Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment

Abstract

1. Introduction

2. Wastewater Treatments

2.1. Slurry-Based Titanium Dioxide (TiO2) System

2.2. TiO2-Based Photocatalytic Reactors

2.3. TiO2-Based Electrospun Nanofibers

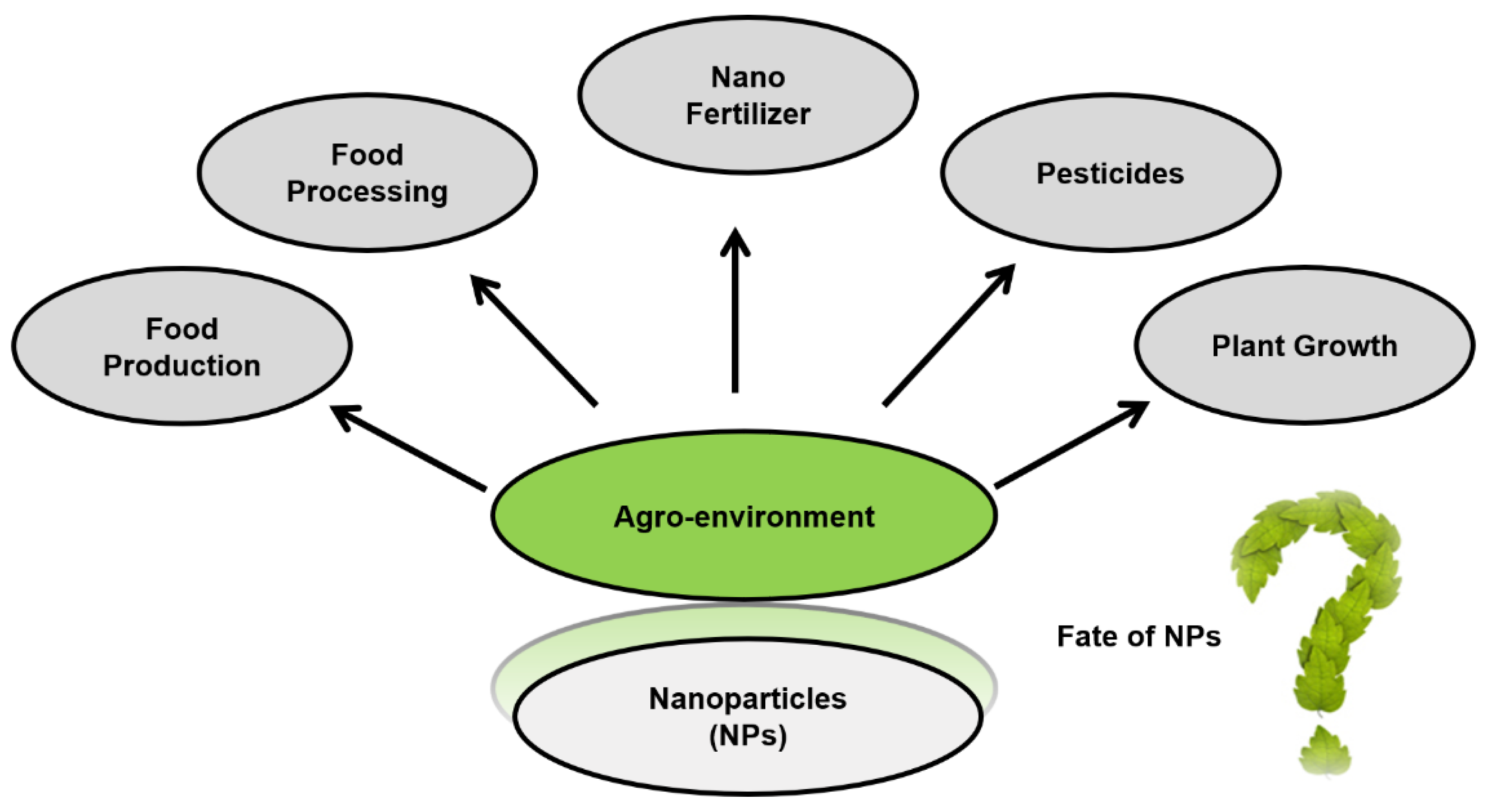

3. Impacts of TiO2 Nanoparticles (NPs) in the Agro-Environment

4. Understanding the Mechanism of Environmental Exposure of NPs

4.1. Occupational Exposure via Industries

4.2. Consumer Exposure

4.3. Environmental Exposure

5. Conclusions and Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Holister, P.; Weener, J.-W.; Vas, C.R.; Harper, T. Nanoparticles. Technol. White Pap. 2003, 3, 1–11. [Google Scholar]

- Siroha, P.; Singh, D.; Soni, R.; Gangwar, J. Comparative study on crystallographic representation of transition metal oxides polymorphs nanomaterials using VESTA software: Case study on Fe2O3 and TiO2. In Proceedings of the AIP Conference; American Institute of Physics Inc.: College Park, MA, USA, 2018; Volume 2006, p. 030038. [Google Scholar]

- Zhang, B.; Cao, S.; Du, M.; Ye, X.; Wang, Y.; Ye, J. Titanium dioxide (TiO2) mesocrystals: Synthesis, growth mechanisms and photocatalytic properties. Catalysts 2019, 9, 91. [Google Scholar] [CrossRef]

- Rajh, T.; Dimitrijevic, N.M.; Bissonnette, M.; Koritarov, T.; Konda, V. Titanium dioxide in the service of the biomedical revolution. Chem. Rev. 2014, 114, 10177–10216. [Google Scholar] [CrossRef] [PubMed]

- Walia, K. Global Titanium Dioxide Market Analysis Report 2018–2025; Value Market Research: Pune, India, 2019. [Google Scholar]

- Xu, Y.; Wei, M.T.; Ou-Yang, H.D.; Walker, S.G.; Wang, H.Z.; Gordon, C.R.; Guterman, S.; Zawacki, E.; Applebaum, E.; Brink, P.R.; et al. Exposure to TiO2 nanoparticles increases Staphylococcus aureus infection of HeLa cells. J. Nanobiotechnol. 2016, 14, 34. [Google Scholar] [CrossRef] [PubMed]

- Consumer Products—The Nanodatabase. Available online: http://nanodb.dk/en/analysis/consumer-products#chartHashsection (accessed on 7 June 2020).

- Tan, W.; Peralta-Videa, J.R.; Gardea-Torresdey, J.L. Interaction of titanium dioxide nanoparticles with soil components and plants: Current knowledge and future research needs—A critical review. Environ. Sci. Nano 2018, 5, 257–278. [Google Scholar] [CrossRef]

- Hou, J.; Wang, L.; Wang, C.; Zhang, S.; Liu, H.; Li, S.; Wang, X. Toxicity and mechanisms of action of titanium dioxide nanoparticles in living organisms. J. Environ. Sci. 2019, 75, 40–53. [Google Scholar] [CrossRef]

- Kalpana, S.R.; Rashmi, H.B.; Rao, N.H. Nanotechnology Patents as R&D Indicators for Disease Management Strategies in Agriculture. J. Intellect. Prop. Rights 2010, 15, 197–205. [Google Scholar]

- Gogos, A.; Knauer, K.; Bucheli, T.D. Nanomaterials in plant protection and fertilization: Current state, foreseen applications, and research priorities. J. Agric. Food Chem. 2012, 60, 9781–9792. [Google Scholar] [CrossRef]

- Kaegi, R.; Ulrich, A.; Sinnet, B.; Vonbank, R.; Wichser, A.; Zuleeg, S.; Simmler, H.; Brunner, S.; Vonmont, H.; Burkhardt, M.; et al. Synthetic TiO2 nanoparticle emission from exterior facades into the aquatic environment. Environ. Pollut. 2008, 156, 233–239. [Google Scholar] [CrossRef]

- Westerhoff, P.; Song, G.; Hristovski, K.; Kiser, M.A. Occurrence and removal of titanium at full scale wastewater treatment plants: Implications for TiO2 nanomaterials. J. Environ. Monit. 2011, 13, 1195–1203. [Google Scholar] [CrossRef]

- Mackevica, A.; Foss Hansen, S. Release of nanomaterials from solid nanocomposites and consumer exposure assessment—A forward-looking review. Nanotoxicology 2016, 10, 641–653. [Google Scholar] [CrossRef] [PubMed]

