Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Creating a Library of Microtextured Surfaces with Known Wettability Properties

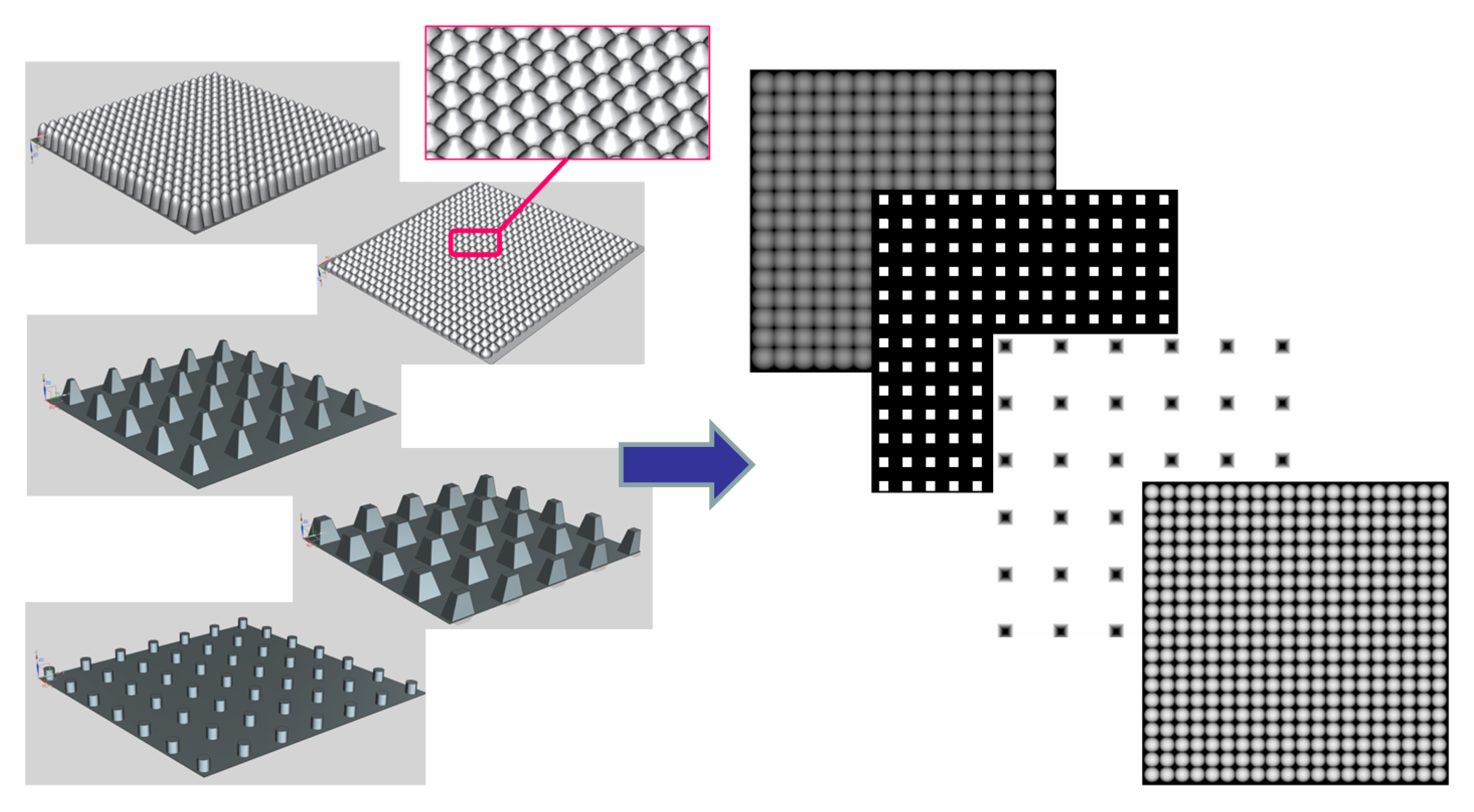

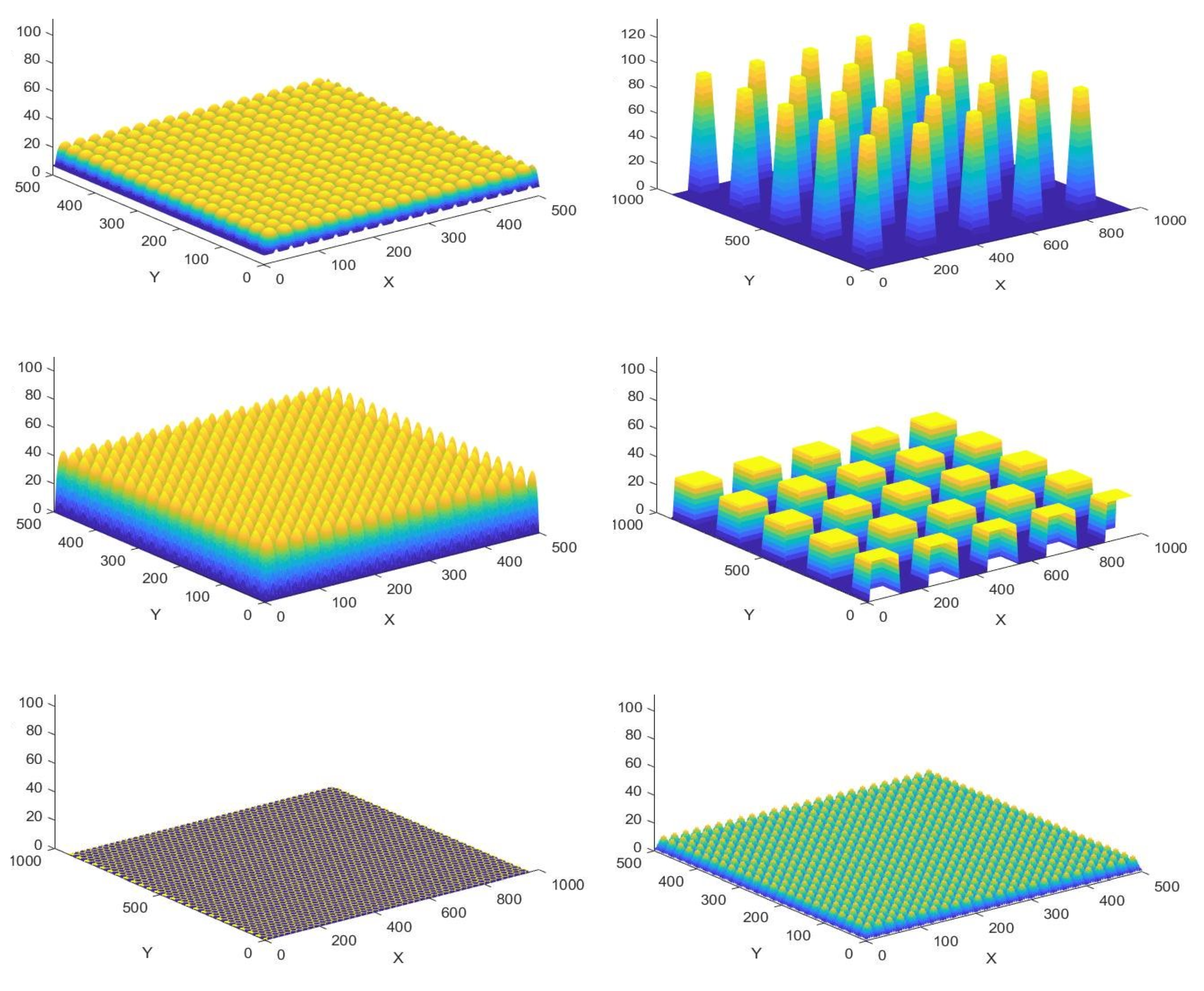

2.2. From 3D CAD Files to Surface Matrices for Further Mathematical Processing

2.3. Structuring and Training Artificial Neural Networks for Predicting the Wettability of Surfaces

2.4. Applying Artificial Intelligence to the Design of Surfaces with Controlled Wettability

