Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review

Abstract

:1. Introduction

- In vat photopolymerization the 3D object is created layer by layer thanks to the curing of a liquid photopolymer resin under the influence of an ultraviolet (UV) light. The liquid photopolymer is held in a vat with a built support submerged near the surface of the resin. Then the UV light is directed to the resin surface following a determined path thus allowing a selective local polymerization of the liquid photopolymer. After that, the built support is re-submerged into the resin and the process is repeated until the 3D object is fully obtained;

- The material jetting principle is used to create a solid 3D object layer by layer from droplets, which are mainly composed of liquid photopolymer resin, that are selectively sprayed by an inkjet-style printhead and immediately cured thanks to the expose of a UV light. Commonly, technologies that work under this principle are compared to the two-dimensional (2D) inkjet printing, which deposits only a single layer of ink droplets;

- In the technologies that operate under the principles of binder jetting a liquid binder, which is selectively deposited by drops onto a powder-based material using an inkjet-style print head, is utilized in order to produce a solid 3D object layer by layer. During the process, alternate layers of powder material and binding material are depositing as follow: powder particles are spread over a built support using a roller while the print head deposits the liquid binder, which acts as a glue between powder particles and layers, on top of the powder bed; after that, the built support is lowered by the model’s layer thickness and then the process is repeated until the 3D object is formed;

- The powder bed fusion category utilizes an energy source that allows the local sintering or melting between the particles of a powder material for the forming of a solid 3D object layer by layer. The energy sources can be lasers or electron beams depending on the using material powder. The electron beam is necessary for metals, while lasers are required for polymers. The forming part process is very similar to binder jetting: powder particles are spread over a built support using a roller while the energy source fuses the first layer; after that, the built support is lowered by the model’s layer thickness and a new layer of powder is spread across the previous layer repeating the process until the 3D object is formed;

- In direct energy deposition the 3D object is created layer by layer thanks to the directly melting of build-material and deposing them on the workpiece using a focused thermal energy source such as laser, electron beam or plasma arc. This principle can be applied for a wide kind of materials such as polymers, ceramics, and metal framework composites; however, it is predominantly used for wire and powder metals, which explains why this technology is often called metal deposition. Direct energy deposition utilizes a nozzle mounted on a multi-axis arm can move freely in any direction of the x, y and z-axes that deposits melted material onto the predetermined workpiece surface, where it is automatically solidified;

- In sheet lamination a 3D part is created by bonding together, layer-by-layer, thin sheets of material (usually supplied via a system of feed rollers), which is then cutting into a final 3D object. In the process, the sheet material is positioned on the cutting bed and then it is bonded over the previous layer using any suitable sticky method; after that, the required shape is cut by laser or knife and the process is repeated until the 3D object is formed. Laminated object manufacturing (LOM) and ultrasonic consolidation (UC) are both examples of sheet lamination techniques;

- Material extrusion is a category of AM, in which the 3D object is formed by a layer by layer selective deposition of the extruded build-material through a nozzle in a continuous stream. In material extrusion, the layers are built when the nozzle deposits a viscoelastic material where it is required. The following layers are added on top of previous layers and bonded upon deposition as the material shows viscoelastic behavior. In the last past years, this technology became popular in the world for its use in 3D printers. Direct Ink Writing (DIW) and Fused deposition modeling (FDM) are the two common technologies that operate under the principles of material extrusion. However, in the last past years, a new AM technique named Pyro-EHD Tethered Electrospinning (TPES) that is based on electrohydrodynamic processes and can be related to material extrusion category became more and more popular [17,18,19].

2. Additive Manufacturing Processes for Ceramic and Their Principles

2.1. Powder-Based Technologies

2.1.1. Selective Laser Sintering (SLS)

2.1.2. Binder Jetting (BJ)

2.1.3. Selective Laser Melting (SLM)

2.2. Slurry-Based Technologies

2.2.1. Stereolithography (SLA)

2.2.2. Digital Light Processing (DLP)

2.2.3. Two-Photon Polymerization (TPP)

2.2.4. Inkjet Printing (IJP)

2.3. Bulk Solid-Based

2.3.1. Laminated Object Manufacturing (LOM)

2.3.2. Fused Deposition Modeling (FDM)

2.3.3. Direct Ink Writing (DIW)

3. Additive Manufacturing for Graphene-Based Materials

3.1. Graphene and Its Derivatives Materials

3.2. Additive Technologies for Graphene-Based Materials

3.2.1. Stereolithography (SLA)

3.2.2. Inkjet Printing (IJP)

3.2.3. Fused Deposition Modeling (FDM)

3.2.4. Direct Ink Writing (DIW)

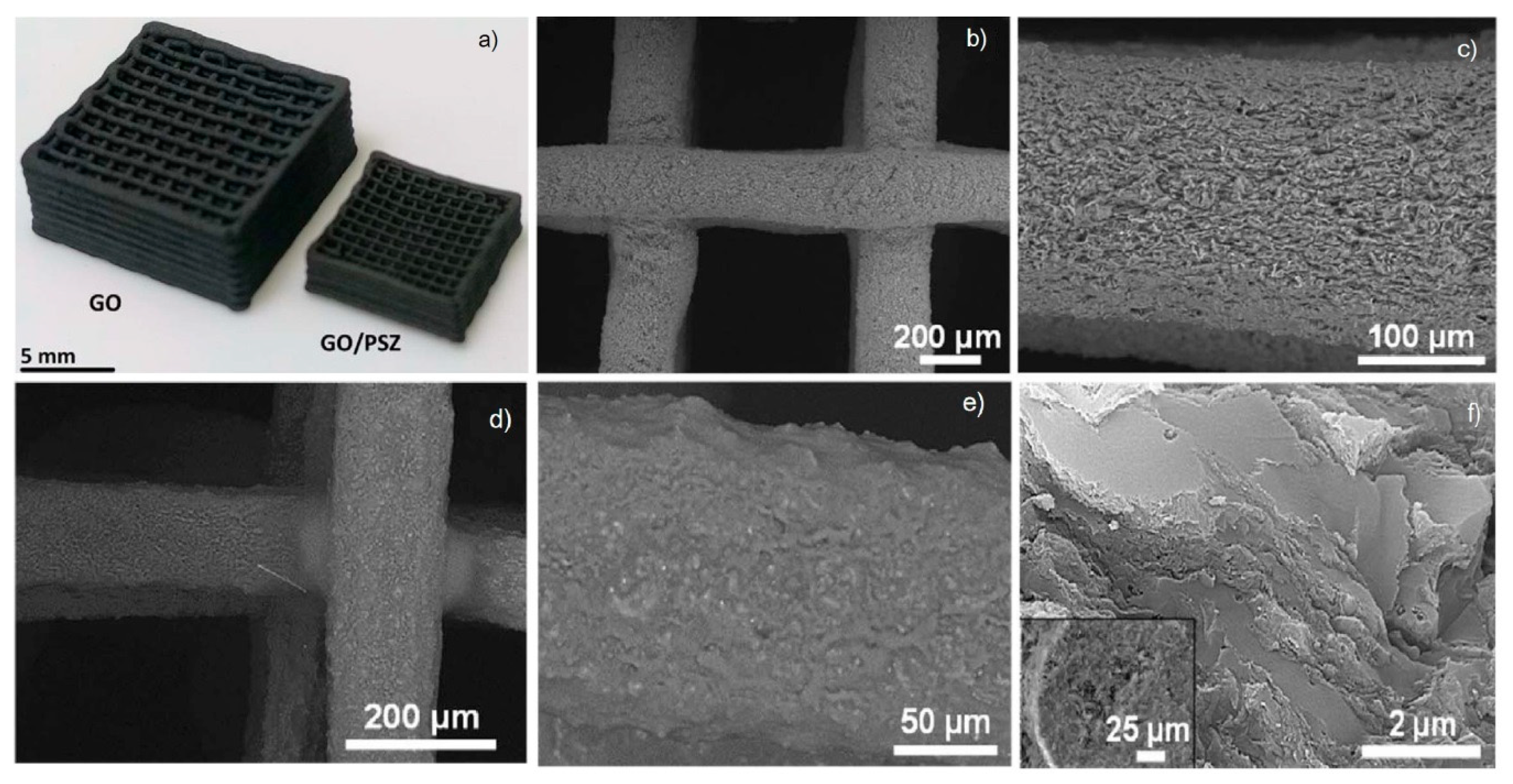

4. Direct Ink Writing Technology of Graphene-Based Ceramic Pastes

5. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics, 2nd ed.; Wiley: New York, NY, USA, 1976; pp. 1–1056. [Google Scholar]

