Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure

Abstract

:1. Introduction

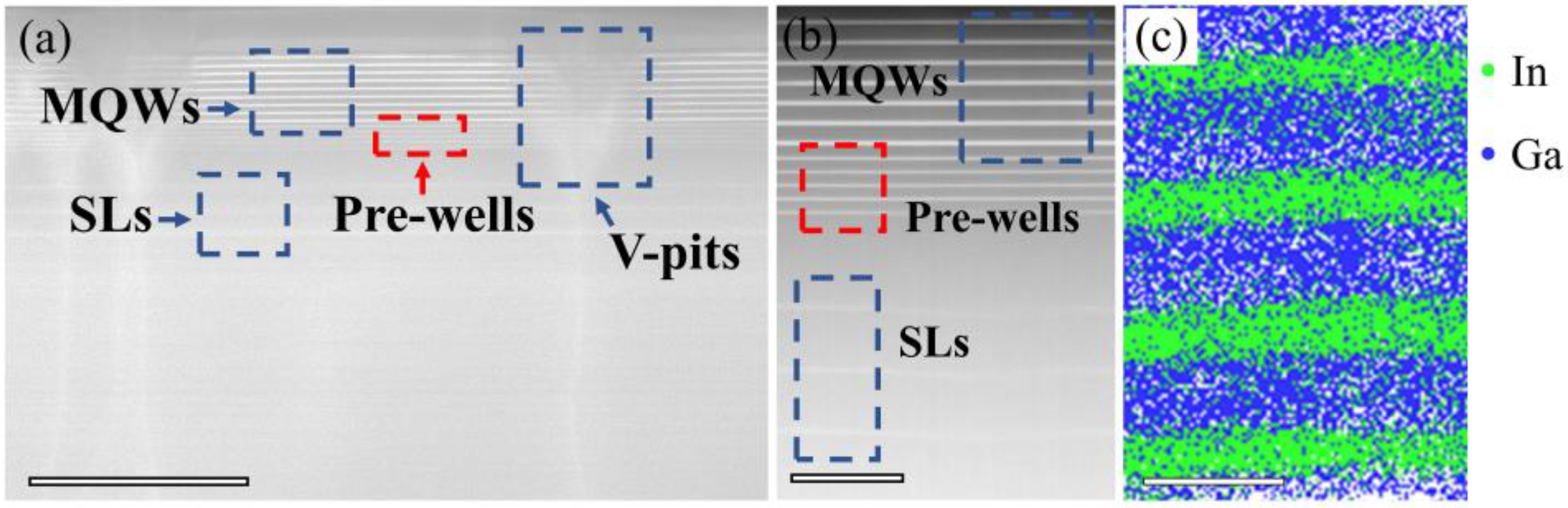

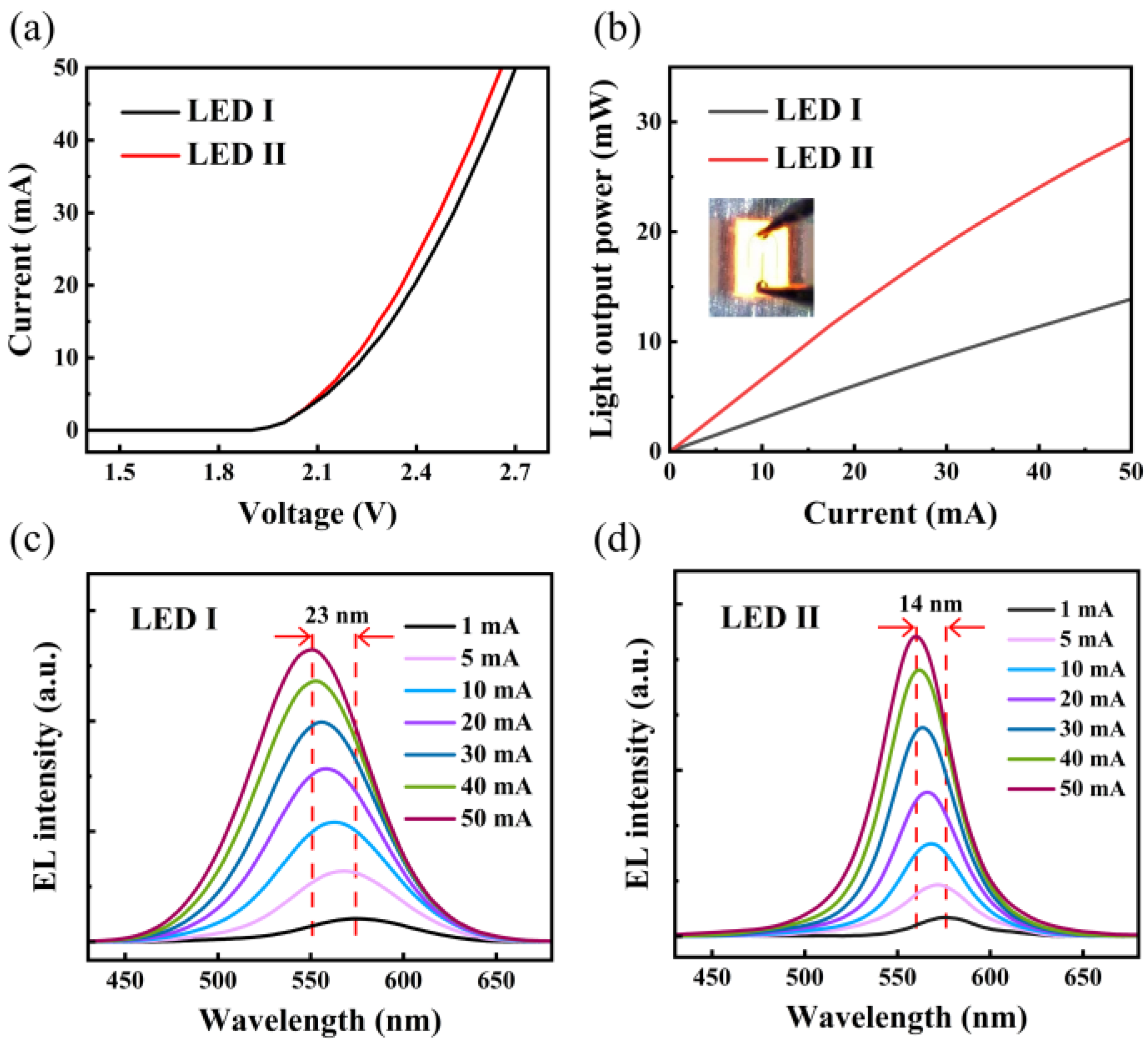

2. Experiments

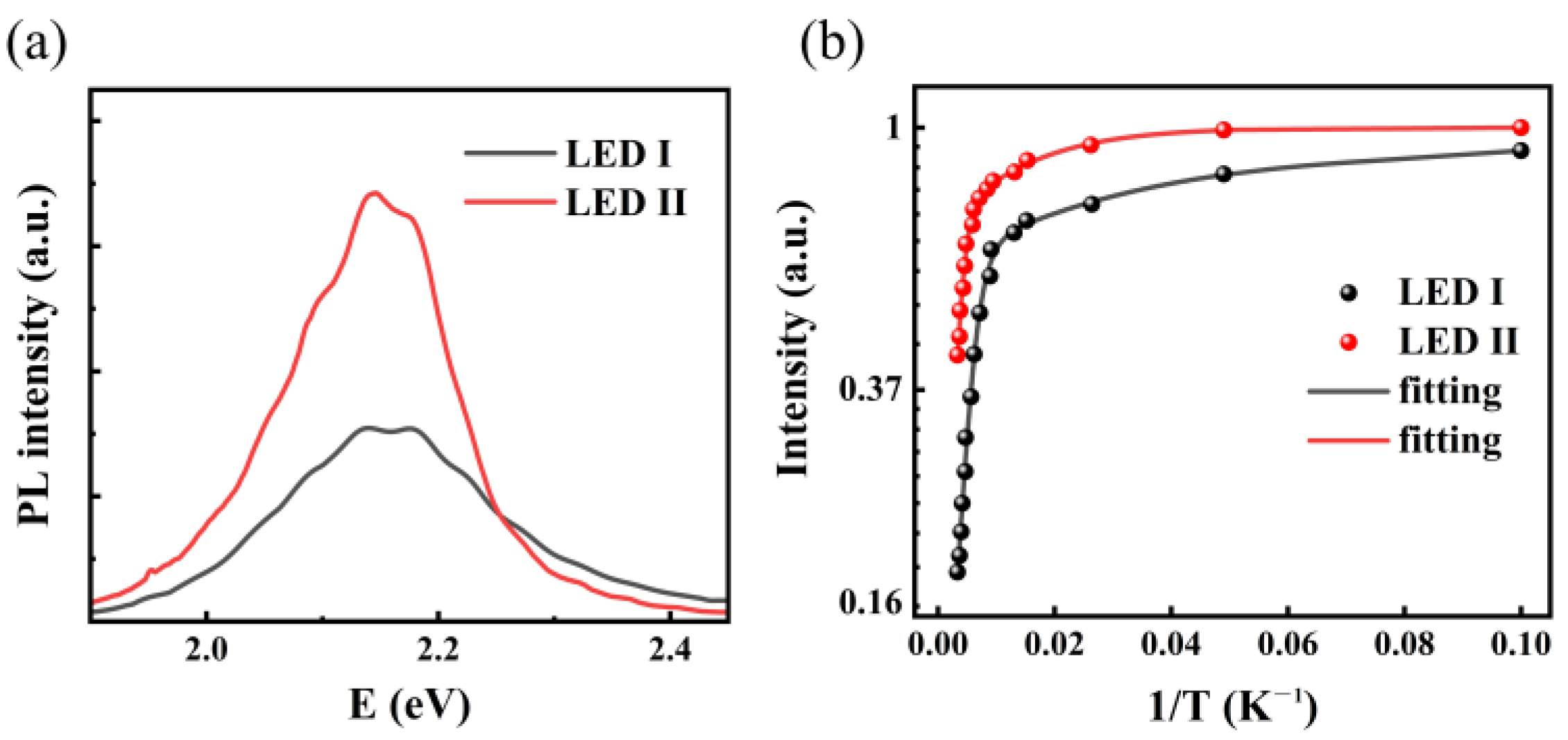

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pimputkar, S.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Prospects for LED lighting. Nat. Photon. 2009, 3, 180–182. [Google Scholar] [CrossRef]

- Crawford, M.H. LEDs for solid-state lighting: Performance challenges and recent advances. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 1028–1040. [Google Scholar] [CrossRef]

