Poly (Vinyl Alcohol) Assisted Synthesis and Anti-Solvent Precipitation of Gold Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Gold Nanoparticle Synthesis

2.3. Further Extraction of GNPs: Anti-Solvent Precipitation

2.4. Optical Characterization and Electron Microscopy

3. Results and Discussion

3.1. PVA Speeds up Formation of Gold Nanoparticles

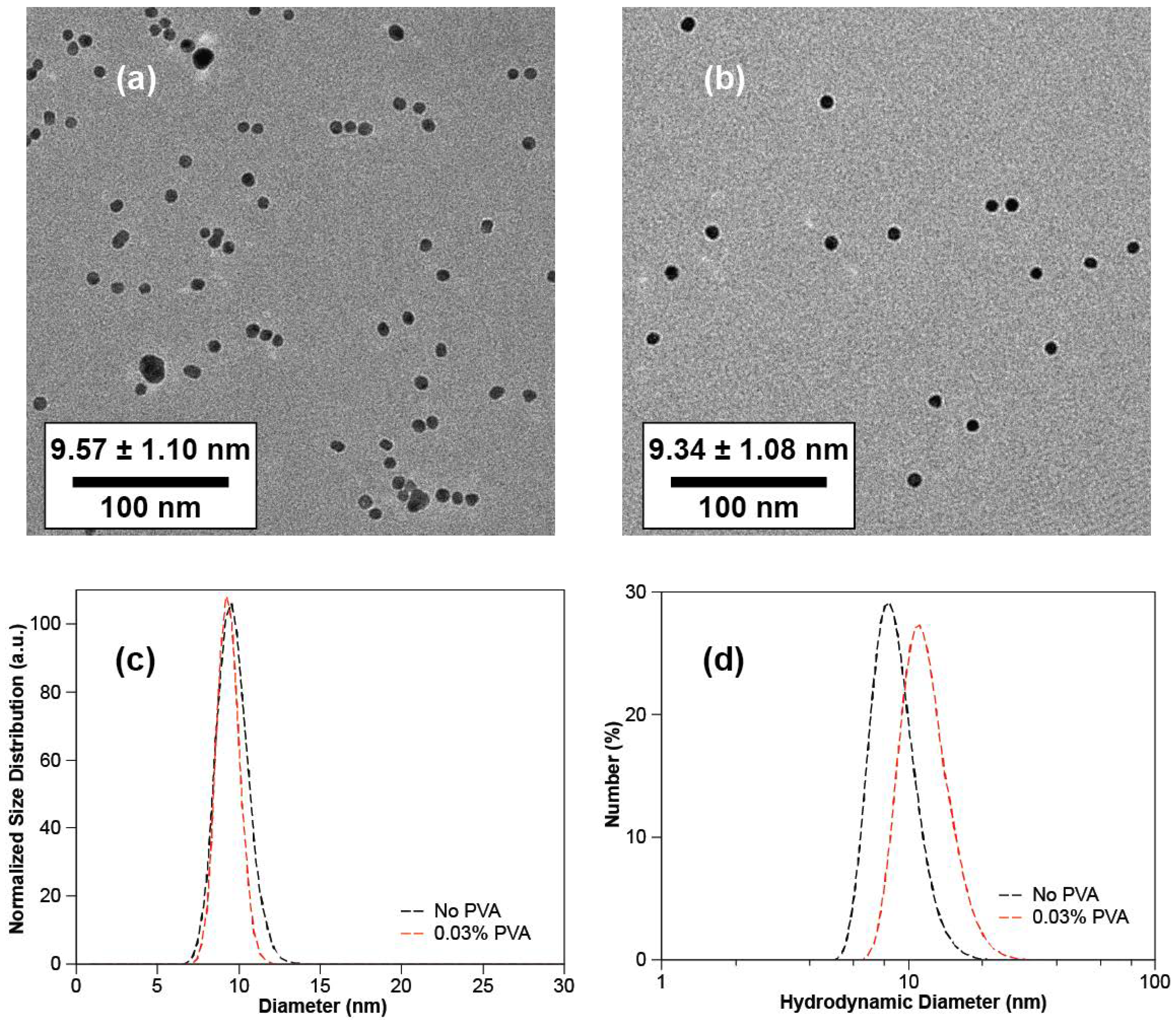

3.2. Impact of PVA on Particles Size

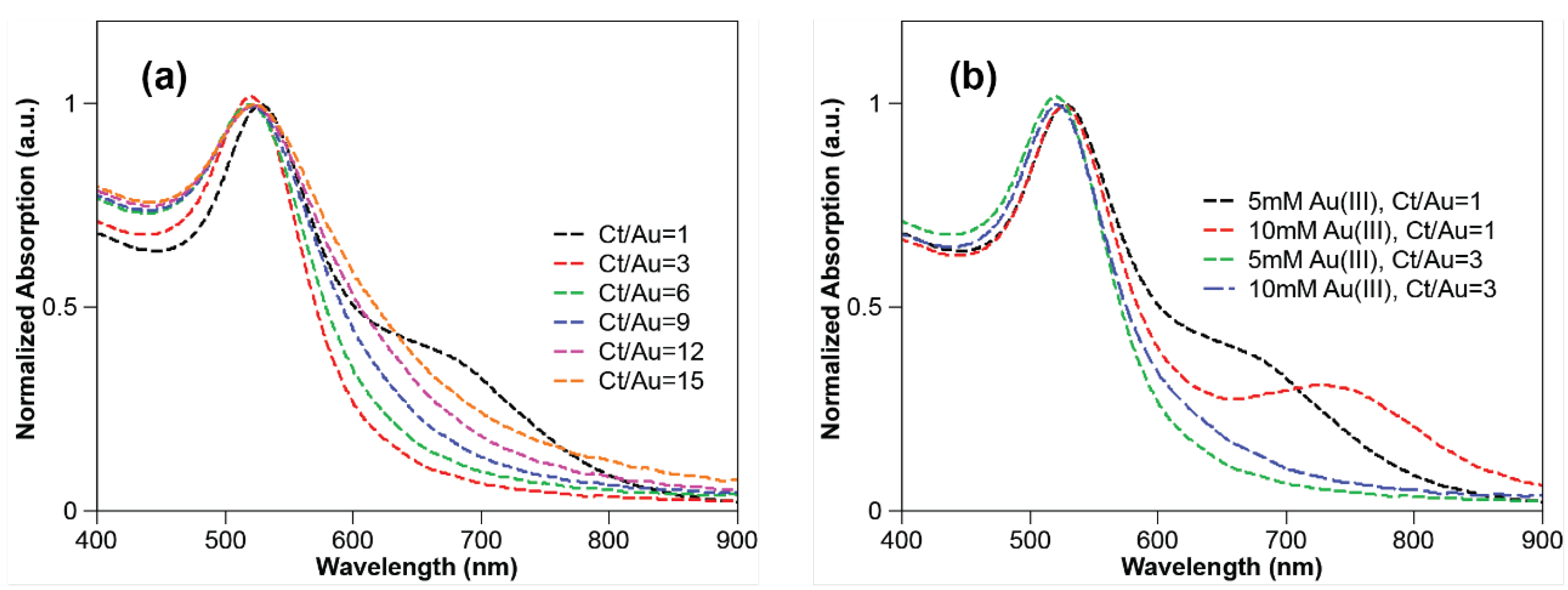

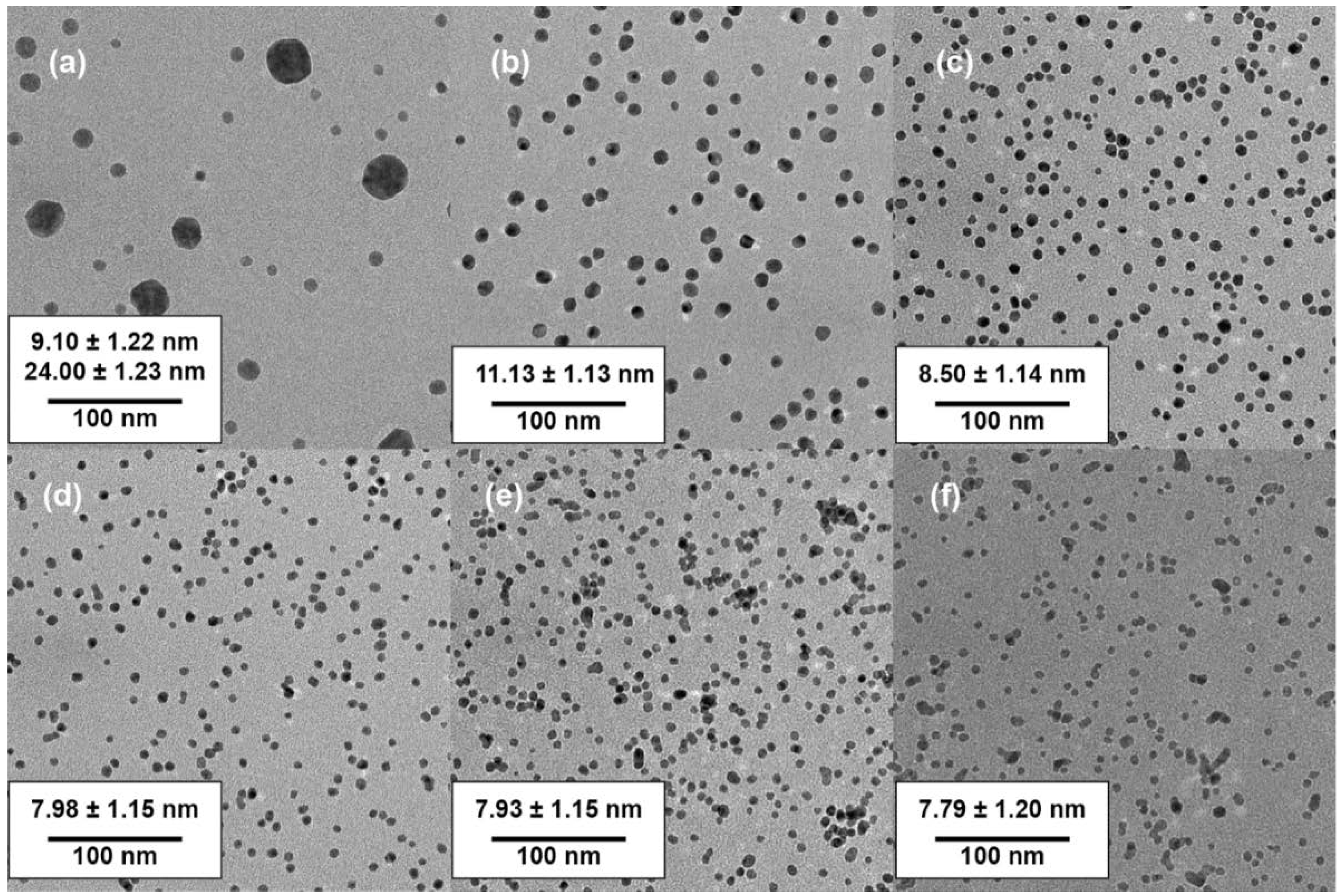

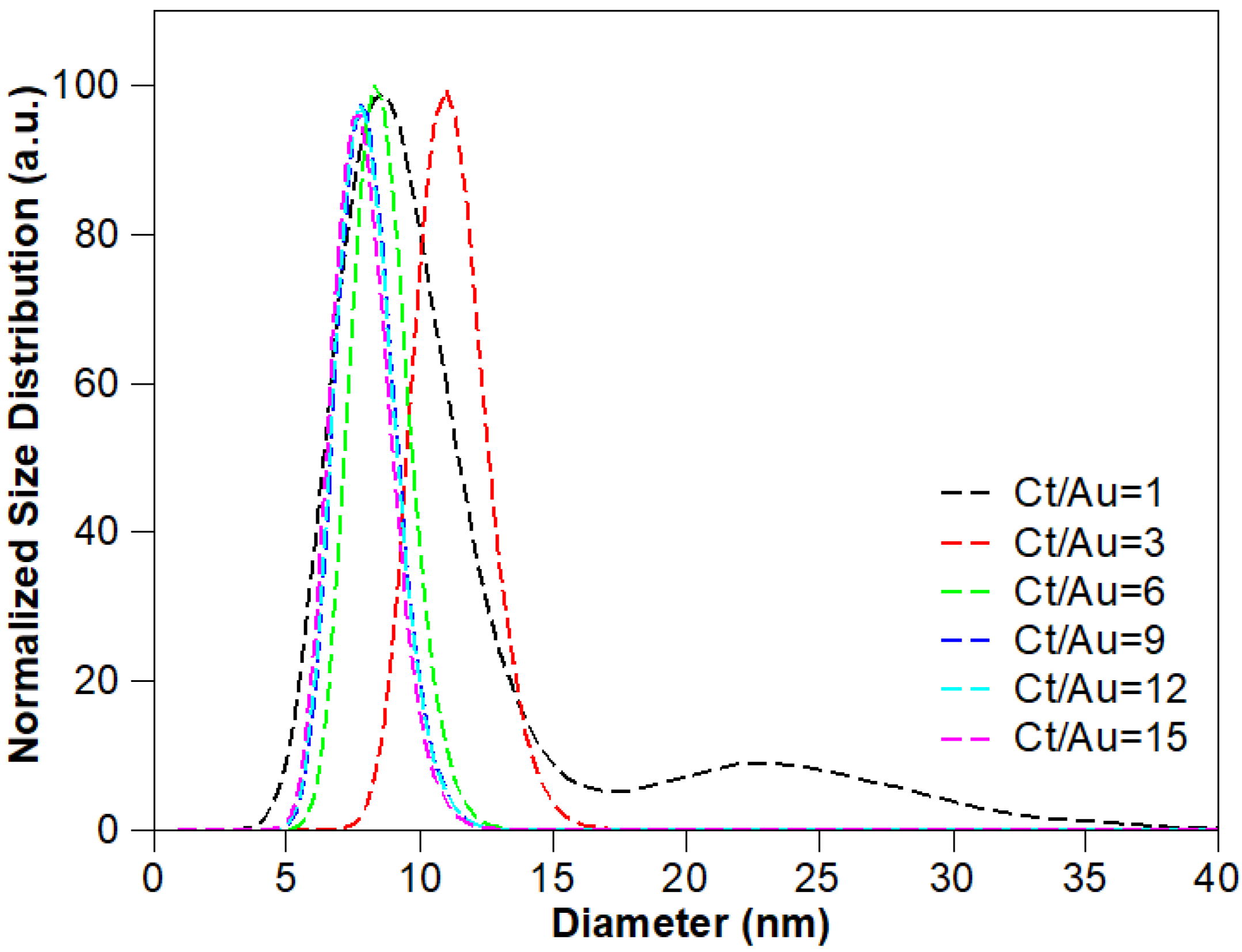

