Various Coating Methodologies of WO3 According to the Purpose for Electrochromic Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

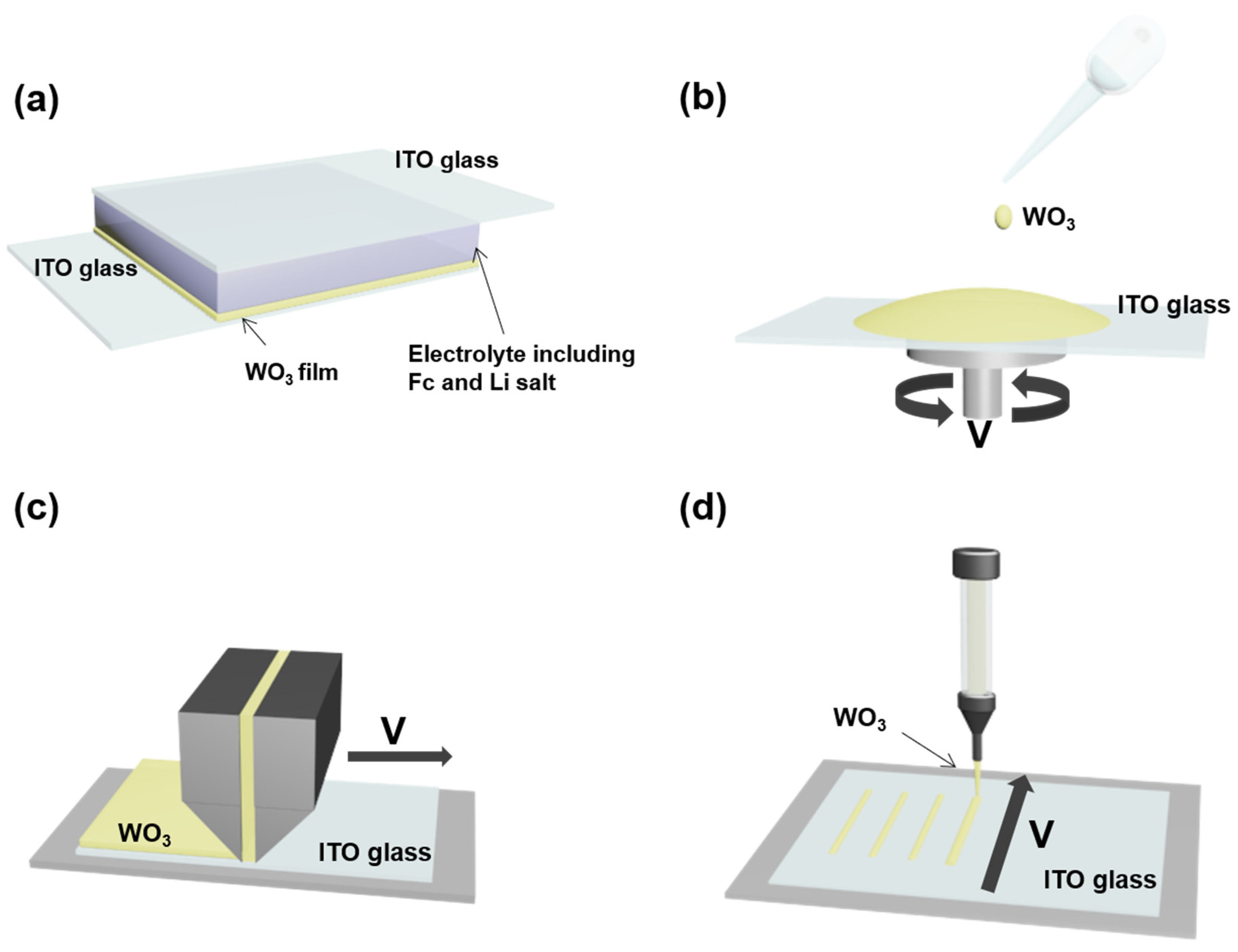

2.2. Fabrication of Tungsten Oxide Film

2.3. Device Fabrication and Characterization

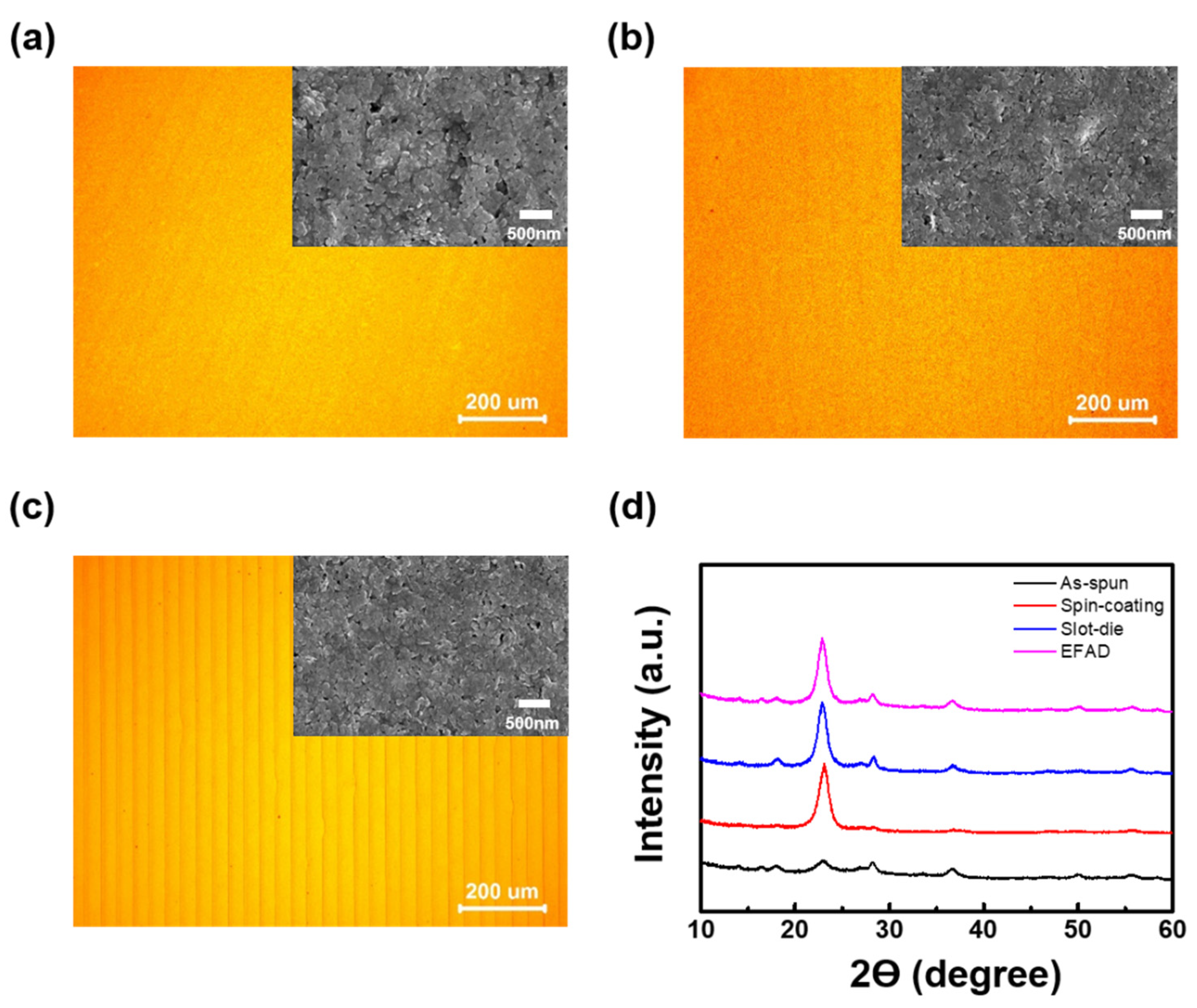

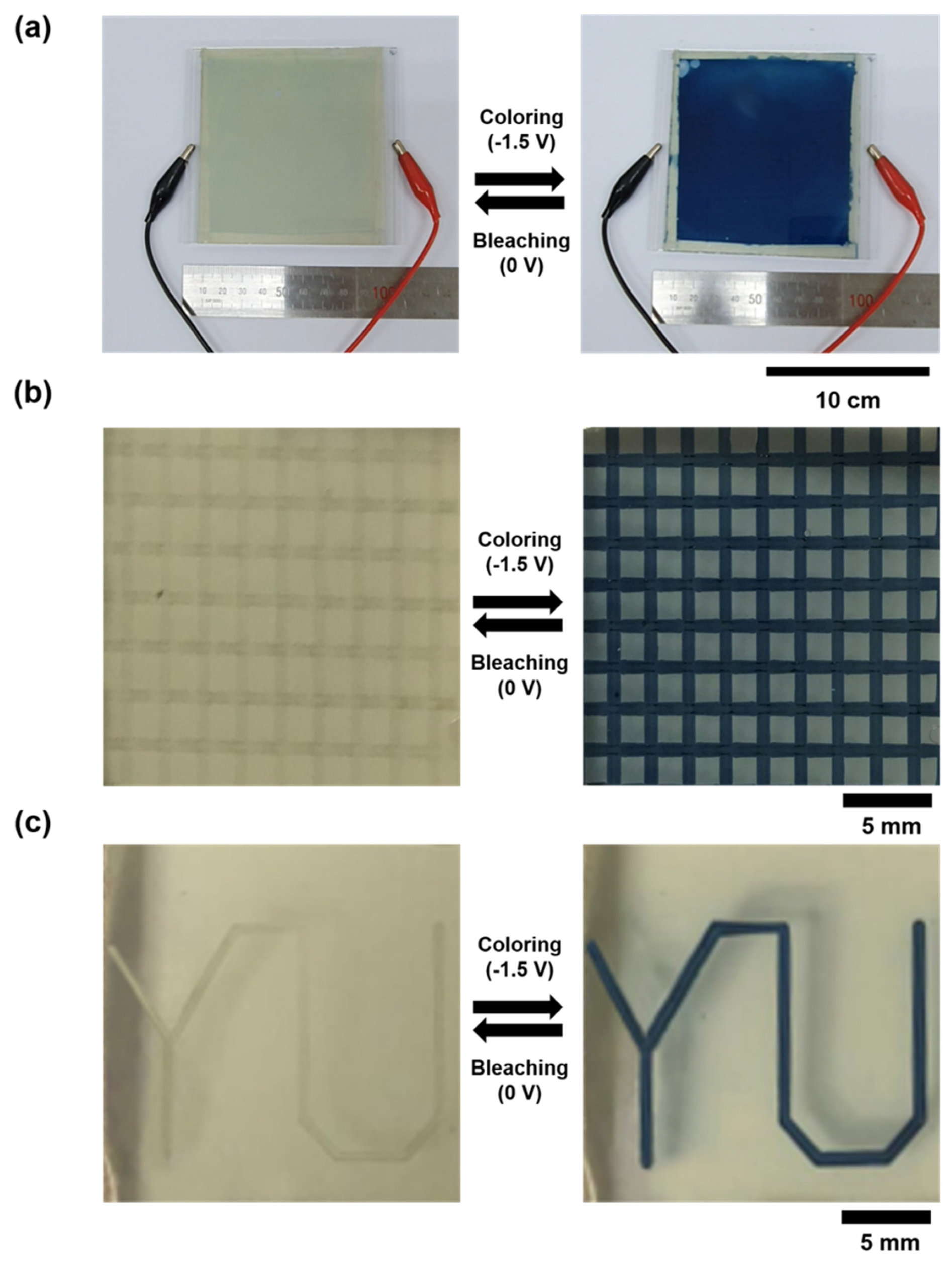

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ricciardulli, A.G.; Blom, P.W.M. Solution-Processable 2D Materials Applied in Light-Emitting Diodes and Solar Cells. Adv. Mater. Technol. 2020, 1900972. [Google Scholar] [CrossRef] [Green Version]

- Duan, L.; Hou, L.; Lee, T.-W.; Qiao, J.; Zhang, D.; Dong, G.; Wang, L.; Qiu, Y. Solution Processable Small Molecules for Organic Light-Emitting Diodes. J. Mater. Chem. 2010, 20, 6392–6407. [Google Scholar] [CrossRef] [Green Version]

- Zhong, C.; Duan, C.; Huang, F.; Wu, H.; Cao, Y. Materials and Devices toward Fully Solution Processable Organic Light-Emitting Diodes. Chem. Mater. 2011, 23, 326–340. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, K.; He, H.; Cai, W.; Tang, N.; Ning, H.; Wu, S.; Gao, J.; Zhou, G.; Lu, X. Solution Processable High Quality ZrO2 Dielectric films for Low Operation Voltage and Flexible Organic Thin Film Transistor Applications. J. Phy. D Appl. Phys. 2018, 51, 115105. [Google Scholar] [CrossRef]