- Windler, L.; Lorenz, C.; von Goetz, N.; Hungerbühler, K.; Amberg, M.; Heuberger, M.; Nowack, B. Release of Titanium Dioxide from Textiles during Washing. Environ. Sci. Technol. 2012, 46, 8181–8188. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.Y.; Bornhöft, N.A.; Hungerbühler, K.; Nowack, B. Dynamic Probabilistic Modeling of Environmental Emissions of Engineered Nanomaterials. Environ. Sci. Technol. 2016, 50, 4701–4711. [Google Scholar] [CrossRef] [PubMed]

- Gottschalk, F.; Sun, T.; Nowack, B. Environmental concentrations of engineered nanomaterials: Review of modeling and analytical studies. Environ. Pollut. 2013, 181, 287–300. [Google Scholar] [CrossRef]

- Kim, B.; Murayama, M.; Colman, B.P.; Hochella, M.F. Characterization and environmental implications of nano- and larger TiO2 particles in sewage sludge, and soils amended with sewage sludge. J. Environ. Monit. 2012, 14, 1129. [Google Scholar] [CrossRef]

- Sharma, B.; Sarkar, A.; Singh, P.; Singh, R.P. Agricultural utilization of biosolids: A review on potential effects on soil and plant grown. Waste Manag. 2017, 64, 117–132. [Google Scholar] [CrossRef]

- Wu, M.; Deng, J.; Li, J.; Li, Y.; Li, J.; Xu, H. Simultaneous biological-photocatalytic treatment with strain CDS-8 and TiO2 for chlorothalonil removal from liquid and soil. J. Hazard. Mater. 2016, 320, 612–619. [Google Scholar] [CrossRef]

- Zimbone, M.; Cacciato, G.; Boutinguiza, M.; Privitera, V.; Grimaldi, M.G. Laser irradiation in water for the novel, scalable synthesis of black TiOx photocatalyst for environmental remediation. Beilstein J. Nanotechnol. 2017, 8, 196–202. [Google Scholar] [CrossRef]

- Starón, A.; Dlugosz, O.; Pulit-Prociak, J.; Banach, M. Analysis of the exposure of organisms to the action of nanomaterials. Materials 2020, 13, 349. [Google Scholar] [CrossRef]

- Geraets, L.; Oomen, A.G.; Krystek, P.; Jacobsen, N.R.; Wallin, H.; Laurentie, M.; Verharen, H.W.; Brandon, E.F.A.; de Jong, W.H. Tissue distribution and elimination after oral and intravenous administration of different titanium dioxide nanoparticles in rats. Part Fibre Toxicol. 2014, 11, 30. [Google Scholar] [CrossRef]

- Zhang, R.; Bai, Y.; Zhang, B.; Chen, L.; Yan, B. The potential health risk of titania nanoparticles. J. Hazard. Mater. 2012, 211–212, 404–413. [Google Scholar] [CrossRef] [PubMed]

- Addams, L.; Boccaletti, G.; Kerlin, M.; Stuchtey, M. Charting Our Water Future: Economic Frameworks to Inform Decision-Making: 2030 Water Resources Group; McKinsey & Company: New York, NY, USA, 2009. [Google Scholar]

- Analouei, R.; Taheriyoun, M.; Safavi, H.R. Risk assessment of an industrial wastewater treatment and reclamation plant using the bow-tie method. Environ. Monit. Assess. 2020, 192, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Chen, J.; Zhang, J.; Zhang, H.; Qiao, L.; Men, Y. Heavy metals in rice and garden vegetables and their potential health risks to inhabitants in the vicinity of an industrial zone in Jiangsu, China. J. Environ. Sci. 2010, 22, 1792–1799. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.; Zhang, X. Recent progress in TiO2-mediated solar photocatalysis for industrial wastewater treatment. Int. J. Photoenergy 2014, 2014. [Google Scholar] [CrossRef]

- Ghaly, M.Y.; Jamil, T.S.; El-Seesy, I.E.; Souaya, E.R.; Nasr, R.A. Treatment of highly polluted paper mill wastewater by solar photocatalytic oxidation with synthesized nano TiO2. Chem. Eng. J. 2011, 168, 446–454. [Google Scholar] [CrossRef]

- Dong, J.; Hu, C.; Qi, W.; An, X.; Liu, H.; Qu, J. Defect-enhanced photocatalytic removal of dimethylarsinic acid over mixed-phase mesoporous TiO2. J. Environ. Sci. 2020, 91, 35–42. [Google Scholar] [CrossRef]

- Sathiyan, K.; Bar-Ziv, R.; Mendelson, O.; Zidki, T. Controllable synthesis of TiO2 nanoparticles and their photocatalytic activity in dye degradation. Mater. Res. Bull. 2020, 126, 110842. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Obotey Ezugbe, E.; Rathilal, S.; Asante-Sackey, D. Removal of COD and SO42− from Oil Refinery Wastewater Using a Photo-Catalytic System—Comparing TiO2 and Zeolite Efficiencies. Water 2020, 12, 214. [Google Scholar] [CrossRef]

- Hiremath, V.; Deonikar, V.G.; Kim, H.; Seo, J.G. Hierarchically assembled porous TiO2 nanoparticles with enhanced photocatalytic activity towards Rhodamine-B degradation. Colloids Surf. A Physicochem. Eng. Asp. 2020, 586, 124199. [Google Scholar] [CrossRef]

- Oliveira, C.P.M.D.; Viana, M.M.; Amaral, M.C.S. Coupling photocatalytic degradation using a green TiO2 catalyst to membrane bioreactor for petroleum refinery wastewater reclamation. J. Water Process Eng. 2020, 34, 101093. [Google Scholar] [CrossRef]

- Goutam, S.P.; Saxena, G.; Singh, V.; Yadav, A.K.; Bharagava, R.N.; Thapa, K.B. Green synthesis of TiO2 nanoparticles using leaf extract of Jatropha curcas L. for photocatalytic degradation of tannery wastewater. Chem. Eng. J. 2018, 336, 386–396. [Google Scholar] [CrossRef]

- Carneiro, J.O.; Samantilleke, A.P.; Parpot, P.; Fernandes, F.; Pastor, M.; Correia, A.; Luís, E.A.; Chivanga Barros, A.A.; Teixeira, V. Visible Light Induced Enhanced Photocatalytic Degradation of Industrial Effluents (Rhodamine B) in Aqueous Media Using TiO2 Nanoparticles. J. Nanomater. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Barndõk, H.; Hermosilla, D.; Han, C.; Dionysiou, D.D.; Negro, C.; Blanco, Á. Degradation of 1,4-dioxane from industrial wastewater by solar photocatalysis using immobilized NF-TiO2 composite with monodisperse TiO2 nanoparticles. Appl. Catal. B Environ. 2016, 180, 44–52. [Google Scholar] [CrossRef]

- Natarajan, T.S.; Thomas, M.; Natarajan, K.; Bajaj, H.C.; Tayade, R.J. Study on UV-LED/TiO2 process for degradation of Rhodamine B dye. Chem. Eng. J. 2011, 169, 126–134. [Google Scholar] [CrossRef]

- Juang, R.S.; Lin, S.H.; Hsueh, P.Y. Removal of binary azo dyes from water by UV-irradiated degradation in TiO2 suspensions. J. Hazard. Mater. 2010, 182, 820–826. [Google Scholar] [CrossRef]

- Gebreyohannes, A.Y.; Mazzei, R.; Poerio, T.; Aimar, P.; Vankelecom, I.F.J.; Giorno, L. Pectinases immobilization on magnetic nanoparticles and their anti-fouling performance in a biocatalytic membrane reactor. RSC Adv. 2016, 6, 98737–98747. [Google Scholar] [CrossRef]

- Ranjbar, P.Z.; Ayati, B.; Ganjidoust, H. Kinetic study on photocatalytic degradation of Acid Orange 52 in a baffled reactor using TiO2 nanoparticles. J. Environ. Sci. 2019, 79, 213–224. [Google Scholar] [CrossRef]

- Vatanpour, V.; Karami, A.; Sheydaei, M. Central composite design optimization of Rhodamine B degradation using TiO2 nanoparticles/UV/PVDF process in continuous submerged membrane photoreactor. Chem. Eng. Process. Process Intensif. 2017, 116, 68–75. [Google Scholar] [CrossRef]

- Hamad, H.A.; Sadik, W.A.; Abd El-latif, M.M.; Kashyout, A.B.; Feteha, M.Y. Photocatalytic parameters and kinetic study for degradation of dichlorophenol-indophenol (DCPIP) dye using highly active mesoporous TiO2 nanoparticles. J. Environ. Sci. 2016, 43, 26–39. [Google Scholar] [CrossRef]

