2.1. Theoretical Background and Modeling

All of the flows involved in the field of engineering, from the simplest ones, such as the two-dimensional flow in pipelines or in a flat plate, to the most complex ones, such as the three-dimensional flows, occur over a certain Reynolds number, which is defined as follows:

where,

V is the velocity of the main flow,

L is the characteristic length, and

v is the kinematic viscosity. The Reynolds number is an important dimensionless quantity, as it indicates the relationship between the inertia forces and the viscous forces and characterizes the turbulence level of the flow.

The Navier–Stokes equations are a non-linear system of partial differential equations (PDE) that fully describe any flow condition and are expressed based on the principles of the conservation of mass, momentum, and energy. The analytical solution of the equations can only be achieved for very simplified systems, such as fluid flow over a flat plate. The analytical solution of the Navier–Stokes equations for more complex problems is considered impossible and, therefore, the equations are solved by numerical methods of computational fluid dynamics.

By introducing the average values of the fluid properties into the Navier–Stokes equations, a new set of equations is obtained, the so-called Reynolds-averaged Navier–Stokes (RANS) equations. Additional unknown properties appear in these equations, which are called Reynolds stresses. For these stresses, no precise mathematical relations can be derived that can calculate them. For this reason, these stresses have to be modelled appropriately. So-called turbulence models are used to model these stresses. A turbulence model is a computational procedure used to approximate the problem created by the unknown Reynolds stresses. For most engineering applications, it is not necessary to solve and model the details of the variations of the fluid properties. What fundamentally matters is the effect of the time-averaged values of the properties in the problem.

For this purpose, several turbulence models were developed to model and solve the RANS equations. This technique focuses on solving the time-averaged values of the flow properties, in which various turbulence models are solved to include the influence of the turbulence. This method calculates the effects of turbulence, rather than the turbulence itself. In essence, the turbulence effect is studied on a larger time scale than that which occurs, ignoring the variations in velocities over short periods of time, since they do not offer significant changes in the results.

The k-omega (k-ω) turbulence model [

9,

10] is one of the models most used to capture the effect of turbulent flow conditions. In addition to the conservation equations, it solves two transport equations (PDEs), which account for the history effects, such as convection and diffusion of turbulent energy. The two transported variables are turbulent kinetic energy (k), which determines the energy in turbulence, and the specific turbulent dissipation rate (ω), which determines the rate of dissipation per unit of turbulent kinetic energy. Its main advantages include its best application for near-wall treatment, as well as its superior performance for complex boundary layer flows under adverse pressure gradients and separations (e.g., external aerodynamics and turbomachinery). Furthermore, this model has also been shown to predict excessive and early separations.

The k-omega shear-stress transport (k-ω SST) turbulence model [

11,

12] combines the advantages of the two-equation k-epsilon (k-ε) and k-ω models. It utilizes the k-ω model in the inner part of the boundary layer, which results in its direct utilization up to the flow wall, below the viscous substrate. Therefore, the k-ω SST model can be used as a low-Re viscosity model without additional equations. It is also converted to a k-ε model in the free-flow region, thus avoiding the common problem of k-ω models, which are very sensitive to the turbulent properties of free flow at the inlet. In addition, it has a much better behavior in flows involving large negative pressure gradients and detachments. However, the k-ω SST model produces slightly higher turbulence levels in regions where strong horizontal forces act, such as stall points and places where there is strong flow acceleration. It is also able to account for the transport of the principal shear stress in adverse pressure gradient boundary layers [

13]. It is the most used model in the industry, given its high accuracy to expense ratio. The equations used by k-ω SST to model the turbulence are presented below:

where

represents the generation of turbulent kinetic energy due to the mean velocity gradients,

represents the effective diffusivity of

k,

represents the dissipation of

k due to turbulence, and

is a user-defined term.

where

represents the generation of

,

represents the effective diffusivity of

,

represents the dissipation of

due to turbulence,

represents the cross-diffusion term, and

is a user-defined term.

The boundary layer was first introduced by Prandtl in 1904. With this invention, Prandtl was able to link the frictionless flow with the flow of real fluids. According to Prandtl, in the case of fluids of relatively low viscosity moving over solids, the effect of internal friction is limited only to a very thin layer of fluid near to the surface of the solid, which is known as the boundary layer. Thus, the flow field can be divided into two distinct regions, the boundary layer and the region outside of it, in which the viscosity ceases to be a significant factor in the flow configuration [

14]. Referring to a two-dimensional domain (

x-

y) with a flow parallel to the

x-axis, the thin layer beside the body where the velocity (

u) gradient perpendicular to the

x-axis is greater than zero is called the boundary layer.

In the present simulation, a custom-designed wing with a high curvature airfoil—Eppler 420—including an appendant custom-designed blended winglet, was studied. The wing section that was selected to be studied resulted from a preliminary study and conceptual design of a UAV. Thus, it is a custom-designed wing that was produced by using computer-aided design (CAD) software from scratch, attempting to fulfil the flight requirements of the aircraft. The main aerodynamic characteristics of the wing are that it is based on the Eppler 420 airfoil, with a sweep angle of 25 degrees, a twist angle of 5 degrees, and a dihedral angle of 2 degrees, while the wingtip has been replaced by a custom-designed blended winglet.

