulate gas flow in the intake system, various analysis models such as chemical reactions and multiphase flow can be applied, and it is possible to model real motion using a dynamic mesh. However, the fact that high-end workstations are needed for calculation, in addition to extensive computation time, presents a problem; thus, it is not suitable to analyze gas flow by modeling the entire engine system in 3D [

16].

Among the 1D gas flow analysis methods, the method of characteristics (MOC) has a fast calculation time, and the accuracy of the calculation results in a straight pipe has been proven; however, the accuracy of the calculation results is poor in complex shapes such as bent pipes, tapered pipes, and junctions [

17]. In addition, it is difficult to visualize the gas flow because it is impossible to express calculation results such as pressure and velocity as contours, and there is a disadvantage in that there is a limitation in applying various analysis models. Therefore, a method of coupling 1D and 3D has been used to analyze the gas flow of the cylinder and the intake and exhaust systems of the CI engine.

The numerical analysis method using 1D–3D coupling can cope with changes in shape and achieve rapid calculation, allowing results to be efficiently obtained for various models. For this reason, advanced research is being conducted on numerical analysis for engines using 1D–3D coupling. Torre et al. simulated fluid dynamics using a coupled 1D–quasi-3D approach for IC engine intake and exhaust systems [

18]. An automatic quasi-3D grid generator was developed, and the fully 3D and quasi-3D OpenFOAM models were coupled with the 1D code GASDYN to simulate the entire engine system. Onorati et al. performed a 1D–3D fluid dynamic simulation for intake and exhaust systems of a turbocharged diesel engine [

19]. In addition to analyzing the flow field of the manifold, which is the main advantage of the 1D–3D simulation, it was confirmed that the predicted wave motion in the intake and exhaust system showed better results compared to the measured data. Millo et al. analyzed the gas flow inside the cylinder of a diesel engine by coupling the 1D commercial code GT-SUITE and the 3D commercial code CONVERGE CFD [

20]. A 1D–3D coupling function built in a commercial code was used, and a method of predicting the performance of a diesel engine was proposed using the results of gas flow analysis. Dimitriou et al. analyzed gas flow for the exhaust gas recirculation system by coupling the 1D commercial code GT-POWER and the 3D commercial code STAR-CCM [

21]. It was found that the 1D–3D coupling function built in the commercial code could obtain accurate results only when analyzing the gas flow for an analysis model that can be accurately calculated using only the 1D code without coupling it with the 3D code.

The above-described studies performed numerical analyses for non-ship engines, and there is a limitation in that the calculation formulas cannot be modified because a 1D–3D coupling function built in a commercial CFD code was used. If there is a limitation that the expression used for calculation cannot be modified according to the user’s request, it then cannot be used to study the physical correlation with the calculation result by analyzing the calculation process. Furthermore, because the built-in 1D–3D coupling method of commercial codes is a method of applying the calculation result of a 1D code to the boundary conditions of a 3D code, there is a functional limitation whereby coupled 1D–3D approaches are only applicable for analysis models that can be used in 1D code. Because of these functional limitations and the disadvantage of not being able to freely modify the calculation formula, the previous methods are not suitable for the simulation of the intake system of a ship CI engine tailored to the needs of various users.

In order to install additional environmental pollutant emission reduction devices in ship engines or to design CI engines to meet the needs of users who want to perform performance tuning and to calculate the kinetic energy of the exhaust gas acting on the turbine for turbocharger matching [

22], the design of the intake and exhaust pipes and ports is being revised, necessitating substantial computation time and cost to perform simulations to predict the performance of custom-designed CI engines [