2.4.1. Design of Innovative Microtextured Surfaces for Validating the Global Strategy

2.4.2. Manufacturing Prototypes of Innovative Microtextured Surfaces for Physical Testing

2.4.3. Wettability Testing and Imaging Procedures and Resources

3. Results and Discussion

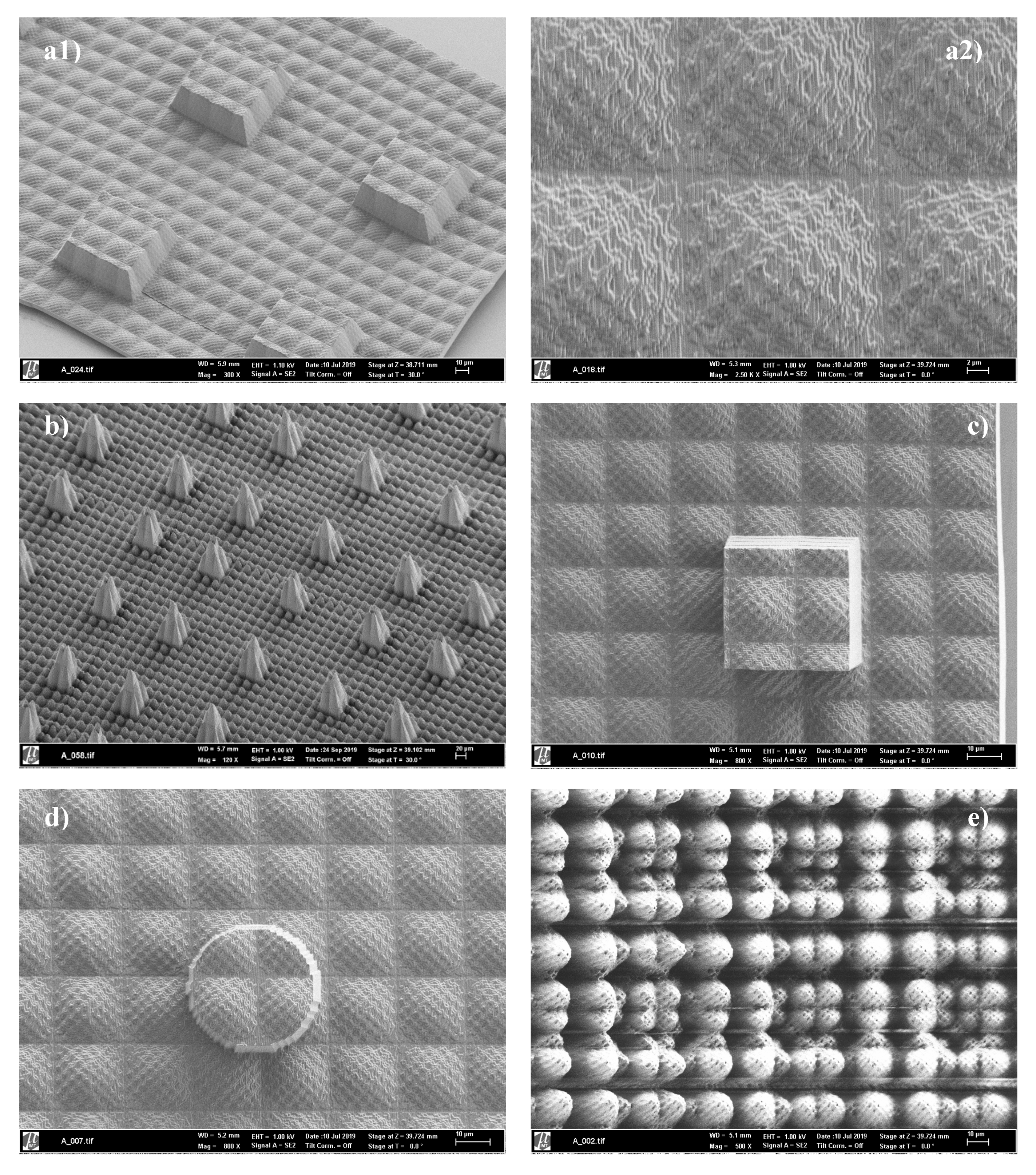

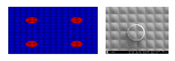

3.1. CAD Models, Prototypes and Wetting Response of the Innovative Microtextured Surfaces

3.2. Performance of the Structured and Trained Artificial Neural Networks: Predictions vs. Real Performance

4. Challenges and Future Proposals

4.1. Potentials, Limitations and Challenges of the Study

4.2. Future Research Proposals

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Interagency Materials Genome Initiative Web Portal. Available online: https://www.mgi.gov (accessed on 1 September 2020).