- Shargh, M.; Behnajady, M.A. A high-efficient batch-recirculated photoreactor packed with immobilized TiO2-P25 nanoparticles onto glass beads for photocatalytic degradation of phenazopyridine as a pharmaceutical contaminant: Artificial neural network modeling. Water Sci. Technol. 2016, 73, 2804–2814. [Google Scholar] [CrossRef]

- Salu, O.A.; Adams, M.; Robertson, P.K.J.; Wong, L.S.; McCullagh, C. Remediation of oily wastewater from an interceptor tank using a novel photocatalytic drum reactor. Desalin. Water Treat. 2011, 26, 87–91. [Google Scholar] [CrossRef]

- McCullagh, C.; Robertson, P.K.J.; Adams, M.; Pollard, P.M.; Mohammed, A. Development of a slurry continuous flow reactor for photocatalytic treatment of industrial waste water. J. Photochem. Photobiol. A Chem. 2010, 211, 42–46. [Google Scholar] [CrossRef]

- Elami, D.; Seyyedi, K. Removing of carmoisine dye pollutant from contaminated waters by photocatalytic method using a thin film fixed bed reactor. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2020, 55, 193–208. [Google Scholar] [CrossRef] [PubMed]

- Behnajady, M.A.; Dadkhah, H.; Eskandarloo, H. Horizontally rotating disc recirculated photoreactor with TiO2-P25 nanoparticles immobilized onto a HDPE plate for photocatalytic removal of p-nitrophenol. Environ. Technol. 2018, 39, 1061–1070. [Google Scholar] [CrossRef] [PubMed]

- Bautista, R.; Anderson, W.; Pagsuyoin, S.; Munoz, J. Degradation of tetracycline in synthesized wastewater using immobilized TiO2 on rotating corrugated aluminum drum. In Proceedings of the 2015 Systems and Information Engineering Design Symposium, Charlottesville, VA, USA, 24 April 2015; pp. 115–119. [Google Scholar]

- Wu, Y.; Yuan, H.; Jiang, X.; Wei, G.; Li, C.; Dong, W. Photocatalytic degradation of 4-tert-octylphenol in a spiral photoreactor system. J. Environ. Sci. 2012, 24, 1679–1685. [Google Scholar] [CrossRef]

- Liu, J.; McCarthy, D.L.; Cowan, M.J.; Obuya, E.A.; DeCoste, J.B.; Skorenko, K.H.; Tong, L.; Boyer, S.M.; Bernier, W.E.; Jones, W.E., Jr. Photocatalytic activity of TiO2 polycrystalline sub-micron fibers with variable rutile fraction. Appl. Catal. B Environ. 2016, 187, 154–162. [Google Scholar] [CrossRef]

- Brame, J.; Long, M.; Li, Q.; Alvarez, P. Trading oxidation power for efficiency: Differential inhibition of photo-generated hydroxyl radicals versus singlet oxygen. Water Res. 2014, 60, 259–266. [Google Scholar]

- Chen, W.; Chung, C.H.; Hsu, C.H.; Chen, Y.S.; Fu, S.L. Surface morphology and applications of TiO2 nanofiber prepared by electrospinning. In Proceedings of the 2014 International Conference on Electronics Packaging (ICEP), Toyama, Japan, 23–25 April 2014; pp. 787–790. [Google Scholar]

- Solcova, O.; Balkan, T.; Guler, Z.; Morozova, M.; Dytrych, P.; Sezai Sarac, A. New preparation route of TiO2 nanofibers by electrospinning: Spectroscopic and thermal characterizations. Sci. Adv. Mater. 2014, 6, 2618–2624. [Google Scholar] [CrossRef]

- Shaham Waldmann, N.; Paz, Y. Photocatalytic Reduction of Cr(VI) by Titanium Dioxide Coupled to Functionalized CNTs: An Example of Counterproductive Charge Separation. J. Phys. Chem. C 2010, 114, 18946–18952. [Google Scholar] [CrossRef]

- Lee, C.G.; Javed, H.; Zhang, D.; Kim, J.H.; Westerhoff, P.; Li, Q.; Alvarez, P.J.J. Porous Electrospun Fibers Embedding TiO2 for Adsorption and Photocatalytic Degradation of Water Pollutants. Environ. Sci. Technol. 2018, 52, 4285–4293. [Google Scholar] [CrossRef]

- Yasin, S.A.; Abbas, J.A.; Ali, M.M.; Saeed, I.A.; Ahmed, I.H. Methylene blue photocatalytic degradation by TiO2 nanoparticles supported on PET nanofibres. Mater. Today Proc. 2020, 20, 482–487. [Google Scholar] [CrossRef]

- Song, M.; Cao, H.; Zhu, Y.; Wang, Y.; Zhao, S.; Huang, C.; Zhang, C.; He, X. Electrochemical and photocatalytic properties of electrospun C/TiO2 nanofibers. Chem. Phys. Lett. 2020, 747, 137355. [Google Scholar] [CrossRef]

- Koysuren, O.; Koysuren, H.N. Photocatalytic activities of poly(methyl methacrylate)/titanium dioxide nanofiber mat. J. Macromol. Sci. Part A 2017, 54, 80–84. [Google Scholar] [CrossRef]

- Li, J.; Qiao, H.; Du, Y.; Chen, C.; Li, X.; Cui, J.; Kumar, D.; Wei, Q. Electrospinning Synthesis and Photocatalytic Activity of Mesoporous TiO2 Nanofibers. Sci. World J. 2012, 2012, 1–7. [Google Scholar]

- Li, Q.; Sun, D.; Kim, H. Fabrication of porous TiO2 nanofiber and its photocatalytic activity. Mater. Res. Bull. 2011, 46, 2094–2099. [Google Scholar] [CrossRef]

- Habib, Z.; Khan, S.J.; Ahmad, N.M.; Shahzad, H.M.A.; Jamal, Y.; Hashmi, I. Antibacterial behaviour of surface modified composite polyamide nanofiltration (NF) membrane by immobilizing Ag-doped TiO2 nanoparticles. Environ. Technol. 2019, 1–13. [Google Scholar] [CrossRef]

- Lazareva, A.; Keller, A.A. Estimating potential life cycle releases of engineered nanomaterials from wastewater treatment plants. In ACS Sustainable Chemistry and Engineering; American Chemical Society: Washington, DC, USA, 2014; Volume 2, pp. 1656–1665. [Google Scholar]

- Simelane, S.; Dlamini, L.N. An investigation of the fate and behaviour of a mixture of WO3 and TiO2 nanoparticles in a wastewater treatment plant. J. Environ. Sci. China 2019, 76, 37–47. [Google Scholar] [CrossRef] [PubMed]

- Nowack, B.; Ranville, J.F.; Diamond, S.; Gallego-Urrea, J.A.; Metcalfe, C.; Rose, J.; Horne, N.; Koelmans, A.A.; Klaine, S.J. Potential scenarios for nanomaterial release and subsequent alteration in the environment. Environ. Toxicol. Chem. 2012, 31, 50–59. [Google Scholar] [CrossRef]

- Singh Sekhon, B. Nanotechnology in agri-food production: An overview. Nanotechnol. Sci. Appl. 2014, 7, 31–53. [Google Scholar] [CrossRef]

- Timmusk, S.; Seisenbaeva, G.; Behers, L. Titania (TiO2) nanoparticles enhance the performance of growth-promoting rhizobacteria. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.; Schimel, J.P.; Holden, P.A. Evidence for negative effects of TiO2 and ZnO nanoparticles on soil bacterial communities. Environ. Sci. Technol. 2011, 45, 1659–1664. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.; Schimel, J.P.; Holdena, P.A. Identification of soil bacteria susceptible to TiO2 and ZnO nanoparticles. Appl. Environ. Microbiol. 2012, 78, 6749–6758. [Google Scholar] [CrossRef] [PubMed]

- Simonin, M.; Martins, J.M.F.; Le Roux, X.; Uzu, G.; Calas, A.; Richaume, A. Toxicity of TiO2 nanoparticles on soil nitrification at environmentally relevant concentrations: Lack of classical dose–response relationships. Nanotoxicology 2017, 11, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Feizi, H.; Kamali, M.; Jafari, L.; Rezvani Moghaddam, P. Phytotoxicity and stimulatory impacts of nanosized and bulk titanium dioxide on fennel (Foeniculum vulgare Mill). Chemosphere 2013, 91, 506–511. [Google Scholar] [CrossRef] [PubMed]

