Experimental Research and Development on the Natural Convection of Suspensions of Nanoparticles—A Comprehensive Review

Abstract

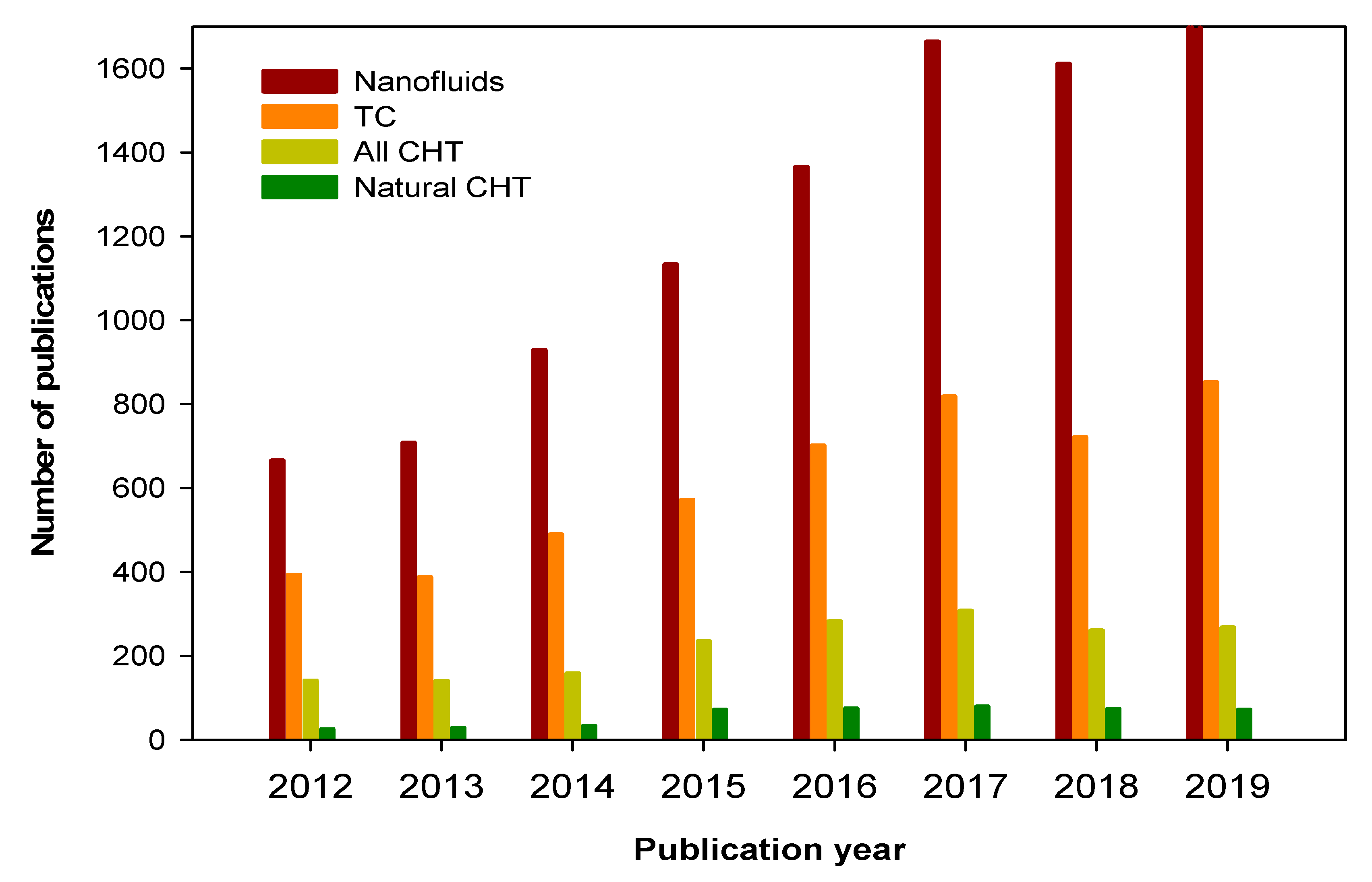

:1. Introduction

2. Formulation and Stability of Mono-Particle and Hybrid Nanofluids

2.1. Nanofluids Formulation

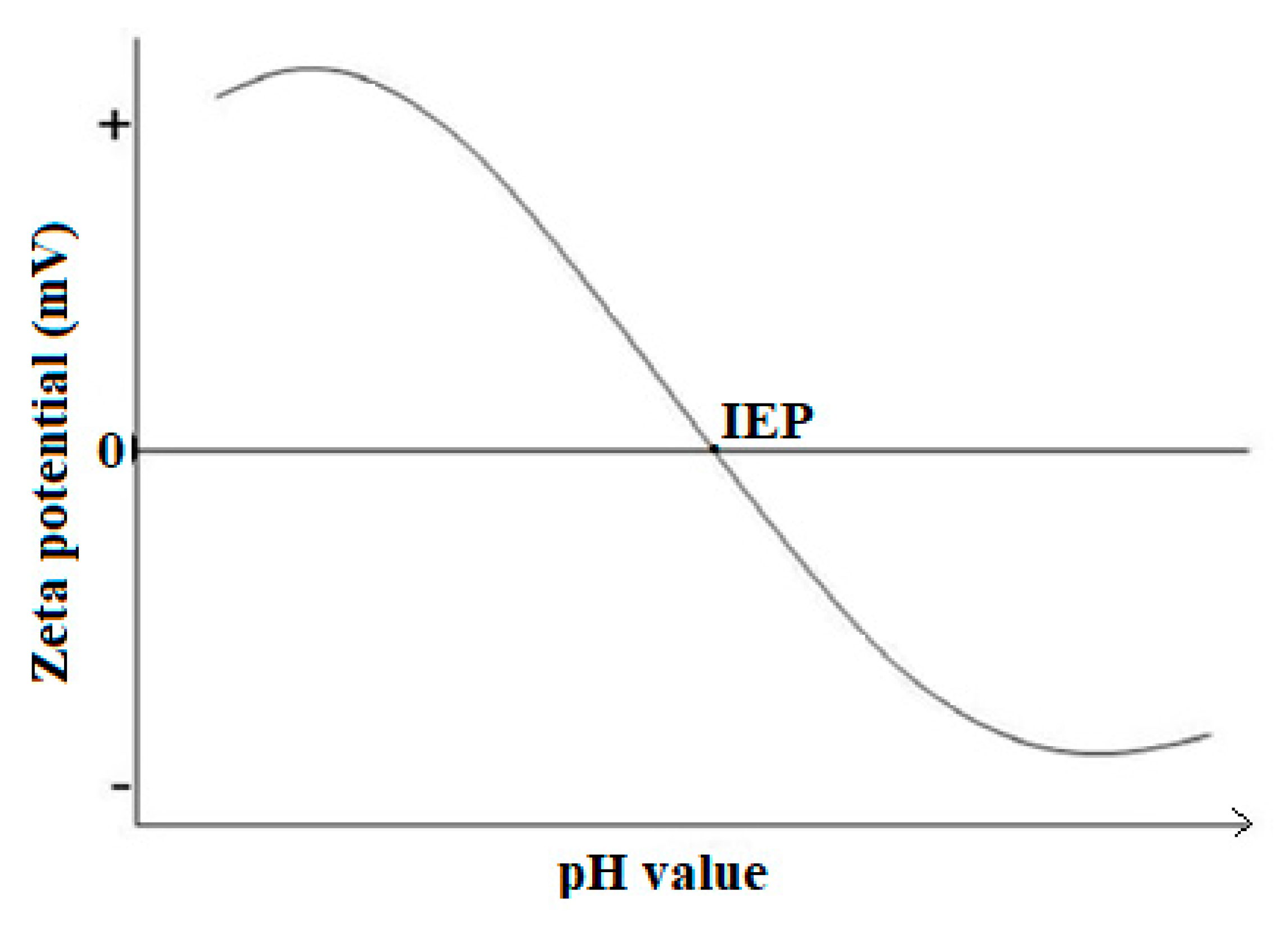

2.2. Stability of Nanofluids

3. Thermophysical Properties of Nanofluids and Hybrid-Nanofluids

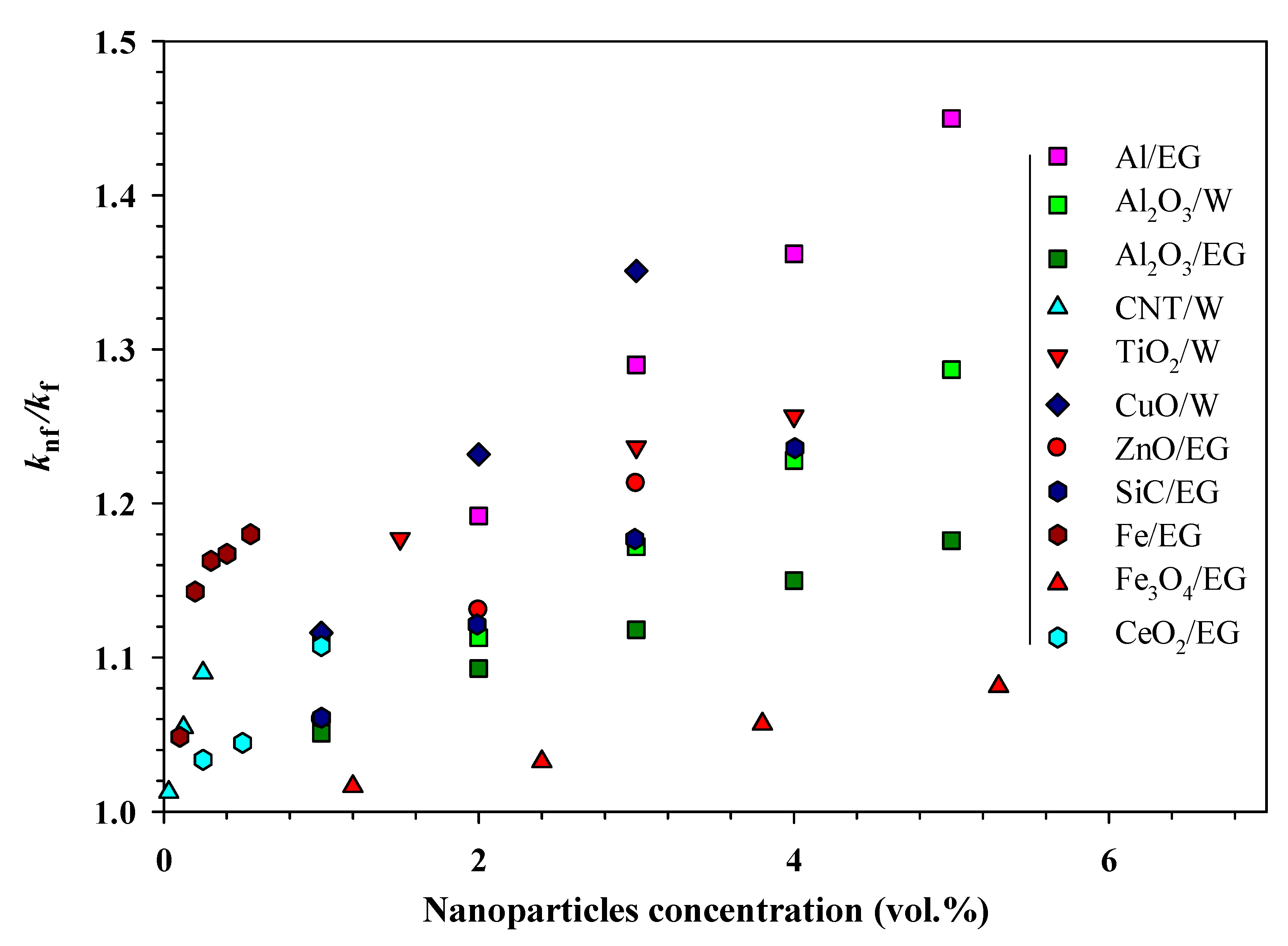

3.1. Thermal Conductivity

3.2. Viscosity

3.3. Other Properties

4. Convective Heat Transfer Performance of Nanofluids

4.1. Convection in Square Cavities

4.2. Convection in Rectangular Cavities

4.3. Convection in Circular Cavities

4.4. Convection in Other Cavities

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Asadi, A.; Alarifi, I.M.; Ali, V.; Nguyen, H.M. An Experimental Investigation on the Effects of Ultrasonication Time on Stability and Thermal Conductivity of MWCNT-Water Nanofluid: Finding the Optimum Ultrasonication Time. Ultrason. Sonochem. 2019, 58, 104639. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Shahsavar, A.; Al-Rashed, A.A.A.A.; Afrand, M. The Impact of Sonication and Stirring Durations on the Thermal Conductivity of Alumina-Liquid Paraffin Nanofluid: An Experimental Assessment. Powder Technol. 2020, 360, 1134–1142. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Heris, S.Z.; Wongwises, S. Natural Convection of Silica Nanofluids in Square and Triangular Enclosures: Theoretical and Experimental Study. Int. J. Heat Mass Transf. 2016, 99, 792–804. [Google Scholar] [CrossRef]