- Carter, C.B.; Norton, M.G. Ceramic Materials: Science and Engineering; Springer: New York, NY, USA, 2013; pp. 1–766. [Google Scholar]

- Smirnov, A.; Kurland, H.-D.; Grabow, J.; Müller, F.A.; Bartolomé, J.F. Microstructure, mechanical properties and low temperature degradation resistance of 2Y-TZP ceramic materials derived from nanopowders prepared by laser vaporization. J. Eur. Ceram. Soc. 2015, 35, 2685–2691. [Google Scholar] [CrossRef]

- Smirnov, A.; Beltrán, J.I.; Rodriguez-Suarez, T.; Pecharromán, C.; Muñoz, M.C.; Moya, J.S.; Bartolomé, J.F. Unprecedented simultaneous enhancement in flaw tolerance and fatigue resistance of zirconia–Ta composites. Sci. Rep. 2017, 7, 44922. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smirnov, A.; Bartolomé, J.F.; Kurland, H.-D.; Grabow, J.; Müller, F.A. Design of a new zirconia-alumina-Ta micro-nanocomposite with unique mechanical properties. J. Am. Ceram. Soc. 2016, 99, 3205–3209. [Google Scholar] [CrossRef]

- Bartolomé, J.F.; Smirnov, A.; Kurland, H.-D.; Grabow, J.; Müller, F.A. New ZrO2/Al2O3 nanocomposites fabricated from hybrid nanoparticles prepared by CO2 laser Co-vaporisation. Sci. Rep. 2016, 6, 20589. [Google Scholar] [CrossRef]

- Smirnov, A.; Bartolomé, J.F. Microstructure and mechanical properties of ZrO2 ceramics toughened by 5–20 vol% ta metallic particles fabricated by pressureless sintering. Ceram. Int. 2014, 40, 1829–1834. [Google Scholar] [CrossRef]

- Gutierrez-Gonzalez, C.F.; Smirnov, A.; Bartolomé, J.F. Cyclic fatigue life- and crack-growth behavior of zirconia-niobium composites. J. Am. Ceram. Soc. 2013, 96, 1709–1712. [Google Scholar]

- Bengisu, M. Engineering Ceramics; Springer: Berlin/Heidelberg, Germany, 2001; p. 620. [Google Scholar]

- Richerson, D.W.; Lee, W.E. Modern Ceramic Engineering: Properties, Processing, and Use in Design, 4th ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 1–791. [Google Scholar]

- Pristinskiy, Y.; Solis Pinargote, N.W.; Smirnov, A. The effect of MgO addition on the microstructure and mechanical properties of alumina ceramic obtained by spark plasma sintering. Mater. Today Proc. 2019, 19, 1990–1993. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 1–498. [Google Scholar]

- International Organization for Standardization. ISO/ASTM 52900:2015 [ASTM F2792] Additive Manufacturing—General Principles—Terminology; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Diegel, O. A Practical Guide to Design for Additive Manufacturing; Series in Advanced Manufacturing; Springer: New York, NY, USA, 2020; p. 226. [Google Scholar]

- Coppola, S.; Nasti, G.; Vespini, V.; Ferraro, P. Layered 3D printing by tethered pyro-electrospinning. Adv. Polym. Technol. 2020, 2, 1–9. [Google Scholar] [CrossRef]

- Coppola, S.; Vespini, V.; Nasti, G.; Gennari, O.; Grilli, S.; Ventre, M.; Iannone, M.; Netti, P.A.; Ferraro, P. Tethered pyro-electrohydrodynamic spinning for patterning well-ordered structures at micro- and nanoscale. Chem. Mater. 2014, 26, 3357–3360. [Google Scholar] [CrossRef] [Green Version]

- Coppola, S.; Nasti, G.; Todino, M.; Olivieri, F.; Vespini, V.; Ferraro, P. Direct writing of microfluidic footpaths by pyro-EHD printing. ACS Appl. Mater. Int. 2017, 9, 16488–16494. [Google Scholar] [CrossRef]

- Lewis, J.A.; Gratson, G.M. Direct writing in three dimensions. Mater. Today 2004, 7, 32–39. [Google Scholar] [CrossRef]

- Martínez-Vázquez, F.J.; Perera, F.H.; Miranda, P.; Pajares, A.; Guiberteau, F. Improving the compressive strength of bioceramic robocast scaffolds by polymer infiltration. Acta Biomater. 2010, 6, 4361–4368. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D printing of kaolinite clay ceramics using the Direct Ink Writing (DIW) technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Martínez-Vázquez, F.J.; Pajares, A.; Miranda, P. A simple graphite-based support material for robocasting of ceramic parts. J. Eur. Ceram. Soc. 2018, 38, 2247–2250. [Google Scholar] [CrossRef]

- Ordoñez, E.; Gallego, J.M.; Colorado, H.A. 3D printing via the direct ink writing technique of ceramic pastes from typical formulations used in traditional ceramics industry. Appl. Clay Sci. 2019, 182, 105285. [Google Scholar] [CrossRef]

- Ahn, B.Y.; Duoss, E.B.; Motala, M.J.; Guo, X.; Park, S.I.; Xiong, Y.; Yoon, J.; Nuzzo, R.G.; Rogers, J.A.; Lewis, J.A. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 2009, 323, 1590–1593. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.-M. Influence of porosity and pore size on the compressive strength of porous hydroxyapatite ceramic. Ceram. Int. 1997, 23, 135–139. [Google Scholar] [CrossRef]

- Yao, Y.; Fu, K.K.; Yan, C.; Dai, J.; Chen, Y.; Wang, Y.; Zhang, B.; Hitz, E.; Hu, L. Three-dimensional printable high-temperature and high-rate heaters. ACS Nano 2016, 10, 5272–5279. [Google Scholar] [CrossRef] [PubMed]

- García-Tunñón, E.; Feilden, E.; Zheng, H.; D’Elia, E.; Leong, A.; Saiz, E. Graphene oxide: An all-in-one processing additive for 3D printing. ACS Appl. Mater. Interfaces 2017, 9, 32977–32989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewis, J.A. Colloidal processing of ceramics. J. Am. Ceram. Soc. 2000, 83, 2341–2359. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. Aqueous liquid crystals of graphene oxide. ACS Nano 2011, 5, 2908–2915. [Google Scholar] [CrossRef] [PubMed]

- Solis Pinargote, N.W.; Peretyagin, P.; Torrecillas, R.; Fernández, A.; Menéndez, J.L.; Mallada, C.; Díaz, L.A.; Moya, J.S. Electrically conductor black zirconia ceramic by SPS using graphene oxide. J. Electroceram. 2017, 38, 119–124. [Google Scholar] [CrossRef]

- Smirnov, A.; Peretyagin, P.; Bartolomé, J.F. Processing and mechanical properties of new hierarchical metal-graphene flakes reinforced ceramic matrix composites. J. Eur. Ceram. Soc. 2019, 39, 3491–3497. [Google Scholar] [CrossRef]