- Hanif, H.U.; Arshad, M.; Ali, M.A.; Ahmed, N.; Qazi, I.A. Phyto-availability of phosphorus to Lactuca sativa in response to soil applied TiO2 nanoparticles. Pak. J. Agric. Sci. 2015, 52, 177–182. [Google Scholar]

- Zahra, Z.; Arshad, M.; Rafique, R.; Mahmood, A.; Habib, A.; Qazi, I.A.; Khan, S.A. Metallic Nanoparticle (TiO2 and Fe3O4) Application Modifies Rhizosphere Phosphorus Availability and Uptake by Lactuca sativa. J. Agric. Food Chem. 2015, 63, 6876–6882. [Google Scholar] [CrossRef] [PubMed]

- Gohari, G.; Mohammadi, A.; Akbari, A.; Panahirad, S.; Dadpour, M.R.; Fotopoulos, V.; Kimura, S. Titanium dioxide nanoparticles (TiO2 NPs) promote growth and ameliorate salinity stress effects on essential oil profile and biochemical attributes of Dracocephalum moldavica. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Ogunkunle, C.O.; Gambari, H.; Agbaje, F.; Okoro, H.K.; Asogwa, N.T.; Vishwakarma, V.; Fatoba, P.O. Effect of Low-Dose Nano Titanium Dioxide Intervention on Cd Uptake and Stress Enzymes Activity in Cd-Stressed Cowpea [Vigna unguiculata (L.) Walp] Plants. Bull. Environ. Contam. Toxicol. 2020, 104, 619–626. [Google Scholar] [CrossRef]

- Ullah, S.; Adeel, M.; Zain, M.; Rizwan, M.; Irshad, M.K.; Jilani, G.; Hameed, A.; Khan, A.; Arshad, M.; Raza, A.; et al. Physiological and biochemical response of wheat (Triticum aestivum) to TiO2 nanoparticles in phosphorous amended soil: A full life cycle study. J. Environ. Manag. 2020, 263, 110365. [Google Scholar] [CrossRef]

- Rizwan, M.; Ali, S.; ur Rehman, M.Z.; Malik, S.; Adrees, M.; Qayyum, M.F.; Alamri, S.A.; Alyemeni, M.N.; Ahmad, P. Effect of foliar applications of silicon and titanium dioxide nanoparticles on growth, oxidative stress, and cadmium accumulation by rice (Oryza sativa). Acta Physiol. Plant. 2019, 41, 1–12. [Google Scholar]

- Zahra, Z.; Maqbool, T.; Arshad, M.; Badshah, M.A.; Choi, H.K.; Hur, J. Changes in fluorescent dissolved organic matter and their association with phytoavailable phosphorus in soil amended with TiO2 nanoparticles. Chemosphere 2019, 227, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Zahra, Z.; Ali, M.A.; Parveen, A.; Kim, E.; Khokhar, M.F.; Baig, S.; Hina, K.; Choi, H.-K.; Arshad, M. Exposure–Response of Wheat Cultivars to TiO2 Nanoparticles in Contrasted Soils. Soil Sediment Contam. Int. J. 2019, 28, 184–199. [Google Scholar] [CrossRef]

- Larue, C.; Baratange, C.; Vantelon, D.; Khodja, H.; Surblé, S.; Elger, A.; Carrière, M. Influence of soil type on TiO2 nanoparticle fate in an agro-ecosystem. Sci. Total Environ. 2018, 630, 609–617. [Google Scholar] [CrossRef] [PubMed]

- Zahra, Z.; Waseem, N.; Zahra, R.; Lee, H.; Badshah, M.A.; Mehmood, A.; Choi, H.-K.; Arshad, M. Growth and Metabolic Responses of Rice (Oryza sativa L.) Cultivated in Phosphorus-Deficient Soil Amended with TiO2 Nanoparticles. J. Agric. Food Chem. 2017, 65, 5598–5606. [Google Scholar] [CrossRef] [PubMed]

- Kořenková, L.; Šebesta, M.; Urík, M.; Kolenčík, M.; Kratošová, G.; Bujdoš, M.; Vávra, I.; Dobročka, E. Physiological response of culture media-grown barley (Hordeum vulgare L.) to titanium oxide nanoparticles. Acta Agric. Scand. Sect. B Soil Plant Sci. 2017, 67, 285–291. [Google Scholar] [CrossRef]

- Rafique, R.; Zahra, Z.; Virk, N.; Shahid, M.; Pinelli, E.; Park, T.J.; Kallerhoff, J.; Arshad, M. Dose-dependent physiological responses of Triticum aestivum L. to soil applied TiO2 nanoparticles: Alterations in chlorophyll content, H2O2 production, and genotoxicity. Agric. Ecosyst. Environ. 2018, 255, 95–101. [Google Scholar] [CrossRef]

- Szymańska, R.; Kołodziej, K.; Ślesak, I.; Zimak-Piekarczyk, P.; Orzechowska, A.; Gabruk, M.; Zadło, A.; Habina, I.; Knap, W.; Burda, K.; et al. Titanium dioxide nanoparticles (100–1000 mg/l) can affect vitamin E response in Arabidopsis thaliana. Environ. Pollut. 2016, 213, 957–965. [Google Scholar] [CrossRef]

- Andersen, C.P.; King, G.; Plocher, M.; Storm, M.; Pokhrel, L.R.; Johnson, M.G.; Rygiewicz, P.T. Germination and early plant development of ten plant species exposed to titanium dioxide and cerium oxide nanoparticles. Environ. Toxicol. Chem. 2016, 35, 2223–2229. [Google Scholar] [CrossRef]

- Gogos, A.; Moll, J.; Klingenfuss, F.; Heijden, M.; Irin, F.; Green, M.J.; Zenobi, R.; Bucheli, T.D. Vertical transport and plant uptake of nanoparticles in a soil mesocosm experiment. J. Nanobiotechnol. 2016, 14, 40. [Google Scholar] [CrossRef]

- Burke, D.; Pietrasiak, N.; Situ, S.; Abenojar, E.; Porche, M.; Kraj, P.; Lakliang, Y.; Samia, A. Iron Oxide and titanium dioxide nanoparticle effects on plant performance and root associated microbes. Int. J. Mol. Sci. 2015, 16, 23630–23650. [Google Scholar] [CrossRef]

- Hatami, M.; Ghorbanpour, M.; Salehiarjomand, H. Nano-anatase TiO2 modulates the germination behavior and seedling vigority of some commercially important medicinal and aromatic plants. J. Biol. Environ. Sci. 2014, 8, 53–59. [Google Scholar]

- Dehkourdi, E.H.; Mosavi, M. Effect of anatase nanoparticles (TiO2) on parsley seed germination (petroselinum crispum) in vitro. Biol. Trace Elem. Res. 2013, 155, 283–286. [Google Scholar] [CrossRef] [PubMed]

- Jaberzadeh, A.; Moaveni, P.; Tohidi Moghadam, H.R.; Zahedi, H. Influence of bulk and nanoparticles titanium foliar application on some agronomic traits, seed gluten and starch contents of wheat subjected to water deficit stress. Not. Bot. Horti Agrobot. Cluj Napoca 2013, 41, 201–207. [Google Scholar] [CrossRef]

- Larue, C.; Veronesi, G.; Flank, A.M.; Surble, S.; Herlin-Boime, N.; Carrière, M. Comparative uptake and impact of TiO2 nanoparticles in wheat and rapeseed. J. Toxicol. Environ. Health Part A Curr. Issues 2012, 75, 722–734. [Google Scholar] [CrossRef]

- Ze, Y.; Liu, C.; Wang, L.; Hong, M.; Hong, F. The Regulation of TiO2 Nanoparticles on the Expression of Light-Harvesting Complex II and Photosynthesis of Chloroplasts of Arabidopsis thaliana. Biol. Trace Elem. Res. 2011, 143, 1131–1141. [Google Scholar] [CrossRef]

- Kurepa, J.; Paunesku, T.; Vogt, S.; Arora, H.; Rabatic, B.M.; Lu, J.; Wanzer, M.B.; Woloschak, G.E.; Smalle, J.A. Uptake and distribution of ultrasmall anatase TiO2 alizarin reds nanoconjugates in arabidopsis thaliana. Nano Lett. 2010, 10, 2296–2302. [Google Scholar] [CrossRef]

- Dağhan, H. Effects of TiO2 nanoparticles on maize (Zea mays L.) growth, chlorophyll content and nutrient uptake. Appl. Ecol. Environ. Res. 2018, 16, 6873–6883. [Google Scholar]

