Green Synthesis and Characterization of Gold Nanoparticles Using Lignin Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of LNPs

2.3. Preparation of Au NPs@ LNPs

2.4. Characterization

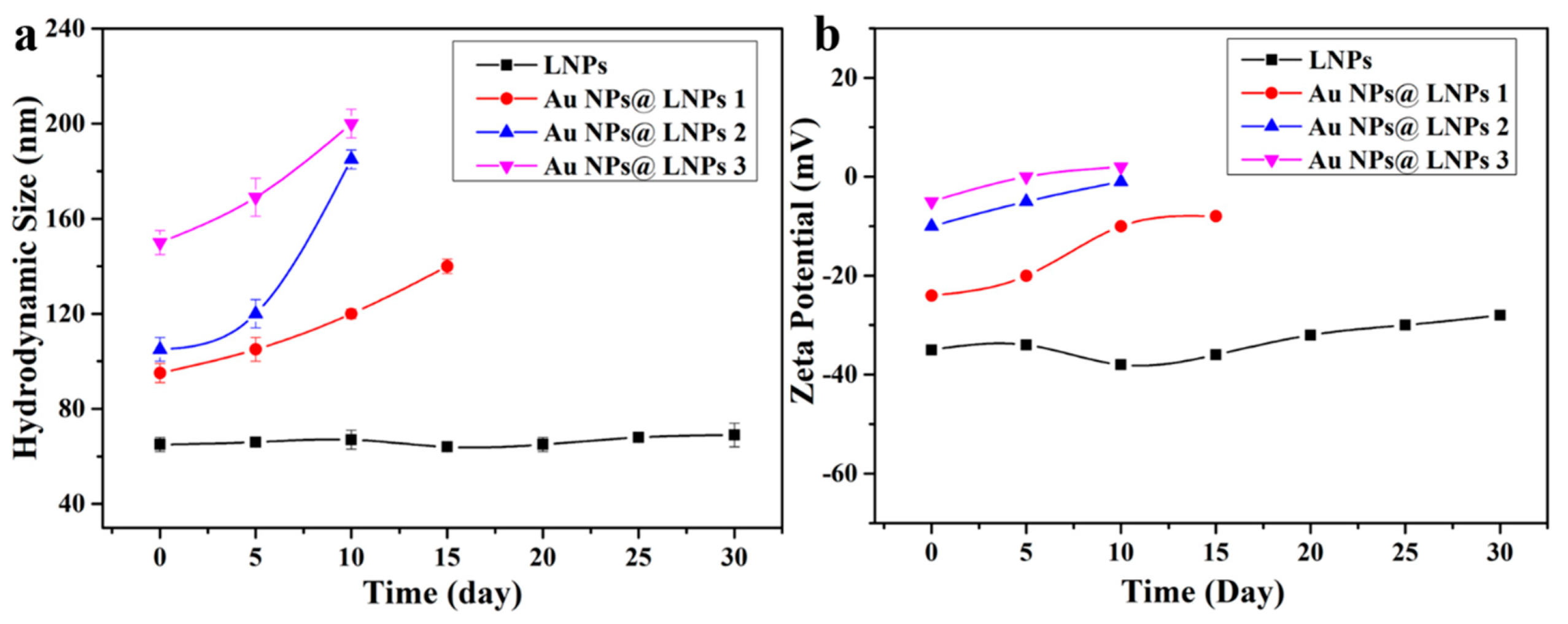

3. Results

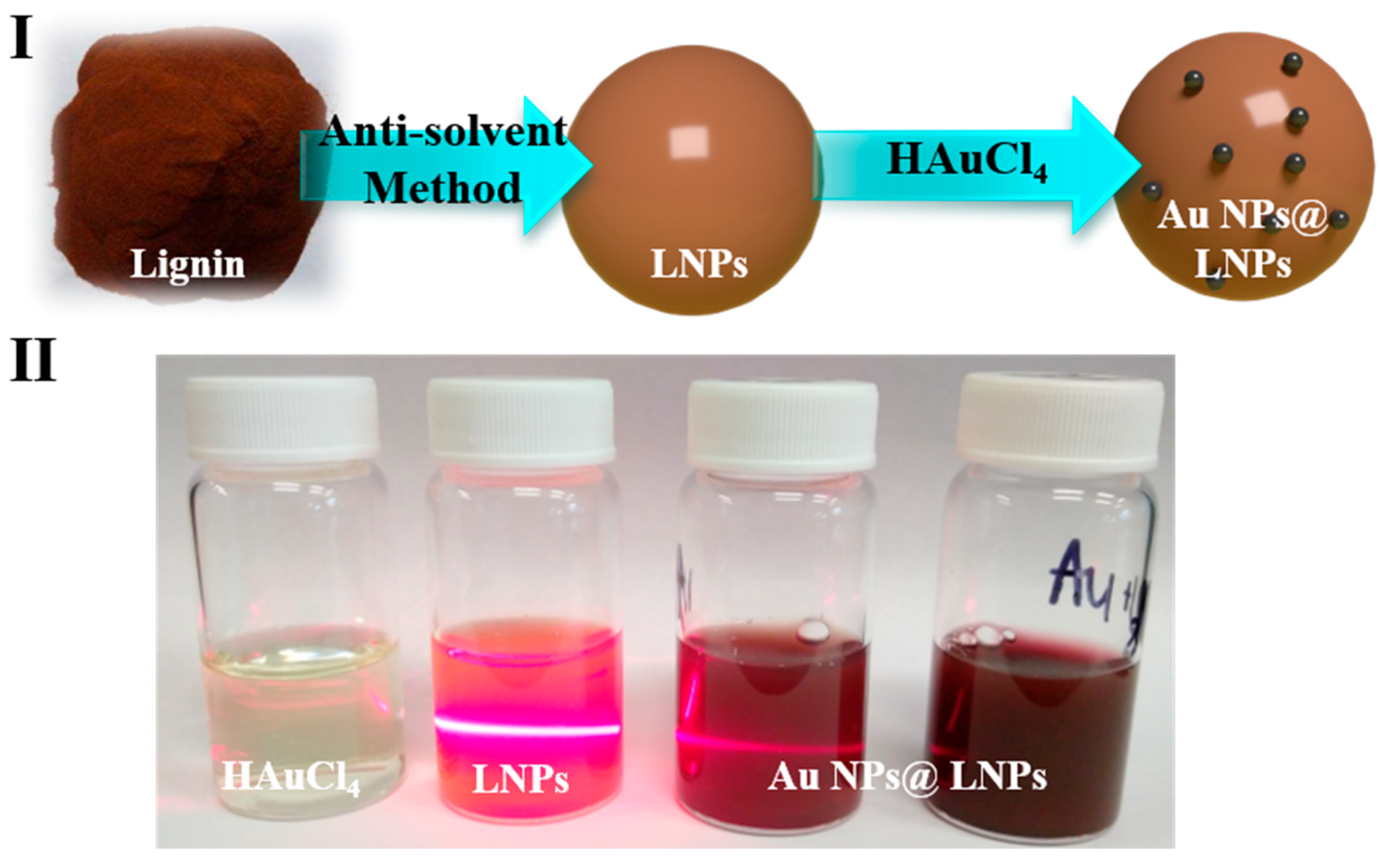