- Yıldız, C.; Arıcı, M.; Karabay, H. Comparison of a Theoretical and Experimental Thermal Conductivity Model on the Heat Transfer Performance of Al2O3-SiO2/Water Hybrid-Nanofluid. Int. J. Heat Mass Transf. 2019, 140, 598–605. [Google Scholar] [CrossRef]

- Ali, M.; Zeitoun, O.; Almotairi, S. Natural Convection Heat Transfer inside Vertical Circular Enclosure Filled with Water-Based Al2O3 nanofluids. Int. J. Therm. Sci. 2013, 63, 115–124. [Google Scholar] [CrossRef]

- Putra, N.; Roetzel, W.; Das, S.K. Natural Convection of Nano-Fluids. Heat Mass Transf. 2003, 39, 775–784. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Natural Convective Heat Transfer of Suspensions of Titanium Dioxide Nanoparticles (Nanofluids). IEEE Trans. Nanotechnol. 2006, 5, 220–227. [Google Scholar]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Investigations of Thermal Conductivity and Viscosity of Nanofluids. Int. J. Therm. Sci. 2008, 47, 560–568. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Leong, K.C.; Yang, C. Thermophysical and Electrokinetic Properties of Nanofluids—A Critical Review. Appl. Therm. Eng. 2008, 28, 2109–2125. [Google Scholar] [CrossRef]

- Adio, S.A.; Mehrabi, M.; Sharifpur, M.; Meyer, J.P. Experimental Investigation and Model Development for Effective Viscosity of MgO-Ethylene Glycol Nanofluids by Using Dimensional Analysis, FCM-ANFIS and GA-PNN Techniques. Int. Commun. Heat Mass Transf. 2016, 72, 71–83. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.M.S.; Estell, P. A State of the Art Review on Viscosity of Nanofluids. Renew. Sustain. Energy Rev. 2017, 76, 1134–1152. [Google Scholar] [CrossRef]

- Sharifpur, M.; Tshimanga, N.; Meyer, J.P.; Manca, O. Experimental Investigation and Model Development for Thermal Conductivity of α-Al2O3-Glycerol Nanofluids. Int. Commun. Heat Mass Transf. 2017, 85, 12–22. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.M.S.; Leong, K.C.; Yang, C.; Nguyen, N.T. Convective Heat Transfer Characteristics of Aqueous TiO2 Nanofluid under Laminar Flow Conditions. Int. J. Nanosci. 2008, 7, 325–331. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.M.S.; Nieto De Castro, C.A.; Loureno, M.J.V.; Lopes, M.L.M.; Santos, F.J.V. A Review of Boiling and Convective Heat Transfer with Nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 2342–2354. [Google Scholar] [CrossRef]

- Ghodsinezhad, H.; Sharifpur, M.; Meyer, J.P. Experimental Investigation on Cavity Flow Natural Convection of Al2O3–Water Nanofluids. Int. Commun. Heat Mass Transf. 2016, 76, 316–324. [Google Scholar] [CrossRef]

- Garbadeen, I.D.; Sharifpur, M.; Slabber, J.M.; Meyer, J.P. Experimental Study on Natural Convection of MWCNT-Water Nanofluids in a Square Enclosure. Int. Commun. Heat Mass Transf. 2017, 88, 1–8. [Google Scholar] [CrossRef]

- Sharifpur, M.; Solomon, A.B.; Ottermann, T.L.; Meyer, J.P. Optimum Concentration of Nanofluids for Heat Transfer Enhancement under Cavity Flow Natural Convection with TiO2—Water. Int. Commun. Heat Mass Transf. 2018, 98, 297–303. [Google Scholar] [CrossRef]

- Lomascolo, M.; Colangelo, G.; Milanese, M.; De Risi, A. Review of Heat Transfer in Nanofluids: Conductive, Convective and Radiative Experimental Results. Renew. Sustain. Energy Rev. 2015, 43, 1182–1198. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R. High-performance Heat Sinking for VLSI. IEEE Electron Dev. Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Lee, S.; Choi, S.U.S. Application of Metallic Nanoparticle Suspensions in Advanced Cooling Systems. In American Society of Mechanical Engineers; ASME: New York, NY, USA, 1996; Volume 72, pp. 227–234. [Google Scholar]

- Hamzah, M.H.; Sidik, N.A.C.; Ken, T.L.; Mamat, R.; Najafi, G. Factors Affecting the Performance of Hybrid Nanofluids: A Comprehensive Review. Int. J. Heat Mass Transf. 2017, 115, 630–646. [Google Scholar] [CrossRef]

- Ijam, A.; Saidur, R.; Ganesan, P.; Moradi Golsheikh, A. Stability, Thermo-Physical Properties, and Electrical Conductivity of Graphene Oxide-Deionized Water/Ethylene Glycol Based Nanofluid. Int. J. Heat Mass Transf. 2015, 87, 92–103. [Google Scholar] [CrossRef]

- Nabil, M.F.; Azmi, W.H.; Hamid, K.A.; Zawawi, N.N.M.; Priyandoko, G.; Mamat, R. Thermo-Physical Properties of Hybrid Nanofluids and Hybrid Nanolubricants: A Comprehensive Review on Performance. Int. Commun. Heat Mass Transf. 2017, 83, 30–39. [Google Scholar] [CrossRef]

- Ghadimi, A.; Saidur, R.; Metselaar, H.S.C. A Review of Nanofluid Stability Properties and Characterization in Stationary Conditions. Int. J. Heat Mass Transf. 2011, 54, 4051–4068. [Google Scholar] [CrossRef]

- Babar, H.; Ali, H.M. Towards Hybrid Nanofluids: Preparation, Thermophysical Properties, Applications, and Challenges. J. Mol. Liq. 2019, 281, 598–633. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, S.; Kumar, S.; Dilbaghi, N.; Said, Z. Up to Date Review on the Synthesis and Thermophysical Properties of Hybrid Nanofluids. J. Cleaner Prod. 2018, 190, 169–192. [Google Scholar] [CrossRef]

- Kumar, D.D.; Arasu, A.V. A Comprehensive Review of Preparation, Characterization, Properties and Stability of Hybrid Nanofluids. Renew. Sustain. Energy Rev. 2018, 81, 1669–1689. [Google Scholar] [CrossRef]

- Kamalgharibi, M.; Hormozi, F.; Zamzamian, S.A.H.; Sarafraz, M.M. Experimental Studies on the Stability of CuO Nanoparticles Dispersed in Different Base Fluids: Influence of Stirring, Sonication and SurfaceActive Agents. Heat Mass Transf. 2016, 52, 55–62. [Google Scholar] [CrossRef]

- Li, F.; Li, L.; Zhong, G.; Zhai, Y.; Li, Z. Effects of Ultrasonic Time, Size of Aggregates and Temperature on the Stability and Viscosity of Cu-Ethylene Glycol (EG) Nanofluids. Int. J. Heat Mass Transf. 2019, 129, 278–286. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Elcioglu, E.B.; Amalina, M.A.; Saidur, R. Stability, Thermophysical Properties and Performance Assessment of Alumina–Water Nanofluid with Emphasis on Ultrasonication and Storage Period. Powder Technol. 2019, 345, 668–675. [Google Scholar] [CrossRef]

- Xian, H.W.; Sidik, N.A.C.; Saidur, R. Impact of Different Surfactants and Ultrasonication Time on the Stability and Thermophysical Properties of Hybrid Nanofluids. Int. Commun. Heat Mass Transf. 2020, 110, 104389. [Google Scholar] [CrossRef]

- Meyer, J.P.; Adio, S.A.; Sharifpur, M.; Nwosu, P.N. The Viscosity of Nanofluids: A Review of the Theoretical, Empirical, and Numerical Models. Heat Transf. Eng. 2016, 37, 387–421. [Google Scholar] [CrossRef]

- Said, Z. Thermophysical and Optical Properties of SWCNTs Nanofluids. Int. Commun. Heat Mass Transf. 2016, 78, 207–213. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Darshan Kothiyal, A.; Singh Bisht, M. A Review of Flow and Heat Transfer Behaviour of Nanofluids in Micro Channel Heat Sinks. Therm. Sci. Eng. Prog. 2018, 8, 477–493. [Google Scholar] [CrossRef]

- Joubert, J.C.; Sharifpur, M.; Solomon, A.B.; Meyer, J.P. Enhancement in Heat Transfer of a Ferrofluid in a Differentially Heated Square Cavity through the Use of Permanent Magnets. J. Magn. Magn. Mater. 2017, 443, 149–158. [Google Scholar] [CrossRef]

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P. Effects of Uniform Magnetic Induction on Heat Transfer Performance of Aqueous Hybrid Ferro Fluid in a Rectangular Cavity. Appl. Therm. Eng. 2020, 170, 115004. [Google Scholar] [CrossRef]

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P. Experimental Investigation into Heat Transfer Performance of Water-Based Magnetic Hybrid Nano Fluids in a Rectangular Cavity Exposed to Magnetic Excitation. Int. Commun. Heat Mass Transf. 2020, 116, 104698. [Google Scholar] [CrossRef]

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P.; Wongwises, S.; Mahian, O. Experimental Measurement of Viscosity and Electrical Conductivity of Water-Based γ-Al2O3/MWCNT Hybrid Nanofluids with Various Particle Mass Ratios. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Giwa, S.O.; Momin, M.; Nwaokocha, C.N.; Sharifpur, M.; Meyer, J.P. Influence of Nanoparticles Size, per Cent Mass Ratio, and Temperature on the Thermal Properties of Water-Based MgO–ZnO Nanofluid: An Experimental Approach. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Torki, M.; Etesami, N. Experimental Investigation of Natural Convection Heat Transfer of SiO2/Water Nanofluid inside Inclined Enclosure. J. Therm. Anal. Calorim. 2020, 139, 1565–1574. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Khattab, R.M.; Girgis, L.G.; El Daidamony, H.; Abdel Aziz, R.E. Stability and Electrical Conductivity of Water-Base Al2O3 Nanofluids for Different Applications. HBRC J. 2016, 12, 227–234. [Google Scholar] [CrossRef] [Green Version]

- Adio, S.A.; Sharifpur, M.; Meyer, J.P. Investigation into Effective Viscosity, Electrical Conductivity, and PH of γ-Al2O3-Glycerol Nanofluids in Einstein Concentration Regime. Heat Transf. Eng. 2015, 36, 1241–1251. [Google Scholar] [CrossRef] [Green Version]

- Sajid, M.U.; Ali, H.M. Thermal Conductivity of Hybrid Nanofluids: A Critical Review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Saidur, R.; Amalina, M.A.; Niza, M.E. Influence of Ultrasonication Duration on Rheological Properties of Nanofluid: An Experimental Study with Alumina-Water Nanofluid. Int. Commun. Heat Mass Transf. 2016, 76, 33–40. [Google Scholar] [CrossRef]

