Influence of the Interface Composition to the Superconductivity of Ti/PdAu Films

Abstract

1. Introduction

2. Materials and Methods

3. Results

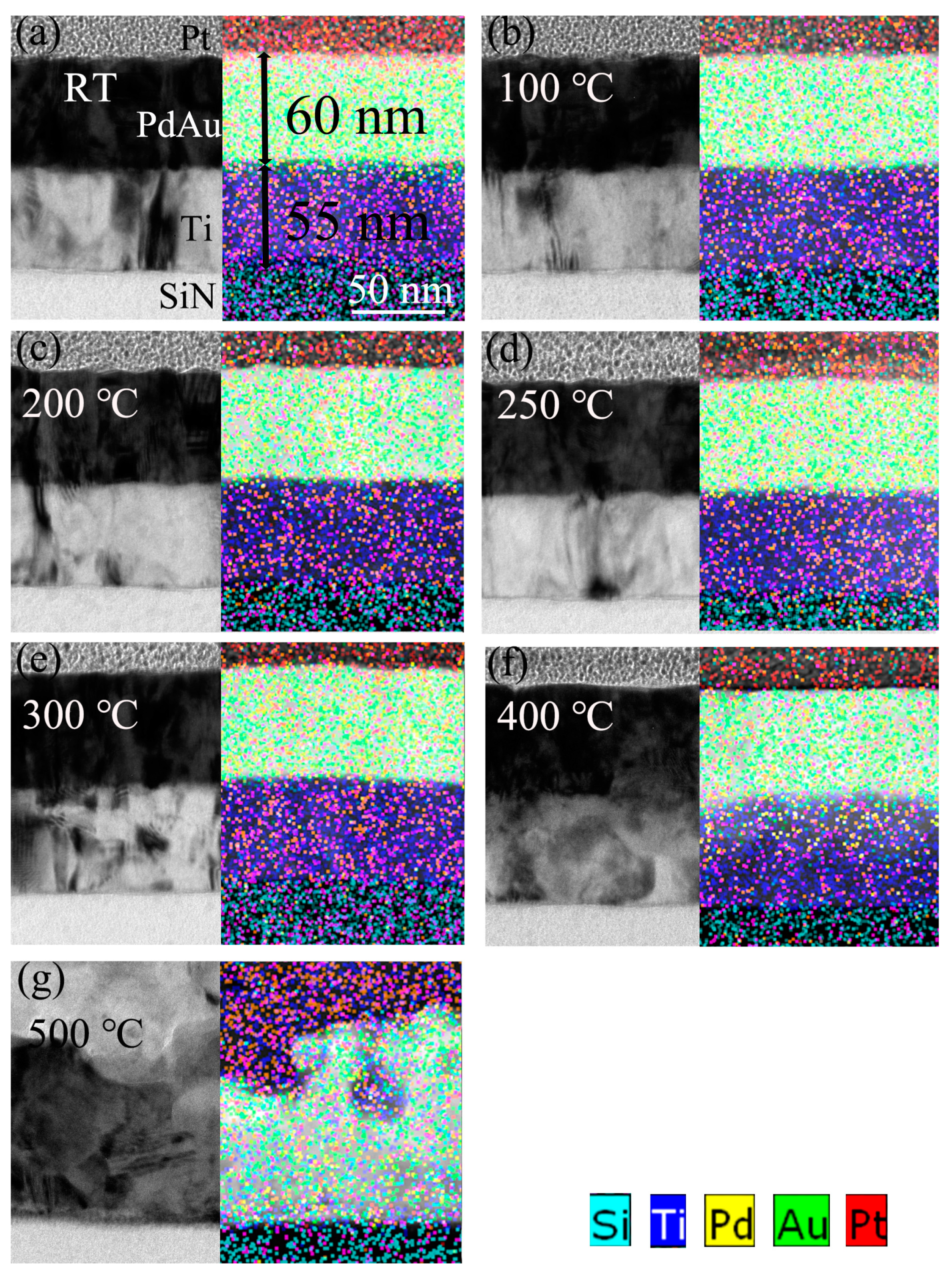

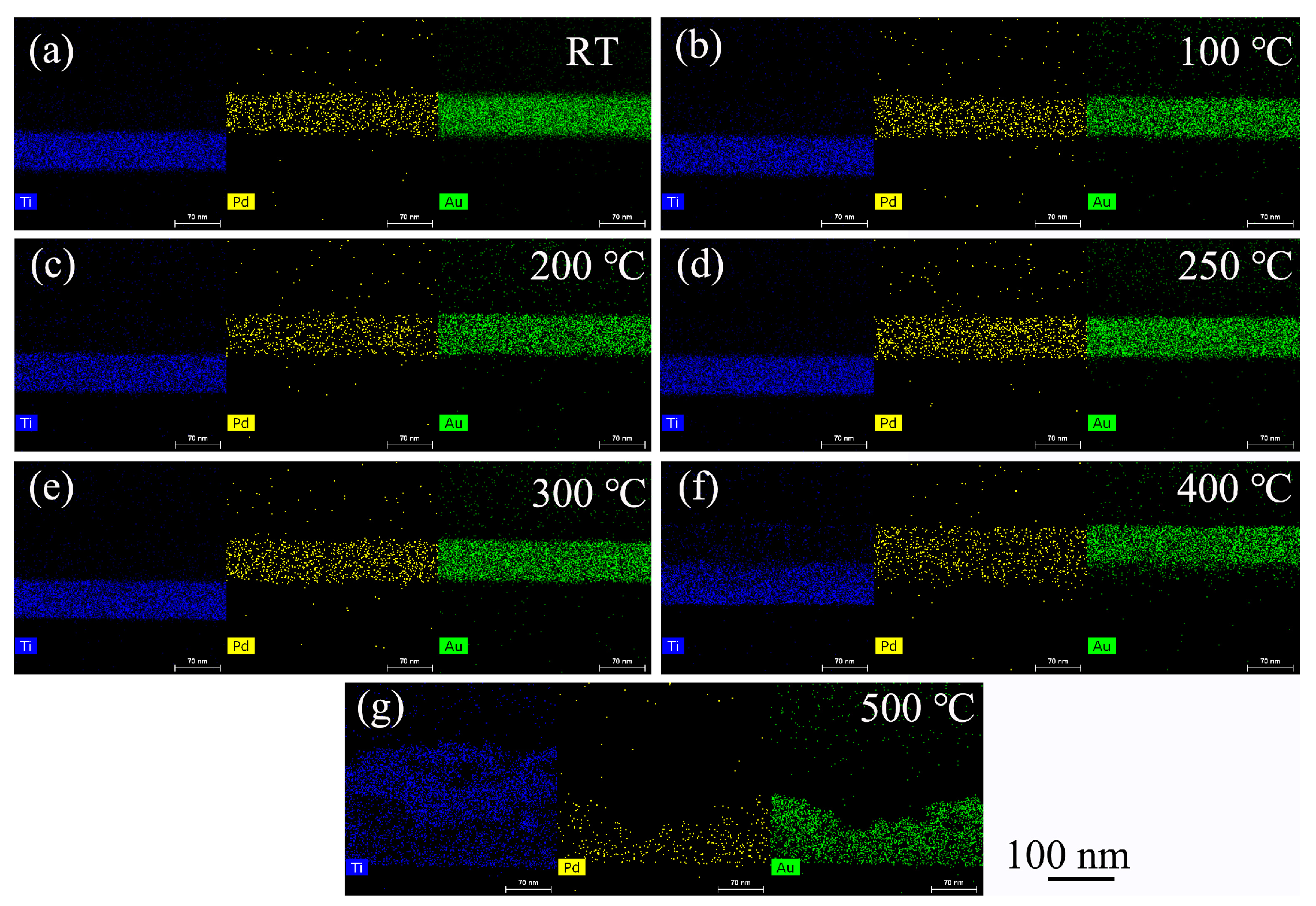

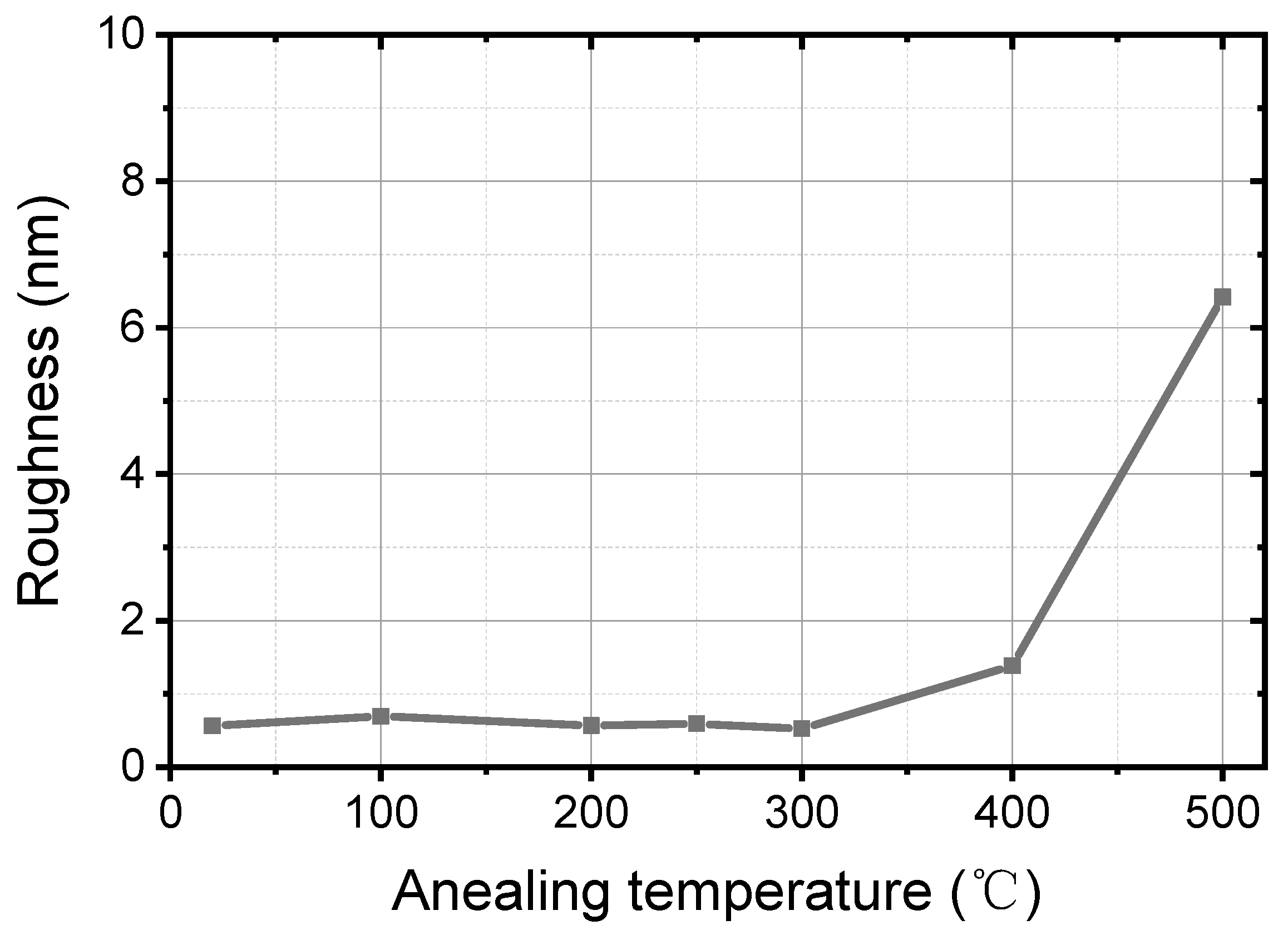

3.1. Morphology of Interface Composition

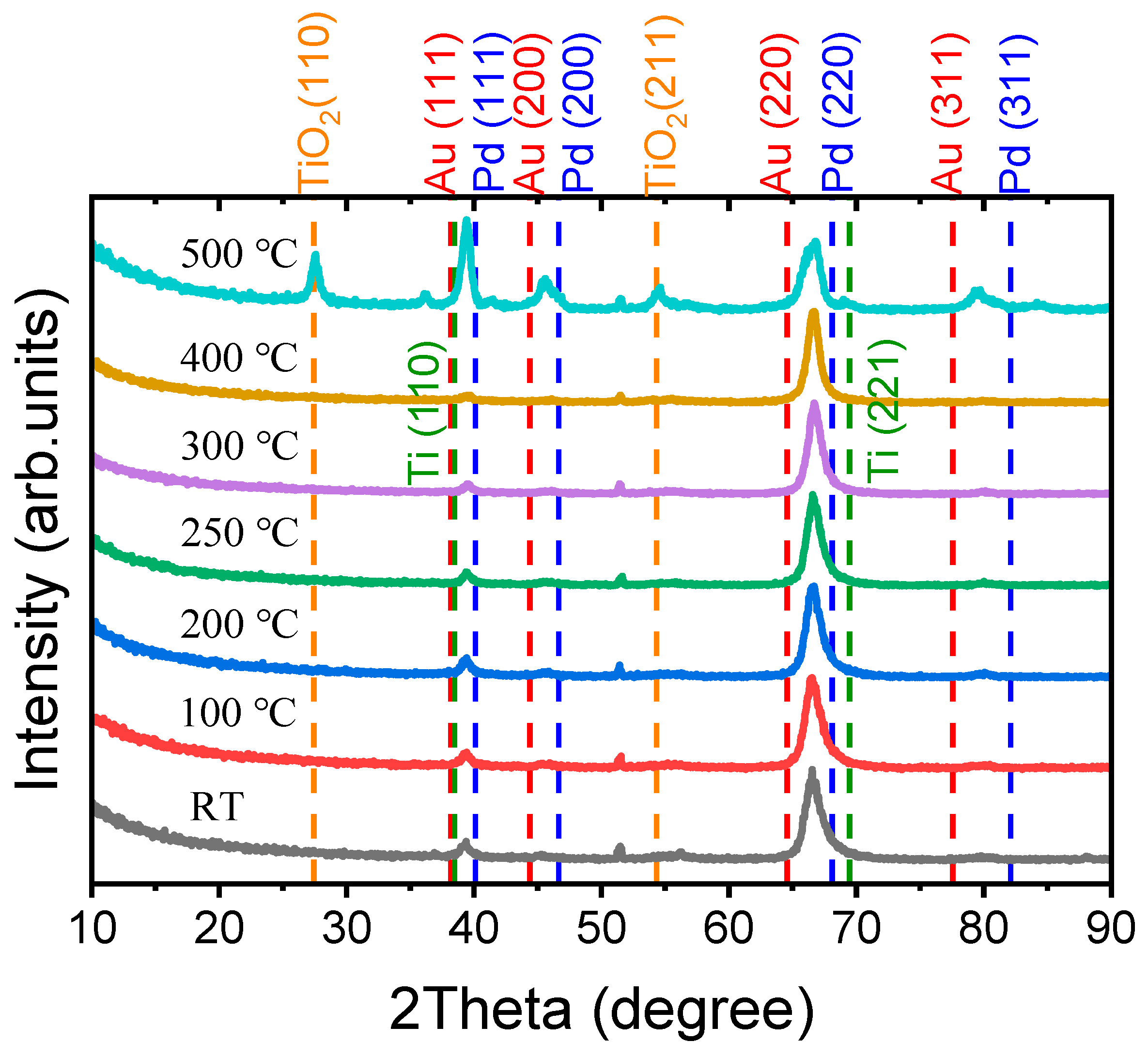

