A Novel Method for Notable Reducing Phase Transition Temperature of VO2 Films for Smart Energy Efficient Windows

Abstract

1. Introduction

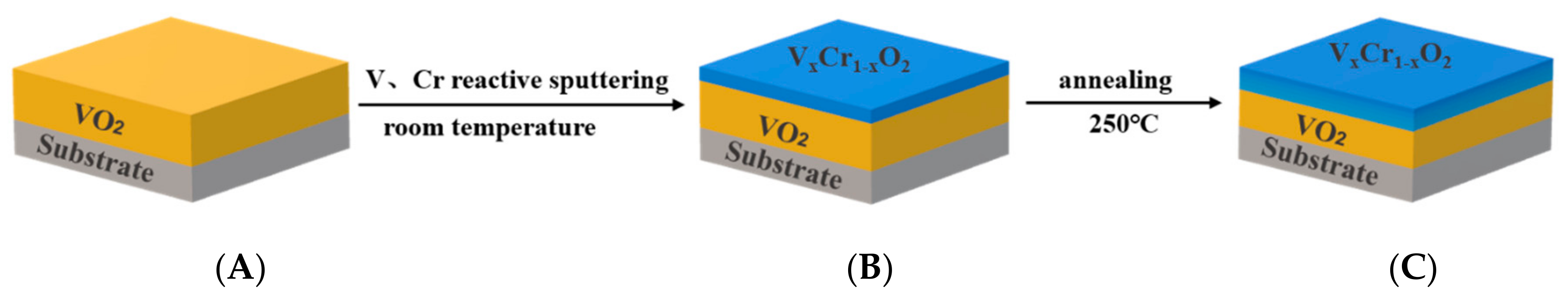

