Spectral Characteristics Simulation of Topological Micro-Nano Structures Based on Finite Difference Time Domain Method

Abstract

:1. Introduction

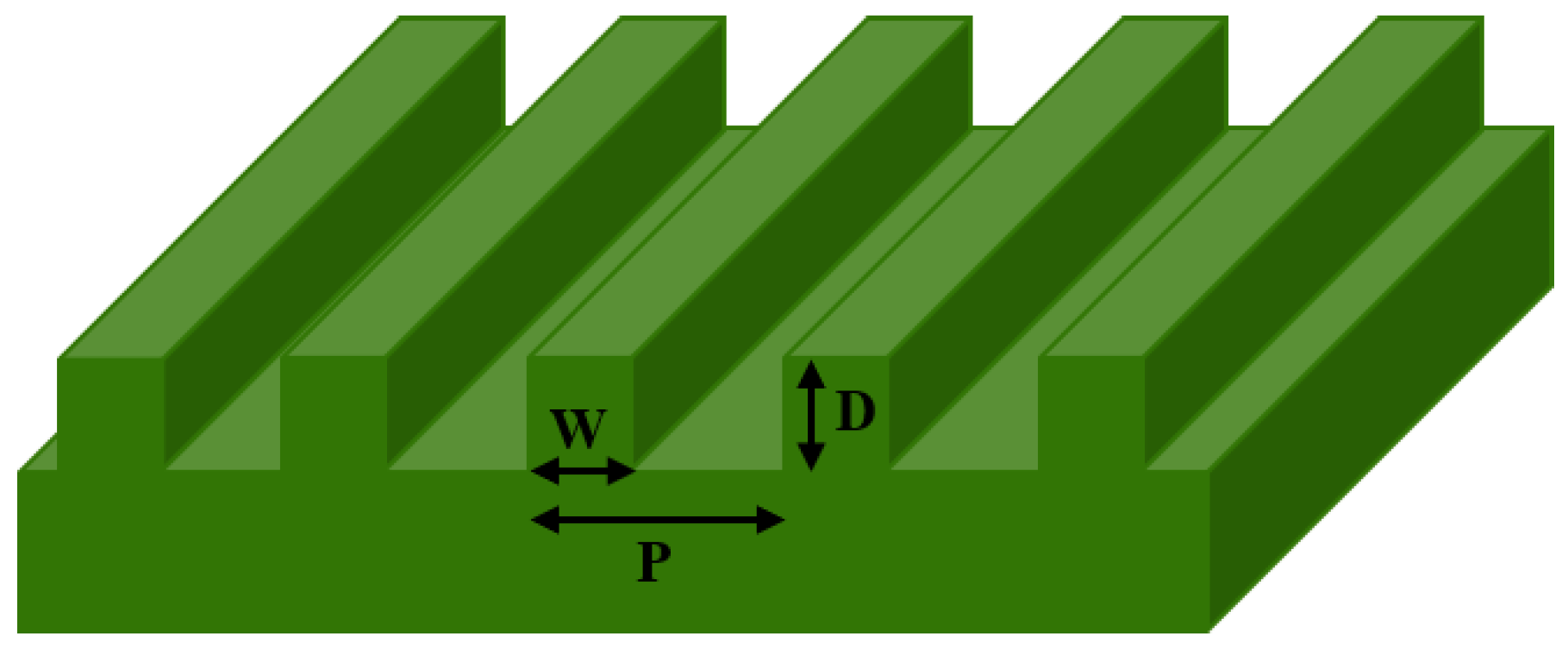