- Valan, A.A.; Dhinesh, K.D.; Idrish, K.A. Experimental Investigation of Thermal Conductivity and Stability of TiO2-Ag/Water Nanocomposite fluid with SDBS and SDS Surfactants. Thermochim. Acta 2019, 678, 178308. [Google Scholar]

- Arani, A.A.A.; Pourmoghadam, F. Experimental Investigation of Thermal Conductivity Behavior of MWCNTS-Al2O3/Ethylene Glycol Hybrid Nanofluid: Providing New Thermal Conductivity Correlation. Heat Mass Transf. 2019, 55, 2329–2339. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Esmaeilzadeh, F.; Wang, X.P. Effects of Temperature and Particles Volume Concentration on the Thermophysical Properties and the Rheological Behavior of CuO/MgO/TiO2 Aqueous Ternary Hybrid Nanofluid Experimental Investigation. J. Therm. Anal. Calorim. 2019, 137, 879–901. [Google Scholar] [CrossRef]

- Giwa, S.O.; Sharifpur, M.; Goodarzi, M.; Alsulami, H.; Meyer, J.P. Influence of base Fluid, Temperature, and Concentration on the Thermophysical Properties of Hybrid Nanofluids of Alumina—Ferrofluid: Experimental Data, Modeling through Enhanced ANN, ANFIS, and Curve Fitting. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Brusly Solomon, A.; van Rooyen, J.; Rencken, M.; Sharifpur, M.; Meyer, J.P. Experimental Study on the Influence of the Aspect Ratio of Square Cavity on Natural Convection Heat Transfer with Al2O3/Water Nanofluids. Int. Commun. Heat Mass Transf. 2017, 88, 254–261. [Google Scholar] [CrossRef]

- Khadangi Mahrood, M.R.; Etemad, S.G.; Bagheri, R. Free Convection Heat Transfer of Non Newtonian Nanofluids under Constant Heat Flux Condition. Int. Commun. Heat Mass Transf. 2011, 38, 1449–1454. [Google Scholar] [CrossRef]

- Amiri, A.; Kazi, S.N.; Shanbedi, M.; Mohd Zubir, M.N.; Yarmand, H.; Chew, B.T. Transformer Oil Based Multi-Walled Carbon Nanotube-Hexylamine Coolant with Optimized Electrical, Thermal and Rheological Enhancements. RSC Adv. 2015, 5, 107222–107236. [Google Scholar] [CrossRef]

- Kouloulias, K.; Sergis, A.; Hardalupas, Y. Sedimentation in Nanofluids during a Natural Convection Experiment. Int. J. Heat Mass Transf. 2016, 101, 1193–1203. [Google Scholar] [CrossRef] [Green Version]

- Beheshti, A.; Shanbedi, M.; Heris, S.Z. Heat Transfer and Rheological Properties of Transformer Oil-Oxidized MWCNT Nanofluid. J. Therm. Anal. Calorim. 2014, 118, 1451–1460. [Google Scholar] [CrossRef]

- Nnanna, A.G.A. Experimental Model of Temperature-Driven Nanofluid. J. Heat Transf. 2007, 129, 697–704. [Google Scholar] [CrossRef]

- Roszko, A.; Fornalik-Wajs, E. Extend of Magnetic Field Interference in the Natural Convection of Diamagnetic Nanofluid. Heat Mass Transf. 2017, 54, 2243–2254. [Google Scholar] [CrossRef]

- Chopkar, M.; Kumar, S.; Bhandari, D.R.; Das, P.K.; Manna, I. Development and Characterization of Al2Cu and Ag2Al Nanoparticle Dispersed Water and Ethylene Glycol Based Nanofluid. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2007, 139, 141–148. [Google Scholar] [CrossRef]

- Jana, S.; Salehi-Khojin, A.; Zhong, W.H. Enhancement of Fluid Thermal Conductivity by the Addition of Single and Hybrid Nano-Additives. Thermochim. Acta 2007, 462, 45–55. [Google Scholar] [CrossRef]

- Baby, T.T.; Ramaprabhu, S. Experimental Investigation of the Thermal Transport Properties of a Carbon Nanohybrid Dispersed Nanofluid. Nanoscale 2011, 3, 2208–2214. [Google Scholar] [CrossRef]

- Sarbolookzadeh Harandi, S.; Karimipour, A.; Afrand, M.; Akbari, M.; D’Orazio, A. An Experimental Study on Thermal Conductivity of F-MWCNTs-Fe3O4/EG Hybrid Nanofluid: Effects of Temperature and Concentration. Int. Commun. Heat Mass Transf. 2016, 76, 171–177. [Google Scholar] [CrossRef] [Green Version]

- Esfe, M.H.; Abbasian Arani, A.A.; Rezaie, M.; Yan, W.M.; Karimipour, A. Experimental Determination of Thermal Conductivity and Dynamic Viscosity of Ag-MgO/Water Hybrid Nanofluid. Int. Commun. Heat Mass Transf. 2015, 66, 189–195. [Google Scholar] [CrossRef]

- Abbasi, S.M.; Rashidi, A.; Nemati, A.; Arzani, K. The Effect of Functionalisation Method on the Stability and the Thermal Conductivity of Nanofluid Hybrids of Carbon Nanotubes/Gamma Alumina. Ceram. Int. 2013, 39, 3885–3891. [Google Scholar] [CrossRef]

- Zadkhast, M.; Toghraie, D.; Karimipour, A. Developing a New Correlation to Estimate the Thermal Conductivity of MWCNT-CuO/Water Hybrid Nanofluid via an Experimental Investigation. J. Therm. Anal. Calorim. 2017, 129, 859–867. [Google Scholar] [CrossRef]

- Wei, B.; Zou, C.; Yuan, X.; Li, X. Thermo-Physical Property Evaluation of Diathermic Oil Based Hybrid Nanofluids for Heat Transfer Applications. Int. J. Heat Mass Transf. 2017, 107, 281–287. [Google Scholar] [CrossRef]

- Akilu, S.; Baheta, A.T.; Mior, M.A.; Minea, A.A.; Sharma, K.V. Properties of Glycerol and Ethylene Glycol Mixture Based SiO2-CuO/C Hybrid Nanofluid for Enhanced Solar Energy Transport. Sol. Energy Mater. Sol. Cells 2018, 179, 118–128. [Google Scholar] [CrossRef]

- Kakavandi, A.; Akbari, M. Experimental Investigation of Thermal Conductivity of Nanofluids Containing of Hybrid Nanoparticles Suspended in Binary Base Fluids and Propose a New Correlation. Int. J. Heat Mass Transf. 2018, 124, 742–751. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Ferro, M.C.; Sousa, A.C.M. Experimental Investigation of the Thermal Transport Properties of Graphene Oxide/Co3O4 Hybrid Nanofluids. Int. Commun. Heat Mass Transf. 2017, 84, 1–10. [Google Scholar] [CrossRef]

- Qing, S.H.; Rashmi, W.; Khalid, M.; Gupta, T.C.S.M.; Nabipoor, M.; Hajibeigy, M.T. Thermal Conductivity and Electrical Properties of Hybrid SiO2-Graphene Naphthenic Mineral Oil Nanofluid as Potential Transformer Oil. Mater. Res. Express 2017, 4, 015504. [Google Scholar] [CrossRef]

- Kumar, M.S.; Vasu, V.; Gopal, A.V. Thermal Conductivity and Rheological Studies for Cu–Zn Hybrid Nanofluids with Various Basefluids. J. Taiwan Inst. Chem. Eng. 2016, 66, 321–327. [Google Scholar] [CrossRef]

- Alirezaie, A.; Saedodin, S.; Esfe, M.H.; Rostamian, S.H. Investigation of Rheological Behavior of MWCNT (COOH-Functionalized)/MgO–Engine Oil Hybrid Nanofluids and Modelling the Results with Artificial Neural Networks. J. Mol. Liq. 2017, 241, 173–181. [Google Scholar] [CrossRef]

- Esfe, M.H.; Sarlak, M.R. Experimental Investigation of Switchable Behavior of CuO-MWCNT (85%–15%)/10W-40 Hybrid Nano-Lubricants for Applications in Internal Combustion Engines. J. Mol. Liq. 2017, 242, 326–335. [Google Scholar] [CrossRef]

- Sundar, L.S.; Shusmitha, K.; Singh, M.K.; Sousa, A.C.M. Electrical Conductivity Enhancement of Nanodiamond-Nickel (ND-Ni) Nanocomposite Based Magnetic Nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 1–7. [Google Scholar] [CrossRef]

- Zawawi, N.N.M.; Azmi, W.H.; Redhwan, A.A.M.; Sharif, M.Z.; Samykano, M. Experimental Investigation on Thermo-Physical Properties of Metal Oxide Composite Nanolubricants. Int. J. Refrig. 2018, 89, 11–21. [Google Scholar] [CrossRef]

- Askari, S.; Koolivand, H.; Pourkhalil, M.; Lotfi, R.; Rashidi, A. Investigation of Fe3O4/Graphene Nanohybrid Heat Transfer Properties: Experimental Approach. Int. Commun. Heat Mass Transf. 2017, 87, 30–39. [Google Scholar] [CrossRef]

- Naddaf, A.; Zeinali Heris, S. Experimental Study on Thermal Conductivity and Electrical Conductivity of Diesel Oil-Based Nanofluids of Graphene Nanoplatelets and Carbon Nanotubes. Int. Commun. Heat Mass Transf. 2018, 95, 116–122. [Google Scholar] [CrossRef]

- Nabil, M.F.; Azmi, W.H.; Abdul Hamid, K.; Mamat, R.; Hagos, F.Y. An Experimental Study on the Thermal Conductivity and Dynamic Viscosity of TiO2-SiO2 Nanofluids in Water: Ethylene Glycol Mixture. Int. Commun. Heat Mass Transf. 2017, 86, 181–189. [Google Scholar] [CrossRef]

- Shahsavar, A.; Salimpour, M.R.; Saghafian, M.; Shafii, M.B. Effect of Magnetic Field on Thermal Conductivity and Viscosity of a Magnetic Nanofluid Loaded with Carbon Nanotubes. J. Mech. Sci. Technol. 2016, 30, 809–815. [Google Scholar] [CrossRef]

- Aparna, Z.; Michael, M.; Pabi, S.K.; Ghosh, S. Thermal Conductivity of Aqueous Al2O3/Ag Hybrid Nano Fluid at Different Temperatures and Volume Concentrations: An Experimental Investigation and Development of New Correlation Function. Powder Technol. 2019, 343, 714–722. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles. ASME Int. Mech. Eng. Congr. Expo. 1995, 66, 99–105. [Google Scholar]

- Lee, S.; Choi, S.U.-S.; Li, S.; Eastman, J.A. Measuring Thermal Conductivity of Fluids Containing Oxide Nanoparticles. J. Heat Transfer 1999, 121, 280–289. [Google Scholar] [CrossRef]

- Eastman, J.A.; Choi, S.U.S.; Li, S.; Yu, W.; Thompson, L.J. Anomalously Increased Effective Thermal Conductivities of Ethylene Glycol-Based Nanofluids Containing Copper Nanoparticles. Appl. Phys. Lett. 2001, 78, 718–720. [Google Scholar] [CrossRef]

- Masuda, H.; Ebata, A.; Teramae, K.; Hishinuma, N. Alteration of Thermal Conductivity and Viscosity of Liquid by Dispersing Ultra-Fine Particles. Netsu Bussei 1993, 7, 227–233. [Google Scholar] [CrossRef]

- Li, Q.; Xuan, Y.; Wang, J. Experimental Investigations on Transport Properties of Magnetic Fluids. Exp. Therm. Fluid Sci. 2005, 30, 109–116. [Google Scholar] [CrossRef]

