Shape Deformation in Ion Beam Irradiated Colloidal Monolayers: An AFM Investigation

Abstract

1. Introduction

- is the nuclear stopping power due to elastic nuclear collisions dominant for low energies E of the impinging ion;

- is the electronic stopping power due to inelastic electronic collisions involving the incident ion and substrate electrons dominant for medium/high energies E of the impinging ion.

2. Materials and Methods

2.1. Self-Assembly of Colloidal Monolayers

2.2. Ion Beam Irradiation of Colloidal Monolayers

2.3. AFM Image Acquisition and Analysis

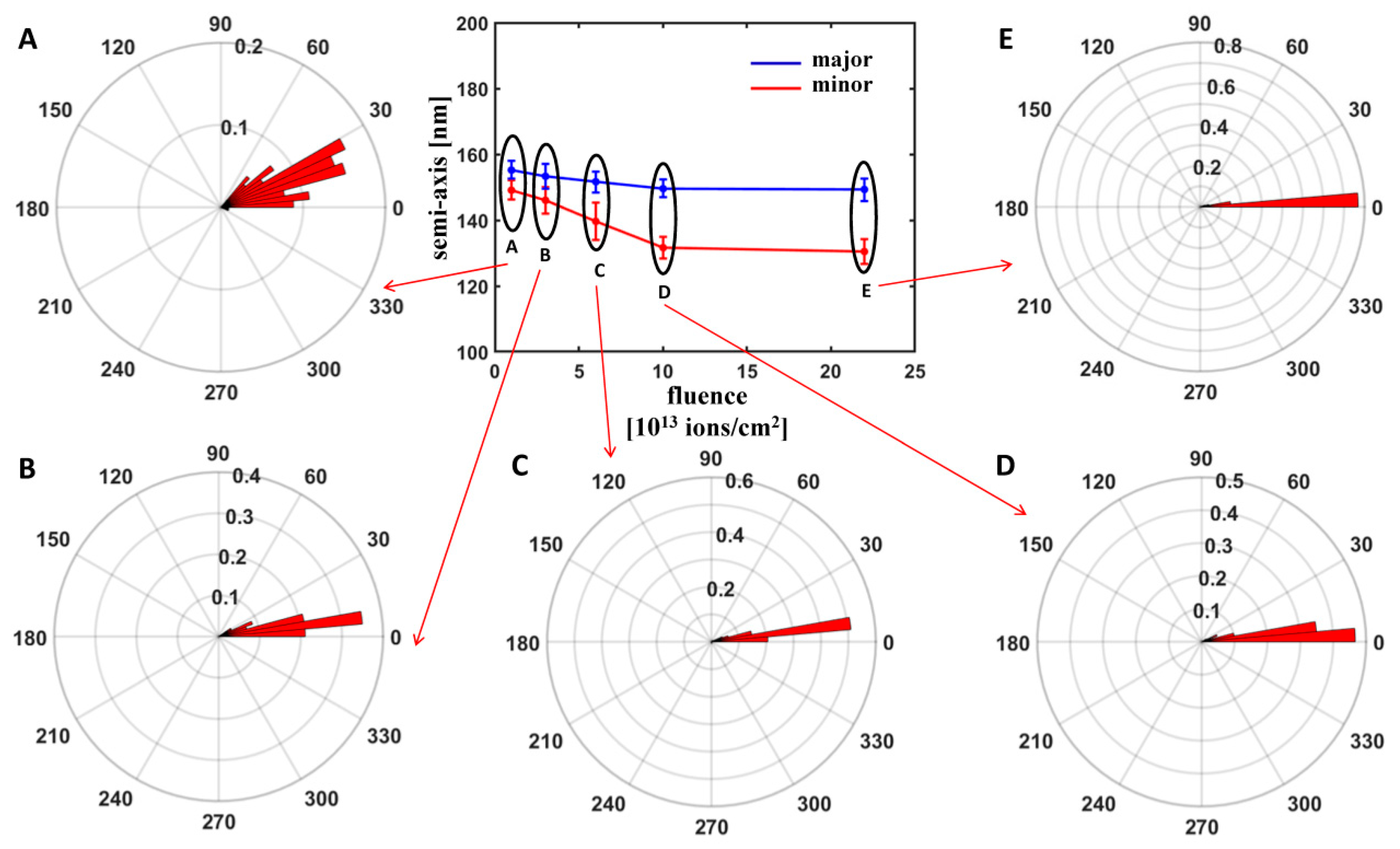

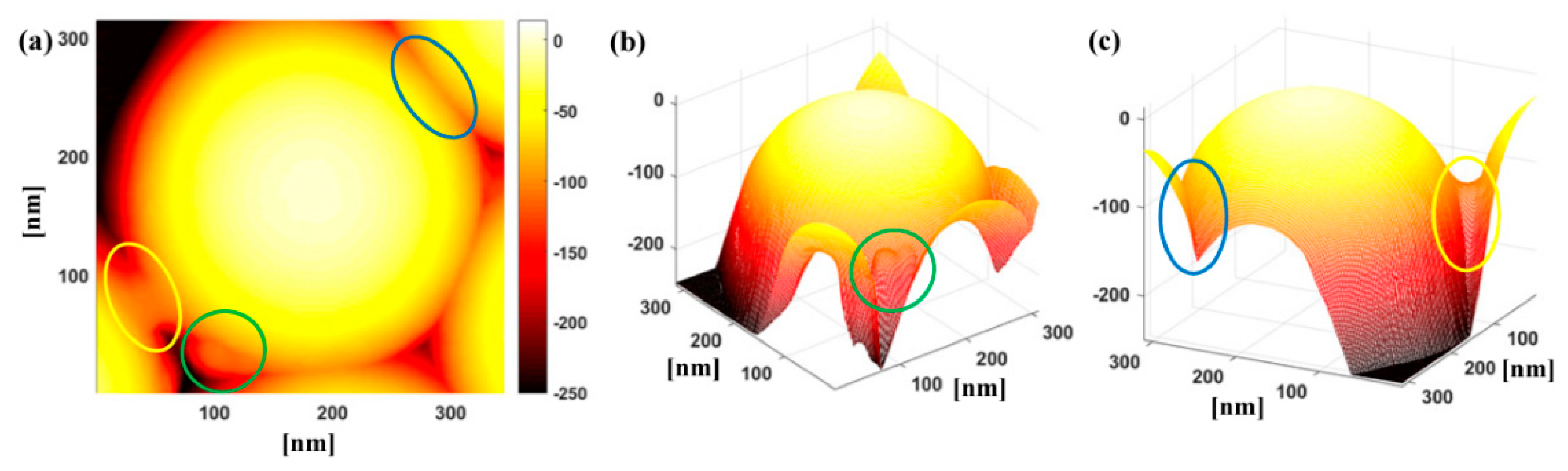

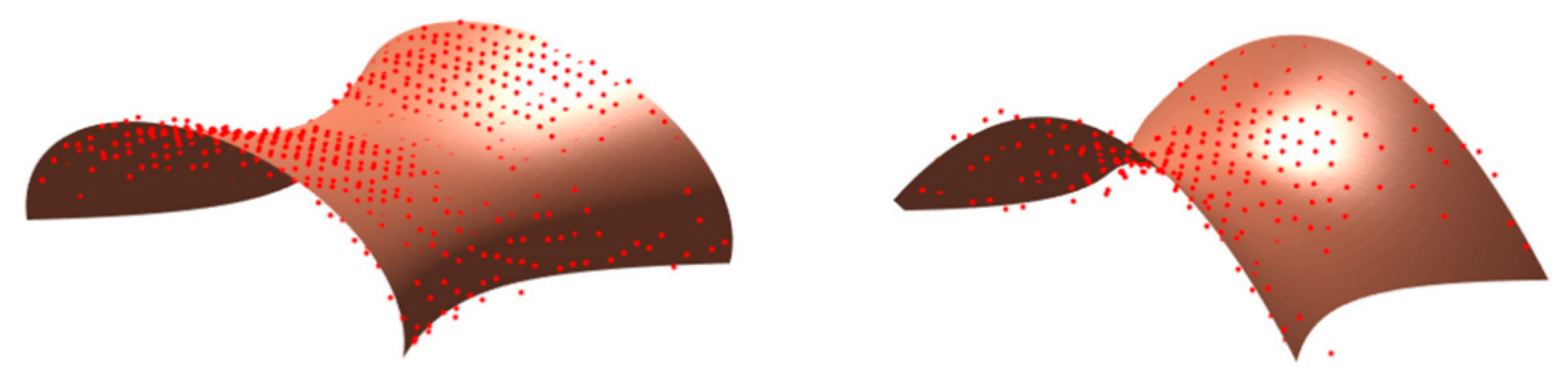

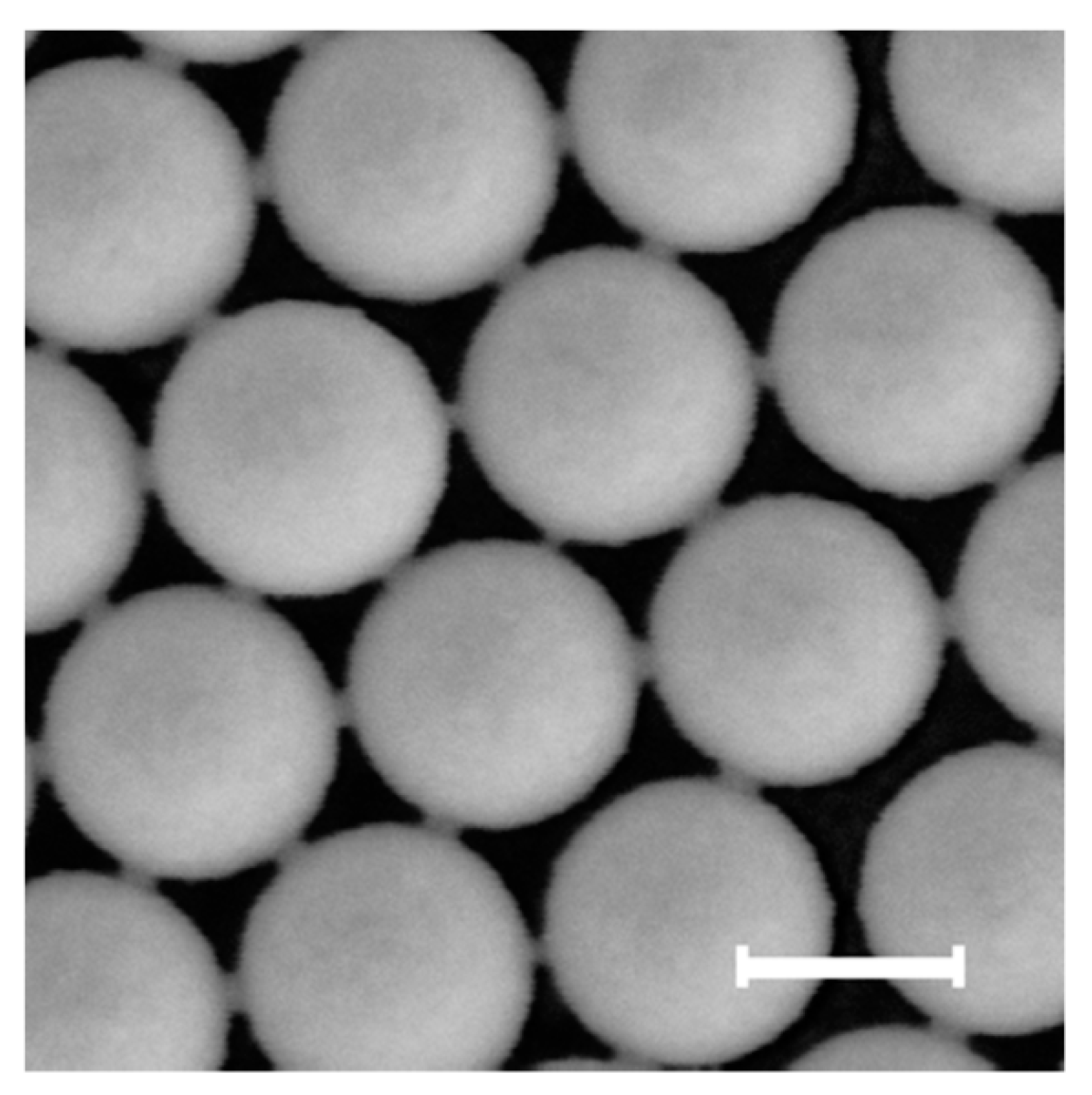

