Anisotropic Characterizations of Electrospun PAN Nanofiber Mats Using Design of Experiments

Abstract

1. Introduction

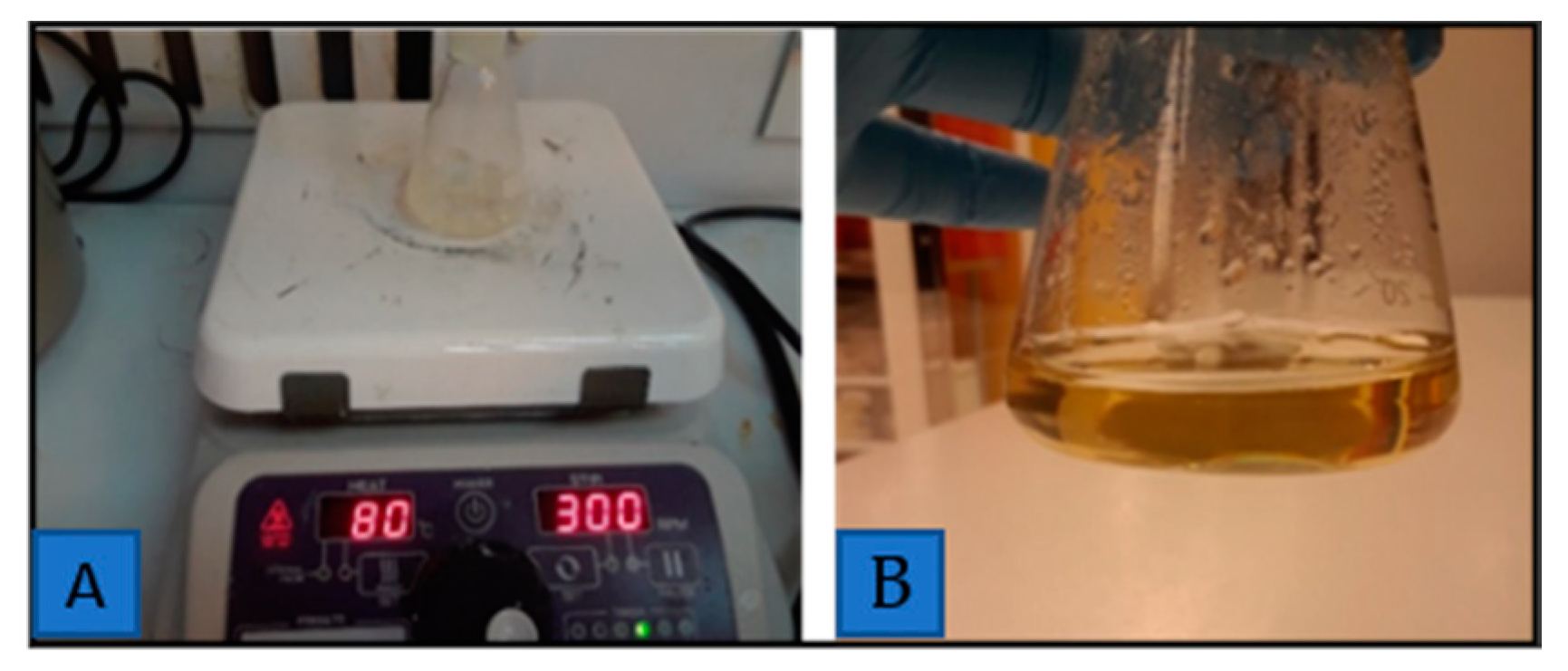

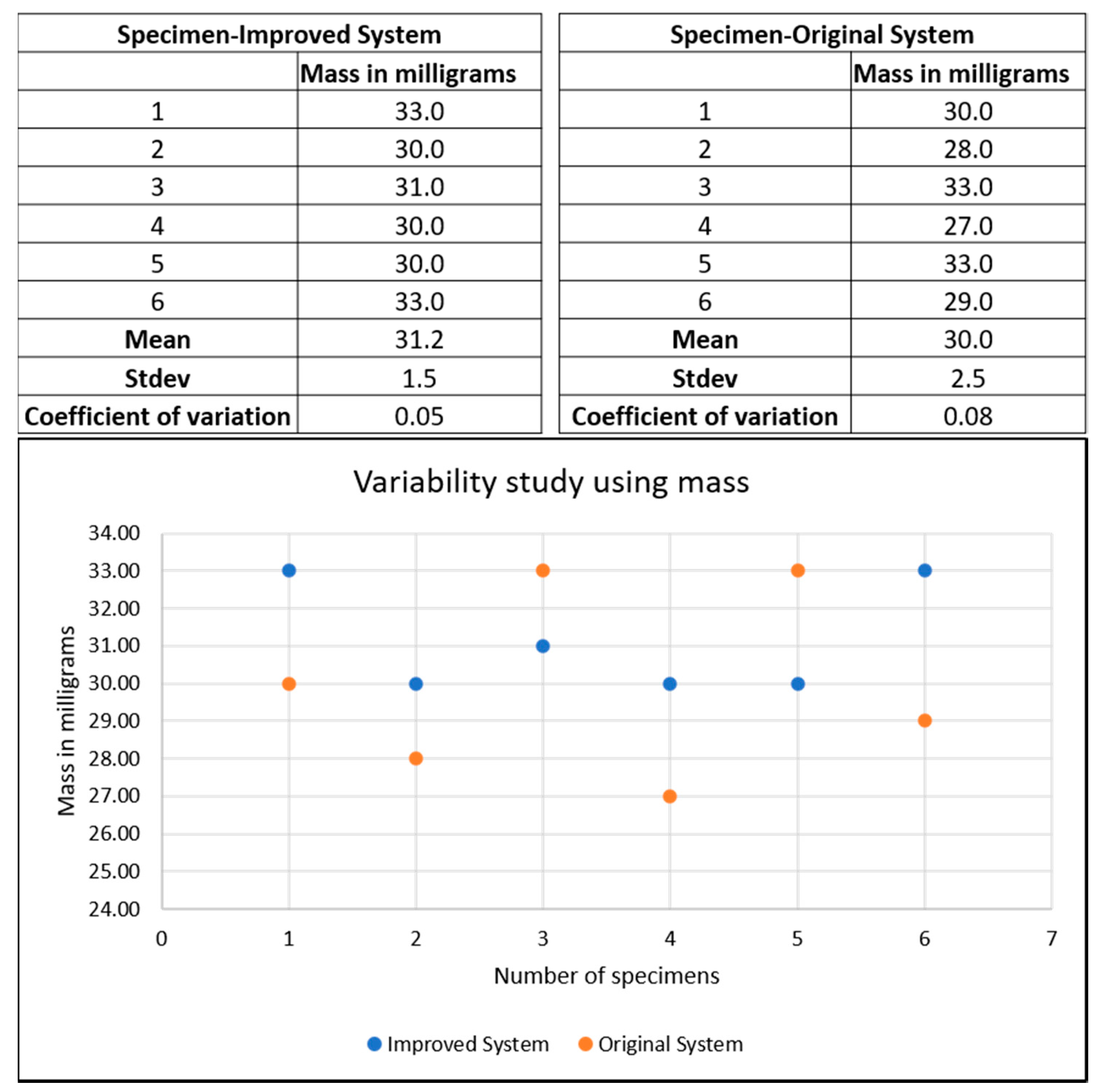

2. Materials and Methods

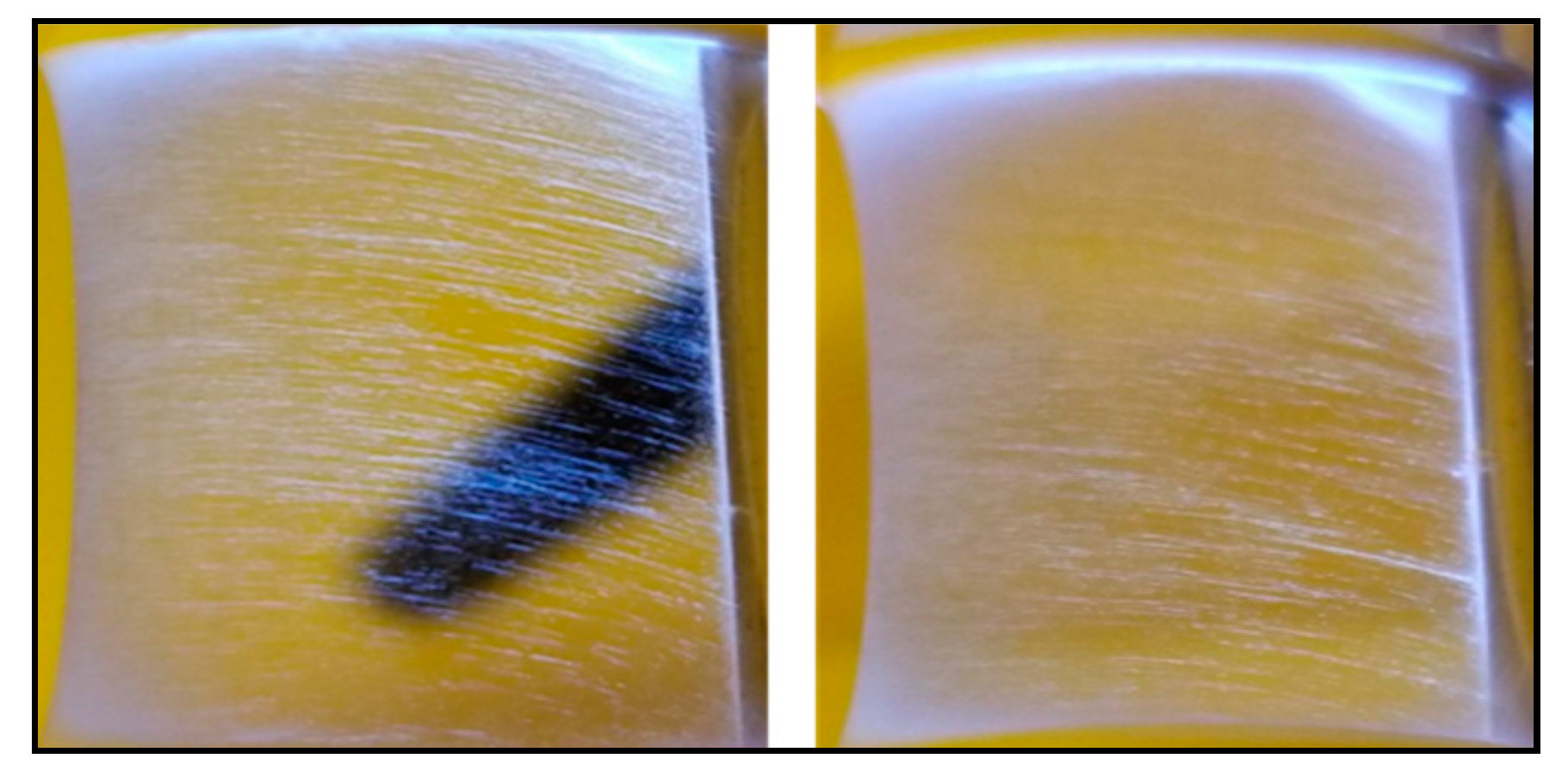

3. Systems and Modifications

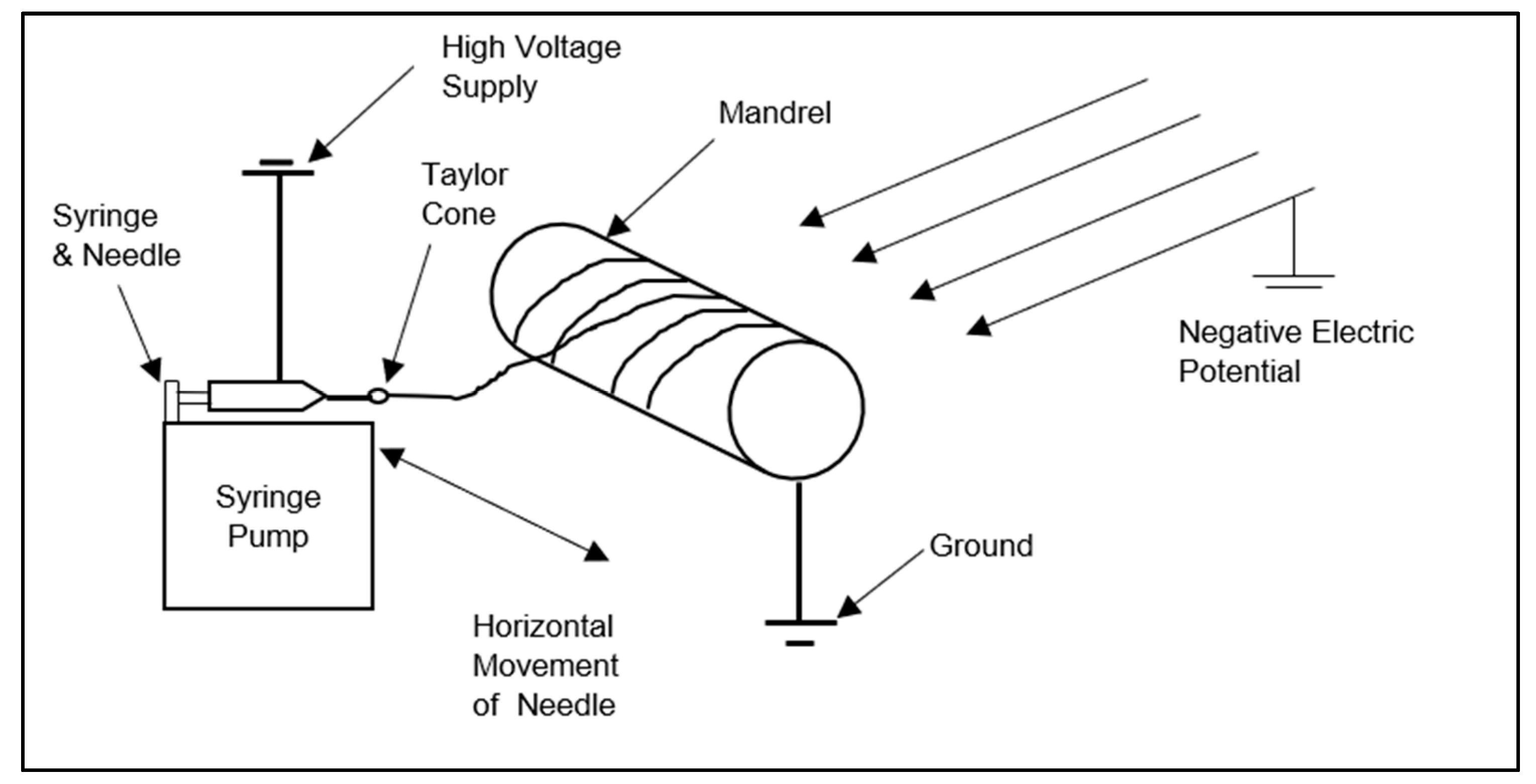

3.1. Working Principle

3.2. Morphological Analysis

