Effect of TiO2 and ZnO Nanoparticles on the Performance of Dielectric Nanofluids Based on Vegetable Esters During Their Aging

Abstract

:1. Introduction

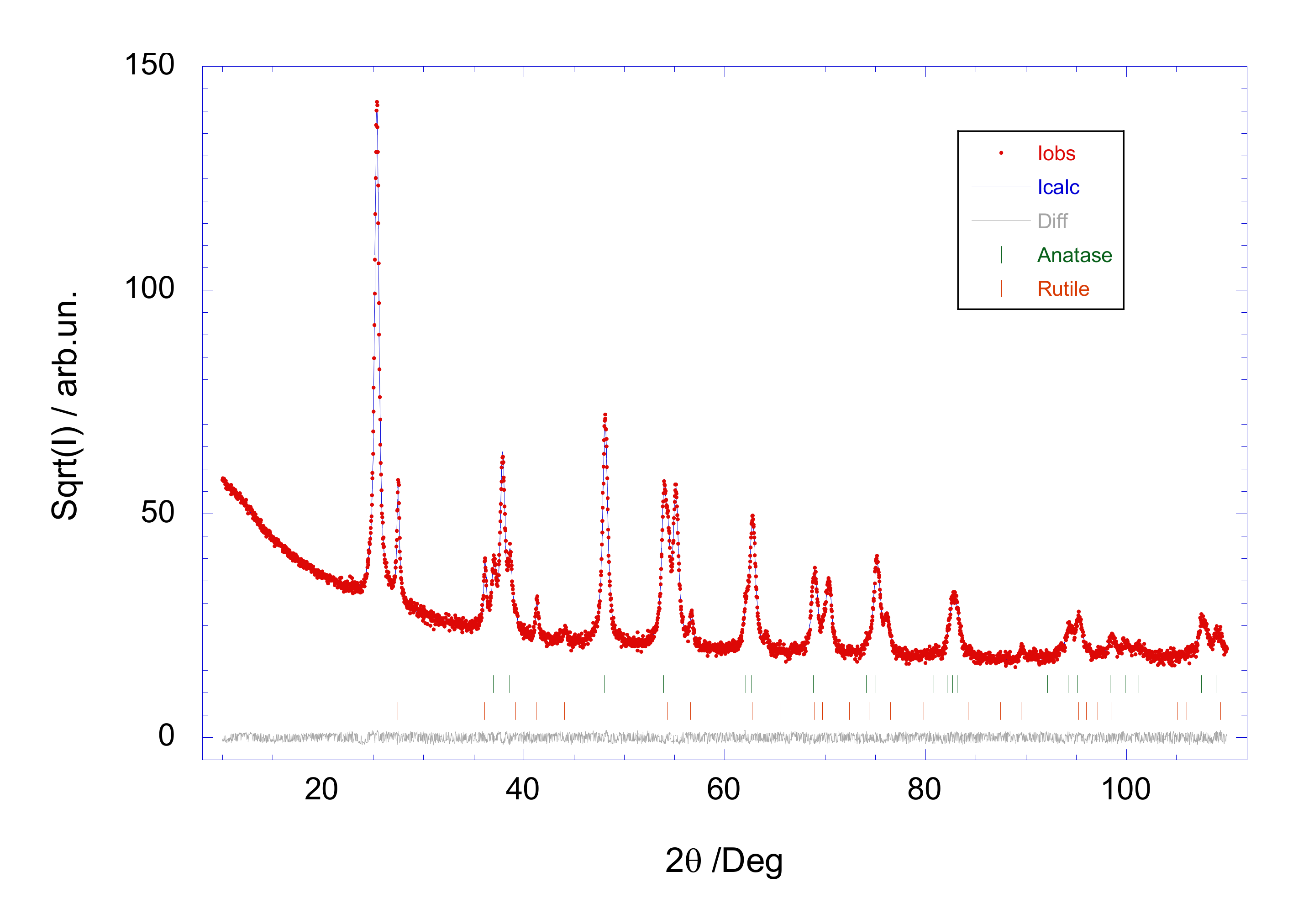

2. Materials and Methods

2.1. Materials

2.2. Nanofluid Synthesis

2.3. Methodology of Thermal Aging

- The dielectric fluids were introduced into steel containers where there were strips of Kraft paper (0.2 mm thickness; Figure 6).

- The Kraft paper was dried at 100 °C for 48 h to reduce its moisture content and the oil was degassed at 60 °C during 6 h.

- By means of a vacuum pump the air was extracted from the containers. Then the containers were filled with nitrogen.

- Finally, the steel containers were introduced into the oven at 150 °C.