- Keblinski, P.; Prasher, R.; Eapen, J. Thermal Conductance of Nanofluids: Is the Controversy Over? J. Nanopart. Res. 2008, 10, 1089–1097. [Google Scholar] [CrossRef]

- Prasher, R.; Song, D.; Wang, J.; Phelan, P. Measurements of Nanofluid Viscosity and Its Implications for Thermal Applications. Appl. Phys. Lett. 2006, 89, 1–4. [Google Scholar] [CrossRef]

- Marín, E.; Bedoya, A.; Alvarado, S.; Calderón, A.; Ivanov, R.; Gordillo-Delgado, F. An Explanation for Anomalous Thermal Conductivity Behaviour in Nanofluids as Measured Using the Hot-Wire Technique. J. Phys. D Appl. Phys. 2014, 47, 085501. [Google Scholar] [CrossRef]

- Pastoriza-Gallego, M.J.; Lugo, L.; Legido, J.L.; Pineiro, M.M. Enhancement of Thermal Conductivity and Volumetric Behavior of FexOy Nanofluids. J. Appl. Phys. 2011, 110, 1–9. [Google Scholar] [CrossRef]

- Azizian, R.; Doroodchi, E.; Moghtaderi, B. Influence of Controlled Aggregation on Thermal Conductivity of Nanofluids. J. Heat Transf. 2015, 138, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.J.; Kim, C.K.; Lee, M.K.; Rhee, C.K.; Kim, S.; Kim, C. Thermal Conductivity Enhancement of ZnO Nanofluid Using a One-Step Physical Method. Thermochim. Acta 2012, 542, 24–27. [Google Scholar] [CrossRef]

- Awua, J.T.; Ibrahim, J.S.; Kwaghger, A.; Sharifpur, M.; Meyer, J.P. Investigation into thermal Conductivity of palm kernel fibre nanofluids with mixture of ethylene glycol/water as base fluid. In Proceedings of the 12th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Costa de Sol, Spain, 11–13 July 2016; pp. 1719–1725. [Google Scholar]

- Xuan, Y.; Li, Q. Heat Transfer Enhancement of Nanofluids. Int. J. Heat Fluid Flow 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Karimi, A.; Afghahi, S.S.S.; Shariatmadar, H.; Ashjaee, M. Experimental Investigation on Thermal Conductivity of MFe2O4 (M = Fe and Co) Magnetic Nanofluids under Influence of Magnetic Field. Thermochim. Acta 2014, 598, 59–67. [Google Scholar] [CrossRef]

- Karimi, A.; Goharkhah, M.; Ashjaee, M.; Shafii, M.B. Thermal Conductivity of Fe2O3 and Fe3O4 Magnetic Nanofluids under the Influence of Magnetic Field. Int. J. Thermophys. 2015, 36, 2720–2739. [Google Scholar] [CrossRef]

- Patel, J.; Parekh, K.; Upadhyay, R.V. Maneuvering Thermal Conductivity of Magnetic Nanofluids by Tunable Magnetic Fields. J. Appl. Phys. 2015, 117, 1–8. [Google Scholar] [CrossRef]

- Abdolbaqi, M.K.; Azmi, W.H.; Mamat, R.; Sharma, K.V.; Najafi, G. Experimental Investigation of Thermal Conductivity and Electrical Conductivity of BioGlycol-Water Mixture Based Al2O3 Nanofluid. Appl. Therm. Eng. 2016, 102, 932–941. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, R.; Verma, K.; Agrawal, N.K.; Singh, R. Sensitivity of Thermal Conductivity for Al2O3 Nanofluids. Exp. Therm. Fluid Sci. 2017, 80, 19–26. [Google Scholar] [CrossRef]

- Parekh, K.; Lee, H.S. Magnetic Field Induced Enhancement in Thermal Conductivity of Magnetite Nanofluid. J. Appl. Phys. 2010, 107, 1–4. [Google Scholar] [CrossRef]

- Shima, P.D.; Philip, J. Tuning of Thermal Conductivity and Rheology of Nanofluids Using an External Stimulus. J. Phys. Chem. C 2011, 115, 20097–20104. [Google Scholar] [CrossRef]

- Nkurikiyimfura, I.; Wang, Y.; Pan, Z. Effect of Chain-like Magnetite Nanoparticle Aggregates on Thermal Conductivity of Magnetic Nanofluid in Magnetic Field. Exp. Therm. Fluid Sci. 2013, 44, 607–612. [Google Scholar] [CrossRef]

- Amani, M.; Amani, P.; Kasaeian, A.; Mahian, O.; Kasaeian, F.; Wongwises, S. Experimental Study on Viscosity of Spinel-Type Manganese Ferrite Nanofluid in Attendance of Magnetic Field. J. Magn. Magn. Mater. 2017, 428, 457–463. [Google Scholar] [CrossRef]

- Esfe, M.H.; Esfandeh, S.; Amiri, M.K.; Afrand, M. A Novel Applicable Experimental Study on the Thermal Behavior of SWCNTs (60%)-MgO (40%)/EG Hybrid Nanofluid by Focusing on the Thermal Conductivity. Powder Technol. 2019, 342, 998–1007. [Google Scholar] [CrossRef]

- Taherialekouhi, R.; Rasouli, S.; Khosravi, A. An Experimental Study on Stability and Thermal Conductivity of Water-Graphene Oxide/Aluminum Oxide Nanoparticles as a Cooling Hybrid Nanofluid. Int. J. Heat Mass Transf. 2019, 145, 118751. [Google Scholar] [CrossRef]

- Jha, N.; Ramaprabhu, S. Synthesis and Thermal Conductivity of Copper Nanoparticle Decorated Multiwalled Carbon Nanotubes Based Nanofluids. J. Phys. Chem. C 2008, 112, 9315–9319. [Google Scholar] [CrossRef]

- Hajiyan, M.; Ebadi, S.; Mahmud, S.; Biglarbegian, M. Experimental Investigation of the Effect of an External Magnetic Field on the Thermal Conductivity and Viscosity of Fe3O4–Glycerol. J. Therm. Anal. Calorim. 2019, 135, 1451–1464. [Google Scholar] [CrossRef]

- Hamid, K.A.; Azmi, W.H.; Nabil, M.F.; Mamat, R.; Sharma, K.V. Experimental Investigation of Thermal Conductivity and Dynamic Viscosity on Nanoparticle Mixture Ratios of TiO2-SiO2 Nanofluids. Int. J. Heat Mass Transf. 2018, 116, 1143–1152. [Google Scholar] [CrossRef]

- Aybar, H.Ş.; Sharifpur, M.; Azizian, M.R.; Mehrabi, M.; Meyer, J.P. A Review of Thermal Conductivity Models for Nanofluids. Heat Transf. Eng. 2014, 36, 1085–1110. [Google Scholar] [CrossRef] [Green Version]

- Murshed, S.M.S.; Sharifpur, M.; Giwa, S.; Meyer, J.P. Stability evaluation, measurements and presentations of convective heat transfer characteristics of nanofluids. In The Art of Measuring in Thermal Sciences; CRC Press: Boca Raton, FL, USA, 2020; in press. [Google Scholar]

- Machrafi, H. Universal Relation between the Density and the Viscosity of Dispersions of Nanoparticles and Stabilized Emulsions. Nanoscale 2020, 12, 15081–15101. [Google Scholar] [CrossRef]

- Lebon, G.; Machrafi, H. A Thermodynamic Model of Nanofluid Viscosity Based on a Generalized Maxwell-Type Constitutive Equation. J. Nonnewton. Fluid Mech. 2018, 253, 1–6. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and Heat Transfer Study of Dispersed Fluids with Submicron Metallic Oxide Particles. Exp. Heat Transf. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Dehghani, Y.; Abdollahi, A.; Karimipour, A. Experimental Investigation toward Obtaining a New Correlation for Viscosity of WO3 and Al2O3 Nanoparticles-Loaded Nanofluid within Aqueous and Non-Aqueous Basefluids Problem of Water Consumption and Waste Production. J. Therm. Anal. Calorim. 2019, 135, 713–728. [Google Scholar] [CrossRef]

- Goodarzi, M.; Toghraie, D.; Reiszadeh, M.; Afrand, M. Experimental Evaluation of Dynamic Viscosity of ZnO–MWCNTs/Engine Oil Hybrid Nanolubricant Based on Changes in Temperature and Concentration. J. Therm. Anal. Calorim. 2019, 136, 513–525. [Google Scholar] [CrossRef]

- Adio, S.A.; Sharifpur, M.; Meyer, J.P. Influence of Ultrasonication Energy on the Dispersion Consistency of Al2O3–Glycerol Nanofluid Based on Viscosity Data, and Model Development for the Required Ultrasonication Energy Density. J. Exp. Nanosci. 2016, 11, 630–649. [Google Scholar] [CrossRef] [Green Version]

- Kallamu, U.M.; Ibrahim, J.S.; Sharifpur, M.; Meyer, J.P. Experimental Investigation on Viscosity of Nanofluids Prepared from Banana Fibre-Nanoparticles. In Proceedings of the 12th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Costa de Sol, Spain, 11–13 July 2016; pp. 1713–1718. [Google Scholar]

- Sharifpur, M.; Solomon, A.B.; Meyer, J.P.; Ibrahim, J.S.; Immanuel, B. Thermal Conductivity and Viscosity of Mango Bark/Water Nanofluids. In Proceedings of the 13th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Portoroz, Slovenia, 17–19 July 2017. [Google Scholar]

- Minea, A.A.; Murshed, S.M.S. A review on development of ionic liquid based nanofluids and their heat transfer behaviour. Renew. Sustain. Energy Rev. 2018, 91, 584–599. [Google Scholar] [CrossRef]

- Dhahri, M.; Aouinet, H.; Sammouda, H. A New Empirical Correlating Equation for Calculating Effective Viscosity of Nanofluids. Heat Transf. Asian Res. 2019, 48, 1547–1562. [Google Scholar] [CrossRef] [Green Version]

- Siddiqui, F.R.; Tso, C.Y.; Chan, K.C.; Fu, S.C.; Chao, C.Y.H. On Trade-off for Dispersion Stability and Thermal Transport of Cu-Al2O3 Hybrid Nanofluid for Various Mixing Ratios. Int. J. Heat Mass Transf. 2019, 132, 1200–1216. [Google Scholar] [CrossRef]

- Alarifi, I.M.; Alkouh, A.B.; Ali, V.; Nguyen, H.M.; Asadi, A. On the Rheological Properties of MWCNT-TiO2/Oil Hybrid Nanofluid: An Experimental Investigation on the Effects of Shear Rate, Temperature, and Solid Concentration of Nanoparticles. Powder Technol. 2019, 355, 157–162. [Google Scholar] [CrossRef]

- Hezaveh, H.; Fazlali, A.; Noshadi, I. Synthesis, Rheological Properties and Magnetoviscos Effect of Fe2O3/Paraffin Ferrofluids. J. Taiwan Inst. Chem. Eng. 2012, 43, 159–164. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Yan, X.; Wang, X.; Feng, B. Investigation on Viscosity of Fe3O4 nanofluid under Magnetic Field. Int. Commun. Heat Mass Transf. 2016, 72, 23–28. [Google Scholar] [CrossRef]

- Malekzadeh, A.; Pouranfard, A.R.; Hatami, N.; Kazemnejad Banari, A.; Rahimi, M.R. Experimental Investigations on the Viscosity of Magnetic Nanofluids under the Influence of Temperature, Volume Fractions of Nanoparticles and External Magnetic Field. J. Appl. Fluid Mech. 2016, 9, 693–697. [Google Scholar] [CrossRef]

- Ghasemi, S.; Karimipour, A. Experimental Investigation of the Effects of Temperature and Mass Fraction on the Dynamic Viscosity of CuO-Paraffin Nanofluid. Appl. Therm. Eng. 2018, 128, 189–197. [Google Scholar] [CrossRef]