- Gutierrez-Gonzalez, C.F.; Smirnov, A.; Centeno, A.; Fernández, A.; Alonso, B.; Rocha, V.G.; Torrecillas, R.; Zurutuza, A.; Bartolomé, J.F. Wear behavior of graphene/alumina nanocomposite. Ceram. Int. 2015, 41, 7434–7438. [Google Scholar] [CrossRef]

- Cascales, A.; Tabares, N.; Bartolomé, J.F.; Cerpa, A.; Smirnov, A.; Moreno, R.; Nieto, M.I. Processing and mechanical properties of mullite and mullite–alumina composites reinforced with carbon nanofibers. J. Eur. Ceram. Soc. 2015, 35, 3613–3621. [Google Scholar] [CrossRef]

- André, J.C.; Le Mehauté, A.; De Witte, O. Dispositif Pour Réalizer un Modèle de Pièce Industrielle. Demande de Brevet d’Invention FR 2567668, 16 July 1984. [Google Scholar]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4,575,330, 8 August 1984. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing)-A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Sachs, E.; Cima, M.; Cornie, J. Three-dimensional printing: Rapid tooling and prototypes directly from a CAD model. CIRP Ann. Manuf. Technol. 1990, 39, 201–204. [Google Scholar] [CrossRef]

- Kruth, J.P. Material incress manufacturing by rapid prototyping techniques. CIRP Ann. Manuf. Technol. 1991, 40, 603–614. [Google Scholar] [CrossRef]

- Peretyagin, N.Y.; Pristinskii, Y.O.; Kuznetsova, E.V.; Peretyagin, P.Y.; Seleznev, A.E.; Solis Pinargote, N.W.; Smirnov, A.V. Microstructure and properties of boron-carbide composites reinforced by graphene. Russ. Eng. Res. 2020, 40, 94–96. [Google Scholar] [CrossRef]

- Smirnov, A.; Solís Pinargote, N.W.; Peretyagin, N.; Pristinskiy, Y.; Peretyagin, P.; Bartolomé, J.F. Zirconia reduced graphene oxide nano-hybrid structure fabricated by the hydrothermal reaction method. Materials 2020, 13, 687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deckard, C.R. Method and Apparatus for Producing Parts by Selective Sintering. U.S. Patent 4,863,538, 17 October 1986. [Google Scholar]

- Rossi, S.; Puglisi, A.; Benaglia, M. Additive manufacturing technologies: 3D printing in organic synthesis. ChemCatChem 2018, 10, 1512. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Zhang, B.; Yan, C.; Shi, Y. The effect of processing parameters on characteristics of selective laser sintering dental glass-ceramic powder. Rapid Prototyp. J. 2010, 16, 138–145. [Google Scholar] [CrossRef]

- Gao, C.; Yang, B.; Hu, H.; Liu, J.; Shuai, C.; Peng, S. Enhanced sintering ability of biphasic calcium phosphate by polymers used for bone scaffold fabrication. Mater. Sci. Eng. C 2013, 33, 3802–3810. [Google Scholar] [CrossRef]

- Leu, M.C.; Pattnaik, S.; Hilmas, G.E. Investigation of laser sintering for freeform fabrication of zirconium diboride parts. Virtual Phys. Prototyp. 2012, 7, 2536. [Google Scholar] [CrossRef]

- Lakshminarayan, U.; Ogrydiziak, S.; Marcus, H. Selective laser sintering of ceramic materials. In Proceedings of the International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 1990. [Google Scholar]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.-P.; Vleugels, J. Preparation and indirect selective laser sintering of alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. U.S. Patent 5,204,055, 8 December 1989. [Google Scholar]

- Sachs, E.; Cima, M.; Williams, P.; Brancazio, D.; Cornie, J. Three dimensional printing: Rapid tooling and prototypes directly from a CAD model. J. Eng. Ind. 1992, 114, 481–488. [Google Scholar] [CrossRef]

- Meiners, W.; Wissenbach, K.; Gasser, A. Shaped Body Especially Prototype or Replacement Part Production. Germany Patent DE 19649865, 2 December 1996. [Google Scholar]

- Simchi, A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features. Mater. Sci. Eng. A 2006, 428, 148–158. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Alumina–zirconium ceramics synthesis by selective laser sintering melting. Appl. Surf. Sci. 2007, 254, 966–970. [Google Scholar] [CrossRef]

- Deckers, J.; Meyers, S.; Kruth, J.; Vleugels, J. Direct selective laser sintering/melting of high density alumina powder layers at elevated temperatures. Phys. Procedia 2014, 56, 117–124. [Google Scholar] [CrossRef] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J. Mater. Process Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Yves-Christian, H.; Jan, W.; Wilhelm, M.; Konrad, W.; Reinhart, P. Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 17296–2:2015 Additive Manufacturing—General Principles—Part 2: Overview of Process Categories and Feedstock; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Kaur, M.; Srivastava, A.K. Photopolymerization: A Review. J. Macromol. Sci. Part C 2002, 42, 481–512. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Ultraviolet curable ceramic suspensions for Stereolithography of ceramics. In Proceedings of the 1994 International Mechanical Engineering Congress and Exposition, Chicago, IL, USA, 6–11 November 1994; pp. 529–534. [Google Scholar]

- Halloran, J.W.; Tomeckova, V.; Gentry, S.; Das, S.; Cilino, P.; Yuan, D.; Guo, R.; Rudraraju, A.; Shao, P.; Wu, T. Photopolymerization of powder suspensions for shaping ceramics. J. Eur. Ceram. Soc. 2011, 31, 2613–2619. [Google Scholar] [CrossRef]

- Chen, Z.; Li, D.; Zhou, W.; Wang, L. Curing characteristics of ceramic Stereolithography for an aqueous-based silica suspension. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 641–651. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, X.; Sun, C. Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 1999, 77, 149–156. [Google Scholar] [CrossRef]

- Kumar, S.; Bhushan, P.; Pandey, M.; Bhattacharya, S. Additive manufacturing as an emerging technology for fabrication of microelectromechanical systems (MEMS). J. Micromanuf. 2019, 2, 175–197. [Google Scholar] [CrossRef]

- Nakamoto, T.; Yamaguchi, K.; Abraha, P.A. Consideration on the producing of high aspect ratio micro parts using UV sensitive photopolymer. In Proceedings of the MHS’96 Seventh International Symposium on Micro Machine and Human Science, Nagoya, Japan, 2–4 October 1996; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 1996; pp. 53–58. [Google Scholar] [CrossRef]

- Lu, Y.; Mapili, G.; Suhali, G.; Chen, S.; Roy, K. A digital micro-mirror device-based system for the microfabrication of complex, spatially patterned tissue engineering scaffolds. J. Biomed. Mater. Res. Part A 2006, 77, 396–405. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Li, S.; Duan, W.; Zhao, T.; Han, W.; Wang, L.; Dou, R.; Wang, G. The fabrication of SiBCN ceramic components from preceramic polymers by digital light processing (DLP) 3D printing technology. J. Eur. Ceram. Soc. 2018, 38, 4597–4603. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Schneider, P.; Homa, J. Lithography-Based Ceramic Manufacturing: A Novel Technique for Additive Manufacturing of High-Performance Ceramics. Adv. Sci. Technol. 2014, 88, 60–64. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Moritz, T.; Michaelis, A. Additive Manufacturing of Ceramic Heat Exchanger: Opportunities and Limits of the Lithography-Based Ceramic Manufacturing (LCM). J. Mater. Eng. Perform. 2017, 27, 14–20. [Google Scholar] [CrossRef]

