Prediction and Inverse Design of Structural Colors of Nanoparticle Systems via Deep Neural Network

Abstract

:1. Introduction

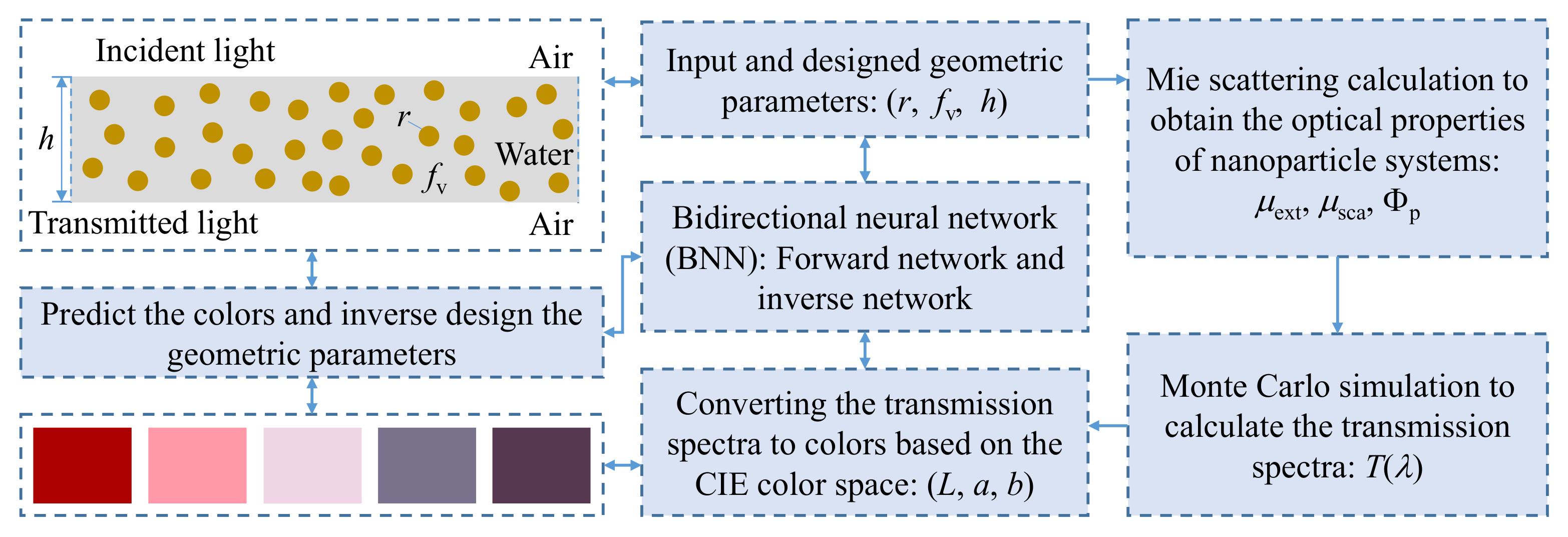

2. Model and Methods

2.1. Model and Dataset Generation

2.2. Optical Properties of Nanoparticle Systems

2.3. Calculation of Transmission Spectra

2.4. Spectrum to Color Calculation

2.5. Machine Learning Method

3. Results and Discussion

3.1. Structural Colors of Gold Nanoparticle Systems

3.2. Forward Neural Networks to Predict the Color Generation

3.3. Inverse Neural Networks to Design the Geometric Parameters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fleischman, D.; Fountaine, K.T.; Bukowsky, C.R.; Tagliabue, G.; Sweatlock, L.A.; Atwater, H.A. High spectral resolution plasmonic color filters with subwavelength dimensions. ACS Photon. 2019, 6, 332–338. [Google Scholar] [CrossRef] [Green Version]

- Shao, L.; Zhuo, X.; Wang, J. Advanced plasmonic materials for dynamic color display. Adv. Mater. 2018, 30, 1704338. [Google Scholar] [CrossRef]