- De Oliveira, L.R.; Ribeiro, S.R.F.L.; Reis, M.H.M.; Cardoso, V.L.; Bandarra Filho, E.P. Experimental Study on the Thermal Conductivity and Viscosity of Ethylene Glycol-Based Nanofluid Containing Diamond-silver Hybrid Material. Diam. Relat. Mater. 2019, 96, 216–230. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K. Specific Heat Measurement of Three Nanofluids and Development of New Correlations. J. Heat Transf. 2009, 131, 071601. [Google Scholar] [CrossRef]

- Nabati Shoghl, S.; Jamali, J.; Keshavarz Moraveji, M. Electrical Conductivity, Viscosity, and Density of Different Nanofluids: An Experimental Study. Exp. Therm. Fluid Sci. 2016, 74, 339–346. [Google Scholar] [CrossRef]

- Sharifpur, M.; Yousefi, S.; Meyer, J.P. A New Model for Density of Nanofluids Including Nanolayer. Int. Commun. Heat Mass Transf. 2016, 78, 168–174. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.G.; Kumaresan, V.; Velraj, R. Stability, Viscosity, Thermal Conductivity, and Electrical Conductivity Enhancement of Multi-Walled Carbon Nanotube Nanofluid Using Gum Arabic. Fullerenes Nanotube. Carbon Nanostruct. 2017, 25, 230–240. [Google Scholar] [CrossRef]

- Ganeshkumar, J.; Kathirkaman, D.; Raja, K.; Kumaresan, V.; Velraj, R. Experimental Study on Density, Thermal Conductivity, Specific Heat, and Viscosity of Water-Ethylene Glycol Mixture Dispersed with Carbon Nanotubes. Therm. Sci. 2017, 21, 255–265. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.X.; Zhou, L.P.; Peng, X.F.; Du, X.Z.; Yang, Y.P. On the Specific Heat Capacity of CuO Nanofluid. Adv. Mech. Eng. 2010, 2, 172085. [Google Scholar]

- Hentschke, R. On the Specific Heat Capacity Enhancement in Nanofluids. Nanoscale Res. Lett. 2016, 11, 88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ganguly, S.; Sikdar, S.; Basu, S. Experimental Investigation of the Effective Electrical Conductivity of Aluminum Oxide Nanofluids. Powder Technol. 2009, 196, 326–330. [Google Scholar] [CrossRef]

- Adio, S.A.; Sharifpur, M.; Meyer, J.P. Factors Affecting the PH and Electrical Conductivity of MgO-Ethylene Glycol Nanofluids. Bull. Mater. Sci. 2015, 38, 1345–1357. [Google Scholar] [CrossRef]

- Zyla, G.; Fal, J. Experimental Studies on Viscosity, Thermal and Electrical Conductivity of Aluminum Nitride-Ethylene Glycol (AlN-EG) Nanofluids. Thermochim. Acta 2016, 637, 11–16. [Google Scholar] [CrossRef]

- Hernaiz, M.; Alonso, V.; Estell, P.; Wu, Z.; Sund, B.; Doretti, L.; Mancin, S.; Obanog, N. The Contact Angle of Nanofluids as Thermophysical Property. J. Colloid Interface Sci. 2019, 547, 393–406. [Google Scholar] [CrossRef] [PubMed]

- Karami, H.; Papari-Zare, S.; Shanbedi, M.; Eshghi, H.; Dashtbozorg, A.; Akbari, A.; Mohammadian, E.; Heidari, M.; Sahin, A.Z.; Teng, C.B. The Thermophysical Properties and the Stability of Nanofluids Containing Carboxyl-Functionalized Graphene Nano-Platelets and Multi-Walled Carbon Nanotubes. Int. Commun. Heat Mass Transf. 2019, 108, 104302. [Google Scholar] [CrossRef]

- Ilyas, S.U.; Pendyala, R.; Narahari, M. Experimental Investigation of Natural Convection Heat Transfer Characteristics in MWCNT-Thermal Oil Nanofluid. J. Therm. Anal. Calorim. 2019, 135, 1197–1209. [Google Scholar] [CrossRef]

- Rao, S.S.; Srivastava, A. Interferometric Study of Natural Convection in a Differentially-Heated Cavity with Al2O3–Water Based Dilute Nanofluids. Int. J. Heat Mass Transf. 2016, 92, 1128–1142. [Google Scholar] [CrossRef]

- Ho, C.J.; Liu, W.K.; Chang, Y.S.; Lin, C.C. Natural Convection Heat Transfer of Alumina-Water Nanofluid in Vertical Square Enclosures: An Experimental Study. Int. J. Therm. Sci. 2010, 49, 1345–1353. [Google Scholar] [CrossRef]

- Choudhary, R.; Subudhi, S. Aspect Ratio Dependence of Turbulent Natural Convection in Al2O3/Water Nanofluids. Appl. Therm. Eng. 2016, 108, 1095–1104. [Google Scholar] [CrossRef]

- Qi, C.; Wang, G.; Ma, Y.; Guo, L. Experimental Research on Stability and Natural Convection of TiO2-Water Nanofluid in Enclosures with Different Rotation Angles. Nanoscale Res. Lett. 2017, 12, 1–14. [Google Scholar] [CrossRef]

- Hu, Y.; He, Y.; Wang, S.; Wang, Q.; Schlaberg, H.I. Experimental and Numerical Investigation on Natural Convection Heat Transfer of TiO2-Water Nanofluids in a Square Enclosure. J. Heat Transf. 2014, 136, 022502. [Google Scholar] [CrossRef]

- Joshi, P.S.; Pattamatta, A. Buoyancy Induced Convective Heat Transfer in Particle, Tubular and Flake Type of Nanoparticle Suspensions. Int. J. Therm. Sci. 2017, 122, 1–11. [Google Scholar] [CrossRef]

- Dixit, D.D.; Pattamatta, A. Natural Convection Heat Transfer in a Cavity Filled with Electrically Conducting Nano- Particle Suspension in the Presence of Magnetic Field. Phys. Fluids 2019, 31, 023302. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; Hu, Y.; Jiang, B.; Huang, Y. Thermophysical and Natural Convection Characteristics of Ethylene Glycol and Water Mixture Based ZnO Nanofluids. Int. J. Heat Mass Transf. 2015, 91, 385–389. [Google Scholar] [CrossRef]

- Ho, C.J.; Chen, D.S.; Yan, W.M.; Mahian, O. Buoyancy-Driven Flow of Nanofluids in a Cavity Considering the Ludwig-Soret Effect and Sedimentation: Numerical Study and Experimental Validation. Int. J. Heat Mass Transf. 2014, 77, 684–694. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Niu, X.-D.; Zhang, X.-R.; Yoshikawa, K. Experimental and Numerical Investigation of Natural Convection of Magnetic Fluids in a Cubic Cavity. J. Magn. Magn. Mater. 2009, 321, 3665–3670. [Google Scholar] [CrossRef]

- Ilyas, S.U.; Pendyala, R.; Narahari, M. An Experimental Study on the Natural Convection Heat Transfer in Rectangular Enclosure Using Functionalized Alumina- Thermal Oil-Based Nanofluids. Appl. Therm. Eng. 2017, 127, 765–775. [Google Scholar] [CrossRef]

- Solomon, A.B.; Sharifpur, M.; Meyer, J.P.; Ibrahim, J.S.; Immanuel, B. Convection heat transfer with water based mango bark nanofluids. In Proceedings of the 13th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Portoroz, Slovenia, 17–19 July 2017. [Google Scholar]

- Solomon, A.B.; Sharifpur, M.; Ottermann, T.; Grobler, C.; Joubert, M.; Meyer, J.P. Natural Convection Enhancement in a Porous Cavity with Al2O3-Ethylene Glycol/Water Nanofluids. Int. J. Heat Mass Transf. 2017, 108, 1324–1334. [Google Scholar] [CrossRef] [Green Version]

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P. Heat Transfer Enhancement of Dilute Al2O3-MWCNT Water Based Hybrid Nanofluids in a Square Cavity. In Proceedings of the International Heat Transfer Conference, Begell House, Beijing, China; 2018; pp. 5365–5372. [Google Scholar]

- Cadena-de La Pe, N.L.; Rivera-Solorio, C.I.; Payn-Rodrguez, L.A.; Garca-Cullar, A.J.; Lpez-Salinas, J.L. Experimental Analysis of Natural Convection in Vertical Annuli Filled with AlN and TiO2/Mineral Oil-Based Nanofluids. Int. J. Therm. Sci. 2017, 111, 138–145. [Google Scholar] [CrossRef]

- Ali, M.; Zeitoun, O.; Almotairi, S.; Al-Ansary, H. The Effect of Alumina–Water Nanofluid on Natural Convection Heat Transfer Inside Vertical Circular Enclosures Heated from Above. Heat Transf. Eng. 2013, 34, 1289–1299. [Google Scholar] [CrossRef]

- Moradi, H.; Bazooyar, B.; Moheb, A.; Etemad, S.G. Optimization of Natural Convection Heat Transfer of Newtonian Nanofluids in a Cylindrical Enclosure. Chinese J. Chem. Eng. 2015, 23, 1266–1274. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Zhang, X.R.; Niu, X.D.; Yoshikawa, K. Thermomagnetic Natural Convection of Thermo-Sensitive Magnetic Fluids in Cubic Cavity with Heat Generating Object Inside. J. Magn. Magn. Mater. 2010, 322, 698–704. [Google Scholar] [CrossRef]

- Ni, R.; Zhou, S.Q.; Xia, K.Q. An Experimental Investigation of Turbulent Thermal Convection in Water-Based Alumina Nanofluid. Phys. Fluids 2011, 23, 022005. [Google Scholar]

- Babu, S.R.; Rao, G.S. Buoyancy-Induced Natural Convective Heat Transfer along a Vertical Cylinder Using Water-Al2O3 Nanofluids. J. Therm. Sci. Eng. Appl. 2018, 10, 1–7. [Google Scholar]

- Giwa, S.O.; Sharifpur, M.; Meyer, J.P. Experimental Study of Thermo-Convection Performance of Hybrid Nanofluids of Al2O3-MWCNT/Water in a Differentially Heated Square Cavity. Int. J. Heat Mass Transf. 2020, 148, 119072. [Google Scholar] [CrossRef]

- Haddad, O.; Baïri, A.; Alilat, N.; Bauzin, J.G.; Laraqi, N. Free Convection in ZnO-Water Nanofluid-Filled and Tilted Hemispherical Enclosures Containing a Cubic Electronic Device. Int. Commun. Heat Mass Transf. 2017, 87, 204–211. [Google Scholar] [CrossRef]

- Dixit, D.D.; Pattamatta, A. Effect of Uniform External Magnetic-Field on Natural Heat Transfer in a Cubical Cavity Filled with Magnetic Nano-Dispersion. Int. J. Heat Mass Transf. 2020, 146, 118828. [Google Scholar] [CrossRef]