3.1. Schematic of Preparing the LNPs@AuNPs

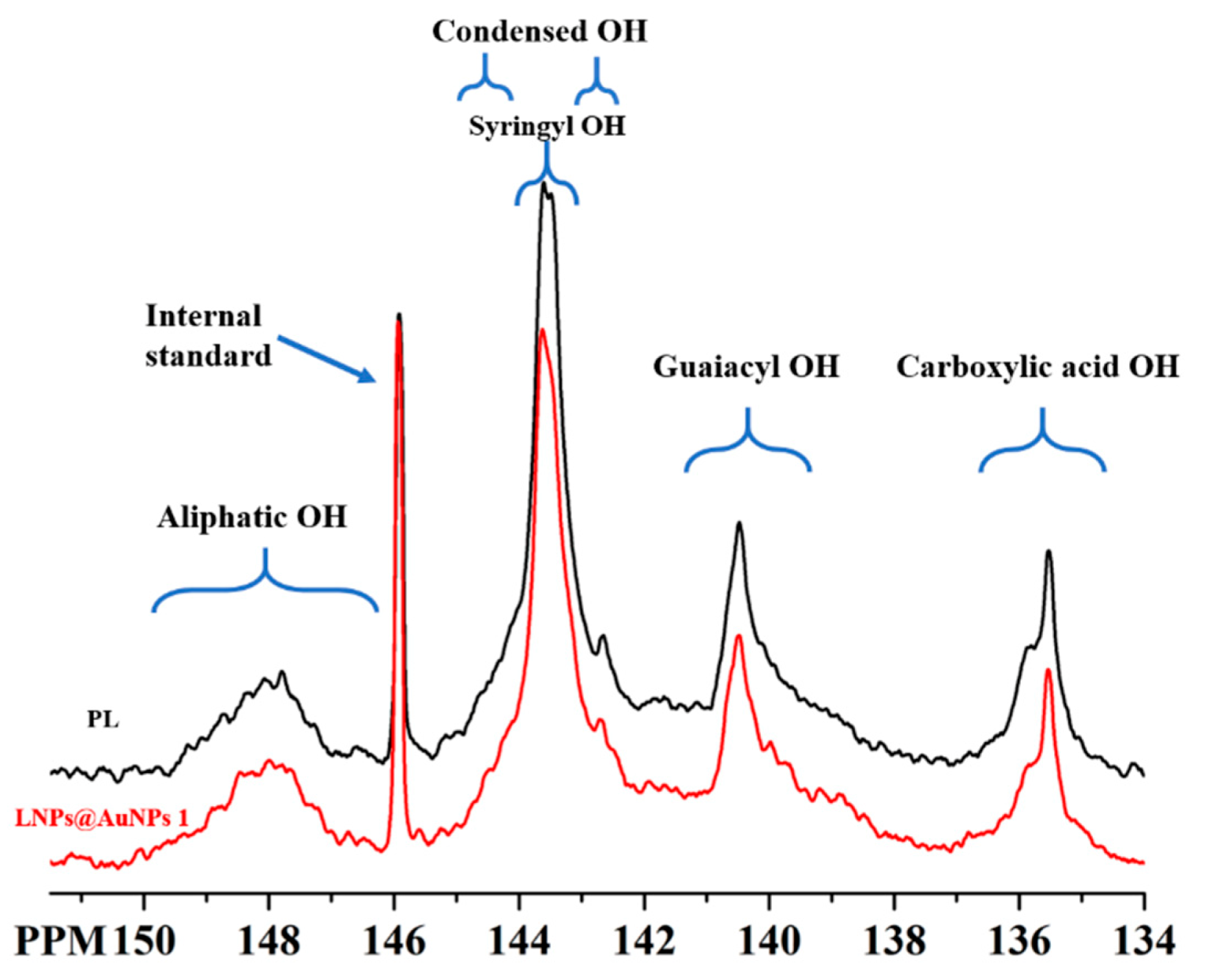

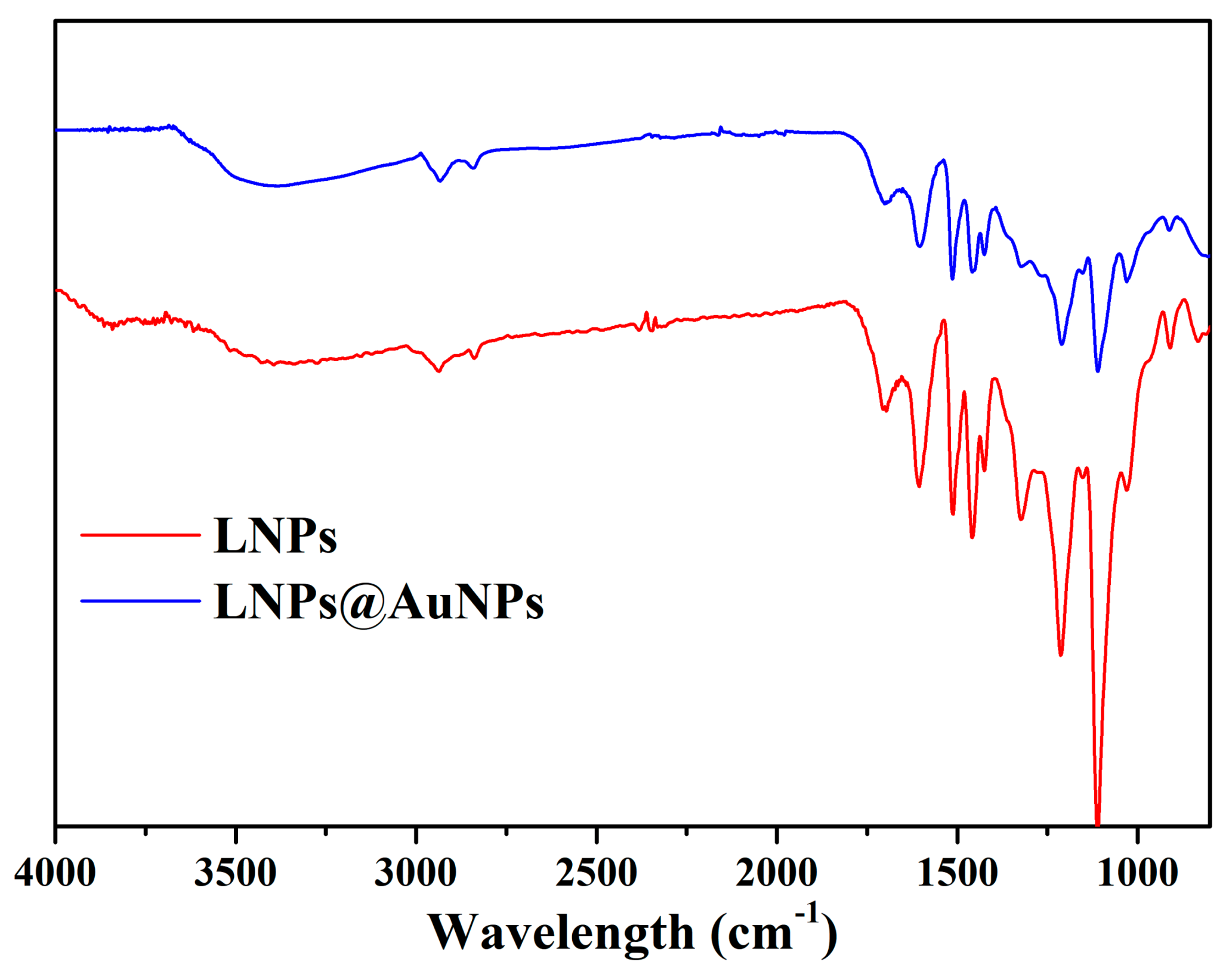