3. Results

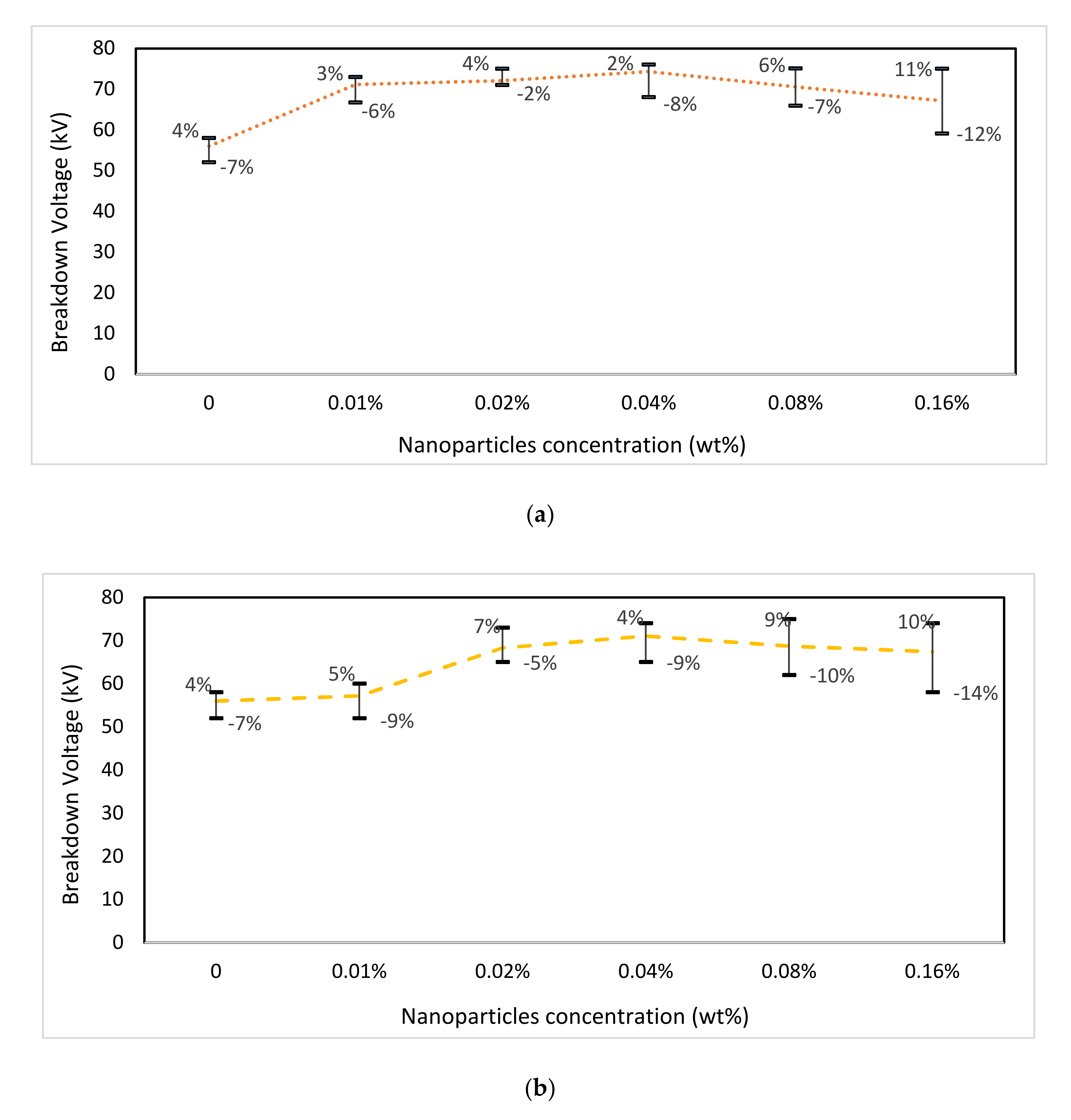

3.1. Optimum Concentration

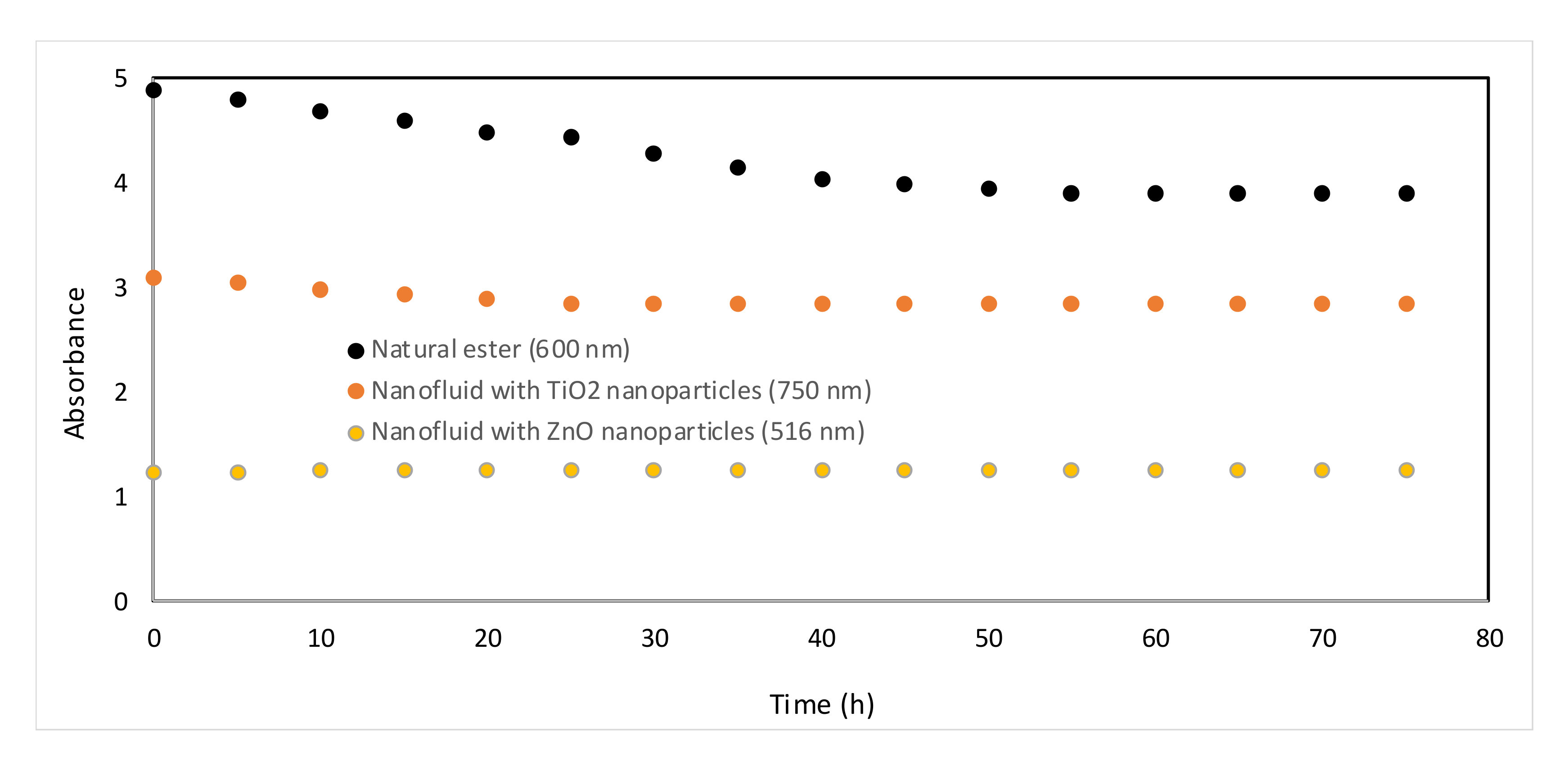

3.2. Nanofluid Stability