- NIST. Gateway to Materials Genome Information. Available online: https://mgi.nist.gov/ (accessed on 1 September 2020).

- Liu, Z.H. Perspective on Materials Genome®. Chin. Sci. Bull. 2014, 59, 1619–1623. [Google Scholar] [CrossRef]

- Qian, C.; Siler, T.; Ozin, G.A. Exploring the possibilities and limitations of a nanomaterials genome. Small 2015, 11, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Raccuglia, P.; Elbert, K.C.; Adler, P.D.F.; Falk, C.; Wenny, M.B.; Mollo, A.; Zeller, M.; Friedler, S.A.; Schrier, J. Machine-learning-assisted materials discovery using failed experiments. Nature 2016, 533, 73–76. [Google Scholar] [CrossRef] [PubMed]

- EU Materials Modeling Council Vision. Available online: https://emmc.info/vision-beyond-h2020/ (accessed on 1 September 2020).

- Lu, W.; Xiao, R.; Yang, J.; Li, H.; Zhang, W. Data-mining aided materials discovery and optimization. J. Mater. 2017, 3, 191–201. [Google Scholar] [CrossRef]

- Winkler, D.A. Biomimetic molecular design tools that learn, evolve, and adapt. Beilstein J. Org. Chem. 2017, 13, 1288–1302. [Google Scholar] [CrossRef] [Green Version]

- Jose, R.; Ramakrishna, S. Materials 4.0: Materials big data enabled materials discovery. Appl. Mater. Today 2018, 10, 127–132. [Google Scholar] [CrossRef]

- Archard, J. Surface topography and tribology. Tribology 1974, 7, 213–220. [Google Scholar] [CrossRef]

- Bushan, B.; Israelachvili, J.; Landman, U. Nanotribology: Friction, wear and lubrication at the atomic scale. Nature 1995, 374, 607–616. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Lafuma, A.; Quere, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef]

- Buxboim, A.; Discher, D.E. Stem cells feel the difference. Nat. Methods 2010, 7, 695–697. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, X.; Peng, R.; Ding, J. Cell-material interactions revealed via material techniques of surface patterning. Mater. Views 2013, 25, 5257–5286. [Google Scholar] [CrossRef] [PubMed]

- Jeon, H.; Koo, S.; Reese, W.M.; Loskills, P.; Grigoropoulos, C.P.; Healy, K.E. Directing cell migration and organization via nanocrater-patterned cell-repellent interfaces. Nat. Mater. 2015, 14, 918–923. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Briones, V.; Aguilera, J.M.; Brown, C. The effect of surface topography on color and gloss of chocolate samples. J. Food Eng. 2006, 77, 776–783. [Google Scholar] [CrossRef]

- Wenzel, R.W. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546. [Google Scholar] [CrossRef]

- Sabatini, E.; Cohen-Boulakia, J.; Bruenig, M.; Rubinstein, I. Thioaromatic monolayers on gold: A new family of self-assembling monolayers. Langmuir 1993, 9, 2974–2981. [Google Scholar] [CrossRef]

- Crudden, C.; Horton, J.; Ebralidze, I.; Zenkina, O.V.; McLean, A.B.; Drevniok, B.; She, Z.; Kraatz, H.B.; Mosey, N.J.; Seki, T.; et al. Ultra-stable self-assembled monolayers of N-heterocyclic carbenes on gold. Nat. Chem. 2014, 6, 409–414. [Google Scholar] [CrossRef]

- Ebralidze, I.I.; Hanif, M.; Arjumand, R.; Azmi, A.A.; Dixon, D.; Cann, N.M.; Crudden, C.M.; Horton, J.H. Solvent induced adhesion interactions between dichlorotriazine films. J. Phys. Chem. C 2012, 116, 4217–4223. [Google Scholar] [CrossRef]