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lotito, V.; Zambelli, T. Approaches to self-assembly of colloidal monolayers: A guide for nanotechnologists. Adv. Colloid Interface Sci. 2017, 246, 217–274. [Google Scholar] [CrossRef]

- Vogel, N.; Weiss, C.K.; Landfester, K. From soft to hard: The generation of functional and complex colloidal monolayers for nanolithography. Soft Matter 2012, 8, 4044–4061. [Google Scholar] [CrossRef]

- Lotito, V.; Zambelli, T. Self-assembly and nanosphere lithography for large-area plasmonic patterns on graphene. J. Colloid Interface Sci. 2015, 447, 202–210. [Google Scholar] [CrossRef] [PubMed]

- Dieringer, J.A.; McFarland, A.D.; Shah, N.C.; Stuart, D.A.; Whitney, A.V.; Yonzon, C.R.; Young, M.A.; Zhang, X.; Van Duyne, R.P. Surface enhanced Raman spectroscopy: New materials, concepts, characterization tools, and applications. Faraday Discuss. 2006, 132, 9–26. [Google Scholar] [CrossRef] [PubMed]

- Willets, K.A.; Van Duyne, R.P. Localized surface plasmon resonance spectroscopy and sensing. Annu. Rev. Phys. Chem. 2007, 58, 267–297. [Google Scholar] [CrossRef]

- Mireles, M.; Gaborski, T.R. Fabrication techniques enabling ultrathin nanostructured membranes for separations. Electrophoresis 2017, 38, 2374–2388. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, P.; Liu, G.; Zhang, J.; Song, R.; Ee, Y.-K.; Kumnorkaew, P.; Gilchrist, J.F.; Tansu, N. Light extraction efficiency enhancement of III-nitride light-emitting diodes by using 2-D close-packed TiO2 microsphere arrays. J. Disp. Technol. 2013, 9, 324–332. [Google Scholar]

- Zhang, J.; Sun, Z.; Yang, B. Self-assembly of photonic crystals from polymer colloids. Curr. Opin. Colloid Interface Sci. 2009, 14, 103–114. [Google Scholar] [CrossRef]