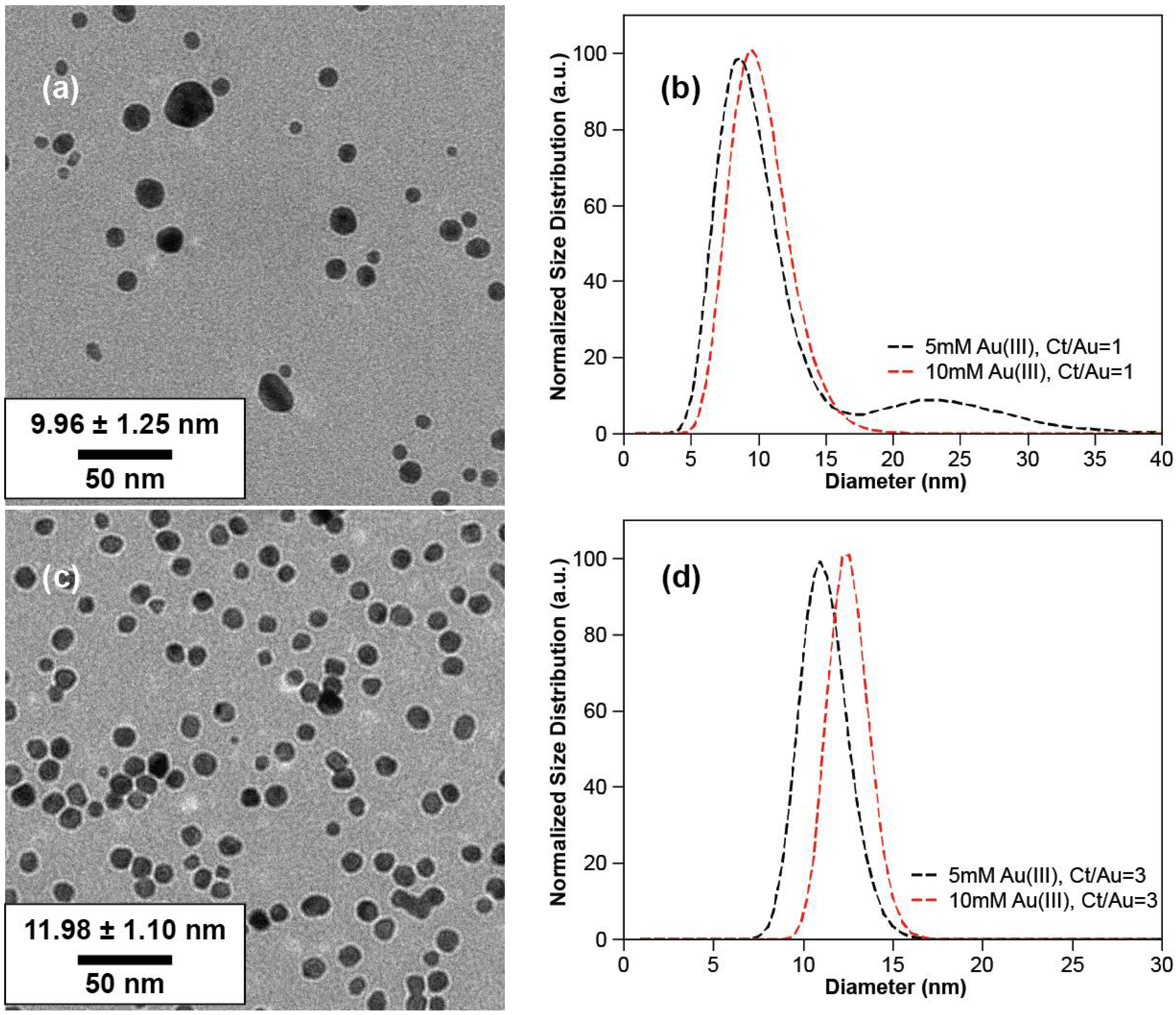

3.3. Effect of Citrate Concentration on Particle Size

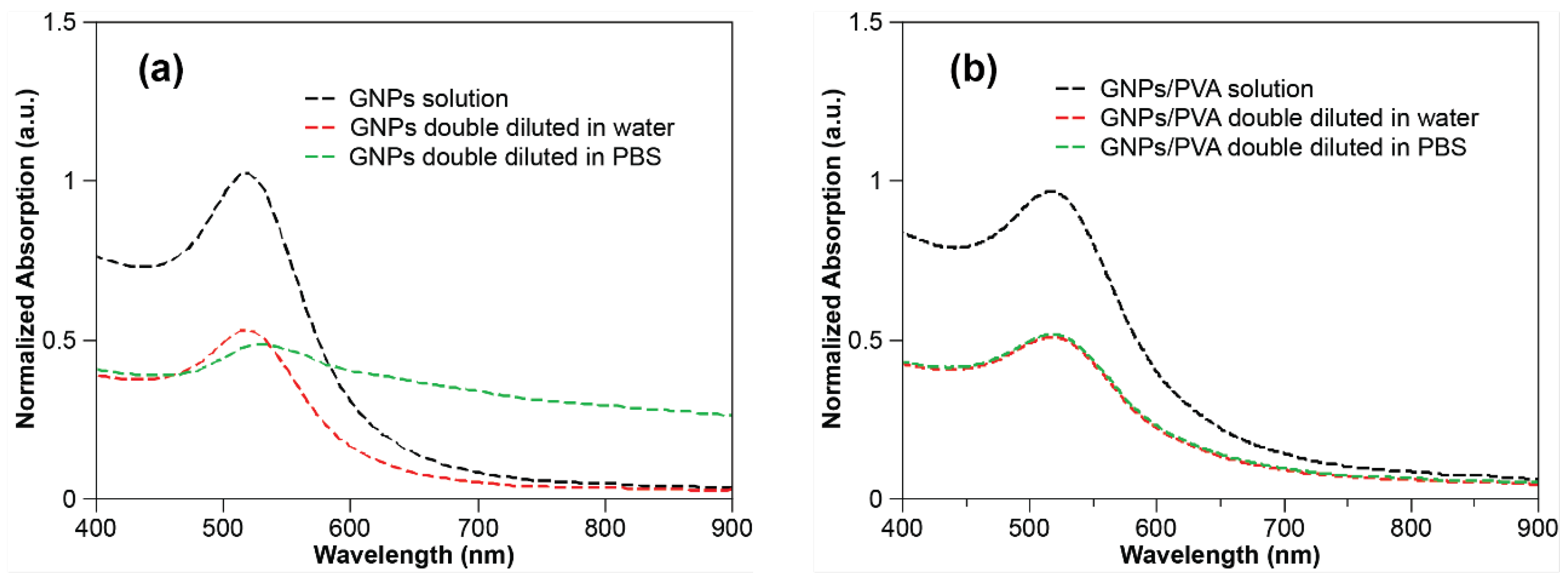

3.4. Relating Particle Stability to the Debye Length

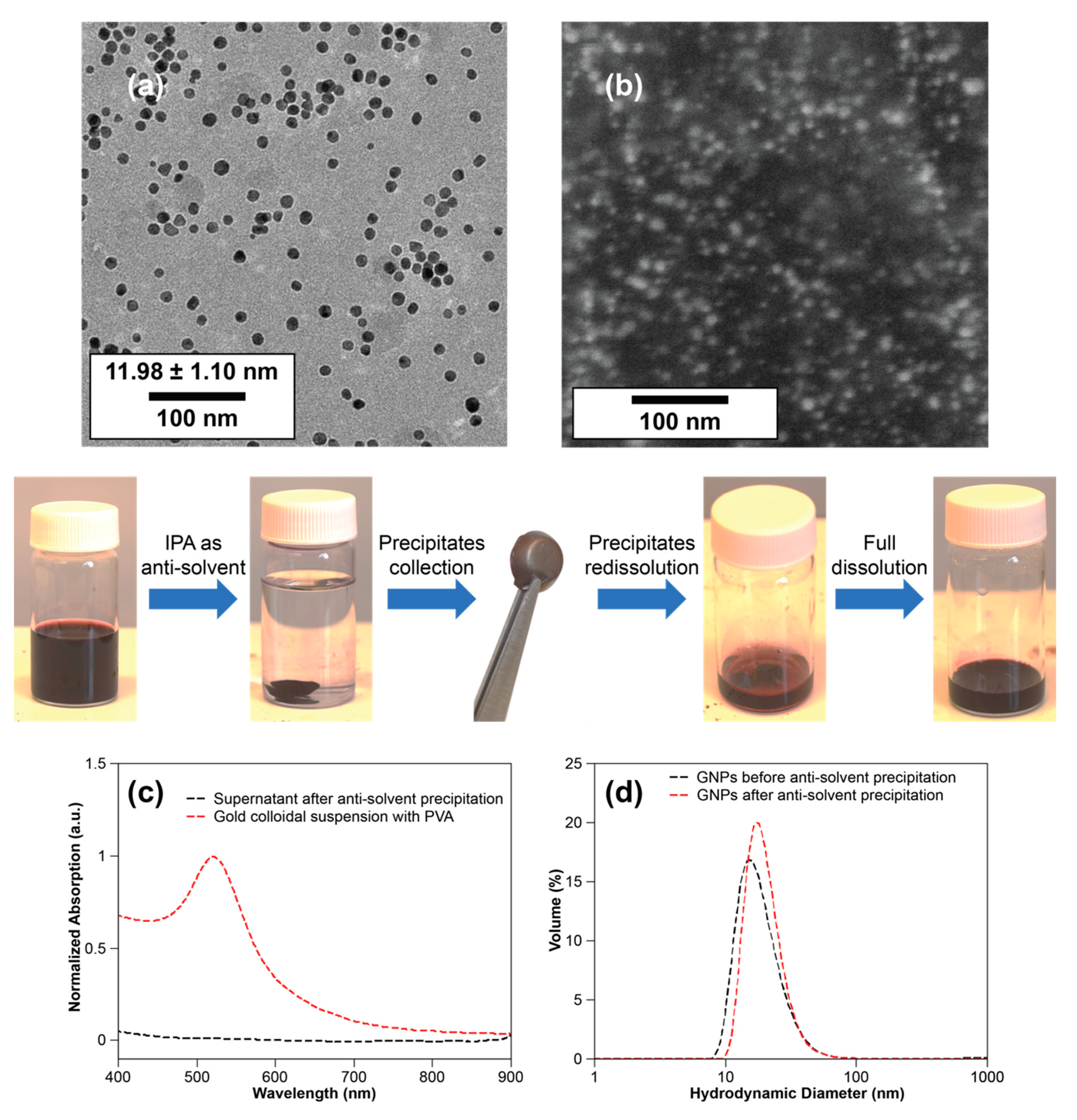

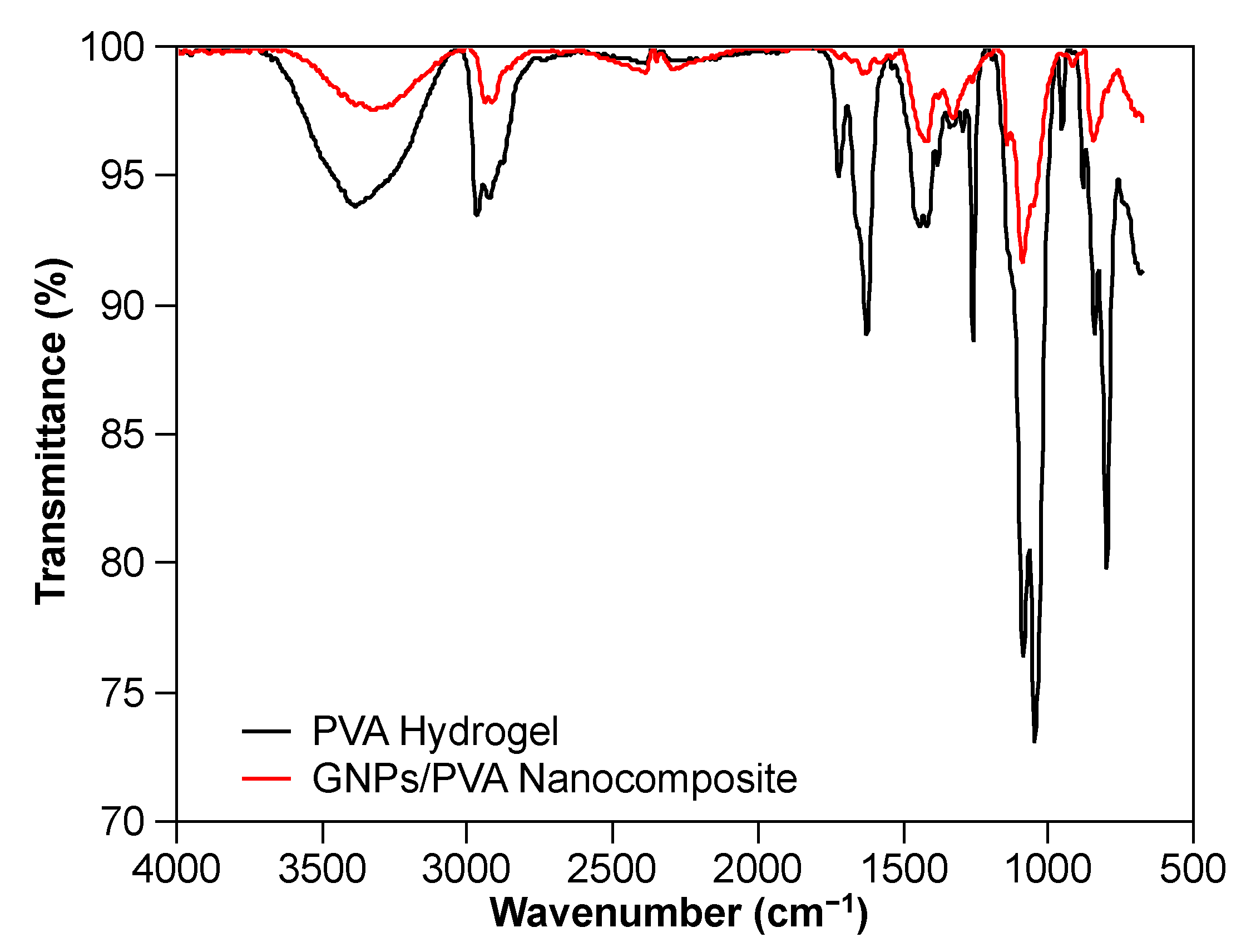

3.5. Concentrating Particle Concentration via Anti-Solvent Precipitation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GNPs | gold nanoparticles |

| PVA | poly (vinyl alcohol) |

| PVP | poly (vinyl pyrrolidone) |

| TEM | transmission electron microscopy |

| SEM | scanning electron microscopy |

| FIB | focused ion beam |

| DLS | dynamic light scattering |

| FT-IR | Fourier-transform infrared spectroscopy |

| Ct | concentration of citrate ions |

| Au | concentration of gold precursor |

References

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef] [PubMed]

