Cobalt Nanoparticles on Plasma-Controlled Nitrogen-Doped Carbon as High-Performance ORR Electrocatalyst for Primary Zn-Air Battery

Abstract

1. Introduction

2. Materials and Methods

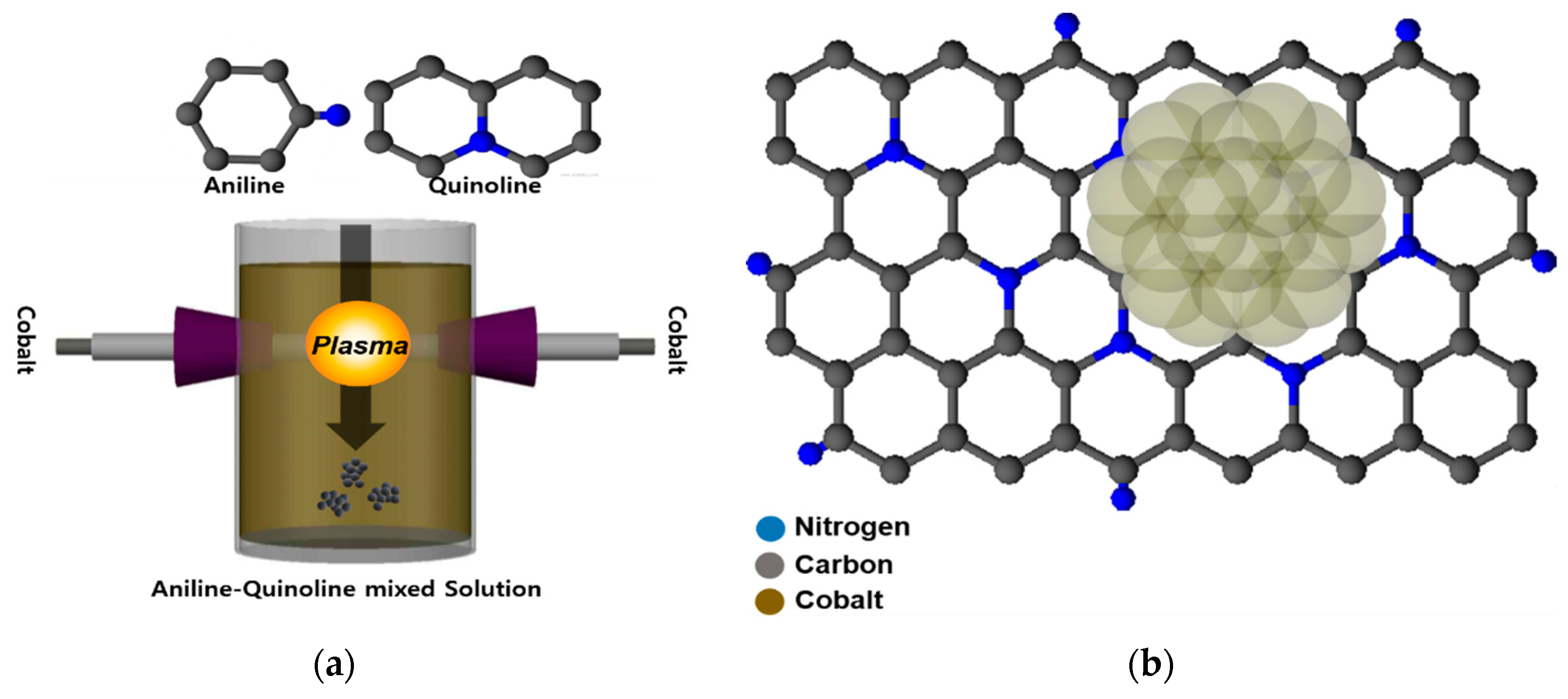

2.1. Synthesis of Co-N/C Catalyst by a Plasma Process

2.2. Structure and Chemical Composition Analysis

2.3. Electrochemical Measurements

2.4. Primary Zn–Air Battery Measurement

3. Results

3.1. Properties of Co Nanoparticles/N-Doped Carbon Catalyst

3.2. Chemical Bonding States of Co Nanoparticles/N-Doped Carbon Catalyst

