Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

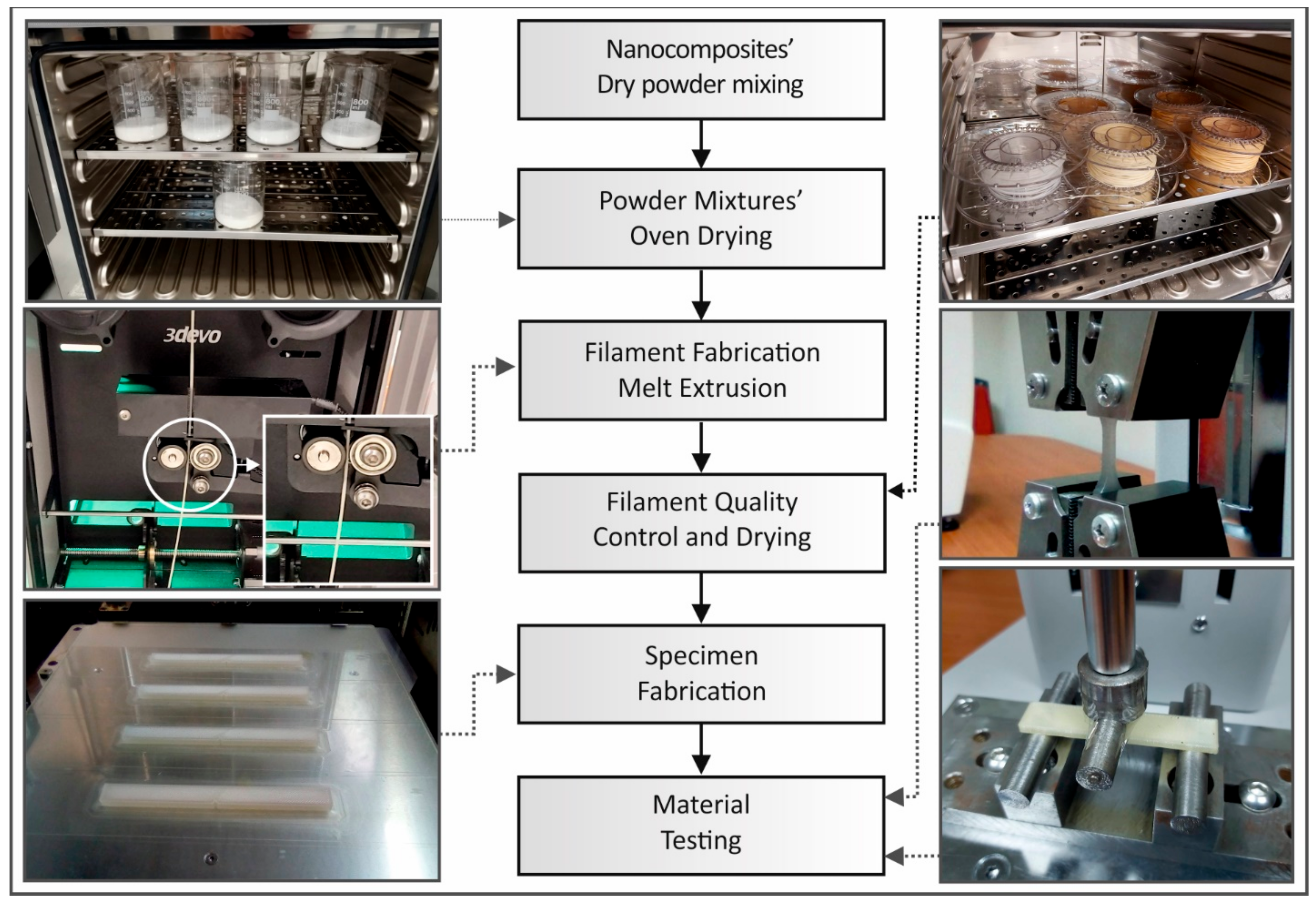

2.2. Methods

2.2.1. Filament Fabrication

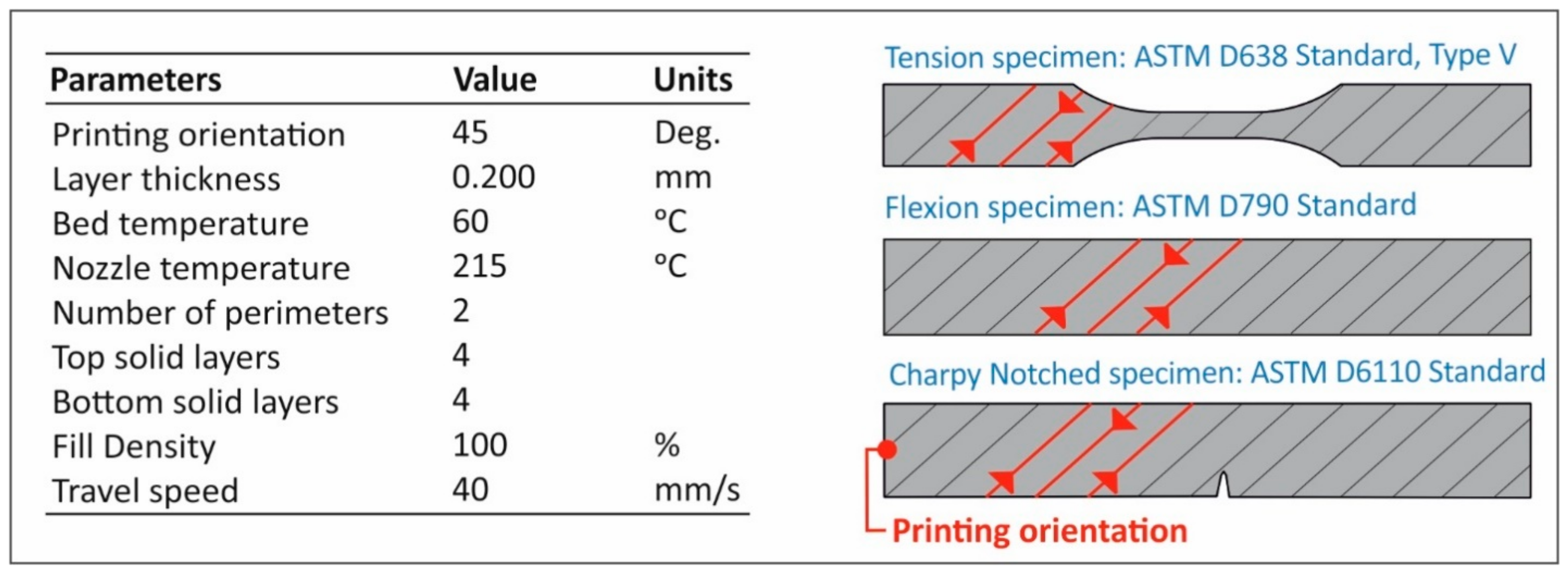

2.2.2. Tensile Specimens’ Fabrication and Testing

2.2.3. Flexure Specimens Fabrication and Testing

2.2.4. Impact Specimens Fabrication and Testing

2.2.5. Micro-Hardness Measurements

2.2.6. Antibacterial Measurements and Specimens’ Fabrication

2.2.7. Characterization Techniques

3. Results

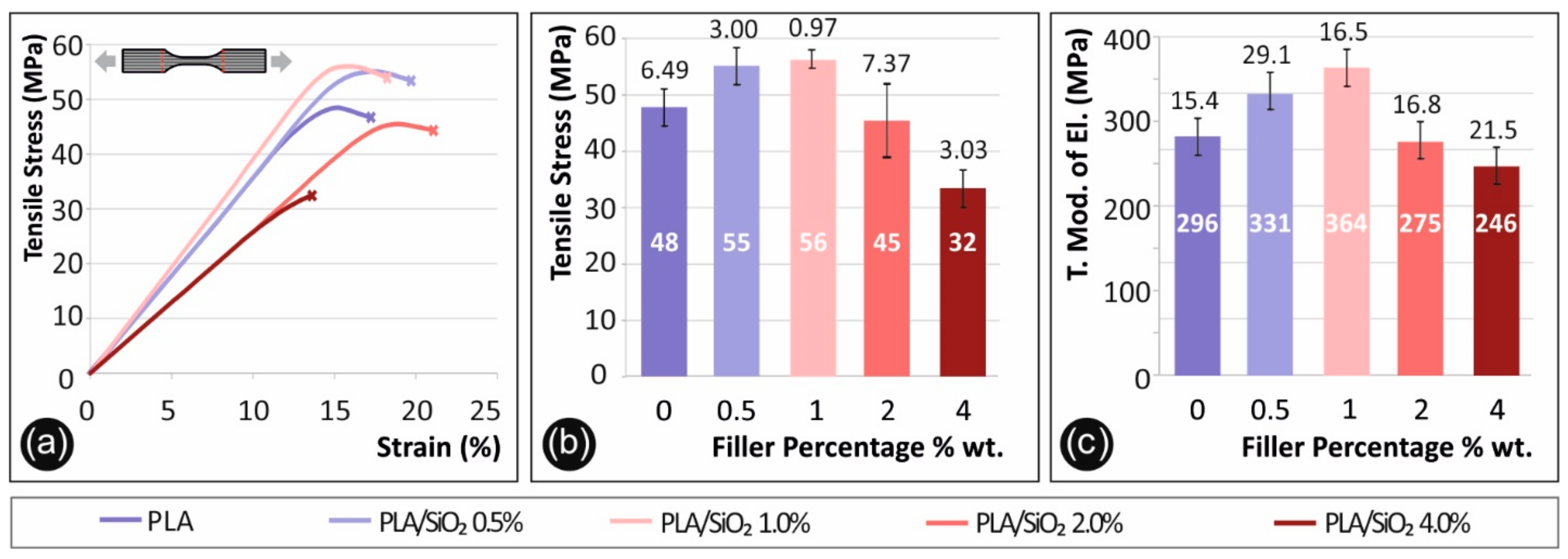

3.1. Tensile Results

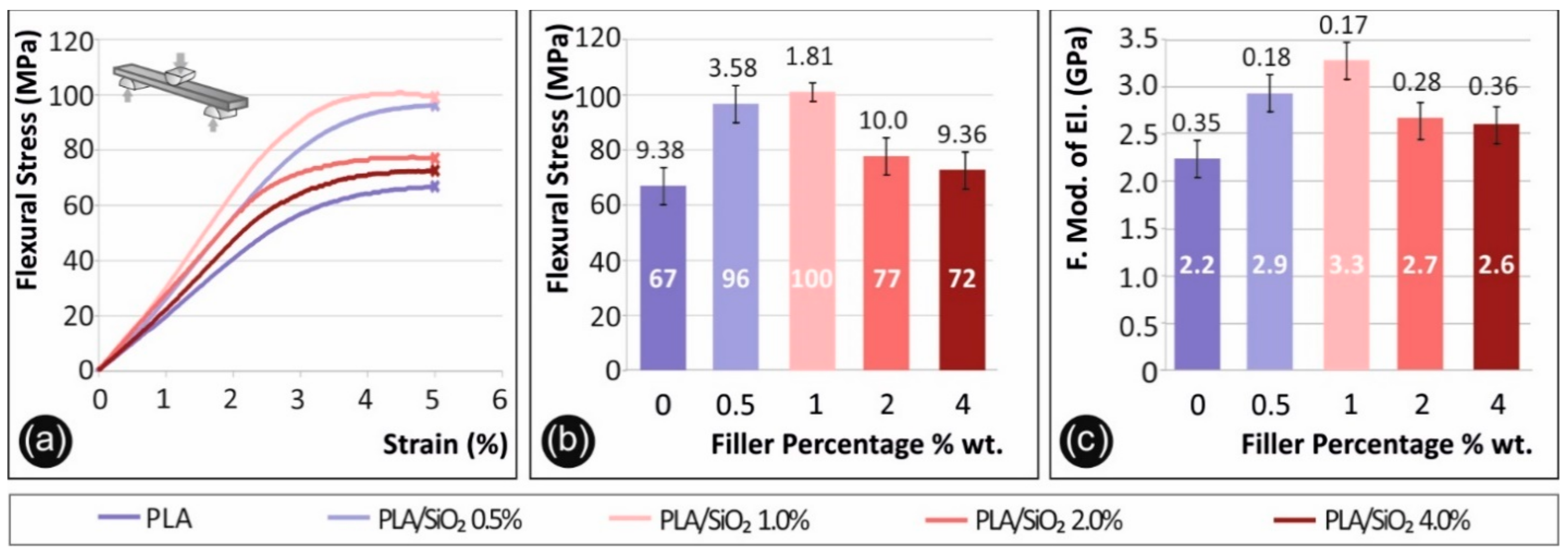

3.2. Flexural Results

