A Numerical Investigation on the Collision Behavior of Unequal-Sized Micro-Nano Droplets

Abstract

1. Introduction

2. Numerical Framework

2.1. Mathematical Formulation

2.2. Numerical Model

2.3. Comparison with Experiments

3. Results and Discussion

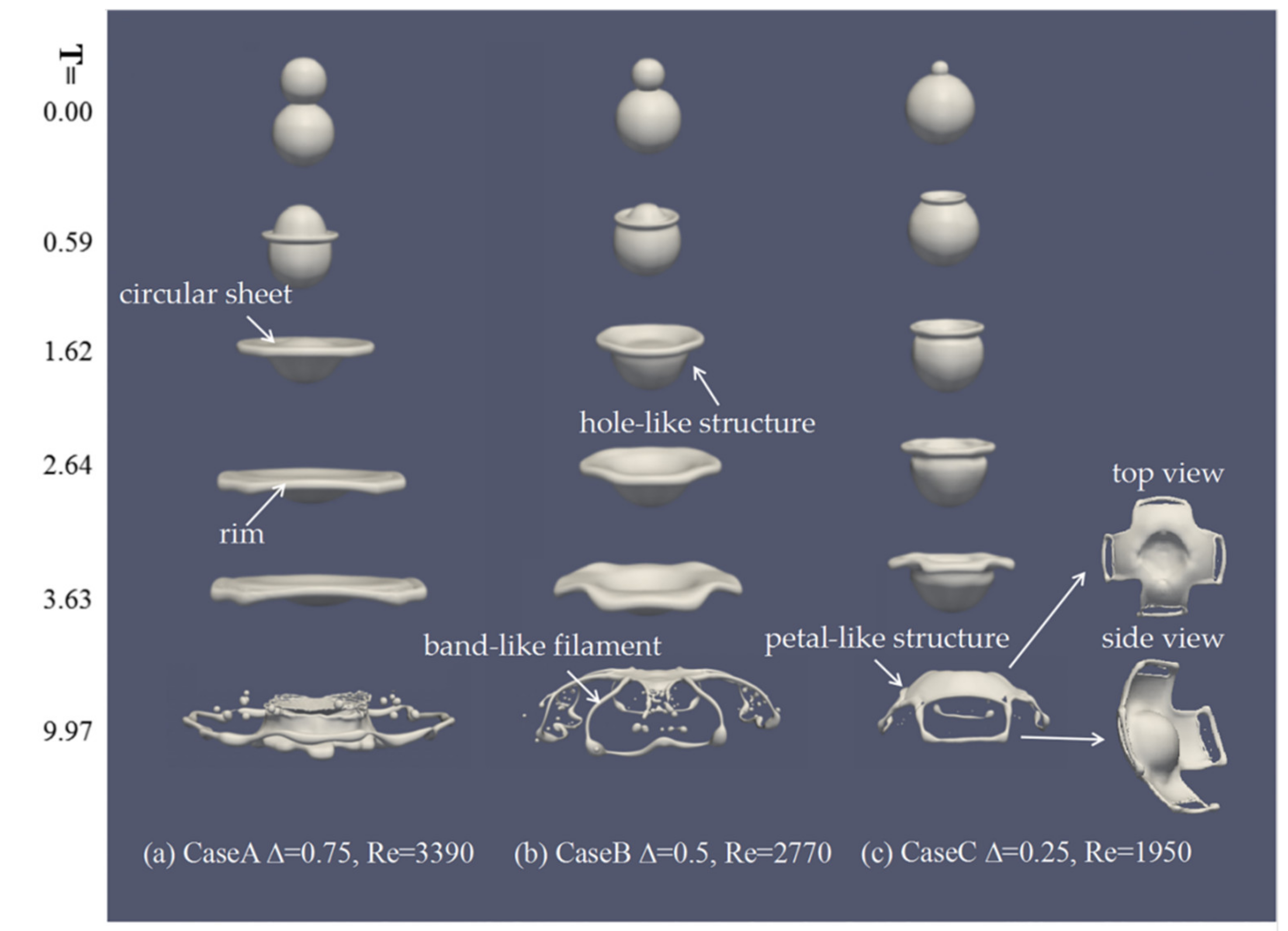

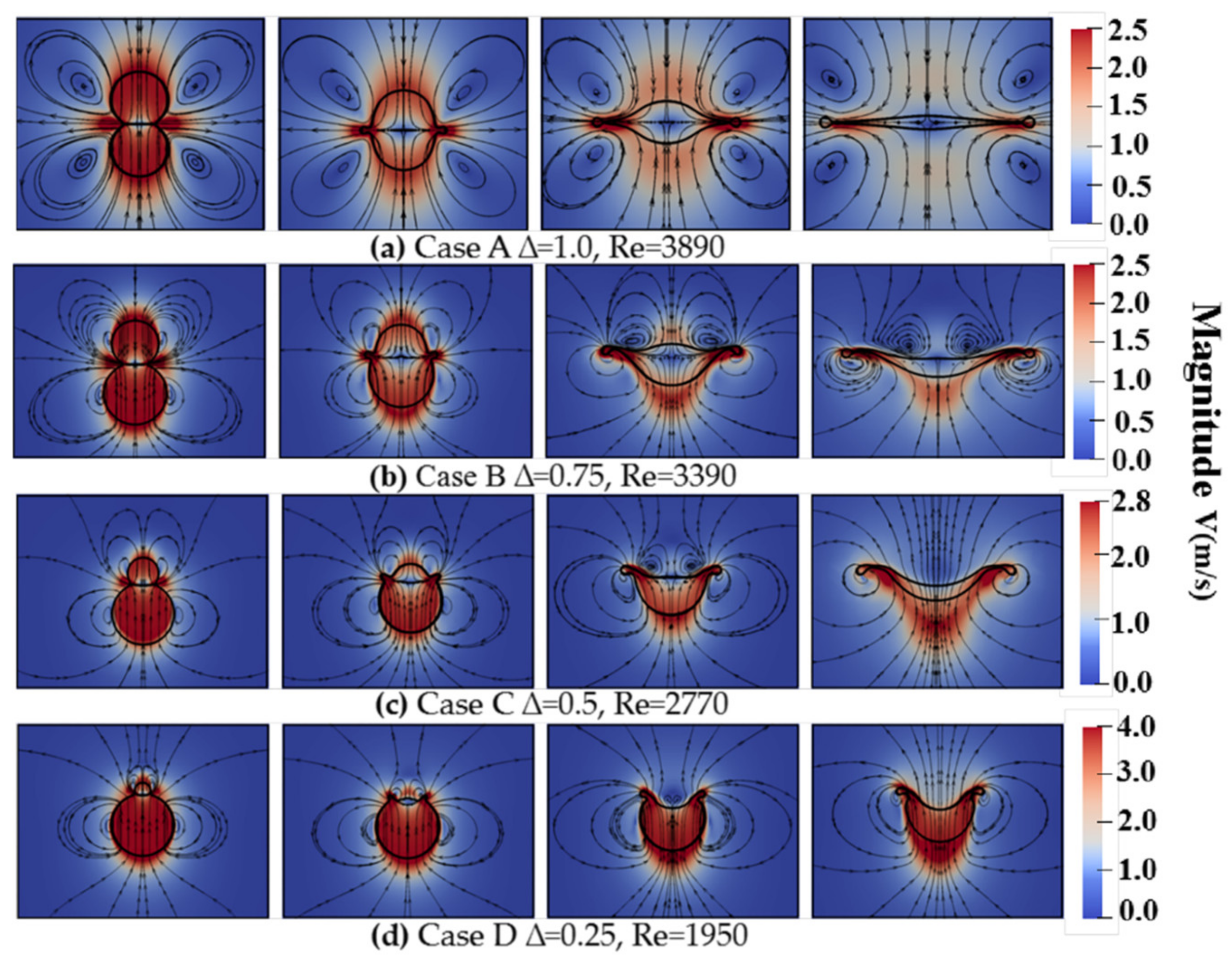

3.1. The Effects of the Size Ratio (Δ)