- Lantada, A.D.; Romero, A.D.B.; Schwentenwein, M.; Jellinek, C.; Homa, J. Lithography-based ceramic manufacture (LCM) of auxetic structures: Present capabilities and challenges. Smart Mater. Struct. 2016, 25, 54015. [Google Scholar] [CrossRef] [Green Version]

- Scheithauer, U.; Schwarzer, E.; Ganzer, G.; Kornig, A.; Becker, W.; Reichelt, E.; Jahn, M.; Har-Tel, A.; Richter, H.; Moritz, T.; et al. Micro-Reactors Made by Lithography-Based Ceramic Manufacturing (LCM). Ceram. Trans. Ser. 2016, 258, 31–41. [Google Scholar] [CrossRef]

- Wu, E.-S.; Strickler, J.H.; Harrell, W.R.; Webb, W.W. Two-photon lithography for microelectronic application. Opt./Laser Microlithogr. V 1992, 1674, 776–782. [Google Scholar] [CrossRef]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 1997, 22, 132. [Google Scholar] [CrossRef] [Green Version]

- Chu, W.; Tan, Y.; Wang, P.; Xu, J.; Li, W.; Qi, J.; Cheng, Y. Centimeter-Height 3D Printing with Femtosecond Laser Two-Photon Polymerization. Adv. Mater. Technol. 2018, 3, 1700396. [Google Scholar] [CrossRef]

- Sun, H.-B.; Kawata, S. Two-Photon Photopolymerization and 3D Lithographic Microfabrication. In Organic Electronics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2006; Volume 170, pp. 169–273. [Google Scholar]

- Fischer, J.; Wegener, M. Three-dimensional optical laser lithography beyond the diffraction limit. Laser Photonics-Rev. 2012, 7, 22–44. [Google Scholar] [CrossRef]

- Pham, T.A.; Kim, D.-P.; Lim, T.-W.; Park, S.-H.; Yang, D.-Y.; Lee, K.-S. Three-Dimensional SiCN Ceramic Microstructures via Nano-Stereolithography of Inorganic Polymer Photoresists. Adv. Funct. Mater. 2006, 16, 1235–1241. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet Printing-Process and Its Applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef]

- Le, H.P. Progress and trends in ink-jet printing technology. J. Imaging Sci. Technol. 1998, 42, 49–62. [Google Scholar]

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 72102. [Google Scholar] [CrossRef]

- Lee, E.R. Microdrop Generation; CRC Press: Boca Raton, FL, USA, 2002; pp. 1–241. [Google Scholar]

- Coppola, S.; Mecozzi, L.; Vespini, V.; Battista, L.; Grilli, S.; Nenna, G.; Loffredo, F.; Villani, F.; Minarini, C.; Ferraro, P. Nanocomposite polymer carbon-black coating for triggering pyro-electrohydrodynamic inkjet printing. Appl. Phys. Lett. 2015, 106, 261603. [Google Scholar] [CrossRef]

- Grimaldi, I.; Coppola, S.; Loffredo, F.; Villani, F.; Nenna, G.; Minarini, C.; Vespini, V.; Miccio, L.; Grilli, S.; Ferraro, P. Graded-size microlens array by the pyro-electrohydrodynamic continuous printing method. Appl. Opt. 2013, 52, 7699–7705. [Google Scholar] [CrossRef]

- Kyser, E.L.; Collins, L.F.; Herbert, N. Design of an impulse ink jet. J. Appl. Photogr. Eng. 1981, 7, 73–79. [Google Scholar]

- Kawase, T.; Shimoda, T.; Newsome, C.; Sirringhaus, H.; Friend, R.H. Inkjet printing of polymer thin film transistors. Thin Solid Film. 2003, 438, 279–287. [Google Scholar] [CrossRef]

- Kawahara, Y.; Hodges, S.; Cook, B.S.; Zhang, C.; Abowd, G.D. Instant inkjet circuits. In Proceedings of the 2013 ACM International Joint Conference, Zurich, Switzerland, 8–12 September 2013; Association for Computing Machinery (ACM): New York, NY, USA, 2013; p. 363. [Google Scholar]

- Nakamura, M.; Kobayashi, A.; Takagi, F.; Watanabe, A.; Hiruma, Y.; Ohuchi, K.; Iwasaki, Y.; Horie, M.; Morita, I.; Takatani, S. Biocompatible Inkjet Printing Technique for Designed Seeding of Individual Living Cells. Tissue Eng. 2005, 11, 1658–1666. [Google Scholar] [CrossRef] [PubMed]

- Blazdell, P.F.; Evans, J.R.G.; Edirisinghe, M.J.; Shaw, P.; Binstead, M.J. The computer aided manufacture of ceramics using multilayer jet printing. J. Mater. Sci. Lett. 1995, 14, 1562–1565. [Google Scholar] [CrossRef]

- Seerden, K.A.M.; Reis, N.; Evans, J.R.G.; Grant, P.; Halloran, J.W.; Derby, B. Ink-Jet Printing of Wax-Based Alumina Suspensions. J. Am. Ceram. Soc. 2001, 84, 2514–2520. [Google Scholar] [CrossRef] [Green Version]

- Kunieda, M.; Nakagawa, T. Manufacturing of laminated deep drawing dies by laser beam cutting. Adv. Technol. Plast. 1984, 1, 520–525. [Google Scholar]

- White, D. Ultrasonic Object Consolidation. U.S. Patent 6,519,500, 23 March 2000. [Google Scholar]

- Mekonnen, B.G.; Bright, G.; Walker, A. A Study on State of the Art Technology of Laminated Object Manufacturing (LOM). In Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials, Surakarta, Indonesia, 16–17 October 2016; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2016; pp. 207–216. [Google Scholar]

- Mathur, R. 3D printing in architecture. Int. J. Innov. Sci. Eng. Technol. 2016, 3, 583–591. [Google Scholar]

- Mueller, B.; Kochan, D. Laminated object manufacturing for rapid tooling and pattern making in foundry industry. Comput. Ind. 1999, 39, 47–53. [Google Scholar] [CrossRef]

- Griffin, C.; Daufenbach, J.; McMillin, S. Solid freeform fabrication of functional ceramic components using a laminated object manufacturing technique. Solid Freedom Fabr. 1994, 17–24. [Google Scholar] [CrossRef]

- Windsheimer, H.; Travitzky, N.; Hofenauer, A.; Greil, P. Laminated object manufacturing of preceramic-paper-derived Si-SiC composites. Adv. Mater. 2007, 19, 4515–4519. [Google Scholar] [CrossRef]

- Gomes, C.M.; Gutbrod, B.; Travitzky, N.; Fey, T.; Greil, P. Preceramic paper derived fibrillar ceramics. Ceram. Trans. 2010, 210, 421–426. [Google Scholar]

- Weisensel, L.; Travitzky, N.; Sieber, H.; Greil, P. Laminated Object Manufacturing (LOM) of SiSiC Composites. Adv. Eng. Mater. 2004, 6, 899–903. [Google Scholar] [CrossRef]

- Griffin, E.; Mumm, D.; Marshall, D. Rapid prototyping of functional ceramic composites. Am. Ceram. Soc. Bull. 1996, 75, 65–68. [Google Scholar]

- Zhang, Y.; Han, J.; Zhang, X.; He, X.; Li, Z.; Du, S. Rapid prototyping and combustion synthesis of TiC/Ni functionally gradient materials. Mater. Sci. Eng. A 2001, 299, 218–224. [Google Scholar] [CrossRef]

- Gomes, C.; Travitzky, N.; Greil, P.; Acchar, W.; Birol, H.; Oliveira, A.P.N.; Hotza, D. Laminated object manufacturing of LZSA glass-ceramics. Rapid Prototyp. J. 2011, 17, 424–428. [Google Scholar] [CrossRef]