3.2. Structure and Phase

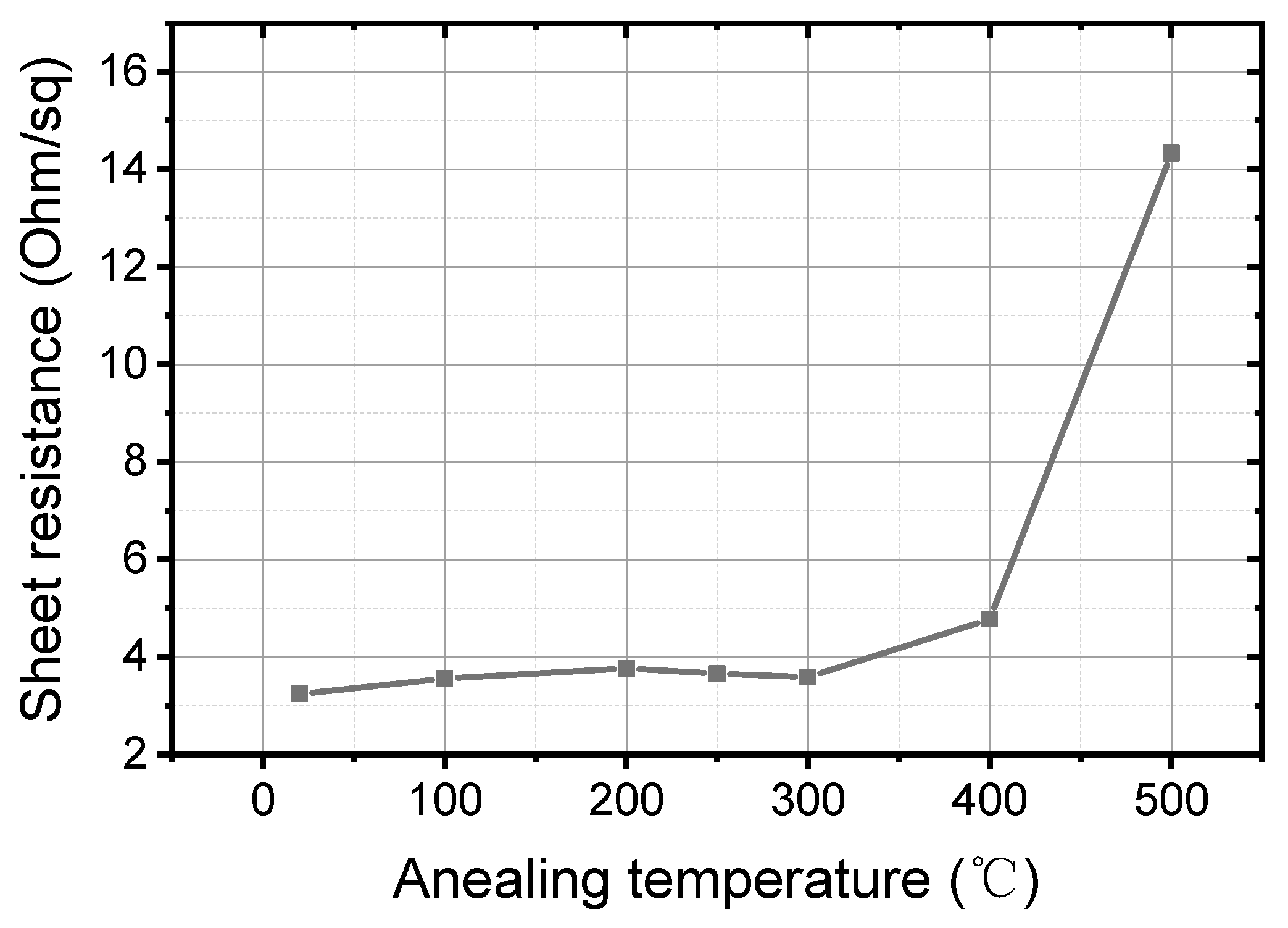

3.3. Electrical Property

3.4. Cryogenic Property

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lita, A.E.; Miller, A.J.; Nam, S.W. Counting near-infrared single-photons with 95% efficiency. Opt. Express 2008, 16, 3032. [Google Scholar] [CrossRef] [PubMed]