- Rullyani, C.; Sung, C.-F.; Lin, H.-C.; Chu, C.-W. Flexible Organic Thin Film Transistors Incorporating a Biodegradable CO2-Based Polymer as the Substrate and Dielectric Material. Sci. Rep. 2018, 8, 8146. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Li, J.; Huang, K.; Li, S.; Wang, Q.; Sun, Z.; Mei, T.; Wang, J.; Zhang, L.; Wang, N.; et al. Low-Temperature and Solution-Processable Zinc Oxide Transistors for Transparent Electronics. ACS Omega 2017, 2, 8990–8996. [Google Scholar] [CrossRef]

- Kim, Y.M.; Moon, H.C. Ionoskins: Non-volatile, Highly Transparent, Ultra-Stretchable Ionic Sensory Platforms for Wearable Electronics. Adv. Funct. Mater. 2020, 30, 1907290. [Google Scholar] [CrossRef]

- Yan, Q.; Gao, L.; Tang, J.; Liu, H. Flexible and Stretchable Photodetectors and Gas Sensors for Wearable Healthcare based on Solution-Processable Metal Chalcogenides. J. Semicond. 2019, 40, 111604. [Google Scholar] [CrossRef]

- Kim, S.; Le, T.-H.; Park, C.S.; Park, G.; Kim, K.H.; Kim, S.; Kwon, O.S.; Lim, G.T.; Yoon, H. A Solution-Processable, Nanostructured, and Conductive Graphene/Polyaniline Hybrid Coating for Metal-Corrosion Protection and Monitoring. Sci. Rep. 2017, 7, 15184. [Google Scholar] [CrossRef]

- Liang, H.-L.; Bay, M.M.; Vadrucci, R.; Barty-King, C.H.; Peng, J.; Baumberg, J.J.; Volder, M.F.L.D.; Vignolini, S. Roll-to-Roll Fabrication of Touch-Responsive Cellulose Photonic Laminates. Nat. Commun. 2018, 9, 4632. [Google Scholar] [CrossRef]

- Tong, S.; Yuan, J.; Zhang, C.; Wang, C.; Liu, B.; Shen, J.; Xia, H.; Zou, Y.; Xie, H.; Sun, J.; et al. Large-scale Roll-to-roll Printed, Flexible and Stable Organic Bulk Heterojunction Photodetector. NPJ Flex. Electron. 2018, 2, 7. [Google Scholar] [CrossRef] [Green Version]

- Espinosa, N.; Dam, H.F.; Tanenbaum, D.M.; Andreasen, J.W.; Jørgensen, M.; Krebs, F.C. Roll-to-Roll Processing of Inverted Polymer Solar Cells using Hydrated Vanadium (V) Oxide as a PEDOT:PSS Replacement. Materials 2011, 4, 169–182. [Google Scholar] [CrossRef] [PubMed]

- Polat, E.O.; Balcı, O.; Kocabas, C. Graphene based Flexible Electrochromic Devices. Sci. Rep. 2015, 4, 6484. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, S.; Chen, S.; Hu, F.; Xu, R.; Yan, B.; Jiang, M.; Gu, Y.; Yang, F.; Cao, Y. Spray-Processable, Large-Area, Patterned and All-Solid-State Electrochromic Device based on Silica/Polyaniline Nanocomposites. Sol. Energy Mater. Sol. Cells 2019, 200, 109951. [Google Scholar] [CrossRef]

- Bellingham, A.; Bromhead, N.; Fontecchio, A. Rapid Prototyping of Slot Die Devices for Roll to Roll Production of EL Fibers. Materials 2017, 10, 594. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Guo, K.; Li, Y.; Li, X.; Guan, G.; Li, H.; Luo, Y.; Zhao, F.; Zhang, Q.; Wei, B. A Colour-Tunable, Weavable Fibre-Shaped Polymer Light-Emitting Electrochemical Cell. Nature 2015, 9, 1–31. [Google Scholar] [CrossRef]

- Chernova, N.A.; Roppolo, M.; Dillon, A.C.; Whittingham, M.S. Layered Vanadium and Molybdenum Oxides: Batteries and Electrochromics. J. Mater. Chem. 2009, 19, 2526–2552. [Google Scholar] [CrossRef]