- Kushwah, K.S.; Patel, S. Effect of Titanium Dioxide Nanoparticles (TiO2 NPs) on Faba bean (Vicia faba L.) and Induced Asynaptic Mutation: A Meiotic Study. J. Plant Growth Regul. 2019, 1–12. [Google Scholar] [CrossRef]

- Ruffini Castiglione, M.; Giorgetti, L.; Bellani, L.; Muccifora, S.; Bottega, S.; Spanò, C. Root responses to different types of TiO2 nanoparticles and bulk counterpart in plant model system Vicia faba L. Environ. Exp. Bot. 2016, 130, 11–21. [Google Scholar] [CrossRef]

- Jahan, S.; Alias, Y.B.; Bakar, A.F.B.A.; Yusoff, I. Bin Toxicity evaluation of ZnO and TiO2 nanomaterials in hydroponic red bean (Vigna angularis) plant: Physiology, biochemistry and kinetic transport. J. Environ. Sci. 2018, 72, 140–152. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, R.; Maali-Amiri, R.; Abbasi, A. Effect of TiO2 Nanoparticles on Chickpea Response to Cold Stress. Biol. Trace Elem. Res. 2013, 152, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Robichaud, C.O.; Dicksen, T.; Mark, R.W. Assessing Life-Cycle Risks of Nanomaterials. In Environmental Nanotechnology: Applications and Impacts of Nanomaterials; McGraw Hill: New York, NY, USA, 2007; pp. 481–524. [Google Scholar]

- Schmid, K.; Riediker, M. Use of Nanoparticles in Swiss Industry: A Targeted Survey. Environ. Sci. Technol. 2008, 42, 2253–2260. [Google Scholar] [CrossRef] [PubMed]

- The National Institute for Occupational Safety and Health (NIOSH). Safe Nanotechnology in the Workplace, An Introduction for Employers, Managers, and Safety and Health Professionals; NIOSH: Washington, DC, USA, 2008.

- Kheiri, S.; Liu, X.; Thompson, M. Nanoparticles at biointerfaces: Antibacterial activity and nanotoxicology. Colloids Surf. B Biointerf. 2019, 184, 110550. [Google Scholar] [CrossRef] [PubMed]

- Bondarenko, O.; Juganson, K.; Ivask, A.; Kasemets, K.; Mortimer, M.; Kahru, A. Toxicity of Ag, CuO and ZnO nanoparticles to selected environmentally relevant test organisms and mammalian cells in vitro: A critical review. Arch. Toxicol. 2013, 87, 1181–1200. [Google Scholar] [CrossRef]

- Vasantharaja, D.; Ramalingam, V.; Reddy, G.A. Oral Toxic Exposure of Titanium Dioxide Nanoparticles on Serum Biochemical Changes in Adult Male Wistar Rats Oral Toxicity of TiO2 Nanoparticles. Nanomed. J. 2015, 2, 46–53. [Google Scholar]

- Iavicoli, I.; Leso, V.; Bergamaschi, A. Toxicological effects of titanium dioxide nanoparticles: A review of in vivo studies. J. Nanomater. 2012, 2012, 36. [Google Scholar] [CrossRef]

- Zhao, L.; Zhu, Y.; Chen, Z.; Xu, H.; Zhou, J.; Tang, S.; Xu, Z.; Kong, F.; Li, X.; Zhang, Y.; et al. Cardiopulmonary effects induced by occupational exposure to titanium dioxide nanoparticles. Nanotoxicology 2018, 12, 169–184. [Google Scholar] [CrossRef]

- Jayaram, D.T.; Kumar, A.; Kippner, L.E.; Ho, P.Y.; Kemp, M.L.; Fan, Y.; Payne, C.K. TiO2 nanoparticles generate superoxide and alter gene expression in human lung cells. RSC Adv. 2019, 9, 25039–25047. [Google Scholar] [CrossRef]

- Gea, M.; Bonetta, S.; Iannarelli, L.; Giovannozzi, A.M.; Maurino, V.; Bonetta, S.; Hodoroaba, V.D.; Armato, C.; Rossi, A.M.; Schilirò, T. Shape-engineered titanium dioxide nanoparticles (TiO2-NPs): Cytotoxicity and genotoxicity in bronchial epithelial cells. Food Chem. Toxicol. 2019, 127, 89–100. [Google Scholar] [CrossRef]

- Moschini, E.; Gualtieri, M.; Colombo, M.; Fascio, U.; Camatini, M.; Mantecca, P. The modality of cell-particle interactions drives the toxicity of nanosized CuO and TiO2 in human alveolar epithelial cells. Toxicol. Lett. 2013, 222, 102–116. [Google Scholar] [CrossRef]

- Alkaladi, A.; El-Deen, N.A.M.N.; Afifi, M.; Zinadah, O.A.A. Hematological and biochemical investigations on the effect of vitamin E and C on Oreochromis niloticus exposed to zinc oxide nanoparticles. Saudi J. Biol. Sci. 2015, 22, 556–563. [Google Scholar] [CrossRef] [PubMed]

- Hansen, S.F.; Michelson, E.S.; Kamper, A.; Borling, P.; Stuer-Lauridsen, F.; Baun, A. Categorization framework to aid exposure assessment of nanomaterials in consumer products. Ecotoxicology 2008, 17, 438–447. [Google Scholar] [CrossRef] [PubMed]

- Wright, C.; Iyer, A.K.V.; Wang, L.; Wu, N.; Yakisich, J.S.; Rojanasakul, Y.; Azad, N. Effects of titanium dioxide nanoparticles on human keratinocytes. Drug Chem. Toxicol. 2017, 40, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Crosera, M.; Prodi, A.; Mauro, M.; Pelin, M.; Florio, C.; Bellomo, F.; Adami, G.; Apostoli, P.; De Palma, G.; Bovenzi, M.; et al. Titanium Dioxide Nanoparticle Penetration into the Skin and Effects on HaCaT Cells. Int. J. Environ. Res. Public Health 2015, 12, 9282–9297. [Google Scholar] [CrossRef] [PubMed]

- Geppert, M.; Schwarz, A.; Stangassinger, L.M.; Wenger, S.; Wienerroither, L.M.; Ess, S.; Duschl, A.; Himly, M. Interactions of TiO2 nanoparticles with ingredients from modern lifestyle products and their effects on human skin cells. Chem. Res. Toxicol. 2020, 33, 1215–1225. [Google Scholar] [CrossRef]

- Wu, F.; Hicks, A.L. Estimating human exposure to titanium dioxide from personal care products through a social survey approach. Integr. Environ. Assess. Manag. 2020, 16, 10–16. [Google Scholar] [CrossRef]

- Hashimoto, K.; Irie, H.; Fujishima, A. TiO2 Photocatalysis: A Historical Overview and Future Prospects. Jpn. J. Appl. Phys. 2005, 44, 8269–8285. [Google Scholar] [CrossRef]

- Hu, J.; Wu, X.; Wu, F.; Chen, W.; Zhang, X.; White, J.C.; Li, J.; Wan, Y.; Liu, J.; Wang, X. TiO2 nanoparticle exposure on lettuce (Lactuca sativa L.): Dose-dependent deterioration of nutritional quality. Environ. Sci. Nano 2020, 7, 501–513. [Google Scholar] [CrossRef]

- Hansen, S.F. Regulation and Risk Assessment of Nanomaterials: Too Little, Too Late? Ph.D. Thesis, Technical Unversity of Denmark, Kongens Lyngby, Denmark, 2009. [Google Scholar]

- Wijnhoven, S.W.P.; Dekkers, S.; Hagens, W.I.; De Jong, W.H. Exposure to Nanomaterials in Consumer Products; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2009. [Google Scholar]

- Du, W.; Sun, Y.; Ji, R.; Zhu, J.; Wu, J.; Guo, H. TiO2 and ZnO nanoparticles negatively affect wheat growth and soil enzyme activities in agricultural soil. J. Environ. Monit. 2011, 13, 822. [Google Scholar] [CrossRef]

- Rondeau-Mouro, C.; Defer, D.; Leboeuf, E.; Lahaye, M. Assessment of cell wall porosity in Arabidopsis thaliana by NMR spectroscopy. Int. J. Biol. Macromol. 2008, 42, 83–92. [Google Scholar] [CrossRef]

- Jia, G.; Wang, H.; Yan, L.; Wang, X.; Pei, R.; Yan, T.; Zhao, Y.; Guo, X. Cytotoxicity of Carbon Nanomaterials: Single-Wall Nanotube, Multi-Wall Nanotube, and Fullerene. Environ. Sci. Technol. 2005, 39, 1378–1383. [Google Scholar] [CrossRef] [PubMed]