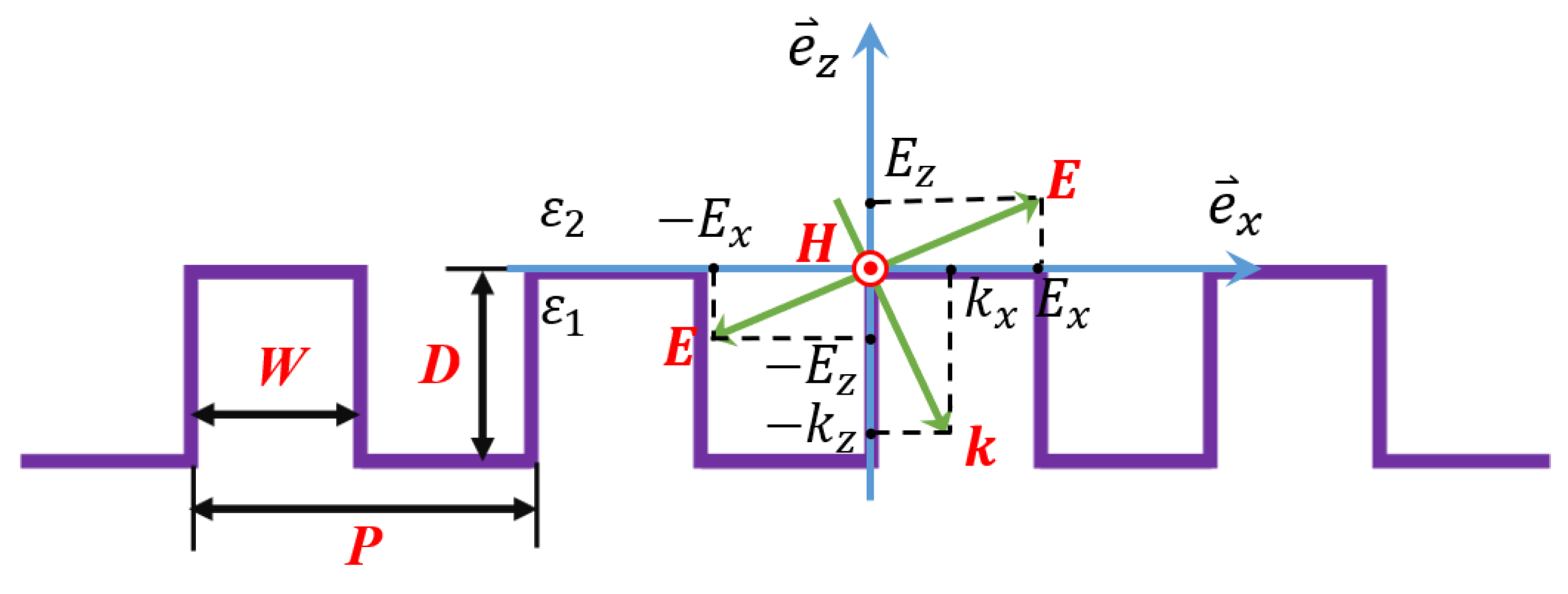

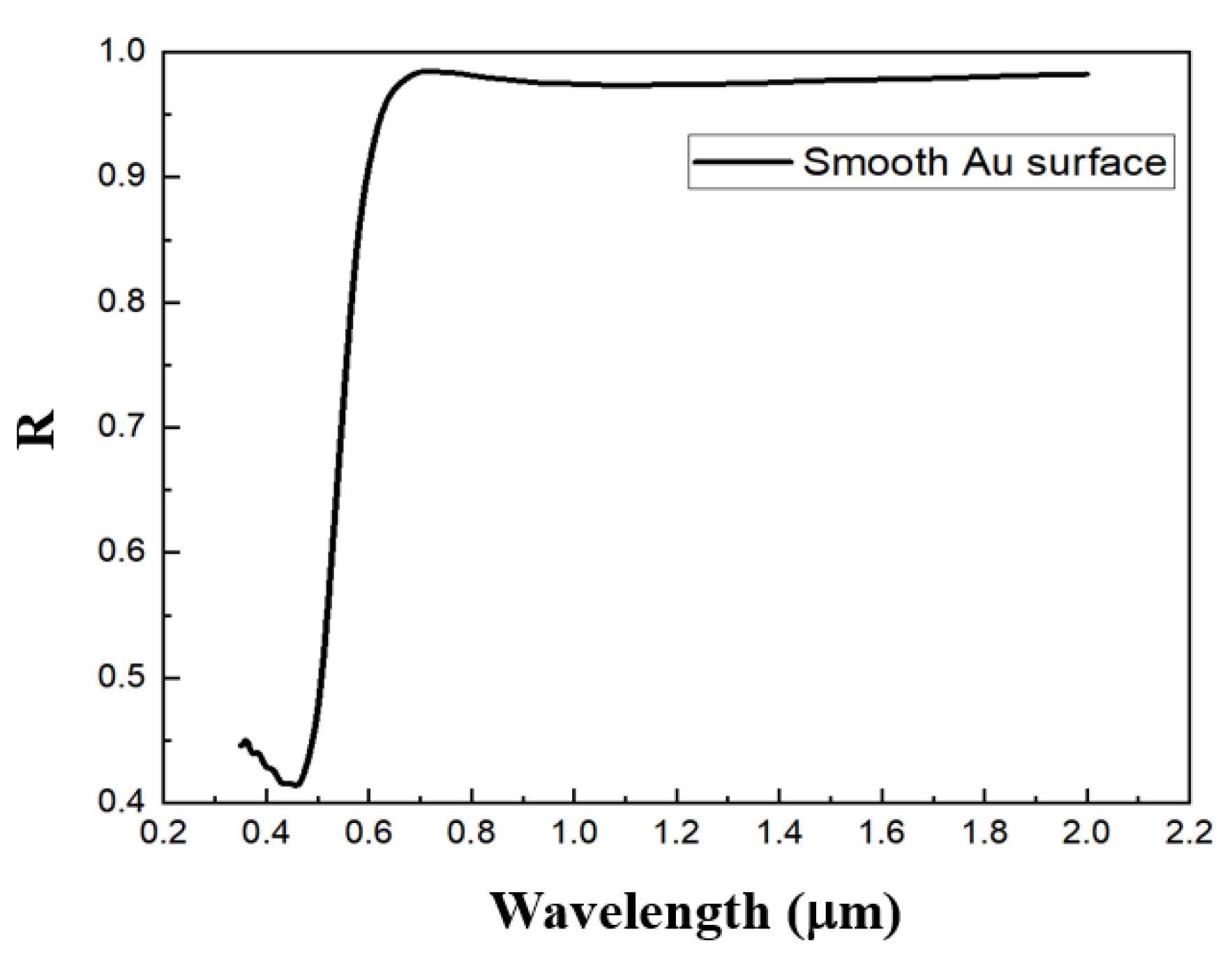

2. Simulation Method and Model Design

3. Results and Discussion