- Salerno, M.; Krenn, J.R.; Lamprecht, B.; Schider, G.; Ditlbacher, H.; Félidj, N.; Leitner, A.; Aussenegg, F.R. Plasmon polaritons in metal nanostructures: The optoelectronic route to nanotechnology. Optoelectron. Rev. 2002, 3, 217–224. [Google Scholar]

- Maier, S.A.; Kik, P.G.; Atwater, H.A.; Meltzer, S.; Harel, E.; Koel, B.E.; Requicha, A.A.G. Local detection of electromagnetic energy transport below the diffraction limit in metal nanoparticle plasmon waveguides. Nat. Mater. 2003, 2, 229–232. [Google Scholar] [CrossRef] [PubMed]

- Krenn, J.R. Watching energy transfer. Nat. Mater. 2003, 2, 210–211. [Google Scholar] [CrossRef] [PubMed]

- Liau, Y.-H.; Unterreiner, A.N.; Chang, Q.; Scherer, N.F. Ultrafast Dephasing of Single Nanoparticles Studied by Two-Pulse Second-Order Interferometry. J. Phys. Chem. B 2001, 105, 2135–2142. [Google Scholar] [CrossRef]

- Yelin, D.; Oron, D.; Thiberge, S.; Moses, E.; Silberberg, Y. Multiphoton plasmon-resonance microscopy. Opt. Express 2003, 11, 1385. [Google Scholar] [CrossRef]

- Nappa, J.; Revillod, G.; Russier-Antoine, I.; Benichou, E.; Jonin, C.; Brevet, P.F. Electric dipole origin of the second harmonic generation of small metallic particles. Phys. Rev. B 2005, 71, 165407. [Google Scholar] [CrossRef]

- Chon, J.W.M.; Bullen, C.; Zijlstra, P.; Gu, M. Spectral encoding on Gold Nanorods Doped in a Silica Sol–Gel Matrix and Its Application to High-Density Optical Data Storage. Adv. Funct. Mater. 2007, 17, 875–880. [Google Scholar] [CrossRef]

- Ditlbacher, H.; Krenn, J.R.; Lamprecht, B.; Leitner, A.; Aussenegg, F.R. Spectrally coded optical data storage by metal nanoparticles. Opt. Lett. 2000, 25, 563. [Google Scholar] [CrossRef]

- Sheehan, S.W.; Noh, H.; Brudvig, G.W.; Cao, H.; Schmuttenmaer, C.A. Plasmonic enhancement of dye-sensitized solar cells using core-shell-shell nanostructures. J. Phys. Chem. C 2013, 117, 927–934. [Google Scholar] [CrossRef]

- Batmunkh, M.; Macdonald, T.J.; Peveler, W.J.; Bati, A.S.R.; Carmalt, C.J.; Parkin, I.P.; Shapter, J.G. Plasmonic Gold Nanostars Incorporated into High-Efficiency Perovskite Solar Cells. ChemSusChem 2017, 10, 3750–3753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brown, M.D.; Suteewong, T.; Kumar, R.S.S.; D’Innocenzo, V.; Petrozza, A.; Lee, M.M.; Wiesner, U.; Snaith, H.J. Plasmonic dye-sensitized solar cells using core-shell metal-insulator nanoparticles. Nano Lett. 2011, 11, 438–445. [Google Scholar] [CrossRef] [PubMed]

- Macdonald, T.J.; Ambroz, F.; Batmunkh, M.; Li, Y.; Kim, D.; Contini, C.; Poduval, R.; Liu, H.; Shapter, J.G.; Papakonstantinou, I.; et al. TiO2 nanofiber photoelectrochemical cells loaded with sub-12 nm AuNPs: Size dependent performance evaluation. Mater. Today Energy 2018, 9, 254–263. [Google Scholar] [CrossRef]

- Kneipp, K.; Kneipp, H.; Itzkan, I.; Dasari, R.R.; Feld, M.S. Surface-enhanced Raman scattering and biophysics. J. Phys. Condens. Matter 2002, 14, R597–R624. [Google Scholar] [CrossRef] [Green Version]

- Boyen, H.-G. Oxidation-Resistant Gold-55 Clusters. Science 2002, 297, 1533–1536. [Google Scholar] [CrossRef]

- Yguerabide, J.; Yguerabide, E. Light-Scattering Submicroscopic Particles as Highly Fluorescent Analogs and Their Use as Tracer Labels in Clinical and Biological Applications | Elsevier Enhanced Reader. Anal. Biochem. 1998, 262, 137–156. [Google Scholar] [CrossRef]

- Raschke, G.; Kowarik, S.; Franzl, T.; Sönnichsen, C.; Klar, T.A.; Feldmann, J.; Nichtl, A.; Kürzinger, K. Biomolecular Recognition Based on Single Gold Nanoparticle Light Scattering. Nano Lett. 2003, 3, 935–938. [Google Scholar] [CrossRef]

- Jain, P.K.; El-Sayed, I.H.; El-Sayed, M.A. Au nanoparticles target cancer. Nano Today 2007, 2, 18–29. [Google Scholar] [CrossRef]