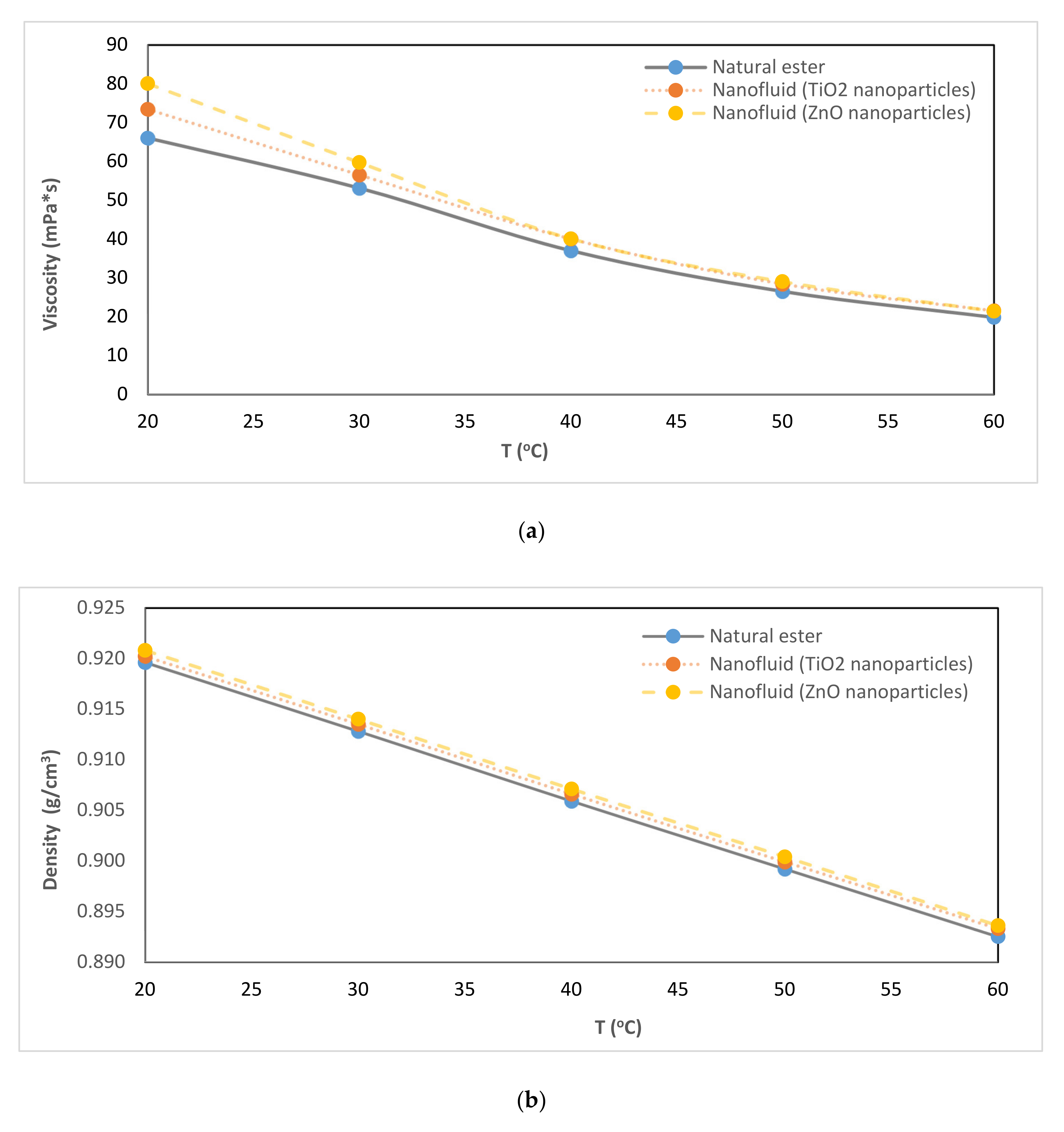

3.3. Density and Viscosity

3.4. Breakdown Voltage

3.5. Moisture

3.6. Dissipation Factor

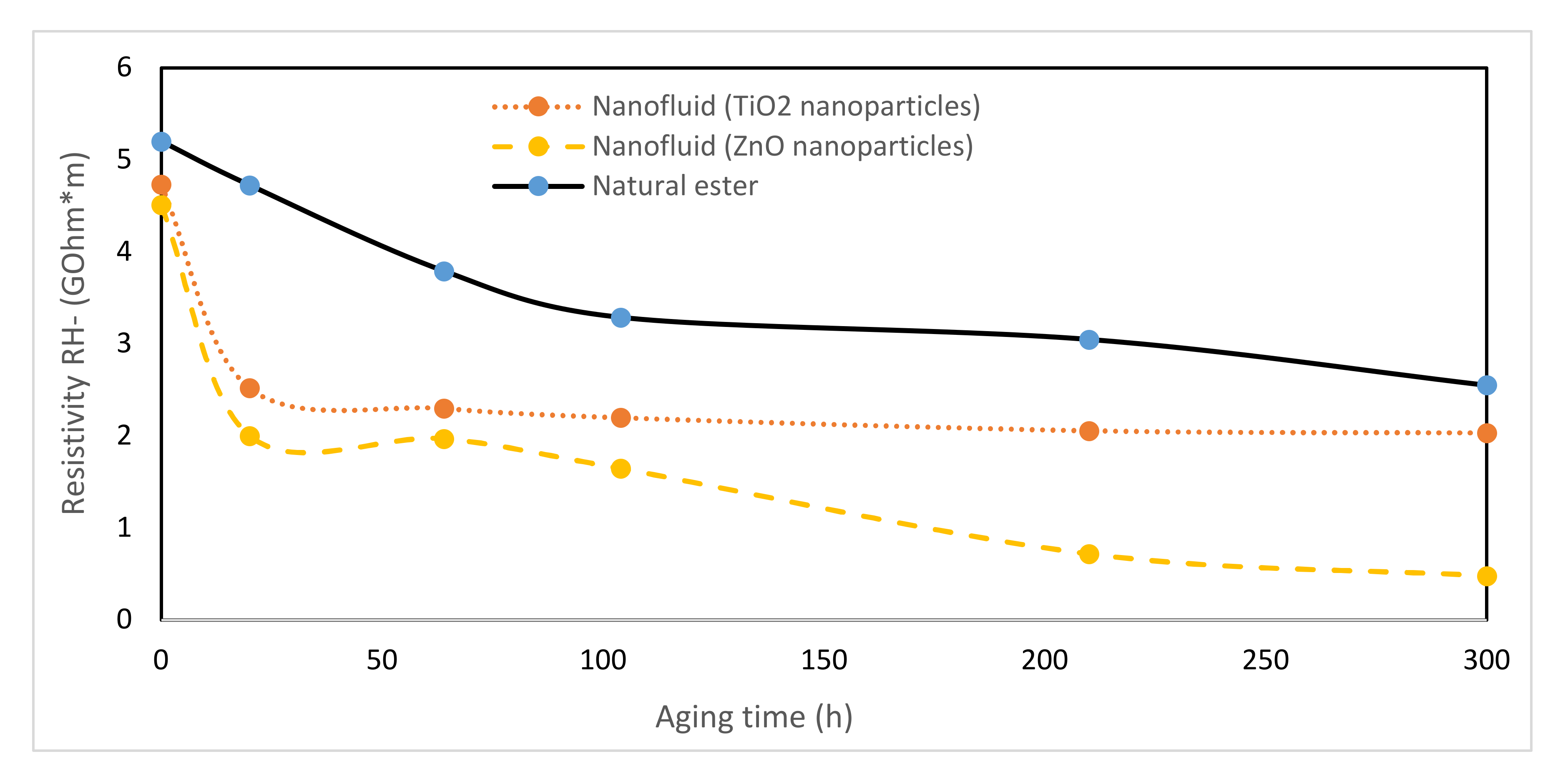