- Yu, J.; Lee, C.-H.; Kan, C.-W. Graphene Oxide/Reduced Graphene Oxide Enhanced Noniridescent Structural Colors Based on Silica Photonic Spray Paints with Improved Mechanical Robustness. Nanomaterials 2021, 11, 949. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Zhou, Z.; Zhang, C.; Gao, Y.; Duan, Z.; Xiao, S.; Song, Q. All-dielectric full-color printing with TiO2 metasurfaces. ACS Nano 2017, 11, 4445–4452. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Zhu, X.; Shao, L.; Wang, J.; Kristensen, A. Plasmonic color laser printing inside transparent gold nanodisk-embedded poly(dimethylsiloxane) matrices. Adv. Opt. Mater. 2020, 8, 1901605. [Google Scholar] [CrossRef]

- Park, J.; Dvoracek, C.; Lee, K.H.; Galloway, J.F.; Bhang, H.; Pomper, M.G.; Searson, P.C. CuInSe/ZnS core/shell NIR quantum dots for biomedical imaging. Small 2011, 7, 3148–3152. [Google Scholar] [CrossRef] [Green Version]

- Kristensen, A.; Yang, J.K.; Bozhevolnyi, S.I.; Link, S.; Nordlander, P.; Halas, N.J.; Mortensen, N.A. Plasmonic colour generation. Nat. Rev. Mater. 2016, 2, 16088. [Google Scholar] [CrossRef]

- Sterl, F.; Herkert, E.; Both, S.; Weiss, T.; Giessen, H. Shaping the color and angular appearance of plasmonic metasurfaces with tailored disorder. ACS Nano 2021, 15, 10318–10327. [Google Scholar] [CrossRef]

- Hwang, V.; Stephenson, A.B.; Barkley, S.; Brandt, S.; Xiao, M.; Aizenberg, J.; Manoharan, V.N. Designing angle-independent structural colors using Monte Carlo simulations of multiple scattering. Proc. Natl. Acad. Sci. USA 2021, 118, e2015551118. [Google Scholar] [CrossRef]

- Ropez, C. Materials aspects of photonic crystals. Adv. Mater. 2003, 15, 1679–1704. [Google Scholar]

- Freymann, G.V.; Kitaev, V.; Lotsch, B.V.; Ozin, G.A. Bottom-up assembly of photonic crystals. Chem. Soc. Rev. 2013, 42, 2528–2554. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sugimoto, H.; Okazaki, T.; Fujii, M. Mie resonator color inks of monodispersed and perfectly spherical crystalline silicon nanoparticles. Adv. Opt. Mater. 2020, 8, 2000033. [Google Scholar] [CrossRef] [Green Version]

- Schertel, L.; Siedentop, L.; Meijer, J.M.; Keim, P.; Aegerter, C.M.; Aubry, G.J.; Maret, G. The structural colors of photonic glasses. Adv. Opt. Mater. 2019, 7, 1900442. [Google Scholar] [CrossRef] [Green Version]

- Quinten, M. The color of finely dispersed nanoparticles. Appl. Phys. B 2001, 73, 317–326. [Google Scholar] [CrossRef]

- Chhatre, A.; Solasa, P.; Sakle, S.; Thaokar, R.; Mehra, A. Color and surface plasmon effects in nanoparticle systems: Case of silver nanoparticles prepared by microemulsion route. Colloids Surf. A 2012, 404, 83–92. [Google Scholar] [CrossRef]

- Yalçın, R.A.; Blandre, E.; Joulain, K.; Dreévillon, J. Colored radiative cooling coatings with nanoparticles. ACS Photon. 2020, 7, 1312–1322. [Google Scholar] [CrossRef]

- Pargoletti, E.; Ortenzi, M.A.; Cappelletti, G. Stable Coloured Micrometric Films from Highly Concentrated Nano-Silver Sols: The Role of the Stabilizing Agents. Nanomaterials 2021, 11, 980. [Google Scholar] [CrossRef]