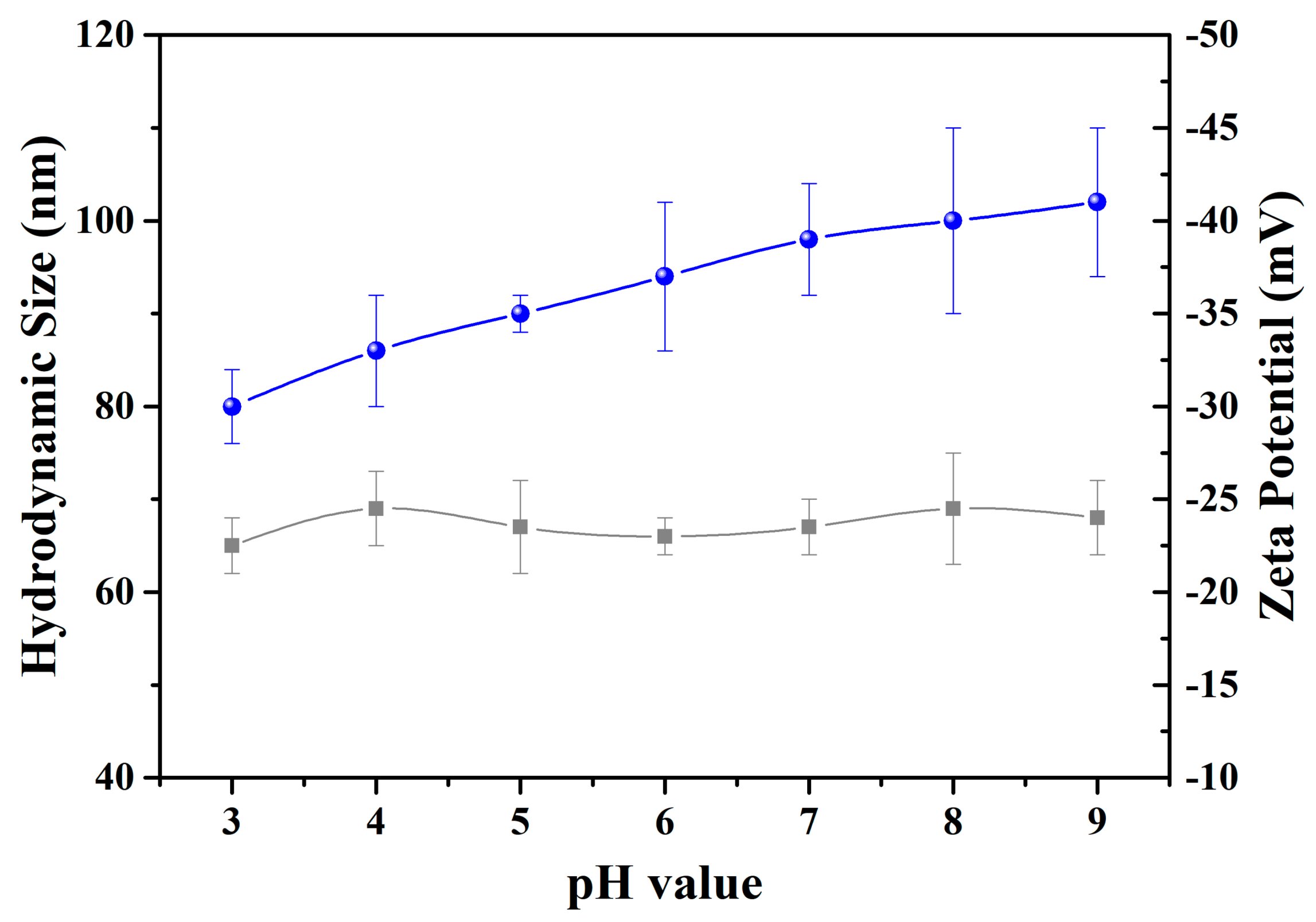

3.2. Characterization of Lignin

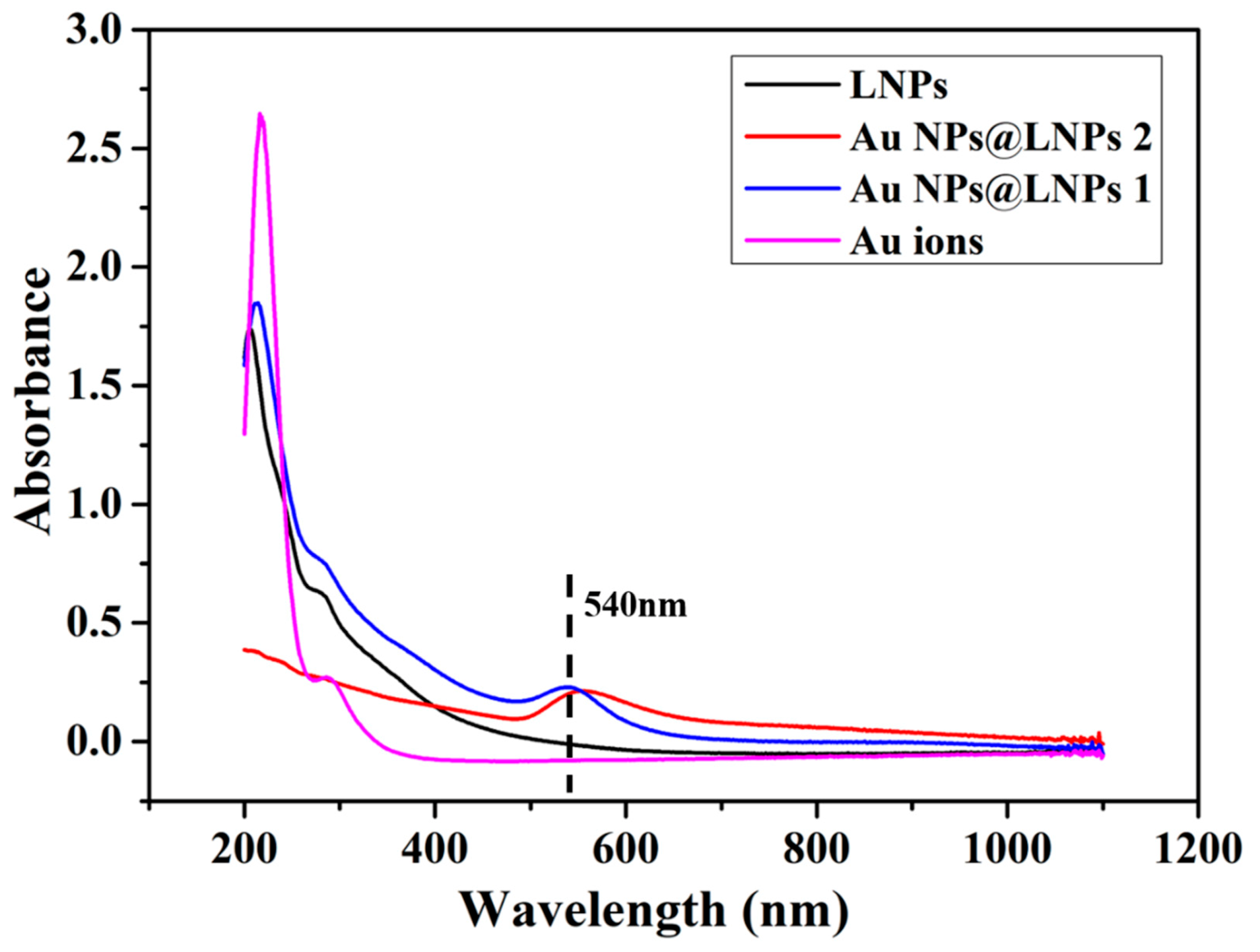

3.3. UV-Vis Spectrum