Effects of Mg and Sb Substitution on the Magnetic Properties of Magnetic Field Annealed MnBi Alloys

Abstract

:1. Introduction

2. Experimental and Calculations

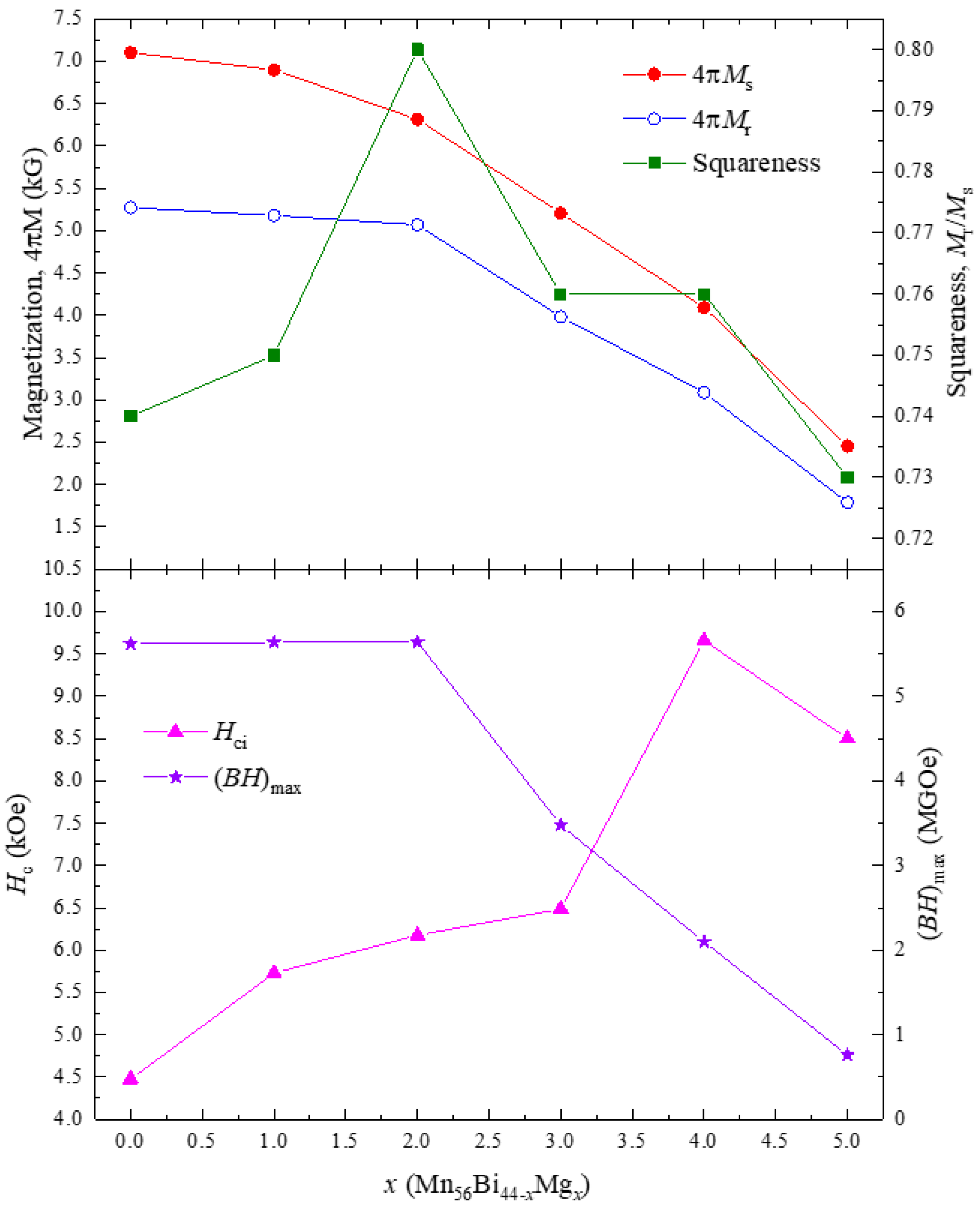

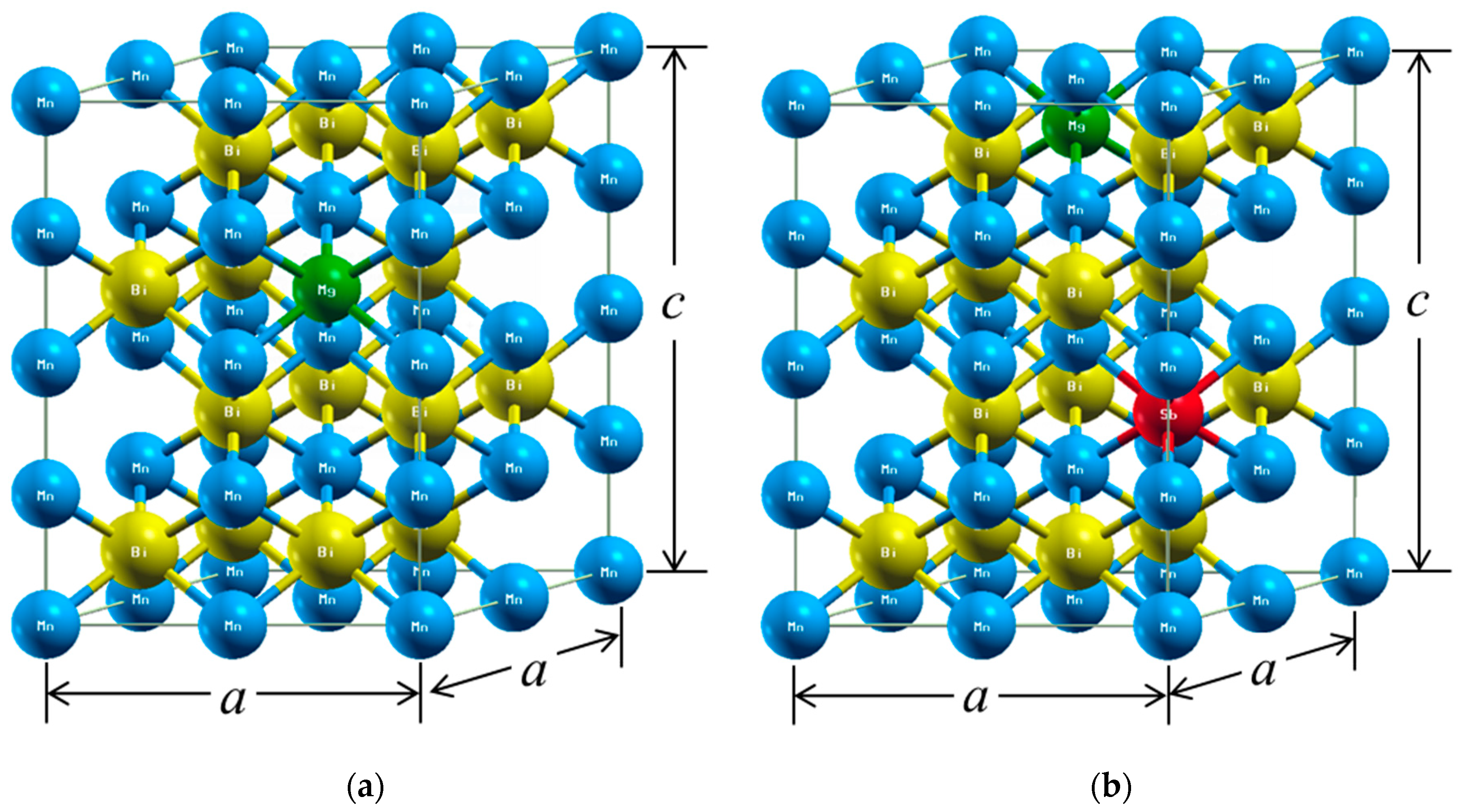

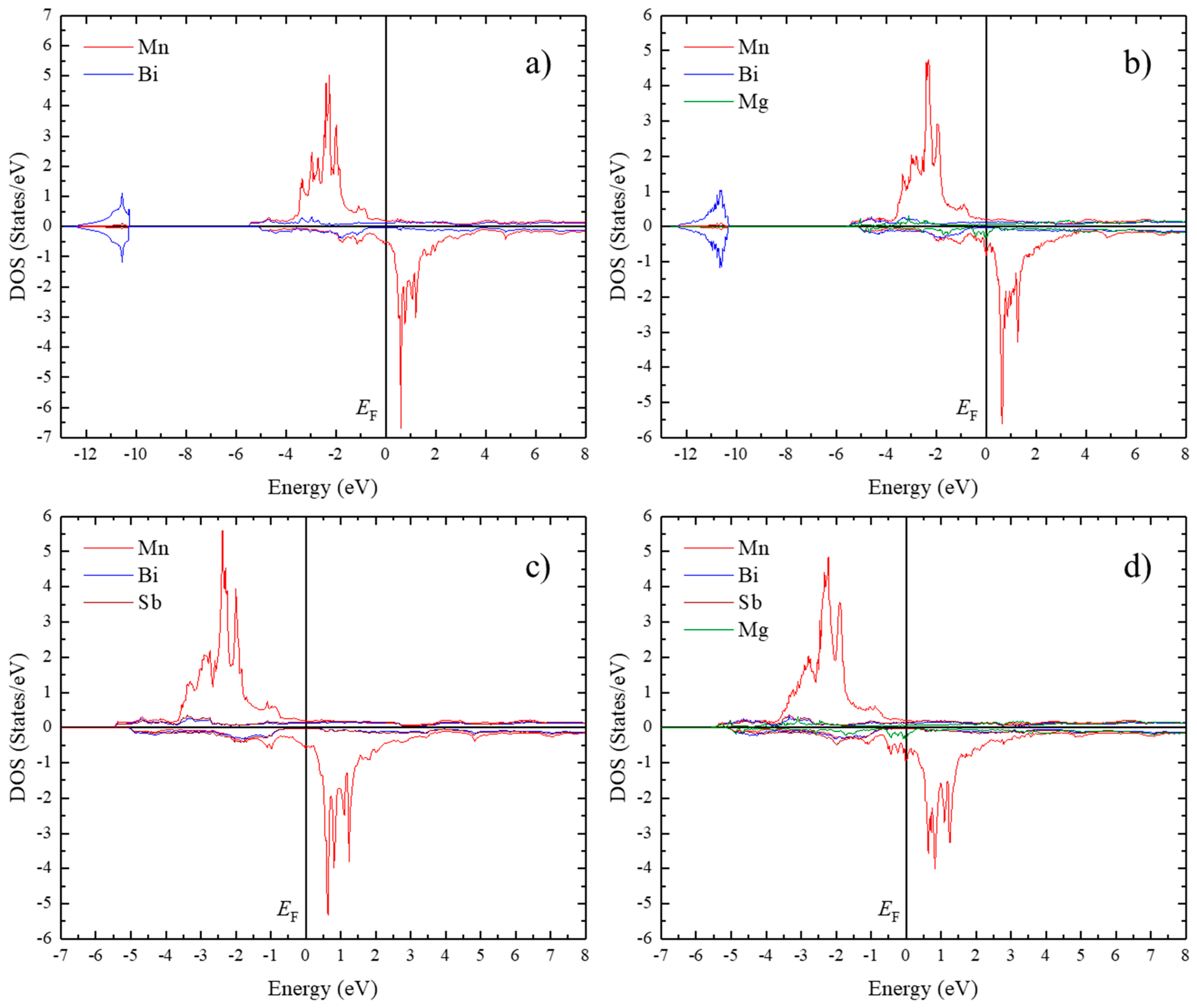

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vagati, A. The Synchronous Reluctance Solution: A New Alternative in AC drives. In Proceedings of the IECON’94–20th Annual Conference of IEEE Industrial