Low-Temperature Fabrication of IZO Thin Film for Flexible Transistors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Precursor Synthesis

2.2. Film Fabrication and Characterization

2.3. Characterizations

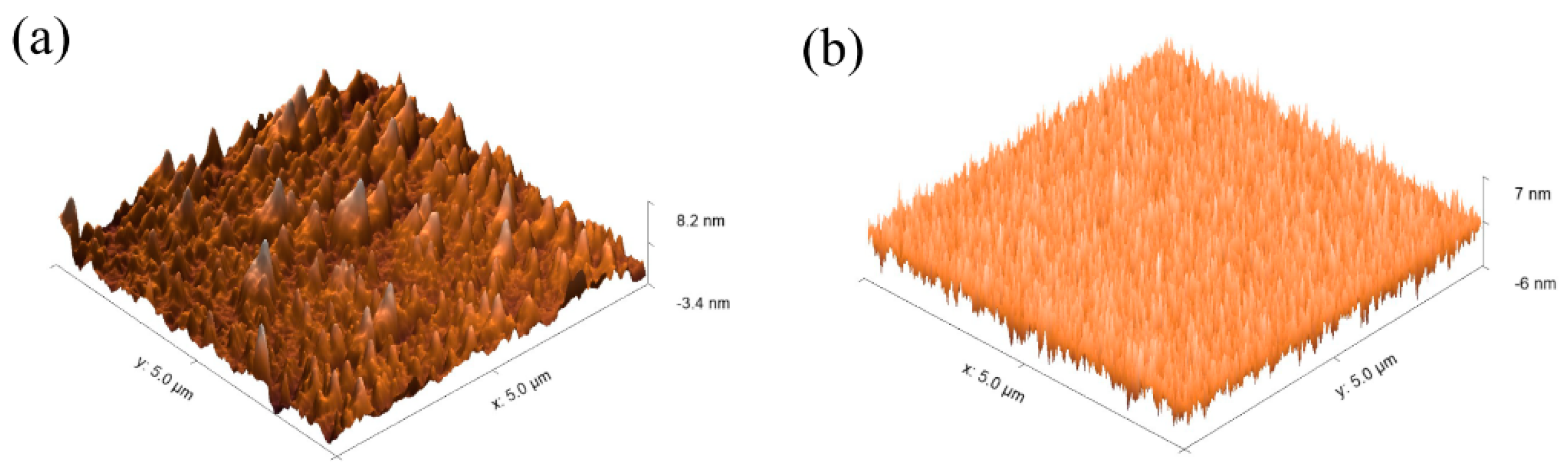

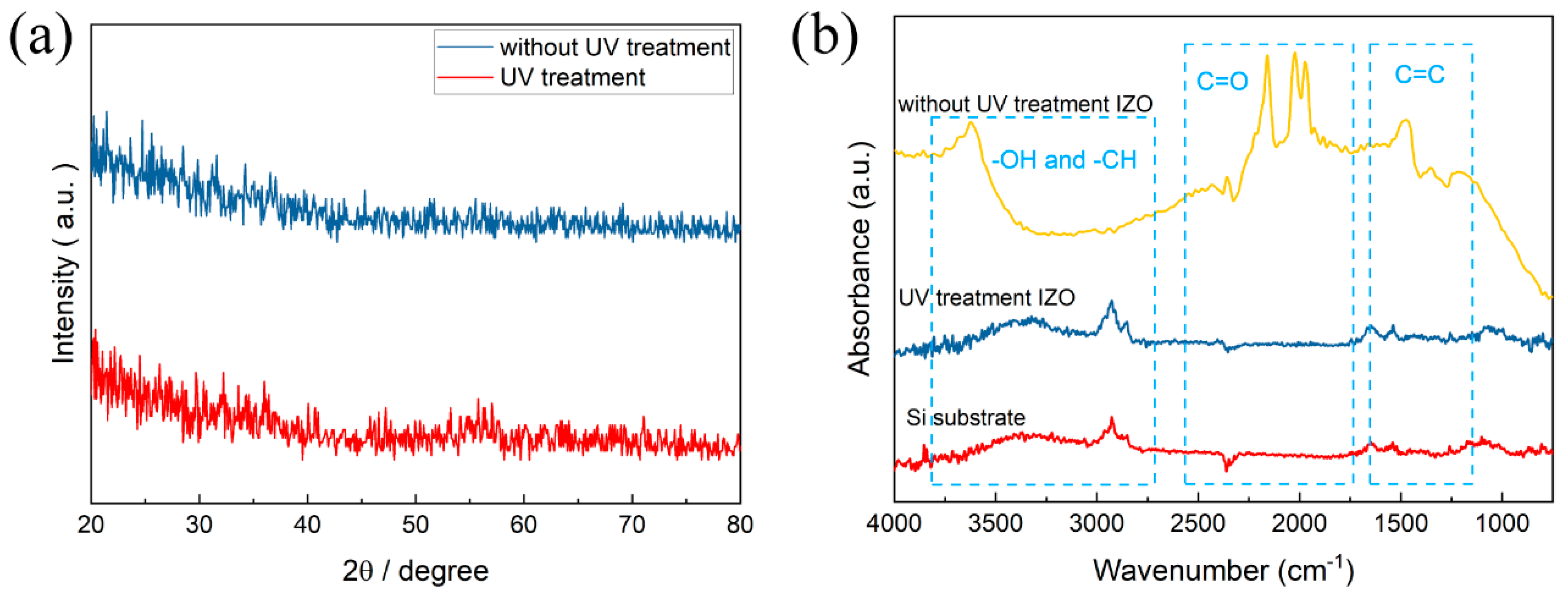

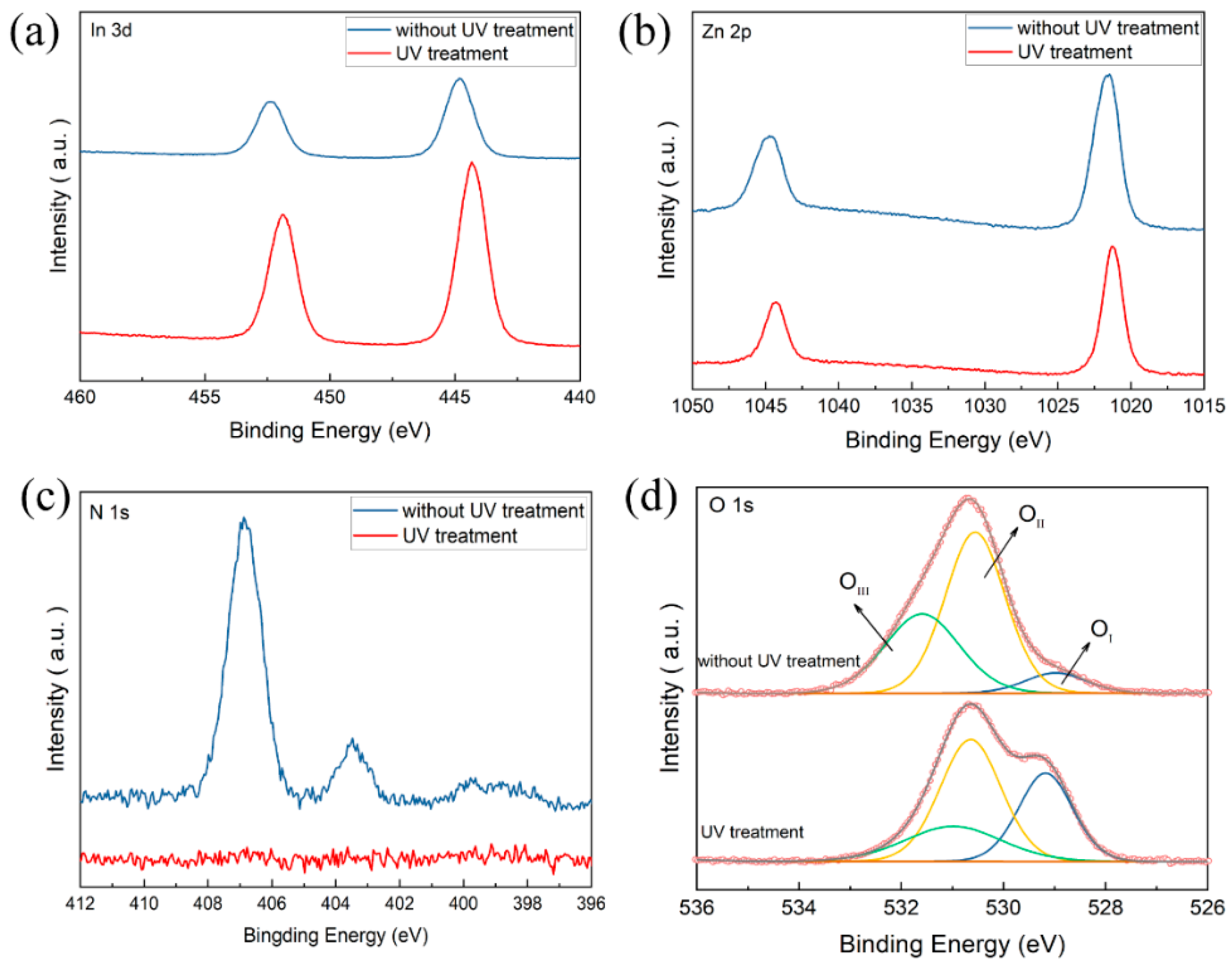

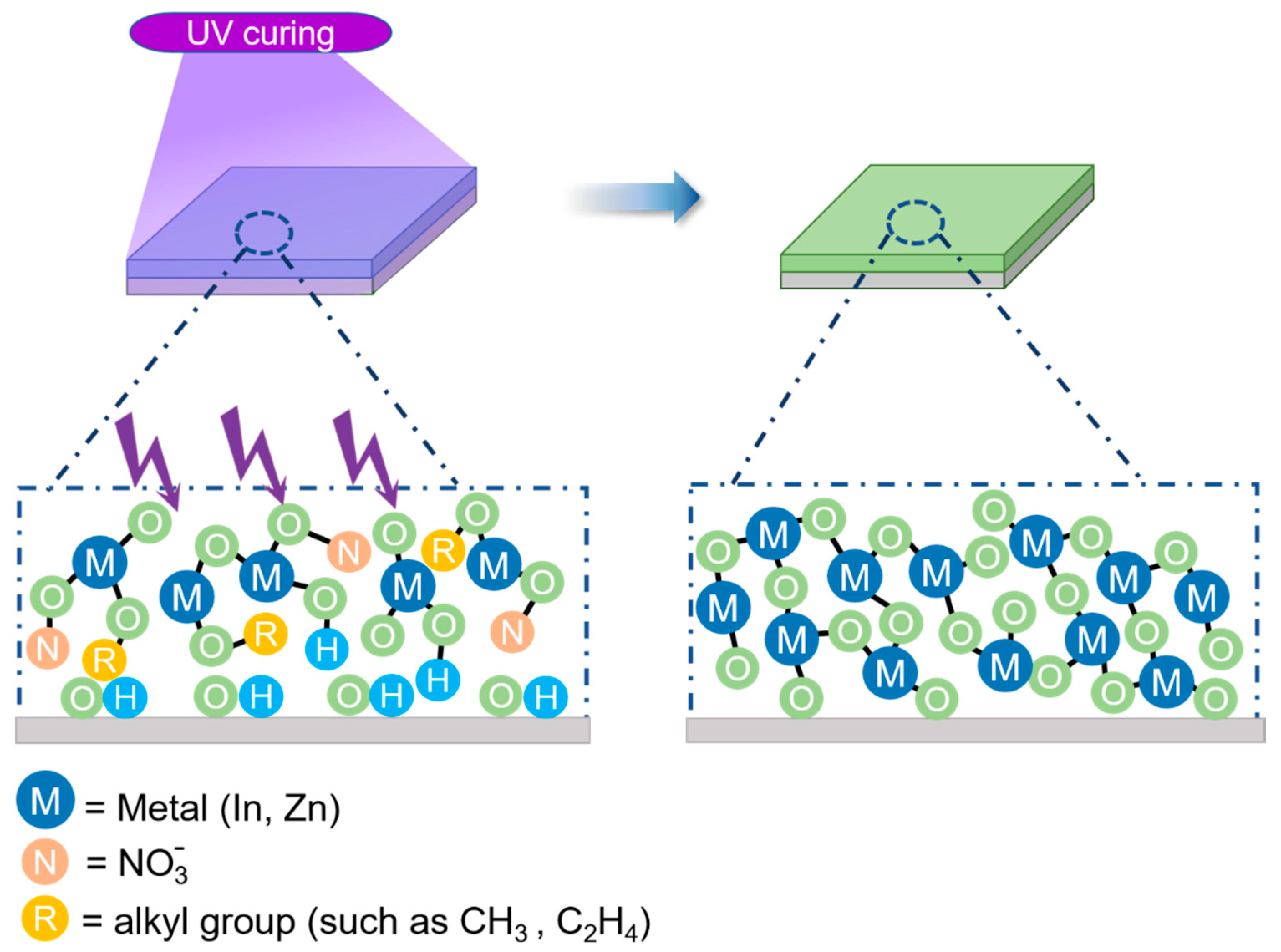

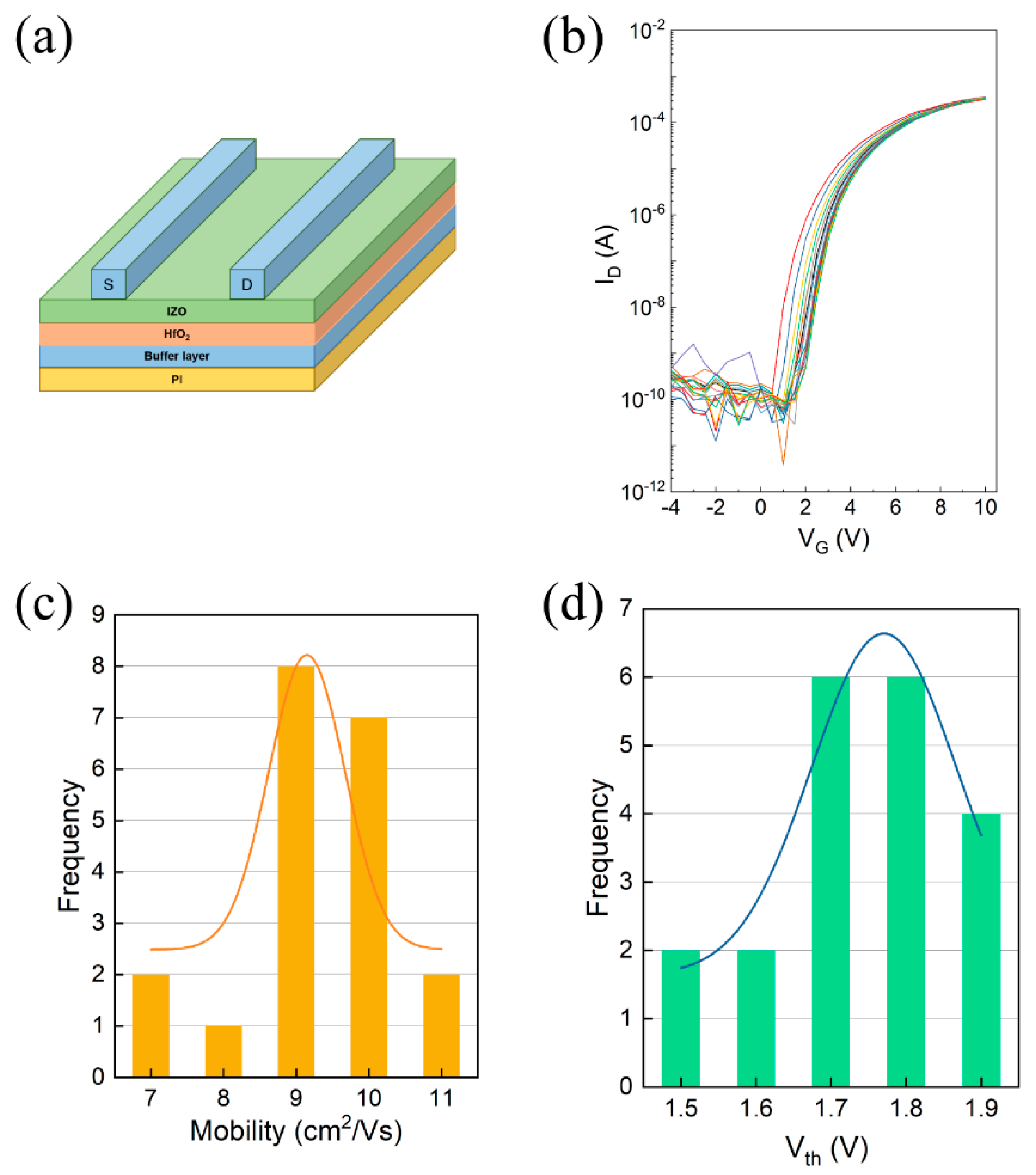

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hwang, Y.H.; Seo, J.-S.; Yun, J.M.; Park, H.; Yang, S.; Park, S.-H.K.; Bae, B.-S. An ‘aqueous route’ for the fabrication of low-temperature-processable oxide flexible transparent thin-film transistors on plastic substrates. Npg Asia Mater. 