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5,121,329, 30 October 1989. [Google Scholar]

- Rundle, G.A. Revolution in the Making; Affirm Press: South Melbourne, Australia, 2014; pp. 1–209. [Google Scholar]

- Ahmad, A.; Darmoul, S.; Ameen, W.; Abidi, M.H.; Al-Ahmari, A. Rapid Prototyping for Assembly Training and Validation. IFAC-PapersOnLine 2015, 48, 412–417. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Danforth, S. Fused Deposition of Ceramics: A New Technique for the Rapid Fabrication of Ceramic Components. Mater. Technol. 1995, 10, 144–146. [Google Scholar] [CrossRef]

- Iyer, S.; McIntosh, J.; Bandyopadhyay, A.; Langrana, N.; Safari, A.; Danforth, S.C.; Clancy, R.B.; Gasdaska, C.; Whalen, P.J. Microstructural Characterization and Mechanical Properties of Si3N4Formed by Fused Deposition of Ceramics. Int. J. Appl. Ceram. Technol. 2008, 5, 127–137. [Google Scholar] [CrossRef]

- Allahverdi, M.; Danforth, S.; Jafari, M.; Safari, A. Processing of advanced electroceramic components by fused deposition technique. J. Eur. Ceram. Soc. 2001, 21, 1485–1490. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Chi, X.; Evans, J. Fine ceramic lattices prepared by extrusion freeforming. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 79, 116–121. [Google Scholar] [CrossRef]

- Jafari, M.; Han, W.; Mohammadi, F.; Safari, A.; Danforth, S.C.; Langrana, N. A novel system for fused deposition of advanced multiple ceramics. Rapid Prototyp. J. 2000, 6, 161–175. [Google Scholar] [CrossRef]

- Sa, M.-W.; Nguyen, B.-N.B.; Moriarty, R.A.; Kamalitdinov, T.; Fisher, J.P.; Kim, J.Y. Fabrication and evaluation of 3D printed BCP scaffolds reinforced with ZrO2 for bone tissue applications. Biotechnol. Bioeng. 2018, 115, 989–999. [Google Scholar] [CrossRef]

- Pilleux, M.E.; Safari, A.; Allahverdi, M.; Chen, Y.; Lu, Y.; Jafari, M.A. 3-D photonic bandgap structures in the microwave regime by fused deposition of multimaterials. Rapid Prototyp. J. 2002, 8, 46–52. [Google Scholar] [CrossRef]

- Chen, Y.; Bartzos, D.; Lu, Y.; Niver, E.; Pilleux, M.E.; Allahverdi, M.; Danforth, S.C.; Safari, A. Simulation, fabrication, and characterization of 3-D alumina photonic bandgap structures. Microw. Opt. Technol. Lett. 2001, 30, 305–307. [Google Scholar] [CrossRef]

- Cesarano, I.; Segalman, R. Robocasting provides moldless fabrication from slurry deposition. Ceram. Ind. 1998, 148, 94–100. [Google Scholar]

- Shen, A.; Caldwell, D.; Ma, A.W.; Dardona, S. Direct write fabrication of high-density parallel silver interconnects. Addit. Manuf. 2018, 22, 343–350. [Google Scholar] [CrossRef]

- Hartmann, K.; Krishnan, R.; Merz, R.; Neplotnik, G.; Prinz, F.B.; Schultz, L.; Terk, M.; Weiss, L.E. Robot-assisted shape deposition manufacturing. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; Volume, 4, pp. 2890–2895. [Google Scholar]

- Cesarano, J., III; Calvert, P.D. Freeforming Objects with Low-Binder Slurry. U.S. Patent 6,027,326, 28 October 1997. [Google Scholar]

- Fu, K.; Wang, Y.; Yan, C.; Yao, Y.; Chen, Y.; Dai, J.; Lacey, S.; Wang, Y.; Wan, J.; Li, T.; et al. Graphene Oxide-Based Electrode Inks for 3D-Printed Lithium-Ion Batteries. Adv. Mater. 2016, 28, 2587–2594. [Google Scholar] [CrossRef]

- Farahani, R.D.; Dubé, M.; Therriault, D. Three-Dimensional Printing of Multifunctional Nanocomposites: Manufacturing Techniques and Applications. Adv. Mater. 2016, 28, 5794–5821. [Google Scholar] [CrossRef]

- Elsayed, H.; Colombo, P.; Bernardo, E. Direct ink writing of wollastonite-diopside glass-ceramic scaffolds from a silicone resin and engineered fillers. J. Eur. Ceram. Soc. 2017, 37, 4187–4195. [Google Scholar] [CrossRef]

- Feilden, E.; Blanca, E.G.-T.; Giuliani, F.; Saiz, E.; Vandeperre, L. Robocasting of structural ceramic parts with hydrogel inks. J. Eur. Ceram. Soc. 2016, 36, 2525–2533. [Google Scholar] [CrossRef]

- Rao, R.B.; Krafcik, K.L.; Morales, A.M.; Lewis, J. Microfabricated Deposition Nozzles for Direct-Write Assembly of Three-Dimensional Periodic Structures. Adv. Mater. 2005, 17, 289–293. [Google Scholar] [CrossRef]

- Schlordt, T.; Schwanke, S.; Keppner, F.; Fey, T.; Travitzky, N.; Greil, P. Robocasting of alumina hollow filament lattice structures. J. Eur. Ceram. Soc. 2013, 33, 3243–3248. [Google Scholar] [CrossRef]

- Simon, J.L.; Michna, S.; Lewis, J.A.; Rekow, E.D.; Thompson, V.P.; Smay, J.E.; Yampolsky, A.; Parsons, J.R.; Ricci, J.L. In vivo bone response to 3D periodic hydroxyapatite scaffolds assembled by direct ink writing. J. Biomed. Mater. Res. Part A 2007, 83, 747–758. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Wei, T.-S.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D Printing of Interdigitated Li-Ion Microbattery Architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef] [Green Version]

- Eqtesadi, S.; Motealleh, A.; Miranda, P.; Lemos, A.; Rebelo, A.; Ferreira, J.M.F. A simple recipe for direct writing complex 45S5 Bioglass® 3D scaffolds. Mater. Lett. 2013, 93, 68–71. [Google Scholar] [CrossRef]

- Miranda, P.; Pajares, A.; Saiz, E.; Tomsia, A.P.; Guiberteau, F. Mechanical properties of calcium phosphate scaffolds fabricated by robocasting. J. Biomed. Mater. Res. Part A 2008, 85, 218–227. [Google Scholar] [CrossRef]

- Smirnov, A.; Peretyagin, P.; Pinargote, N.W.S.; Gershman, I.; Bartolomé, J.F. Wear Behavior of Graphene-Reinforced Alumina–Silicon Carbide Whisker Nanocomposite. Nanomaterials 2019, 9, 151. [Google Scholar] [CrossRef] [Green Version]

- Solis, N.W.; Peretyagin, P.; Seleznev, A.; Torrecillas, R.; Moya, J.S. Black zirconia-graphene nanocomposite produced by spark plasma sintering. AIP Conf. Proc. 2016, 1785, 40074. [Google Scholar] [CrossRef] [Green Version]

- Fokin, P.; Pinargote, N.W.S.; Kuznetsova, E.; Peretyagin, P.Y.; Smirnov, A. Effect of Drying Methods of Alumina Powder and Graphene Oxide Mixture on the Mechanical and Electrical Properties of Sintered Composites Fabricated by Spark Plasma Sintering. Inorg. Mater. Appl. Res. 2018, 9, 930–936. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solís, W.; Diaz, L.; Fernández, A.; Torrecillas, R. Effect of graphene addition on the mechanical and electrical properties of Al2O3–SiCw ceramics. J. Eur. Ceram. Soc. 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal’Ko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Gerstner, E. Nobel Prize 2010: Andre Geim & Konstantin Novoselov. Nat. Phys. 2010, 6, 836. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Nayak, T.R.; Andersen, H.; Makam, V.S.; Khaw, C.; Bae, S.; Xu, X.; Ee, P.-L.R.; Ahn, J.-H.; Hong, B.H.; Pastorin, G.; et al. Graphene for controlled and accelerated osteogenic differentiation of human mesenchymal stem cells. ACS Nano 2011, 5, 4670–4678. [Google Scholar] [CrossRef] [Green Version]