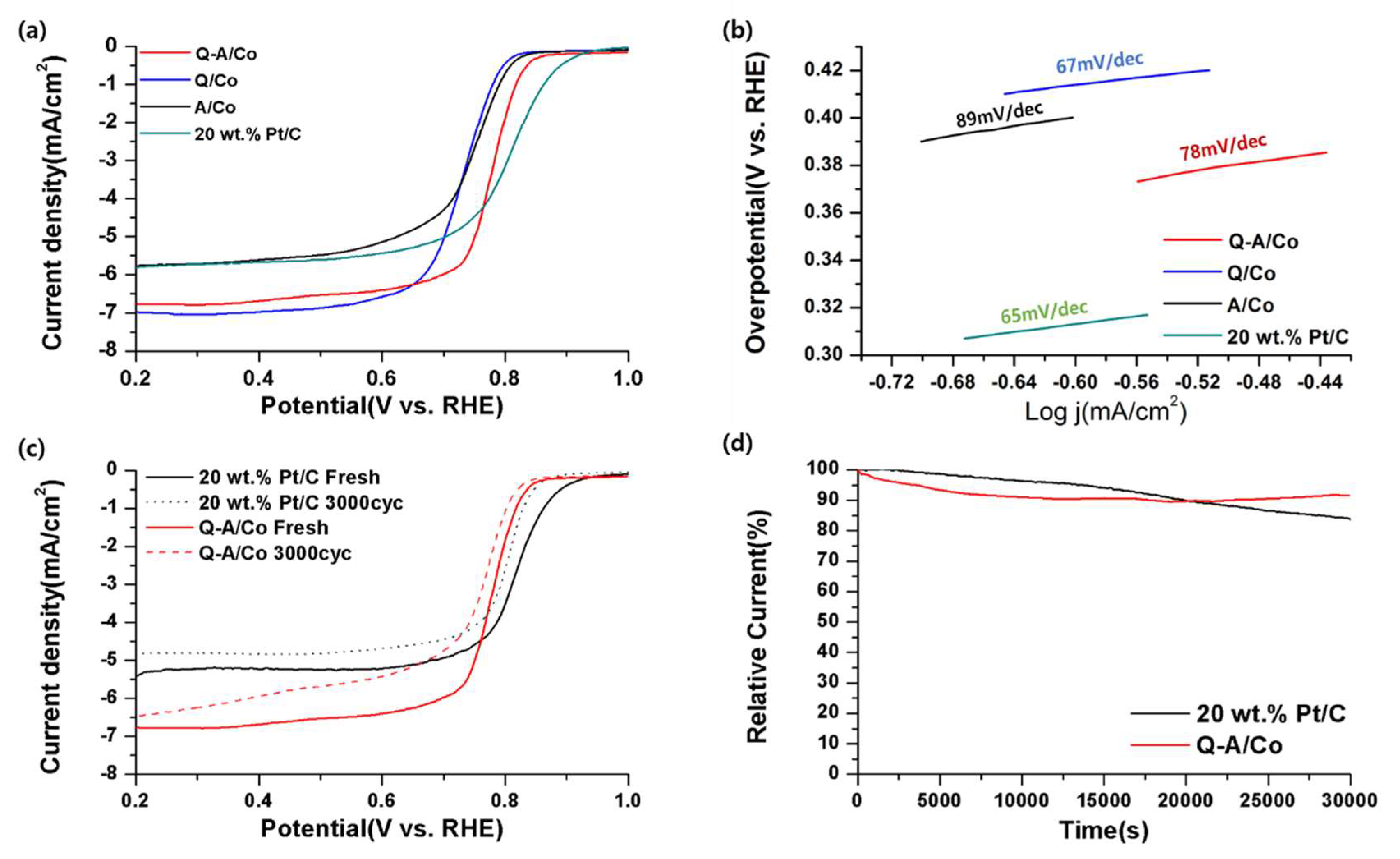

3.3. Electrochemical Properties of Co Nanoparticles/N-Doped Carbon Catalyst

3.4. Primary Zn–Air Battery Test of Co Nanoparticles/N-Doped Carbon Catalyst (Q-A/Co)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fan, W.; Li, Z.; You, C.; Zong, X.; Tian, X.; Miao, S.; Shu, T.; Li, C.; Liao, S. Binary Fe, Cu-doped bamboo-like carbon nanotubes as efficient catalyst for the oxygen reduction reaction. Nano Energy 2017, 37, 187–194. [Google Scholar] [CrossRef]