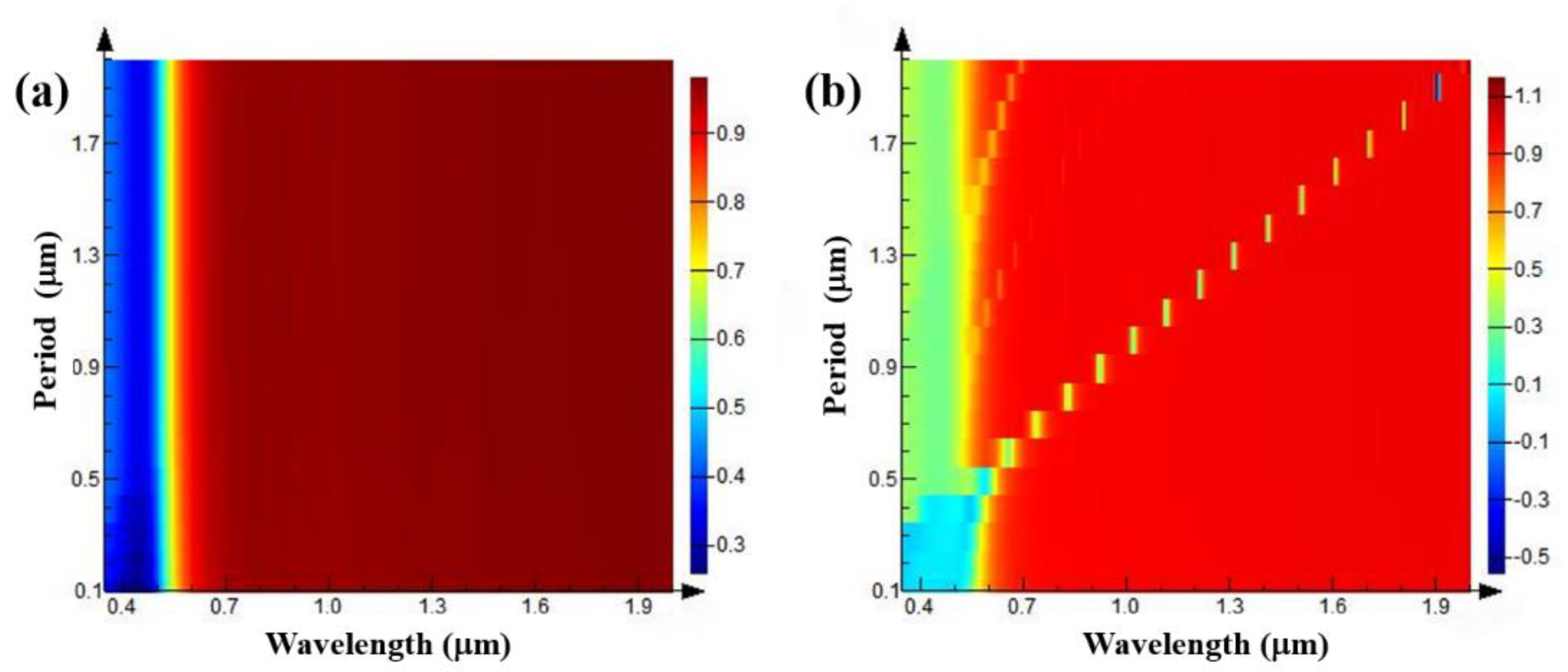

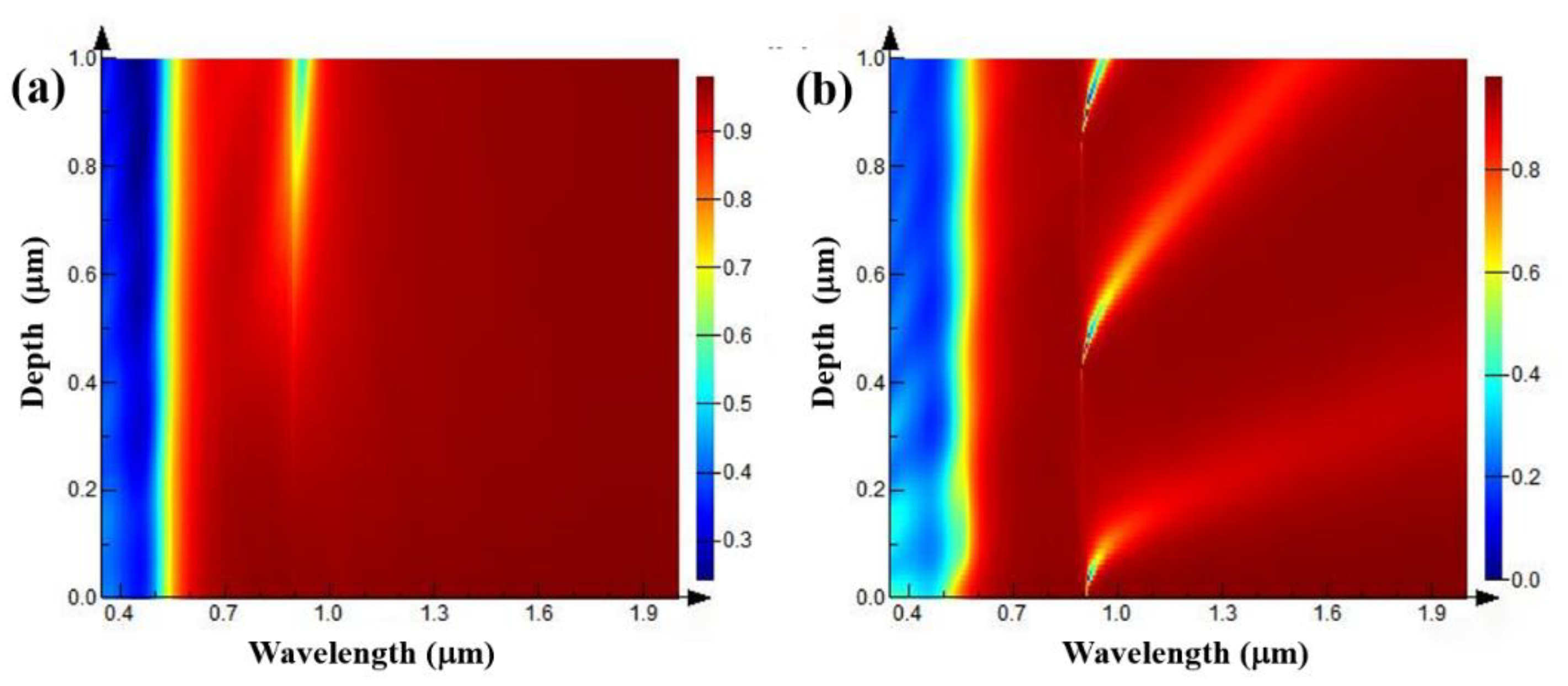

3.1. The Influence of Grating Depth–Width Ratio on Reflection Spectra

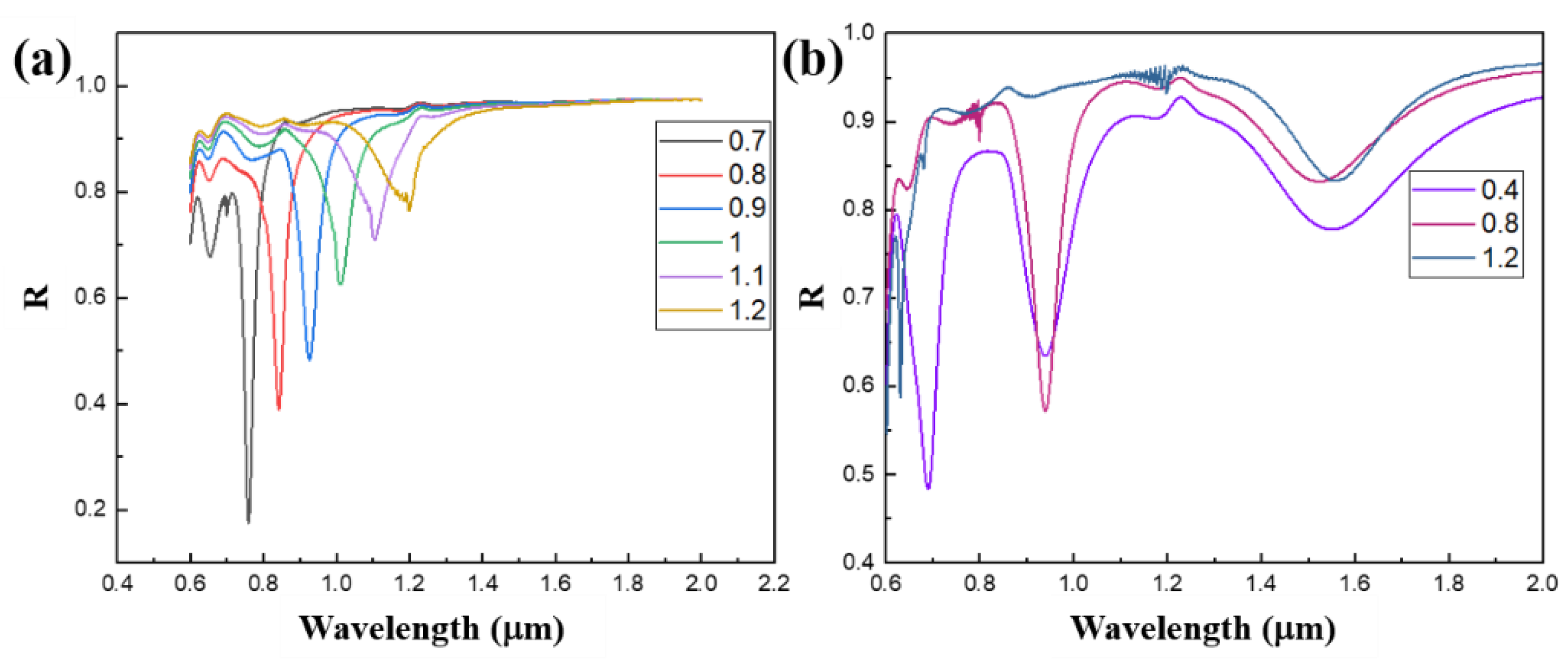