- Plettl, A.; Enderle, F.; Saitner, M.; Manzke, A.; Pfahler, C.; Wiedemann, S.; Ziemann, P. Non-closepacked crystals from self-assembled polystyrene spheres by isotropic plasma etching: Adding flexibility to colloidal lithography. Adv. Funct. Mater. 2009, 19, 3279–3284. [Google Scholar] [CrossRef]

- Li, N.; Yan, F.; Pang, S.; Zeng, B.; Luo, Y. Novel nanofabricated Mo field-emitter array for low-cost and large-area application. IEEE. Trans. Electron. Dev. 2018, 65, 4369–4374. [Google Scholar] [CrossRef]

- Kosiorek, A.; Kandulski, W.; Glaczynska, H.; Giersig, M. Fabrication of nanoscale rings, dots and rods by combining shadow nanosphere lithography and annealed polystyrene nanosphere masks. Small 2005, 1, 439–444. [Google Scholar] [CrossRef] [PubMed]

- Geng, C.; Zheng, L.; Yu, J.; Yan, Q.; Wei, T.; Wang, X.; Shen, D. Thermal annealing of colloidal monolayer at the air/water interface: A facile approach to transferrable colloidal mask with tunable interstice size for nanosphere lithography. J. Mater. Chem. 2012, 22, 22678–22685. [Google Scholar] [CrossRef]

- Yu, J.; Geng, C.; Zheng, L.; Ma, Z.; Tan, T.; Wang, X.; Yan, Q.; Shen, D. Preparation of high-quality colloidal mask for nanosphere lithography by a combination of air/water interface self-assembly and solvent vapour annealing. Langmuir 2012, 28, 12681–12689. [Google Scholar] [CrossRef]

- Snoeks, E.; Van Blaaderen, A.; Van Dillen, T.; Van Kats, C.M.; Brongersma, M.L.; Polman, A. Colloidal ellipsoids with continuously variable shape. Adv. Mater. 2000, 12, 1511–1514. [Google Scholar] [CrossRef]

- Van Dillen, T.; Snoeks, E.; Fukarek, W.; Van Kats, C.M.; Velikov, K.P.; Van Blaaderen, A.; Polman, A. Anisotropic deformation of colloidal particles under MeV ion irradiation. Nucl. Instrum. Methods Phys. Res. B 2001, 225, 350–356. [Google Scholar] [CrossRef]

- Van Dillen, T.; Polman, A.; Fukarek, W.; Van Blaaderen, A. Energy-dependent anisotropic deformation of colloidal silica particles under MeV Au irradiation. Appl. Phys. Lett. 2001, 78, 910–912. [Google Scholar] [CrossRef]

- Wesch, W.; Steinbach, T.; Ridgway, M.C. Swift heavy ion irradiation of amorphous semiconductors. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 10; Volume 61, pp. 403–440. [Google Scholar]

- Gärtner, K. Ion-solid interaction. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 1; Volume 61, pp. 3–62. [Google Scholar]

- Rizza, G.; Ridgway, M.C. Synthesis of nanostructures using ion-beams: An overview. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 4; Volume 61, pp. 137–185. [Google Scholar]

- Dufour, C.; Toulemonde, M. Models for the description of track formation. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 2; Volume 61, pp. 63–104. [Google Scholar]

- Weber, W.J.; Wendler, E. Modelling effects of radiation damage. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 3; Volume 61, pp. 105–136. [Google Scholar]

- Wesch, W.; Schnor, C.S. Swift heavy ion irradiation of crystalline semiconductors. In Ion Beam Modification of Solids—Ion-Solid Interaction and Radiation Damage; Wesch, W., Wendler, E., Eds.; Springer Series in Surface Sciences; Springer International Publishing: Cham, Switzerland, 2016; Chapter 9; Volume 61, pp. 365–402. [Google Scholar]

- Van Dillen, T. Ion Irradiation Effects in Silica Glasses. Master’s Thesis, Utrech University, Utrech, The Netherlands, 1999. [Google Scholar]

- Snoeks, E.; Van Blaaderen, A.; Van Dillen, T.; Van Kats, C.M.; Velikov, K.; Brongersma, M.L.; Polman, A. Colloidal assemblies modified by ion irradiation. Nucl. Instrum. Methods Phys. Res. B 2001, 178, 62–68. [Google Scholar] [CrossRef]

- Cheang-Wong, J.C.; Morales, U.; Reséndiz, E.; Lopez-Suarez, A.; RodrÍguez-Fernàndez, L. Dependence of the MeV ion-induced deformation of colloidal silica particles on the irradiation angle. Nucl. Instrum. Methods Phys. Res. B 2008, 266, 3162–3165. [Google Scholar] [CrossRef]

- Cheang-Wong, J.C.; Morales, U.; Oliver, A.; RodrÍguez-Fernàndez, L.; Rickards, J. MeV ion beam deformation of colloidal silica particles. Nucl. Instrum. Methods Phys. Res. B 2006, 242, 452–454. [Google Scholar] [CrossRef]