of the Preparation of LNPs@AuNPs

4. Discussion

4.1. TEM of LNPs and Au NPs@ LNPs

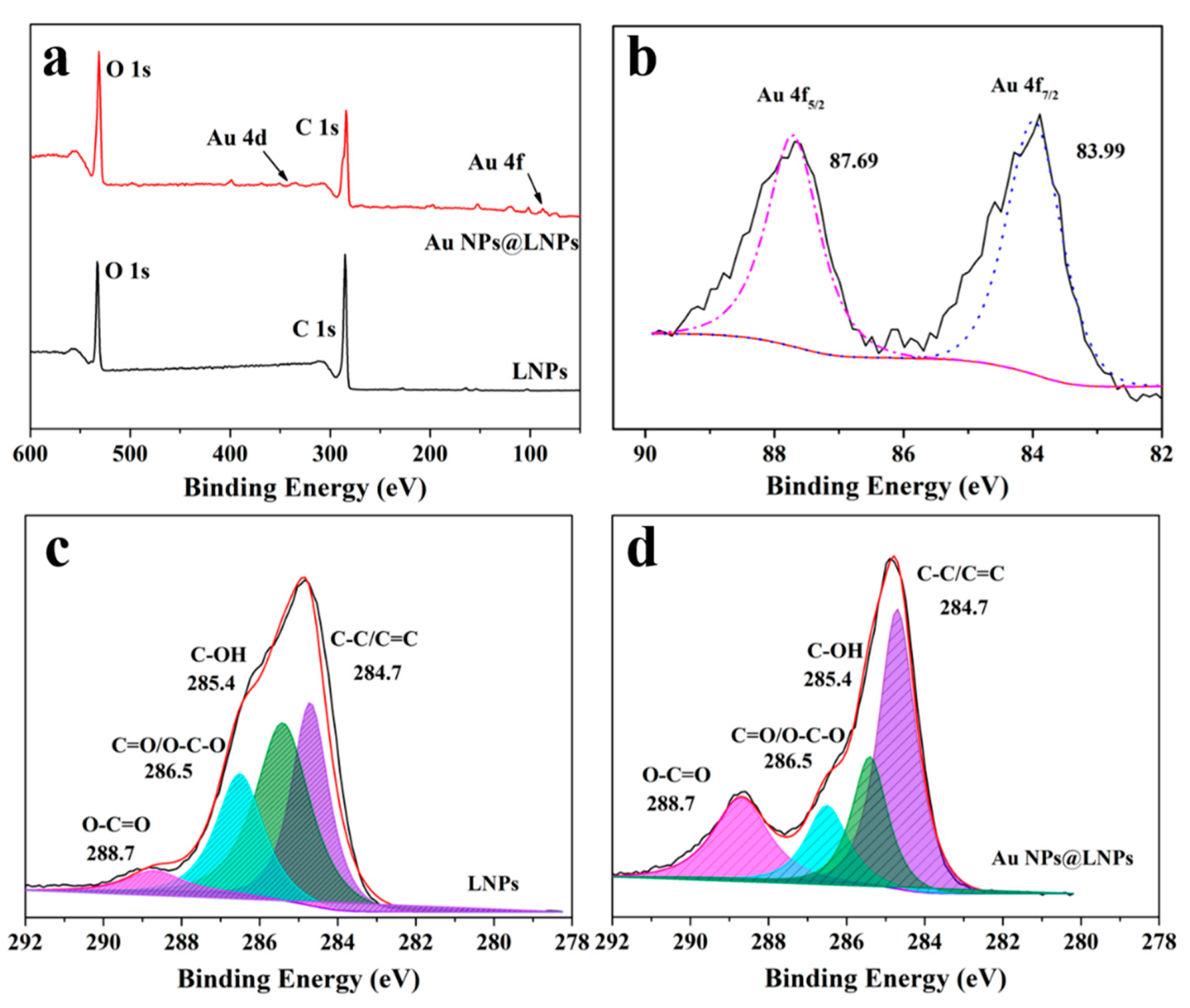

4.2. XPS of LNPs and Au NPs@ LNPs

4.3. Proposed Mechanism for the Preparation of LNPs@AuNPs

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar]