- Hezi-Yamit, A.; Sullivan, C.; Wong, J.; David, L.; Chen, M.; Cheng, P.; Shumaker, D.; Wilcox, J.N.; Udipi, K. Impact of polymer hydrophilicity on biocompatibility: Implication for DES polymer design. J. Biomed. Mater. Res. A 2009, 90, 133–141. [Google Scholar] [CrossRef]

- Singh, A.V.; Baylan, S.; Park, B.W.; Richter, G.; Sitti, M. Hydrophobic pinning with copper nanowhiskers leads to bactericidal properties. PLoS ONE 2017, 12, e0175428. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ueda, E.; Levkin, P.A. Emerging applications of superhydrophilic-superhydrophobic micropatterns. Adv. Mater. 2013, 25, 1234–1247. [Google Scholar] [CrossRef]

- Geyer, F.L.; Ueda, E.; Liebel, U.; Grau, N.; Levkin, P.A. Superhydrophobic–superhydrophilic micropatterning: Towards genome-on-a-chip cell microarrays. Angew. Chem. Int. Ed. 2011, 50, 8424–8427. [Google Scholar] [CrossRef]

- Abagnale, G.; Sechi, A.; Steger, M.; Zhou, Q.; Kuo, C.-C.; Aydin, G.; Schalla, C.; Muller-Newen, G.; Zenke, M.; Costa, I.G.; et al. Surface topography guides morphology and spatial patterning of induced pluripotent stem cell colonies. Stem Cell Rep. 2017, 9, 654–666. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hengsbach, S.; Díaz Lantada, A. Rapid prototyping of multi-scale biomedical microdevices by combining additive manufacturing technologies. Biomed. Microdev. 2014, 16, 617–627. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Díaz Lantada, A.; Piotter, V.; Plewa, K.; Barie, N.; Guttmann, M.; Wissmann, M. Toward mass production of microtextured microdevices: Linking rapid prototyping with microinjection molding. Int. J. Adv. Manuf. Technol. 2015, 76, 1011–1020. [Google Scholar] [CrossRef] [Green Version]

- Díaz Lantada, A.; Hengsbach, S.; Bade, K. Lotus-on-chip: Computer-aided design and 3D direct laser writing of bioinspired surfaces for controlling the wettability of materials and devices. Bioinspir. Biomim. 2017, 12, 066004. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.; Chang, W.; Luo, X.; Qin, Y. Hydrophobicity of Pyramid Structures Fabricated by Micro Milling. In Proceedings of the 2017 World Congress on Micro and Nano Manufacturing, Kaohsiung, Taiwan, 27–30 March 2017; pp. 1–4. [Google Scholar]

- Fernández, A.; Francone, A.; Thamdrup, L.H.; Johansson, A.; Bilenberg, B.; Nielsen, T.; Guttman, M.; Sotomayot Torres, C.M.; Kehagias, N. Hierarchical surfaces for enhanced self-cleaning applications. J. Micromech. Microeng. 2017, 27, 045020. [Google Scholar] [CrossRef]

- Schulte, A.J.; Droste, D.M.; Koch, K.; Barthlott, W. Hierarchically structured superhydrophobic flowers with low hysteresis of the wild pansy (Viola tricolor)-new design principles for biomimetic materials. Beilstein J. Nanotechnol. 2011, 2, 228–236. [Google Scholar] [CrossRef] [Green Version]

- Weng, C.; Wang, F.; Zhou, M.; Yang, D.; Jiang, B. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Fernández, A.; Francone, A.; Johansson, A.; Bilenberd, B. Design of hierarchical surfaces for tuning wetting characteristics. ACS Appl. Mater. Interfaces 2017, 9, 7701–7709. [Google Scholar] [CrossRef] [PubMed]

- Demuth, H.; Beale, M. Neuronal Network Toolbox User’s Guide. Version 4; The MathWorks Inc.: Natick, MA, USA, 2004. [Google Scholar]

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Epiphany_(feeling) (accessed on 1 September 2020).