- Belhaj Abdallah, B.; Andreu, I.; Chatti, A.; Landoulsi, A.; Gates, B.D. Size Fractionation of Titania Nanoparticles in Wild Dittrichia Viscosa Grown in a Native Environment. Environ. Sci. Technol. 2020. [Google Scholar] [CrossRef] [PubMed]

- Larue, C.; Castillo-Michel, H.; Sobanska, S.; Trcera, N.; Sorieul, S.; Cécillon, L.; Ouerdane, L.; Legros, S.; Sarret, G. Fate of pristine TiO2 nanoparticles and aged paint-containing TiO2 nanoparticles in lettuce crop after foliar exposure. J. Hazard. Mater. 2014, 273, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.C.D.; Oliva, M.A.; Azevedo, A.A.; Araújo, J.M. De Responses of restinga plant species to pollution from an iron pelletization factory. Water. Air. Soil Pollut. 2006, 175, 241–256. [Google Scholar] [CrossRef]

- Nair, R.; Varghese, S.H.; Nair, B.G.; Maekawa, T.; Yoshida, Y.; Kumar, D.S. Nanoparticulate material delivery to plants. Plant Sci. 2010, 179, 154–163. [Google Scholar] [CrossRef]

- Amde, M.; Liu, J.F.; Tan, Z.Q.; Bekana, D. Transformation and bioavailability of metal oxide nanoparticles in aquatic and terrestrial environments. A review. Environ. Pollut. 2017, 230, 250–267. [Google Scholar] [CrossRef] [PubMed]

- Movafeghi, A.; Khataee, A.; Abedi, M.; Tarrahi, R.; Dadpour, M.; Vafaei, F. Effects of TiO2 nanoparticles on the aquatic plant Spirodela polyrrhiza: Evaluation of growth parameters, pigment contents and antioxidant enzyme activities. J. Environ. Sci. 2018, 64, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Hou, J.; Zhu, Y.; Lin, D. Multigenerational exposure to TiO2 nanoparticles in soil stimulates stress resistance and longevity of survived C. elegans via activating insulin/IGF-like signaling. Environ. Pollut. 2020, 263, 114376. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wu, X.; Liu, Y.; Zhang, J.; Lin, D. Integration of transcriptomics and metabolomics reveals the responses of earthworms to the long-term exposure of TiO2 nanoparticles in soil. Sci. Total Environ. 2020, 719, 137492. [Google Scholar] [CrossRef]

- Sánchez-López, K.B.; De Los Santos-Ramos, F.J.; Gómez-Acata, E.S.; Luna-Guido, M.; Navarro-Noya, Y.E.; Fernández-Luqueño, F.; Dendooven, L. TiO2 nanoparticles affect the bacterial community structure and Eisenia fetida (Savigny, 1826) in an arable soil. PeerJ 2019, 2019, e6939. [Google Scholar] [CrossRef]

- Mu, W.; Wang, Y.; Huang, C.; Fu, Y.; Li, J.; Wang, H.; Jia, X.; Ba, Q. Effect of Long-Term Intake of Dietary Titanium Dioxide Nanoparticles on Intestine Inflammation in Mice. J. Agric. Food Chem. 2019, 67, 9382–9389. [Google Scholar] [CrossRef] [PubMed]

- Relier, C.; Dubreuil, M.; Garcìa, O.L.; Cordelli, E.; Mejia, J.; Eleuteri, P.; Robidel, f.; Loret, T.; Pacchierotti, F.; Lucas, S.; et al. Study of TiO2 P25 nanoparticles genotoxicity on lung, blood, and liver cells in lung overload and non-overload conditions after repeated respiratory exposure in rats. Toxicol. Sci. 2017, 156, 527–537. [Google Scholar] [PubMed]

- Liu, S.; Zeng, P.; Li, X.; Thuyet, D.Q.; Fan, W. Effect of chronic toxicity of the crystalline forms of TiO2 nanoparticles on the physiological parameters of Daphnia magna with a focus on index correlation analysis. Ecotoxicol. Environ. Saf. 2019, 181, 292–300. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, M.; Venkatesan, M.; Arumugam, V.; Natesan, G.; Saravanan, N.; Murugesan, S.; Ramachandran, S.; Ayyasamy, R.; Pugazhendhi, A. Green synthesis and characterization of titanium dioxide nanoparticles (TiO2 NPs) using Sesbania grandiflora and evaluation of toxicity in zebrafish embryos. Process Biochem. 2019, 80, 197–202. [Google Scholar] [CrossRef]

- Abd El-Atti, M.; Desouky, M.M.A.; Mohamadien, A.; Said, R.M. Effects of titanium dioxide nanoparticles on red swamp crayfish, Procambarus clarkii: Bioaccumulation, oxidative stress and histopathological biomarkers. Egypt. J. Aquat. Res. 2019, 45, 11–18. [Google Scholar] [CrossRef]

- Fırat, Ö.; Bozat, R.C. Assessment of biochemical and toxic responses induced by titanium dioxide nanoparticles in Nile tilapia Oreochromis niloticus. Hum. Ecol. Risk Assess. 2019, 25, 1438–1447. [Google Scholar] [CrossRef]

- Kachenton, S.; Jiraungkoorskul, W.; Kangwanrangsan, N.; Tansatit, T. Cytotoxicity and histopathological analysis of titanium nanoparticles via Artemia salina. Environ. Sci. Pollut. Res. 2019, 26, 14706–14711. [Google Scholar] [CrossRef]

| Type of Pollutant | Photo-Catalyst | Experimental Conditions | Light Source | Photocatalytic Activity | Ref. | |

|---|---|---|---|---|---|---|

| Catalyst Dose | Contaminant Conc. | |||||

| Dimethyl arsenic acid (DMA) | Mesoporous TiO2 NPs | 0.8 g/L | 200 µg/L, 100 mL | 300 W Xe-arc lamp | 95.12% DMA removal at pH 7.5 and further increase was observed between pH 3–5 | [30] |

| Methylene blue (MB) and Congo red (CR) | TiO2 NPs | 25 mg/mL | 15 mL, MB (10 mg/L), CR (20 mg/L) | UV–Vis light (λ = 304–785 nm) | 85% MB removal at pH 11.25, 99.7% CR removal at pH 5.40 | [31] |

| Chemical Oxygen Demand (COD) and SO42− from oil refinery wastewater | TiO2 NPs | 0.5–1.5 g/L | 1 L real refinery effluent | 18 W UV lamp (λ = 400 nm) | 91.21% of COD and 86% SO42− removal after 15 min | [32] |

| Rhodamine B | Porous TiO2 NPs | 0.100 g/100 mL | 400 mg/L | 300 W tungsten filament solar lamp | 98% degradation within 20 min | [33] |

| Refinery wastewater | TiO2 NPs | 100 mg/L | 150 mL real refinery effluent | 6 W low-pressure mercury vapor lamp (λ = 254 nm) | 32% Total Organic Carbon (TOC) and 67% Total Nitrogen (TN) after 90 min | [34] |

| Tannery wastewater | TiO2 NPs | 5 g/L | 5 L real tannery effluent | Solar radiations of intensity 985 W/m2 | 83% COD and 76% Cr+6 after 5 h | [35] |

| Rhodamine B | TiO2 NPs | 20 g/L | 4 mg/L, 400 mL | Visible light (λ ~ 365 nm) | 65% Rhodamine B degradation | [36] |

| 1,4-dioxane | Degussa P25-TiO2 | 1.24 g/L | (25, 50, 100, 150 and 200 mg L−1), 20 mL | 1000 Wm−2 Xe lamp (λ = 315–400 nm) | 50% COD and 40% TOC after 6 h | [37] |

| Rhodamine B | Degussa P-25 TiO2 | 1.6 g/L | 20 mg/L, 25 mL | Blue UV light (λ = 390–410 nm) | 96% degradation in 60 min | [38] |

| Acid Orange 7 | Degussa P-25 TiO2 | 0.5 g/L | 40 mg/L, 800 mL | 400 W HP Hg lamp (λ = 253.7 nm) | 100% degradation in 120 min | [39] |

| Reactor Type | Reactor Name with Photocatalyst | Target Pollutant Conc. | Findings | Ref. |

|---|---|---|---|---|

| Suspended | Baffled reactor using Degussa P25-TiO2 NPs | Acid orange 52 (50 mg/L) | Complete mineralization after 30 h at a flow rate of 14.4 L/h | [41] |