- Cheang-Wong, J.C.; Morales, U.; Reséndiz, E.; Lopez-Suarez, A. Energy-dependent deformation of colloidal silica nanoparticles under room temperature irradiation with MeV Si ions. J. Nano. Res. 2009, 5, 61–67. [Google Scholar] [CrossRef]

- Van Dillen, T.; Polman, A.; Van Kats, C.M.; Van Blaaderen, A. Ion beam-induced anisotropic plastic deformation at 300 keV. Appl. Phys. Lett. 2003, 83, 4315–4317. [Google Scholar] [CrossRef]

- Cheang-Wong, J.C.; Morales, U.; Reséndiz, E.; Oliver, A.; RodrÍguez-Fernàndez, L. Deformation of colloidal silica particles using MeV Si ion irradiation. J. Non-Cryst. Solids. 2007, 353, 1925–1929. [Google Scholar] [CrossRef]

- Penninkhof, J.J.; Graf, C.; Van Dillen, T.; Vredenberg, A.M.; Van Blaaderen, A.; Polman, A. Angle-dependent extinction of anisotropic silica/Au core/shell colloids made via ion irradiation. Adv. Mater. 2005, 17, 1484–1488. [Google Scholar] [CrossRef]

- Velikov, K.P.; Van Dillen, T.; Polman, A.; Van Blaaderen, A. Photonic crystals of shape-anisotropic colloidal particles. Appl. Phys. Lett. 2002, 81, 838–840. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.; Chen, Y.; Lan, D.; Wang, Y. Anisotropic deformation of polystyrene particles by MeV Au ion irradiation. Nucl. Instrum. Methods Phys. Res. B 2008, 266, 894–898. [Google Scholar] [CrossRef][Green Version]

- Klaumünzer, S. Ion hammering of silica colloids. Nucl. Instrum. Methods Phys. Res. B 2004, 215, 345–352. [Google Scholar] [CrossRef]

- Vossen, D.L.J.; Fific, D.; Penninkhof, J.; Van Dillen, T.; Polman, A.; Van Blaaderen, A. Combined optical tweezers/ion Beam technique to tune colloidal masks for nanolithography. Nano Lett. 2005, 5, 1175–1179. [Google Scholar] [CrossRef]

- Lindner, J.K.N.; Gehl, B.; Stritzker, B. Shape modifications of self-organised colloidal silica nanomasks on silicon. Nucl. Instrum. Methods Phys. Res. B 2006, 242, 167–169. [Google Scholar] [CrossRef]

- Lugomer, S.; Zolnai, Z.; Tóth, A.L.; Bàrsony, I. Self-organization of silica nano-particles induced by the ion beam. Phys. Stat. Solidi. C 2011, 9, 2858–2861. [Google Scholar] [CrossRef]

- Lugomer, S.; Zolnai, Z.; Tóth, A.L.; Bàrsony, I.; Maksimović, A.; Nagy, N. Reorganization of Langmuir–Blodgett layers of silica nanoparticles induced by the low energy, high fluence ion irradiation. Thin Solid Films 2012, 520, 4046–4056. [Google Scholar] [CrossRef]

- Lugomer, S.; Zolnai, Z.; Tóth, A.L.; Deàk, A.; Nagy, N. Ar+ ion irradiation-induced reorganization of colloidal silica nanoparticles in Langmuir–Blodgett monolayers. Thin Solid Films 2015, 574, 136–145. [Google Scholar] [CrossRef]

- Kraus, D.; Lindner, J.K.N.; Stritzker, B. Ion beam induced sintering of colloidal polystyrene nano-masks. Nucl. Instrum. Methods Phys. Res. B 2007, 257, 455–458. [Google Scholar] [CrossRef]

- Song, X.; Dai, Z.; Xiao, X.; Li, W.; Zheng, X.; Shang, X.; Zhang, X.; Cai, G.; Wu, W.; Meng, F.; et al. Formation of carbonized polystyrene sphere/hemisphere shell arrays by ion beam irradiation and subsequent annealing or chloroform treatment. Sci. Rep. 2015, 5, 17529. [Google Scholar] [CrossRef]

- Klaumünzer, S.; Zhu, Q.Q.; Schnabel, W.; Schumacher, G. Ion-beam-induced crosslinking of polystyrene—Still 32 an unsolved puzzle. Nucl. Instrum. Methods Phys. Res. B 1996, 116, 154–158. [Google Scholar]

- Bogdanović Radović, I.; Buljan, M.; Karlušić, M.; Jerčinović, M.; Dražić, G.; Bernstorff, S.; Boettger, R. Modification of semiconductor or metal nanoparticle lattices in amorphous alumina by MeV heavy ions. New J. Phys. 2016, 18, 093032. [Google Scholar] [CrossRef]

- Karlušić, M.; Škrabić, M.; Majer, M.; Buljan, M.; Skuratov, V.A.; Jung, H.K.; Gamulin, O.; Jakšić, M. Infrared spectroscopy of ion tracks in amorphous SiO2 and comparison to gamma irradiation induced changes. J. Nucl. Mater. 2019, 514, 4–83. [Google Scholar] [CrossRef]