- Du, J.; Cheng, F.; Zhang, T.; Chen, J. M(Salen)-derived Nitrogen-doped M/C(M = Fe, Co, Ni) Porous Nanocomposites for electrocatalytic Oxygen Reduction. Sci. Rep. 2014, 4, 4386. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Liu, F.; Lut, X.; Liao, S.; You, C.; Tian, X.; Nan, H.; Luo, F.; Song, H.; Fu, Z.; et al. Effect of Transition Metals on the structure and Performance of the Doped Carbon Catalysts Derived from Polyaniline and Melamine for ORR Application. ACS Catal. 2014, 5, 3797–3805. [Google Scholar] [CrossRef]

- Ratso, S.; Kruusenberg, I.; Kaarik, M.; Kook, M.; Puust, L.; Saar, R.; Leis, G.; Tammeveski, K. Highly efficient transition metal and nitrogen co-doped carbide-derived carbon electrocatalysts for anion exvhange membrane fuel cells. J. Power Sources 2018, 375, 233–243. [Google Scholar] [CrossRef]

- Martinez, U.; Babu, S.K.; Holby, E.F.; Chung, H.T.; Yin, X.; Zelenay, P. Progress in the Development of Fe-Based PGM-free Electrocatalysts for the Oxygen Reduction Reaction. Adv. Mater. 2019, 31, 1806545. [Google Scholar] [CrossRef]

- Cai, S.; Meng, Z.; Tang, H.; Wang, Y.; Tsiakaras, P. 3D Co-N-doped hollow carbon sphere as excellent bifunctional electrocatalysts for oxygen reduction reaction and oxygen evolution reaction. Appl. Catal. B Environ. 2017, 217, 477–484. [Google Scholar] [CrossRef]

- Fu, G.; Liu, Y.; Chen, Y.; Tang, Y.; Goodenough, J.B.; Lee, J.M. Robust N-doped carbon aerogels strongly coupled with iron-cobalt particles as efficient bifunctional catalysts for rechargeable Zn-air batteries. Nanoscale 2018, 10, 19937. [Google Scholar] [CrossRef]

- Ghanbarlou, H.; Rowshanzair, S.; Kazeminasab, B.; Parnian, M.J. Non-precious metal nanoparticles supported on nitrogen0doped graphene as a promising catalyst for oxygen reduction reaction: Synthesis, characterization and electrocatalytic performance. J. Power Sources 2015, 273, 981–989. [Google Scholar] [CrossRef]

- Sharma, M.; Jang, J.H.; Shin, D.Y.; Kwon, J.A.; Lim, D.H.; Choi, D.; Sung, H.; Jang, J.H.; Lee, S.Y.; Lee, K.Y.; et al. Work function-tailored graphene via transition metal encapsulation as a highly active and durable catalyst for the oxygen reduction reaction. Energy Environ. Sci. 2019, 12, 2200–2211. [Google Scholar] [CrossRef]

- Guo, H.; Feng, Q.; Zhu, J.; Xu, J.; Li, Q.; Liu, S.; Xu, K.; Zhang, C.; Liu, T. Cobalt nanoparticle-embedded nitrogen-doped carbon/carbon nanotube frameworks derived from a metal-organic framework for tri-functional ORR, OER and HER electrocatalysis. J. Mater. Chem. A 2019, 7, 3664. [Google Scholar] [CrossRef]