2. Experimental Details

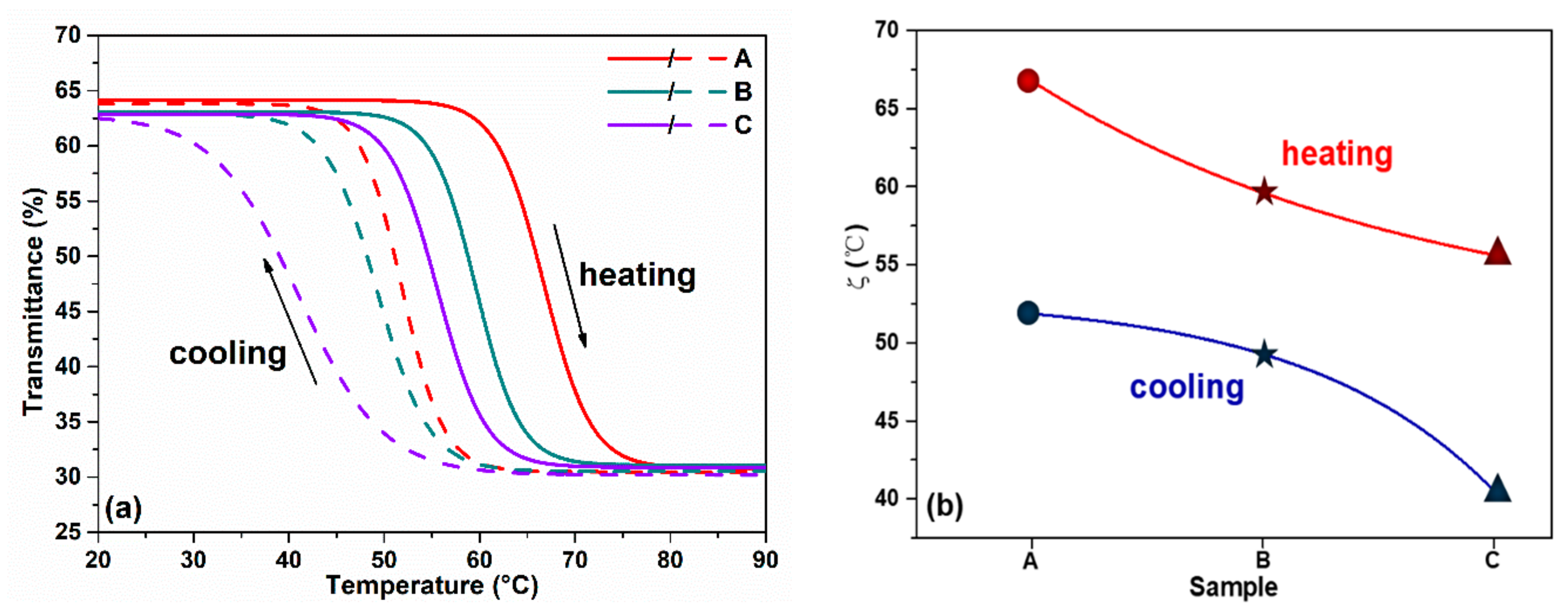

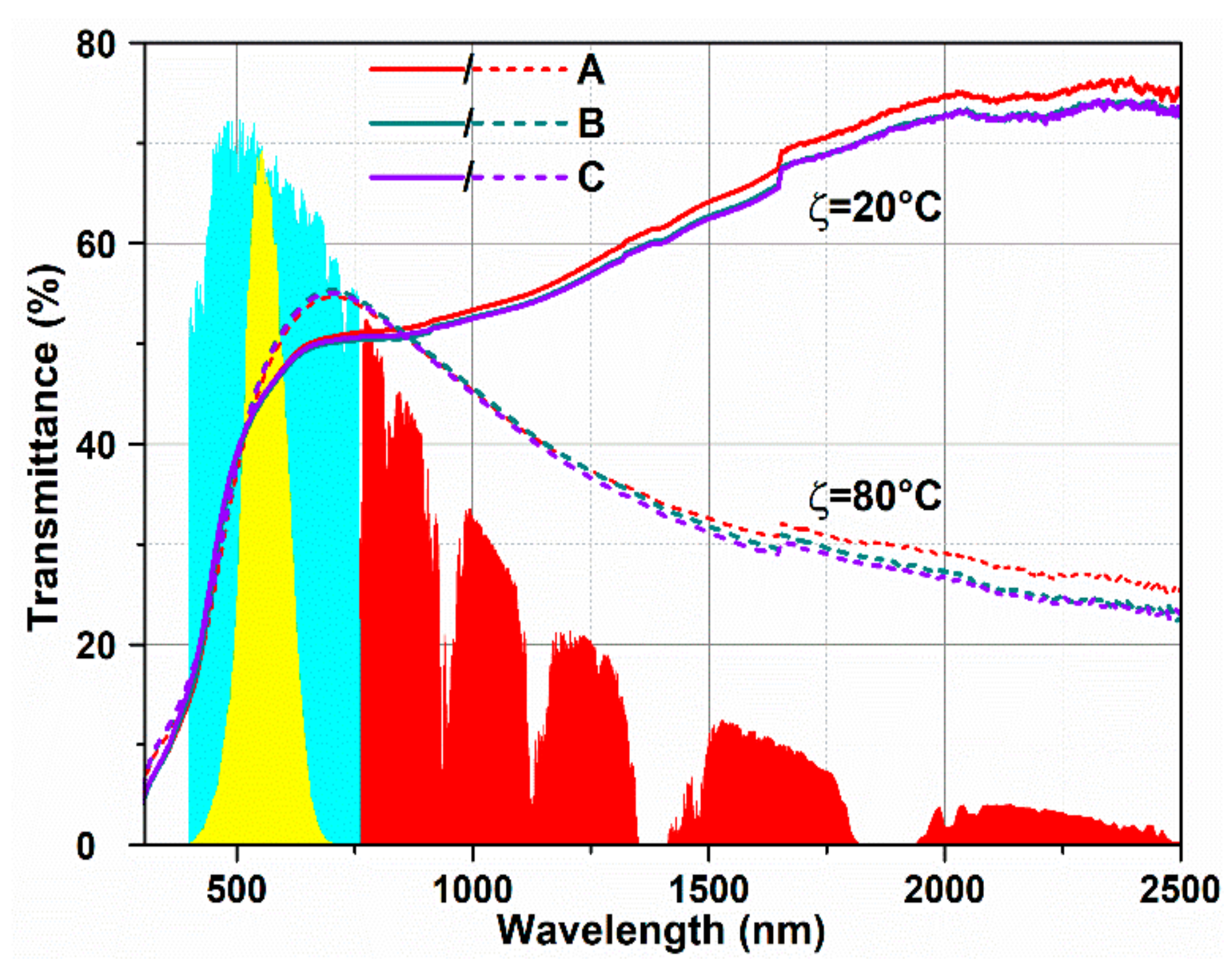

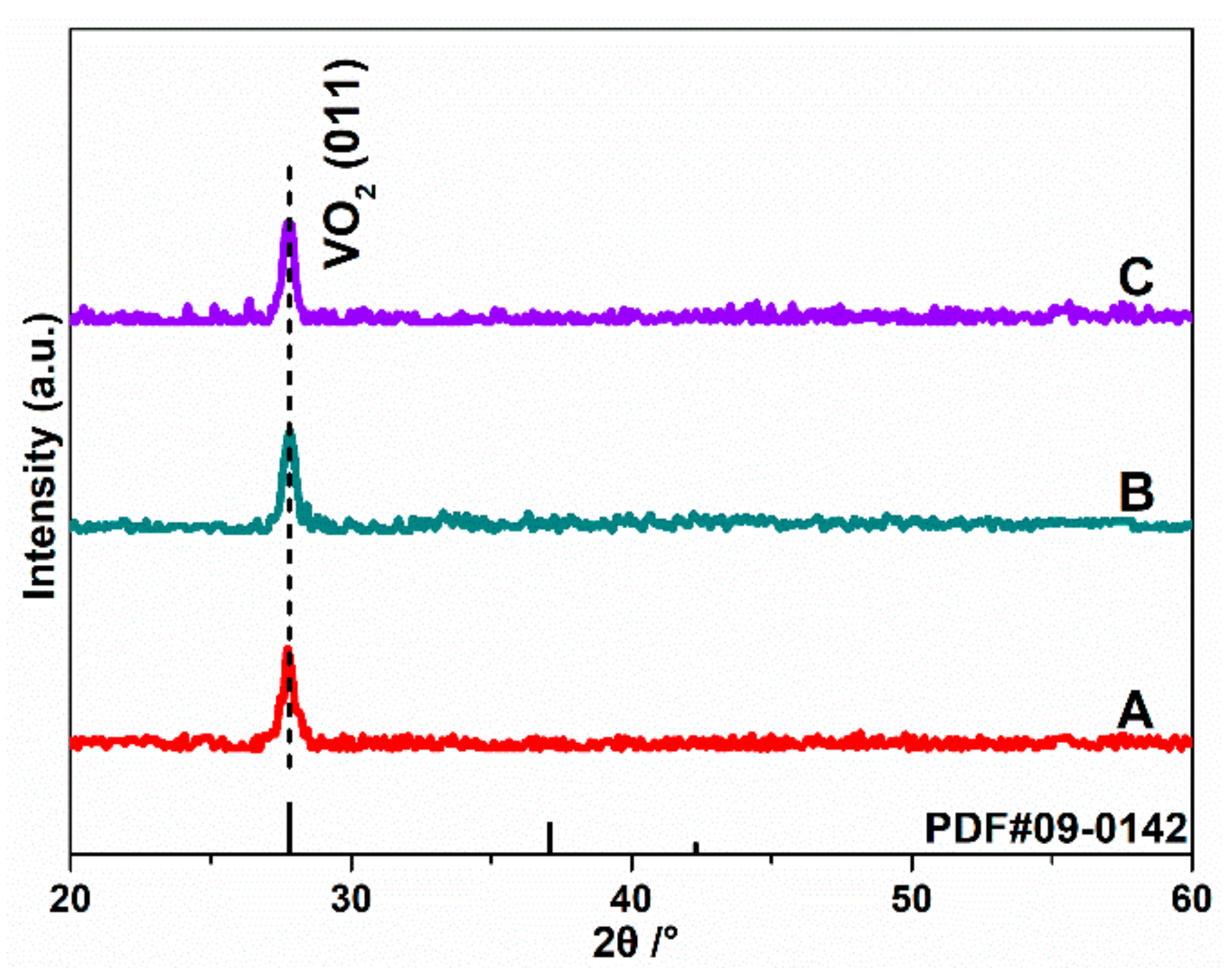

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Case, F.C. Modifications in the phase Transition Properties of Predeposited VO2 Films. J. Vac. Sci. Technol. A Vac. Surf. Film. 1984, 2, 1509–1512. [Google Scholar] [CrossRef]