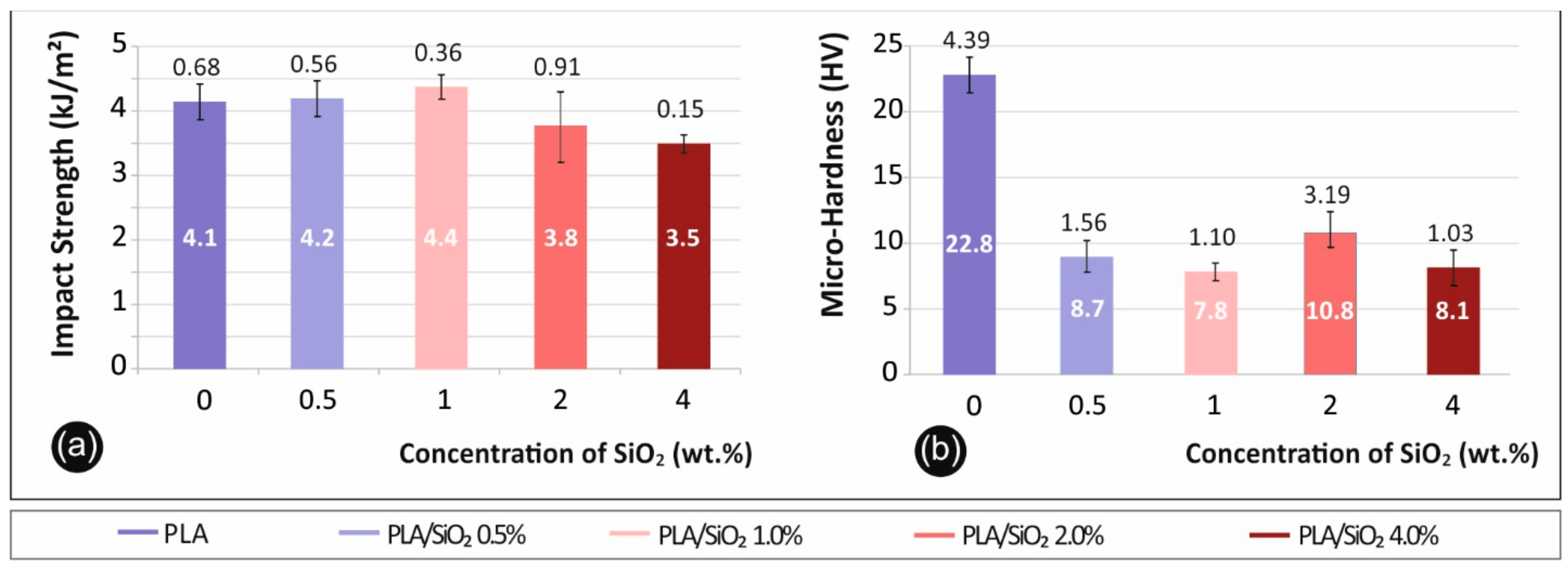

3.3. Impact-Microhardness Results

3.4. Antibacterial Results

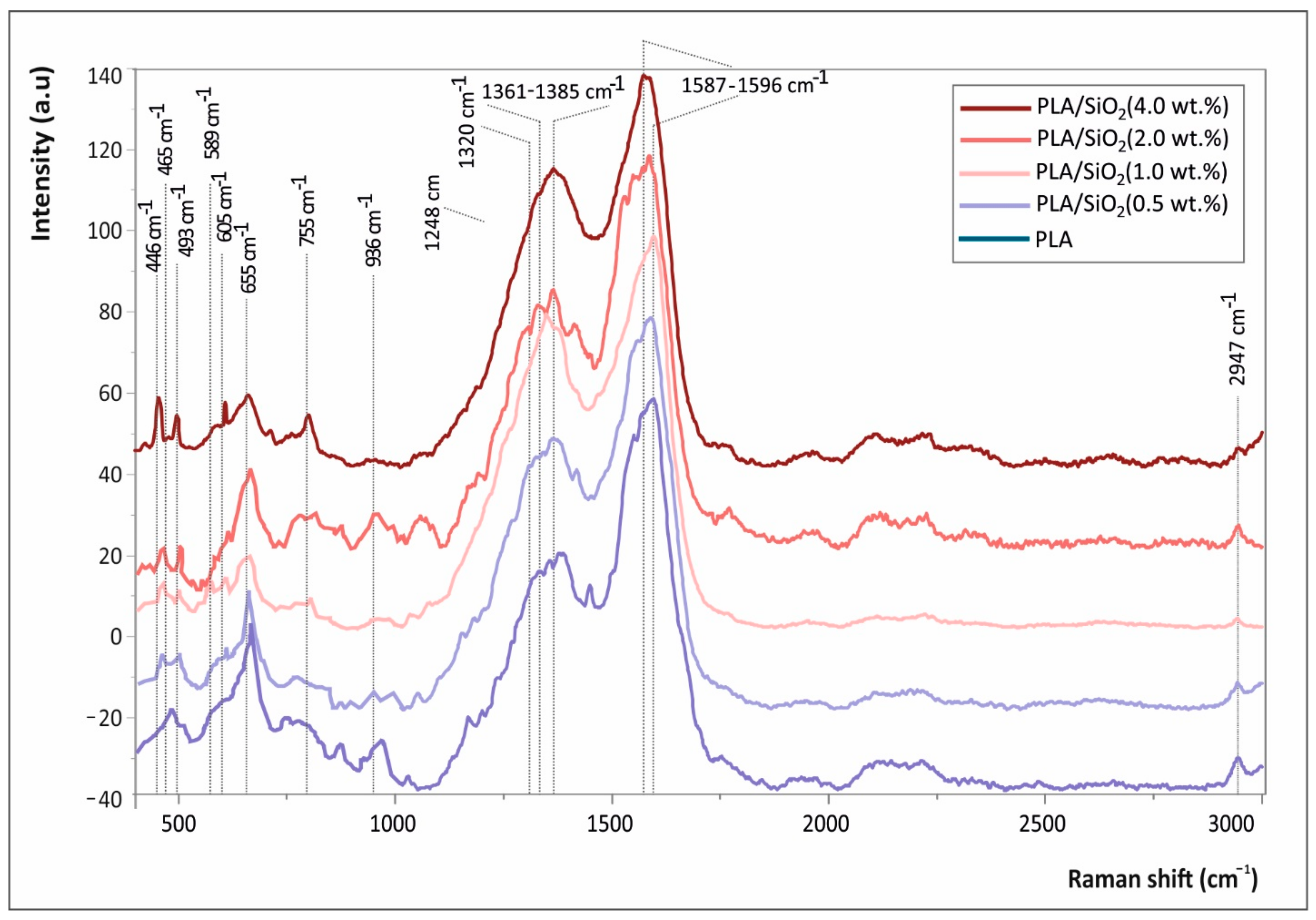

3.5. Raman Spectra of 3D Pritned PLA and PLA/SiO2 Nanocomposites

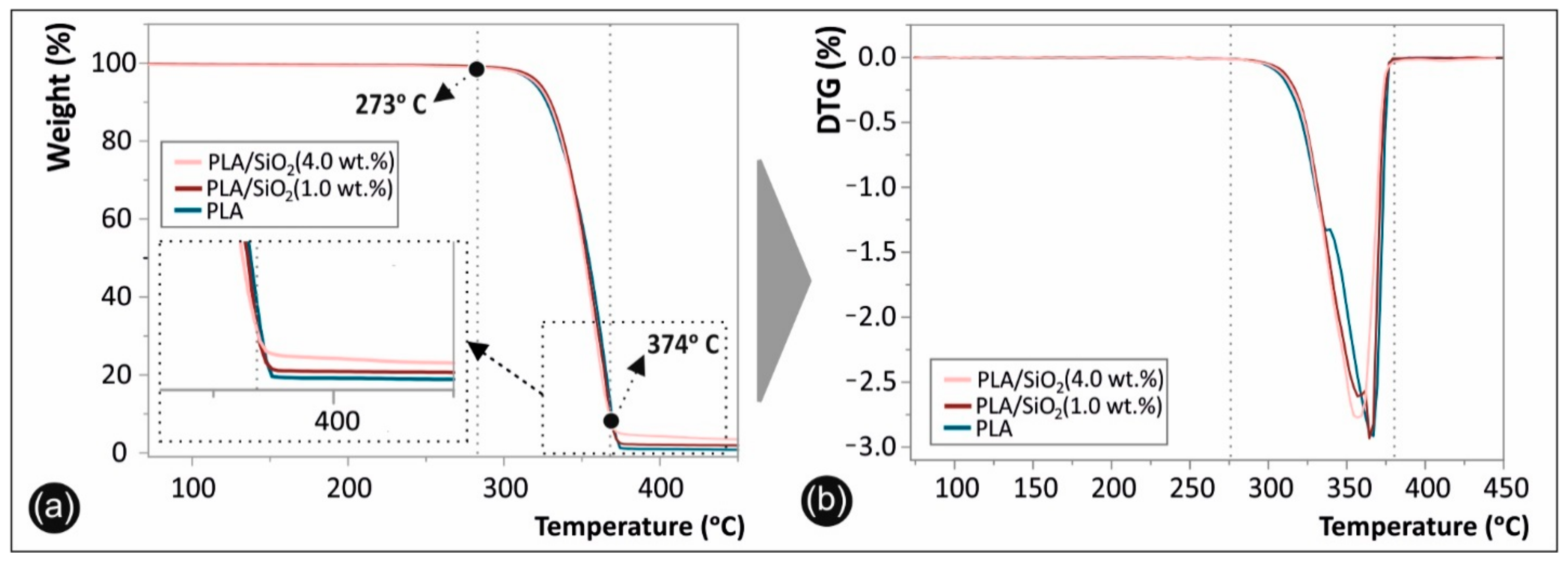

3.6. Thermogravimetric Analysis of 3D Printed Neat PLA and PLA/SiO2 Nanocomposites

3.7. SEM Microstructural Analysis

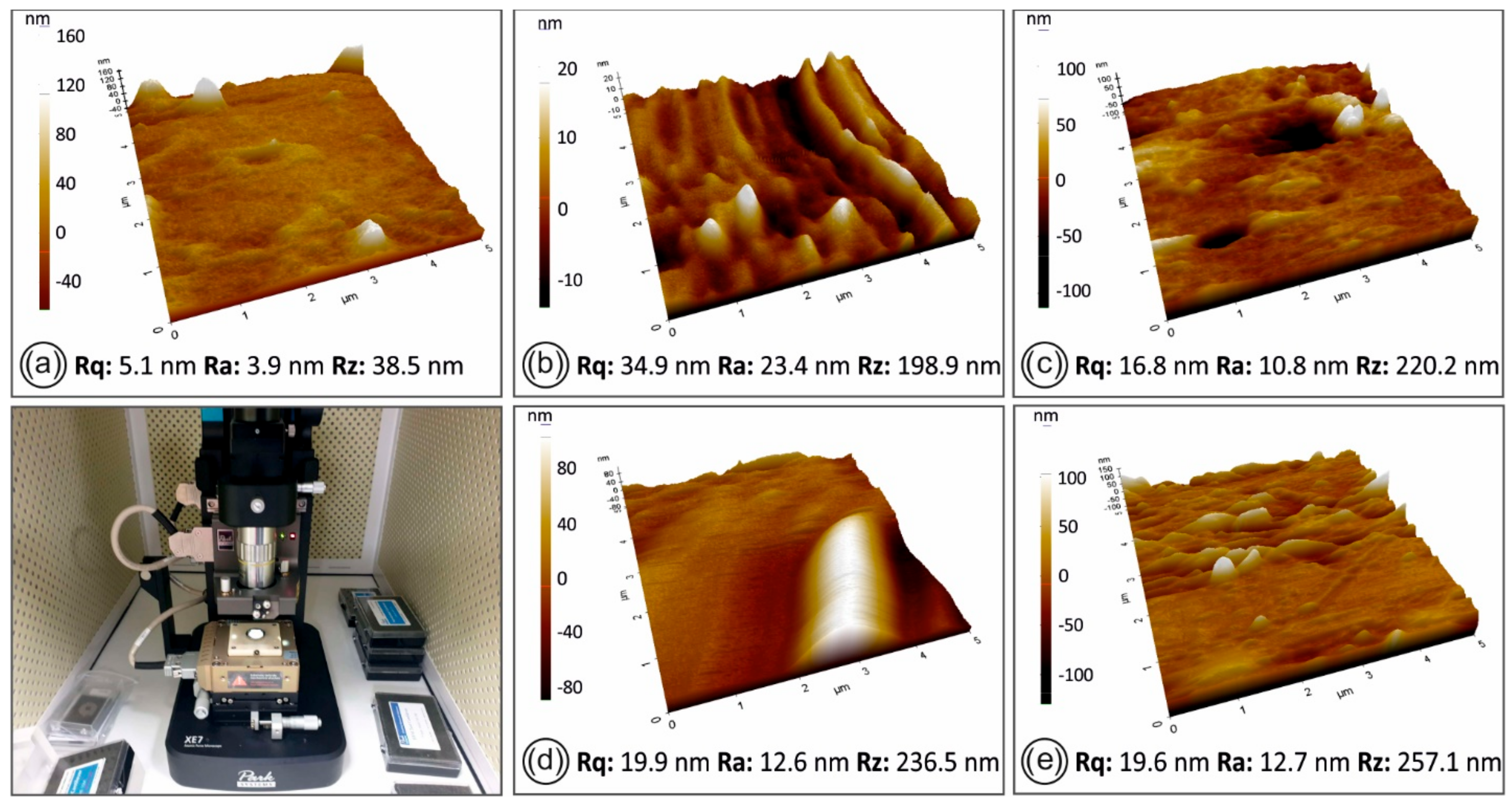

3.8. AFM Filament Measurements

4. Discussion

4.1. Mechanical Properties

4.2. Antibacterial Properties

4.3. Raman Spectra of 3D Pritned PLA and PLA/SiO2 Nanocomposites