- Taralli, E.; Lolli, L.; Portesi, C.; Monticone, E.; Rajteri, M.; Wang, T.-S.; Chen, J.-K.; Zhou, X. Reduced Active Area in Transition-Edge Sensors for Visible-NIR Photon Detection: A Comparison of Experimental Data and Two-Fluid Model. IEEE Trans. Appl. Supercond. 2015, 25, 1–4. [Google Scholar] [CrossRef]

- Jaeckel, F.T.; Ambarish, C.V.; Christensen, N.; Gruenke, R.; Hu, L.; McCammon, D.; McPheron, M.; Meyer, M.; Nelms, K.L.; Roy, A.; et al. Energy Calibration of High-Resolution X-Ray TES Microcalorimeters with 3 eV Optical Photons. IEEE Trans. Appl. Supercond. 2019, 29, 3–6. [Google Scholar] [CrossRef] [PubMed]

- Jaeckel, F.T.; Le, L.N.; Martin, K.W.; Boyd, S.T.P. Development of a Precision Scanning Optical Pulser for Low-Temperature Particle Detectors. IEEE Trans. Appl. Supercond. 2013, 23, 1301005. [Google Scholar] [CrossRef]

- Enss, C. Cryogenic Particle Detection; Enss, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 94, ISBN 978-3-540-31478-3. [Google Scholar]