- Zhang, C.L.; Lu, B.R.; Cao, F.H.; Wu, Z.Y.; Zhang, W.; Cong, H.P.; Yu, S.H. Electrospun metal-organic framework nanoparticle fibers and their derived electrocatalysts for oxygen reduction reaction. Nano Energy 2019, 55, 226–233. [Google Scholar] [CrossRef]

- Guo, B.; Ma, R.; Li, Z.; Guo, S.; Luo, J.; Yang, M.; Liu, Q.; Thomas, T.; Wang, J. Hierarchical N-Doped Porous Carbons for Zn-Air Batteries and Supercapacitors. Nano-Micro Lett. 2020, 12, 20. [Google Scholar] [CrossRef]

- Khan, Z.; Park, S.O.; Yang, J.; Park, S.; Shanker, R.; Song, H.K.; Kim, Y.; Kwak, S.K.; Ko, H. Binary N,S-doped carbon nanospheres from bio-inspired artificial melanosomes: A route to efficient air electrodes for seawater batteries. J. Mater. Chem. A 2018, 6, 24459. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, D.W.; Amal, R.; Dai, L. Carbon-Based Metal-Free Catalyst for Key Reactions Involved in Energy Conversion and Storage. Adv. Mater. 2019, 31, 1801526. [Google Scholar] [CrossRef] [PubMed]

- Guo, D.; Shibuya, R.; Akiba, C.; Saji, S.; Kondo, T.; Nakamura, J. Active sites of nitrogen-doped carbon materials for oxygen reduction reaction clarified using model catalysts. Science 2016, 351, 6271. [Google Scholar] [CrossRef] [PubMed]

- Yan, P.; Liu, J.; Yuan, S.; Liu, Y.; Cen, W.; Chen, Y. The promotion effects of graphitic and pyridinic N combinational doping on graphene for ORR. Appl. Surf. Sci. 2018, 445, 398–403. [Google Scholar] [CrossRef]

- Wu, G.; Santandreu, A.; Kellogg, W.; Gupta, S.; Ogoke, O.; Zhang, H.; Wang, H.L.; Dai, L. Carbon nanocomposite catalysts for oxygen reduction and evolution reactions: From nitrogen doping to transition-metal addition. Nano Energy 2016, 29, 83–110. [Google Scholar] [CrossRef]

- Dumont, J.H.; Martinez, U.; Artyushkove, K.; Purdy, G.M.; Dattelbaum, A.M.; Zelenay, P.; Mohite, A.; Atanassov, P.; Gupta, G. Nitrogen-Doped Graphene Oxide Electrocatalysts for the Oxygen Reduction Reaction. ACS Appl. Nano Mater. 2019, 2, 1675–16785. [Google Scholar] [CrossRef]

- Vilaplana, A.F.; Herrero, E. Understanding the chemisorption-based activation mechanism of the oxygen reduction reaction on nitrogen-doped graphitic materials. Electrochim. Acta 2016, 204, 245–254. [Google Scholar] [CrossRef]

- Hu, F.; Yang, H.; Wang, C.; Zhang, Y.; Lu, H.; Wang, Q. Co-N-Doped Mesoporous Carbon Hollow Spheres as Highly Efficient Electrocatalysts for Oxygen Reduction Reaction. Small 2017, 13, 1602507. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, X.; Huang, J.; Sun, L.; Li, Q.; Yang, X. Fine Co Nanoparticles Encapsulated in a N-Doped Porous Carbon Matrix with Superfical N-doped Porous Carbon nanofibers for Efficient Oxygen Reduction. ACS Appl. Mater. Interfaces 2017, 9, 21747–21755. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wang, Z.; Zhou, S.; Yu, F.; Yu, M.; Chiang, C.Y.; Zhou, W.; Zhao, J.; Qiu, J. Metal-Organic-Framework-Derived Hybrid Carbon Nanocages as a Bifunctional Electrocatalyst for Oxygen Reduction and Evolution. Adv. Mater. 2017, 29, 1700874. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Wang, X.; Dong, Y.; Pan, X.; Liu, X.; Zhao, Z.; Qiu, J. Nitrogen-doped carbon nanotubes decorated with cobalt nanoparticles derived from zeolitic imidazolate framework-67 for highly efficient oxygen reduction reaction electrocatalyst. Carbon 2018, 132, 580–588. [Google Scholar] [CrossRef]