4.4. Thermogravimetric Analysis of 3D Printed Neat PLA and PLA/SiO2 Nanocomposites

4.5. SEM Microstructural Analysis

4.6. AFM Microstructural Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Aliaa, N.N.S.; Fazliah, M.S.N.; Fatimah, S.S.; Syazana, A.N. Synthesis and Characterization of PLA-PEG Biocomposite Incorporated with Sol-Gel Derived 45S5 Bioactive Glass. Mater. Today Proc. 2019, 17, 982–988. [Google Scholar] [CrossRef]

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly-Lactic Acid Synthesis for Application in Bio-medical Devices A Review. Biotechnol. Adv. 2012, 30, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Bleach, N.; Nazhat, S.; Tanner, K.; Kellomäki, M.; Törmälä, P. Effect of filler content on mechanical and dynamic mechanical properties of particulate biphasic calcium phosphate—polylactide composites. Biomaterials 2002, 23, 1579–1585. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Mukherjee, T.; Kao, N. PLA Based Biopolymer Reinforced with Natural Fibre: A Review. J. Polym. Environ. 2011, 19, 714–725. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A comprehensive investigation of the mechanical behavior and the dielectrics of pure polylactic acid (PLA) and PLA with graphene (GnP) in fused deposition modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Kadhum, S.A. The Effect of two Types of Nano-Particles (ZnO and SiO2) on Different Types of Bacterial Growth. Biomed. Pharmacol. J. 2017, 10, 1701–1708. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Curosu, I.; Choudhury, S.; Hempel, S.; Davoodabadi, M.; Dinh, T.T.; Yang, J.; Mechtcherine, V. Electrophoretic deposition of nano-silica onto carbon fiber surfaces for an improved bond strength with cementitious matrices. Cem. Concr. Compos. 2020, 114, 103777. [Google Scholar] [CrossRef]