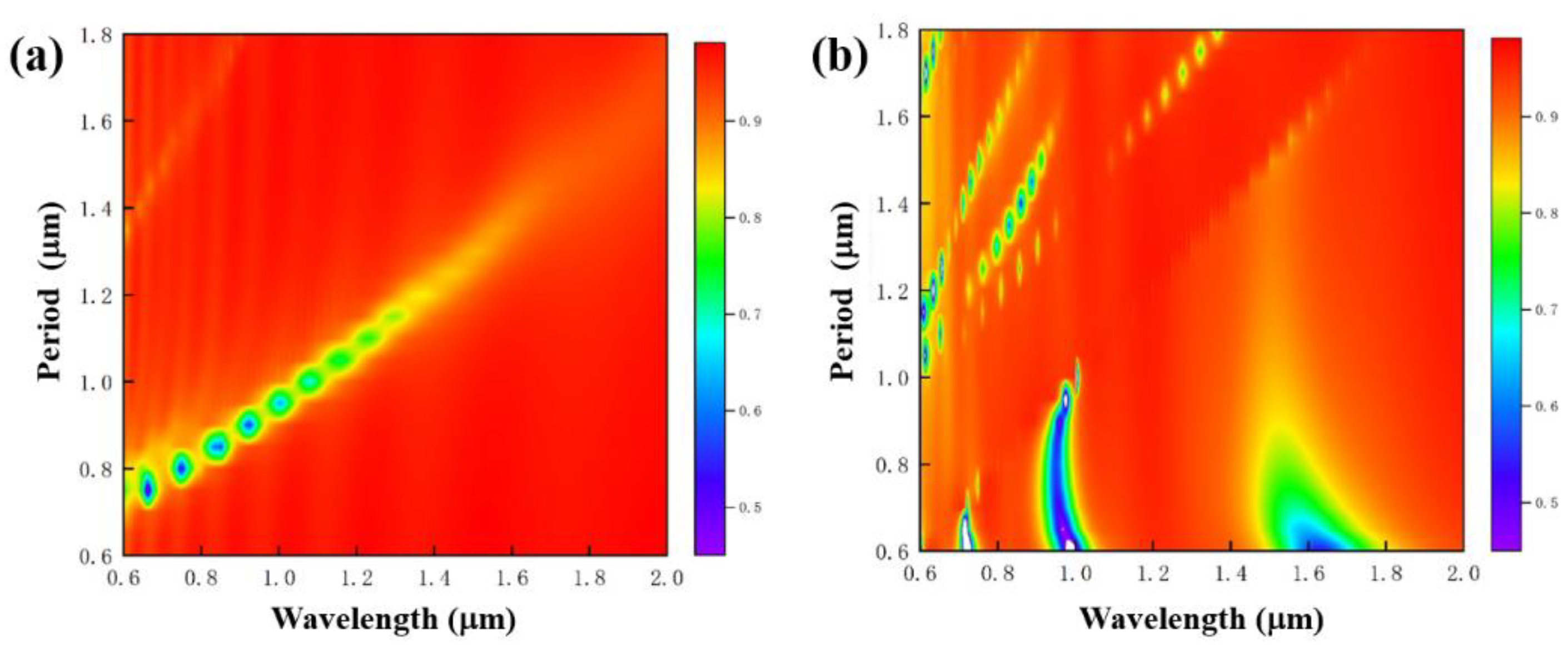

3.2. The Influence of Grating Duty Ratio on Reflection Spectra

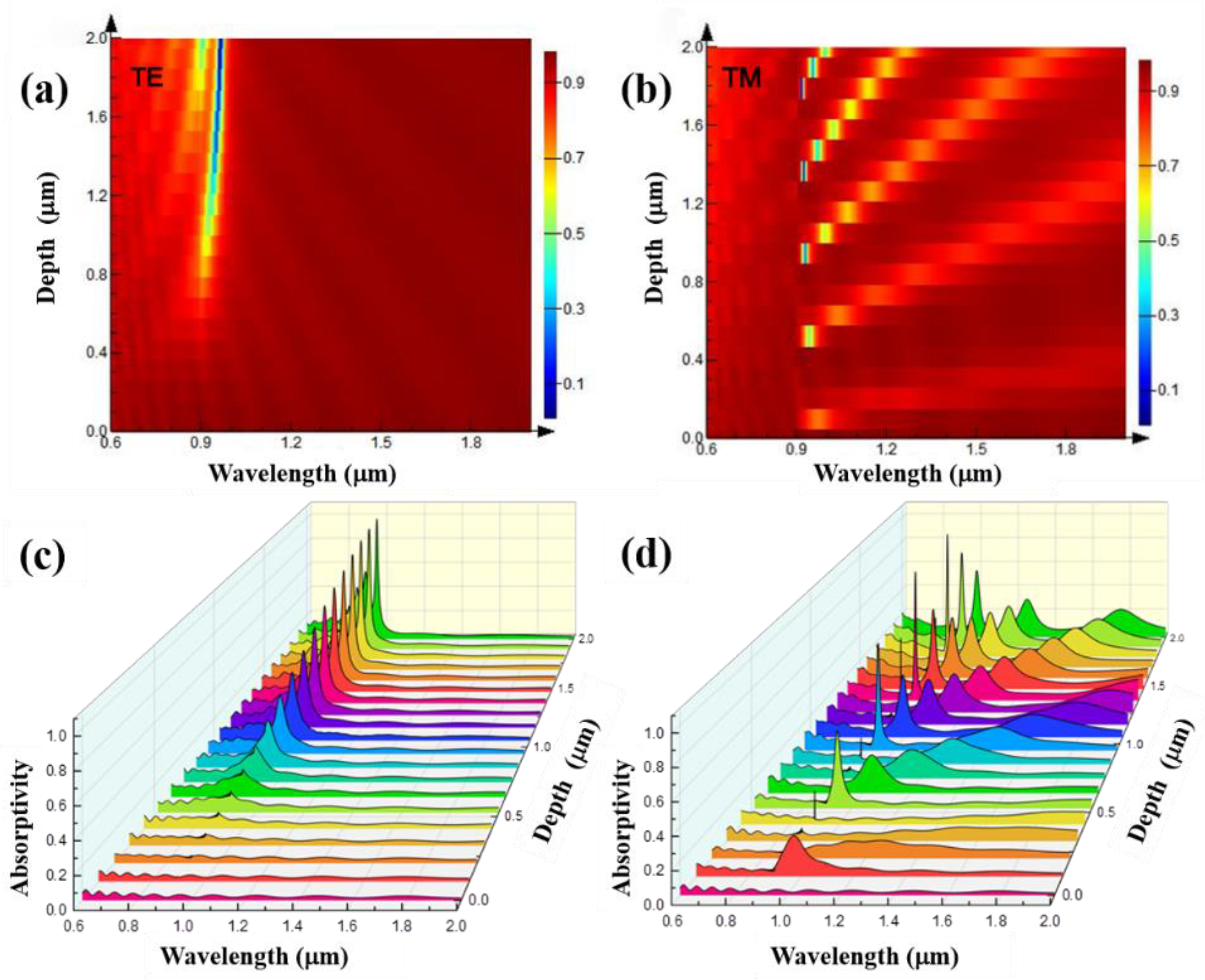

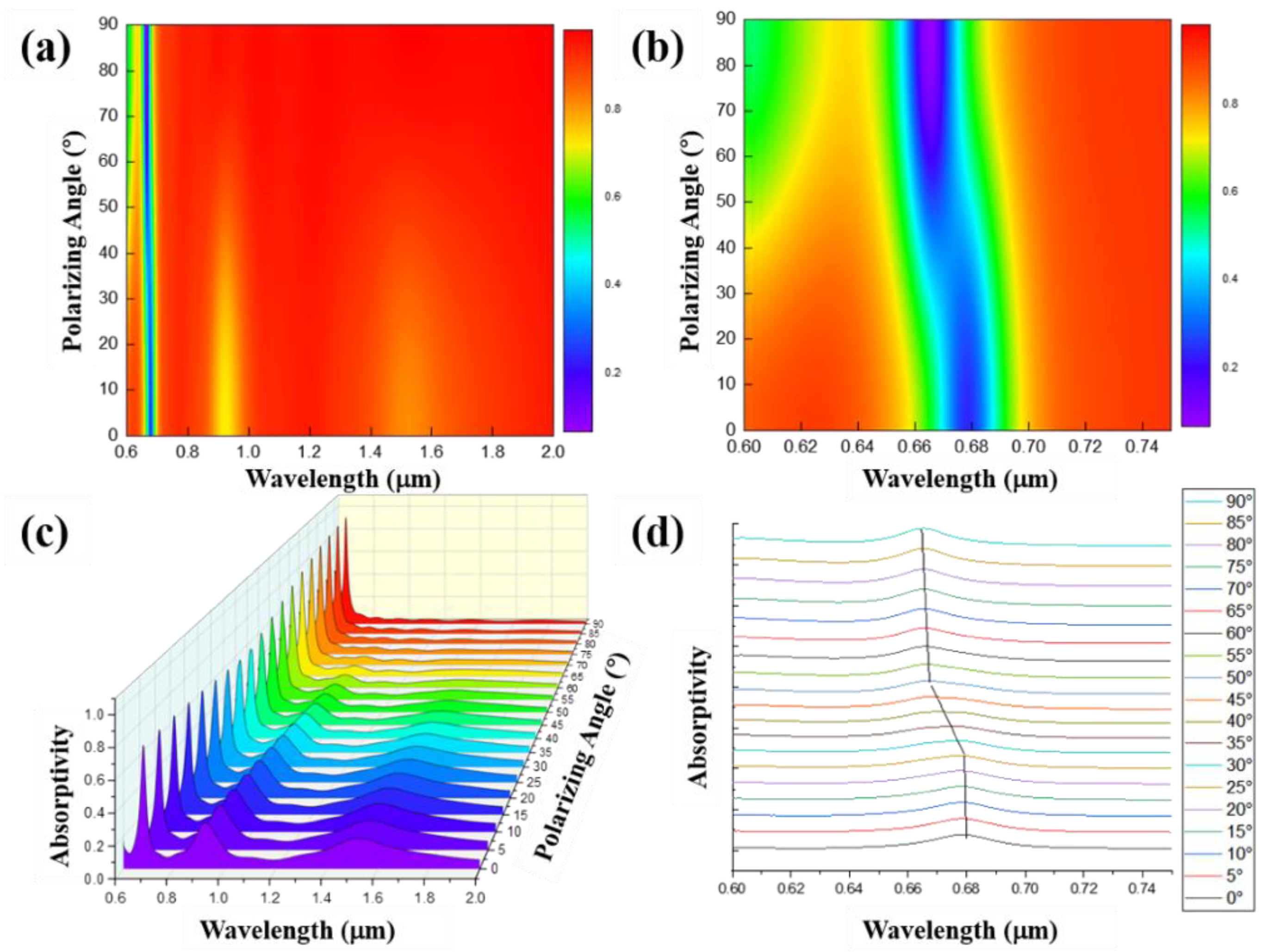

3.3. The Influence of Light Source Polarization Angle on Reflection Spectra

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Hooke, R. Micrographia: Or Some Physiological Descriptions of Minute Bodies Made by Magnifying Glasses with Observations and Inquiries Thereupon; Lond. R. Soc.: London, UK, 1665; pp. 1635–1703. [Google Scholar]