- Lolli, L.; Taralli, E.; Rajteri, M.; Numata, T.; Fukuda, D. Characterization of Optical Fast Transition-Edge Sensors With Optimized Fiber Coupling. IEEE Trans. Appl. Supercond. 2013, 23, 2100904. [Google Scholar] [CrossRef]

- Xu, X.; Li, J.; Wang, X.; Zhong, Q.; Zhong, Y.; Cao, W.; Li, W.; Chen, J.; Zhao, Z.; Gao, Y.; et al. Investigation of Superconducting Titanium films for Transition Edge Sensors. In Proceedings of the 2020 Conference on Precision Electromagnetic Measurements (CPEM), Denver, CO, USA, 24–28 August 2020; pp. 1–2. [Google Scholar]

- Bonetti, J.A.; Day, P.K.; Kenyon, M.; Kuo, C.L.; Turner, A.; LeDuc, H.G.; Bock, J.J. Characterization of antenna-coupled tes bolometers for the spider experiment. IEEE Trans. Appl. Supercond. 2009, 19, 520–523. [Google Scholar] [CrossRef]

- Portesi, C.; Taralli, E.; Lolli, L.; Rajteri, M.; Monticone, E. Fabrication and Characterization of Fast TESs With Small Area for Single Photon Counting. IEEE Trans. Appl. Supercond. 2015, 25, 1–4. [Google Scholar] [CrossRef]

- Vaccaro, D.; Siri, B.; Baldini, A.M.; Biasotti, M.; Cei, F.; Ceriale, V.; De Gerone, M.; Galli, L.; Gallucci, G.; Gatti, F.; et al. Tuning the TC of Titanium Thin Films for Transition-Edge Sensors by Annealing in Argon. J. Low Temp. Phys. 2018, 193, 1122–1128. [Google Scholar] [CrossRef]

- Fukuda, D.; Fujii, G.; Numata, T.; Amemiya, K.; Yoshizawa, A.; Tsuchida, H.; Fujino, H.; Ishii, H.; Itatani, T.; Inoue, S.; et al. Titanium-based transition-edge photon number resolving detector with 98% detection efficiency with index-matched small-gap fiber coupling. Opt. Express 2011, 19, 870. [Google Scholar] [CrossRef]

- Jaeckel, F.T.; Kripps, K.L.; Morgan, K.M.; Zhang, S.; McCammon, D. Fabrication of Superconducting Mo/Cu Bilayers Using Ion-Beam-Assisted e-Beam Evaporation. J. Low Temp. Phys. 2016, 184, 647–653. [Google Scholar] [CrossRef]

- Jaeckel, F.T.; Kripps, K.L.; McCammon, D.; Wulf, D.; Zhang, S.; Zhou, Y. Effects of Uniaxial Stress on Mo and Mo/Cu Bilayer Superconducting Transitions. IEEE Trans. Appl. Supercond. 2017, 27, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Parra-Borderias, M.; Fernandez-Martinez, I.; Fabrega, L.; Camon, A.; Gil, O.; Costa-Kramer, J.L.; Gonzalez-Arrabal, R.; Sese, J.; Bueno, J.; Briones, F. Characterization of a Mo/Au thermometer for ATHENA. IEEE Trans. Appl. Supercond. 2013, 23, 2300405. [Google Scholar] [CrossRef]

- Morgan, K.; Jaeckel, F.T.; Kripps, K.L.; McCammon, D. Ion-Beam-Assisted Deposition of Mo Thin Films for TES Applications. IEEE Trans. Appl. Supercond. 2015, 25, 1–5. [Google Scholar] [CrossRef]

- Lolli, L.; Taralli, E.; Portesi, C.; Rajteri, M.; Monticone, E. Aluminum–Titanium Bilayer for Near-Infrared Transition Edge Sensors. Sensors 2016, 16, 953. [Google Scholar] [CrossRef]

- Taralli, E.; Portesi, C.; Rocci, R.; Rajteri, M.; Monticone, E. Investigation of Ti/Pd bilayer for single photon detection. IEEE Trans. Appl. Supercond. 2009, 19, 493–495. [Google Scholar] [CrossRef]