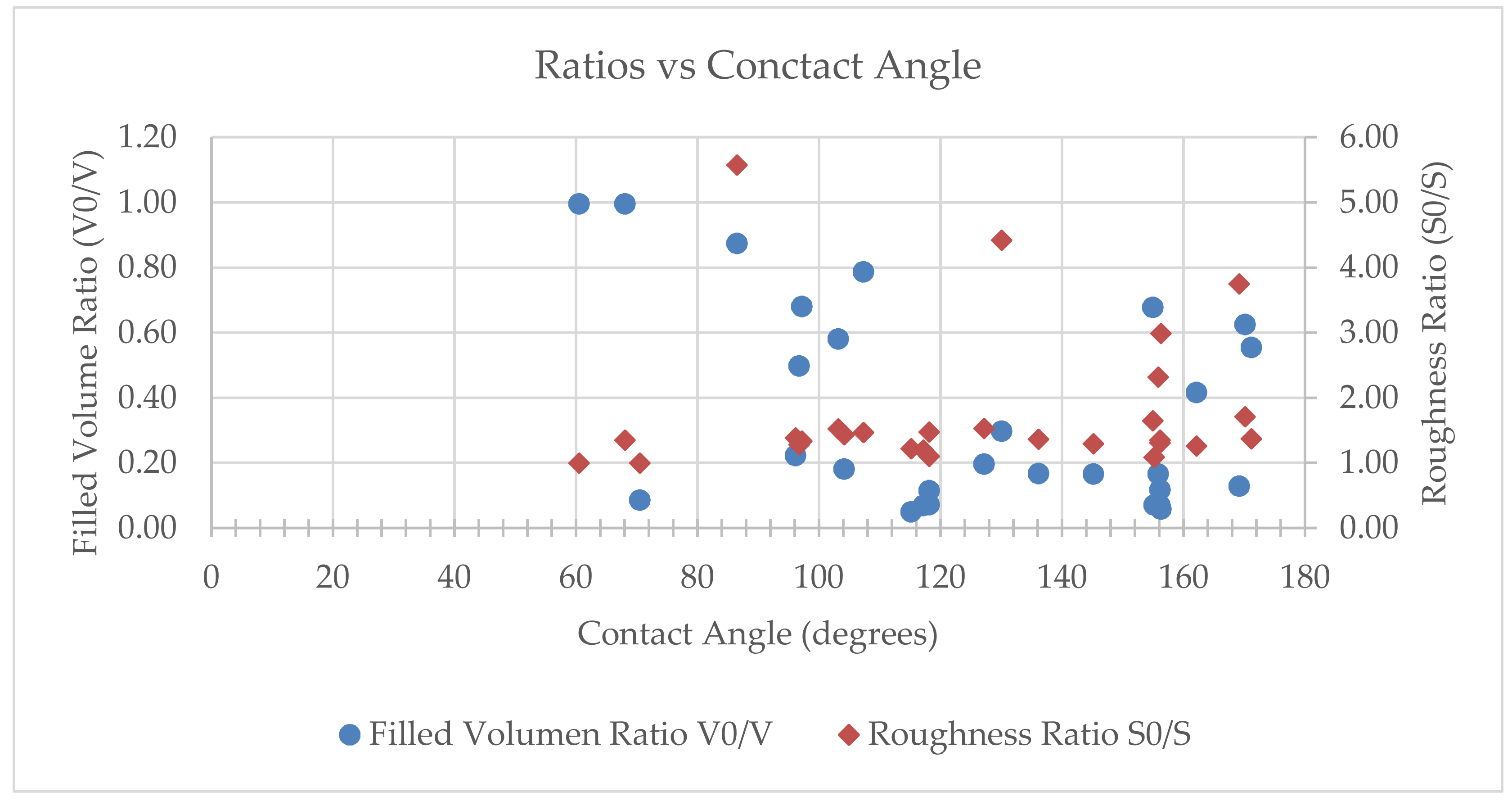

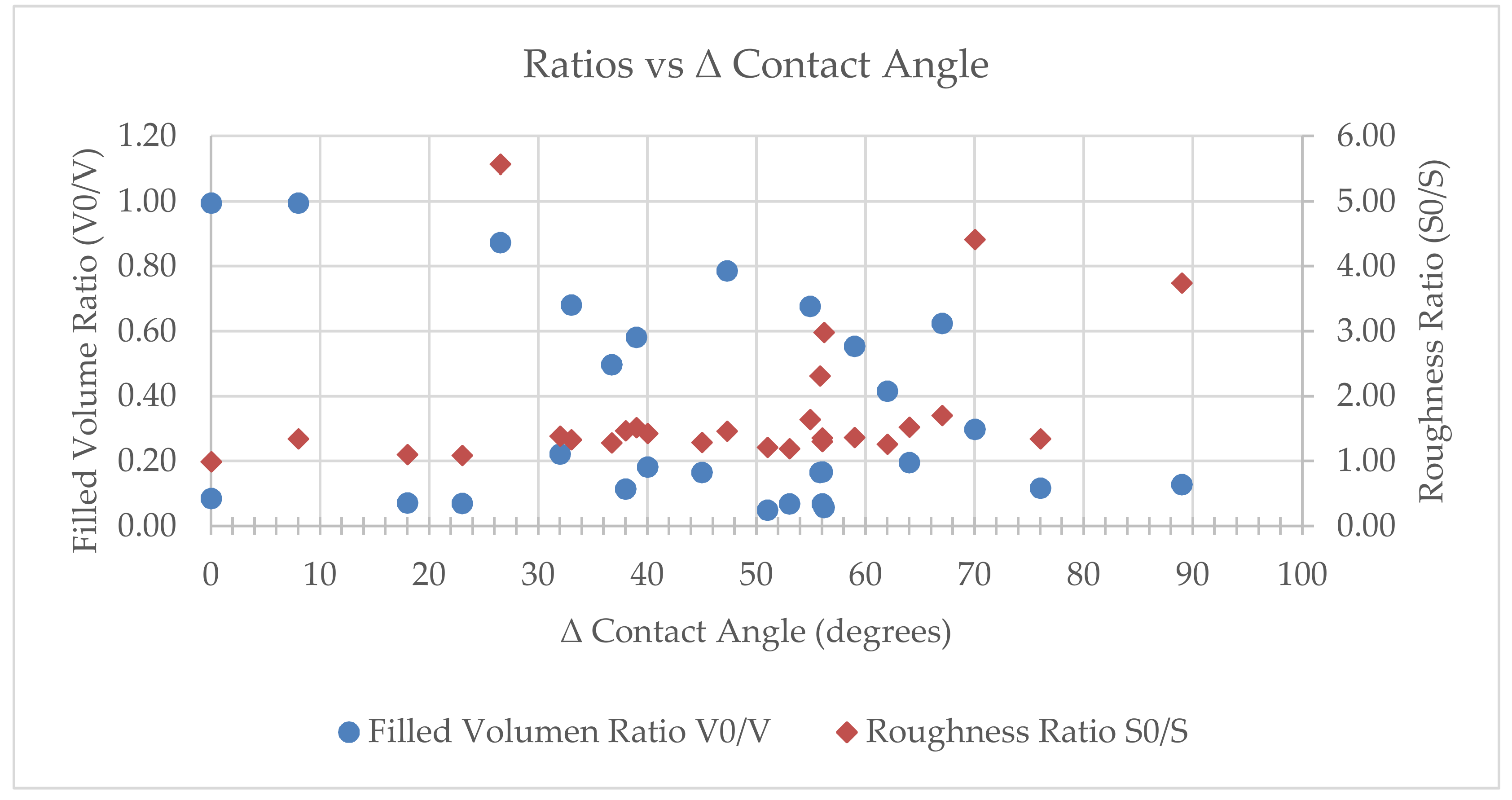

| Surface View | Surface | CA (°) | ΔCA (°) | V0/V | S0/S | Ref. |

|---|---|---|---|---|---|---|

| 1 | ≈60 | 0 | 0.996004 (1.0) | 0.996004 (1.0) | Present study |

| 2 | ≈70 | 0 | 0.996004 (1.0) | 0.996004 (1.0) | [27] |

| 3 | 96 | 32 | 0.681005 | 1.385686 | [28] |

| 4 | 97 | 33 | 0.581493 | 1.332758 | [28] |

| 5 | 103 | 39 | 0.050000 | 1.520136 | [28] |

| 6 | 104 | 40 | 0.06869 | 1.433589 | [28] |

| 7 | 115 | 51 | 0.196086 | 1.219188 | [28] |

| 8 | 117 | 53 | 0.297979 | 1.196545 | [28] |

| 9 | 118 | 18 | 0.874239 | 1.102110 | [29] |

| 10 | 118 | 38 | 0.787298 | 1.470737 | [30] |

| 11 | 127 | 64 | 0.117611 | 1.529714 | [28] |

| 12 | 136 | 56 | 0.677470 | 1.364492 | [30] |

| 13 | 145 | 45 | 0.072338 | 1.293813 | [29] |

| 14 | 154.9 | 54.9 | 0.167083 | 1.645769 | [31] |

| 15 | 155 | 23 | 0.222987 | 1.08823 | [29] |

| 16 | 155.8 | 55.8 | 0.166315 | 2.317966 | [31] |

| 17 | 156 | 56 | 0.069969 | 1.305968 | [29] |