4. Characterization for Dielectric and Tensile Tests

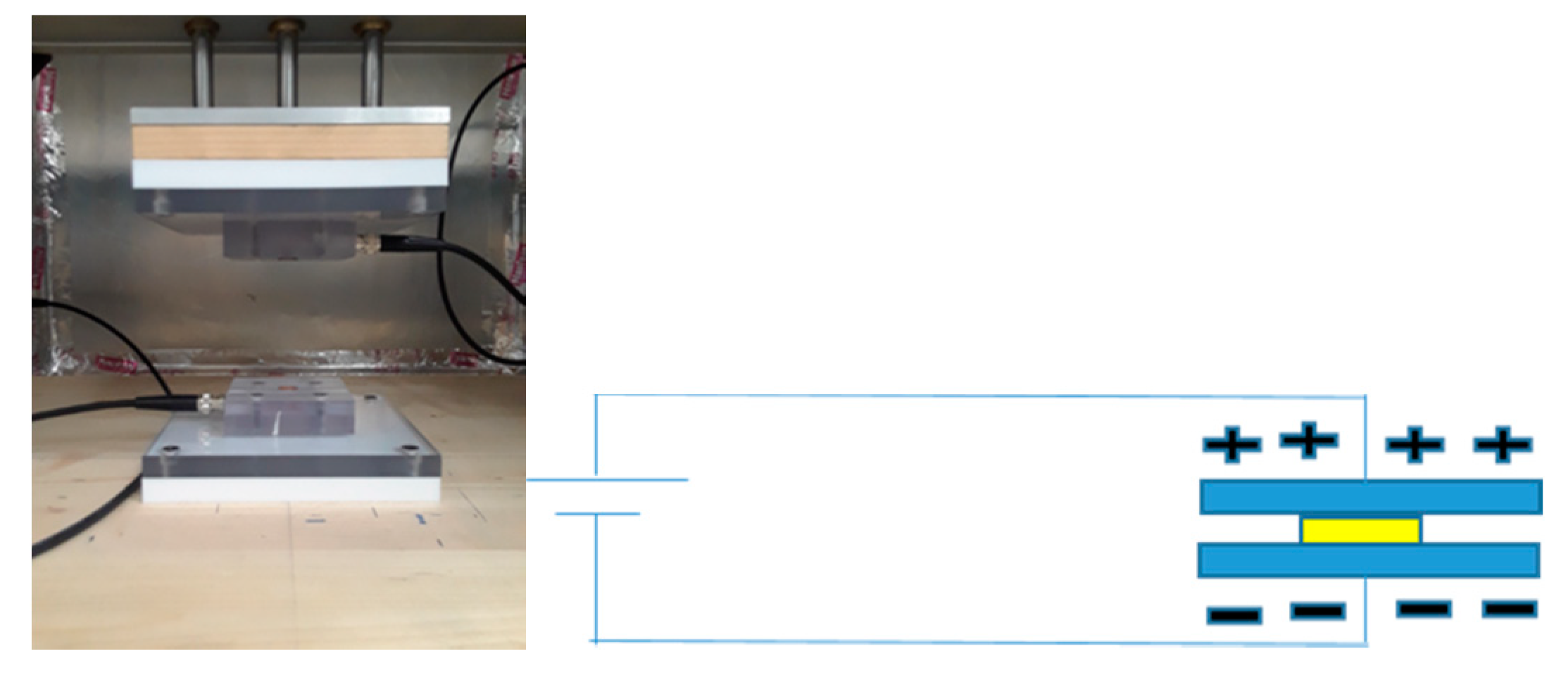

4.1. Dielectric Test

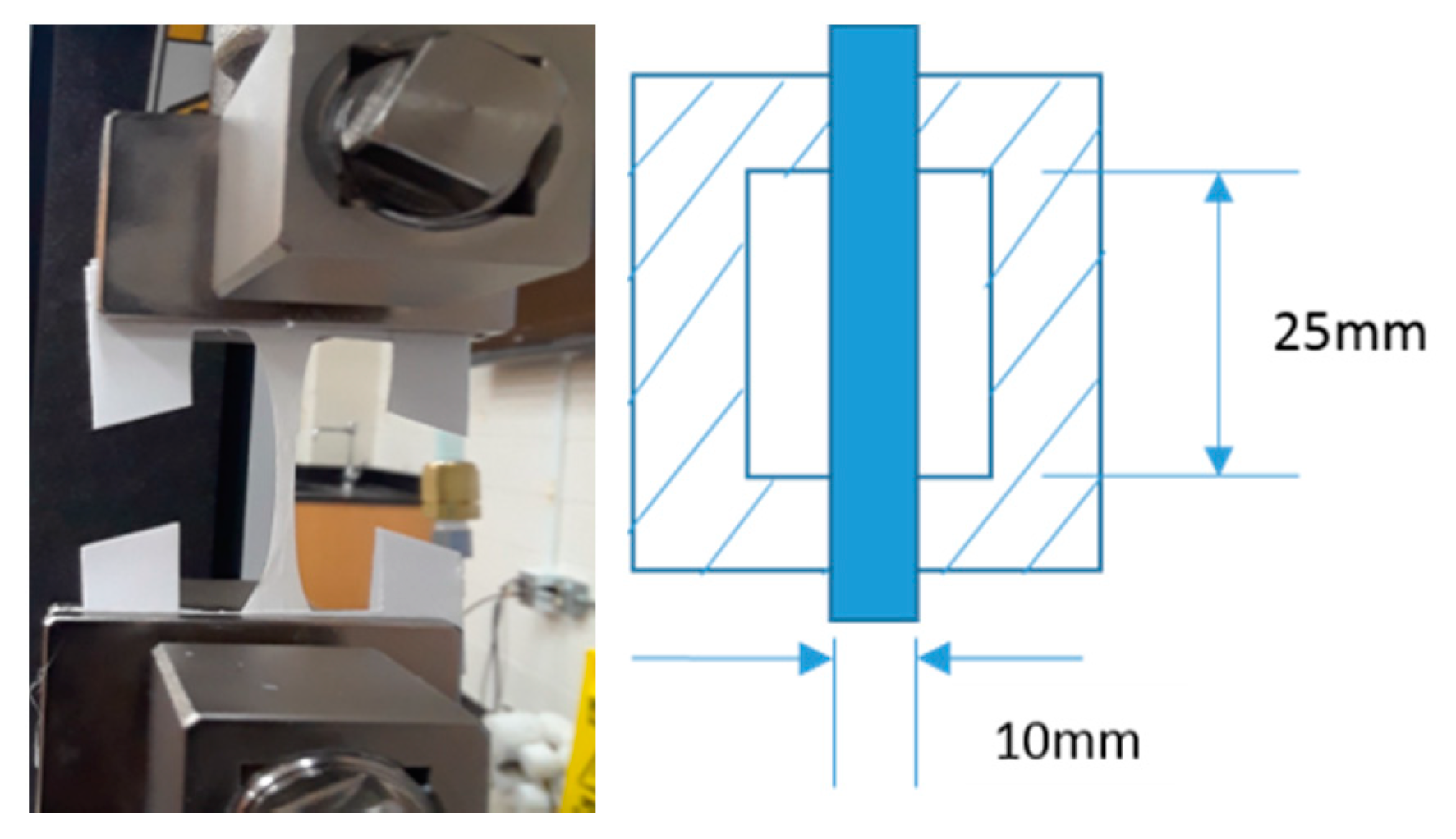

4.2. Tensile Test

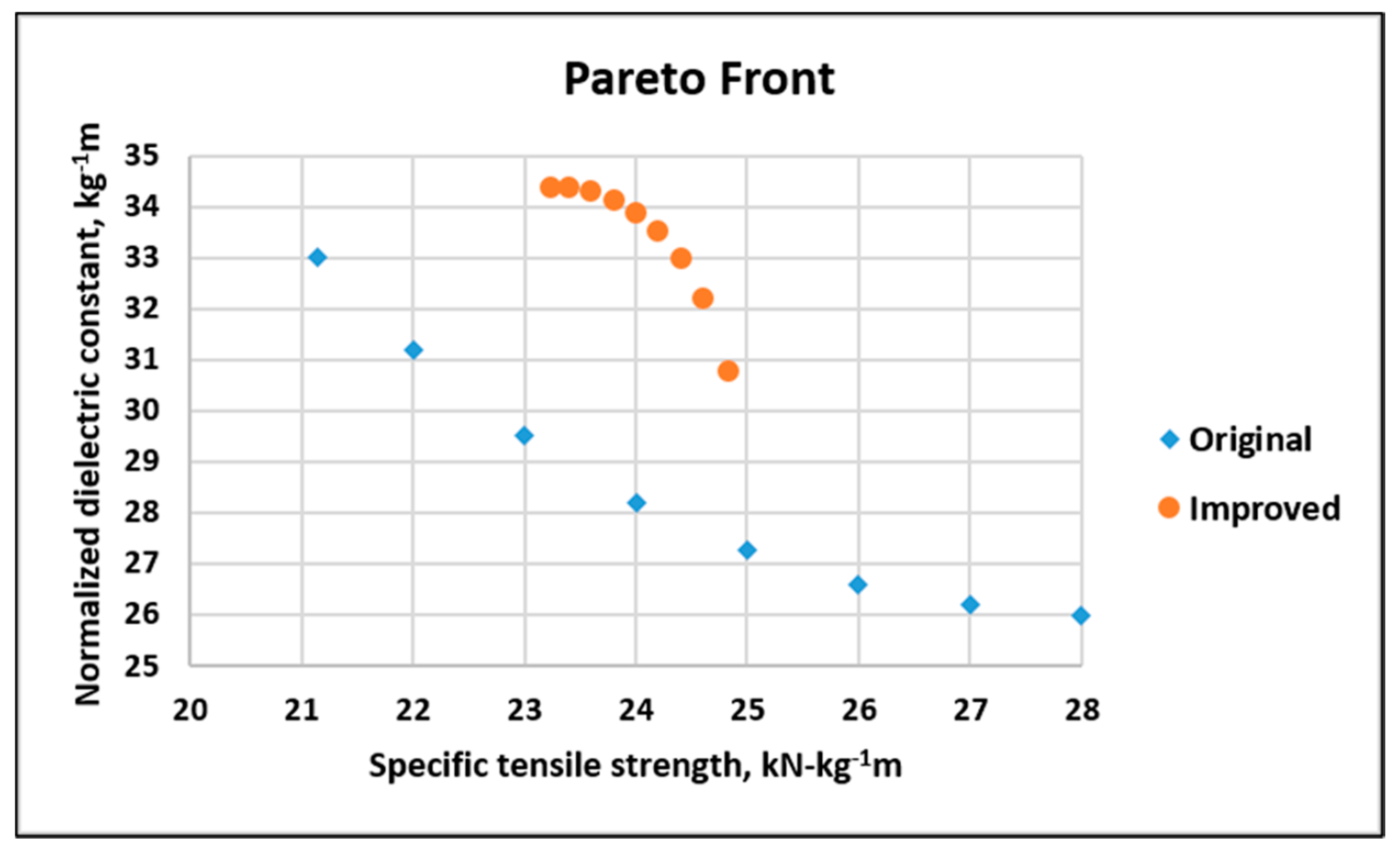

5. Results and Discussion

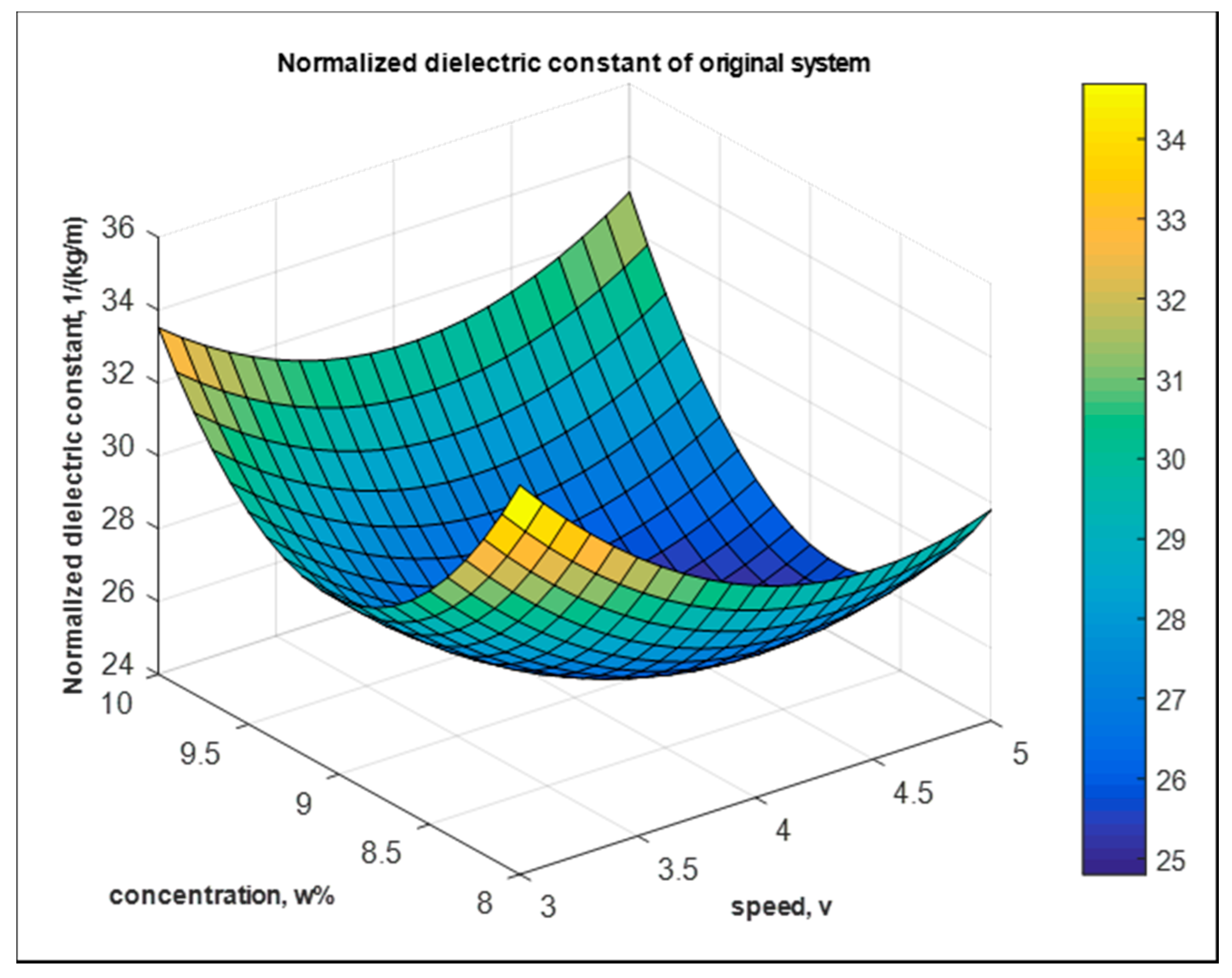

5.1. Dielectric—Main Effects and Interactions

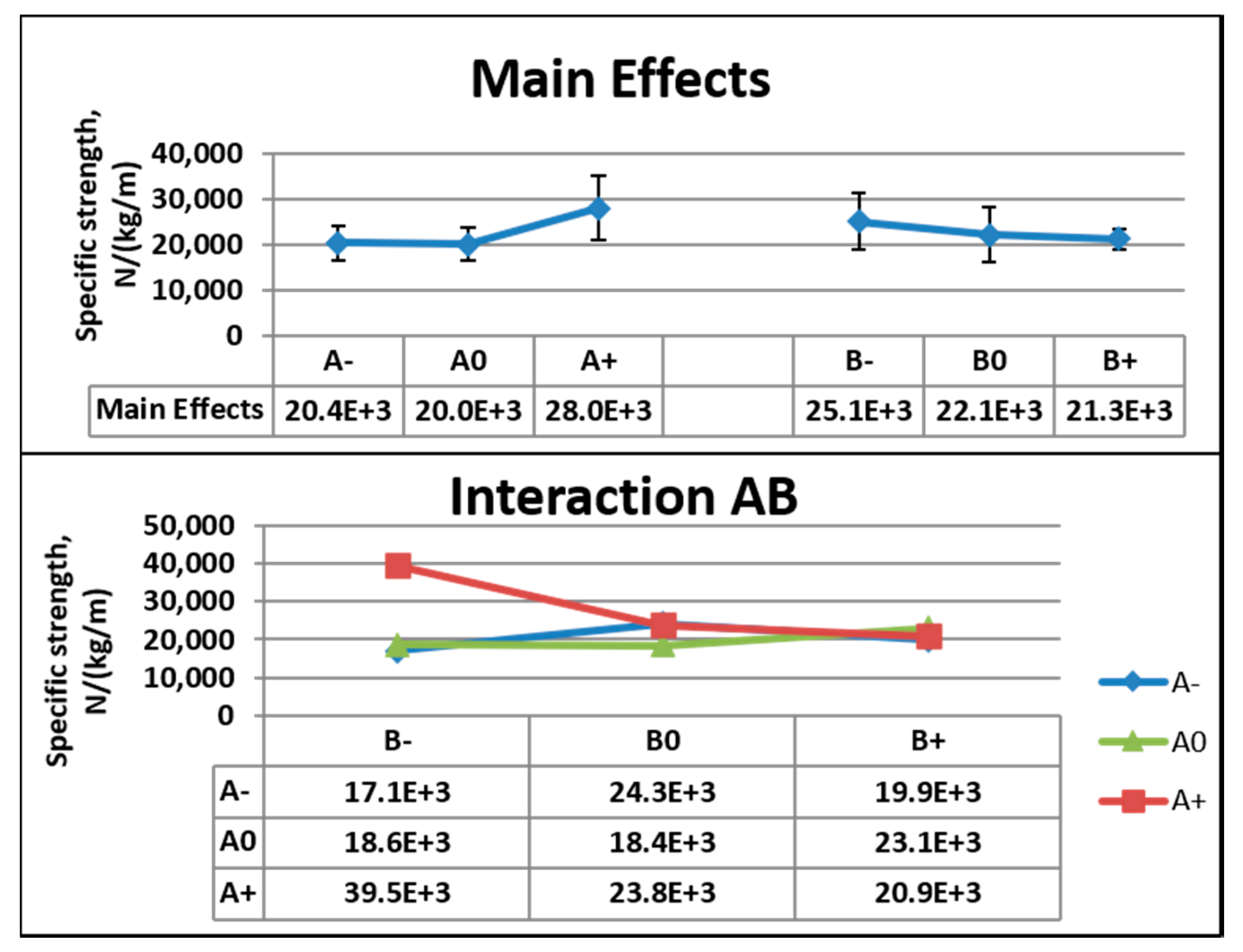