- Boriskov, P.P.; Velichko, A.A.; Pergament, A.L.; Stefanovich, G.B.; Stefanovich, D.G. The Effect of Electric Field on Metal-Insulator Phase Transition in Vanadium Dioxide. Tech. Phys. Lett. 2002, 28, 406–408. [Google Scholar] [CrossRef]

- Zhao, Y.; Hwan Lee, J.; Zhu, Y.; Nazari, M.; Chen, C.; Wang, H.; Bernussi, A.; Holtz, M.; Fan, Z. Structural, Electrical, and Terahertz Transmission Properties of VO2 Thin Films Grown on c-, r-, and m-Plane Sapphire Substrates. J. Appl. Phys. 2012, 111, 053533. [Google Scholar] [CrossRef]

- Hao, R.; Li, Y.; Liu, F.; Sun, Y.; Tang, J.; Chen, P.; Jiang, W.; Wu, Z.; Xu, T.; Fang, B. Electric Field Induced Metal–Insulator Transition in VO2 Thin Film Based on FTO/VO2/FTO Structure. Infrared Phys. Technol. 2016, 75, 82–86. [Google Scholar] [CrossRef]

- Chen, S.; Ma, H.; Yi, X.; Xiong, T.; Wang, H.; Ke, C. Smart VO2 Thin Film for Protection of Sensitive Infrared Detectors from Strong Laser Radiation. Sens. Actuators A Phys. 2004, 115, 28–31. [Google Scholar] [CrossRef]

- Belyaev, M.A.; Putrolaynen, V.V.; Velichko, A.A.; Stefanovich, G.B.; Pergament, A.L. Field-Effect Modulation of Resistance in VO2 Thin Film at Lower Temperature. Jpn. J. Appl. Phys. 2014, 53, 111102. [Google Scholar] [CrossRef]

- Tselev, A.; Lavrik, N.V.; Kolmakov, A.; Kalinin, S.V. Scanning Near-Field Microwave Microscopy of VO2 and Chemical Vapor Deposition Graphene. Adv. Funct. Mater. 2013, 23, 2635–2645. [Google Scholar] [CrossRef]

- Arcangeletti, E.; Baldassarre, L.; Di Castro, D.; Lupi, S.; Malavasi, L.; Marini, C.; Perucchi, A.; Postorino, P. Evidence of a Pressure-Induced Metallization Process in Monoclinic VO2. Phys. Rev. Lett. 2007, 98, 196406. [Google Scholar] [CrossRef]

- Li, W.; Chang, S.; Wang, X.; Lin, L.; Bai, J. A Thermally Tunable Terahertz Bandpass Filter with Insulator-Metal Phase Transition of VO2 Thin Film. Optoelectron. Lett. 2014, 10, 180–183. [Google Scholar] [CrossRef]

- Ha, S.D.; Zhou, Y.; Fisher, C.J.; Ramanathan, S.; Treadway, J.P. Electrical Switching Dynamics and Broadband Microwave Characteristics of VO2 Radio Frequency Devices. J. Appl. Phys. 2013, 113, 184501. [Google Scholar] [CrossRef]

- Radu, I.P.; Martens, K.; Mertens, S.; Adelmann, C.; Shi, X.; Tielens, H.; Schaekers, M.; Pourtois, G.; Van Elshocht, S.; De Gendt, S.; et al. (Invited) Vanadium Oxide as a Memory Material. ECS Trans. 2011, 35, 233–243. [Google Scholar]

- Huang, Z.; Chen, S.; Lv, C.; Huang, Y.; Lai, J. Infrared Characteristics of VO2 Thin Films for Smart Window and Laser Protection Applications. Appl. Phys. Lett. 2012, 101, 191905. [Google Scholar] [CrossRef]

- Liao, F.; Zhu, Z.; Yan, Z.; Yao, G.; Huang, Z.; Gao, M.; Pan, T.; Zhang, Y.; Li, Q.; Feng, X.; et al. Ultrafast Response Flexible Breath Sensor Based on Vanadium Dioxide. J. Breath Res. 2017, 11, 036002. [Google Scholar] [CrossRef] [PubMed]