- Umar, E.; Kamajaya, K.; Tandian, N.P. Experimental Study of Natural Convective Heat Transfer of Water-ZrO2 Nanofluids in Vertical Sub Channel. Contemp. Eng. Sci. 2015, 8, 1593–1605. [Google Scholar] [CrossRef]

| Average Zeta Potential (±mV) | Stability State |

|---|---|

| <25 | Flocculation or coagulation (within short time) |

| 25 to 40 | Physically stable |

| 40 to 60 | Good stability |

| >60 | Very good to excellent stability |

| Researchers | HNP (Ratio) | Base Fluid | Properties | Temp. (C) | φ (vol.%) | Enhancement (%) | Surfactant |

|---|---|---|---|---|---|---|---|

| Chopkar et al. [56] | Al2Cu, Ag2Al (Al = 70%; Cu & Ag = 30%) | EG & DIW | κ | Room temp. | 0.2–1.5 | 50–150% | Oleic acid |

| Jana et al. [57] | Au, CNT, Cu, CNT-Cu & CNT-Au (1.5–2.5) | DIW | κ | Room temp | 0.3 & 0.5 (CNT) 1.4 (Au) & 0.05–0.3 (Cu) | 74 (Cu) | Laurate salt |

| Baby and Ramaprabhu [58] | f-MWCNT-f-HEG (50:50 wt.%) | DIW & EG | κ | 25–50 | 0.5–5.0 | 20 (DIW); 3 (EG) | - |

| Harandi et al. [59] | f-MWCNT-Fe3O4 (50:50) | EG | κ | 25–50 | 0.1–2.3 | 30 | - |

| Esfe et al. [60] | Ag-MgO (50:50) | DW | κ & μ | Room temp | 0–2 | - | CTAB |

| Mousavi et al. [47] | CuO-MgO-TiO2 (5 diff. ratios) | DW | κ, μ, ρ, Cp & surface tension | 15–60 | 0.1–0.5 | - | SDS |

| Abbasi et al. [61] | MWCNT-Al2O3 (1:1) | DIW | κ | Room temp | 0.1 | 20.68 | GA |

| Zadkhast et al. [62] | MWCNT-CuO (50:50) | DIW | κ | 25–50 | 0.05–0.6 | 30.38 | - |

| Wei et al. [63] | SiC-TiO2 (50:50 wt.%) | Diathermic oil | κ & μ | 17–43 | 0.1–1.0 | 8.39 (κ) | Oleic acid |

| Akilu et al. [64] | SiO2-CuO/C (80:20 wt.%) | GL-EG (60:40 wt.%) | Cp, κ, & μ | 30–80 | 0.5–2.0 | 1.15X (μ); 21.1 (cp); 26.9 (κ) | - |

| Kakavandi and Akbari [65] | MWCNT-SiC (50:50 wt.%) | W-EG (50:50 vol.%) | κ | 25–50 | 0.05–0.75 | 33 | - |

| Sundar et al. [66] | GO-Co3O4 (67:33 wt.%) | EG & DW | κ & μ | 20–60 | 0.05–0.2 | EG (μ = 1.42-times & κ = 11.85) & DW (μ = 1.70-times & κ = 19.14) | - |

| Qing et al. [67] | SiO2-G | Naphthenic mineral oil | κ, μ, & σ | 20–100 | 0.01–0.08 wt.% | κ (80 (HNF) & 29 (NF)); μ (29.7 (HNF) & 12.87 (NF); σ (557–97) | - |

| Kumar et al. [68] | Cu-Zn (50:50) | EO, VO, paraffin | μ, κ & FP | 30 | 0.1–0.5 | Cu-Zn/VO (best) | SDS |

| Alirezaie et al. [69] | MWCNT-MgO (10:90) | EO | μ | 25–50 | 0.0625–1.0 | - | GA |

| Esfe and Sarlak [70] | CuO-MWCNT (85:15) | EO | μ | 5–55 | 0.05–1.0 | 43.52 | - |

| Sundar et al. [71] | ND-Ni (84:16 wt.%) | DW & EG | σ | 24–65 | 0.02–0.1 | 199.52–200.23 (EG); 1339.81–853.13 (κ) | - |

| Zawawi et al. [72] | Al2O3-SiO2; Al2O3-TiO2; TiO2-SiO2 | PAG | μ | 30–80 | 0.02–1.0 | μ = 20.50 (Al2O3-TiO2/PAG); κ = 2.41 (Al2O3-SiO2) at 30 °C. | - |

| Askari et al. [73] | Fe3O4-G | DIW | μ, κ, & ρ | 20–40 | 0.1–1.0 | 14–32 | - |

| Naddaf et al. [74] | G-MWCNT (1:1) | Diesel oil | σ & κ | 5–100 | 0.05–0.5 wt.% | - | Oleic acid and HA |

| Nabil et al. [75] | TiO2-SiO2 (50:50 vol.%) | DW-EG (60:40 vol.%) | κ & μ | 30–80 | 0.5–3.0 | 22.8 (κ); 62.6 (μ) | - |

| Shahsavar et al. [76] | Fe3O4-CNT (1:2; 1:1; 2:1) | W | κ & μ | 25–35 | - | 45.41 (no magnet); 152.95 (magnet) | TMAH (Fe3O4) & GA (CNT) |

| Aparna et al. [77] | Al2O3-Ag (50:50; 30:70; 70:30) | DW | κ | 25–52 | 0.005–0.1 | 23.82 | PVP |

| Researchers | NF (φ) | Cavity Dimension | Rayleigh Number (Ra) | Measured Thermal Properties | Preparation Method (Stability Test) | Remark |

|---|---|---|---|---|---|---|

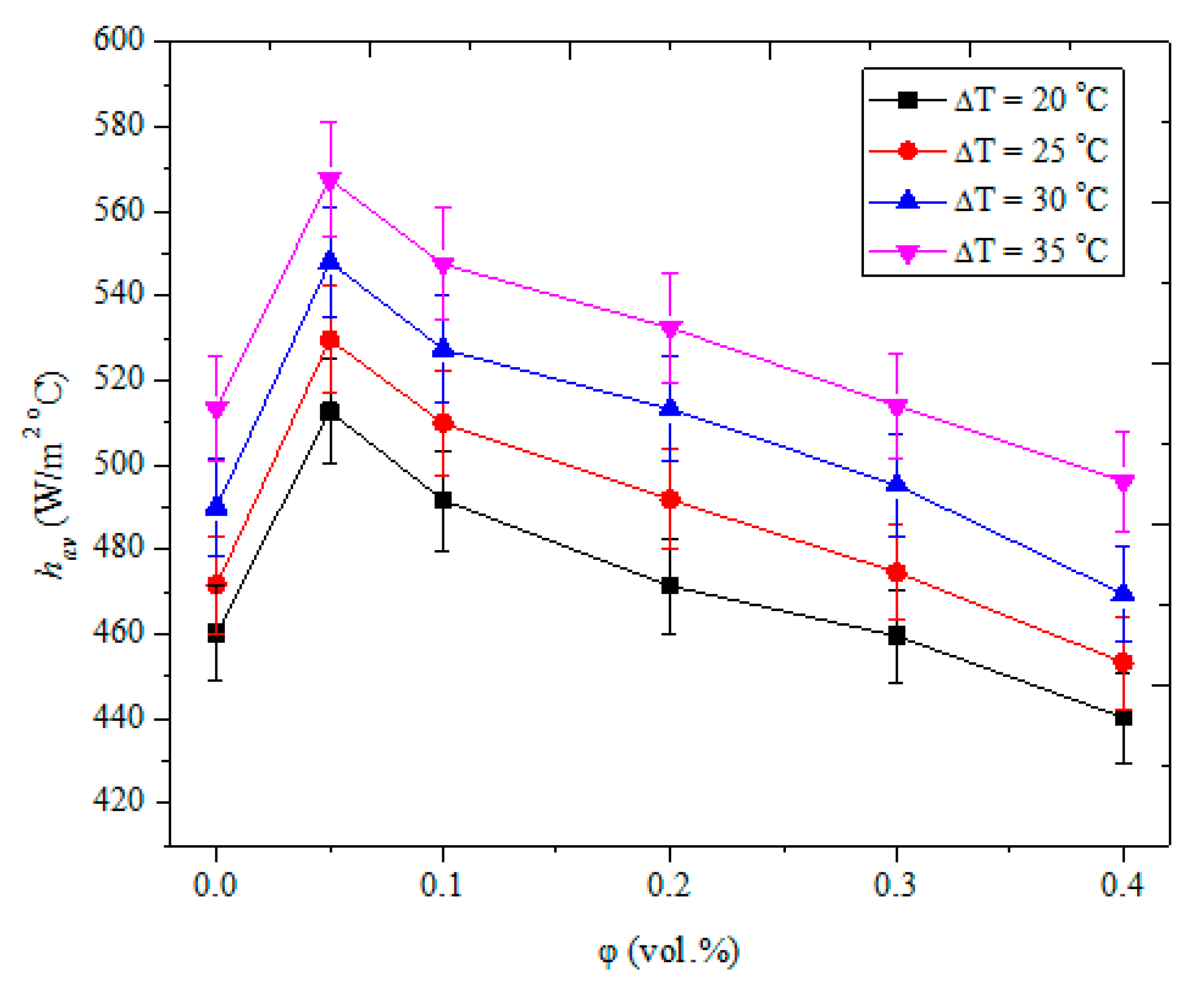

| Kouloulias et al. [52] | γ-Al2O3/DIW (0.01–0.12 vol.%) | Cubic with 1 × 10−3 m3. | 2.5 × 109–5.2 × 109 | - | 2-step (-) | Nu and h deteriorate with φ increase at different ΔT conditions. |

| Ilyas et al. [136] | MWCNT/Thermal oil (0–1 mass%) | Vertical rectangular (12 × 4 × 3 cm) with AR = 4. | 2.5 × 105–2.7 × 106 | μ, Cp, β and κ | 2-step (-) | Deterioration of hav (21.3%) and Nuav (35.74%) as φ increases despite high TC. |

| Rao and Srivastava [137] | Al2O3/DIW (0.01–0.04 vol.%) | Rectangular (l = 60 mm, b = 25 mm, h = 20 mm) | 5.0 × 104–3.5 × 105 | - | 2-step (visual) | Enhancements of hav (28.43–38.03) and Nuav (1.92–14.97) of NF in comparison to BF with increasing φ at different ΔT regimes. |

| Ho et al. [138] | Al2O3/W (1–4 vol.%) | Vertical rectangular (l = 60 mm, b = 25 mm, h = 25 mm) | 5.78 × 105–3.11 × 106 | - | (visual) | Enhancement of Nuav with φ. Sedimentation has more impact than Brownian motion and Ludwig-Soret effect. |

| Amiri et al. [51] | MWCNT- hexylamine/TO ((0.001 and 0.005 wt.%) | Cubic (203 × 100 × 221 mm3) | ND | μ, ρ, PP, σ, Cp, voltage breakdown, FP, and κ | 2-step (UV-vis, ZP and poly-disparity index) | Both Nu and h are enhanced with φ. |

| Choudhary and Subudhi [139] | Al2O3/DW (0.01 and 0.1 vol.%) | Rectangular (120 × 120 × 365 (h) mm3) with AR (0.3–2.5) | 107–1012 | - | 2-step (visual) | At low φ, heat transfer is enhanced but deteriorated at high φ. Heat transfer is related to AR, Ra, and φ. |

| Qi et al. [140] | TiO2-W (0.1, 0.3 and 0.5 wt.%) | Three rectangles with AR = 0.25, 0.5 and 1, and inclined at −45°, 0°, 45° and 90°) | ND | - | 2-step (UV-Vis, visual) | Nu is augmented with increasing φ and Q. Highest heat transfer is achieved using the cavity with AR = 1 and at 0°. |

| Hu et al. [141] | TiO2/DIW (3.85, 7.41 and 10.71 wt.%) | Vertical square (180 × 80 × 80 mm3) | 4.04 × 107–21.07 × 107 | μ and κ | 2-step (-) | Heat transfer of NF is deteriorated when compared with the base fluid. |

| Joshi and Pattamatta [142] | Al2O3/DW, MWCNT/DW and Graphene/DW (0.1, 0.3 and 0.5 vol.%) | Square (40 × 40 × 200) | 7 × 105–1 × 107 | μ and κ | 1-step (G), 2-step (Al2O3 and MWCNT) (visual) | At Ra = 106, DW-based MWCNT and Graphene NF enhance heat transfer for 0.1 and 0.3 vol.%, whereas at Ra = 107, only MWCNT/DW and Al2O3/DW NF reveal the same at similar concentrations. |

| Dixit and Pattamatta [143] | SiO2/DW, MWCNT/DW, Graphene/DW, and Cu/DW (0.057, 1, and 2 vol.%) | Cubic (25 × 50 × 50 mm3) + magnetic field (0.13 T and 0.3 T) | 1 × 106–1 × 107 | μ and κ | 2-step (ZP) | Heat transfer is augmented for all the graphene samples and MWCNT at 0.1 vol.%, without magnetic field. Generally, heat transfer in all the NF samples is deteriorated with magnetic field. |