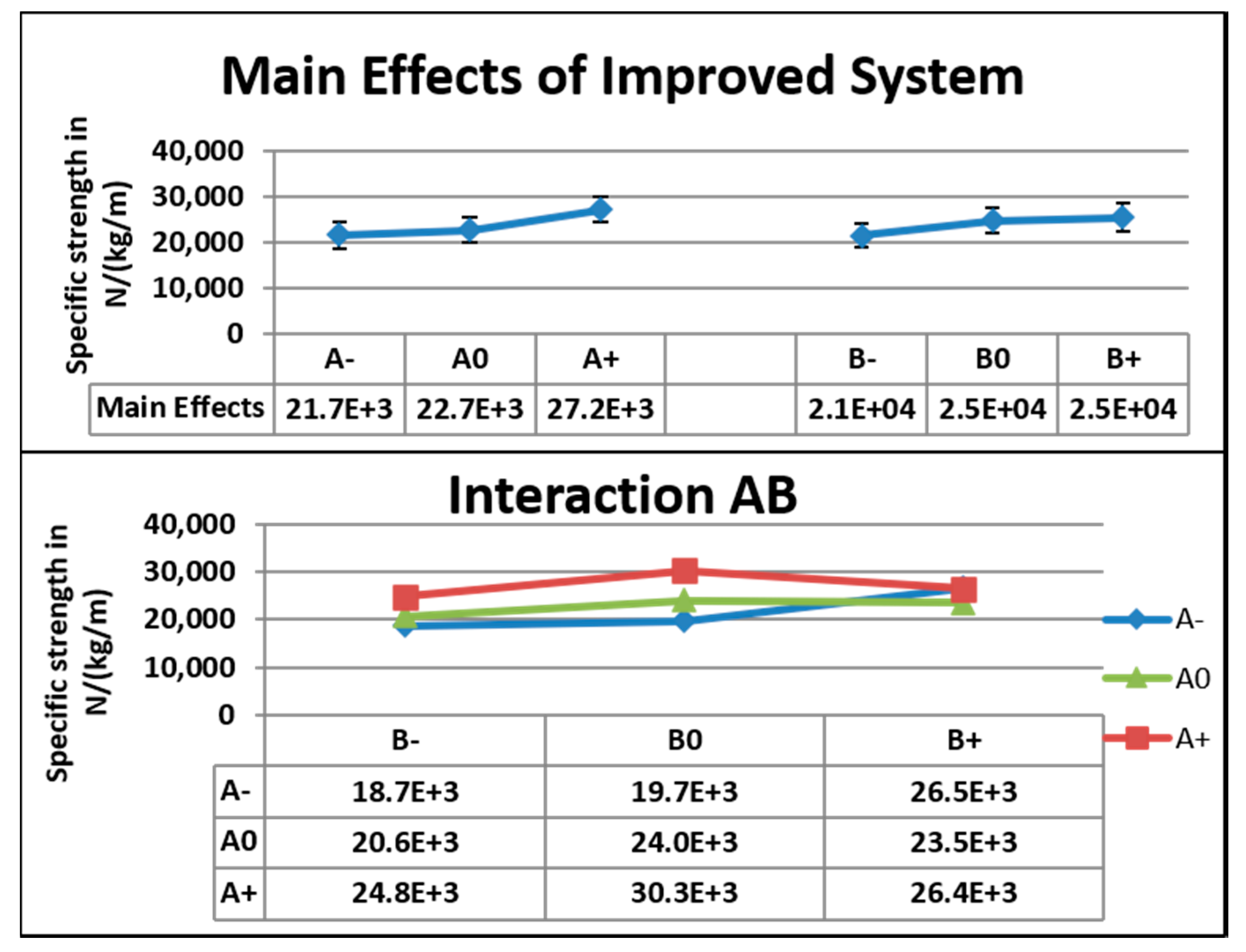

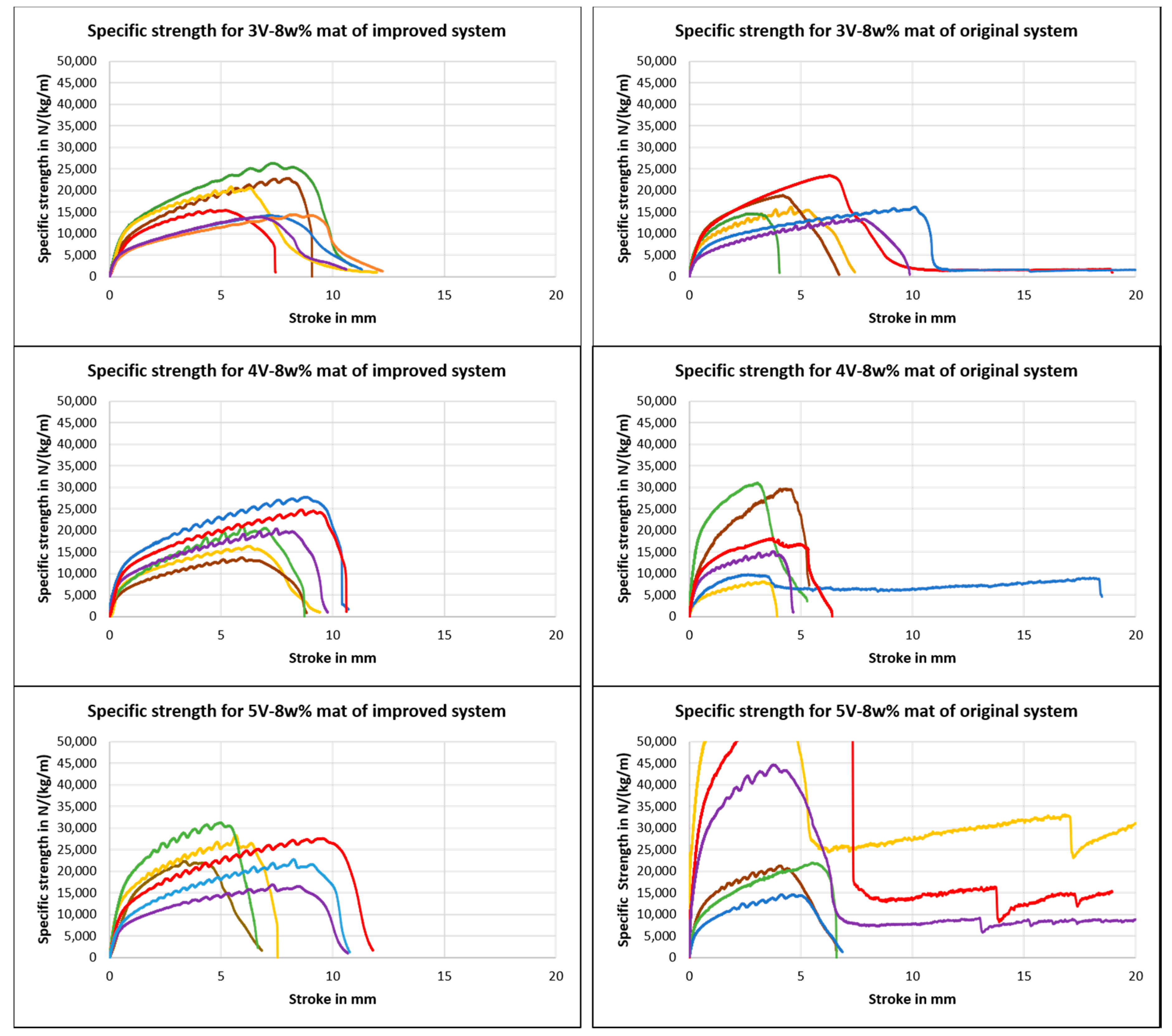

5.2. Tensile—Main Effects and Interactions

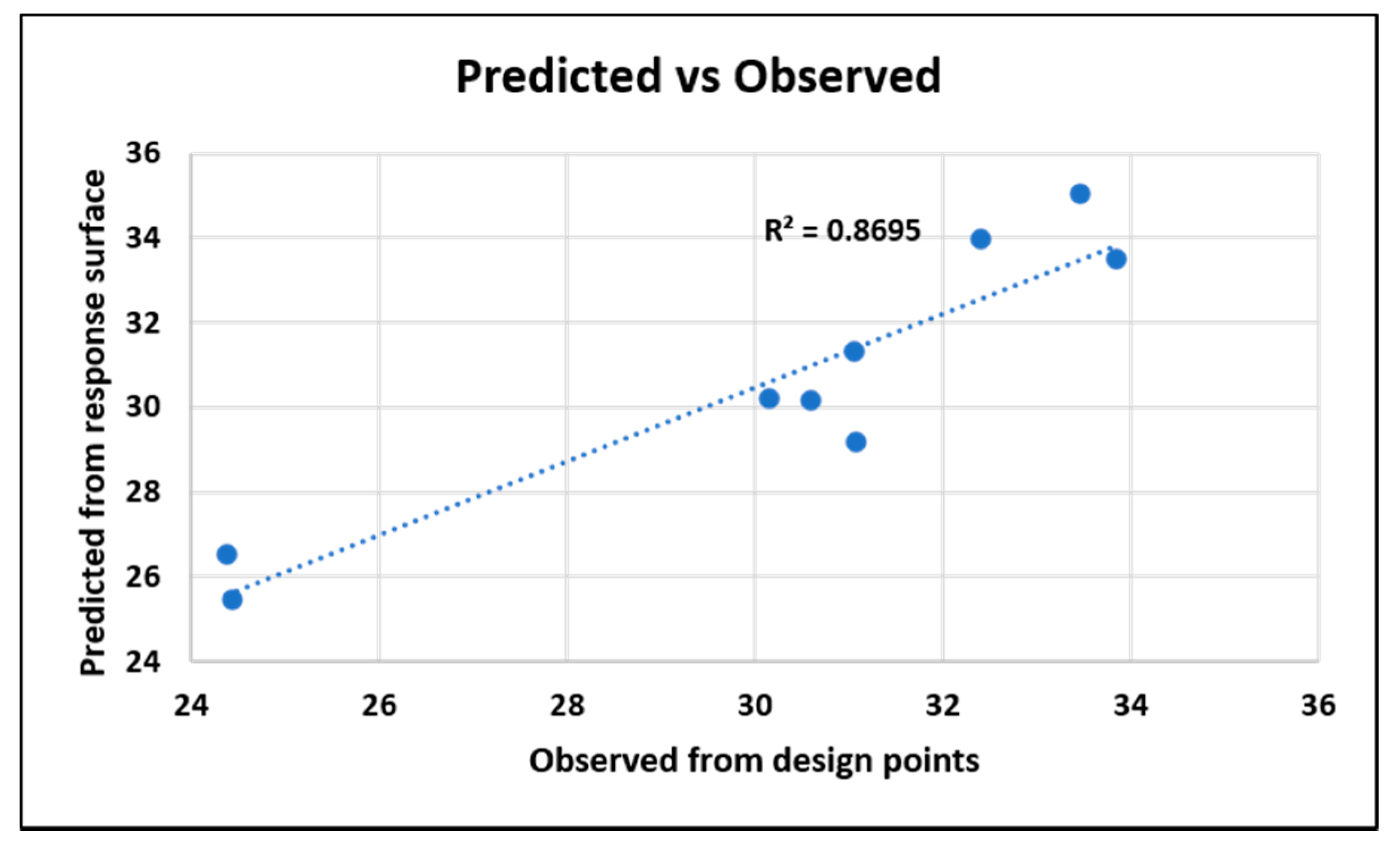

5.3. Linear Regression Model

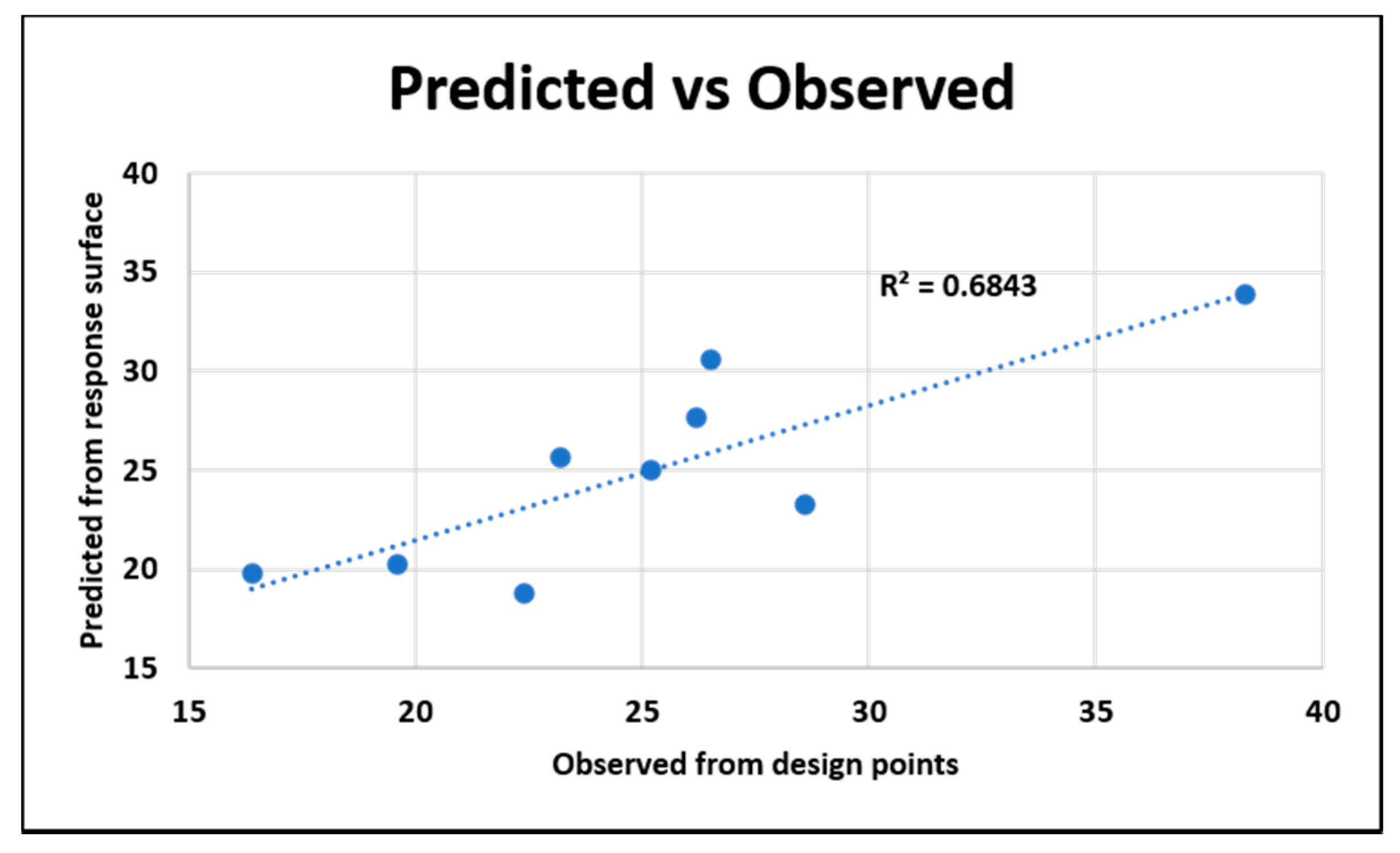

5.3.1. Dielectric—The Original System

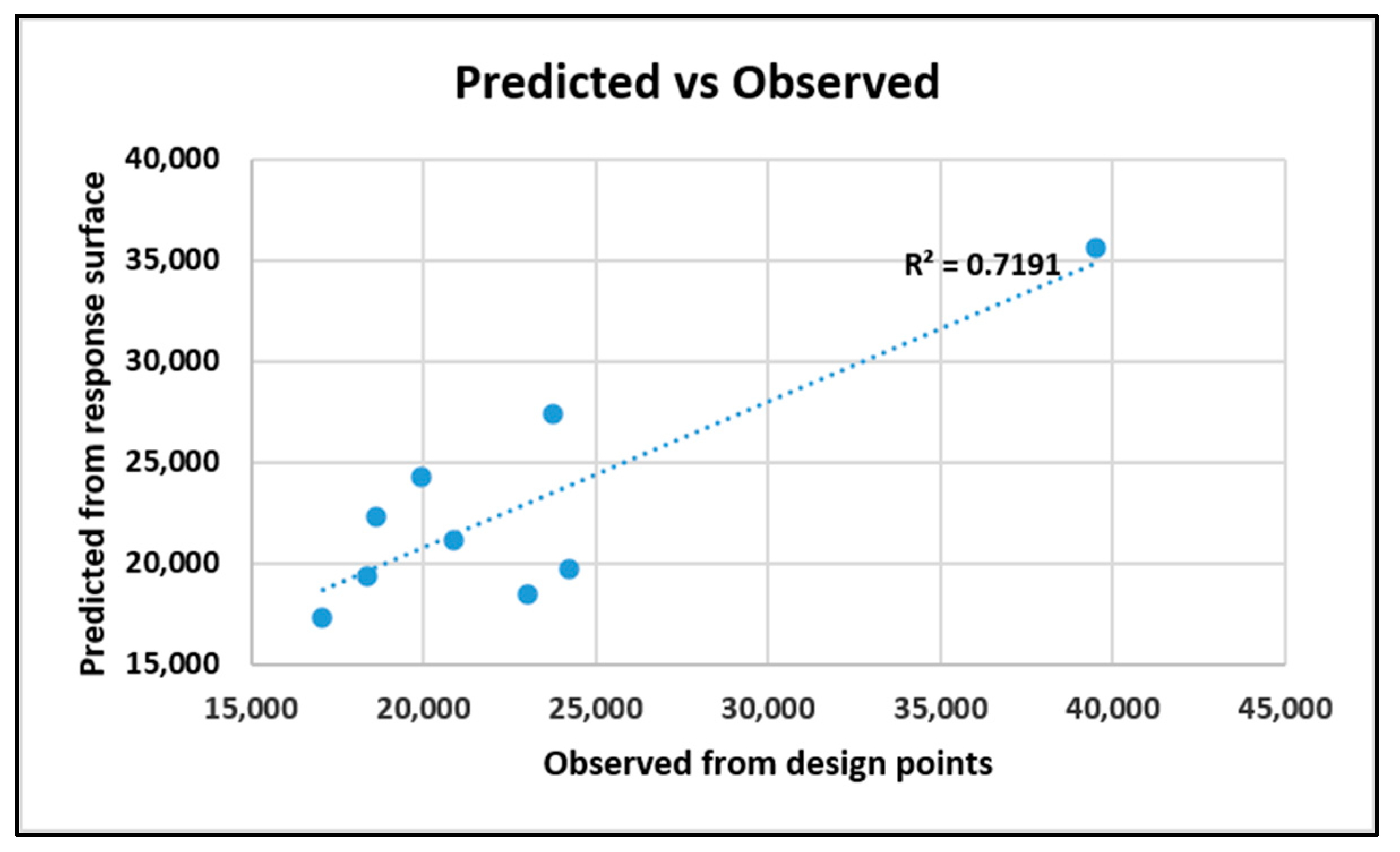

5.3.2. Dielectric—The Improved System

5.3.3. Tensile—The Original System