- Belyaev, M.A.; Velichko, A.A.; Boriskov, P.P.; Kuldin, N.A.; Putrolaynen, V.V.; Stefanovitch, G.B. The Field Effect and Mott Transistor Based on Vanadium Dioxide. J. Sel. Top. Nano Electron. Comput. 2014, 1, 26–30. [Google Scholar] [CrossRef]

- Xiao, L.; Ma, H.; Liu, J.; Zhao, W.; Jia, Y.; Zhao, Q.; Liu, K.; Wu, Y.; Wei, Y.; Fan, S.; et al. Fast Adaptive Thermal Camouflage Based on Flexible VO2/Graphene/CNT Thin Films. Nano Lett. 2015, 15, 8365–8370. [Google Scholar] [CrossRef]

- Li, S.-Y.; Niklasson, G.A.; Granqvist, C.G. Thermochromic Fenestration with VO2-Based Materials: Three Challenges and How They can be Met. Thin Solid Film. 2012, 520, 3823–3828. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Jiang, M.; Ji, S.; Luo, H.; Gao, Y.; Jin, P. Preparation and Characterization of Self-Supporting Thermochromic Films Composed of VO2(M)@SiO2 Nanofibers. ACS Appl. Mater. Interfaces 2013, 5, 6453–6457. [Google Scholar] [CrossRef]

- Yuan, N.; Li, J.; Li, G.; Chen, X. The Large Modification of Phase Transition Characteristics of VO2 Films on SiO2/Si Substrates. Thin Solid Film. 2006, 515, 1275–1279. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Y.; Pan, X.; Kuryatkov, V.; Bernussi, A.; Holtz, M.; Fan, Z. Influence of Defects on Structural and Electrical Properties of VO2 Thin Films. J. Appl. Phys. 2011, 110, 023707. [Google Scholar] [CrossRef]

- Appavoo, K.; Lei, D.Y.; Sonnefraud, Y.; Wang, B.; Pantelides, S.T.; Maier, S.A.; Haglund, R.F. Role of Defects in the Phase Transition of VO2 Nanoparticles Probed by Plasmon Resonance Spectroscopy. Nano Lett. 2012, 12, 780–786. [Google Scholar] [CrossRef]

- Piccirillo, C.; Binions, R.; Parkin, I.P. Nb-Doped VO2 Thin Films Prepared by Aerosol-Assisted Chemical Vapour Deposition. Eur. J. Inorg. Chem. 2007, 2007, 4050–4055. [Google Scholar] [CrossRef]

- Khan, G.R.; Asokan, K.; Ahmad, B. Room Temperature Tunability of Mo-doped VO2 Nanofilms across Semiconductor to Metal Phase Transition. Thin Solid Film. 2017, 625, 155–162. [Google Scholar] [CrossRef]

- Piccirillo, C.; Binions, R.; Parkin, I.P. Synthesis and Characterisation of W-doped VO2 by Aerosol Assisted Chemical Vapour Deposition. Thin Solid Film. 2008, 516, 1992–1997. [Google Scholar] [CrossRef]

- Wang, N.; Duchamp, M.; Dunin-Borkowski, R.E.; Liu, S.; Zeng, X.; Cao, X.; Long, Y. Terbium-Doped VO2 Thin Films: Reduced Phase Transition Temperature and Largely Enhanced Luminous Transmittance. Langmuir 2016, 32, 759–764. [Google Scholar] [CrossRef]

- Chae, B.G.; Kim, H.T.; Yun, S.J. Characteristics of W- and Ti-Doped VO2 hin Films Prepared by Sol-Gel Method. Electrochem. Solid State Lett. 2008, 11, D53. [Google Scholar] [CrossRef]

- Panagopoulou, M.; Gagaoudakis, E.; Boukos, N.; Aperathitis, E.; Kiriakidis, G.; Tsoukalas, D.; Raptis, Y.S. Thermochromic Performance of Mg-doped VO2 Thin Films on Functional Substrates for Glazing Applications. Sol. Energy Mater. Sol. Cells 2016, 157, 1004–1010. [Google Scholar] [CrossRef]