- Shu, J.; Niu, Q.; Wang, N.; Nie, J.; Ma, G. Alginate derived Co/N doped hierarchical porous carbon microspheres for efficient oxygen reduction reaction. Appl. Surf. Sci. 2019, 485, 520–528. [Google Scholar] [CrossRef]

- Sun, M.; Wu, X.; Deng, X.; Zhang, W.; Xie, Z.; Huang, Q.; Huang, B. Synthesis of pyridinic-N doped carbon nanofibers and its electro-catalytic activity for oxygen reduction reaction. Mater. Lett. 2018, 220, 313–316. [Google Scholar] [CrossRef]

- Muthuswamy, N.; Buan, M.E.M.; Walmsley, J.C.; Ronning, M. Evaluation of ORR active sites in nitrogen-doped carbon nanofibers by KOH post treatment. Catalysis Today 2018, 301, 11–16. [Google Scholar] [CrossRef]

- Zhang, C.; Hao, R.; Liao, H.; Hou, Y. Synthesis of amino-functionalized graphene as metal-free catalyst and exploration of the roles of various nitrogen stated in oxygen reduction reaction. Nano Energy 2013, 2, 88–97. [Google Scholar] [CrossRef]

- Li, O.L.; China, S.; Wada, Y.; Panomsuwan, G.; Ishizaki, T. synthesis of graphitic -N and amino-N in nitrogen-doped carbon via a solution plasma process and exploration of their synergic effect for advanced oxygen reduction reaction. J. Mater. Chem. A 2017, 5, 2073. [Google Scholar] [CrossRef]

- Mamtani, K.; Jain, D.; Dogu, D.; Gustin, V.; Gunduz, S.; Co, A.C.; Ozkan, U.S. Insights into oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) active sites for nitrogen-doped carbon nanostructures (CNx) in acidic media. Appl. Catal. B Environ. 2018, 220, 88–97. [Google Scholar] [CrossRef]

- Singh, S.K.; Takeyasu, K.; Nakamura, J. Active sites and Mechanism of Oxygen Reduction Reaction Electrocatalysis on Nitrogen-Doped Carbon Materials. Adv. Mater. 2019, 31, 1804297. [Google Scholar] [CrossRef]

- Chatterjee, K.; Ashokkumar, M.; gullapalli, H.; Gong, Y.; Vajtal, R.; Thanikaivelan, P.; Ajayan, P.M. Nitrogen-rich carbon nano-onions for oxygen reduction reaction. Carbon 2018, 130, 645–651. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Q.; Qian, W.; Tian, W.; Zhang, H.; Zhang, Q.; Liu, Z. Ultrahigh Oxygen Reduction Reaction Electrocatalytic Activity and Stability over Hierarchical Nanoporous N-doped Carbon. Sci. Rep. 2018, 8, 2863. [Google Scholar] [CrossRef] [PubMed]

- Lv, Q.; Si, W.; He, J.; Sun, L.; Zhang, C.; Wang, N.; Yang, Z.; Li, X.; Wang, X.; Deng, W.; et al. Selectively nitrogen-doped carbon materials as superior Metal-free catalysts for oxygen reduction. Nat. Commun. 2018, 9, 3376. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.B.; Miao, J.; Hung, S.F.; Chen, J.; Tao, H.B.; Wang, X.; Zhang, L.; Chen, R.; Gao, J.; Chen, H.M.; et al. Identification of catalytic sites for oxygen reduction and oxygen evolution in N-doped graphene materials: Development of highly efficient metal-free bifunctional electrocatalyst. Sci. Adv. 2016, 2, 1501122. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Lu, B.; Li, L.; Niu, W.; Tang, Z.; Kang, X.; Chen, S. Graphitic Nitrogen is responsible for oxygen electroreduction on Nitrogen-Doped Carbons in Alkaline Electrolytes: Insights from Activity Attenuation Studies and Theoretical Calculations. ACS Catal. 2018, 8, 6827–6836. [Google Scholar] [CrossRef]

