Extensive Broadband Near-Infrared Emissions from GexSi1−x Alloys on Micro-Hole Patterned Si(001) Substrates

Abstract

:1. Introduction

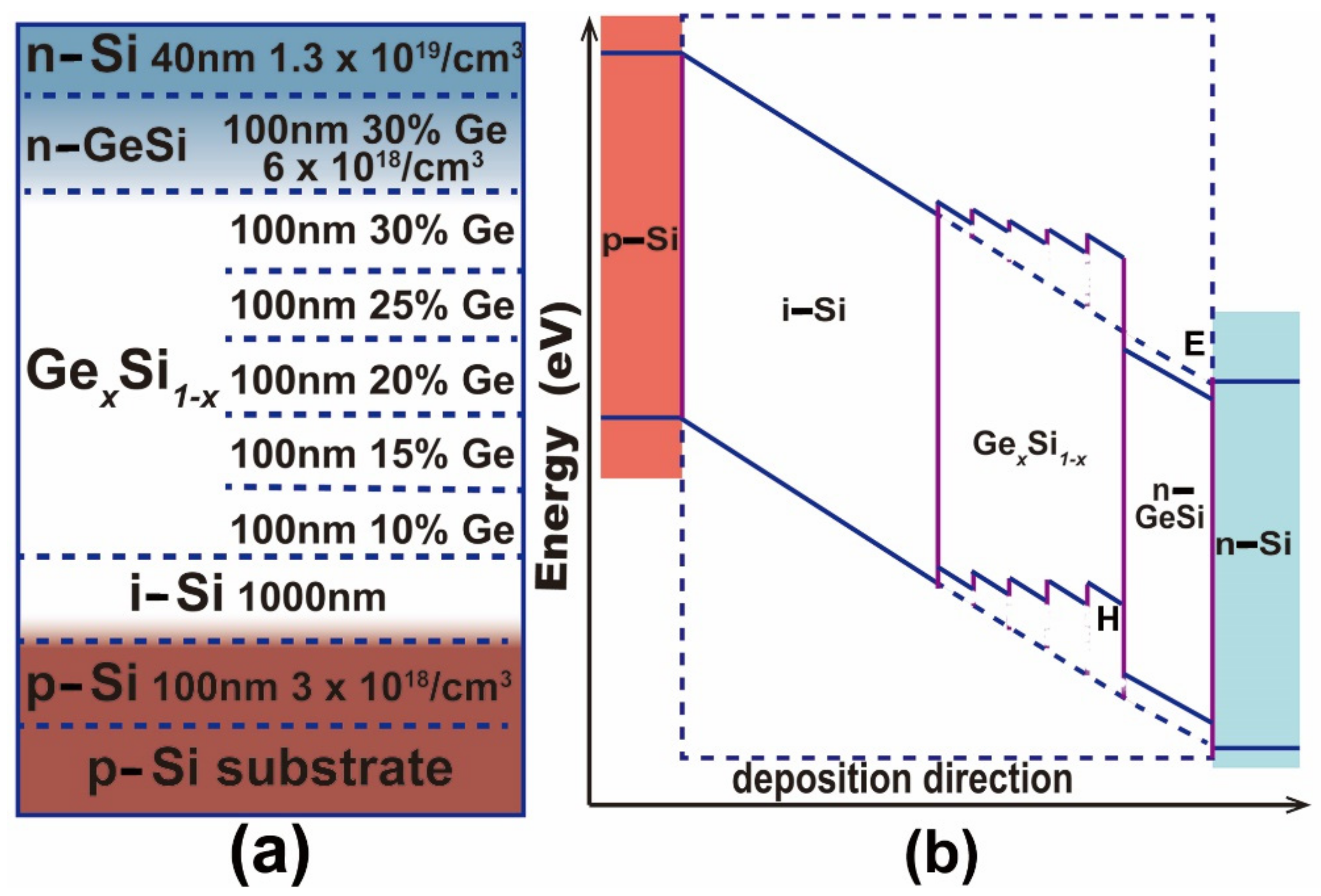

2. Materials and Methods

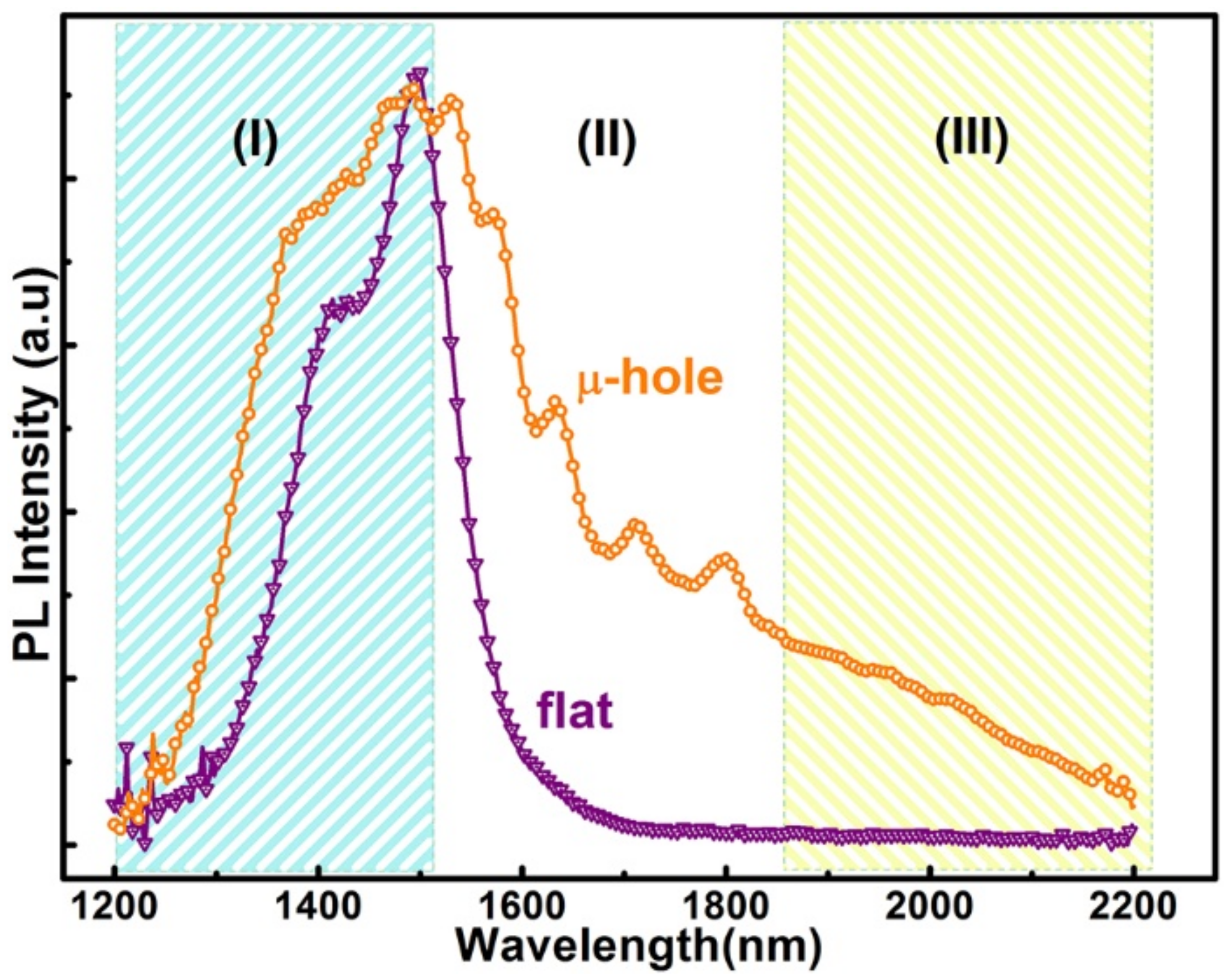

3. Results and Discussion