- Farenzena, L.S.; Livi, R.P.; De Araújo, M.A.; Bermudez, G.G.; Papaléo, R.M. Cratering and plastic deformation in polystyrene induced by MeV heavy ions: Dependence on the molecular weight. Phys. Rev. B 2001, 63, 104108. [Google Scholar] [CrossRef]

- Lotito, V.; Zambelli, T. Self-assembly of single-sized and binary colloidal particles at air/water interface by surface confinement and water discharge. Langmuir 2016, 32, 9582–9590. [Google Scholar] [CrossRef]

- Lotito, V.; Zambelli, T. Pattern formation in binary colloidal assemblies: Hidden symmetries in a kaleidoscope of structures. Langmuir 2018, 34, 7827–7843. [Google Scholar] [CrossRef]

- Lotito, V.; Zambelli, T. A Journey through the Landscapes of Small Particles in Binary Colloidal Assemblies: Unveiling Structural Transitions from Isolated Particles to Clusters upon Variation in Composition. Nanomaterials 2019, 9, 921. [Google Scholar] [CrossRef]

- Maestro, A. Tailoring the interfacial assembly of colloidal particles by engineering the mechanical properties of the interface. Curr. Opin. Colloid Interface Sci. 2019, 39, 232–250. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, H.; Biggs, S.; Xu, Z.; Cayre, O.; Harbottle, D. The rheology of polyvinylpyrrolidone-coated silica nanoparticles positioned at an air-aqueous interface. J. Colloid Interface Sci. 2018, 527, 346–355. [Google Scholar] [CrossRef]

- Mireles, M.; Soule, C.W.; Dehghani, M.; Gaborski, T.R. Use of Nanosphere Self-Assembly to Pattern Nanoporous Membranes for the Study of Extracellular Vesicles. bioRxiv 2019. [Google Scholar] [CrossRef]

- Carrasco-Fadanelli, V.; Castillo, R. Measurement of the force between uncharged colloidal particles trapped at a flat air/water interface. Soft Matter 2019, 15, 5815–5818. [Google Scholar] [CrossRef]

- Lyutskanova-Zhekova, G.; Danov, K. Effect of ionic strength on the electro-dipping force. In Proceedings of the 9th International conference on Numerical Methods and Applications NMA, Borovets, Bulgaria, 20–24 August 2018; Lecture Notes in Computer Science LNCS Volume 11189. Springer Nature: Basel, Switzerland, 2019. [Google Scholar]

- Azar, E.; Blanc, C.; Mehdi, A.; Nobili, M.; Stocco, A. Mesoporous silica colloids: Wetting, surface diffusion, and cationic surfactant adsorption. J. Phys. Chem. C 2019, 123, 26226–26235. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, M.-W.; Jo, Y.-R.; Kim, N.-Y.; Kang, D.; Lee, S.Y.; Yim, S.-Y.; Kim, B.-J.; Kim, J.H. Hollow porous gold nanoshells with controlled nanojunctions for highly tunable plasmon resonances and intense field enhancements for surface-enhanced Raman scattering. ACS Appl. Mater. Interfaces 2019, 11, 44458–44465. [Google Scholar] [CrossRef]

- Das, S.; Koplik, J.; Farinato, R.; Nagaraj, D.R.; Maldarelli, C.; Somasundaran, P. The translational and rotational dynamics of a colloid moving along the air-liquid interface of a thin film. Sci. Rep. 2018, 8, 8910. [Google Scholar] [CrossRef]

- Jang, M.; Lee, H.; Lee, W. Large area honeycomb-structured TiO2 film for photocatalytic water splitting. ACS Appl. Nano Mater. 2020, 3, 131–137. [Google Scholar] [CrossRef]

- Karlušić, M.; Fazinić, S.; Siketić, Z.; Tadić, T.; Cosic, D.D.; Božičević-Mihalić, I.; Zamboni, I.; Jakšić, M.; Schleberger, M. Monitoring Ion Track Formation Using In Situ RBS/c, ToF-ERDA, and HR-PIXE. Materials 2017, 10, 1041. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.B.; Littmark, U. The Stopping and Range of Ions in Solids, Version SRIM2013.00. Available online: www.srim.org (accessed on 20 January 2020).