- Ning, X.; Li, Y.; Ming, J.; Wang, Q.; Wang, H.; Cao, Y.; Peng, F.; Yang, Y.; Yu, H. Electronic synergism of pyridinic- and graphitic- nitrogen on N-doped carbons for the oxygen reduction reaction. Chem. Sci. 2019, 10, 1589. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.W.; Li, O.L.; Pootawang, P.; Saito, N. Solution plasma synthesis process of tungsten carbide on N-doped carbon nanocomposite with enhanced catalytic ORR activity and durability. RSC Adv. 2014, 4, 16813. [Google Scholar] [CrossRef]

- Panomsuwan, G.; Saito, N.; Ishizaki, T. Nitrogen-doped carbon nanoparticles derived from acrylonitrile plasma for electrochemical oxygen reduction. Phys. Chem. Chem. Phys. 2015, 17, 6227. [Google Scholar] [CrossRef]

- Panomsuwan, G.; China, S.; Kaneko, Y.; Saito, N.; Ishizaki, T. In situ solution plasma synthesis of nitrogen-doped carbon nanoparticles as metal-free electrocatalysts for the oxygen reduction reaction. J. Mater. Chem. A 2014, 2, 18677. [Google Scholar] [CrossRef]

- Panomsuwan, G.; Saito, N.; Ishizaki, T. Simple one-step synthesis of fluorine-doped carbon nanoparticles as potential alternative metal-free electrocatalysts for oxygen reduction reaction. J. Mater. Chem. A 2015, 3, 9972. [Google Scholar] [CrossRef]

- Panomsuwan, G.; Saito, N.; Ishizaki, T. Electrocatalytic oxygen reduction activity of boron-doped carbon nanoparticles synthesized via solution plasma process. Electrochem. Commun. 2015, 59, 81–85. [Google Scholar] [CrossRef]

- Li, O.L.; Wada, Y.; Kaneko, A.; Lee, H.; Ishizaki, T. Oxygen Reduction Reaction Activity of Thermally Tailored Nitrogen-Doped Carbon Electrocatalysts Prepared through Plasma Synthesis. ChemElectroChem 2018, 5, 1995–2001. [Google Scholar] [CrossRef]

- Li, O.L.; prabaka, K.; Kaneko, A.; Park, H.; Ishizaki, T. Exploration of Lewis basicity and oxygen reduction reaction activity activity in plasma-tailored nitrogen-doped carbon electrocatalysts. Catal. Today 2019, 337, 102–109. [Google Scholar] [CrossRef]

- Li, O.L.; Shi, Z.; Lee, H.; Ishizaki, T. Enhanced Electrocatalytic Stability of Platinum Nanoparticles Supported on Sulfur-Doped Carbon using in-situ solution plasma. Sci. Rep. 2019, 9, 12704. [Google Scholar] [CrossRef]

- Zhou, R.; Zheng, Y.; Jaroniec, M.; Qiao, S.Z. Determination of the Electron Transfer Number for the Oxygen Reduction Reaction: From Theory to Experiment. ACS Catal. 2016, 6, 4720–4728. [Google Scholar] [CrossRef]

- Kang, J.; Li, O.L.; Saito, N. Synthesis of structure-controlled carbon nano spheres by solution plasma process. Carbon 2013, 60, 292–298. [Google Scholar] [CrossRef]

- Ferrero, G.A.; Fuertes, A.B.; Sevilla, M.; Titrici, M.M. Efficient metal-free N-doped mesoporous carbon catalyst for ORR by a template-free approach. Carbon 2016, 106, 179–187. [Google Scholar] [CrossRef]

- An, L.; Jiang, N.; Li, B.; Hua, S.; Fu, Y.; Liu, J.; Hao, W.; Xia, D.; Sun, Z. A highly active and durable iron/cobalt alloy catalyst encapsulated in N-doped graphitic carbon nanotubes for oxygen reduction reaction by a nanofibrous dicyandiamide template. J. Mater. Chem. A 2018, 6, 5962. [Google Scholar] [CrossRef]