- Wakeham, N.A.; Adams, J.S.; Bandler, S.R.; Chervenak, J.A.; Datesman, A.M.; Eckart, M.E.; Finkbeiner, F.M.; Kelley, R.L.; Kilbourne, C.A.; Miniussi, A.R.; et al. Effects of Normal Metal Features on Superconducting Transition-Edge Sensors. J. Low Temp. Phys. 2018, 193, 231–240. [Google Scholar] [CrossRef]

- Hilton, G.C.; Martinis, J.M.; Irwin, K.D.; Bergren, N.F.; Wollman, D.A.; Huber, M.E.; Deiker, S.; Nam, S.W. Microfabricated transition-edge X-ray detectors. IEEE Trans. Appl. Supercond. 2001, 11, 739–742. [Google Scholar] [CrossRef]

- Kuromaru, G.; Kuwabara, K.; Miyazaki, N.; Suzuki, S.; Hosoya, S.; Koizumi, Y.; Ohashi, T.; Ishisaki, Y.; Ezoe, Y.; Yamada, S.; et al. Investigation of Surface Roughness Effect on Transition Edge Sensor Microcalorimeters Using Multilayer Readout Wiring. J. Low Temp. Phys. 2016, 184, 38–44. [Google Scholar] [CrossRef]

- Sadleir, J.E.; Smith, S.J.; Robinson, I.K.; Finkbeiner, F.M.; Chervenak, J.A.; Bandler, S.R.; Eckart, M.E.; Kilbourne, C.A. Proximity effects and nonequilibrium superconductivity in transition-edge sensors. Phys. Rev. B Condens. Matter Mater. Phys. 2011, 84, 1–9. [Google Scholar] [CrossRef]

- Martinis, J.M.; Hilton, G.C.; Irwin, K.D.; Wollman, D.A. Calculation of TC in a normal-superconductor bilayer using the microscopic-based Usadel theory. Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2000, 444, 23–27. [Google Scholar] [CrossRef]

- Portesi, C.; Taralli, E.; Rocci, R.; Rajteri, M.; Monticone, E. Fabrication of Au/Ti TESs for optical photon counting. J. Low Temp. Phys. 2008, 151, 261–265. [Google Scholar] [CrossRef]

- Lolli, L.; Taralli, E.; Rajteri, M. Ti/Au TES to Discriminate Single Photons. J. Low Temp. Phys. 2012, 167, 803–808. [Google Scholar] [CrossRef]

- Lolli, L.; Taralli, E.; Portesi, C.; Alberto, D.; Rajteri, M.; Monticone, E. Ti/Au transition-edge sensors coupled to single mode optical fibers aligned by Si V-groove. IEEE Trans. Appl. Supercond. 2011, 21, 215–218. [Google Scholar] [CrossRef]

- Taralli, E.; Gottardi, L.; Nagayoshi, K.; Ridder, M.; Visser, S.; Khosropanah, P.; Akamatsu, H.; van der Kuur, J.; Bruijn, M.; Gao, J.R. Characterization of High Aspect-Ratio TiAu TES X-ray Microcalorimeter Array Under AC Bias. J. Low Temp. Phys. 2020, 199, 80–87. [Google Scholar] [CrossRef]

- Van Der Heijden, N.J.; Khosropanah, P.; Van Der Kuur, J.; Ridder, M.L. Diffusion behaviour in superconducting Ti/Au bilayers for SAFARI TES detectors. J. Low Temp. Phys. 2014, 176, 370–375. [Google Scholar] [CrossRef]

- Taralli, E.; Pobes, C.; Khosropanah, P.; Fabrega, L.; Camón, A.; Gottardi, L.; Nagayoshi, K.; Ridder, M.L.; Bruijn, M.P.; Gao, J.R. AC/DC Characterization of a Ti/Au TES with Au/Bi Absorber for X-ray Detection. J. Low Temp. Phys. 2020, 199, 102–109. [Google Scholar] [CrossRef]

- Nagayoshi, K.; Ridder, M.L.; Bruijn, M.P.; Gottardi, L.; Taralli, E.; Khosropanah, P.; Akamatsu, H.; Visser, S.; Gao, J.R. Development of a Ti/Au TES Microcalorimeter Array as a Backup Sensor for the Athena/X-IFU Instrument. J. Low Temp. Phys. 2020, 199, 943–948. [Google Scholar] [CrossRef]