2013, 5, e45. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; He, K.; Chen, G.; Leow, W.R.; Chen, X. Nature-inspired structural materials for flexible electronic devices. Chem. Rev. 2017, 117, 12893–12941. [Google Scholar] [CrossRef]

- Ahmed, S.; Yi, J. Two-dimensional transition metal dichalcogenides and their charge carrier mobilities in field-effect transistors. Nano-Micro Lett. 2017, 9, 1–23. [Google Scholar] [CrossRef]

- Liu, A.; Zhu, H.; Noh, Y.-Y. Solution-processed inorganic p-channel transistors: Recent advances and perspectives. Mater. Sci. Eng. R Rep. 2019, 135, 85–100. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Qin, C.; Ding, X.; Zhang, J. Enhanced Stability in Zr-Doped ZnO TFTs With Minor Influence on Mobility by Atomic Layer Deposition. IEEE Trans. Electron Devices 2019, 66, 1760–1765. [Google Scholar] [CrossRef]

- Paterson, A.F.; Singh, S.; Fallon, K.J.; Hodsden, T.; Han, Y.; Schroeder, B.C.; Bronstein, H.; Heeney, M.; McCulloch, I.; Anthopoulos, T.D. Recent progress in high-mobility organic transistors: A reality check. Adv. Mater. 2018, 30, 1801079. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Tang, W.; Wang, Q.; Sun, W.; Zhang, Q.; Guo, X.; Wang, X.; Yan, F. Solution-processable organic and hybrid gate dielectrics for printed electronics. Mater. Sci. Eng. R Rep. 2018, 127, 1–36. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.H.; Kim, H.J. A review of low-temperature solution-processed metal oxide thin-film transistors for flexible electronics. Adv. Funct. Mater. 2020, 30, 1904632. [Google Scholar] [CrossRef]

- Park, S.; Kim, K.H.; Jo, J.W.; Sung, S.; Kim, K.T.; Lee, W.J.; Kim, J.; Kim, H.J.; Yi, G.R.; Kim, Y.H. In-Depth Studies on Rapid Photochemical Activation of Various Sol–Gel Metal Oxide Films for Flexible Transparent Electronics. Adv. Funct. Mater. 2015, 25, 2807–2815. [Google Scholar] [CrossRef]

- Yang, J.; Wang, B.; Zhang, Y.; Ding, X.; Zhang, J. Low-temperature combustion synthesis and UV treatment processed p-type Li: NiO x active semiconductors for high-performance electronics. J. Mater. Chem. C 2018, 6, 12584–12591. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Heo, J.-S.; Kim, T.-H.; Park, S.; Yoon, M.-H.; Kim, J.; Oh, M.S.; Yi, G.-R.; Noh, Y.-Y.; Park, S.K. Flexible metal-oxide devices made by room-temperature photochemical activation of sol–gel films. Nature 2012, 489, 128–132. [Google Scholar] [CrossRef]

- Wang, B.; Huang, W.; Chi, L.; Al-Hashimi, M.; Marks, T.J.; Facchetti, A. High-k gate dielectrics for emerging flexible and stretchable electronics. Chem. Rev. 2018, 118, 5690–5754. [Google Scholar] [CrossRef]