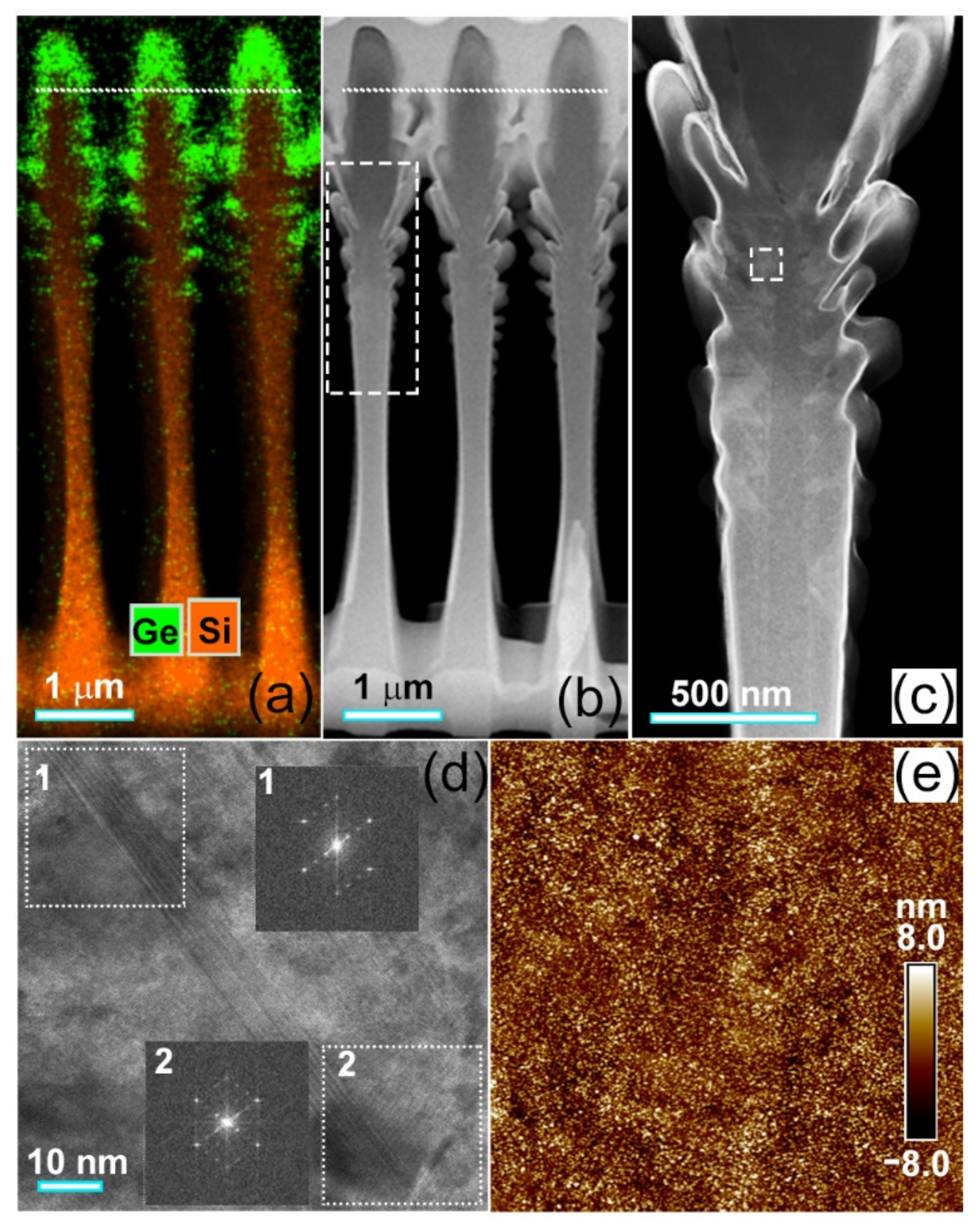

3.1. Morphologies and Structure Properties

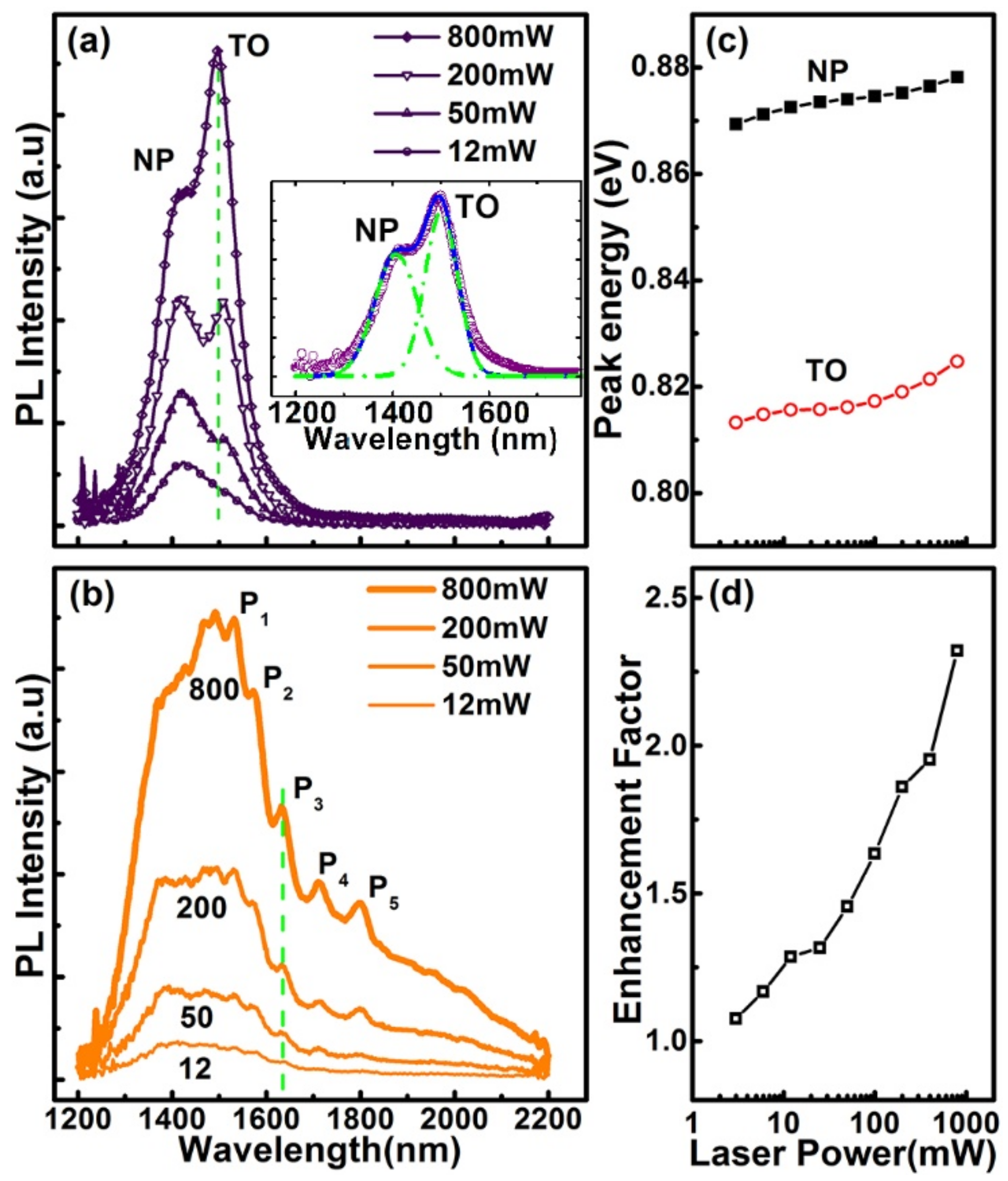

3.2. Power Dependent PL Spectra

3.3. FDTD Simulations

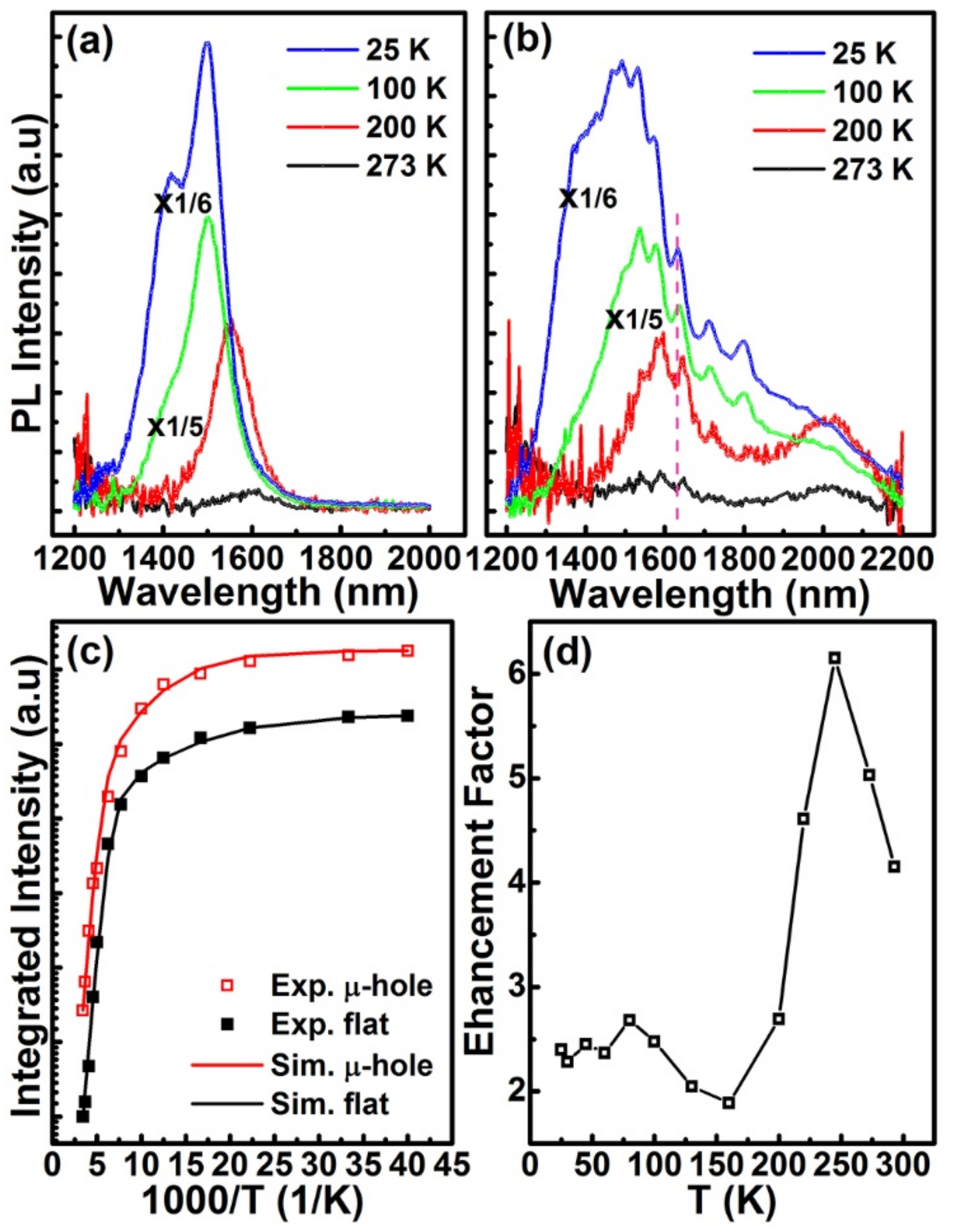

3.4. Temperature Dependent PL Spectra

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, L.; Choi, J.J.; Stachnik, D.; Bartnik, A.C.; Hyun, B.; Malliaras, G.G.; Hanrath, T.; Wise, F.W. Bright infrared quantum-dot light-emitting diodes through inter-dot spacing control. Nat. Nanotechnol. 2012, 7, 369–373. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.; Zhou, G.; Zhou, Y.; Zhang, Q.; Xia, Z. Divalent europium-doped near-infrared-emitting phosphor for light-emitting diodes. Nat. Commun. 2019, 10, 5267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goossens, S.; Navickaite, G.; Monasterio, C.; Gupta, S.; Piqueras, J.J.; Pérez, R.; Burwell, G.; Nikitskiy, I.; Lasanta, T.; Galán, T.; et al. Broadband image sensor array based on graphene–CMOS integration. Nat. Photonics 2017, 11, 366–371. [Google Scholar] [CrossRef]