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.B. SRIM—The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Yefimov, N.V. Quadratic Forms and Matrices; Springer Series in Surface Sciences; Academic Press Inc.: New York, NY, USA; London, UK, 1964. [Google Scholar]

- Zwillinger, D. CRC Standard Mathematical Tables and Formulas, 33rd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Reventos Tarrida, A. Affine Maps, Euclidean Motions and Quadrics; Springer: London, UK, 2011. [Google Scholar]

- Krivoshapko, S.N.; Ivanov, V.N. Encyclopedia of Analytical Surfaces; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Schmidt, B.; Wetzig, K. Ion Beams in Materials Processing and Analysis; Springer: Wien, Austria, 2013; Volume 61. [Google Scholar]

- Zolnai, Z.; Deàk, A.; Nagy, N.; Tóth, A.L.; Kótai, E.; Battistig, G. A 3D-RBS study of irradiation-induced deformation and masking properties of ordered colloidal nanoparticulate masks. Nucl. Instrum. Methods Phys. Res. B 2010, 268, 79–86. [Google Scholar] [CrossRef]

- Toulemonde, M.; Paumier, E.; Dufour, C. Thermal spike model in the electronic stopping power regime. Radiat. Eff. Defects Solids 1993, 126, 201–206. [Google Scholar] [CrossRef]

- Calcagno, L.; Foti, G. Ion irradiation of polymers. Nucl. Instrum. Methods Phys. Res. Sect. B 1991, 59, 1153–1158. [Google Scholar] [CrossRef]

- Marletta, G. Chemical reactions and physical property modifications indiced by keV ion beams in polymers. Nucl. Instrum. Methods Phys. Res. B 1990, 46, 295–305. [Google Scholar] [CrossRef]

- Lee, E.H. Ion-beam modification of polymeric materials—Fundamental principles and applications. Nucl. Instrum. Methods Phys. Res. B 1990, 151, 29–41. [Google Scholar] [CrossRef]

- Kumar, V.; Chaudhary, B.; Sharma, V.; Verma, K. Radiation Effects in Polymeric Materials; Springer Nature: Basel, Switzerland, 2019. [Google Scholar]

- Calcagno, L.; Foti, G. Density enhancement in ion implanted polymers. Nucl. Instrum. Methods Phys. Res. Sect. B 1987, 19, 895–898. [Google Scholar] [CrossRef]

- Davenas, J.; Thévenard, P.; Boiteux, G.; Fallavier, M.; Lu, X. Hydrogenated carbon layers produced by ion beam irradiation of PMMA and polystyrene films. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1990, 46, 317–323. [Google Scholar] [CrossRef]

- Bouffard, S.; Balanzat, E.; Leroy, C.; Busnel, J.; Guevelou, G. Cross-links induced by swift heavy ion irradiation in polystyrene. Nucl. Instrum. Methods Phys. Res. Sect. B 1997, 131, 79–84. [Google Scholar] [CrossRef]

- Balanzat, E.; Bouffard, S.; Bouquerel, A.; Devy, J.; Gaté, C. Swift heavy ion irradiation of polystyrene. Nucl. Instrum. Methods Phys. Res. Sect. B 1996, 116, 159–163. [Google Scholar] [CrossRef]

- Singh, L.; Samra, K.S.; Singh, R. Optical and Structural Modifications in Heavy Ion Irradiated Polystyrene. J. Macromol. Sci. Part B 2007, 46, 749–759. [Google Scholar] [CrossRef]

- Güven, O. Crosslinking and scission in polymers. In NATO ASI Series C: Mathematical and Physical Sciences; Kluwer Academic Publishers: Dordrecht, The Netherlands; Boston, MA, USA; London, UK, 1990; Volume 292. [Google Scholar]

- Scott, G. Mechanisms of Polymer Degradation and Stabilization; Elsevier Science Publishers: London, UK; New York, NY, USA, 1990. [Google Scholar]

- German, R.M.; Munir, Z.A. The geometry of sintering wires. J. Mater. Sci. 1975, 10, 1719–1724. [Google Scholar] [CrossRef]

- German, R.; Munir, Z.A. Morphology relations during surface-transport controlled sintering. Met. Mater. Trans. A 1975, 6, 289–294. [Google Scholar] [CrossRef]

- German, R.; Munir, Z.A. Morphology relations during bulk-transport sintering. Met. Mater. Trans. A 1975, 6, 2229. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, H.; Huang, C.; Liu, M. Asymptotics of a catenoid liquid bridge between two spherical particles with different radii and contact angles. Phys. Fluids 2019, 31, 062102. [Google Scholar]

- Navaz, H.K.; Zand, A.; Atkinson, T.; Nowakowski, A.; Gat, A.D.; Paikoff, S. Contact dynamic modeling of a liquid droplet between two approaching porous materials. AIChE J. 2014, 60, 2346–2353. [Google Scholar] [CrossRef]

- Bartlett, C.T.; Généro, G.A.; Bird, J.C. Coalescence and break-up of nearly inviscid conical droplets. J. Fluid Mech. 2015, 763, 369–385. [Google Scholar] [CrossRef]

- Wu, P.; Peng, L.; Tuo, X.; Wang, X.; Yuan, J. Control of deposition channels in nanosphere templates for high-density nanodot array production. Nanotechnology 2005, 16, 1693–1696. [Google Scholar] [CrossRef]

- Cong, C.; Junus, W.C.; Shen, Z.; Yu, T. New colloidal lithographic nanopatterns fabricated by combining pre-heating and reactive ion etching. Nanoscale Res. Lett. 2009, 4, 1324–1328. [Google Scholar] [CrossRef]