- Munz, M.; Giusca, C.E.; Myers-Ward, R.L.; Gaskill, D.K.; Kazakova, O. Thickness-dependent hydrophobicity of epitaxial graphene. ACS Nano 2015, 9, 8401–8411. [Google Scholar] [CrossRef] [Green Version]

- Bagherzadeh, M.; Farahbakhsh, A. Surface functionalization of graphene. Graphene Mater. 2015, 25–65. [Google Scholar] [CrossRef]

- Sun, X.; Li, B.; Lu, M. A covalent modification for graphene by adamantane groups through two-step chlorination-Grignard reactions. J. Solid State Chem. 2017, 251, 194–197. [Google Scholar] [CrossRef]

- Qi, X.; Pu, K.Y.; Li, H.; Zhou, X.; Wu, S.; Fan, Q.L.; Liu, B.; Boey, F.; Huang, W.; Zhang, H. Amphiphilic graphene composites. Angew. Chem. Int. Ed. 2010, 49, 9426–9429. [Google Scholar] [CrossRef]

- Zaaba, N.I.; Foo, K.L.; Hashim, U.; Tan, S.J.; Liu, W.-W.; Voon, C.H. Synthesis of graphene oxide using modified hummers method: Solvent influence. Procedia Eng. 2017, 184, 469–477. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Chen, X.; Wu, N.; Nguyen, S.T.; Ruoff, R.S. Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J. Mater. Chem. 2006, 16, 155–158. [Google Scholar] [CrossRef]

- An, B.W.; Kim, K.; Kim, M.; Kim, S.Y.; Hur, S.H.; Park, J.U. Direct printing of reduced graphene oxide on planar or highly curved surfaces with high resolutions using electrohydrodynamics. Small 2015, 11, 2263–2268. [Google Scholar] [CrossRef]

- Zhang, J.-X.; Liang, Y.-X.; Wang, X.; Zhou, H.-J.; Li, S.-Y.; Zhang, J.; Feng, Y.; Lu, N.; Wang, Q.; Guo, Z. Strengthened epoxy resin with hyperbranched polyamineester anchored graphene oxide via novel phase transfer approach. Adv. Compos. Hybrid Mater. 2018, 1, 300–309. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Itkis, M.E.; Bekyarova, E.; Haddon, R.C. Graphite nanoplatelet-epoxy composite thermal interface materials. J. Phys. Chem. C 2007, 111, 7565–7569. [Google Scholar] [CrossRef]

- Syurik, Y.V.; Ghislandi, M.G.; Tkalya, E.E.; Paterson, G.; McGrouther, D.; Ageev, O.A.; Loos, J. Graphene network organisation in conductive polymer composites. Macromol. Chem. Phys. 2012, 213, 1251–1258. [Google Scholar] [CrossRef]

- Yan, J.; Wei, T.; Qiao, W.; Shao, B.; Zhao, Q.; Zhang, L.; Fan, Z. Rapid microwave-assisted synthesis of graphene nanosheet/Co3O4 composite for supercapacitors. Electrochim. Acta 2010, 55, 6973–6978. [Google Scholar] [CrossRef]

- Ahmad, J.; Majid, K. In-situ synthesis of visible-light responsive Ag2O/graphene oxide nanocomposites and effect of graphene oxide content on its photocatalytic activity. Adv. Compos. Hybrid Mater. 2018, 1, 374–388. [Google Scholar] [CrossRef]

- Acquah, S.F.A.; Leonhardt, B.E.; Nowotarski, M.S.; Magi, J.M.; Al-Hariri, L.A. Carbon nanotubes and graphene as additives in 3D printing. In Carbon Nanotubes-Current Progress of Their Polymer Composites, Mohamed Reda Berber and Inas Hazzaa Hafez; IntechOpen: London, UK, 2016. [Google Scholar]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- An, X.; Butler, T.W.; Washington, M.; Nayak, S.K.; Kar, S. Optical and sensing properties of 1-pyrenecarboxylic acidfunctionalized graphene films laminated on polydimethylsiloxane membranes. ACS Nano 2011, 5, 1003–1011. [Google Scholar] [CrossRef]

- Chu, K.; Li, W.-S.; Jia, C.-C.; Tang, F.-L. Thermal conductivity of composites with hybrid carbon nanotubes and graphene nanoplatelets. Appl. Phys. Lett. 2012, 101, 211903. [Google Scholar] [CrossRef]

- Hicks, J.; Behnam, A.; Ural, A. A computational study of tunneling-percolation electrical transport in graphene-based nanocomposites. Appl. Phys. Lett. 2009, 95, 213103. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.-B.; Zheng, W.-G.; Yan, Q.; Yang, Y.; Wang, J.-W.; Lu, Z.-H.; Ji, G.-Y.; Yu, Z.-Z. Electrically conductive polyethylene terephthalate/graphene nanocomposites prepared by melt compounding. Polymer 2010, 51, 1191–1196. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Gong, L.; Young, R.J.; Kinloch, I.A.; Riaz, I.; Jalil, R.; Novoselov, K.S. Optimizing the reinforcement of polymer-based nanocomposites by graphene. ACS Nano 2012, 6, 2086–2095. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D stereolithography printing of graphene oxide reinforced complex architectures. Nanotechnology 2015, 26, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Lin, D.; Richard, L.C.; Cheng, G.J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement. Acta Mater. 2014, 80, 183–193. [Google Scholar] [CrossRef]

- Lin, D.; Ye, C.; Liao, Y.; Suslov, S.; Liu, R.; Cheng, G.J. Mechanism of fatigue performance enhancement in a laser sintered superhard nanoparticles reinforced nanocomposite followed by laser shock peening. J. Appl. Phys. 2013, 113, 133509. [Google Scholar] [CrossRef]

- Verdejo, R.; Bernal, M.M.; Romasanta, L.J.; Lopez-Manchado, M.A. Graphene filled polymer nanocomposites. J. Mater. Chem. 2011, 21, 3301–3310. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Liu, Y.; Fan, Z.; Wang, W.; Wang, B.; Guo, Z. Ink-based 3D printing technologies for graphene-based materials a review. Adv. Compos. Hybrid Mater. 2019, 2, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Lv, R.; Bai, S. Recent advances on 3D printing graphene-based composites. Nano Mater. Sci. 2019, 1, 101–115. [Google Scholar] [CrossRef]

- Palaganas, N.B.; Mangadlao, J.D.; De Leon, A.C.C.; Palaganas, J.O.; Pangilinan, K.D.; Lee, Y.J.; Advincula, R.C. 3D printing of photocurable cellulose nanocrystal composite for fabrication of complex architectures via stereolithography. ACS Appl. Mater. Interfaces 2017, 9, 34314–34324. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Iftikhar, U. Nanoscribe Introduces Quantum X, A Two-Photon 3D Printer for Microoptics. Available online: https://3dprintingindustry.com/news/nanoscribe-introduces-quantumx-a-two-photon-3d-printer-for-microoptics-157656/ (accessed on 8 March 2020).