- Pradhan, S.; Dalmases, M.; Konstantatos, G. Solid-State Thin-Film Broadband Short-Wave Infrared Light Emitters. Adv. Mater. 2020, 32, 2003830. [Google Scholar] [CrossRef]

- He, S.; Zhang, L.; Wu, H.; Wu, H.; Pan, G.; Hao, Z.; Zhang, X.; Zhang, L.; Zhang, H.; Zhang, J. Efficient Super Broadband NIR Ca2LuZr2Al3O12:Cr3+,Yb3+ Garnet Phosphor for pc-LED Light Source toward NIR Spectroscopy Applications. Adv. Optical Mater. 2020, 8, 1901684. [Google Scholar] [CrossRef]

- Medintz, I.L.; Uyeda, H.T.; Goldman, E.R.; Mattoussi, H. Quantum dot bioconjugates for imaging, labelling and sensing. Nat. Mater. 2005, 4, 435–446. [Google Scholar] [CrossRef]

- Thimsen, E.; Sadtler, B.; Berezin, M.Y. Shortwave-infrared (SWIR) emitters for biological imaging: A review of challenges and opportunities. Nanophotonics 2017, 6, 1043–1054. [Google Scholar] [CrossRef]

- Eggebrecht, A.T.; Ferradal, S.L.; Robichaux-Viehoever, A.; Hassanpour, M.S.; Dehghani, H.; Snyder, A.Z.; Hershey, T.; Culver, J.P. Mapping distributed brain function and networks with diffuse optical tomography. Nat. Photonics 2014, 8, 448–454. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, D.; van Dongen, A.M.; Boerekamp, J.; Spoor, S.; Lucassen, G.; Schleipen, J. A broadband LED source in visible to short-wave-infrared wavelengths for spectral tumor diagnostics. Appl. Phys. Lett. 2017, 110, 233701. [Google Scholar] [CrossRef]

- Basore, E.T.; Xiao, W.; Liu, X.; Wu, J.; Qiu, J. Broadband Near-Infrared Garnet Phosphors with Near-Unity Internal Quantum Efficiency. Adv. Optical Mater. 2020, 8, 2000296. [Google Scholar] [CrossRef]

- Gao, L.; Quan, L.; García de Arquer, F.P.; Zhao, Y.; Munir, R.; Proppe, A.; Quintero-Bermudez, R.; Zou, C.; Yang, Z.; Saidaminov, M.I.; et al. Efficient near-infrared light-emitting diodes based on quantum dots in layered perovskite. Nat. Photonics 2020, 14, 227. [Google Scholar] [CrossRef]

- Atabaki, A.H.; Moazeni, S.; Pavanello, F.; Gevorgyan, H.; Notaros, J.; Alloatti, L.; Wade, M.T.; Sun, C.; Kruger, S.A.; Meng, H.; et al. Integrating photonics with silicon nanoelectronics for the next generation of systems on a chip. Nature 2018, 556, 349. [Google Scholar] [CrossRef]

- Knight, M.W.; Sobhani, H.; Nordlander, P.; Halas, N.J. Photodetection with Active Optical Antennas. Science 2011, 332, 702. [Google Scholar] [CrossRef] [PubMed]

- Ackert, J.J.; Karar, A.S.; Paez, D.J.; Jessop, P.E.; Cartledge, J.C.; Knights, A.P. 10 Gbps silicon waveguide-integrated infrared avalanche photodiode. Opt. Express 2013, 21, 19530. [Google Scholar] [CrossRef]