- Kamat, P.V. Photophysical, Photochemical and Photocatalytic Aspects of Metal Nanoparticles. J. Phys. Chem. B 2002, 106, 7729–7744. [Google Scholar]

- Chou, C.; Chen, C.; Wang, C.R.C. Highly efficient, wavelength-tunable, gold nanoparticle based optothermal nanoconvertors. J. Phys. Chem. B 2005, 109, 11135–11138. [Google Scholar]

- Huang, P.; Lin, J.; Li, W.; Rong, P.; Wang, Z.; Wang, S.; Wang, X.; Sun, X.; Aronova, M.A.; Niu, G. Biodegradable Gold Nanovesicles with an Ultrastrong Plasmonic Coupling Effect for Photoacoustic Imaging and Photothermal Therapy. Angew. Chem. 2013, 52, 13958–13964. [Google Scholar]

- Gaiduk, A.; Ruijgrok, P.V.; Yorulmaz, M.; Orrit, M. Making gold nanoparticles fluorescent for simultaneous absorption and fluorescence detection on the single particle level. Phys. Chem. Chem. Phys. 2011, 13, 149–153. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, H.J.; Ha, Y.J.; Park, Y.N.; Lee, S.K.; Park, Y.; Yoo, K. Targeted chemo-photothermal treatments of rheumatoid arthritis using gold half-shell multifunctional nanoparticles. ACS Nano 2013, 7, 50–57. [Google Scholar]

- Tangeysh, B.; Tibbetts, K.M.; Odhner, J.H.; Wayland, B.B.; Levis, R.J. Gold Nanoparticle Synthesis Using Spatially and Temporally Shaped Femtosecond Laser Pulses: Post-Irradiation Auto-Reduction of Aqueous [AuCl4]−. J. Phys. Chem. C 2013, 117, 18719–18727. [Google Scholar]

- Lu, X.; Tuan, H.; Korgel, B.A.; Xia, Y. Facile synthesis of gold nanoparticles with narrow size distribution by using AuCl or AuBr as the precursor. Chem. Eur. J. 2008, 14, 1584–1591. [Google Scholar]

- Soliwoda, K.; Rosowski, M.; Tomaszewska, E.; Tkaczszczesna, B.; Celichowski, G.; Psarski, M.; Grobelny, J. Synthesis of monodisperse gold nanoparticles via electrospray-assisted chemical reduction method in cyclohexane. Colloids Surf. A Physicochem. Eng. Asp. 2015, 482, 148–153. [Google Scholar]

- Huang, H.; Yang, X. Synthesis of polysaccharide-stabilized gold and silver nanoparticles: A green method. Carbohydr. Res. 2004, 339, 2627–2631. [Google Scholar]

- Coccia, F.; Tonucci, L.; Bosco, D.; Bressan, M.; Dalessandro, N. One-pot synthesis of lignin-stabilised platinum and palladium nanoparticles and their catalytic behaviour in oxidation and reduction reactions. Green Chem. 2012, 14, 1073–1078. [Google Scholar]

- Ratanasumarn, N.; Chitprasert, P. Cosmetic potential of lignin extracts from alkaline-treated sugarcane bagasse: Optimization of extraction conditions using response surface methodology. Int. J. Biol. Macromol. 2020, 153, 138–145. [Google Scholar] [CrossRef]

- Tarasov, D.; Leitch, M.; Fatehi, P. Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol. Biofuels 2018, 11, 269. [Google Scholar] [CrossRef] [Green Version]

- Han, G.; Wang, X.; Hamel, J.; Zhu, H.; Sun, R. Lignin-AuNPs liquid marble for remotely-controllable detection of Pb2+. Sci. Rep. 2016, 6, 38164. [Google Scholar] [CrossRef]