- Palaganas, J.O.; Palaganas, N.B.; Ramos, L.J.I.; David, C.P.C. 3D printing of covalent functionalized graphene oxide nanocomposite via stereolithography. ACS Appl. Mater. Interfaces 2019, 11, 46034–46043. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Mangadlao, J.D.; Tiu, B.D.B.; Tritchler, G.C.; Advincula, R.C. High-strength stereolithographic 3D printed nanocomposites-graphene oxide metastability. ACS Appl. Mater. Interfaces 2017, 9, 10085–10093. [Google Scholar] [CrossRef]

- Feng, Z.; Li, Y.; Hao, L.; Yang, Y.; Tang, T.; Tang, D.; Xiong, W. Graphene-reinforced biodegradable resin composites for stereolithographic 3d printing of bone structure scaffolds. J. Nanomater. 2019, 2019, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Hensleigh, R.M.; Cui, H.; Oakdale, J.S.; Ye, J.C.; Campbell, P.G.; Duoss, E.B.; Spadaccini, C.M.; Zheng, X.; Worsley, M.A. Additive manufacturing of complex micro-architected graphene aerogels. Mater. Horiz. 2018, 5, 1035–1041. [Google Scholar]

- Ren, Y.; Zhang, Y.; Fang, H.; Ding, T.; Li, J.; Bai, S.-L. Simultaneous enhancement on thermal and mechanical properties of polypropylene composites filled with graphite platelets and graphene sheets. Compos. Appl. Sci. Manuf. 2018, 112, 57–63. [Google Scholar] [CrossRef]

- Bauer, J.; Schroer, A.; Schwaiger, R.; Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. Nat. Mater. 2016, 15, 438–443. [Google Scholar] [CrossRef] [PubMed]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Desai, J.A.; Biswas, C.; Kaul, A.B. Inkjet printing of liquid exfoliated, highly conducting graphene/poly(3,4 ethylenedioxythiophene):poly(styrenesulfonate) nanosheets for organic electronics. J. Vac. Sci. Technol. B 2017, 35, D112. [Google Scholar] [CrossRef]

- He, Q.; Das, S.R.; Garland, N.T.; Jing, D.; Hondred, J.A.; Cargill, A.A.; Ding, S.; Karunakaran, C.; Claussen, J.C. Enabling inkjet printed graphene for ion selective electrodes with postprint thermal annealing. ACS Appl. Mater. Interfaces 2017, 9, 12719–12727. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nikolaou, I.; Hallil, H.; Conédéra, V.; Plano, B.; Tamarin, O.; Lachaud, J.L.; Talaga, D.; Bonhommeau, S.; Dejous, C.; Rebiere, D. Electro-mechanical properties of inkjet-printed graphene oxide nanosheets. Phys. Status Solidi A 2017, 214, 1600492. [Google Scholar] [CrossRef]

- Saidina, D.S.; Eawwiboonthanakit, N.; Mariatti, M.; Fontana, S.; Herold, C. Recent development of graphene-based ink and other conductive material-based inks for flexible electronics. J. Electron. Mater. 2019, 48, 3428–3450. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Sollami Delekta, S.; Zhang, P.; Yang, S.; Lohe, M.R.; Zhuang, X.; Feng, X.; Ostling, M. Scalable fabrication and integration of graphene microsupercapacitors through full inkjet printing. ACS Nano 2017, 11, 8249–8256. [Google Scholar] [CrossRef]

- Li, J.; Ye, F.; Vaziri, S.; Muhammed, M.; Lemme, M.C.; Östling, M. Efficient inkjet printing of graphene. Adv. Mater. 2013, 25, 3985–3992. [Google Scholar] [CrossRef]

- Dubowska-Sarapuk, L.; Kielbasinski, K.; Arazna, A.; Futera, K.; Skalski, A.; Janczak, D.; Sloma, M.; Jakubowska, M. Efficient inkjet printing of graphene-based elements: Influence of dispersing agent on ink viscosity. Nanomaterials 2018, 8, 602. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Derby, B. Experimental study of the parameters for stable drop-on-demand inkjet performance. Phys. Fluids 2019, 31, 032004. [Google Scholar] [CrossRef] [Green Version]

- Sinar, D.M. Synthesis and Drop-on-Demand Deposition of Graphene Derivative Inks for Flexible Thin Film Electronics. Ph.D. Thesis, The University of Western Ontario, London, ON, Canada, 2018. [Google Scholar]

- Guo, J.; Asli, A.E.N.; Williams, K.R.; Lai, P.L.; Wang, X.; Montazami, R.; Hashemi, N.N. Viability of neural cells on 3D printed graphene bioelectronics. Biosensors 2019, 9, 112. [Google Scholar] [CrossRef] [Green Version]

- Asli, A.E.N.; Guo, J.; Lai, P.L.; Montazami, R.; Hashemi, N.N. High-yield production of aqueous graphene for electrohydrodynamic drop-on-demand printing of biocompatible conductive patterns. Biosensors 2020, 10, 6. [Google Scholar] [CrossRef] [Green Version]

- Delekta, S.S. Inkjet Printing of Graphene-Based Microsupercapacitors for Miniaturized Energy Storage Applications. Ph.D. Thesis, KTH Royal Institute of Technology, School of Electrical Engineering and Computer Science (EECS), Stockholm, Sweden, 13 September 2019. [Google Scholar]

- Martinez-Flores, R.; Canto-Aguilar, E.J.; Rodriguez-Gattorno, G.; Oskam, G.; Meneses-Rodriguez, D.; Ruiz-Gomez, M.A. Inkjet-printed reduced graphene oxide (rGO) films for electrocatalytic applications. J. Electrochem. Soc. 2019, 165, 3279–3285. [Google Scholar] [CrossRef]

- Bassetto, V.C.; Xiao, J.; Oveisi, E.; Amstutz, V.; Liu, B.; Girault, H.H.; Lesch, A. Rapid inkjet printing of high catalytic activity Co3O4/N-rGO layers for oxygen reduction reaction. Appl. Catal. A Gen. 2018, 563, 9–17. [Google Scholar] [CrossRef]

- Li, L.; Secor, E.B.; Chen, K.-S.; Zhu, J.; Liu, X.; Gao, T.Z.; Seo, J.-W.T.; Zhao, Y.; Hersam, M.C. High-performance solid-state supercapacitors and microsupercapacitors derived from printable graphene inks. Adv. Energy Mater. 2016, 6, 1600909. [Google Scholar] [CrossRef]

- Li, J.; Mishukova, V.; Östling, M. All-solid-state micro-supercapacitors based on inkjet printed graphene electrodes. Appl. Phys. Lett. 2016, 109, 123901. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Malandarki, A.; Butterworth, S.; Beach, C.; Rigout, M.; Novoselov, K.S.; Casson, A.J.; Yeates, S.G. All inkjet-printed graphene-based conductive patterns for wearable e-textile applications. J. Mater. Chem. C 2017, 5, 11640–11648. [Google Scholar] [CrossRef] [Green Version]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Fraser, D.; Patoary, N.H.; Moore, A.L.; Weiss, L.; Radadia, A.D. Temperature-dependent electrical resistance of conductive polylactic acid filament for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2018, 99, 1215–1224. [Google Scholar]

- Tambrallimath, V.; Keshavamurthy, R.; Saravanbavan, D.; Kumar, G.S.P.; Kumar, M.H. Synthesis and characterization of graphene filled PC-ABS filament for FDM applications. AIP Conf. Proc. 2019, 2057, 020039. [Google Scholar]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D printable graphene composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D printing biocompatible polyurethane/poly(lactic acid)/graphene oxide nanocomposites: Anisotropic properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef]

- Vernardou, D.; Vasilopoulos, K.C.; Kenanakis, G. 3D printed graphene-based electrodes with high electrochemical performance. Appl. Phys. A 2017, 123, 623. [Google Scholar] [CrossRef]