| Li et al. [144] | ZnO/EG-DW (75:25, 85:15 and 95:5 vol) (5.25 wt.%) | Square (180 × 80 × 80 mm3) | 5.25 × 107–1.08 × 108 | μ and κ | 2-step (PVP) | Under the experimental condition, heat transfer is deteriorated with an increase in EG content. |

| Nnanna [54] | Al2O3/DIW (0.2–7.9 vol.%) | Cuboid (35 mm × 40.32 mm × 215 mm) | 0.3 × 107–3.2 × 107 | μ and κ | 1-step (visual) | Heat transfer is augmented at low concentration of NF (0.2–2 vol.%) but detracts at higher concentration. |

| Ho et al. [145] | Al2O3/DIW (0.1–4 vol.%) | Cuboid (25 × 25 × 60, 40 × 40 × 90, and 80 × 80 × 180) | 6.21 × 105–2.56 × 108 | μ, ρ, and κ | 2-step (-) | Enhancement of heat transfer at lower concentrations (0.1 and 0.3 vol.%) is observed, which increases with cavity size. |

| Yamaguchi et al. [146] | Mg-Zn ferrite/kerosene (ND) | Cubic (7.5 mm each side) with a heat-generating object (brass and square) | Gr = 0–160; Grm = 1.22 × 103–4.4 × 104 | μ, ρ, Cp, β, M, and κ | 2-step (-) | Exposure to the magnetic field enhanced heat transfer and irrespective of the size of the heat-generating objects. |

| Sharifpur et al. [17] | TiO2/DIW (0.05–0.8 vol.%) | Rectangular (96 × 103 × 120 mm3) | 4.9 × 108–1.47 × 109 | - | 1-step (-) | Heat transfer is enhanced for 0.05–0.2 vol.% and thereafter decreased, with maximum of 8.2% attained with 0.05 vol.% at ΔT of 50 °C. |

| Solomon et al. [49] | Al2O3/DIW (0.1–0.6 vol.%) | Rectangular with AR = 1,2 and 4. | 6.9 × 106–4.0 × 108 | - | 1-step (UV-Vis and viscosity) | Enhancement of heat transfer is observed to be related to AR, Ra and φ. Highest heat transfer occurs at 0.1, 0.2 and 0.3 vol.% for AR = 1,2, and 4, respectively. |

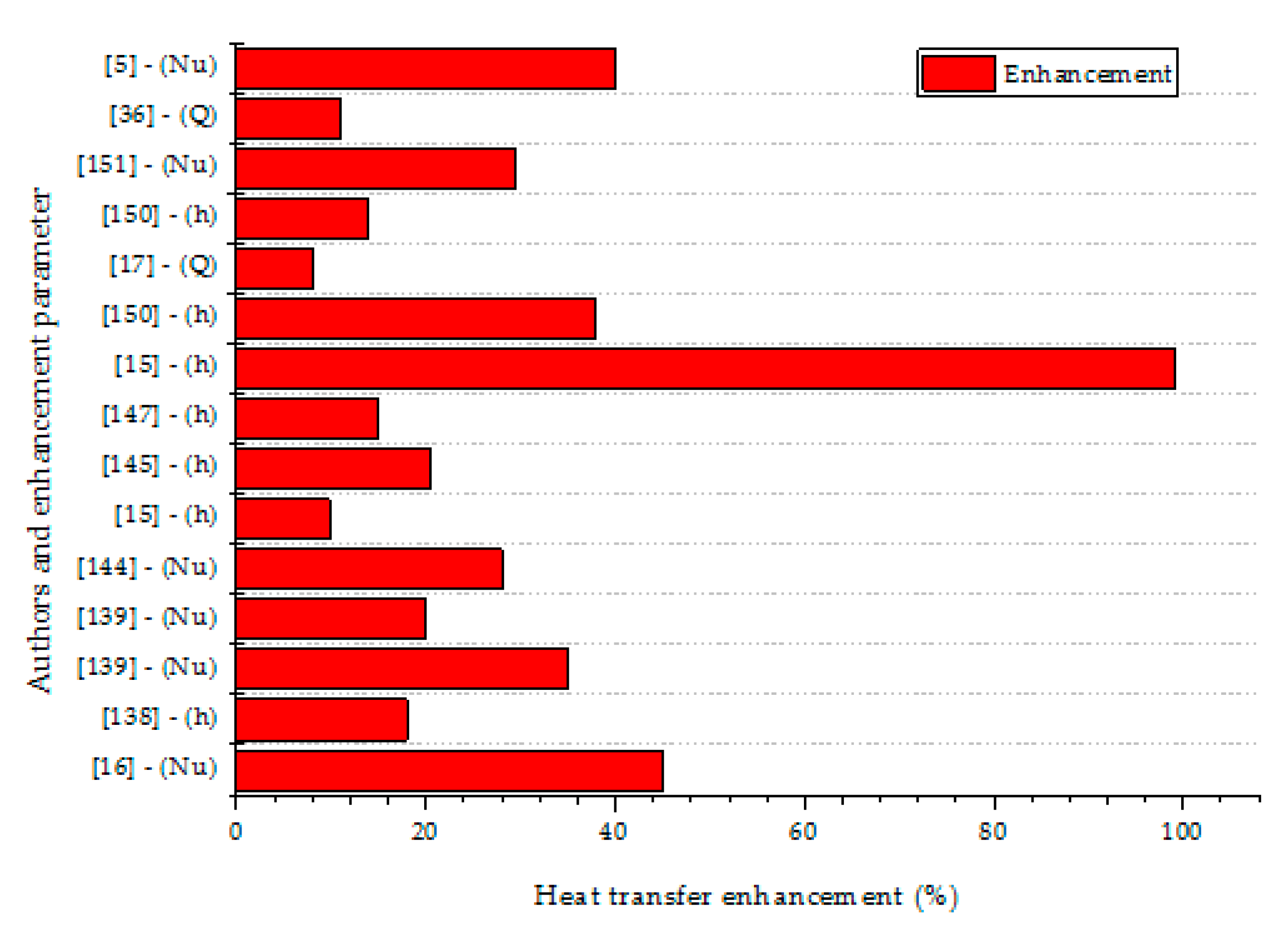

| Ghodsinezhad et al. [15] | Al2O3/DIW (0.05–0.6 vol.%) | Rectangular (96 × 120 × 102 mm3) | 3.49 × 108–1.05 × 109 | μ | 1-step (ZP, UV-vis and visual) | Enhancement of h up till 0.1 vol.% is observed. At 0.1 vol.%, h is 15% augmented compared to base fluid |

| Garbadeen et al. [16] | MWCNT/DIW (0–1 vol.%) | Cuboid (96 × 96 × 105 mm3) | 1 × 108 | μ and κ | 2-step (viscosity and visual) | Optimum heat transfer occurred at 0.1 vol.% with 45% enhancement of h relative to the base fluid. |

| Ilyas et al. [147] | f-MWCNT/THO (0.5–3 wt.%) | Cuboid (12 × 4 × 3 cm3) | 4.43 × 105–2.59 × 106 | μ, ρ, Cp, and κ | 2-step (-) | The h is enhanced as volume concentration increased whereas Nu is attenuated. |

| Solomon et al. [148] | Mango bark/DIW NF (0.01–0.5 vol.%) | Cuboid (120 × 96 × 103 mm3) | 0.2 x108–6 × 108 | μ and κ | 2-step (UV-vis and viscosity) | Deterioration of NF is observed with increase in volume concentration. |

| Roszko andFornalik-Wajs [55] | Ag/DW (0.1 vol.%) | Cubical with 0.032 m under magnetic field (10 T) | 2.5 × 106–2.2 × 107 | - | 2-step (-) | Nu is dependent on the magnetic field and structure of the flow. The energy transfer is altered because of the magnetic field. |

| Solomon et al. [149] | Al2O3/EG (60%)-DIW (40%) (0.05–0.4 vok%) | Cuboid (120 × 96 × 103 mm3) | 3 × 103–1.3 × 104 and 1.2 × 108–4 × 108 | μ and κ | 1-step (UV-vis, viscosity and visual) | Heat transfer is enhanced by 10% for the porous cavity at 0.1 vol.% and ΔT = 50 °C, compared to the base fluid. |

| Joubert et al. [35] | Fe2O3/DIW (0.05–0.3 vol.%) | Rectangle (99 × 96 × 120 mm3) under magnetic field intensity of 300 G and 700 G. | 1.77 × 108–4.26 × 108 | μ | 2-step (visual and viscosity) | Without magnetic field, Nu is maximally enhanced by 5.63% for 0.1 vol.% NF while with magnetic field, an additional maximum augmentation of 2.81% is recorded. |

| Giwa et al. [150] | MWCNT-Al2O3 (95:5 and 90:10)/DIW (0.1 vol.%) | Square (96 × 96 × 105 mm3) | 2.27 × 108–4.7 × 108 | μ and κ | 2-step (-) | The HNF enhance heat transfer better than both NF of Al2O3/DIW and base fluid. |

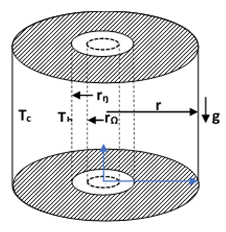

| Putra et al. [6] | Al2O3/DW and CuO/DW (1 and 4 vol.%) | Horizontal cylinder (inner diameter = 40 mm) at AR = 0.5 and 1. | 1.6 × 107–9.2 × 107 | ρ, μ, κ, and γ | 2-step (visual) | For both NF, heat transfer deteriorates as AR and concentration increased but decreased with Nu. |

| Ali et al. [5] | Al2O3/W (0.21, 0.51 and 0.75 vol.%) | Two vertical cylinders (D = 0.2 m) with AR = 0.0635 and 0.127. Heated on the top wall. | 3.0 × 105–1.3 × 108 | ρ, μ, and κ | 1-step (-) | The Nu and h of the NF are more deteriorated than the base fluid, which is related to volume concentration and AR. |

| Cadena-de la Peña et al. [151] | AIN and TiO2/mineral oil (0.01, 0.1 and 0.5 wt.%) | Annular and vertical (opened) with AR of 3.98 and 4.78. | 1.4 × 109–3.2 × 1013 | μ, and κ (at 24 and 40 °C) | 2-step (visual) | Nuav and hav are improved relative to the base fluid at certain conditions (low AR and φ, and high Ra). TiO2/mineral oil NF (hav = 2.63 -5.35% and Nuav = 3.45% maximum) performing better than the AIN/mineral oil NF (hav = 3.91% maximum) |

| Ali et al. [152] | Al2O3/W (0.21, 0.51 and 0.75 vol.%) | Two vertical cylinders (D = 0.2 m) with AR = 0.0635 and 0.127. Heated at the bottom. | 3.0 × 105–1.3 × 108 | ρ, μ, and κ | 1-step (visual) | Compared to the base fluid, h is augmented for 0.21 vol.% and attenuated with concentration increase. HTC is AR dependent with higher h for lower AR. |

| Wen and Ding [7] | TiO2/DW (0.8, 1.5, and 2.5 wt.%) | Horizontal cylinder (240 mm diameter) | 2.3 × 104–1.4 × 105 | μ and κ | 2-step (ZP and visual) | HTC attenuates with increase in NF concentration with maximum reduction of 30% recorded. |

| Mahian, et al. [3] | SiO2/W (0.5, 1.0, and 2.0 vol.%) | Square, inclined square (45°) and triangular | 1.0 × 105–1.0 × 106 | ρ, μ, and κ. | 2-step (visual) | For all the cavities, the maximum HTC ratio is observed at Ra = 106 and 0.5% concentration. High prediction accuracy of the HTC is noticed when the thermophysical properties of the NF are measured. |