- Hu, H.; Tang, B.; Wan, H.; Sun, H.; Zhou, S.; Dai, J.; Chen, C.; Liu, S.; Guo, L.J. Boosted ultraviolet electroluminescence of InGaN/AlGaN quantum structures grown on high-index contrast patterned sapphire with silica array. Nano Energy 2020, 69, 104427. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Yan, H.; Chen, Z.; Liu, Y.; Liu, S. Highly efficient GaN-based high-power flip-chip light-emitting diodes. Opt. Express 2019, 27, A669–A692. [Google Scholar] [CrossRef] [PubMed]

- Mun, S.H.; Kang, C.M.; Min, J.H.; Choi, S.Y.; Jeong, W.L.; Kim, G.G.; Lee, J.S.; Kim, K.P.; Ko, H.C.; Lee, D.S. Highly Efficient Full-Color Inorganic LEDs on a Single Wafer by Using Multiple Adhesive Bonding. Adv. Mater. Interfaces 2021, 8, 1–7. [Google Scholar] [CrossRef]

- Tao, G.; Zhao, X.; Zhou, S. Stacked GaN/AlN last quantum barrier for high-efficiency InGaN-based green light-emitting diodes. Opt. Lett. 2021, 46, 4593–4596. [Google Scholar] [CrossRef] [PubMed]

- Tang, B.; Gong, L.; Hu, H.; Sun, H.; Zhou, S. Toward efficient long-wavelength III-nitride emitters using a hybrid nucleation layer. Opt. Express 2021, 29, 27404. [Google Scholar] [CrossRef]