- Newton, I. Opticks: Or, A Treatise of the Reflections, Refractions, Inflections and Colours of light. Based on the 4th ed. London, 1730; Dover Publications, Inc.: Mineola, NY, USA, 1952. [Google Scholar]

- Tayeb, G.; Gralak, B.; Enoch, S. Structural colors in nature and butterflywing modelling. Opt. Photonics News 2003, 14, 38–43. [Google Scholar] [CrossRef] [Green Version]

- Lussange, J.; Guérout, R.; Rosa, F.S.; Greffet, J.-J.; Lambrecht, A.; Reynaud, S. Radiative heat transfer between two dielectric nanogratings in the scattering approach. Phys. Rev. B 2012, 86, 085432. [Google Scholar] [CrossRef] [Green Version]

- Chung, K.; Yu, S.; Heo, C.-J.; Shim, J.W.; Yang, S.-M.; Han, M.G.; Lee, H.-S.; Jin, Y.; Lee, S.Y.; Park, N.; et al. Flexible, angle-independent, structural color reflectors inspired by morpho butterfly wings. Adv. Mater. 2012, 24, 2366. [Google Scholar] [CrossRef]

- Biehs, S.-A.; Tschikin, M.; Ben-Abdallah, P. Hyperbolic metamaterials as an analog of a blackbody in the near field. Phys. Rev. Lett. 2012, 109, 104301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rinnerbauer, V.; Lenert, A.; Bierman, D.M.; Yeng, Y.X.; Chan, W.R.; Geil, R.D.; Senkevich, J.J.; Joannopoulos, J.D.; Wang, E.N.; Soljačić, M. Metallic photonic crystal absorber-emitter for efficient spectral control in high-temperature solar thermophotovoltaics. Adv. Energy Mater. 2014, 4, 1400334. [Google Scholar] [CrossRef]

- Li, P.; Liu, B.; Ni, Y.; Liew, K.K.; Sze, J.; Chen, S.; Shen, S. Large-Scale Nanophotonic Solar Selective Absorbers for High-Efficiency Solar Thermal Energy Conversion. Adv. Mater. 2015, 27, 4585–4591. [Google Scholar] [CrossRef] [PubMed]

- Fudouzi, H.; Xia, Y. Photonic papers and inks: Color writing with colorless materials. Adv. Mater. 2003, 15, 892–896. [Google Scholar] [CrossRef]

- Arsenault, A.C.; Puzzo, D.P.; Manners, I.; Ozin, G.A. Photonic-crystal full-colour displays. Nat. Photonics 2007, 1, 468–472. [Google Scholar] [CrossRef] [Green Version]

- Diest, K.; Dionne, J.A.; Spain, M.; Atwater, H.A. Tunable color filters based on metal-insulator-metal resonators. Nano Lett. 2009, 9, 2579–2583. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, A.F.; Xu, T.; Guo, L.J. High efficiency resonance-based spectrum filters with tunable transmission bandwidth fabricated using nanoimprint lithography. Appl. Phys. Lett. 2011, 99, 824. [Google Scholar] [CrossRef] [Green Version]

- Yokogawa, S.; Burgos, S.P.; Atwater, H.A. Plasmonic color filters for CMOS image sensor applications. Nano Lett. 2012, 12, 4349–4354. [Google Scholar] [CrossRef]

- Jiang, X.; Gu, Q.; Wang, F.; Lv, J.; Ma, Z.; Si, G. Fabrication of coaxial plasmonic crystals by focused ion beam milling and electron-beam lithography. Mater. Lett. 2013, 100, 192–194. [Google Scholar] [CrossRef]

- Si, G.; Zhao, Y.; Lv, J.; Lu, M.; Wang, F.; Liu, H.; Xiang, N.; Huang, T.J.; Danner, A.J.; Teng, J.; et al. Reflective plasmonic color filters based on lithographically patterned silver nanorod arrays. Nanoscale 2013, 5, 6243–6248. [Google Scholar] [CrossRef] [Green Version]

- Si, G.; Zhao, Y.; Hong, L.; Teo, S.; Zhang, M.; Huang, T.J.; Danner, A.J.; Teng, J. Annular aperture array based color filter. Appl. Phys. Lett. 2011, 99, 033105. [Google Scholar] [CrossRef]

- Perchec, J.L.; Desieres, Y.; Rochat, N.; Lamaestre, R.E.D. Subwavelength optical absorber with an integrated photon sorter. Appl. Phys. Lett. 2012, 100, 73. [Google Scholar] [CrossRef]

- Burgos, S.P.; Yokogawa, S.; Atwater, H.A. Color imaging via nearest neighbor hole coupling in plasmonic color filters integrated onto a complementary metal-oxide semiconductor image sensor. ACS Nano 2013, 7, 10038–10047. [Google Scholar] [CrossRef] [Green Version]