| Mahrood et al. [50] | Al2O3 and TiO2/CMC (0.1 ≤ φ ≤ 1.5 vol.%) | Vertical cylinder with AR = 0.5, 1.0 and 1.5. | 4.0 × 106–3.0 × 107 | n.d. | 2-step (-) | Heat transfer is enhanced below 0.5 and 1 vol.% with optimum values at 0.1 and 0.2 vol.%, for CMC-based TiO2 and Al2O3 NF, respectively. TiO2 NF is a better heat transfer medium than Al2O3 NF. Increasing AR is found to enhance heat transfer for both NF. |

| Moradi et al. [153] | Al2O3/DIW and TiO2/DIW (0.1 ≤ φ ≤ 1.5 vol.%) | Inclined (30°, 60° and 90°) vertical cylindrical (diameter = 80 mm and length = 250 mm) with AR (0.5, 1.0 and 1.5) | 1.2 × 108–3.7 × 108 | Ρ | 2-step (visual) | Maximum enhancements of Nu (6.76% and 2.33% relative to DIW) occur at 0.2 vol.% and 0.1 vol.% for Al2O3/DIW and TiO2/DIW NF, respectively. Nu is noticed to augment with increase in AR. |

| Yamaguchi et al. [154] | Mg-Zn ferrite/alkyl-naphthalene | Cubic with a magnetic field. | Ra (3.0 × 103–8.0 × 103), Ram (1.0 × 108–1.25 × 108) | - | 2-step (-) | Heat transfer is enhanced on exposure to magnetic field. An increase in the magnetic strength enhanced heat transfer further. |

| Ni et al. [155] | Al2O3/W (0.0108 vol.%) | Cylindrical (ID = 19.3 cm, h = 2.00 cm) | 2.6 × 108–7.7 × 108 | - | 1-step (-) | Deterioration of Nu. |

| Babu and Rao [156] | Al2O3/DIW (0.05–0.6 vol.%) | Vertical cylinder (D = 12.7mm, l = 250mm) | 2.7 × 109–6.4 × 109 | - | 2-step (UV-vis) | Improvement of heat transfer by 13.8% for 0.1 vol.%. |

| Torki and Etesami [40] | SiO2/DIW (0.01–1.0 vol.%) | Inclined rectangle (60 × 60 × 135 mm3) | 1.0 × 107–8.0 × 107 | - | 2-step (-) | Maximum h and Nu at φ = 0.01 vol.% and θ = 0°. Attenuation are observed at >0.01 vol.% and >0°. |

| Giwa et al. [157] | Al2O3-MWCNT (80:20–20:80) (0.1 vol.%) | Square (96 × 96 × 105 mm3) | 1.65 × 108–3.8 × 108 | μ and κ | 2-step (UV-vis) | Maximum enhancements of 16.2%, 19.4%, and 20.5% are reported for Nuav, Qav, and hav, respectively, for Al2O3-MWCNT/DIW NF with 60:40 percent weight of NP. |

| Haddad et al. [158] | ZnO/W (0.01–0.1 vol.%) | Inclined hemisphere with a cubical object. | 5.21 × 107–7.29 × 1010 | μ, κ, Cp, β, ρ, and B. | 2-step (-) | Heat transfer is slightly enhanced with an increase in φ while increasing θ does not affect it. |

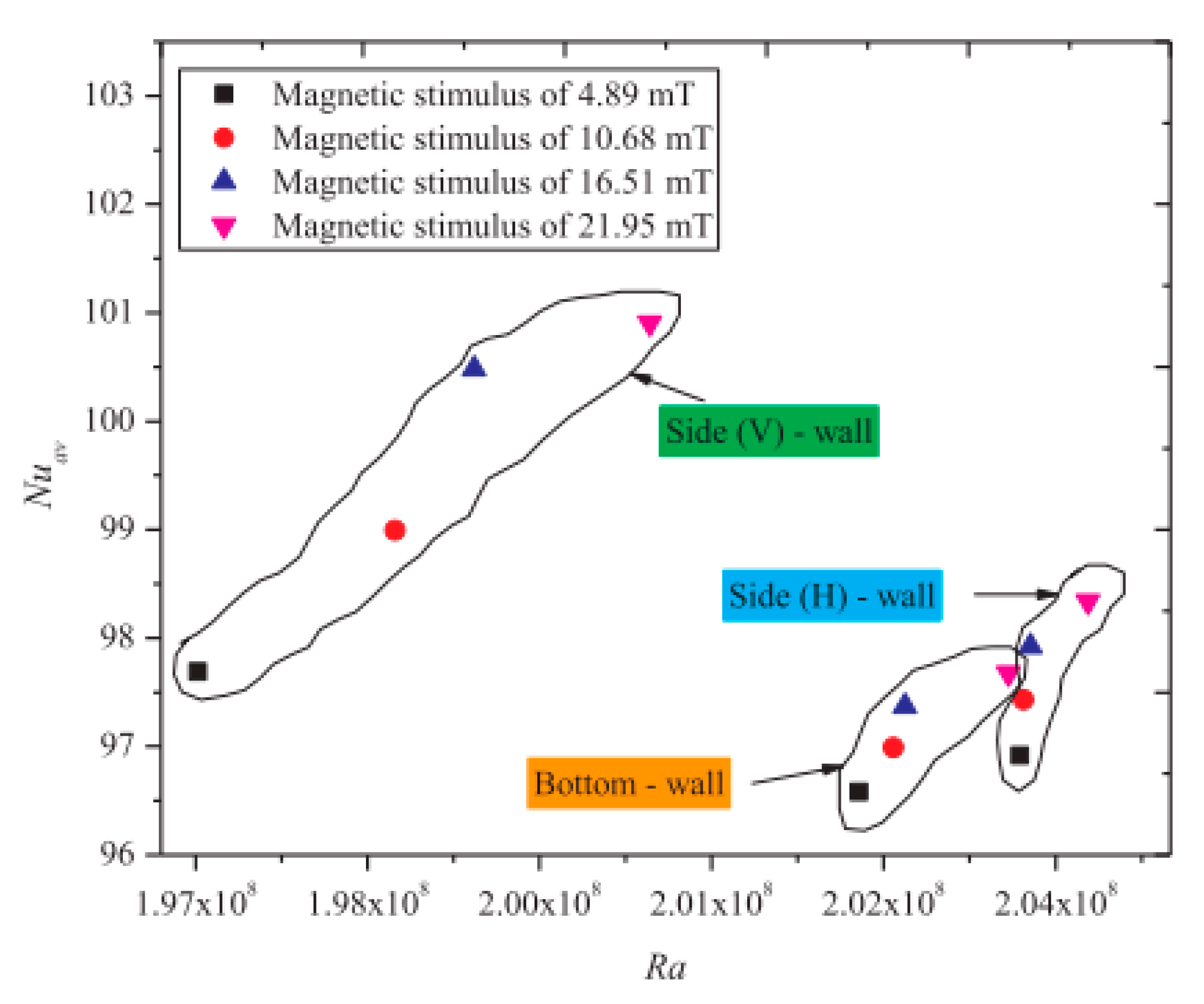

| Giwa et al. [36] | Al2O3-Fe2O3/DIW (0.05–0.3 vol.%) | Rectangular (120.8 × 99.7 × 113.2 mm3) with a magnetic field of 48.9 G–219.5 G. | 1.49 × 108–3.04 × 108 | μ, κ, and B. | 2-step (UV-vis) | Without magnetic induction, heat transfer is enhanced by 10.79% for 0.1 vol.% while in the presence of the magnetic induction heat transfer is further enhanced. Imposing the magnetic field vertically on the side wall of the cavity led to maximum heat transfer. |

| Dixit and Pattamatta [159] | Fe3O4/DI (0.05 and 0.2 vol.%) and Fe/DI (0.2 vol.%) | Cubic (25 mm each) with a magnetic field of 0.3 T. | 4.23 × 105–1.0 × 107 | μ, κ, and B. | 2-step (ZP) | For both types of NF, deterioration is observed on exposing the vertical walls (heated and non-heated) to the magnetic field. Heat transfer is enhanced by 11.0% (0.05 vol) and 28% (0.2 vol) for Fe3O4/DI NF on exposing the heated bottom wall to the magnetic field. |

| Enclosure | Configuration | Remark (References) |

|---|---|---|

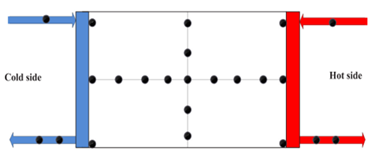

| Rectangle |  | Natural convection of hybrid nanofluid (e.g., [36,40]) |

| Square |  | Natural convection of mono nanofluid (e.g., [16,137,143]) |

| Cylinder |  | Natural convection of mono nanofluid (e.g., [151]) |

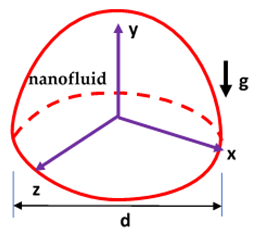

| Hemisphere |  | Natural convection of mono nanofluid with and without cavity inclination (e.g., [158]) |

| Researchers | NF | Geometry | Correlation |

|---|---|---|---|

| Ali et al. [152] | Al2O3/W | Vertical cylinders | |

| Ho et al. [145] | Al2O3/W | Vertical squares | |

| Cadena-de la Peña et al. [151] | AIN and TiO2/mineral oil | Opened vertical annular | Maximum deviation = 1.6% |

| Ali et al. [5] | Al2O3/W | Vertical cylinders | |

| Ghodsinezhad et al. [15] | Al2O3/W | Square | (for φ ≤ 0.1) (for φ ≥ 0.1); R2 = 0.94 |

| Ilyas et al. [147] | f-Al2O3/THO | Rectangular | ; 228 ≤ Pr ≤ 592; 0.97 ≤1− (wt. frac.) ≤ 1; |

| Nnanna et al. [54] | Al2O3/DIW | Rectangular | ε = 4 × 10−7; m = 11; 105 ≤ φRae−mφ ≤ 106 |

| Babu and Rao [156] | Al2O3/DIW | Vertical cylinder | (0 < φ < 0.10 vol.%); R2 = 0.995 (0.1 < φ < 0.60 vol.%); R2 = 0.997 |

| Choudhary and Subudhi [139] | Al2O3/DW | Square | (φ < 0.01 vol.%) (φ < 0.10 vol.%) ; (φ < 0.01 vol.%) ; (φ < 0.10 vol.%) |

| Rao and Babu [156] | Al2O3/W | Cylinder | (0 ) (0.1 ) |

| Giwa et al. [36] | Fe2O3-Al2O3/DIW | Rectangular | |

| Haddad et al. [158] | ZnO/W | Hemisphere | ; Valid for ; ; |

| Giwa et al. [157] | Al2O3-MWCNT/DIW | Square | |

| Umar et al. [160] | ZrO2/water | Triangular and rectangular | and |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murshed, S.M.S.; Sharifpur, M.; Giwa, S.; Meyer, J.P. Experimental Research and Development on the Natural Convection of Suspensions of Nanoparticles—A Comprehensive Review. Nanomaterials 2020, 10, 1855. https://doi.org/10.3390/nano10091855

Murshed SMS, Sharifpur M, Giwa S, Meyer JP. Experimental Research and Development on the Natural Convection of Suspensions of Nanoparticles—A Comprehensive Review. Nanomaterials. 2020; 10(9):1855. https://doi.org/10.3390/nano10091855

Chicago/Turabian StyleMurshed, S. M. Sohel, Mohsen Sharifpur, Solomon Giwa, and Josua P. Meyer. 2020. "Experimental Research and Development on the Natural Convection of Suspensions of Nanoparticles—A Comprehensive Review" Nanomaterials 10, no. 9: 1855. https://doi.org/10.3390/nano10091855

APA StyleMurshed, S. M. S., Sharifpur, M., Giwa, S., & Meyer, J. P. (2020). Experimental Research and Development on the Natural Convection of Suspensions of Nanoparticles—A Comprehensive Review. Nanomaterials, 10(9), 1855. https://doi.org/10.3390/nano10091855