| 18 | 156.2 | 56.2 | 0.166411 | 2.987631 | [31] |

| 19 | 156 | 76 | 0.624982 | 1.349546 | [30] |

| 20 | 162 | 62 | 0.057735 | 1.261909 | [32] |

| 21 | 169 | 89 | 0.554934 | 3.748147 | [30] |

| 22 | 170 | 67 | 0.415654 | 1.707897 | [27] |

| 23 | 171 | 59 | 0.069264 | 1.366480 | [29] |

| Neuronal Network | Neurons | AE1 (°) | AE2 (°) | AE3 (°) | AE4 (°) | AE5 (°) |

|---|---|---|---|---|---|---|

| 1 | 8 | 3.713 | 3.074 | 1.288 | 36.671 | 0.268 |

| 2 | 7 | 0.235 | 2.295 | 3.9059 | 31.927 | 0.763 |

| 3 | 13 | 3.207 | 0.061 | 1.138 | 39.448 | 0.183 |

| Surface View (CAD and Prototype) | CAm (°) | ΔCAm (°) | CAp (°) | ΔCAp (°) | V0/V | S0/S | AE (°) |

|---|---|---|---|---|---|---|---|

| 96.7 | 36.7 | 96.9352 | 36.9352 | 0.1819 | 1.2823 | 0.235 |

| 130 | 70 | 129.9391 | 69.9391 | 0.1290 | 4.4183 | 2.295 |

| 107.3 | 47.3 | 106.1618 | 46.1618 | 0.1147 | 1.4630 | 3.9059 |

| 68 | 8 | 99.9270 | 39.9270 | 0.0856 | 1.3471 | 31.927 |

| 86.5 | 26.5 | 86.3132 | 26.3132 | 0.4977 | 5.5729 | 0.763 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz Lantada, A.; Franco-Martínez, F.; Hengsbach, S.; Rupp, F.; Thelen, R.; Bade, K. Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability. Nanomaterials 2020, 10, 2287. https://doi.org/10.3390/nano10112287

Díaz Lantada A, Franco-Martínez F, Hengsbach S, Rupp F, Thelen R, Bade K. Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability. Nanomaterials. 2020; 10(11):2287. https://doi.org/10.3390/nano10112287

Chicago/Turabian StyleDíaz Lantada, Andrés, Francisco Franco-Martínez, Stefan Hengsbach, Florian Rupp, Richard Thelen, and Klaus Bade. 2020. "Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability" Nanomaterials 10, no. 11: 2287. https://doi.org/10.3390/nano10112287

APA StyleDíaz Lantada, A., Franco-Martínez, F., Hengsbach, S., Rupp, F., Thelen, R., & Bade, K. (2020). Artificial Intelligence Aided Design of Microtextured Surfaces: Application to Controlling Wettability. Nanomaterials, 10(11), 2287. https://doi.org/10.3390/nano10112287