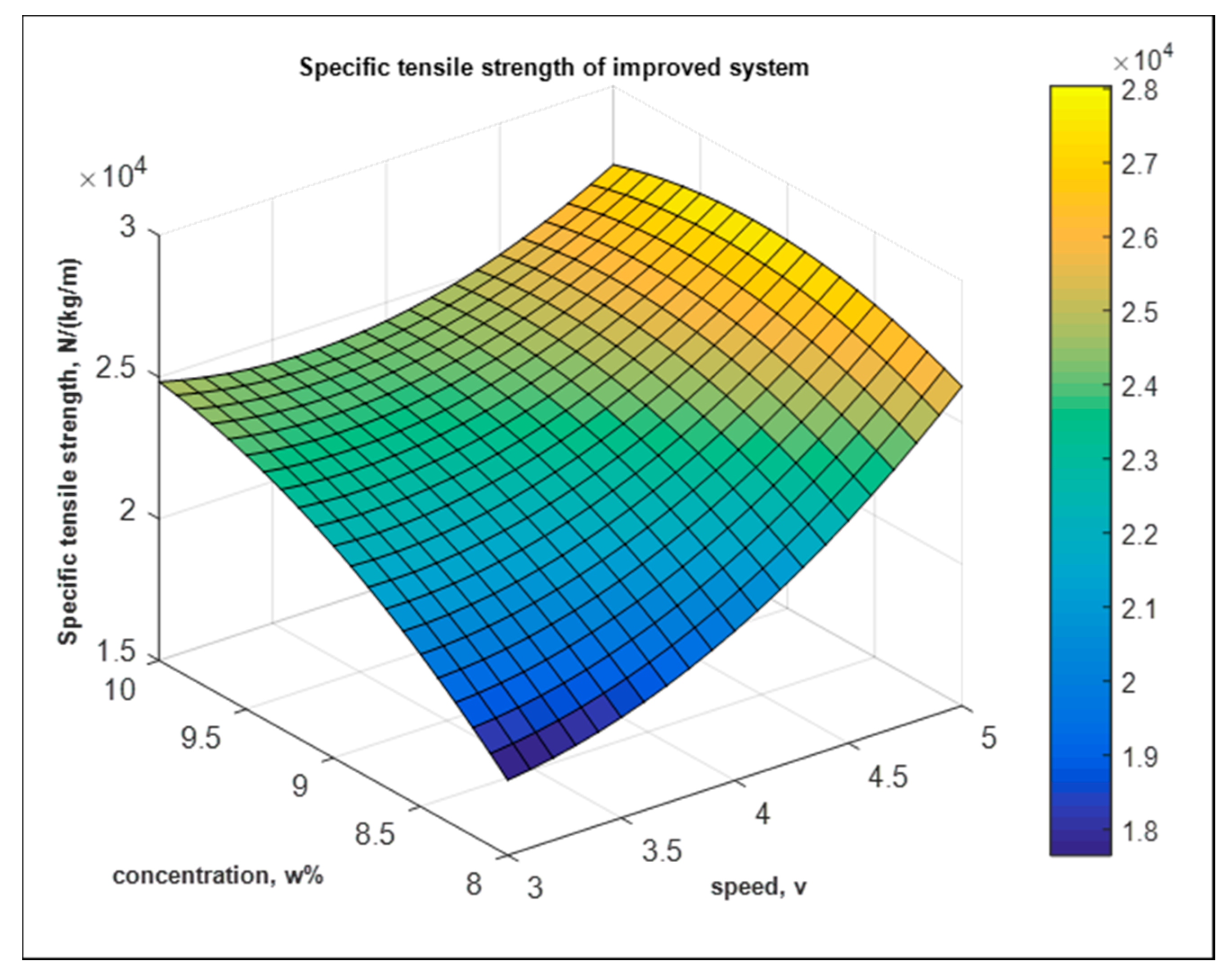

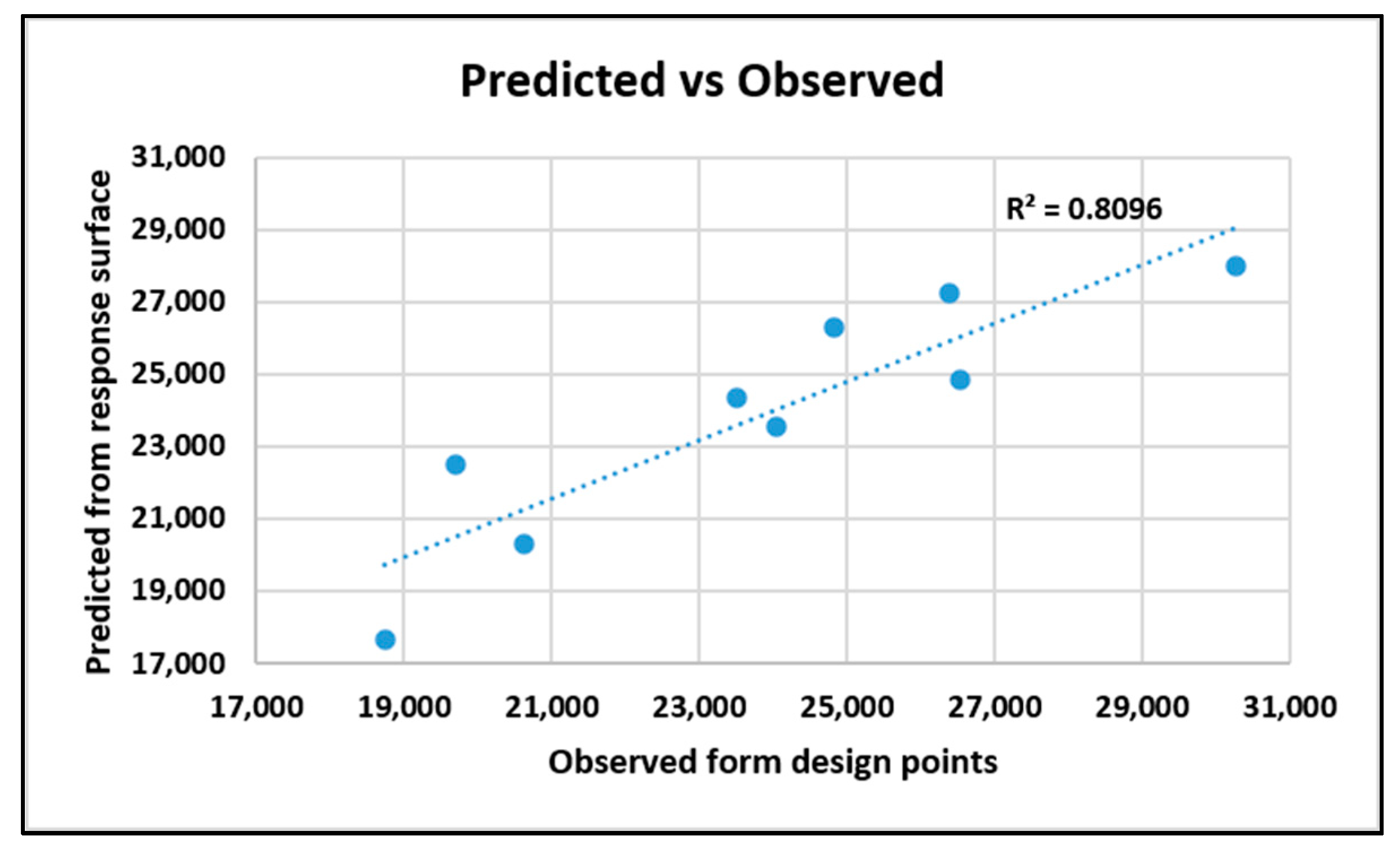

5.3.4. Tensile—The Improved System

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anton, F. Process and Apparatus for Preparing Artificial Threads. U.S. Patent 1,975,504, 2 October 1934. [Google Scholar]

- Taylor, G.I. Disintegration of water drops in an electric field. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1964, 280, 383–397. [Google Scholar]