Electronics, Bologna, Italy, 5–9 September 1994; Volume 1, pp. 1–13. [Google Scholar]

- Lipo, T.A. Synchronous reluctance machines-a viable alternative for AC drives? Electr. Mach. Power Syst. 1991, 19, 659–671. [Google Scholar] [CrossRef]

- Rama Rao, N.V.; Gabay, A.M.; Hadjipanayis, G.C. Anisotropic fully dense MnBi permanent magnet with high energy product and high coercivity at elevated temperatures. J. Phys. D Appl. Phys. 2013, 46, 062001. [Google Scholar] [CrossRef]

- Cao, J.; Huang, Y.L.; Hou, Y.H.; Shi, Z.Q.; Yan, X.T.; Zhong, Z.C.; Wang, G.P. Microstructure and magnetic properties of MnBi alloys with high coercivity and significant anisotropy prepared by surfactant assisted ball milling. J. Magn. Magn. Mater. 2019, 473, 505–510. [Google Scholar] [CrossRef]

- Chinnasamy, C.; Jasinski, M.M.; Ulmer, A.; Li, W.; Hadjipanayis, G.; Liu, J. Mn-Bi magnetic powders with high coercivity and magnetization at room temperature. IEEE Trans. Magn. 2012, 48, 3641–3643. [Google Scholar] [CrossRef]