3.7. Resistivity

3.8. Acidity

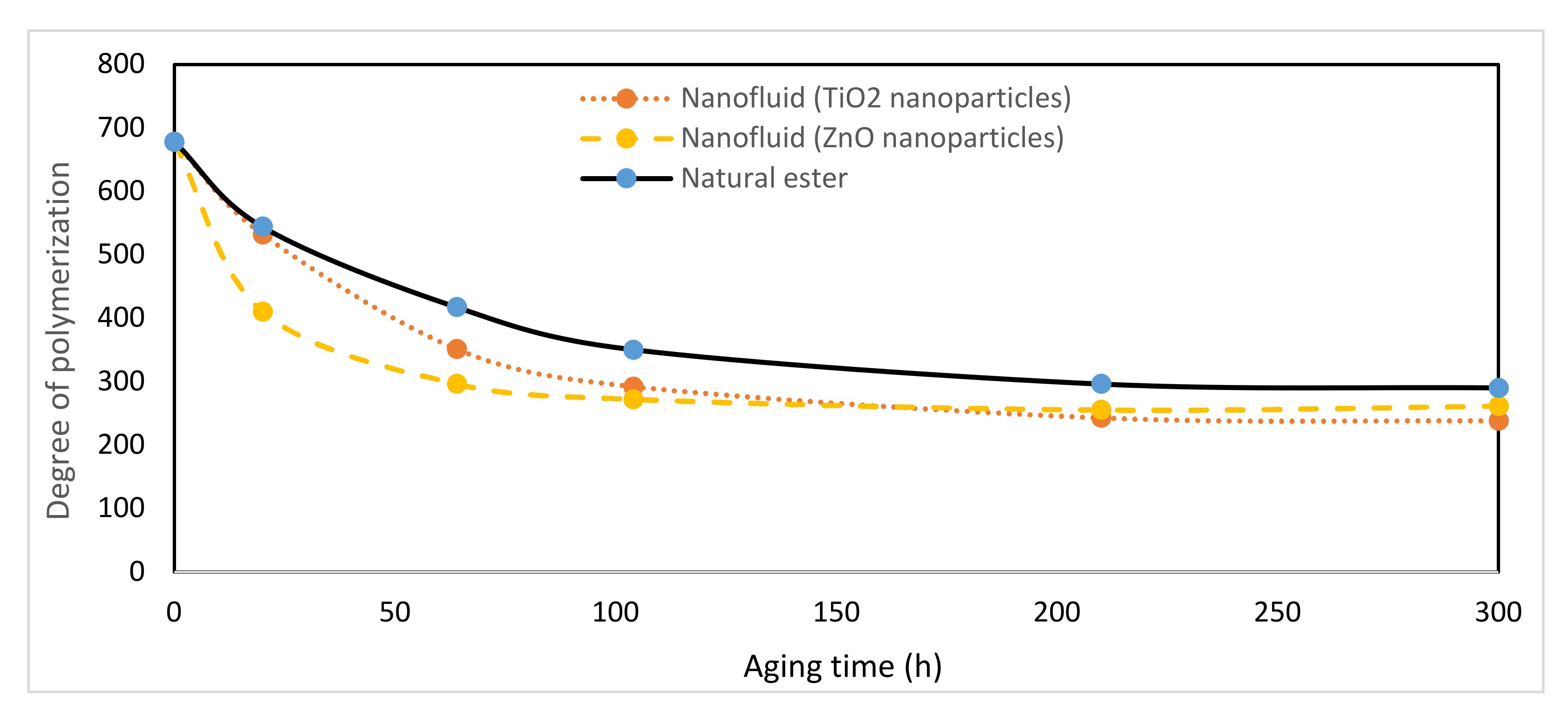

3.9. Degree of Polymerization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Du, B.X.; Li, X.L.; Xiao, M. High thermal conductivity transformer oil filled with BN nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 851–858. [Google Scholar] [CrossRef]