- Yadav, D.; Amini, F.; Ehrmann, A. Recent advances in carbon nanofibers and their applications—A review. Eur. Polym. J. 2020, 138, 109963. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef] [PubMed]

- Subbiah, T.; Bhat, G.S.; Tock, R.W.; Parameswaran, S.; Ramkumar, S.S. Electrospinning of nanofibers. J. Appl. Polym. Sci. 2005, 96, 557–569. [Google Scholar] [CrossRef]

- Thavasi, V.; Singh, G.; Ramakrishna, S. Electrospun nanofibers in energy and environmental applications. Energy Environ. Sci. 2008, 1, 205–221. [Google Scholar] [CrossRef]

- Kumbar, S.; James, R.; Nukavarapu, S.; Laurencin, C. Electrospun nanofiber scaffolds: Engineering soft tissues. Biomed. Mater. 2008, 3, 034002. [Google Scholar] [CrossRef]

- Fang, J.; Niu, H.; Lin, T.; Wang, X. Applications of electrospun nanofibers. Chin. Sci. Bull. 2008, 53, 2265–2286. [Google Scholar] [CrossRef]

- Coles, S.R.; Jacobs, D.K.; Meredith, J.O.; Barker, G.; Clark, A.J.; Kirwan, K.; Stanger, J.; Tucker, N. A design of experiments (DoE) approach to material properties optimization of electrospun nanofibers. J. Appl. Polym. Sci. 2010, 117, 2251–2257. [Google Scholar] [CrossRef]