- Roberts, A.S.; Pors, A.; Albrektsen, O.; Bozhevolnyi, S.I. Subwavelength plasmonic color printing protected for ambient use. Nano Lett. 2014, 14, 783–787. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Duan, H.; Hegde, R.S.; Koh, S.; Wei, J.N.; Yang, J.K.W. Printing colour at the optical diffraction limit. Nat. Nanotechnol. 2012, 7, 557–561. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.-K.R.; Hollowell, A.E.; Zhang, C.; Guo, L.J. Angle-insensitive structural colours based on metallic nanocavities and coloured pixels beyond the diffraction limit. Sci. Rep. 2013, 3, 1194. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, S.J.; Zhang, L.; Zhu, D.; Goh, X.M.; Wang, Y.; Kumar, K.; Qiu, C.-W.; Yang, J.K.W. Plasmonic color palettes for photorealistic printing with aluminum nanostructures. Nano Lett. 2014, 14, 4023–4029. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, X.; Zhou, K.; Yang, X.; Yu, Y. Wide-gamut and polarization-independent structural color at optical sub-diffraction-limit spatial resolution based on uncoupled lspps. Nanoscale Res. Lett. 2019, 14, 214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Younkin, R.; Carey, J.E.; Mazur, E. Infrared absorption by conical silicon mic restructures made in a variety of background gases using femtosecond-laser pulses. J. Appl. Phys. 2002, 93, 2626–2629. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Metal pumps liquid uphill. Appl. Phys. Lett. 2009, 94, 224102. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Makin, V.S.; Guo, C. Brighter light sources from black metal: Significant increase in emission efficiency of incandescent light sources. Phys. Rev. Lett. 2009, 102, 234301. [Google Scholar] [CrossRef] [PubMed]

- Ellenbogen, T.; Seo, K.; Crozier, K.B. Chromatic plasmonic polarizers for active visible color filtering and polarimetry. Nano Lett. 2012, 12, 1026–1031. [Google Scholar] [CrossRef]

- Meng, J.; Song, H.; Li, X.; Liu, S. Femtosecond laser fabricating black silicon in alkaline solution. Appl. Phys. A 2015, 118, 1197–1203. [Google Scholar] [CrossRef]

- Liu, S.; Liu, S. Spectral enhancement of thermal radiation by laser fabricating grating structure on nickel surface. Chin. Phys. B 2015, 24, 054401. [Google Scholar] [CrossRef]

- Meng, J.; Song, H.; Li, X.; Liu, S. Influence of femtosecond laser pulse energy on the surface reflection of black silicon in alkaline solution. J. Laser Appl. 2016, 28, 012005. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Feng, S.; Liu, Y.; Hu, J.; Wang, C.; Wei, B. Enhanced Tunable Light Absorption in Nanostructured Si Arrays Based on Double-Quarter-Wavelength Resonance. Adv. Opt. Mater. 2019, 7, 1900845. [Google Scholar] [CrossRef]

- Mao, P.; Liu, C.; Song, F.; Han, M.; Maier, S.A.; Zhang, S. Manipulating disordered plasmonic systems by external cavity with transition from broadband absorption to reconfigurable reflection. Nat. Commun. 2020, 11, 1538. [Google Scholar] [CrossRef]

- Honda, H.; Wei, J. Enhanced boiling heat transfer from electronic components by use of surface microstructures. Exp. Therm. Fluid Sci. 2004, 28, 159–169. [Google Scholar] [CrossRef]

- Liu, T.; Luo, R.; Qiao, W.; Yoon, S.-H.; Mochida, I. Microstructure of carbon derived from mangrove charcoal and its application in Li-ion batteries. Electrochim. Acta 2010, 55, 1696–1700. [Google Scholar] [CrossRef]

- Narayanaswamy, A.; Chen, G. Surface modes for near field thermophotovoltaics. Appl. Phys. Lett. 2003, 82, 3544–3546. [Google Scholar] [CrossRef] [Green Version]

- Ilic, O.; Jablan, M.; Joannopoulos, J.D.; Celanovic, I.; Soljačić, M. Overcoming the black body limit in plasmonic and graphene near-field thermophotovoltaic systems. Opt. Express 2012, 20, A366–A384. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Neuner, B., III; John, J.; Milder, A.; Zollars, B.; Savoy, S.; Shvets, G. Metamaterial-based integrated plasmonic absorber/emitter for solar thermo-photovoltaic systems. J. Opt. 2012, 14, 024005. [Google Scholar] [CrossRef]

- Tong, Y.; Wang, B.; Ge, C.; Song, H.; Liu, S. Study on spectral properties of local graphene-assisted micro-nanostructures. Results Phys. 2021, 25, 104207. [Google Scholar] [CrossRef]

- Maier, S.A. Plasmonics: Fundamentals and Applications; Springer: New York, NY, USA, 2007. [Google Scholar]

- Alexei-A, M. Structured Surfaces as Optical Metamaterials; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Du, B.; Tan, S.; Song, H.; Liu, S. Spectral Characteristics Simulation of Topological Micro-Nano Structures Based on Finite Difference Time Domain Method. Nanomaterials 2021, 11, 2622. https://doi.org/10.3390/nano11102622

Ma X, Du B, Tan S, Song H, Liu S. Spectral Characteristics Simulation of Topological Micro-Nano Structures Based on Finite Difference Time Domain Method. Nanomaterials. 2021; 11(10):2622. https://doi.org/10.3390/nano11102622

Chicago/Turabian StyleMa, Xiaoran, Bairui Du, Shengwang Tan, Haiying Song, and Shibing Liu. 2021. "Spectral Characteristics Simulation of Topological Micro-Nano Structures Based on Finite Difference Time Domain Method" Nanomaterials 11, no. 10: 2622. https://doi.org/10.3390/nano11102622

APA StyleMa, X., Du, B., Tan, S., Song, H., & Liu, S. (2021). Spectral Characteristics Simulation of Topological Micro-Nano Structures Based on Finite Difference Time Domain Method. Nanomaterials, 11(10), 2622. https://doi.org/10.3390/nano11102622