- Foster, C.W.; Down, M.P.; Zhang, Y.; Ji, X.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D printed graphene based energy storage devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Foo, C.Y.; Lim, H.N.; Mahdi, M.A.; Wahid, M.H.; Huang, N.M. Three-dimensional printed electrode and its novel applications in electronic devices. Sci. Rep. 2018, 8, 7399. [Google Scholar] [CrossRef]

- Huang, C.-T.; Kumar Shrestha, L.; Ariga, K.; Hsu, S.-H. A graphene-polyurethane composite hydrogel as a potential bioink for 3D bioprinting and differentiation of neural stem cells. J. Mater. Chem. B 2017, 5, 8854–8864. [Google Scholar] [CrossRef]

- Naficy, S.; Jalili, R.; Aboutalebi, S.H.; Gorkin, R.A., III; Konstantinov, K.; Innis, P.C.; Spinks, G.M.; Poulin, P.; Wallace, G.G. Graphene oxide dispersions: Tuning rheology to enable fabrication. Mater. Horiz. 2014, 1, 326–331. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Chang, W.S.; Kim, D.; Yang, J.R.; Han, J.T.; Lee, G.W.; Kim, J.T.; Seol, S.K. 3D printing of reduced graphene oxide nanowires. Adv. Mater. 2015, 27, 157–161. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, B.; Xu, Q.; Hou, Y.; Seyedin, S.; Qin, S.; Wallace, G.G.; Beirne, S.; Razal, J.M.; Chen, J. Development of graphene oxide/polyaniline inks for high performance flexible microsupercapacitors via extrusion printing. Adv. Funct. Mater. 2018, 28, 1706592. [Google Scholar] [CrossRef]

- Jakus, A.E.; Secor, E.B.; Rutz, A.L.; Jordan, S.W.; Hersam, M.C.; Shah, R.N. Three dimensional printing of high-content graphene scaffolds for electronic and biomedical applications. ACS Nano 2015, 9, 4636–4648. [Google Scholar] [CrossRef]

- Roman-Manso, B.; Figueiredo, F.M.; Achiaga, B.; Barea, R.; Perez-Coll, D.; Morelos-Gomez, A.; Terrones, M.; Osendi, M.I.; Belmonte, M.; Miranzo, P. Electrically functional 3D-architectured graphene-SiC composites. Carbon 2016, 100, 318–328. [Google Scholar] [CrossRef]

- Zhong, J.; Zhou, G.-X.; He, P.-G.; Yang, Z.-H.; Jia, D.-C. 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide. Carbon 2017, 117, 421–426. [Google Scholar] [CrossRef]

- Tubio, C.R.; Rama, A.; Gomez, M.; del Rio, F.; Guitian, F.; Gil, A. 3D-printed graphene-Al2O3 composites with complex mesoscale architecture. Ceram. Int. 2018, 44, 5760–5767. [Google Scholar] [CrossRef]

- Moyano, J.J.; Gomez-Gomez, A.; Perez-Coll, D.; Belmonte, M.; Miranzo, P.; Osendi, M.I. Filament printing of graphene-based inks into self-supported 3D architectures. Carbon 2019, 151, 94–102. [Google Scholar] [CrossRef]

- de la Osa, G.; Perez-Coll, D.; Miranzo, P.; Osendi, M.I.; Belmonte, M. Printing of graphene nanoplatelets into highly electrically conductive three-dimensional porous macrostructures. Chem. Mater. 2016, 28, 6321–6328. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Liu, T.; Qian, F.; Han, T.Y.-J.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A.; Li, Y. Supercapacitors based on three-dimensional hierarchical graphene aerogels with periodic macropores. Nano Lett. 2016, 16, 3448–3456. [Google Scholar] [CrossRef]

- Shen, C.; Calderon, J.E.; Barrios, E.; Soliman, M.; Khater, A.; Jeyaranjan, A.; Tetard, L.; Gordon, A.; Seal, S.; Zhai, L. Anisotropic electrical conductivity in polymer derived ceramics induced by graphene aerogels. J. Mater. Chem. C 2017, 5, 11708–11716. [Google Scholar] [CrossRef]

- Bernardo, E.; Fiocco, L.; Parcianello, G.; Storti, E.; Colombo, P. Advanced ceramics from preceramic polymers modified at the nano-scale-a review. Materials 2014, 7, 1927–1956. [Google Scholar] [CrossRef]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of micrometric SiOC ceramic structures using a preceramic polymer. J. Eur. Ceram. Soc. 2016, 36, 1589–1594. [Google Scholar] [CrossRef]

- Manso, B.R.; Moyano, J.J.; Perez-Coll, D.; Belmonte, M.; Miranzo, P.; Osendi, M.I. Polymer-derived ceramic-graphene oxide architected composite with high electrical conductivity and enhanced thermal resistance. J. Eur. Ceram. Soc. 2018, 38, 2265–2271. [Google Scholar] [CrossRef]

- Moyano, J.J.; Mosa, J.; Aparicio, M.; Pérez-Coll, D.; Belmonte, M.; Miranzo, P.; Osendi, M.I. Strong and light cellular silicon carbonitride–Reduced graphene oxide material with enhanced electrical conductivity and capacitive response. Addit. Manuf. 2019, 30, 100849. [Google Scholar] [CrossRef]

- You, X.; Yang, J.; Huang, K.; Wang, M.; Zhang, X.; Dong, S. Multifunctional silicon carbide matrix composites optimized by three-dimensional graphene scaffolds. Carbon 2019, 155, 215–222. [Google Scholar] [CrossRef]

| Category | Additive Manufacturing Technology Type | Abbreviation | Feedstock |

|---|---|---|---|

| Vat photopolymerization | Stereolithography | SLA | Liquid photopolymers, hybrid polymer-ceramic, hybrid polymer-graphene |

| Digital Light Processing | DLP | ||

| Two-Photon Polymerization | TPP | ||

| Continuous Liquid Interface Production | CLIP | Liquid photopolymers | |

| Powder bed fusion | Multi Jet Fusion | MJF | Thermoplastic polymers |

| Selective Laser Sintering | SLS | Plastics, composites | |

| Selective Laser Melting | SLM | Metals | |

| Electron Beam Melting | EBM | Metals | |

| Material jetting | Material Jetting | MJ | Photopolymers |

| NanoParticle Jetting | NPJ | Metals, ceramics | |

| Drop On Demand | DOD | Wax, ceramic-, graphene-inks | |

| Material Extrusion | Fused Deposition Modeling | FDM | Thermoplastic polymers, metal-, ceramic-, graphene-reinforced polymers |

| Direct Ink Writing | DIW | Ceramics | |

| Direct Energy Deposition | Electron Beam Additive Manufacturing | EBAM | Metals and alloys in the form of powder or wire |

| Laser Engineering Net Shape | LENS | ||

| Binder jetting | Binder Jetting | BJ | Ceramic, metal, gypsum, sand |

| Sheet Lamination | Laminated Object Manufacturing | LOM | Ceramic, metal-filled tapes, paper, polymer composites. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. https://doi.org/10.3390/nano10071300

Solís Pinargote NW, Smirnov A, Peretyagin N, Seleznev A, Peretyagin P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials. 2020; 10(7):1300. https://doi.org/10.3390/nano10071300

Chicago/Turabian StyleSolís Pinargote, Nestor Washington, Anton Smirnov, Nikita Peretyagin, Anton Seleznev, and Pavel Peretyagin. 2020. "Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review" Nanomaterials 10, no. 7: 1300. https://doi.org/10.3390/nano10071300

APA StyleSolís Pinargote, N. W., Smirnov, A., Peretyagin, N., Seleznev, A., & Peretyagin, P. (2020). Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials, 10(7), 1300. https://doi.org/10.3390/nano10071300