- Zou, H.; Li, X.; Dai, G.; Peng, W.; Ding, Y.; Zhang, Y.; Wang, A.C.; Zhang, S.L.; Xu, C.; Zhang, S.; et al. Dramatically Enhanced Broadband Photodetection by Dual Inversion Layers and Fowler-Nordheim Tunneling. ACS Nano 2019, 13, 2289–2297. [Google Scholar] [CrossRef] [PubMed]

- Katiyar, A.K.; Thai, K.Y.; Yun, W.S.; Lee, J.; Ahn, J. Breaking the absorption limit of Si toward SWIR wavelength range via strain engineering. Sci. Adv. 2020, 6, eabb0576. [Google Scholar] [CrossRef] [PubMed]

- Atalla, M.R.M.; Assali, S.; Attiaoui, A.; Lemieux-Leduc, C.; Kumar, A.; Abdi, S.; Moutanabbir, O. All-Group IV Transferable Membrane Mid-Infrared Photodetectors. Adv. Funct. Mater. 2020, 31, 2006329. [Google Scholar] [CrossRef]

- Kruck, P.; Helm, M.; Fromherz, T.; Bauer, G.; Nutzel, J.F.; Abstreiter, G. Mediumwavelength, normalincidence, ptype Si/SiGe quantum well infrared photodetector with background limited performance up to 85 K. Appl. Phys. Lett. 1996, 69, 3372–3374. [Google Scholar] [CrossRef]

- Krapf, D.; Adoram, B.; Shappir, J.; Sa’ar, A.; Thomas, S.G.; Liu, J.L.; Wang, K.L. Infrared multispectral detection using Si/Six Ge 1−x quantum well infrared Photodetectors. Appl. Phys. Lett. 2001, 78, 495–497. [Google Scholar] [CrossRef] [Green Version]

- Rauter, P.; Fromherz, T.; Falub, C.; Grutzmacher, D.; Bauer, G. SiGe quantum well infrared photodetectors on pseudosubstrate. Appl. Phys. Lett. 2009, 94, 081115. [Google Scholar] [CrossRef]

- Michel, J.; Liu, J.; Kimerling, L.C. High-performance Ge-on-Si photodetectors. Nat. Photonics 2010, 4, 527–534. [Google Scholar] [CrossRef]

- Rauter, P.; Mussler, G.; Grutzmacher, D.; Fromherz, T. Tensile strained SiGe quantum well infrared photodetectors based on a light-hole ground state. Appl. Phys. Lett. 2011, 98, 211106. [Google Scholar] [CrossRef] [Green Version]

- Bandara, S.V.; Gunapala, S.D.; Liu, J.K.; Rafol, S.B.; Hill, C.J.; Ting, D.Z.-Y.; Mumolo, J.M.; Trinh, T.Q.; Fastenau, J.M.; Liu, A.W.K. Tuning and tailoring of broadband quantum-well infrared photodetector responsivity Spectrum. Appl. Phys. Lett. 2005, 86, 151104. [Google Scholar] [CrossRef] [Green Version]

- Gallas, B.; Hartmann, J.M.; Berbezier, I.; Abdallah, M.; Zhang, J.; Harris, J.J.; Joyce, B.A. Influence of misfit and threading dislocations on the surface morphology of SiGe graded-layers. J. Cryst. Growth 1999, 201, 547–550. [Google Scholar] [CrossRef]

- Peng, K.; Zhang, N.; Chen, P.; Zhang, L.; Jiang, Z.; Zhong, Z. Manipulations of light by ordered micro-holes in silicon substrates. Opt. Express 2020, 28, 16151–16162. [Google Scholar] [CrossRef] [PubMed]

- Sutter, E.; Sutter, P.; Bernard, J.E. Extended shape evolution of low mismatch Si1−xGex alloy islands on Si(100). Appl. Phys. Lett. 2004, 84, 2262–2264. [Google Scholar] [CrossRef]