- Yang, Y.; Park, J.; Lim, J.T.; Kim, J.-W.; Li, O.L.; Choi, C.-J. Effect of phase purity on enhancing the magnetic properties of Mn-Bi alloy. J. Magn. Magn. Mater. 2021, 517, 167344. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.P.; Li, G.; Polikarpov, E.; Darsell, J.; Overman, N.; Olszta, M.; Schreiber, D.; Bowden, M.; Droubay, T.; et al. Thermal stability of MnBi magnetic materials. J. Phys. Condens. Matter 2014, 26, 064212. [Google Scholar] [CrossRef]

- Kim, S.; Moon, H.; Jung, H.; Kim, S.-M.; Lee, H.-S.; Choi-Yim, H.; Lee, W. Magnetic properties of large-scaled MnBi bulk magnets. J. Alloys Compd. 2017, 708, 1245–1249. [Google Scholar] [CrossRef]

- Yang, J.B.; Yelon, W.B.; James, W.J.; Cai, Q.; Kornecki, M.; Roy, S.; Ali, N.; L’Heritier, P. Crystal structure, magnetic properties and electronic structure of the MnBi intermetallic compound. J. Phys. Condens. Matter 2002, 14, 6509–6519. [Google Scholar] [CrossRef]

- Poudyal, N.; Liu, X.; Wang, W.; Nguyen, V.V.; Ma, Y.; Gandha, K.; Elkins, K.; Liu, J.P.; Sun, K.; Kramer, M.J.; et al. Processing of MnBi bulk magnets with enhanced energy product. AIP Adv. 2016, 6, 056004. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Hong, Y.-K.; Lee, J.; Lee, W.; Kim, S.-G.; Choi, C.-J. Electronic structure and maximum energy product of MnBi. Metals 2014, 4, 455–464. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Kim, J.-W.; Si, P.-Z.; Qian, H.-D.; Shin, Y.; Wang, X.; Park, J.; Li, O.L.; Wu, Q.; Ge, H.; et al. Effects of Ga-doping on the microstructure and magnetic properties of MnBi alloys. J. Alloys Compd. 2018, 769, 813–816. [Google Scholar] [CrossRef]

- Sakuma, A.; Manabe, Y.; Kota, Y. First principles calculation of magnetocrystalline anisotropy energy of MnBi and MnBi1-xSnx. J. Phys. Soc. Jpn. 2013, 82, 073704. [Google Scholar] [CrossRef]

- Qian, H.-D.; Park, J.; Lim, J.T.; Yang, Y.; Si, P.-Z.; Kim, J.W.; Choi, C.-J.; Cho, K.M. Magnetic properties of MnBi bulk magnets with NaCl and C addition. AIP Adv. 2019, 9, 115213. [Google Scholar] [CrossRef]

- Wang, X.; Qian, H.; Si, P.-Z.; Yang, Y.; Choi, C.-J.; Park, J.; Wang, X.; Ge, H.; Shinde, K.P.; Chung, K. Structure and magnetic properties of MnBi nanoparticles prepared by laser ablation and arc-discharge method. IEEE Trans. Magn. 2018, 54, 2301005. [Google Scholar] [CrossRef]

- Yasuda, H.; Ohnaka, I.; Yamamoto, Y.; Tokieda, K.; Kishio, K. Formation of crystallographically aligned BiMn grains by semi-solid processing of rapidly solidified Bi-Mn alloys under a magnetic field. Mater. Trans. 2003, 44, 2207–2212. [Google Scholar] [CrossRef]

- Ren, Z.-M.; Li, X.; Deng, K.; Wang, H.; Zhuang, Y. Solidification structures of Bi-Mn alloys under a high magnetic field. J. Shanghai Univ. 2006, 10, 74–77. [Google Scholar] [CrossRef]

- Kobayashi, R.; Mitsui, Y.; Takahashi, K.; Uda, S.; Koyama, K. In-field annealing and quenching for ferromagnetic MnBi under 19 T. IEEE Trans. Magn. 2019, 55, 1000204. [Google Scholar] [CrossRef]

- Mitsui, Y.; Abematsu, K.; Umetsu, R.Y.; Takahashi, K.; Koyama, K. Magnetic field effects on liquid-phase reactive sintering of MnBi. J. Magn. Magn. Mater. 2016, 400, 304–306. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Kharel, P.; George, T.; Li, X.Z.; Mukherjee, P.; Valloppilly, S.; Sellmyer, D.J. Grain alignment due to magnetic-field annealing in MnBi:Bi nanocomposites. J. Phys. D Appl. Phys. 2016, 49, 455002. [Google Scholar] [CrossRef] [Green Version]

- Si, P.Z.; Yang, Y.; Yao, L.L.; Qian, H.D.; Ge, H.L.; Park, J.; Chung, K.C.; Choi, C.J. Magnetic-field-enhanced reactive synthesis of MnBi from Mn nanoparticles. J. Magn. Magn. Mater. 2019, 476, 243–247. [Google Scholar] [CrossRef]