- Wang, Z.; Nayak, P.K.; Caraveo-Frescas, J.A.; Alshareef, H.N. Recent Developments in p-Type Oxide Semiconductor Materials and Devices. Adv. Mater. 2016, 28, 3831–3892. [Google Scholar] [CrossRef] [Green Version]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three Dimensional Surfaces: Basics and Applications; Napoca Star: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Mwema, F.M.; Akinlabi, E.T.; Oladijo, O.P.; Fatoba, O.S.; Akinlabi, S.A.; Tălu, S. Advances in manufacturing analysis: Fractal theory in modern manufacturing. In Modern Manufacturing Processes; Woodhead Publishing: Cambridge, UK, 2020; pp. 13–39. [Google Scholar]

- Ivanda, M.; Musić, S.; Popović, S.; Gotić, M. XRD, Raman and FT-IR spectroscopic observations of nanosized TiO2 synthesized by the sol–gel method based on an esterification reaction. J. Mol. Struct. 1999, 480, 645–649. [Google Scholar] [CrossRef]

- Umeda, K.; Miyasako, T.; Sugiyama, A.; Tanaka, A.; Suzuki, M.; Tokumitsu, E.; Shimoda, T. Impact of UV/O3 treatment on solution-processed amorphous InGaZnO4 thin-film transistors. J. Appl. Phys. 2013, 113, 184509. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Wu, Q.; Dussarrat, C.; Qi, J.; Zhu, W.; Ding, X.; Zhang, J. High-Performance 1-V ZnO Thin-Film Transistors With Ultrathin, ALD-Processed ZrO2 Gate Dielectric. IEEE Trans. Electron Devices 2019, 66, 3382–3386. [Google Scholar] [CrossRef]

- Liu, A.; Liu, G.; Shan, F.; Zhu, H.; Xu, S.; Liu, J.; Shin, B.; Lee, W. Room-temperature fabrication of ultra-thin ZrOx dielectric for high-performance InTiZnO thin-film transistors. Curr. Appl. Phys. 2014, 14, S39–S43. [Google Scholar] [CrossRef]

- Lee, E.; Ko, J.; Lim, K.H.; Kim, K.; Park, S.Y.; Myoung, J.M.; Kim, Y.S. Gate Capacitance-Dependent Field-Effect Mobility in Solution-Processed Oxide Semiconductor Thin-Film Transistors. Adv. Funct. Mater. 2014, 24, 4689–4697. [Google Scholar] [CrossRef]

- Xu, W.; Li, H.; Xu, J.-B.; Wang, L. Recent advances of solution-processed metal oxide thin-film transistors. ACS Appl. Mater. Interfaces 2018, 10, 25878–25901. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Che, B.; Yang, J.; Zhang, J.; Ding, X. A New “Ammonia Bath” Method for Realizing Nitrogen Doping in ZnSnO Transistors. IEEE Electron Device Lett. 2020, 41, 389–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Yang, J.; Ding, X.; Zhang, J. Solution-Processed Yttrium-Doped IZTO Semiconductors for High-Stability Thin Film Transistor Applications. IEEE Trans. Electron Devices 2019, 66, 5170–5176. [Google Scholar] [CrossRef]

- Xu, X.; Cui, Q.; Jin, Y.; Guo, X. Low-voltage zinc oxide thin-film transistors with solution-processed channel and dielectric layers below 150 C. Appl. Phys. Lett. 2012, 101, 222114. [Google Scholar] [CrossRef]

- John, R.A.; Chien, N.A.; Shukla, S.; Tiwari, N.; Shi, C.; Ing, N.G.; Mathews, N. Low-Temperature Chemical Transformations for High-Performance Solution-Processed Oxide Transistors. Chem. Mater. 2016, 28, 8305–8313. [Google Scholar] [CrossRef]

- Jallorina, M.P.A.; Bermundo, J.P.S.; Fujii, M.N.; Ishikawa, Y.; Uraoka, Y. Significant mobility improvement of amorphous In-Ga-Zn-O thin-film transistors annealed in a low temperature wet ambient environment. Appl. Phys. Lett. 2018, 112, 193501. [Google Scholar] [CrossRef] [Green Version]