- Lin, X.; Zhao, J.; Wu, M.; Kuga, S.; Huang, Y. Green Synthesis of Gold, Platinum and Palladium Nanoparticles by Ligninand Hemicellulose. Res. Rev. J. Microbiol. Biotechnol. 2016, 5, 14–18. [Google Scholar]

- Chatterjee, S.; Saito, T. Lignin-derived advanced carbon materials. ChemSusChem 2015, 8, 3941–3958. [Google Scholar]

- Chen, L.; Shi, Y.; Gao, B.; Zhao, Y.; Jiang, Y.; Zha, Z.; Xue, W.; Gong, L. Lignin Nanoparticles: Green Synthesis in a γ-Valerolactone/Water Binary Solvent and Application to Enhance Antimicrobial Activity of Essential Oils. ACS Sustain. Chem. Eng. 2019, 8, 714–722. [Google Scholar] [CrossRef]

- Rangan, A.; Manjula, M.; Satyanarayana, K.; Menon, R. Lignin/nanolignin and their biodegradable composites. In Biodegradable Green Composites; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 167–198. [Google Scholar]

- Dai, L.; Li, Y.; Kong, F.; Liu, K.; Si, C.; Ni, Y. Lignin-Based Nanoparticles Stabilized Pickering Emulsion for Stability Improvement and Thermal-Controlled Release of trans-Resveratrol. ACS Sustain. Chem. Eng. 2019, 7, 13497–13504. [Google Scholar] [CrossRef]

- Chen, S.; Wang, G.; Sui, W.; Parvez, A.M.; Dai, L.; Si, C. Novel lignin-based phenolic nanosphere supported palladium nanoparticles with highly efficient catalytic performance and good reusability. Ind. Crop. Prod. 2020, 145, 112164. [Google Scholar] [CrossRef]

- Ma, M.; Dai, L.; Si, C.; Hui, L.; Liu, Z.; Ni, Y. A facile approach to prepare super long-term stable lignin nanoparticles from black liquor. ChemSusChem 2019, 12, 5239. [Google Scholar] [CrossRef]

- Shen, Z.; Luo, Y.; Wang, Q.; Wang, X.; Sun, R. High-Value Utilization of Lignin to Synthesize Ag Nanoparticles with Detection Capacity for Hg2+. ACS Appl. Mater. Interfaces 2014, 6, 16147–16155. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, X.; Zhou, M.; Qian, Y.; Yu, H.; Qiu, X. Investigation of Aggregation and Assembly of Alkali Lignin Using Iodine as a Probe. Biomacromolecules 2011, 12, 1116–1125. [Google Scholar] [CrossRef]

- Martinez, J.C.; Chequer, N.A.; Gonzalez, J.L.; Cordova, T. Alternative Metodology for Gold Nanoparticles Diameter Characterization Using PCA Technique and UV-VIS Spectrophotometry. Nanosci. Nanotechnol. 2013, 2, 184–189. [Google Scholar]

- Bährle, C.; Nick, T.U.; Bennati, M.; Jeschke, G.; Vogel, F. High-Field Electron Paramagnetic Resonance and Density Functional Theory Study of Stable Organic Radicals in Lignin: Influence of the Extraction Process, Botanical Origin, and Protonation Reactions on the Radical g Tensor. J. Phys. Chem. A 2015, 119, 6475–6482. [Google Scholar] [CrossRef]

| Samples | Aliphatic OH | Condensed OH | Syringyl OH | Guaiacyl OH | Carboxylic OH |

|---|---|---|---|---|---|

| PL | 2.54 | 5.78 | 8.66 | 5.81 | 2.17 |

| LNPs@AuNPs | 2.36 | 4.97 | 6.37 | 4.10 | 2.34 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Yang, G.; Chen, J.; Fang, G. Green Synthesis and Characterization of Gold Nanoparticles Using Lignin Nanoparticles. Nanomaterials 2020, 10, 1869. https://doi.org/10.3390/nano10091869

Wang B, Yang G, Chen J, Fang G. Green Synthesis and Characterization of Gold Nanoparticles Using Lignin Nanoparticles. Nanomaterials. 2020; 10(9):1869. https://doi.org/10.3390/nano10091869

Chicago/Turabian StyleWang, Baobin, Guihua Yang, Jiachuan Chen, and Guigan Fang. 2020. "Green Synthesis and Characterization of Gold Nanoparticles Using Lignin Nanoparticles" Nanomaterials 10, no. 9: 1869. https://doi.org/10.3390/nano10091869