- Rafiq, M.; Lv, Y.; Li, C. A Review on properties, opportunities, and challenges of transformer oil-based nanofluids. Nanomaterials 2016, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Contreras, J.E.E.; Rodriguez, A.; Taha-Tijerina, J. Nanotechnology applications for electrical transformers—A review. Electr. Power Syst. Res. 2017, 143, 573–584. [Google Scholar] [CrossRef]

- Lv, Y.Z.; Zhou, Y.; Li, C.R.; Wang, Q.; Qi, B. Recent progress in nanofluids based on transformer oil: Preparation and electrical insulation properties. IEEE Electr. Insul. Mag. 2014, 30, 23–32. [Google Scholar] [CrossRef]

- Ibrahim, M.E.; Abd-Elhady, A.M.; Izzularab, M.A. Effect of nanoparticles on transformer oil breakdown strength: Experiment and theory. IET Sci. Meas. Technol. 2016, 10, 839–845. [Google Scholar] [CrossRef]

- Sima, W.; Shi, J.; Yang, Q.; Huang, S.; Cao, X. Effects of conductivity and permittivity of nanoparticle on transformer oil insulation performance: Experiment and theory. IEEE Trans. Dielectr. Electr. Insul. 2014, 22, 380–390. [Google Scholar] [CrossRef]

- Wang, Q.; Rafiq, M.; Lv, Y.; Li, C.; Yi, K. Preparation of three types of transformer oil-based nanofluids and comparative study on the effect of nanoparticle concentrations on insulating property of transformer oil. J. Nanotechnol. 2016, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Madavan, R.; Balaraman, S. Investigation on effects of different types of nanoparticles on critical parameters of nano-liquid insulation systems. J. Molec. Liq. 2017, 230, 437–444. [Google Scholar]

- Li, J.; Zhang, Z.; Zou, P.; Grzybowski, S.; Zahn, M. Preparation of a vegetable oil-based nanofluid and investigation of its breakdown and dielectric properties. IEEE Electr. Insul. Mag. 2012, 28, 43–50. [Google Scholar] [CrossRef]

- Olmo, C.; Méndez, C.; Ortiz, F.; Delgado, F.; Valiente, R.; Werle, P. Maghemite nanofluid based on natural ester: Cooling and insulation properties assessment. IEEE Access 2019, 7, 145851–145860. [Google Scholar] [CrossRef]

- Patel, J.; Parekh, K.; Upadhyay, R.V. Prevention of hot spot temperature in a distribution transformer using magnetic fluid as a coolant. Int. J. Therm. Sci. 2016, 103, 35–40. [Google Scholar] [CrossRef]

- Danescu, L.P.; Morega, A.M.; Morega, M.; Stoica, V.; Marinic, O.M.; Noura, F.; Paduraru, N.; Borbáth, I.; Borbáth, T. Prototyping a ferrofluid-cooled transformer. IEEE Trans. Ind. Appl. 2013, 49, 1289–1298. [Google Scholar] [CrossRef]

- Patel, J.; Parekh, K.; Upadhyay, R.V. Performance of Mn-Zn ferrite magnetic fluid in a prototype distribution transformer under varying loading conditions. Int. J. Therm. Sci. 2017, 114, 64–71. [Google Scholar] [CrossRef]

- Fernández, I.; Delgado, F.; Ortiz, F.; Ortiz, A.; Fernández, C.; Renedo, C.J.; Santisteban, A. Thermal degradation assessment of Kraft paper in power transformers insulated with natural esters. Appl. Therm. Eng. 2016, 104, 129–138. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Diego, C.; Ortiz, A.; Carrascal, I.A.; Fernández, I.; Renedo, C.J.; Delgado, F.; Diego, S. Damage assessment of transformer Kraft paper insulation aged in mineral and vegetable oils. Cellulose 2019, 26, 2653–2672. [Google Scholar] [CrossRef]

- Zmarzly, D.; Dobry, D. Analysis of properties of aged mineral oil doped with C60 fullerenes. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1119–1126. [Google Scholar] [CrossRef]

- Chen, M.-t.; Du, Y.-f.; Lv, Y.-z.; Zhou, J.-q.; Li, X.; Li, C. Effect of nanoparticles on the dielectric strength of aged transformer oil. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011; pp. 664–667. [Google Scholar]