- Turkevich, J.; Stevenson, P.C.; Hillier, J. A study of the nucleation and growth processes in the synthesis of colloidal gold. Discuss. Faraday Soc. 1951, 11, 55. [Google Scholar] [CrossRef]

- Enustun, B.V.; Turkevich, J. Coagulation of Colloidal Gold. J. Am. Chem. Soc. 1963, 85, 3317–3328. [Google Scholar] [CrossRef]

- Frens, G. Controlled Nucleation for the Regulation of the Particle Size in Monodisperse Gold Suspensions. Nat. Phys. Sci. 1973, 241, 20. [Google Scholar] [CrossRef]

- Ji, X.; Song, X.; Li, J.; Bai, Y.; Yang, W.; Peng, X. Size Control of Gold Nanocrystals in Citrate Reduction: The Third Role of Citrate. J. Am. Chem. Soc. 2007, 129, 13939–13948. [Google Scholar] [CrossRef] [PubMed]

- Pong, B.-K.; Elim, H.I.; Chong, J.-X.; Ji, W.; Trout, B.L.; Lee, J.-Y. New Insights on the Nanoparticle Growth Mechanism in the Citrate Reduction of Gold(III) Salt: Formation of the Au Nanowire Intermediate and Its Nonlinear Optical Properties. J. Phys. Chem. C 2007, 111, 6281–6287. [Google Scholar] [CrossRef]

- Kumar, S.; Gandhi, K.S.; Kumar, R. Modeling of Formation of Gold Nanoparticles by Citrate Method. Ind. Eng. Chem. Res. 2007, 46, 3128–3136. [Google Scholar] [CrossRef]

- Polte, J.; Ahner, T.T.; Delissen, F.; Sokolov, S.; Emmerling, F.; Thünemann, A.F.; Kraehnert, R. Mechanism of Gold Nanoparticle Formation in the Classical Citrate Synthesis Method Derived from Coupled In Situ XANES and SAXS Evaluation. J. Am. Chem. Soc. 2010, 132, 1296–1301. [Google Scholar] [CrossRef] [PubMed]

- Ojea-Jiménez, I.; Bastús, N.G.; Puntes, V. Influence of the Sequence of the Reagents Addition in the Citrate-Mediated Synthesis of Gold Nanoparticles. J. Phys. Chem. C 2011, 115, 15752–15757. [Google Scholar] [CrossRef]

- Zabetakis, K.; Ghann, W.E.; Kumar, S.; Daniel, M.-C. Effect of high gold salt concentrations on the size and polydispersity of gold nanoparticles prepared by an extended Turkevich–Frens method. Gold Bull. 2012, 45, 203–211. [Google Scholar] [CrossRef] [Green Version]

- Schulz, F.; Homolka, T.; Bastús, N.G.; Puntes, V.; Weller, H.; Vossmeyer, T. Little Adjustments Significantly Improve the Turkevich Synthesis of Gold Nanoparticles. Langmuir 2014, 30, 10779–10784. [Google Scholar] [CrossRef]

- Du Toit, H.; Macdonald, T.J.; Huang, H.; Parkin, I.P.; Gavriilidis, A. Continuous flow synthesis of citrate capped gold nanoparticles using UV induced nucleation. RSC Adv. 2017, 7, 9632–9638. [Google Scholar] [CrossRef] [Green Version]

- Panariello, L.; Damilos, S.; Du Toit, H.; Wu, G.; Radhakrishnan, A.N.P.; Parkin, I.P.; Gavriilidis, A. Highly reproducible, high-yield flow synthesis of gold nanoparticles based on a rational reactor design exploiting the reduction of passivated Au(iii). React. Chem. Eng. 2020, 5, 663–676. [Google Scholar] [CrossRef] [Green Version]

- Tsai, Y.-C.; Huang, J.-D.; Chiu, C.-C. Amperometric ethanol biosensor based on poly(vinyl alcohol)-multiwalled carbon nanotube-alcohol dehydrogenase biocomposite. Biosens. Bioelectron. 2007, 22, 3051–3056. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.-J.; Zhao, F.-Q.; Zeng, B.-Z. Characterization and electrochemical study of hemoglobin–carbon nanoparticles–polyvinyl alcohol nanoporous hybrid film. J. Solid State Electrochem. 2008, 12, 1167–1172. [Google Scholar] [CrossRef]

- Porta, F.; Prati, L.; Rossi, M.; Coluccia, S.; Martra, G. Metal sols as a useful tool for heterogeneous gold catalyst preparation: Reinvestigation of a liquid phase oxidation. Catal. Today 2000, 61, 165–172. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Yang, S.; Du, J.; Wang, S.; Zheng, J.; Wang, Y.; Yang, Q.; Chen, X.; Jing, X. A simple and effective route for the preparation of poly(vinylalcohol) (PVA) nanofibers containing gold nanoparticles by electrospinning method. Solid State Commun. 2007, 141, 292–295. [Google Scholar] [CrossRef]

- Omidfar, K.; Dehdast, A.; Zarei, H.; Sourkohi, B.K.; Larijani, B. Development of urinary albumin immunosensor based on colloidal AuNP and PVA. Biosens. Bioelectron. 2011, 26, 4177–4183. [Google Scholar] [CrossRef] [PubMed]

- Rithesh Raj, D.; Prasanth, S.; Vineeshkumar, T.V.; Sudarsanakumar, C. Surface Plasmon Resonance based fiber optic sensor for mercury detection using gold nanoparticles PVA hybrid. Opt. Commun. 2016, 367, 102–107. [Google Scholar] [CrossRef]

- Kim, R.; Park, H.S.; Yu, T.; Yi, J.; Kim, W.S. Aqueous synthesis and stabilization of highly concentrated gold nanoparticles using sterically hindered functional polymer. Chem. Phys. Lett. 2013, 575, 71–75. [Google Scholar] [CrossRef]