- Jeong, J.; Wang, Q.; Cha, J.; Jin, D.K.; Shin, D.H.; Kwon, S.; Kang, B.K.; Jang, J.H.; Yang, W.S.; Choi, Y.S.; et al. Remote heteroepitaxy of GaN microrod heterostructures for deformable light-emitting diodes and wafer recycle. Sci. Adv. 2020, 6, z5180. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.E.; Park, J.H.; Jang, D.; Shin, J.H.; Im, T.H.; Lee, J.H.; Hong, S.K.; Wang, H.S.; Kwak, M.S.; Peddigari, M.; et al. Optogenetic brain neuromodulation by stray magnetic field via flash-enhanced magneto-mechano-triboelectric nanogenerator. Nano Energy 2020, 75, 104951. [Google Scholar] [CrossRef]

- Narukawa, Y.; Ichikawa, M.; Sanga, D.; Sano, M.; Mukai, T. White light emitting diodes with super-high luminous efficacy. J. Phys. D Appl. Phys. 2010, 43, 354002. [Google Scholar] [CrossRef]

- Takeuchi, T.; Sota, S.; Katsuragawa, M.; Komori, M.; Takeuchi, H.; Amano, H.; Akasaki, I. Quantum-confined Stark effect due to piezoelectric fields in GaInN strained quantum wells. Jpn. J. Appl. Phys. 1997, 36, L382–L385. [Google Scholar] [CrossRef]

- Masui, H.; Nakamura, S.; DenBaars, S.P.; Mishra, U.K. Nonpolar and semipolar III-nitride light-emitting diodes: Achievements and challenges. IEEE Trans. Electron Devices 2010, 57, 88–100. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, J.; Xu, L.; Ding, J.; Wang, G.; Wu, X.; Wang, X.; Mo, C.; Quan, Z.; Guo, X.; et al. Efficient InGaN-based yellow-light-emitting diodes. Photon. Res. 2019, 7, 144–148. [Google Scholar] [CrossRef]

- Leem, S.J.; Shin, Y.C.; Kim, K.C.; Kim, E.H.; Sung, Y.M.; Moon, Y.; Hwang, S.M.; Kim, T.G. The effect of the low-mole InGaN structure and InGaN/GaN strained layer superlattices on optical performance of multiple quantum well active layers. J. Cryst. Growth 2008, 311, 103–106. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, G.; Zhang, J.; Poplawsky, J.D.; Dierolf, V.; Tansu, N. Approaches for high internal quantum efficiency green InGaN light-emitting diodes with large overlap quantum wells. Opt. Express 2011, 19, A991–A1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, X.; Tang, B.; Gong, L.; Bai, J.; Ping, J.; Zhou, S. Rational construction of staggered InGaN quantum wells for efficient yellow light-emitting diodes. Appl. Phys. Lett. 2021, 118, 182102. [Google Scholar] [CrossRef]

- Huang, C.F.; Liu, T.C.; Lu, Y.C.; Shiao, W.Y.; Chen, Y.S.; Wang, J.K.; Lu, C.F.; Yang, C.C. Enhanced efficiency and reduced spectral shift of green light-emitting-diode epitaxial structure with prestrained growth. J. Appl. Phys. 2008, 104, 123106. [Google Scholar] [CrossRef]

- Niu, N.H.; Wang, H.B.; Liu, J.P.; Liu, N.X.; Xing, Y.H.; Han, J.; Deng, J.; Shen, G.D. Improved quality of InGaN/GaN multiple quantum wells by a strain relief layer. Cryst. J. Growth 2006, 286, 209–212. [Google Scholar]

- Hu, X.L.; Xiao, F.A.; Zhou, Q.B.; Zheng, Y.D.; Liu, W.J. High-luminous efficacy green light-emitting diodes with InGaN/GaN quasi-superlattice interlayer and Al-doped indium tin oxide film. J. Alloys Compd. 2019, 794, 137–143. [Google Scholar] [CrossRef]

- Tsai, C.L. Effects of underlying InGaN/GaN superlattice structures on the structural and optical properties of InGaN LEDs. J. Lumin. 2016, 174, 36–41. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, K.; Bruckbauer, J.; Shen, S.; Zhu, C.; Fletcher, P.; Feng, Y.; Cai, J.; Bai, C.; Trager-Cowan, R.; et al. Influence of an InGaN superlattice pre-layer on the performance of semi-polar (11–22) green LEDs grown on silicon. Sci. Rep. 2020, 10, 1–8. [Google Scholar]