- Guan, B.Y.; Yu, L.; Lou, X.W. Formation of Single-Holed Cobalt/N-Doped Carbon Hollow Particles with Enhanced Electrocatalytic Activity toward Oxygen Reduction Reaction in Alkaline Media. Adv. Sci. 2017, 4, 1700247. [Google Scholar] [CrossRef]

- Lai, L.; Potts, J.R.; Zhan, D.; Wang, L.; Poh, C.K.; Tang, C.; Gong, H.; Shen, Z.; Lin, J.; Ruoff, R.S. Exploration of the active center structure of nitrogen-doped graphene-based catalysts for oxygen reduction reaction. Energy Environ. Sci. 2012, 5, 7936. [Google Scholar] [CrossRef]

| BET Surface Area | BJH Adsorption Pore Volume | BJH Adsorption Average Pore Width | |

|---|---|---|---|

| Q-A/Co | 211.1 m2/g | 0.6711 cm3/g | 10.1 nm |

| A/Co | 210.2 m2/g | 0.6708 cm3/g | 13.08 nm |

| Q/Co | 206.2 m2/g | 0.5871 cm3/g | 15.3 nm |

| Bonding | Binding Energy | Q-A/Co | A-Co | Q-Co |

|---|---|---|---|---|

| Relative Percentage (%) | ||||

| N1(Pyridinic-N) | 398.4–398.6 eV | 14 | 16 | 22 |

| N2(Amino-N) | 399.4–399.6 eV | 31 | 35 | 18 |

| N3(Pyrrolic-N) | 400.1–400.3 eV | 20 | 24 | 25 |

| N4(Quaternary-N) | 401.1–401.5 eV | 30 | 21 | 32 |

| N5(Oxide-N) | 403.3–403.7 eV | 5 | 4 | 3 |

| Q-A/Co | Q/Co | A/Co | 20 wt.% Pt/C | |

|---|---|---|---|---|

| Onset Potential | 0.87 V vs. RHE | 0.84 V vs. RHE | 0.85 V vs. RHE | 0.95 V vs. RHE |

| Potential at −3 mA/cm2 | 0.78 V vs. RHE | 0.74 V vs. RHE | 0.74 V vs. RHE | 0.81 V vs. RHE |

| Current density At 0.6 V vs. RHE | −6.27 mA/cm2 | −6.41 mA/cm2 | −5.17 mA/cm2 | −5.43 mA/cm2 |

| Potential at −3 mA/cm2 After 3000 cycles Figure 7c | 0.77 V vs. RHE | - | - | 0.79 V vs. RHE |

| Current density After 3000 cycles Figure 7d | 9% decrease | - | - | 16% decrease |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Park, H.; Li, O.L. Cobalt Nanoparticles on Plasma-Controlled Nitrogen-Doped Carbon as High-Performance ORR Electrocatalyst for Primary Zn-Air Battery. Nanomaterials 2020, 10, 223. https://doi.org/10.3390/nano10020223

Kim S, Park H, Li OL. Cobalt Nanoparticles on Plasma-Controlled Nitrogen-Doped Carbon as High-Performance ORR Electrocatalyst for Primary Zn-Air Battery. Nanomaterials. 2020; 10(2):223. https://doi.org/10.3390/nano10020223

Chicago/Turabian StyleKim, Seonghee, Hyun Park, and Oi Lun Li. 2020. "Cobalt Nanoparticles on Plasma-Controlled Nitrogen-Doped Carbon as High-Performance ORR Electrocatalyst for Primary Zn-Air Battery" Nanomaterials 10, no. 2: 223. https://doi.org/10.3390/nano10020223

APA StyleKim, S., Park, H., & Li, O. L. (2020). Cobalt Nanoparticles on Plasma-Controlled Nitrogen-Doped Carbon as High-Performance ORR Electrocatalyst for Primary Zn-Air Battery. Nanomaterials, 10(2), 223. https://doi.org/10.3390/nano10020223