- Deb, S.K. Opportunities and challenges in science and technology of WO3 for electrochromic and related applications. Sol. Energy Mater. Sol. Cells 2008, 92, 245–258. [Google Scholar] [CrossRef]

- Moon, H.C.; Kim, C.-H.; Lodge, T.P.; Frisbie, C.D. Multicolored, Low Power, Flexible Electrochromic Devices Based on Ion Gels. ACS Appl. Mater. Interfaces 2016, 8, 6252–6260. [Google Scholar] [CrossRef]

- Kao, S.-Y.; Kawahara, Y.; Nakatsuji, S.; Ho, K.-C. Achieving a Large Contrast, Low Driving Voltage, and High Stability Electrochromic Device with a Viologen Chromophore. J. Mater. Chem. C 2015, 3, 3266–3272. [Google Scholar] [CrossRef]

- Wang, X.; Guo, L.; Cao, S.; Zhao, W. Highly Stable Viologens-Based Electrochromic Devices with Low Operational Voltages Utilizing Polymeric Ionic Liquids. Chem. Phys. Lett. 2020, 749, 137434. [Google Scholar] [CrossRef]

- Li, G.; Zhang, B.; Wang, J.; Zhao, H.; Ma, W.; Xu, L.; Zhang, W.; Zhou, K.; Du, Y.; He, G. Electrochromic Poly(chalcogenoviologen)s as Anode Materials for High-Performance Organic Radical Lithium-Ion Batteries. Angew. Chem. 2019, 58, 8468–8473. [Google Scholar] [CrossRef]

- Kim, J.-W.; Myoung, J.-M. Flexible and Transparent Electrochromic Displays with Simultaneously Implementable Subpixelated Ion Gel-Based Viologens by Multiple Patterning. Adv. Funct. Mater. 2019, 29, 1808911. [Google Scholar] [CrossRef]

- Kao, S.-Y.; Lu, H.-C.; Kung, C.-W.; Chen, H.-W.; Chang, T.-H.; Ho, K.-C. Thermally Cured Dual Functional Viologen-Based All-in-One Electrochromic Devices with Panchromic Modulation. ACS Appl. Mater. Interfaces 2016, 8, 4175–4184. [Google Scholar] [CrossRef] [PubMed]

- Sydam, R.; Deepa, M.; Joshi, A.G. A Novel 1,1′-bis[4-(5,6-dimethyl-1H-benzimidazole-1-yl)butyl]-4,4′-bipyridinium dibromide (Viologen) for a High Contrast Electrochromic Device. Org. Eletcon. 2013, 14, 1027–1036. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Li, K.; Wang, G.; Li, L.; Zhang, Q.; Yan, J.; Chen, Y.; Zhang, Q.; Hou, C.; Li, Y.; et al. Ion-Transport Design for High-Performance Na+-Based Electrochromics. ACS Nano 2018, 12, 3759–3768. [Google Scholar] [CrossRef] [PubMed]

- Mortimer, R.J. Organic Electrochromic Materials. Electrochim. Acta 1999, 44, 2971–2981. [Google Scholar] [CrossRef]

- Roy, S.; Chakraborty, C. Nanostructured Metallo-Supramolecular Polymer-based Gel-type Electrochromic Devices with Ultrafast Switching Time and High Colouration Efficiency. J. Mater. Chem. C 2019, 7, 2871–2879. [Google Scholar] [CrossRef]

- Han, F.S.; Higuchi, M.; Kurth, D.G. Metallo-Supramolecular Polymers Based on Functionalized Bis-terpyridines as Novel Electrochromic Materials. Adv. Mater. 2007, 19, 3928–3931. [Google Scholar] [CrossRef]

- Higuchi, M.; Kurth, D.G. Electrochemical functions of metallosupramolecular nanomaterials. Chem. Rec. 2007, 7, 203–209. [Google Scholar] [CrossRef]

- Han, F.S.; Higuchi, M.; Kurth, D.G. Metallosupramolecular Polyelectrolytes Self-Assembled from Various Pyridine Ring-Substituted Bisterpyridines and Metal Ions: Photophysical, Electrochemical, and Electrochromic Properties. J. Am. Chem. Soc. 2008, 130, 2073–2081. [Google Scholar] [CrossRef]