- Jin, P.; Tazawa, M.; Yoshimura, K.; Igarashi, K.; Tanemura, S.; Macák, K.; Helmersson, U. Epitaxial Growth of W-Doped VO2/V2O3 Multilayer on α-Al2O3(110) by Reactive Magnetron Sputtering. Thin Solid Film. 2000, 375, 128–131. [Google Scholar] [CrossRef]

- Batista, C.; Ribeiro, R.M.; Teixeira, V. Synthesis and Characterization of VO2-Based Thermochromic Thin Films for Energy-Efficient Windows. Nanoscale Res. Lett. 2011, 6, 301. [Google Scholar] [CrossRef]

- Balin, I.; Wang, S.; Wang, P.; Long, Y.; Abdulhalim, I. Enhanced Transition-Temperature Reduction in a Half-Sphere Au/VO2 Core-Shell Structure: Local Plasmonics Versus Induced Stress and Percolation Effects. Phys. Rev. Appl. 2019, 11, 034064. [Google Scholar] [CrossRef]

- Schilbe, P. Raman Scattering in VO2. Phys. B Condens. Matter 2002, 316–317, 600–602. [Google Scholar] [CrossRef]

- Pan, M.; Liu, J.; Zhong, H.; Wang, S.; Li, Z.; Chen, X.; Lu, W. Raman Study of the Phase Transition in VO2 Thin Films. J. Cryst. Growth 2004, 268, 178–183. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Q.; Koughia, C.; Ye, F.; Sanayei, M.; Wen, S.-J.; Kasap, S. Characterization of Vanadium Oxide Thin Films with Different Stoichiometry Using Raman Spectroscopy. Thin Solid Film. 2016, 620, 64–69. [Google Scholar] [CrossRef]

- Shibuya, K.; Tsutsumi, J.; Hasegawa, T.; Sawa, A. Fabrication and Raman Scattering Study of Epitaxial VO2 Films on MgF2 (001) Substrates. Appl. Phys. Lett. 2013, 103, 021604. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Zhu, Y.; Li, Z.; Vajtai, R.; Ci, L.; Ajayan, P.M. Nanostructured VO2 Photocatalysts for Hydrogen Production. ACS Nano 2008, 2, 1492–1496. [Google Scholar] [CrossRef]

- Pan, M.; Zhong, H.; Wang, S.; Liu, J.; Li, Z.; Chen, X.; Lu, W. Properties of VO2 Thin Film Prepared with Precursor VO2. J. Cryst. Growth 2004, 265, 121–126. [Google Scholar] [CrossRef]

- Liu, H.; Wan, D.; Ishaq, A.; Chen, L.; Guo, B.; Shi, S.; Luo, H.; Gao, Y. Sputtering Deposition of Sandwich-Structured V2O5/Metal(V, W)/V2O5 Multilayers for the Preparation of High-Performance Thermally Sensitive VO2 Thin Films with Selectivity of VO2(B) and VO2(M) Polymorph. ACS Appl. Mater. Interfaces 2016, 8, 7884–7890. [Google Scholar] [CrossRef]

- Mai, L.Q.; Hu, B.; Hu, T.; Chen, W.; Gu, E.D. Electrical Property of Mo-Doped VO2 Nanowire Array Film by Melting−Quenching Sol−Gel Method. J. Phys. Chem. B 2006, 110, 19083–19086. [Google Scholar] [CrossRef]

- Lee, D.; Lee, J.; Song, K.; Xue, F.; Choi, S.-Y.; Ma, Y.; Podkaminer, J.; Liu, D.; Liu, S.-C.; Chung, B.; et al. Sharpened VO2 Phase Transition via Controlled Release of Epitaxial Strain. Nano Lett. 2017, 17, 5614–5619. [Google Scholar] [CrossRef]

- Dai, L.; Cao, C.; Gao, Y.; Luo, H. Synthesis and Phase Transition Behavior of Undoped VO2 with a Strong Nano-Size Effect. Sol. Energy Mater. Sol. Cells 2011, 95, 712–715. [Google Scholar] [CrossRef]

- Ji, H.; Wei, J.; Natelson, D. Modulation of the Electrical Properties of VO2 Nanobeams Using an Ionic Liquid as a Gating Medium. Nano Lett. 2012, 12, 2988–2992. [Google Scholar] [CrossRef]