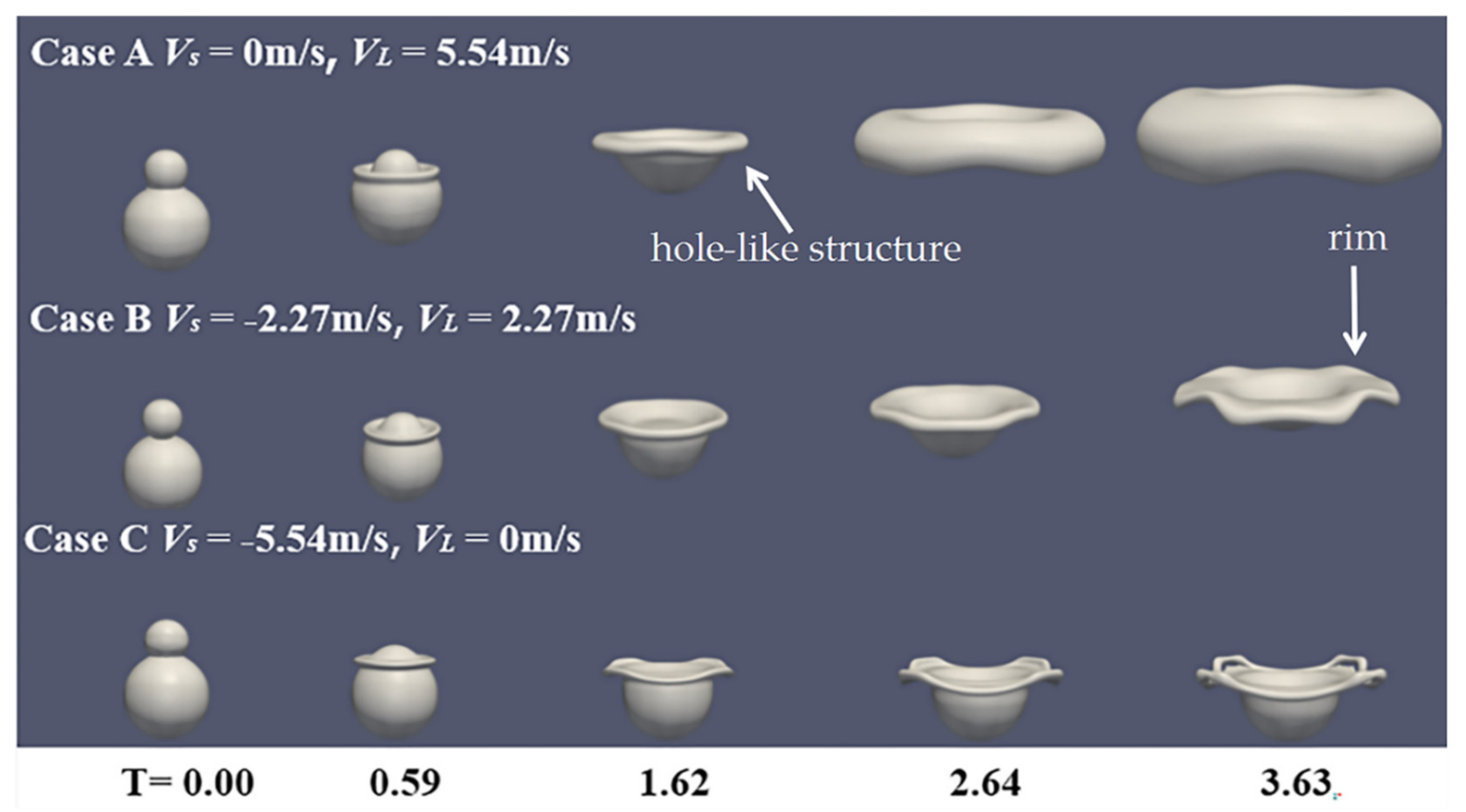

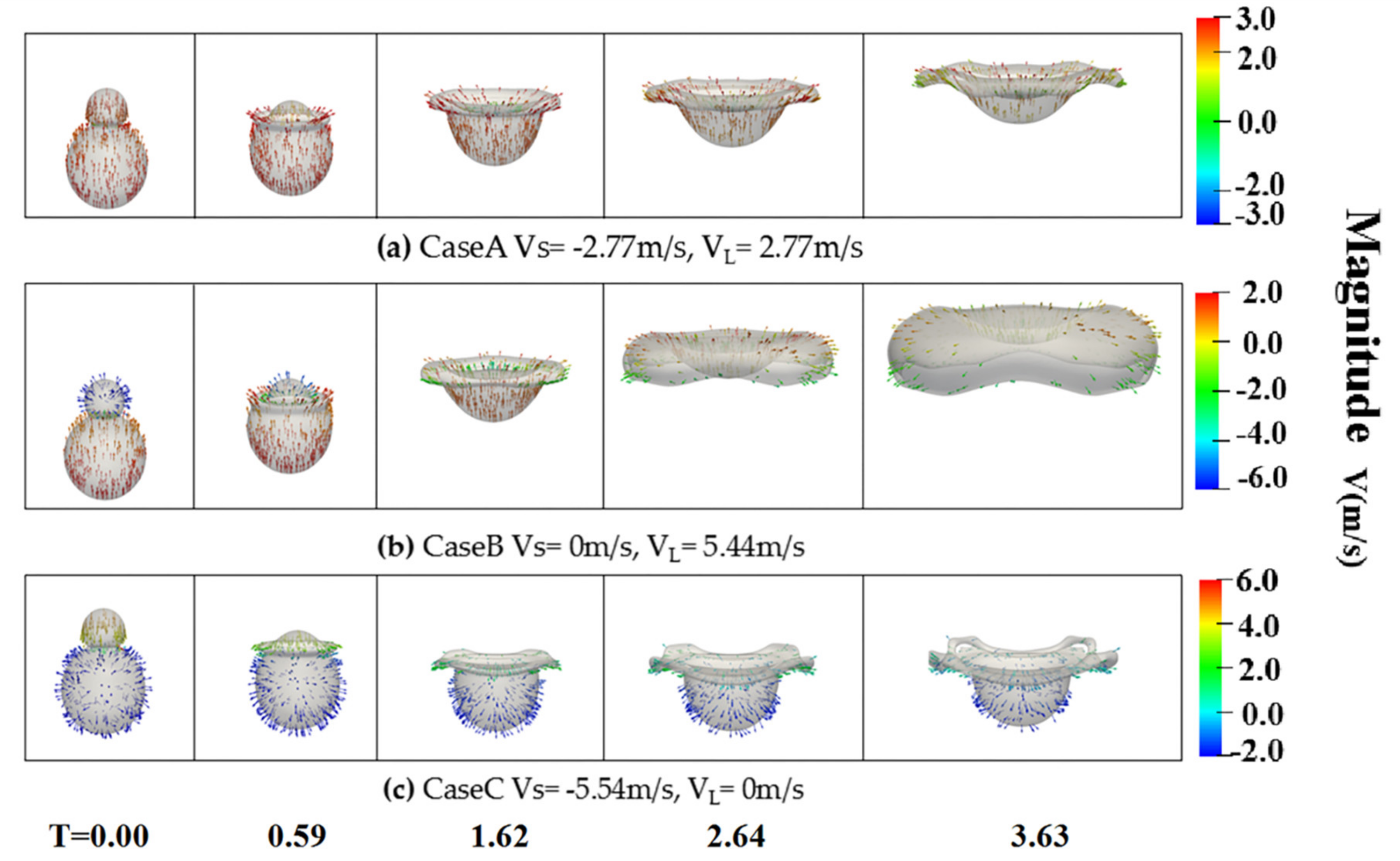

3.2. The Effects of the Initial Velocity

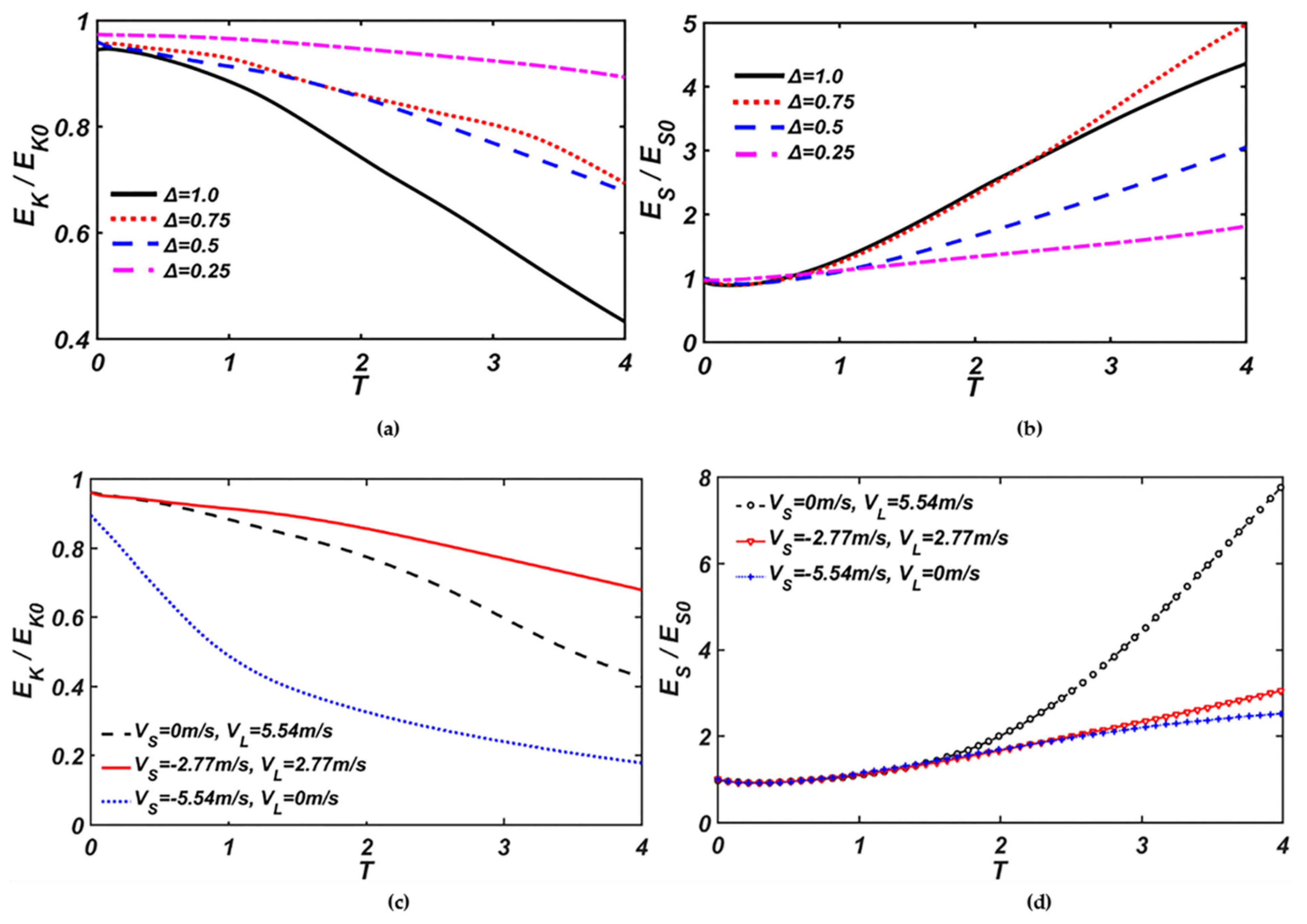

3.3. Evolution of Dimensionless Energy

4. Conclusions

- For binary unequal-sized micro-nano droplet collisions, the maximum axial deformation of the complex droplet increases when the difference of the diameter between two droplets becomes smaller, and the complex droplet reaches its maximum value of radial deformation when ∆ = 1.

- The spreading effect of the collision complex becomes more clear as the size-ratio increases and conversely facilitates the mixing effect of the collision complex. As for the atomization combustion, the complex droplets contact the gaseous medium sufficiently when the collision droplets are equal-sized, which could promote the efficiency of combustion.

- When two droplets keep the constant relative velocity, the motion tendency of the droplets after the collision is mainly dominated by the large droplet. As for a steam separator, the velocity direction of complex droplets is maintained by increasing the velocity of large droplets due to the large momentum of large droplets. The complex droplets are hardly affected by the steam flow and much easier to remove by the wave-type vanes as a result.

- The mixing effect can be improved by suppressing the initial velocity of the larger droplet. Moreover, it is difficult to separate a droplet from another after the collision since the small droplets tend to penetrate into the large one.