- Mohammad Khanlou, H.; Chin Ang, B.; Talebian, S.; Muhammad Afifi, A.; Andriyana, A. Electrospinning of polymethyl methacrylate nanofibers: Optimization of processing parameters using the Taguchi design of experiments. Text. Res. J. 2015, 85, 356–368. [Google Scholar] [CrossRef]

- Ruiter, F.A.A.; Alexander, C.; Rose, F.R.; Segal, J. A design of experiments approach to identify the influencing parameters that determine poly-D, L-lactic acid (PDLLA) electrospun scaffold morphologies. Biomed. Mater. 2017, 12, 055009. [Google Scholar] [CrossRef]

- Albetran, H.; Dong, Y.; Low, I.M. Characterization and optimization of electrospun TiO2/PVP nanofibers using Taguchi design of experiment method. J. Asian Ceram. Soc. 2015, 3, 292–300. [Google Scholar] [CrossRef]

- Seyedmahmoud, R.; Rainer, A.; Mozetic, P.; Maria Giannitelli, S.; Trombetta, M.; Traversa, E.; Licoccia, S.; Rinaldi, A. A primer of statistical methods for correlating parameters and properties of electrospun poly (l-lactide) scaffolds for tissue engineering—PART 1: Design of experiments. J. Biomed. Mater. Res. Part A 2015, 103, 91–102. [Google Scholar] [CrossRef] [PubMed]

- Arshad, S.N.; Naraghi, M.; Chasiotis, I. Strong carbon nanofibers from electrospun polyacrylonitrile. Carbon 2011, 49, 1710–1719. [Google Scholar] [CrossRef]

- Mei, L.; Han, R.; Gao, Y.; Fu, Y.; Liu, Y. Effect of electric field intensity on the morphology of magnetic-field-assisted electrospinning PVP nanofibers. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2013, 28, 1107–1111. [Google Scholar] [CrossRef]

- Papkov, D.; Zou, Y.; Andalib, M.N.; Goponenko, A.; Cheng, S.Z.; Dzenis, Y.A. Simultaneously strong and tough ultrafine continuous nanofibers. ACS Nano 2013, 7, 3324–3331. [Google Scholar] [CrossRef] [PubMed]

- Jalili, R.; Morshed, M.; Ravandi, S.A.H. Fundamental parameters affecting electrospinning of PAN nanofibers as uniaxially aligned fibers. J. Appl. Polym. Sci. 2006, 101, 4350–4357. [Google Scholar] [CrossRef]

- Khan, Z.; Kafiah, F.; Shafi, H.Z.; Nufaiei, F.; Furquan, S.A.; Matin, A. Morphology, mechanical properties and surface characteristics of electrospun polyacrylonitrile (PAN) nanofiber mats. IJAENT 2015, 2, 15–22. [Google Scholar]

- Gu, S.; Ren, J.; Vancso, G. Process optimization and empirical modeling for electrospun polyacrylonitrile (PAN) nanofiber precursor of carbon nanofibers. Eur. Polym. J. 2005, 41, 2559–2568. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer nanocomposites—A comparison between carbon nanotubes, graphene, and clay as nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef]

- Matulevicius, J.; Kliucininkas, L.; Martuzevicius, D.; Krugly, E.; Tichonovas, M.; Baltrusaitis, J. Design and characterization of electrospun polyamide nanofiber media for air filtration applications. J. Nanomater. 2014, 2014, 859656. [Google Scholar] [CrossRef]

- Nataraj, S.; Yang, K.; Aminabhavi, T. Polyacrylonitrile-based nanofibers—A state-of-the-art review. Prog. Polym. Sci. 2012, 37, 487–513. [Google Scholar] [CrossRef]

- Eom, Y.; Kim, B.C. Solubility parameter-based analysis of polyacrylonitrile solutions in N, N-dimethyl formamide and dimethyl sulfoxide. Polymer 2014, 55, 2570–2577. [Google Scholar] [CrossRef]

- Edmondson, D.; Cooper, A.; Jana, S.; Wood, D.; Zhang, M. Centrifugal electrospinning of highly aligned polymer nanofibers over a large area. J. Mater. Chem. 2012, 22, 18646–18652. [Google Scholar] [CrossRef]

- Issa, A.A.; Al-Maadeed, M.A.; Luyt, A.S.; Ponnamma, D.; Hassan, M.K. Physico-mechanical, dielectric, and piezoelectric properties of PVDF electrospun mats containing silver nanoparticles. C—J. Carbon Res. 2017, 3, 30. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, R.; Rodriguez, V.; Ceylan, M. Enhancing thermal and ionic conductivities of electrospun PAN and PMMA nanofibers by graphene nanoflake additions for battery-separator applications. Int. J. Energy Res. 2014, 38, 2044–2051. [Google Scholar] [CrossRef]

- Chen, J.; Harrison, I. Modification of polyacrylonitrile (PAN) carbon fiber precursor via post-spinning plasticization and stretching in dimethyl formamide (DMF). Carbon 2002, 40, 25–45. [Google Scholar] [CrossRef]

- Wan, L.Y.; Wang, H.; Gao, W.; Ko, F. An analysis of the tensile properties of nanofiber mats. Polymer 2015, 73, 62–67. [Google Scholar] [CrossRef]

- Cipitria, A.; Skelton, A.; Dargaville, T.; Dalton, P.; Hutmacher, D. Design, fabrication and characterization of PCL electrospun scaffolds—A review. J. Mater. Chem. 2011, 21, 9419–9453. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Yördem, O.; Papila, M.; Menceloğlu, Y.Z. Effects of electrospinning parameters on polyacrylonitrile nanofiber diameter: An investigation by response surface methodology. Mater. Des. 2008, 29, 34–44. [Google Scholar] [CrossRef]

| Speed A | Concentration B | Tensile | Dielectric | |

|---|---|---|---|---|

| 1 | + | + | 6 | 6 |

| 2 | 0 | + | 6 | 6 |

| 3 | - | + | 6 | 6 |

| 4 | + | 0 | 6 | 6 |

| 5 | 0 | 0 | 6 | 6 |

| 6 | - | 0 | 6 | 6 |

| 7 | + | - | 6 | 6 |

| 8 | 0 | - | 6 | 6 |

| 9 | - | - | 6 | 6 |

| 10 | 54 | 54 |

| Speed A | Concentration B | |

|---|---|---|

| + | 5 V | 10 wt.% |

| - | 3 V | 8 wt.% |

| 0 | 4 V | 9 wt.% |

| Increase in Specific Tensile Strength | Percentage Increase | ||||||

|---|---|---|---|---|---|---|---|

| 10 wt.% | 9 wt.% | 8 wt.% | 10 wt.% | 9 wt.% | 8 wt.% | ||

| 5 V | 55.0 × 102 | 65.2 × 102 | −14.7 × 103 | 5 V | 26.3% | 27.5% | −37.1% |

| 4 V | 4.5 × 102 | 56.4 × 102 | 20.1 × 102 | 4 V | 1.9% | 30.7% | 10.8% |

| 3 V | 66.0 × 102 | −45.6 × 102 | 16.6 × 102 | 3 V | 33.1% | −18.8% | 9.7% |

| Increase in Dielectric Data | Percentage Increase | ||||||

|---|---|---|---|---|---|---|---|

| 10 wt.% | 9 wt.% | 8 wt.% | 10 wt.% | 9 wt.% | 8 wt.% | ||

| 5 V | −14.3 | −1.2 | −8.2 | 5 V | −42.2% | −4.9% | −26.8% |

| 4 V | −2.5 | 1.8 | −13.8 | 4 V | −8.0% | 7.4% | −45.7% |

| 3 V | −5.9 | 7.2 | −8.3 | 3 V | −18.2% | 23.2% | −24.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Isaac, B.; Taylor, R.M.; Reifsnider, K. Anisotropic Characterizations of Electrospun PAN Nanofiber Mats Using Design of Experiments. Nanomaterials 2020, 10, 2273. https://doi.org/10.3390/nano10112273

Isaac B, Taylor RM, Reifsnider K. Anisotropic Characterizations of Electrospun PAN Nanofiber Mats Using Design of Experiments. Nanomaterials. 2020; 10(11):2273. https://doi.org/10.3390/nano10112273

Chicago/Turabian StyleIsaac, Blesson, Robert M. Taylor, and Kenneth Reifsnider. 2020. "Anisotropic Characterizations of Electrospun PAN Nanofiber Mats Using Design of Experiments" Nanomaterials 10, no. 11: 2273. https://doi.org/10.3390/nano10112273

APA StyleIsaac, B., Taylor, R. M., & Reifsnider, K. (2020). Anisotropic Characterizations of Electrospun PAN Nanofiber Mats Using Design of Experiments. Nanomaterials, 10(11), 2273. https://doi.org/10.3390/nano10112273