- Mishima, T. Magnet Steel Containing Nickel and Aluminium. U.S. Patent 2,027,994, 14 January 1936. [Google Scholar]

- Zhang, W.; Balasubramanian, B.; Kharel, P.; Pahari, R.; Valloppilly, S.R.; Li, X.; Yue, L.; Skomski, R.; Sellmyer, D.J. High energy product of MnBi by field annealing and Sn alloying. APL Mater. 2019, 7, 121111. [Google Scholar] [CrossRef] [Green Version]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. Effect of Sb substitution on crystal structure, texture and hard magnetic properties of melt-spun MnBi alloys. J. Alloys Compd. 2019, 792, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. New anisotropic MnBi permanent magnets by field-annealing of compacted melt-spun alloys modified with Mg and Sb. J. Magn. Magn. Mater. 2020, 495, 165860. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C. Effect of Mg content in melt-spun Mn–Bi–Mg–Sb–In alloys on the structure and properties of field-annealed magnets. IEEE Magn. Lett. 2020, 11, 7503304. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. Development of rare-earth-free bulk magnets with energy product up to 12 MGOe in field annealed Mn–Bi–Mg–In–Sb alloys. J. Alloys Compd. 2020, 822, 153663. [Google Scholar] [CrossRef]

- Blaha, P.; Schwarz, K.; Madsen, G.; Kvasnicka, D.; Luitz, J. WIEN2k: An Augmented Plane Wave Plus Local Orbitals Program for Calculating Crystal Properties; Vienna University of Technology: Vienna, Austria, 2001. [Google Scholar]

- Roberts, B.W. Neutron diffraction study of the structures and magnetic properties of manganese bismuthide. Phys. Rev. 1956, 104, 607–616. [Google Scholar] [CrossRef]

- Chen, T. Contribution to the equilibrium phase diagram of the Mn-Bi system near MnBi. J. Appl. Phys. 1974, 45, 2358–2360. [Google Scholar] [CrossRef]

- Christopher, N.R.; Singh, N.; Singh, S.K.; Gahtori, B.; Mishra, S.K.; Dhar, A.; Awana, V.P.S. Appreciable magnetic moment and energy density in single-step normal route synthesized MnBi. J. Supercond. Novel Magn. 2013, 26, 3161–3165. [Google Scholar] [CrossRef] [Green Version]

- Coey, J.M.D. Magnetism and Magnetic Materials, 1st ed.; Cambridge University Press: Cambridge, UK, 2009; pp. 401–404. [Google Scholar]

| Materials | Mn | Bi | Mg | Sb | Interstitial, Int. | Total Magnetic Moments, μB | Anisotropy Constant, K (×106 J/m3) |

|---|---|---|---|---|---|---|---|

| MnBi | 3.571 | −0.103 | - | - | 0.104 | 7.044 | −0.850 |

| MnMg | 2.331 | - | 0.002 | - | 0.006 | 0.067 | 19.690 |

| Mn16Bi15Mg | 3.577 | −0.108 | −0.071 | - | 0.790 | 56.371 | −0.898 |

| Mn16Bi15Sb | 3.573 | −0.121 | - | −0.124 | 0.741 | 56.210 | 6.042 |

| Mn16Bi14SbMg | 3.579 | −0.134 | −0.071 | −0.131 | 0.784 | 56.368 | −0.441 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, H.-D.; Yang, Y.; Lim, J.T.; Kim, J.-W.; Choi, C.-J.; Park, J. Effects of Mg and Sb Substitution on the Magnetic Properties of Magnetic Field Annealed MnBi Alloys. Nanomaterials 2020, 10, 2265. https://doi.org/10.3390/nano10112265

Qian H-D, Yang Y, Lim JT, Kim J-W, Choi C-J, Park J. Effects of Mg and Sb Substitution on the Magnetic Properties of Magnetic Field Annealed MnBi Alloys. Nanomaterials. 2020; 10(11):2265. https://doi.org/10.3390/nano10112265

Chicago/Turabian StyleQian, Hui-Dong, Yang Yang, Jung Tae Lim, Jong-Woo Kim, Chul-Jin Choi, and Jihoon Park. 2020. "Effects of Mg and Sb Substitution on the Magnetic Properties of Magnetic Field Annealed MnBi Alloys" Nanomaterials 10, no. 11: 2265. https://doi.org/10.3390/nano10112265