- Singh, L.; Karade, S.; Bhattacharyya, S.; Yousuf, M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Sikora, P.; Chougan, M.; Cuevas, K.; Liebscher, M.; Mechtcherine, V.; Ghaffar, S.H.; Stephan, D. The effects of nano-and micro-sized additives on 3D printable cementitious and alkali-activated composites: A review. Appl. Nanosci. 2021, 1–19. [Google Scholar] [CrossRef]

- Ren, Z.; Zhou, W.; Qing, Y.; Duan, S.; Pan, H.; Zhou, Y.; Li, N. Microwave absorption and mechanical properties of SiCf/SiOC composites with SiO2 fillers. Ceram. Int. 2021, 47, 8478–8485. [Google Scholar] [CrossRef]

- Pedna, A.; Pinho, L.; Frediani, P.; Mosquera, M.J. Obtaining SiO2–fluorinated PLA bionanocomposites with application as reversible and highly-hydrophobic coatings of buildings. Prog. Org. Coat. 2016, 90, 91–100. [Google Scholar] [CrossRef]

- Liu, W.; Wu, X.; Zhan, H.; Yan, F. Synthesis of bioactive poly(ethylene glycol)/SiO2-CaO-P2O5 hybrids for bone regeneration. Mater. Sci. Eng. C 2012, 32, 707–711. [Google Scholar] [CrossRef]

- Jia, H.; Hou, W.; Wei, L.; Xu, B.; Liu, X. The structures and antibacterial properties of nano-SiO2 supported silver/zinc–silver materials. Dent. Mater. 2008, 24, 244–249. [Google Scholar] [CrossRef]