- Gogel, D.; Weinl, M.; Lindner, J.K.N.; Stritzker, B. Plasma modification of nanosphere lithography masks made of polystyrene beads. J. Optoelectron. Adv. Mater. 2010, 12, 740–744. [Google Scholar]

- Domonkos, M.; Izak, T.; Stolcova, L.; Proska, J.; Kromka, A. Controlled structuring of self-assembled polystyrene microsphere arrays by two different plasma systems. In Proceedings of the 5th International Conference NanoCon, Brno, Czech Republic, 16–18 October 2013. [Google Scholar]

- Silencieux, F.; Bouchoucha, M.; Mercier, O.; Turgeon, S.; Chevallier, P.; Kleitz, F.; Fortin, M.-A. Mesoporous Silica Nanoparticles under Sintering Conditions: A Quantitative Study. Langmuir 2015, 31, 13011–13021. [Google Scholar] [CrossRef]

- Yi, D.K.; Seo, E.-M.; Kim, D.-Y. Fabrication of a Mesoscale Wire: Sintering of a Polymer Colloid Arrayed Inside a One-Dimensional Groove Pattern. Langmuir 2002, 18, 5321–5323. [Google Scholar] [CrossRef]

- Lotito, V.; Sennhauser, U.; Hafner, C.; Bona, G.-L. Fully metal-coated scanning near-field optical microscopy probes with spiral corrugations for superfocusing under arbitrarily oriented linearly polarised excitation. Plasmonics 2011, 6, 327–336. [Google Scholar] [CrossRef][Green Version]

- Lotito, V.; Sennhauser, U.; Hafner, C.; Bona, G.-L. Interaction of an asymmetric scanning near field optical microscopy probe with fluorescent molecules. Prog. Electromagn. Res. 2011, 121, 281–299. [Google Scholar] [CrossRef][Green Version]

- Chibani, H.; Dukenbayev, K.; Mensi, M.; Sekatskii, S.K.; Dietler, G. Near-field scanning optical microscopy using polymethylmethacrylate optical fiber probes. Ultramicroscopy 2010, 110, 211–215. [Google Scholar] [CrossRef] [PubMed]

- Lotito, V.; Sennhauser, U.; Hafner, C. Finite element analysis of asymmetric scanning near field optical microscopy probes. J. Comput. Theor. Nanosci. 2010, 7, 1596–1609. [Google Scholar] [CrossRef]

- Lotito, V.; Sennhauser, U.; Hafner, C. Effects of asymmetric surface corrugations on fully metal-coated scanning near field optical microscopy tips. Opt. Express 2010, 18, 8722–8734. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.; Sherman Jr., R. L.; Ford, W.T. Nanoscale compression of polymer microspheres by atomic force microscopy. Langmuir 2004, 20, 7015–7020. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Zheng, L.; Wang, X.; Yan, Q. Quantitative characterization of mechanical property of annealed monolayer colloidal crystal. Langmuir 2016, 32, 451–459. [Google Scholar] [CrossRef]

- Paik, P.; Kar, K.K.; Deva, D.; Sharma, A. Measurement of mechanical properties of polymer nanospheres by atomic force microscopy: Effects of particle size. Micro Nano Lett. 2007, 2, 72–77. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, L.; Yan, Q.; Guo, D.; Xie, G. Size dependent mechanical properties of monolayer densely arranged polystyrene nanospheres. Langmuir 2016, 32, 13187–13192. [Google Scholar] [CrossRef]

- Guo, D.; Li, J.; Xie, G.; Wang, Y.; Luo, J. Elastic properties of polystyrene nanospheres evaluated with atomic force microscopy: Size effect and error analysis. Langmuir 2014, 30, 7206–7212. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lotito, V.; Karlušić, M.; Jakšić, M.; Tomić Luketić, K.; Müller, U.; Zambelli, T.; Fazinić, S. Shape Deformation in Ion Beam Irradiated Colloidal Monolayers: An AFM Investigation. Nanomaterials 2020, 10, 453. https://doi.org/10.3390/nano10030453

Lotito V, Karlušić M, Jakšić M, Tomić Luketić K, Müller U, Zambelli T, Fazinić S. Shape Deformation in Ion Beam Irradiated Colloidal Monolayers: An AFM Investigation. Nanomaterials. 2020; 10(3):453. https://doi.org/10.3390/nano10030453

Chicago/Turabian StyleLotito, Valeria, Marko Karlušić, Milko Jakšić, Kristina Tomić Luketić, Ulrich Müller, Tomaso Zambelli, and Stjepko Fazinić. 2020. "Shape Deformation in Ion Beam Irradiated Colloidal Monolayers: An AFM Investigation" Nanomaterials 10, no. 3: 453. https://doi.org/10.3390/nano10030453

APA StyleLotito, V., Karlušić, M., Jakšić, M., Tomić Luketić, K., Müller, U., Zambelli, T., & Fazinić, S. (2020). Shape Deformation in Ion Beam Irradiated Colloidal Monolayers: An AFM Investigation. Nanomaterials, 10(3), 453. https://doi.org/10.3390/nano10030453