- Li, X.; Liu, J.; Su, X.; Huang, S.; Tian, A.; Zhou, W.; Jiang, L.; Ikeda, M.; Yang, H. Effect of graded-indium-content superlattice on the optical and structural properties of yellow-emitting InGaN/GaN quantum wells. Materials 2021, 14, 1877. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Liu, X.; Yan, H.; Gao, Y.; Xu, H.; Zhao, J.; Quan, Z.; Gui, C.; Liu, S. The effect of nanometre-scale V-pits on electronic and optical properties and efficiency droop of GaN-based green light-emitting diodes. Sci. Rep. 2018, 8, 1–12. [Google Scholar]

- Kuroda, T.; Tackeuchi, A. Influence of free carrier screening on the luminescence energy shift and carrier lifetime of InGaN quantum wells. J. Appl. Phys. 2002, 92, 3071–3074. [Google Scholar] [CrossRef]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman investigation of strain in GaN and AlxGa1−xN/GaN heterostructures grown on Si (111). J. Appl. Phys. 2002, 92, 3503–3510. [Google Scholar] [CrossRef]

- Kontos, A.G.; Raptis, Y.S.; Pelekanos, N.T.; Georgakilas, A.; Bellet-Amalric, E.; Jalabert, D. Micro-Raman characterization of InxGa1-xN/GaN/Al2O3 heterostructures. Phys. Rev. B 2005, 72, 155336. [Google Scholar] [CrossRef]

- Sun, Y.; Cho, Y.H.; Kim, H.M.; Kang, T.W.; Kwon, S.Y.; Yoon, E. Effect of growth interruption on optical properties of In-rich InGaN/GaN single quantum well structures. J. Appl. Phys. 2006, 100, 043520. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Wang, L.; Liu, N.; Yang, W.; Li, D.; Chen, W.; Feng, Z.; Lee, Y.; Ferguson, I.; Hu, X. Investigation of the light emission properties and carrier dynamics in dual-wavelength InGaN/GaN multiple-quantum well light emitting diodes. J. Appl. Phys. 2012, 112, 083101. [Google Scholar] [CrossRef]

- Lin, T.; Kuo, H.C.; Jiang, X.D.; Feng, Z.C. Recombination pathways in green InGaN/GaN multiple quantum wells. Nanoscale Res. Lett. 2017, 12, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, S. RT-CW Operation of InGaN multi-quantum-well structure laser diodes. Mater. Sci. Eng. B 1997, 50, 277–284. [Google Scholar] [CrossRef]

- Chierchia, R.; BWttcher, T.; Heinke, H.; Einfeldt, S.; Figge, S.; Hommel, D. Microstructure of heteroepitaxial GaN revealed by X-ray diffraction. J. Appl. Phys. 2003, 93, 8918–8925. [Google Scholar] [CrossRef]

- Massabuau, F.C.; Chen, P.; Horton, M.K.; Rhode, S.L.; Ren, C.X.; O’Hanlon, T.J.; Kovács, A.; Kappers, M.J.; Humphreys, C.J.; Dunin-Borkowski, R.E.; et al. Carrier localization in the vicinity of dislocations in InGaN. J. Appl. Phys. 2017, 121, 13104. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Wan, Z.; Gong, L.; Tao, G.; Zhou, S. Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure. Nanomaterials 2021, 11, 3231. https://doi.org/10.3390/nano11123231

Zhao X, Wan Z, Gong L, Tao G, Zhou S. Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure. Nanomaterials. 2021; 11(12):3231. https://doi.org/10.3390/nano11123231

Chicago/Turabian StyleZhao, Xiaoyu, Zehong Wan, Liyan Gong, Guoyi Tao, and Shengjun Zhou. 2021. "Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure" Nanomaterials 11, no. 12: 3231. https://doi.org/10.3390/nano11123231

APA StyleZhao, X., Wan, Z., Gong, L., Tao, G., & Zhou, S. (2021). Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure. Nanomaterials, 11(12), 3231. https://doi.org/10.3390/nano11123231