- Safaruddin, A.S.; Bermundo, J.P.S.; Yoshida, N.; Nonaka, T.; Fujii, M.N.; Ishikawa, Y.; Uraoka, Y. Highly reliable low-temperature (180 °C) solution-processed passivation for amorphous In–Zn–O thin-film transistors. Appl. Phys. Express 2019, 12, 064002. [Google Scholar] [CrossRef]

- Kim, G.H.; Jeong, W.H.; Du Ahn, B.; Shin, H.S.; Kim, H.J.; Kim, H.J.; Ryu, M.-K.; Park, K.-B.; Seon, J.-B.; Lee, S.-Y. Investigation of the effects of Mg incorporation into InZnO for high-performance and high-stability solution-processed thin film transistors. Appl. Phys. Lett. 2010, 96, 163506. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, J.; Jeong, S.M.; Jeong, J. Storage-period dependent bias-stress instability of solution-processed amorphous indium–zinc-oxide thin-film transistors. Curr. Appl. Phys. 2015, 15, S64–S68. [Google Scholar] [CrossRef]

- Chiu, I.-C.; Cheng, I.-C. Gate-bias stress stability of p-type SnO thin-film transistors fabricated by RF-sputtering. IEEE Electron Device Lett. 2013, 35, 90–92. [Google Scholar] [CrossRef]

- Safaruddin, A.S.; Bermundo, J.P.S.; Yoshida, N.; Nonaka, T.; Fujii, M.N.; Ishikawa, Y.; Uraoka, Y. Improvement in Bias Stress Stability of Solution-Processed Amorphous InZnO Thin-Film Transistors via Low-Temperature Photosensitive Passivation. IEEE Electron Device Lett. 2020, 41, 1372–1375. [Google Scholar] [CrossRef]

- Liu, G.; Liu, A.; Zhu, H.; Shin, B.; Fortunato, E.; Martins, R.; Wang, Y.; Shan, F. Low-Temperature, Nontoxic Water-Induced Metal-Oxide Thin Films and Their Application in Thin-Film Transistors. Adv. Funct. Mater. 2015, 25, 2564–2572. [Google Scholar] [CrossRef]

- Koo, C.Y.; Song, K.; Jun, T.; Kim, D.; Jeong, Y.; Kim, S.-H.; Ha, J.; Moon, J. Low Temperature Solution-Processed InZnO Thin-Film Transistors. J. Electrochem. Soc. 2010, 157, J111. [Google Scholar] [CrossRef]

- Choi, J.; Park, J.; Lim, K.-H.; Cho, N.-k.; Lee, J.; Jeon, S.; Kim, Y.S. Photosensitivity of InZnO thin-film transistors using a solution process. Appl. Phys. Lett. 2016, 109, 132105. [Google Scholar] [CrossRef]

- Xu, W.; Long, M.; Zhang, T.; Liang, L.; Cao, H.; Zhu, D.; Xu, J.-B. Fully solution-processed metal oxide thin-film transistors via a low-temperature aqueous route. Ceram. Int. 2017, 43, 6130–6137. [Google Scholar] [CrossRef]

- Xia, W.; Xia, G.; Tu, G.; Dong, X.; Wang, S.; Liu, R. Sol-gel processed high-k aluminum oxide dielectric films for fully solution-processed low-voltage thin-film transistors. Ceram. Int. 2018, 44, 9125–9131. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, X.; Yang, B.; Xu, H.; Qi, J.; Li, X.; Zhang, J. Low-Temperature Fabrication of IZO Thin Film for Flexible Transistors. Nanomaterials 2021, 11, 2552. https://doi.org/10.3390/nano11102552

Ding X, Yang B, Xu H, Qi J, Li X, Zhang J. Low-Temperature Fabrication of IZO Thin Film for Flexible Transistors. Nanomaterials. 2021; 11(10):2552. https://doi.org/10.3390/nano11102552

Chicago/Turabian StyleDing, Xingwei, Bing Yang, Haiyang Xu, Jie Qi, Xifeng Li, and Jianhua Zhang. 2021. "Low-Temperature Fabrication of IZO Thin Film for Flexible Transistors" Nanomaterials 11, no. 10: 2552. https://doi.org/10.3390/nano11102552