- Molesky, S.; Lin, Z.; Piggott, A.Y.; Jin, W.; Vucković, J.; Rodriguez, A.W. Inverse design in nanophotonics. Nat. Photon. 2018, 12, 659–670. [Google Scholar] [CrossRef] [Green Version]

- Andonegui, I.; Calvo, I.; Garcia-Adeva, A.J. Inverse design and topology optimization of novel photonic crystal broadband passive devices for photonic integrated circuits. Appl. Phys. A 2014, 115, 433–438. [Google Scholar] [CrossRef]

- Kokhanovskiy, A.; Kuprikov, E.; Bednyako, V.A.; Popkov, I.; Turitsyn, S. Inverse design of mode-locked fiber laser by particle swarm optimization algorithm. Sci. Rep. 2021, 11, 13555. [Google Scholar] [CrossRef]

- Wiecha, P.R.; Arbouet, A.; Girard, C.; Muskens, O.L. Deep learning in nano-photonics: Inverse design and beyond. Photon. Res. 2021, 9, B182–B200. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Carleo, G.; Cirac, I.; Cranmer, K.; Daudet, L.; Schuld, M.; Tishby, N.; Vogt-Maranto, L.; Zdeborová, L. Machine learning and the physical sciences. Rev. Mod. Phys. 2019, 91, 045002. [Google Scholar] [CrossRef] [Green Version]

- Hussain, R.; Noyan, M.A.; Woyessa, G.; Marín, R.R.R.; Martinez, P.A.; Mahdi, F.M.; Finazzi, V.; Hazlehurst, T.A.; Hunter, T.N.; Coll, T. An ultra-compact particle size analyser using a CMOS image sensor and machine learning. Light Sci. Appl. 2020, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Barbastathis, G.; Ozcan, A.; Situ, G. On the use of deep learning for computational imaging. Optica 2019, 6, 921–943. [Google Scholar] [CrossRef]

- Khatib, O.; Ren, S.; Malof, J.; Padilla, W.J. Deep learning the electromagnetic properties of metamaterials—A comprehensive review. Adv. Funct. Mater. 2021, 31, 2101748. [Google Scholar] [CrossRef]

- Gao, L.; Chai, Y.; Zibar, D.; Yu, Z. Deep learning in photonics: Introduction. Photon. Res. 2021, 9, DLP1–DLP3. [Google Scholar] [CrossRef]

- Baxter, J.; Calà Lesina, A.; Guay, J.-M.; Weck, A.; Berini, P.; Ramunno, L. Plasmonic colours predicted by deep learning. Sci. Rep. 2019, 9, 8074. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Li, X.; Liu, D.; Wang, L.; Yu, Z. A bidirectional deep neural network for accurate silicon color design. Adv. Mater. 2019, 31, 1905467. [Google Scholar] [CrossRef]

- Zang, J.; Huang, Z.; Liu, X. Inverse design of structural color using machine learning. Nanoscale 2019, 11, 21748–21758. [Google Scholar]

- Dai, P.; Wang, Y.; Hu, Y.; Groot, C.; Huang, R. Accurate inverse design of Fabry–Perot-cavity-based color filters far beyond sRGB via a bidirectional artificial neural network. Photon. Res. 2021, 9, B236–B246. [Google Scholar] [CrossRef]

- He, X.; Gu, Y.; Yu, B.; Liu, Z.; Zhu, K.; Wu, N.; Zhao, X.; Wei, Y.; Zhou, J.; Song, Y. Multi-mode structural-color anti-counterfeiting labels based on physically unclonable amorphous photonic structures with convenient artificial intelligence authentication. J. Mater. Chem. C 2019, 7, 14069–14074. [Google Scholar] [CrossRef]

- Hemmatyar, O.; Abdollahramezani, S.; Kiarashinejad, Y.; Zandehshahvar, M.; Adibi, A. Full color generation with fano-type resonant HfO2 nanopillars designed by a deep-learning approach. Nanoscale 2019, 11, 21266–21274. [Google Scholar] [CrossRef] [Green Version]