| Submerged membrane photocatalysis reactor (SMPR) using UV/TiO2 | Rhodamine B | 95% removal was observed at a catalyst loading of 0.1 g/L under 3 ultraviolet (UV) c lamps at pH 8 | [42] | |

| Slurry photoreactor having mesoporous TiO2 NPs | Dichlorophenol-indophenol (DCPIP) dye (1 to 4 × 10−4 mol/L) | 96.4% DCPIP degradation occurred within 3 min at 1 × 10−4 mol/L concentration and pH 3 | [43] | |

| Packed bed photoreactor | Phenazopyridine (10, 20, 30, 40 mg/L) | 90% decrease in TOC was observed after 150 min | [44] | |

| Photocatalytic drum reactor having TiO2 NPs | MB (10 μM) and 4-Chlorophenol (100 μM) | 93% MB degradation after 15 min and 94% 4-CP removal after 90 min | [45] | |

| Rotating drum reactor having Degussa P25-TiO2 | MB | 98% of MB removal was observed at 30 g/L TiO2 after 60 min | [46] | |

| Immobilized | Thin-film fixed bed reactor having TiO2 NPs | Carmoisine dye (10 mg/L) | 97% removal was observed at pH 2 after 45 min at a flow rate of 0.25 L min−1 | [47] |

| Baffled reactor immobilized with TiO2 NPs | Acid orange 52 (AO52) (50 mg L−1) | After 4 h, dye converted into benzene annular compound, intermediates gradually decreased after 10 h and complete mineralization into CO2 and H2O in 30 h | [41] | |

| Rotating disc photoreactor, TiO2 (P25) immobilized on High Density Polyethylene (HDPE) plate | p-nitrophenol (15 mg L−1) | 83% removal was observed at pH 5 after 118 min at 800 mL volume | [48] | |

| Rotating aluminum drum with TiO2-coated corrugated aluminum drum | Tetracycline (0.5, 1, 5, 10, 30, 50, 60, and 80 ppm) | 93% Tetracycline was observed after 20 min | [49] | |

| Spiral photoreactor system sintered with TiO2 thin film | 4-tert-octylphenol (4-t-OP) (2, 5, 8 and 10 mg L−1) | 90% 4-t-OP degradation was observed at 10 mg/L concentration with single layer TiO2 film (13.6% TiO2 precursor) | [50] |

| Type of Pollutant | Photo-Catalyst | Experimental Conditions | Light Source | Photocatalytic Activity | Ref. | |

|---|---|---|---|---|---|---|

| Catalyst Dose | Contaminant Conc. | |||||

| MB | Carbonized TiO2 nanofibers | 2, 4 and 6 mg/40 mL | MB-blue (10 mg/L) | 300 W Xenon lamp | At 4 mg dose, 94.98 ± 0.02% degradation was observed after 120 min which decreased up to 83.20 ± 0.01% after 5th cycle | [58] |

| MB | TiO2 NPs supported on Polyethylene terephthalate (PET) nanofibers | 0.0032 g of TiO2 adsorbed on 0.011 g of PET nanofibers in 10 mL | MB (10 mg/L) | 100 W Xenon lamp | 88% degradation after 10 min | [57] |

| MB, Bisphenol A (BPA) and 17α-ethynylestradiol (EE2) | TiO2 nanofibers | 4 × 5 cm2 rectangular coupons/50 mL | MB (6.4 mg/L), BPA and EE2 (C0 = 5.0 mg/L) | Six UV-A lamps (λ = 365 nm) | 97% MB adsorbed in 240 min and degraded completely in less than 90 min, 96% removal for BPA and EE2 within 4 h and 1.5 h, respectively | [56] |

| MB | Polymethyl methacrylate (PMMA)/TiO2 nanofibers | 3 × 3 cm2 rectangular coupons/50 mL | MB (10 mg/L) | 8 W UV (λ = 254 nm) | 20% degradation after 180 min | [59] |

| Rhodamine B | TiO2 nanofibers | 0.1 g/100 mL | Rhodamine B (5 mg/L) | 500-Watt tungsten halogen lamp (λ ~ 420 nm) | 99% of degradation was observed after 2.5 h for nanofibers calcined at 500 °C | [60] |

| CR | Porous TiO2 nanofibers after silica leaching | 0.5 g/L | CR (20 mg/L) | UV irradiation in a photochemical reactor | 76.56 wt% photocatalytic degradation after 1 h | [61] |

| Experimental Conditions | Plants | Impacts of TiO2 | Ref. |

|---|---|---|---|

| TiO2 NPs Size: 20–30 nm Treatments: 0, 50, 100 and 200 mg L−1) in the growth medium of cocopite and perlite. Period: 60 days | Moldavian balm | Plants cultivated in salt stress conditions were observed to have improved physical traits and increased antioxidant enzyme activity in response to TiO2 NPs treatment compared to control. | [74] |

| TiO2 NPs Size: 50 and 68 nm Treatments: 100 mg nTiO2/kg on 10 mg kg−1 of Cd-spiked soils Period: 14 days | Cowpea | No change in chlorophylls occurred. In leaves and roots, both ascorbate peroxidase and catalase activities were improved by NPs. TiO2 NPs have the potential for soil nano-remediation and could be an environmentally friendly option to tolerate soil Cd toxicity in cowpea plants. | [75] |

| TiO2 NPs Size: 30 nm Treatments: 0, 30, 50 and 100 mg kg−1 Period: 60 days | Wheat | TiO2 NPs without P fertilizer increased Ca (316%), Cu (296%), Al (171%), and Mg (187%) contents in shoots at 50 mg kg−1 TiO2 NPs treatment which shows improved grain quality and crop growth. | [76] |

| TiO2 NPs Treatments: 0, 5, 10, 15, and 20 mg L−1 (foliar spray) Medium: Soil Period: 55 days | Rice (Oryza sativa) | The foliar spray of TiO2 NPs reduced the soil bioavailable Cd by 10, 14, 28, and 32% in response to 5, 10, 20, and 30 mg/L NPs treatments compared to their control values. These NPs also significantly decreased the Cd concentration in the shoot as well. | [77] |

| TiO2 NPs Size: <40 nm Treatments: 0, 50, and 100/mg kg−1 Medium: Soil Period: 40 days | Wheat (Triticum aestivum) | Shoots and root lengths of wheat plants increased by16% and 4%, respectively. Phosphorus in shoots and roots was increased by 23.4% and 17.9% at 50/mg kg−1 of soil compare to control. | [78] |

| TiO2 NPs Size: <40 nm Treatments: 0, 25, 50, 150, 250, 500, 750 and 1000 mg L−1 Medium: Soil | Wheat (Triticum aestivum) | TiO2 NPs at the highest treatment level of 1000 mg kg−1, plant growth, biomass. Phosphorus content along with other tested parameters did not shown any improvement in the testing soils. | [79] |

| TiO2 NPs Treatments: 0, 100 and 500 mg kg−1 Medium: soil Period: 60 days | Wheat (Triticum aestivum) | No effect of phytotoxicity was observed in plant growth, chlorophyll content, and biomass. | [80] |

| TiO2 NPs Treatments: 0–750 mg kg−1 Medium: Soil Period: 90 days | Rice (Oryza sativa) | Phosphorus concentration was increased in roots by 2.6-fold, shoots 2.4-fold, and grains 1.3-fold upon 750 mg kg−1 of NPs treatment. Metabolomics study revealed that levels of amino acids, glycerol content, and palmitic acid were also improved in grains. | [81] |

| TiO2 NPs Treatments: 0, 100, 150, 200, 400, 600, and 1000 mg L−1 Medium: Hydroponics Period: 7 days | Barley (Hordeum vulgare L.) | No adverse effect on shoot growth. Root growth inhibited as the concentration of TiO2 NPs increases. No effect on chlorophyll a and b. No significant effect on biomass. | [82] |

| TiO2 NPs Treatments: 0–100 mg kg−1 Medium: Soil Period: 60 days | Wheat (Triticum aestivum) | NPs treatment at the rate of 20, 40, and 60 mg kg−1 increased plant growth and phosphorus uptake. 32.3% of chlorophyll content increased at 60 mg kg−1 while 11.1% decrease at 100 mg kg−1. | [83] |

| TiO2 NPs Size: >20 nm Treatments: 0, 100, 250, 500 and 1000 mg L−1 Medium: Soil Period: 5 weeks | Arabidopsis thaliana (L.) | Plant biomass and chlorophyll content decreased as the NPs treatment increase. Higher concentrations of NPs improved root growth. NPs treatments from 100 to 1000 µg mL−1 affect vitamin E content in plants. Decrease in plant biomass by 3-fold in response to 500 and 1000 mg/mL NPs treatment, whereas, at 100 mg/mL, the biomass decreases to half relative to control. | [84] |