A thorough perspective of the designed wing section is illustrated in

Figure 1 and

Figure 2, while the values of the aerodynamic features are presented in

Table 1. The geometric features of the winglet are presented in

Table 2.

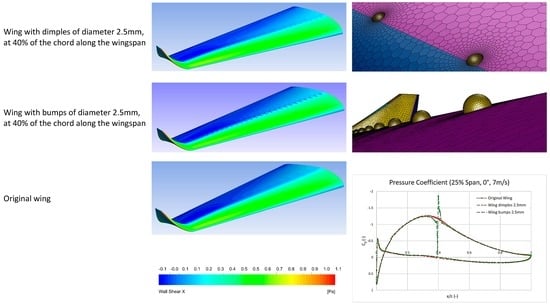

Two modified configurations of the original wing were designed afterwards. Specifically, the first configuration regarded the application of hemispherical bumps measuring 2.5 mm in diameter. These were placed along the entire length of the semi-wingspan in an imaginary straight line, joining the wing root to the wingtip, and intersecting the airfoils’ chords at 40% of their length, as illustrated in

Figure 3a. In regard to the second configuration, the construction of inward dimples was selected, again of a hemispherical shape measuring 2.5 mm in diameter. These were placed at exactly the same points that the bumps had been implemented in the first configuration, as illustrated in

Figure 3b.

The above referred configurations were exhibited in a macroscopic scale. Examining these on a more microscopic scale, the geometry of both the bumps and dimples can be observed in

Figure 4. Specifically,

Figure 4a shows the geometry of the first configuration, with 2.5 mm diameter bumps, whereas

Figure 4b shows the geometry of the second configuration, with 2.5 mm diameter dimples.

After the completion of the CAD design, this study involved the utilization of the commercial CFD ANSYS FLUENT code to execute the numerical simulations. A three-dimensional domain was created, in which the designed wing would be contained, and the RANS equations would be solved. Due to its reliability, and the reasonable time needed for the simulation’s execution, a mosaic poly-hexcore mesh was developed. This mesh configuration was based on the connection of high-quality octree hexahedra in the bulk region and isotropic poly-prisms in the boundary layer with the mosaic polyhedral elements. Three mesh-independence studies were carried out, each concerning a different configuration of the wing, and are exhibited in

Figure 5 for all three of the different wing configurations. For the original wing, 4 meshes were created with cells ranging from 1,722,541 to 5,864,829. For the wing with dimples, similarly, 4 meshes were created with cell numbers ranging from 2,164,941 to 6,612,759, while for the wing with the bumps, the corresponding meshes consisted of a cell count ranging from 2,360,756 to 7,221,884. The meshes selected for the simulations appear in

Table 3 and provide satisfactory solutions, independent of the number of cells. It should be noted that the mesh study was conducted for both velocities, 9 m/s and 27 m/s, leading to the same result concerning the suitability of the mesh selected.

The computational domain was a rectangular parallelepiped, as shown in

Figure 6, and the dimensions of the domain are expressed in units of the mean aerodynamic chord (MAC). The inlet and outward surfaces of the domain consisted of a square measuring 20 MAC × 20 MAC, while the remaining four side surfaces consisted of a parallelogram measuring 50 MAC × 20 MAC.

It should be mentioned that bodies of influence were applied around the wing and the added configurations on the suction side as well. This led the simulations to yield more accurate results, without increasing the number of domain cells to a prohibitive and unreasonable number. The final meshes exported after the independence study are exhibited in

Figure 7a–c for the original wing, the wing with dimples, and the wing with bumps, respectively. Moreover, the volumetric meshes of the wings’ configurations with dimples and bumps are exhibited in

Figure 7d,e.

Following the completion of the mesh development and the independence study, the next step was to define the numerical simulation parameters. As mentioned previously, the selected turbulence model for this case was k-ω SST. Its ability to provide better prediction of flow separation compared to most RANS models, in conjunction with its improved behavior in adverse pressure gradients, were catalytic parameters for this choice. Taking into consideration that Eppler 420 airfoil is characterized by a relatively high camber, along with the fact that it will be studied in high angles of attack up to 16°, explains its suitability as a turbulence model.

For the numerical simulations, the solver utilized in the FLUENT code was the pressure-based solver, considering a time-steady airflow, since the flow field conditions can be considered time-independent. The pseudo-transient approach was utilized to reassure the case stability and time reasonable convergence of the solution. Regarding pressure–velocity coupling, the pressure-based coupled algorithm was used to enable it in full. The second-order upwind scheme decreases the numerical discretization error; therefore, it was applied to the spatial discretization from the start of the calculations. This was mandated by the need for higher accuracy in the results, since the final comparison among the solutions was expected to yield minor deviations, and because of the mesh cell geometries. Regarding the boundary conditions, these are presented in

Table 4.

After the completion of the setup of the solver and the simulation parameters, the numerical simulations were ready for execution. In total, 30 simulations were performed and gathered and are presented in

Table 5.