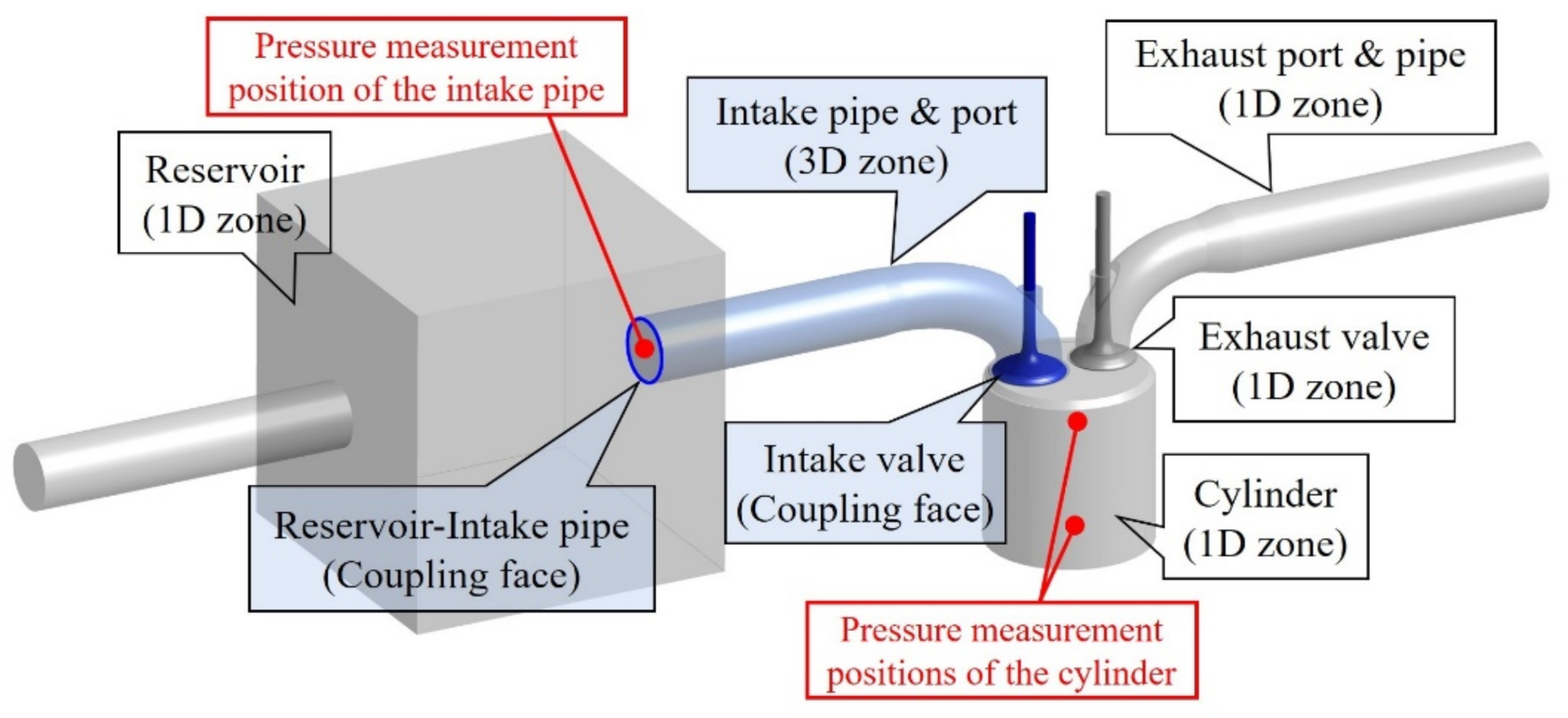

23]. The purpose of this study was to develop a 1D–3D coupling algorithm that can analyze the gas flow of a CI engine at a low cost and in a short time, as well as to propose a 1D–3D coupled gas flow analysis method for the air-intake system. In order to reduce the time required for calculation, only the part that needs to be visualized is modeled as a 3D zone. The 1D–3D coupling algorithm was written in user-defined functions (UDFs) based on the MOC, and the 1D and 3D zones were simultaneously calculated using the commercial CFD code Ansys Fluent R15.0. Compared with the experimental results, the results of the gas flow analysis were verified, and we propose a simulation method capable of actively responding to changes in various intake systems and capable of rapid calculations at low cost. We intend to use the 1D–3D coupling gas flow analysis method of the air-intake system proposed in this study to predict the flow state and performance according to the shape of the intake system in the development stage of ship CI engines. In addition, by reducing the computational time required for numerical analysis of the gas flow of the entire engine system to a level of several minutes, we intend to use it to develop a simulation model that can respond quickly to changes in the intake and exhaust systems. In the following section, we will discuss the theory used in the calculation of the 1D zone, the 1D–3D coupling method, and the verification compared with the experimental results.

4. Validation

In order to verify the results of analyzing the gas flow using the 1D–3D coupling algorithm for the air-intake system of the CI engine, the results were compared with the results measured through experiments. In order to develop an experiment with the same characteristics as the gas flow analysis conditions, the intake pipe and cylinder pressures were measured in cold flow by connecting an electric motor to the flywheel of the experimental apparatus engine, comparing the results at engine speeds of 700, 900, and 1100 RPM.

Figure 6 shows a comparison of the cylinder pressure results measured through the experiment and the cylinder pressure results of the 1D–3D coupling gas flow analysis. When the cylinder pressure increased and decreased, the results of the experiment and analysis were the same; furthermore, since the valve profile of the experimental apparatus engine was applied to the gas flow analysis, the timing of the increase and decrease in the pressure result was considered to be the same.

Table 1 presents a comparison of the analysis results based on the results of measuring the peak cylinder pressure through an experiment, whereby the peak cylinder pressure was found at the TDC (0 CA°) of the compression stroke. Compared with the experimental results, the result of gas flow analysis was considered to be valid because there was an average pressure error of 2.14%. It is expected that the results of the gas flow analysis will appear higher than the experimental results because of the difference between the theoretical calculation and the actual phenomenon, but the error is expected to decrease in the future if the exhaust system is modeled on the shape of the experimental device and calculated in a 3D zone.

Figure 7 shows a comparison of the cylinder pressure results for the process of closing the intake valve (482–598 CA°) during the gas exchange process of the cylinder. At this time, the piston moves downward to the BDC (540 CA°); however, since the intake valve is open, there is little change in the cylinder pressure. After the BDC (540 CA°), the piston moves upward, and the cylinder pressure increases. After the AVC (580 CA°), the intake valve is closed, and the cylinder pressure increases significantly. In the results of the 1D–3D coupling gas flow analysis, the phase during which the cylinder pressure increased was similar to that found experimentally.