- Unni, M.; Uhl, A.M.; Savliwala, S.; Savitzky, B.H.; Dhavalikar, R.; Garraud, N.; Arnold, D.P.; Kourkoutis, L.F.; Andrew, J.S.; Rinaldi, C. Thermal Decomposition Synthesis of Iron Oxide Nanoparticles with Diminished Magnetic Dead Layer by Controlled Addition of Oxygen. ACS Nano 2017, 11, 2284–2303. [Google Scholar] [CrossRef]

- Gao, Y.; Torrente-Murciano, L. Mechanistic insights of the reduction of gold salts in the Turkevich protocol †. Nanoscale 2020, 12, 2740–2751. [Google Scholar] [CrossRef]

- Winslow, A.M. Numerical solution of the quasilinear poisson equation in a nonuniform triangle mesh. J. Comput. Phys. 1966, 1, 149–172. [Google Scholar] [CrossRef]

- Wright, M.R. An Introduction to Aqueous Electrolyte Solutions, 1st ed.; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Burns, C.; Spendel, W.U.; Puckett, S.; Pacey, G.E. Solution ionic strength effect on gold nanoparticle solution color transition. Talanta 2006, 69, 873–876. [Google Scholar] [CrossRef] [PubMed]

- Yethiraj, A.; Blaaderen, A. van A colloidal model system with an interaction tunable from hard sphere to soft and dipolar. Nature 2003, 421, 513. [Google Scholar] [CrossRef] [PubMed]

- Gilles, S.; Kaulen, C.; Pabst, M.; Simon, U.; Offenhäusser, A.; Mayer, D. Patterned self-assembly of gold nanoparticles on chemical templates fabricated by soft UV nanoimprint lithography. Nanotechnology 2011, 22, 295301. [Google Scholar] [CrossRef] [PubMed]

- Tojo, C.; Barroso, F.; De Dios, M. Critical nucleus size effects on nanoparticle formation in microemulsions: A comparison study between experimental and simulation results. J. Colloid Interface Sci. 2006, 296, 591–598. [Google Scholar] [CrossRef]

- Soejima, T.; Oshiro, S.; Nakatsuji, Y.; Ito, S. Dense aqueous colloidal gold nanoparticles prepared from highly concentrated precursor solution. J. Colloid Interface Sci. 2011, 362, 325–329. [Google Scholar] [CrossRef]

- Kyrychenko, A.; Pasko, D.A.; Kalugin, O.N. Poly(vinyl alcohol) as a water protecting agent for silver nanoparticles: The role of polymer size and structure. Phys. Chem. Chem. Phys. 2017, 19, 8742–8756. [Google Scholar] [CrossRef]

| Samples | Number (nm) | Volume (nm) | Intensity (nm) | Zeta Potential (mV) |

|---|---|---|---|---|

| GNPs, no PVA | 8.9 ± 1.9 | 10.1 ± 2.5 | 11.7 ± 2.781.0 ± 22.1 | −44.1 ± 8.0 |

| GNPs, 0.03% PVA added during synthesis | 12.0 ± 2.9 | 14.0 ± 3.9 | 17.2 ± 4.7 | −24 ± 7.5 |

| Estimated thickness of PVA | 1.6 ± 1.7 | 2.0 ± 2.3 | 2.8 ± 2.7 | - |

| Ct/Au | 1 | 3 | 6 | 9 | 12 | 15 | 18 | |

|---|---|---|---|---|---|---|---|---|

| Au (III) | ||||||||

| 5 mM | (P) 2.3 | (R) 1.7 | (R) 1.3 | (R) 1.1 | (P) 0.96 | (P) 0.87 | (A) 0.80 | |

| 10 mM | (P) 1.6 | (R) 1.2 | (A) 0.92 | (A) 0.78 | (A) 0.68 | (A) 0.62 | (A) 0.57 | |

| 15 mM | (P) 1.3 | (A) 0.98 | (A) 0.75 | (A) 0.64 | (A) 0.55 | (A) 0.50 | (A) 0.46 | |

| 20 mM | (P) 1.1 | (A) 0.85 | (A) 0.65 | (A) 0.55 | (A) 0.48 | (A) 0.44 | (A) 0.40 | |

| Ct/Au | 3 | 6 | 9 | 12 | 15 | 18 | 21 | |

|---|---|---|---|---|---|---|---|---|

| Au (III) | ||||||||

| 0.5 mM | (R) 5.33 | (R) 4.10 | (R) 3.45 | (R) 3.04 | (R) 2.75 | (R) 2.52 | (R) 2.35 | |

| 1.0 mM | (R) 3.77 | (R) 2.90 | (R) 2.44 | (R) 2.15 | (A) 1.94 | (A) 1.78 | (A) 1.66 | |

| 1.5 mM | (R) 3.09 | (P) 2.37 | (P) 1.99 | (A) 1.76 | (A) 1.59 | (A) 1.46 | (A) 1.36 | |

| 2.0 mM | (R) 2.67 | (P) 2.05 | (A) 1.73 | (A) 1.52 | (A) 1.37 | (A) 1.26 | (A) 1.17 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Lanier, O.L.; Chauhan, A. Poly (Vinyl Alcohol) Assisted Synthesis and Anti-Solvent Precipitation of Gold Nanoparticles. Nanomaterials 2020, 10, 2359. https://doi.org/10.3390/nano10122359

Liu Z, Lanier OL, Chauhan A. Poly (Vinyl Alcohol) Assisted Synthesis and Anti-Solvent Precipitation of Gold Nanoparticles. Nanomaterials. 2020; 10(12):2359. https://doi.org/10.3390/nano10122359

Chicago/Turabian StyleLiu, Zhen, Olivia L. Lanier, and Anuj Chauhan. 2020. "Poly (Vinyl Alcohol) Assisted Synthesis and Anti-Solvent Precipitation of Gold Nanoparticles" Nanomaterials 10, no. 12: 2359. https://doi.org/10.3390/nano10122359