- Kengo, K.; Ezoe, Y.; Kitazawa, S.; Hayakawa, R.; Nunomura, K.; Ohashi, T.; Ishisaki, Y.; Yamada, S.; Hidaka, M.; Satoh, T.; et al. Study of Surface Roughness Effect on Super–Normal Transition of Ti/Au Transition Edge Sensor Calorimeters. J. Low Temp. Phys. 2018, 193, 349–355. [Google Scholar] [CrossRef]

- Carter, F.W.; Ade, P.A.R.; Ahmed, Z.; Anderson, A.J.; Austermann, J.E.; Avva, J.S.; Thakur, R.B.; Bender, A.N.; Benson, B.A.; Carlstrom, J.E.; et al. Tuning SPT-3G Transition-Edge-Sensor Electrical Properties with a Four-Layer Ti–Au–Ti–Au Thin-Film Stack. J. Low Temp. Phys. 2018, 193, 695–702. [Google Scholar] [CrossRef]

- Ridder, M.L.; Nagayoshi, K.; Bruijn, M.P.; Gottardi, L.; Taralli, E.; Khosropanah, P.; Akamatsu, H.; van der Kuur, J.; Ravensberg, K.; Visser, S.; et al. Study of TES Detector Transition Curve to Optimize the Pixel Design for Frequency-Division Multiplexing Readout. J. Low Temp. Phys. 2020, 199, 962–967. [Google Scholar] [CrossRef]

- Xu, J.; Guo, S.; Jia, L.; Zhang, W. Palygorskite supported AuPd alloy nanoparticles as efficient nano-catalysts for the reduction of nitroarenes and dyes at room temperature. Nanomaterials 2018, 8, 1000. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, T.J.; Jusys, Z.; Gasteiger, H.A.; Behm, R.J.; Endruschat, U.; Boennemann, H. On the CO tolerance of novel colloidal PdAu/carbon electrocatalysts. J. Electroanal. Chem. 2001, 501, 132–140. [Google Scholar] [CrossRef]

- Feng, Y.Y.; Liu, Z.H.; Xu, Y.; Wang, P.; Wang, W.H.; Kong, D.S. Highly active PdAu alloy catalysts for ethanol electro-oxidation. J. Power Sources 2013, 232, 99–105. [Google Scholar] [CrossRef]

- Geraldes, A.N.; Da Silva, D.F.; Pino, E.S.; Da Silva, J.C.M.; De Souza, R.F.B.; Hammer, P.; Spinacé, E.V.; Neto, A.O.; Linardi, M.; Dos Santos, M.C. Ethanol electro-oxidation in an alkaline medium using Pd/C, Au/C and PdAu/C electrocatalysts prepared by electron beam irradiation. Electrochim. Acta 2013, 111, 455–465. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Rajteri, M.; Li, J.; Zhang, S.; Chen, J.; Monticone, E.; Zhong, Q.; Gao, H.; Li, W.; Li, X.; et al. Influence of the Interface Composition to the Superconductivity of Ti/PdAu Films. Nanomaterials 2021, 11, 39. https://doi.org/10.3390/nano11010039

Xu X, Rajteri M, Li J, Zhang S, Chen J, Monticone E, Zhong Q, Gao H, Li W, Li X, et al. Influence of the Interface Composition to the Superconductivity of Ti/PdAu Films. Nanomaterials. 2021; 11(1):39. https://doi.org/10.3390/nano11010039

Chicago/Turabian StyleXu, Xiaolong, Mauro Rajteri, Jinjin Li, Shuo Zhang, Jian Chen, Eugenio Monticone, Qing Zhong, Huifang Gao, Wei Li, Xu Li, and et al. 2021. "Influence of the Interface Composition to the Superconductivity of Ti/PdAu Films" Nanomaterials 11, no. 1: 39. https://doi.org/10.3390/nano11010039

APA StyleXu, X., Rajteri, M., Li, J., Zhang, S., Chen, J., Monticone, E., Zhong, Q., Gao, H., Li, W., Li, X., Li, Q., Zhong, Y., Cao, W., Wang, S., Gao, Y., Liu, Z., & Wang, X. (2021). Influence of the Interface Composition to the Superconductivity of Ti/PdAu Films. Nanomaterials, 11(1), 39. https://doi.org/10.3390/nano11010039