- Chen, F.H.; Fan, L.L.; Chen, S.; Liao, G.M.; Chen, Y.L.; Wu, P.; Song, L.; Zou, C.W.; Wu, Z.Y. Control of the Metal–Insulator Transition in VO2 Epitaxial Film by Modifying Carrier Density. ACS Appl. Mater. Interfaces 2015, 7, 6875–6881. [Google Scholar] [CrossRef] [PubMed]

- Stefanovich, G.; Pergament, A.; Stefanovich, D. Electrical Switching and Mott Transition in VO2. J. Phys. Condens. Matter 2000, 12, 8837–8845. [Google Scholar] [CrossRef]

- Pergament, A. Metal–Insulator Transition: The Mott Criterion and Coherence Length. J. Phys. Condens. Matter 2003, 15, 3217–3223. [Google Scholar] [CrossRef]

- Kasırga, T.S.; Coy, J.M.; Park, J.H.; Cobden, D.H. Visualization of One-Dimensional Diffusion and Spontaneous Segregation of Hydrogen in Single Crystals of VO2. Nanotechnology 2016, 27, 345708. [Google Scholar] [CrossRef] [PubMed]

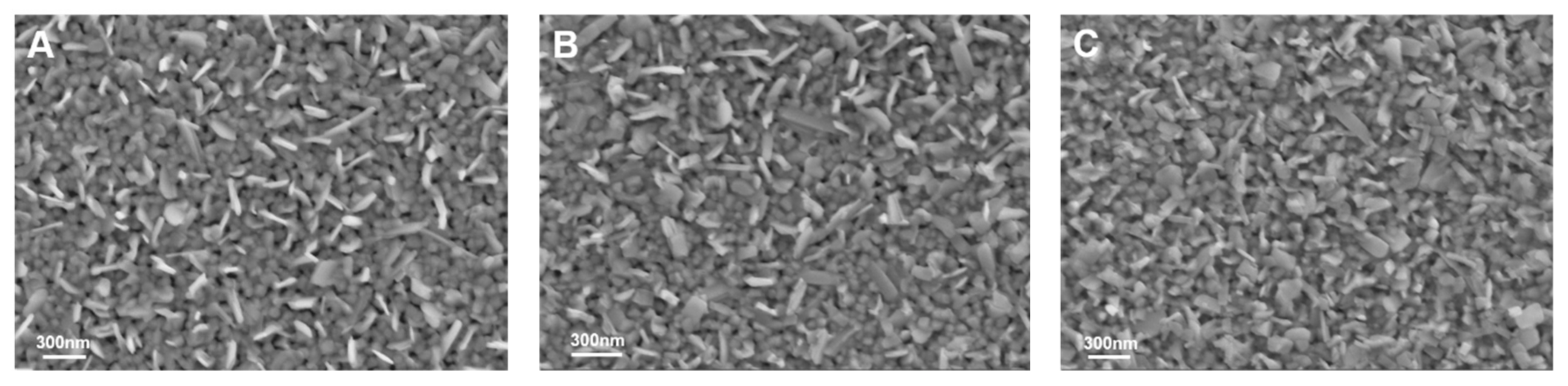

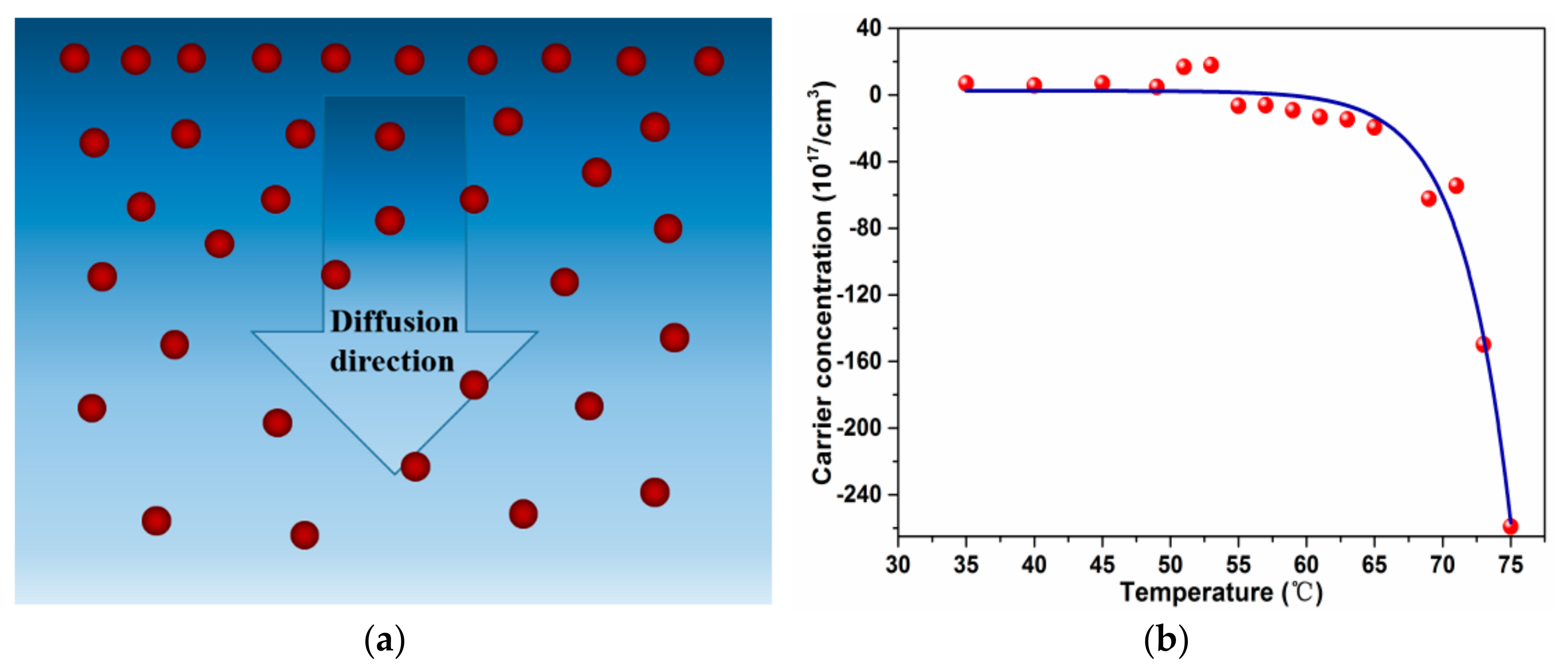

| Sample | A | B | C |

|---|---|---|---|

| activation energy ΔE (eV) | 0.33 | 0.27 | 0.23 |

| conductivity σ (S/m2) | 12.95 | 24.10 | 86.70 |