- Wan, J.; Jin, G.; Jiang, Z.; Luo, Y.; Liu, J.; Wang, K.L. Band alignments and photon-induced carrier transfer from wetting layers to Ge islands grown on Si(001). Appl. Phys. Lett. 2001, 78, 1763–1765. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Lei, H.; Zhou, T.; Fan, Y.; Zhong, Z. Fabrication and characterization of SiGe coaxial quantum wells on ordered Si nanopillars. Nanotechnology 2014, 25, 055204. [Google Scholar] [CrossRef] [PubMed]

- Venezuela, P.; Tersoff, J.; Floro, J.A.; Chason, E.; Follstaedt, D.M.; Liu, F.; Lagally, M.G. Self-organized growth of alloy superlattices. Nature 1999, 397, 678–681. [Google Scholar] [CrossRef] [Green Version]

- Aqua, J.-N.; Berbezier, I.; Favre, L.; Frisch, T.; Ronda, A. Growth and self-organization of SiGe nanostructures. Phys. Rep. 2013, 522, 59–189. [Google Scholar] [CrossRef]

- Gatti, R.; Uhlík, F.; Montalenti, F. Intermixing in heteroepitaxial islands: Fast, self-consistent calculation of the concentration profile minimizing the elastic energy. New J. Phys. 2008, 10, 083039. [Google Scholar] [CrossRef]

- Denker, U.; Stoffel, M.; Schmidt, O.G.; Sigg, H. Ge hut cluster luminescence below bulk Ge band gap. Appl. Phys. Lett. 2003, 82, 454–456. [Google Scholar] [CrossRef]

- Kamenev, B.V.; Lee, E.-K.; Chang, H.-Y.; Han, H.; Grebel, H.; Tsybeskov, L.; Kamins, T.I. Excitation-dependent photoluminescence in Ge Si Stranski-Krastanov nanostructures. Appl. Phys. Lett. 2006, 89, 153106. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Yin, Y.; Liu, T.; Lin, D.; Li, D.; Yang, X.; Jiang, Z.; Zhong, Z. Promising features of low-temperature grown Ge nanostructures on Si(001) Substrates. Nanotechnology 2017, 28, 115701. [Google Scholar] [CrossRef] [PubMed]

- Takagahara, T.; Takeda, K. Theory of the quantum confinement effect on excitons in quantum dots of indirect-gap materials. Phys. Rev. B 1992, 46, 15578–15581. [Google Scholar] [CrossRef] [PubMed]

- Schatzl, M.; Hackl, F.; Glaser, M.; Rauter, P.; Brehm, M.; Spindlberger, L.; Simbula, A.; Galli, M.; Fromherz, T.; Schaffler, F. Enhanced telecom emission from single group-iv quantum dots by precise cmos-compatible positioning in photonic crystal cavities. ACS Photonics 2017, 4, 665–673. [Google Scholar] [CrossRef] [PubMed]

- Tong, S.; Liu, J.L.; Wan, J.; Wang, K.L. Normal-incidence Ge quantum-dot photodetectors at 1.5 μm based on Si substrate. Appl. Phys. Lett. 2002, 80, 1189–1191. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, K.; Zhang, N.; Zhang, J.; Chen, P.; Yan, J.; Zheng, C.; Jiang, Z.; Zhong, Z. Extensive Broadband Near-Infrared Emissions from GexSi1−x Alloys on Micro-Hole Patterned Si(001) Substrates. Nanomaterials 2021, 11, 2545. https://doi.org/10.3390/nano11102545

Peng K, Zhang N, Zhang J, Chen P, Yan J, Zheng C, Jiang Z, Zhong Z. Extensive Broadband Near-Infrared Emissions from GexSi1−x Alloys on Micro-Hole Patterned Si(001) Substrates. Nanomaterials. 2021; 11(10):2545. https://doi.org/10.3390/nano11102545

Chicago/Turabian StylePeng, Kun, Ningning Zhang, Jiarui Zhang, Peizong Chen, Jia Yan, Changlin Zheng, Zuimin Jiang, and Zhenyang Zhong. 2021. "Extensive Broadband Near-Infrared Emissions from GexSi1−x Alloys on Micro-Hole Patterned Si(001) Substrates" Nanomaterials 11, no. 10: 2545. https://doi.org/10.3390/nano11102545