- Emara, M.M.; Mansour, D.E.A.; Azmy, A.M. Dielectric properties of aged mineral oil filled with TiO2 nanoparticles. In Proceedings of the 4th International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 24–26 November 2015; pp. 1–5. [Google Scholar]

- Prasath, R.T.A.R.; Karthik, R.; Iruthayarajan, M.W. Enhancement of critical properties of pure and aged transformer oil using nanocomposites. In Proceedings of the International Conference on Circuits, Power and Computing Technologies [ICCPCT], Nagercoil, India, 20–21 March 2014; pp. 382–387. [Google Scholar]

- Swamy, V.; Kuznetsov, A.; Dubrovinsky, L.S.; Caruso, R.A.; Shchukin, D.G.; Muddle, B.C. Finite-size and pressure effects on the Raman spectrum of nanocrystalline anatase TiO2. Phys. Rev. 2005, B71, 184302. [Google Scholar] [CrossRef]

- Mazza, T.; Barborini, E.; Piseri, P.; Milani, P.; Cattaneo, D.; Li Bassi, A.; Bottani, C.E.; Ducati, C. Raman spectroscopy characterization of TiO2 rutile nanocrystals. Phys. Rev. 2007, B75, 045416. [Google Scholar] [CrossRef]

- Cuscó, R.; Alarcón-Llado, E.; Ibáñez, J.; Artús, L.; Jiménez, J.; Wang, B.; Callahan, M.J. Temperature dependence of Raman scattering in ZnO. Phys. Rev. 2007, B75, 165202. [Google Scholar] [CrossRef]

- Primo, V.A.; Pérez-Rosa, D.; García, B.; Cabanelas, J.C. Evaluation of the stability of dielectric nanofluids for use in transformers under real operating conditions. Nanomaterials 2019, 9, 143. [Google Scholar] [CrossRef] [Green Version]

- Choudhary, R.; Khurana, D.; Kumar, A.; Subudhi, S. Stability analysis of Al2O3/water nanofluids. J. Exp. Nanosci. 2017, 12, 140–151. [Google Scholar] [CrossRef] [Green Version]

- IEC. Power Transformers—Part 2: Temperature Rise for Liquid-Immersed Transformers. In IEC Standards; IEC 60076-2:2011; IEC: Geneva, Switzerland, 2011. [Google Scholar]

- IEC. Insulating Liquids—Determination of the Breakdown Voltage at Power Frequency—Test method. In IEC Standards; IEC 60156:2018; IEC: Geneva, Switzerland, 2018. [Google Scholar]

- Swati, K.; Yadav, K.S.; Sarathi, R.; Vinu, R.; Danikas, M.G. Understanding corona discharge activity in titania nanoparticles dispersed in transformer oil under AC and DC voltages. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2325–2336. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, N.; Wang, Z.; Cui, W.; Chen, W.; Sui, S.; Yang, X. Modified propagating behavior of creeping streamers at TiO2 nanofluid/pressboard interface. J. Molec. Liq. 2019, 291, 111270. [Google Scholar] [CrossRef]

- Sun, P.; Sima1, W.; Zhang, D.; Chen, Q.; Ye, L.; Chen, J. Effects of impulse waveform parameters on the breakdown characteristics of nano-tio2 modified transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1651–1659. [Google Scholar] [CrossRef]

- Katiyar, A.; Dhar, P.; Nandi, T.; Das, S.K. Effects of nanostructure permittivity and dimensions on the increased dielectric strength of nano insulating oils. Coll. Surf. A 2016, 509, 235–243. [Google Scholar] [CrossRef]

- Kalteha, M.; Abbassi, A.; Saffar-Avval, M.; Frijns, A.; Anton, F.; Darhuber, A.; Harting, J. Experimental and numerical investigation of nanofluid forced convection inside a wide microchannel heat sink. Appl. Therm. Eng. 2012, 36, 260–268. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.Z.; Li, C.; Chen, M.; Zhou, J.; Li, X.; Zhou, Y.; Tu, Y. Effect of electron shallow trap on breakdown performance of transformer oil- based nanofluids. J. Appl. Phys. 2011, 110, 104104. [Google Scholar] [CrossRef]

- Hwang, J.G.; Zahn1, M.; O’Sullivan, F.M.; Pettersson, L.A.A.; Hjortstam, O.; Liu, R. Effects of nanoparticle charging on streamer development in transformer oil-based nanofluids. J. Appl. Phys. 2010, 107, 014310. [Google Scholar] [CrossRef] [Green Version]

- Timofeeva, E.V.; Moravek, M.R.; Singh, D. Improving the heat transfer efficiency of synthetic oil with silica nanoparticles. J. Colloid Interface Sci. 2011, 364, 71–79. [Google Scholar] [CrossRef]