- Petousis, M.; Tzounis, L.; Papageorgiou, D.; Vidakis, N. Decoration of SiO2 and Fe3O4 Nanoparticles onto the Surface of MWCNT-Grafted Glass Fibers: A Simple Approach for the Creation of Binary Nanoparticle Hierarchical and Multifunctional Composite Interphases. Nanomaterials 2020, 10, 2500. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, H. Tunable optical properties of SiO2/Ag double-layer and SiO2/Ag/SiO2 triple-layer hybrid structures. Phys. B Condens. Matter 2020, 605, 412772. [Google Scholar] [CrossRef]

- Ren, Z.; Zhou, W.; Qing, Y.; Duan, S.; Pan, H.; Zhou, Y. Improved mechanical and microwave absorption properties of SiCf/SiC composites with SiO2 filler. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the Strain Rate Sensitivity of Fused Filament Fabrication (FFF) Processed PLA, ABS, PETG, PA6, and PP Thermoplastic Polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Tzounis, L. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 2020, 5, 42. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. On the compressive behavior of an FDM Steward Platform part. J. Comput. Des. Eng. 2017, 4, 339–346. [Google Scholar] [CrossRef]

- Hakim, R.H.; Cailloux, J.; Santana, O.O.; Bou, J.; Sánchez-Soto, M.; Odent, J.; Raquez, J.M.; Dubois, P.; Carrasco, F.; Maspoch, M.L. PLA/SiO2 composites: Influence of the filler modifications on the morphology, crystallization behavior, and mechanical properties. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers 2020, 12, 1589. [Google Scholar] [CrossRef]

- Balouiri, M.; Sadiki, M.; Ibnsouda, S.K. Methods for in vitro evaluating antimicrobial activity: A review. J. Pharm. Anal. 2016, 6, 71–79. [Google Scholar] [CrossRef]

- Wu, J.-H.; Yen, M.-S.; Kuo, M.; Chen, B.-H. Physical properties and crystallization behavior of silica particulates reinforced poly(lactic acid) composites. Mater. Chem. Phys. 2013, 142, 726–733. [Google Scholar] [CrossRef]

- Lv, H.; Song, S.; Sun, S.; Ren, L.; Zhang, H. Enhanced properties of poly(lactic acid) with silica nanoparticles. Polym. Adv. Technol. 2016, 27, 1156–1163. [Google Scholar] [CrossRef]

- Mukherjee, P.K.; Roy, M.; Mandal, B.P.; Dey, G.K.; Ghatak, J.; Tyagi, A.K.; Kale, S.P. Green synthesis of highly stabilized nanocrystalline silver particles by a non-pathogenic and agriculturally important fungus T. asperellum. Nanotechnology 2008, 19, 075103. [Google Scholar] [CrossRef]

- Biswas, R.K.; Khan, P.; Mukherjee, S.; Mukhopadhyay, A.K.; Ghosh, J.; Muraleedharan, K. Study of short range structure of amorphous Silica from PDF using Ag radiation in laboratory XRD system, RAMAN and NEXAFS. J. Non-Cryst. Solids 2018, 488, 1–9. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Truşcă, R.-D.; Ilie, C.-I.; Oprea, O.-C.; Andronescu, E. Innovative Antimicrobial Chitosan/ZnO/Ag NPs/Citronella Essential Oil Nanocomposite—Potential Coating for Grapes. Foods 2020, 9, 1801. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Tzounis, L.; Liebscher, M.; Grammatikos, S.A. Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content. Nanomaterials 2021, 11, 1012. https://doi.org/10.3390/nano11041012

Vidakis N, Petousis M, Velidakis E, Mountakis N, Tzounis L, Liebscher M, Grammatikos SA. Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content. Nanomaterials. 2021; 11(4):1012. https://doi.org/10.3390/nano11041012

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Emanuel Velidakis, Nikolaos Mountakis, Lazaros Tzounis, Marco Liebscher, and Sotirios A. Grammatikos. 2021. "Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content" Nanomaterials 11, no. 4: 1012. https://doi.org/10.3390/nano11041012

APA StyleVidakis, N., Petousis, M., Velidakis, E., Mountakis, N., Tzounis, L., Liebscher, M., & Grammatikos, S. A. (2021). Enhanced Mechanical, Thermal and Antimicrobial Properties of Additively Manufactured Polylactic Acid with Optimized Nano Silica Content. Nanomaterials, 11(4), 1012. https://doi.org/10.3390/nano11041012