- Honda, K.; Fujita, M.; Ishida, H.; Yamamoto, R.; Ohgaki, K. Solid-State Electrochromic Devices Composed of Prussian Blue, WO3, and Poly (ethylene oxide)-Polysiloxane Hybrid-Type Ionic Conducting Membrane. J. Electrochem. Soc. 1988, 135, 3151–3154. [Google Scholar] [CrossRef]

- Jiang, M.; Zhao, Z.F. Novel Stable Electrochromic Thin Film: A Prussian Blue Analogue based on Palladium Hexacyanoferrate. J. Electroanal. Chem. 1990, 292, 281–287. [Google Scholar] [CrossRef]

- Shirota, Y. Organic materials for electronic and optoelectronic devices. J. Mater. Chem. 2000, 10, 1–25. [Google Scholar] [CrossRef]

- Heuer, H.W.; Wehrmann, R.; Kirchmeyer, S. Electrochromic Window Based on Conducting Poly(3,4-ethylenedioxythiophene)–Poly(styrene sulfonate). Adv. Funct. Mater. 2002, 12, 89–94. [Google Scholar] [CrossRef]

- Li, X.; Yun, T.Y.; Kim, K.-W.; Kim, S.H.; Moon, H.C. Voltage-Tunable Dual Image of Electrostatic Force-Assisted Dispensing Printed, Tungsten Trioxide-Based Electrochromic Devices with a Symmetric Configuration. ACS Appl. Mater. Interfaces 2020, 12, 4022–4030. [Google Scholar] [CrossRef]

- Jensen, J.; Dam, H.F.; Reynolds, J.R.; Dyer, A.L.; Krebs, F.C. Manufacture and Demonstration of Organic Photovoltaic-Powered Electrochromic Displays using Roll Coating Methods and Printable Electrolytes. J. Polym. Sci. B Polym. Phys. 2012, 50, 536–545. [Google Scholar] [CrossRef]

- Liu, H.-S.; Chang, W.-C.; Chou, C.-Y.; Pan, B.-C.; Chou, Y.-S.; Liou, G.-S.; Liu, C.-L. Controllable Electrochromic Polyamide Film and Device Produced by Facile Ultrasonic Spray-coating. Sci. Rep. 2017, 7, 11982. [Google Scholar] [CrossRef] [Green Version]

- Cai, G.F.; Cui, M.Q.; Kumar, V.; Darmawan, P.; Wang, J.X.; Wang, X.; Eh, A.L.-S.; Qian, K.; Lee, P.S. Ultra-large Optical Modulation of Electrochromic Porous WO3 film and the Local Monitoring of Redox Activity. Chem. Sci. 2016, 7, 1373–1382. [Google Scholar] [CrossRef] [Green Version]

- Layani, M.; Darmawan, P.; Foo, W.L.; Liu, L.; Kamyshny, A.; Mandler, D.; Magdassi, S.; Lee, P.S. Nanostructured Electrochromic films by Inkjet Printing on Large Area and Flexible Transparent Silver Electrodes. Nanoscale 2014, 6, 4572–4576. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.-W.; Kim, Y.M.; Li, X.; Ha, T.; Kim, S.H.; Moon, H.C.; Lee, S.W. Various Coating Methodologies of WO3 According to the Purpose for Electrochromic Devices. Nanomaterials 2020, 10, 821. https://doi.org/10.3390/nano10050821

Kim K-W, Kim YM, Li X, Ha T, Kim SH, Moon HC, Lee SW. Various Coating Methodologies of WO3 According to the Purpose for Electrochromic Devices. Nanomaterials. 2020; 10(5):821. https://doi.org/10.3390/nano10050821

Chicago/Turabian StyleKim, Keon-Woo, Yong Min Kim, Xinlin Li, Taehwa Ha, Se Hyun Kim, Hong Chul Moon, and Seung Woo Lee. 2020. "Various Coating Methodologies of WO3 According to the Purpose for Electrochromic Devices" Nanomaterials 10, no. 5: 821. https://doi.org/10.3390/nano10050821

APA StyleKim, K.-W., Kim, Y. M., Li, X., Ha, T., Kim, S. H., Moon, H. C., & Lee, S. W. (2020). Various Coating Methodologies of WO3 According to the Purpose for Electrochromic Devices. Nanomaterials, 10(5), 821. https://doi.org/10.3390/nano10050821