Author Contributions

Funding

Conflicts of Interest

References

- Xiong, H.; Zhang, C.; Zhang, K.; Shao, X. Effects of Atomization Injection on Nanoparticle Processing in Suspension Plasma Spray. Nanomaterials 2016, 6, 94. [Google Scholar] [CrossRef]

- Finotello, G. Droplet Collision Dynamics in a Spray Dryer: Experiments and Simulations. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, February 2019. [Google Scholar]

- Solomon, Y.; DeFini, S.J.; Pourpoint, L.; Anderson, W.E. Gelled monomethyl hydrazine hypergolic droplet investigation. J. Propul. Power 2013, 29, 79–86. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, P.; Yuan, Y.; Zhang, T. Hypergolic ignition by head-on collision of N,N,N’,N’−tetramethylethylenediamine and white fuming nitric acid droplets. Combust. Flame 2016, 173, 276–287. [Google Scholar] [CrossRef]

- Sui, G.; Wang, J.; Lee, C.C.; Lu, W.; Lee, S.P.; Leyton, J.V.; Wu, A.M.; Tseng, H.R. Solution-phase surface, modification in intact poly microfluidic channels. Anal. Chem. 2006, 78, 5543–5551. [Google Scholar] [CrossRef] [PubMed]

- Andersson, H.; Berg, A. Microtechnologies and nanotechnologies for single-cell analysis. Curr. Opin. Biotech. 2004, 15, 44–49. [Google Scholar] [CrossRef]

- Bi, Y.N.; Zhang, H.J. Application of Microfluidic-Chip in Biomedicine. Chin. J. Biotechnol. 2006, 22, 167–171. [Google Scholar]

- Perini, F.; Reitz, R.D. Improved atomization, collision and sub-grid scale momentum coupling models for transient vaporizing engine sprays. Int. J. Multiphas. Flow 2016, 79, 107–123. [Google Scholar] [CrossRef]

- Di, Z.; Qi, L.; Wei, H.; Kan, W. Numerical investigation of Binary Droplet Collision in Steam Separator. J. Nucl. Power Engr. 2015, 36, 18–22. [Google Scholar]

- Alamoodi, N.; Alazzam, A. Droplet Coalescence by Selective Wettability Enhancement in Microfluidic Devices. Nanomaterials 2020, 10, 737. [Google Scholar] [CrossRef]

- Lian, Z.; Xu, J.; Ren, W.; Wang, Z.; Yu, H. Bouncing Dynamics of Impact Droplets on the Biomimetic Plane and Convex Superhydrophobic Surfaces with Dual-Level and Three-Level Structures. Nanomaterials 2019, 9, 1524. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, P.; Law, C.K. Bouncing, coalescence, and separation in head-on collision of unequal-sized droplets. Phys. Fluids 2012, 24, 022101. [Google Scholar] [CrossRef]

- Bardia, R.; Liang, Z.; Keblinski, P.; Trujillo, M.F. Continuum and molecular-dynamics simulation of nanodroplet collisions. Phys. Rev. 2016, 93, 053104. [Google Scholar] [CrossRef] [PubMed]

- Kim, S. Collision of Polymer Nano Droplets: Molecular Dynamics Study. Phys. Procedia 2012, 34, 66–69. [Google Scholar] [CrossRef]

- Nikolopoulos, N.; Strotos, G.; Nikas, K.S.; Bergeles, G. The effect of Weber number on the central binary collision outcome between unequal-sized droplets. Int. J. Heat Mass Transf. 2012, 55, 2137–2150. [Google Scholar] [CrossRef]

- Kuan, C.K.; Pan, K.L.; Shyy, W. Study on high-Weber-number droplet collision by a parallel, adaptive interface-tracking method. J. Fluid Mech. 2014, 759, 104–133. [Google Scholar] [CrossRef]

- Nikolopoulos, N.; Bergeles, G. The effect of gas and liquid properties and droplet size ratio on the central collision between two unequal-size droplets in the reflexive regime. Int. J. Heat Mass Transf. 2011, 54, 678–691. [Google Scholar] [CrossRef]

- Kwakkel, M.; Breugem, W.P.; Boersma, B.J. Extension of a CLSVOF method for droplet-laden flows with a coalescence/breakup mode. J. Comput. Phys. 2013, 253, 166–188. [Google Scholar] [CrossRef]