- Vasheghani, M.; Marzbanrad, E.; Zamani, C.; Aminy, M.; Raissi, B.; Ebadzadeh, T.; Barzegar-Bafrooei, H. Effect of Al2O3 phases on the enhancement of thermal conductivity and viscosity of nanofluids in engine oil. Heat Transf. Eng. 2011, 47, 1401–1405. [Google Scholar] [CrossRef]

- Putra, N.; Roetzel, W.; Das, S.K. Natural convection of nano-fluids. Heat Mass. Transf. 2003, 39, 775–784. [Google Scholar] [CrossRef]

- Lewand, L. Laboratory evaluation of several synthetic and agricultural-based dielectric liquids. In Proceedings of the 68th Annual International Conference of Doble Clients, Doble Engineering Company, Watertown, MA, USA, 5‒8 March 2001. [Google Scholar]

- IEEE. IEEE Guide for Acceptance and Maintenance of Insulating oil in Equipment; C57.106–2006; IEEE: New York, NY, USA, 2006. [Google Scholar]

- Rapp, K.J.; McShane, C.P.; Luksich, J. Interaction mechanisms of natural ester dielectric fluid and Kraft paper. In Proceedings of the IEEE International Conference on Dielectric Liquids, ICDL, Coimbra, Portugal, 26 June–1 July 2005; pp. 387–390. [Google Scholar]

- Garcia, B.; Garcia, T.; Primo, V.; Burgos, J.C.; Urquiza, D. Studying the loss of life of natural-ester-filled transformer insulation: Impact of moisture on the aging rate of paper. IEEE Electr. Insul. Mag. 2017, 33, 15–23. [Google Scholar] [CrossRef]

- IEC. Insulating liquids—Oil-impregnated paper and pressboard—Determination of water by automatic coulometric Karl Fischer titration. In IEC Standards; IEC 60814:1997; IEC: Geneva, Switzerland, 1997. [Google Scholar]

- IEC. Insulating liquids—Measurement of relative permittivity, dielectric dissipation factor (tan d) and d.c. resistivity. In IEC Standards; IEC 60247:2004; IEC: Geneva, Switzerland, 2004. [Google Scholar]

- IEC. Insulating liquids—Determination of acidity—Part 3: Test methods for non-mineral insulating oils. In IEC Standards; IEC 62021-3:2014; IEC: Geneva, Switzerland, 2014. [Google Scholar]

- IEC. CSV Consolidated version Measurement of the average viscometric degree of polymerization of new and aged cellulosic electrically insulating materials. In IEC Standards; IEC 60450:2004+AMD1:2007; IEC: Geneva, Switzerland, 2007. [Google Scholar]

| Property | Specification |

|---|---|

| Breakdown Voltage kV | >75 |

| Kinematic Viscosity at 40 °C | 37 |

| Density at 20 °C | 0.92 |

| Pour point °C | −31 |

| Property | Specification ZnO | Specification TiO2 |

|---|---|---|

| Density (g/cm3) | 5.61 | 3.89 |

| Specific surface area (m2/g) | >50 | >120 |

| Purity (%) | 99.5 | 99.5 |

| Average diameter (nm) | 60 | 45 |

| Fluid | Characteristics | |||||

|---|---|---|---|---|---|---|

| tan δ- | ε- | DC Resistivity | Moisture | Acidity | ||

| GΩ-m (+) | GΩ-m (−) | ppm | mg KOH/g | |||

| Ester | 0.030 | 2.80 | 5.60 | 5.20 | 281 | <0.07 |

| Ester + ZnO | 0.098 | 2.80 | 4.42 | 4.51 | 358 | 0.23 |

| Ester + TiO2 | 0.080 | 2.80 | 4.91 | 4.73 | 297 | 0.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, I.; Valiente, R.; Ortiz, F.; Renedo, C.J.; Ortiz, A. Effect of TiO2 and ZnO Nanoparticles on the Performance of Dielectric Nanofluids Based on Vegetable Esters During Their Aging. Nanomaterials 2020, 10, 692. https://doi.org/10.3390/nano10040692

Fernández I, Valiente R, Ortiz F, Renedo CJ, Ortiz A. Effect of TiO2 and ZnO Nanoparticles on the Performance of Dielectric Nanofluids Based on Vegetable Esters During Their Aging. Nanomaterials. 2020; 10(4):692. https://doi.org/10.3390/nano10040692

Chicago/Turabian StyleFernández, Inmaculada, Rafael Valiente, Félix Ortiz, Carlos J. Renedo, and Alfredo Ortiz. 2020. "Effect of TiO2 and ZnO Nanoparticles on the Performance of Dielectric Nanofluids Based on Vegetable Esters During Their Aging" Nanomaterials 10, no. 4: 692. https://doi.org/10.3390/nano10040692