| carrier concentration n (cm−3) | 3.0163 × 1017 | −6.8935 × 1017 | −1.9045 × 1018 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, H.; Zhang, D.; Yang, Y.; Liu, Y.; Zhong, A.; He, Q.; Qi, J.; Fan, P. A Novel Method for Notable Reducing Phase Transition Temperature of VO2 Films for Smart Energy Efficient Windows. Nanomaterials 2020, 10, 58. https://doi.org/10.3390/nano10010058

Guan H, Zhang D, Yang Y, Liu Y, Zhong A, He Q, Qi J, Fan P. A Novel Method for Notable Reducing Phase Transition Temperature of VO2 Films for Smart Energy Efficient Windows. Nanomaterials. 2020; 10(1):58. https://doi.org/10.3390/nano10010058

Chicago/Turabian StyleGuan, Huan, Dongping Zhang, Yu Yang, Yi Liu, Aihua Zhong, Qicong He, Jiahua Qi, and Ping Fan. 2020. "A Novel Method for Notable Reducing Phase Transition Temperature of VO2 Films for Smart Energy Efficient Windows" Nanomaterials 10, no. 1: 58. https://doi.org/10.3390/nano10010058

APA StyleGuan, H., Zhang, D., Yang, Y., Liu, Y., Zhong, A., He, Q., Qi, J., & Fan, P. (2020). A Novel Method for Notable Reducing Phase Transition Temperature of VO2 Films for Smart Energy Efficient Windows. Nanomaterials, 10(1), 58. https://doi.org/10.3390/nano10010058