Table 2 presents a comparison of the results of cylinder pressure at the AVC (580 CA°), which is the moment when the intake valve is closed. In a study by Tadros et al. comparing simulated data and measured data of in-cylinder pressure at three different loads, the error was found to be less than 5.7% [

30]. In this study, when comparing the cylinder pressure measured through the experiment as a standard, the pressure error occurring in the result of the 1D–3D coupling gas flow analysis was, on average, 4.08%, which can be considered a valid result.

Figure 8 shows a comparison of the result of 1D–3D coupling gas flow analysis based on the result of measuring the pressure of the intake pipe through the experiment, highlighting the pressure of the intake pipe at 342–580 CA° when the intake valve was opened. Since the intake air entered the cylinder from the time the intake valve was opened, negative pressure appeared in the intake pipe, and the time at which the maximum negative pressure appeared slowed as the engine speed increased. As for the phase of pressure change, the results of the experiment and the 1D–3D coupling gas flow analysis were similar, whereby the pressure of the intake pipe increased after the TDC (360 CA°). After the valve overlapping period, the pressure in the intake pipe increased to atmospheric pressure, and a phase in which the pressure decreased to near the BDC (540 CA°) appeared.

Table 3 presents a comparison of the maximum negative pressure results of the 1D–3D coupling gas flow analysis based on the maximum negative pressure of the intake pipe measured through the experiment. The maximum negative pressure results of the 1D–3D gas flow analysis was 0.58% on average, and the error was reduced by 1.28% compared to the average of 1.86% in the author’s previous study, which analyzed the gas flow by modeling the entire CI engine in 1D. The reason for the reduction in error compared to the results of the 1D gas flow analysis is that it is possible to calculate the influence of the reflected wave generated when the flow passes through a complex shape by calculating the intake ports that are bent or tapered in a 3D zone, thus facilitating an accurate calculation of the influence of pressure and reflected waves.

5. Conclusions

A 1D–3D coupling algorithm was developed for the air-intake system of a CI engine, and the result of analyzing gas flow through its application was verified by comparing it with an experimental study. In terms of the peak pressure of the cylinder, the magnitude and phase of the pressure were similar to the experimental results, and the pressure result of the cylinder during the intake gas exchange process was also similar to the experimental results, thereby verifying the results.

In addition, valid results were obtained by comparing the results of the 1D–3D combined gas flow analysis of the intake pipe pressure with the experimental results; moreover, using the 1D–3D coupling algorithm to analyze the gas flow, it was possible to reduce the error in magnitude and phase of the pressure that occurred in the 1D gas flow analysis. In order to accurately calculate the influence of the pressure wave and the reflected wave of the gas flow passing through the intake port, which is a complex shape, it was considered necessary to model this in a 3D zone.

In the gas flow analysis using the 1D–3D coupling algorithm, results such as the velocity and pressure of the intake port and pipe, which are 3D zones, can be expressed as contours. Therefore, they can be used to observe detailed gas flow, design the shape of the intake port, and predict the performance of the CI engine according to the shape.

Figure 9 shows the result of the velocity of gas flow passing through the intake port at the moment when the intake valve was fully open. This is a state in which gas flow enters the cylinder through the intake port. As the gas flow passed through the bend, the speed increased, whereby a faster engine speed led to greater differences in speed distribution.

Figure 10 shows the pressure result as a contour at the same moment, showing the area where the pressure increased or decreased while passing through the bend area of the intake port. In this way, it was possible to analyze the contours of the analysis results by modeling the shape of bent and tapered pipes in 3D, which would be simplified to straight pipes in a 1D gas flow analysis.

The time required to analyze the gas flow of the CI engine using the 1D–3D coupling in this study was about 20 minutes using a computer with an 8-core central processing unit (CPU) for the 700 RPM model. It is expected that this can be used as a numerical analysis method that can quickly obtain calculation results without using a high-resolution workstation.

A 1D–3D coupling algorithm was developed to analyze gas flow by modeling the cylinder and exhaust system in 1D and the intake system in 3D for CI engines, and the results were verified through comparison with an experiment, as summarized below:

- (1)

Using the MOC and a commercial CFD code, a 1D–3D coupling algorithm was developed that can analyze the gas flow of the air-intake system of a CI engine in 3D.

- (2)

The 1D–3D coupling algorithm of the intake system was able to calculate the influence of the reflected waves on bent and tapered pipes, and its validity was verified upon obtaining an error of 0.58% as a result of comparing the calculation with the pressure of the intake pipe achieved through an experiment.

- (3)

The calculation could be completed within tens of minutes using the 1D–3D coupling algorithm of the air-intake system, and it is expected to be used as a method to accurately and quickly calculate the unsteady gas flow of various ship CI engines.

If it is used in conjunction with the 1D–3D coupling gas flow analysis of exhaust systems in the future, it is expected that it can be used to analyze the effect of the environmental pollutant emissions reduction devices installed in the intakes and exhaust systems of CI engines.