- Dianat, M.; Skarysz, M.; Garmory. A. A Coupled Level Set and Volume of Fluid method for automotive exterior water management applications. Int. J. Multiph. Flow. 2017, 91, 19–38. [Google Scholar] [CrossRef]

- Chen, B.; Wang, B.; Mao, F.; Tian, R.; Lu, C. Analysis of liquid droplet impacting on liquid film by CLSVOF. Ann. Nucl. Energy 2020, 143, 107468. [Google Scholar] [CrossRef]

- Pan, K.L.; Chou, P.C.; Tseng, Y.J. Binary droplet collision at high Weber number. J. Physical Review E 2009, 80, 036301. [Google Scholar] [CrossRef]

- Weller, H.G. The Development of a New Flame Area Combustion Model Using Conditional Averaging; Thermo-Fluids Section Report TF 9307; Imperial College of Science Technology and Medicine: London, UK, 1993. [Google Scholar]

- Qian, L.; Cong, H.; Zhu, C. A Numerical Investigation on the Collision Behavior of Polymer Droplets. Polymers 2020, 12, 263. [Google Scholar] [CrossRef] [PubMed]

- Culick, F.E.C. Comments on a ruptured soap film. J. Appl. Phys. 1960, 31, 1128–1129. [Google Scholar] [CrossRef]

- Taylor, G.I. The instability of liquid surfaces when accelerated in a direction perpendicular to their planes. Proc. R. Soc. Lond. A. 1950, 201, 192–196. [Google Scholar]

- Taylor, G.I. The dynamics of thin sheets of fluid. III disintegration of fluid sheets. Proc. R. Soc. Lond. A. 1959, 253, 313–321. [Google Scholar]

- Sun, K.; Zhang, P.; Jia, M.; Wang, T. Collision-induced jet-like mixing for droplets of unequal-sizes. Int. J. Heat Mass Transfer. 2018, 120, 218–227. [Google Scholar] [CrossRef]

- Yoshino, M.; Sawadac, J.; Suzuki, K. Numerical simulation of head-on collision dynamics of binary droplets with various diameter ratios by the two-phase lattice kinetic scheme. Comput. Fluids 2018, 168, 304–317. [Google Scholar] [CrossRef]

- Saroka, M.D.; Ashgriz, N.; Movassat, M. Numerical Investigation of Head-on Binary Drop Collision in a Dynamically Inert Environment. J. Appl. Fluid. Mech. 2012, 5, 23–37. [Google Scholar]

- Mohammad, P.F.; Ehsan, R. Coalescence Collision of Two Droplets: Bubble Entrapment and the Effects of Important Parameters. In Proceedings of the 14th Annual (International) Mechanical Engineering Conference, Isfahan, Iran, 1 May 2006. [Google Scholar]

| Cases | We | Re | VS | VL | Vr = VS − VL | ∆ = DS/DL |

|---|---|---|---|---|---|---|

| A | 210 | 3390 | −2.26 | 2.26 | 4.52 | 0.75 |

| B | 210 | 2770 | −2.27 | 2.27 | 5.54 | 0.5 |

| C | 210 | 1950 | −3.9 | 3.9 | 7.8 | 0.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, L.; Liu, J.; Cong, H.; Zhou, F.; Bao, F. A Numerical Investigation on the Collision Behavior of Unequal-Sized Micro-Nano Droplets. Nanomaterials 2020, 10, 1746. https://doi.org/10.3390/nano10091746

Qian L, Liu J, Cong H, Zhou F, Bao F. A Numerical Investigation on the Collision Behavior of Unequal-Sized Micro-Nano Droplets. Nanomaterials. 2020; 10(9):1746. https://doi.org/10.3390/nano10091746

Chicago/Turabian StyleQian, Lijuan, Jingqi Liu, Hongchuan Cong, Fang Zhou, and Fubing Bao. 2020. "A Numerical Investigation on the Collision Behavior of Unequal-Sized Micro-Nano Droplets" Nanomaterials 10, no. 9: 1746. https://doi.org/10.3390/nano10091746

APA StyleQian, L., Liu, J., Cong, H., Zhou, F., & Bao, F. (2020). A Numerical Investigation on the Collision Behavior of Unequal-Sized Micro-Nano Droplets. Nanomaterials, 10(9), 1746. https://doi.org/10.3390/nano10091746