| TiO2 NPs Treatments: 250 and 500 µg/mL | Cabbage, Cucumber, Onion | The germination of cabbage significantly increased. In cucumber and onion, significant root elongation was observed. | [85] |

| TiO2 NPs P25: 29 ± 9 nm, E171: 92 ± 31nm, Non-nanomaterial TiO2: 145 ± 46 nm Treatments: 1, 10, 100, 1000 mg kg−1 Period: 12 weeks | Wheat, Red clover | TiO2 NPs showed restricted mobility from soil to leachate. No significant translocation of Ti was observed in both plant species, while average Ti content increased from 4 to 8 mg kg−1 at the highest treatments. | [86] |

| TiO2 NPs Size: 22 and 25 nm Period: 6 weeks | Soya bean | Plant growth significantly decreased which corresponds to the reduced carbon content in leaves. | [87] |

| TiO2 NPs Treatments: 0, 10, 20, 40 and 80 mg L−1 Medium: Petri dish Period: 10 days | Alyssum homolocarpum, Salvia mirzayanii, Carum copticum, Sinapis alba, and Nigella sativa | TiO2 NPs affected the germination and seedling vigor of 5 medicinal plants. Appropriate concentration levels had improved the germination as well as the vigor index of the subjected plant. | [88] |

| TiO2 NPs Treatments: 0, 10, 20, 30, and 40 mg mL−1 | Parsley | Significant increase in seedlings germination percentage, germination rate index, shoot-root length, fresh biomass, vigor index, and chlorophyll content. 30 mg mL−1 was observed to be the optimum concentration of NPs. Increased germination percentage (92.46%) was observed at 40 mg mL−1 treatment, relative to the lowest one (44.97%) at control. | [89] |

| TiO2 NPs Treatments: 0, 0.01%, 0.02%, and 0.03% Medium: Soil Period: 14 days | Wheat (Triticum aestivum) | Under the water-stressed conditions, the plant’s length, biomass, and seed number along with the other tested traits like gluten and starch content were increased at 0.02% of NPs treatment. | [90] |

| TiO2 NPs Size: 14–655 nm | Wheat (Triticum aestivum) | NPs treatment improved root length. NPs above 140 nm diameter are not accumulated in wheat roots. NPs above 36 nm threshold diameter, can be accumulated (at concentration 109 mg Ti/kg dry weight) in wheat root parenchyma cells but are unable to translocate to the shoot. Enhanced wheat root elongation was observed when exposed to 14 and 22 nm TiO2 NPs. | [91] |

| TiO2 NPs Size: 5 nm Treatments: 0.25% NPs Medium: Hoagland nutritive fluid Period: 35 days | Arabidopsis thaliana | Improved photosynthesis and growth in plants were reported. Generally, the absorption of light in chloroplast and light-harvesting complex II was supposed to be stimulated by TiO2 NPs; thus, enhancing the transformation of light energy to electronic energy, the evolution of oxygen, and water photolysis. | [92] |

| TiO2 NPs (43%) with sucrose coating Size: >5 nm | Arabidopsis thaliana | Results revealed that small NPs entered plant cells and got accumulated in distinct subcellular locations. | [93] |

| TiO2 NPs Size: <100 nm Treatments: 0, 5, 10 and 20 mg L−1 Period: 20 days | Zea mays L. | TiO2 NPs treatment significantly reduced the shoot, root biomass, and chlorophyll contents of leaves in a dose-dependent manner. Whereas positive effects were reported on the N, P, K, Zn Mn, and Cu contents except for Fe. | [94] |

| TiO2 NPs Size: <100 nm Treatments: 15, 30, 60, 120 and 240 mg L−1 Period: at different time intervals up to a maximum of 82 days | Vicia faba | TiO2 NPs were reported to induce variations in a meiotic activity which results in an increased number of chromosomal abnormalities in the plant’s reproductive parts. | [95] |

| TiO2 NPs Size: <100 nm (tetragonal crystals), <10 nm (spherical shape) Treatments: 50 mg L−1 Period: 3 days | Vicia faba L. | Based on the characteristics of size and shape, TiO2 NPs can induce different levels of toxicity in terms of seed vigor index, aberration index and oxidative stress in plants. | [96] |

| Experimental Conditions | Organisms | Impacts of TiO2 | Ref. |

|---|---|---|---|

| Terrestrial Organisms | |||

| TiO2 NPs Size: 25 nm Treatments: 500 and 5000 mg kg−1 Period: up to 48 days | Nematodes (C. elegans) | Increased generation of intracellular reactive oxygen species. Toxicity reduced and the lifespan of survived nematodes increased in response to TiO2 NPs exposure. | [129] |

| TiO2 NPs Treatments: 0, 5, 50, and 500 mg kg−1 Period: 120 days | Earthworm (Eisenia fetida) | Lower glutathione/oxidized glutathione (GSH/GSSG) ratio and significant decrease in superoxide dismutase (SOD) activity was observed for 500 mg/kg TiO2 concentration. | [130] |

| TiO2 NPs Size: 50–100 nm Treatments: 0, 150 or 300 mg kg−1 of dry soil Period: 15, 30, 60 and 90 days | Bacterial community and Eisenia fetida | Unamended and earthworm—amended soil increased certain available bacterial groups such as Firmicutes and Acetobacter whereas decreased Verrucomicrobia and Pedobacter abundance. | [131] |

| TiO2 NPs (anatase) Treatments: 10, 50, and 100 nm Period: 2–3 months | Mice | Intestinal inflammation with lower body weight. Mice with removed gut microbiota did not show this phenomenon. | [132] |

| TiO2 NPs Size: 23 ± 6.8 nm Treatments: 0.5, 2.5, and 10 mg kg−1 Period: 2 h and 35 days | Sprague–Dawley rats | Persistent inflammation of lung and liver genotoxicity. | [133] |

| Aquatic Organisms | |||

| TiO2 NPs Treatments: 0.25, 0.5, and 1.0 mg L−1 Period: 21 days | Daphnia magna | TiO2 with 20% rutile and 80% anatase had a highest mortality rate as compared to other crystalline forms. | [134] |

| Biosynthesized TiO2 NPs Size: 43–56 nm Treatments: 0, 2.5, 5, 10, 20, and 40 mg L−1 | Zebrafish (Danio rerio) | Significant malformations such as tail curvature, egg coagulation, bend the spine and delayed hatching was observed at a concentration of 2.5 mg L−1 during 8 to 120 h post fertilized period. | [135] |

| TiO2 NPs Treatments: 25, 125, and 250/mg L−1 Period: 28/days | Red swamp crayfish (Procambarus clarkia) | The mortality rate was observed to be 0, 3.3, and 10% in response to 25, 125, and 250/mg L−1 of TiO2 NPs, respectively. | [136] |

| TiO2 NPs Treatments: 1.0 and 5.0 mg L−1 Period: 4 and 14 days | Nile tilapia (Oreochromis niloticus) | Acute exposure caused oxidative stress with a decrease in catalase (60%), superoxide dismutase (27%), and glutathione peroxidase (37%), while 14 days of exposure elevated the catalase (61%), glutathione-S-transferase (54%), glutathione peroxidase (32%), and glutathione reductase (93%). | [137] |

| TiO2 NPs Treatments: 500, 1000, 1500, and 2000 mg L−1 Period: 24 h | Brine shrimp (Artemia salina) | Mortality rate of 5, 20, 20, 53, and 57% was observed in response to 0, 500, 1000, 1500, and 2000 mg L−1 TiO2 NPs, respectively. | [138] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahra, Z.; Habib, Z.; Chung, S.; Badshah, M.A. Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment. Nanomaterials 2020, 10, 1469. https://doi.org/10.3390/nano10081469

Zahra Z, Habib Z, Chung S, Badshah MA. Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment. Nanomaterials. 2020; 10(8):1469. https://doi.org/10.3390/nano10081469

Chicago/Turabian StyleZahra, Zahra, Zunaira Habib, Sujin Chung, and Mohsin Ali Badshah. 2020. "Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment" Nanomaterials 10, no. 8: 1469. https://doi.org/10.3390/nano10081469

APA StyleZahra, Z., Habib, Z., Chung, S., & Badshah, M. A. (2020). Exposure Route of TiO2 NPs from Industrial Applications to Wastewater Treatment and Their Impacts on the Agro-Environment. Nanomaterials, 10(8), 1469. https://doi.org/10.3390/nano10081469