- Nishi, H.; Tatsuma, T. Full-color scattering based on plasmon and Mie resonances of gold nanoparticles modulated by Fabry-Pérot Interference for coloring and image projection. ACS Appl. Nano Mater. 2019, 2, 5071–5078. [Google Scholar] [CrossRef]

- Priyadarshini, M.; Acharyya, J.N.; Mahajan, S.; Prakash, G.V. Optical nonlinearities in chemically synthesized and femtosecond laser fabricated gold nanoparticle colloidal solutions. Opt. Laser Technol. 2021, 139, 107008. [Google Scholar] [CrossRef]

- Yang, C.-M.; Chen, F.-C. Position Effects of Metal Nanoparticles on the Performance of Perovskite Light-Emitting Diodes. Nanomaterials 2021, 11, 993. [Google Scholar] [CrossRef]

- Modest, M.F. Radiative Heat Transfer; Academic Press: San Diego, CA, USA, 2013. [Google Scholar]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles; Wiley: New York, NY, USA, 1983. [Google Scholar]

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Segelstein, D.J. The Complex Refractive Index of Water; University of Missouri-Kansas City: Kansas City, MO, USA, 1981. [Google Scholar]

- Chandrasekhar, S. Radiative Transfer; Oxford University: Oxford, UK, 1950. [Google Scholar]

- Ma, L.; Wang, F.; Wang, C.; Wang, C.; Tan, J. Monte Carlo simulation of spectral reflectance and BRDF of the bubble layer in the upper ocean. Opt. Express 2015, 23, 24274–24289. [Google Scholar] [CrossRef]

- Ma, L.X.; Wang, C.; Tan, J.Y. Light scattering by densely packed optically soft particle systems, with consideration of the particle agglomeration and dependent scattering. Appl. Opt. 2019, 58, 7336–7345. [Google Scholar] [CrossRef]

- Fairman, H.S.; Brill, M.H.; Hemmendinger, H. How the CIE 1931 color-matching functions were derived from Wright-Guild data. Color Res. Appl. 1998, 22, 11–23. [Google Scholar] [CrossRef]

- Wyszecki, G.; Stiles, W.S. Color Science: Concepts and Method, Auantitative Data and Formulae; John Wiley & Sons: New York, NY, USA, 1982. [Google Scholar]

- Schanda, J. Colorimetry: Understanding the CIE System; John Wiley & Sons: New Jersey, NJ, USA, 2007. [Google Scholar]

- Li, W.; Shi, Y.; Chen, Z.; Fan, S. Photonic thermal management of coloured objects. Nat. Commun. 2018, 9, 4240. [Google Scholar] [CrossRef] [PubMed]

- Habekost, M. Which color differencing equation should be used. Int. Circ. Graph. Educ. Res. 2013, 6, 20–33. [Google Scholar]

- Liu, D.; Tan, Y.; Khoram, E.; Yu, Z. Training deep neural networks for the inverse design of nanophotonic structures. ACS Photon. 2018, 5, 1365–1369. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Hu, K.; Wang, C.; Yang, J.-Y.; Liu, L. Prediction and Inverse Design of Structural Colors of Nanoparticle Systems via Deep Neural Network. Nanomaterials 2021, 11, 3339. https://doi.org/10.3390/nano11123339

Ma L, Hu K, Wang C, Yang J-Y, Liu L. Prediction and Inverse Design of Structural Colors of Nanoparticle Systems via Deep Neural Network. Nanomaterials. 2021; 11(12):3339. https://doi.org/10.3390/nano11123339

Chicago/Turabian StyleMa, Lanxin, Kaixiang Hu, Chengchao Wang, Jia-Yue Yang, and Linhua Liu. 2021. "Prediction and Inverse Design of Structural Colors of Nanoparticle Systems via Deep Neural Network" Nanomaterials 11, no. 12: 3339. https://doi.org/10.3390/nano11123339