The Influence of Scandium on the Composition and Structure of the Ti-Al Alloy Obtained by “Hydride Technology”

Abstract

:1. Introduction

2. Materials and Methods

2.1. Obtaining Alloys

2.2. Research Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deng, T.; Li, S.; Liang, Y.; Sun, L.; Zhang, Y. Effects of scandium and silicon addition on the microstructure and mechanical properties of Ti-6Al-4V alloy. J. Mater. Res. Technol. 2020, 9, 5676–5688. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys; Science and Technology, Ed.; Wiley-VCH Verlag & Co. KGaA: Weinheim, Germany, 2011; pp. 1–745. [Google Scholar]

- Qbau, N.; Nam, N.D.; Ca, N.X.; Hien, N.T. The crack healing effect of scandium in aluminum alloys during laser additive manufacturing. J. Manuf. Process. 2020, 50, 241–246. [Google Scholar] [CrossRef]

- Glazoff, M.; Khvan, V.; Zolotorevsky, V.; Belov, N.; Dinsdale, A. Influence of heat treatment upon microstructure of casting aluminum alloys. In Casting Aluminum Alloys; Butterworth-Heinemann: London, UK, 2019; pp. 235–312. [Google Scholar]

- Songbo, Y.; Boyun, H.; Zhimin, Y. Effect of minor Sc on high temperature mechanical properties of Ti–Al based alloys. Mater. Sci. Eng. A 2000, 280, 204–207. [Google Scholar] [CrossRef]

- Lazurenko, D.V.; Stark, A.; Esikov, M.A.; Paul, J.; Bataev, I.A.; Kashimbetova, A.A.; Pyczak, F. Ceramic-reinforced γ-TiAl-based composites: Synthesis, structure, and properties. Materials 2019, 12, 629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Inui, H.; Oh, M.H.; Nakamura, A.; Yamaguchi, M. Ordered domains in TiAl coexisting with Ti3Al in the lamellar structure of Ti-rich TiAl compounds. Philos. Mag. A 1992, 66, 539–555. [Google Scholar] [CrossRef]

- Harada, Y.; Dunand, D. Microstructure of Al3Sc with ternary transition-metal additions. Mater. Sci. Eng. A 2002, 329, 686–695. [Google Scholar] [CrossRef] [Green Version]

- Kurzina, I.A. Ion-implanted nanodimensional intermetallic phases. Inorg. Mater. Appl. Res. 2010, 1, 254–269. [Google Scholar] [CrossRef]

- Nikonenko, A.V.; Popova, N.A.; Nikonenko, E.L.; Kurzina, I.A. The effect of aluminum ion implantation on the grain size and structure of UFG titanium. Surf. Coat. Tech. 2020, 393, 125750. [Google Scholar] [CrossRef]

- Hyde, K.B.; Norman, A.F.; Prangnell, P.B. The effect of cooling rate on the morphology of primary Al3Sc intermetallic particles in Al–Sc alloys. Acta Mater. 2001, 49, 1327–1337. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Zu, Q.; Han, B.; Han, X.; Cui, C. Significantly improved particle strengthening of Al–Sc alloy by high Sc composition design and rapid solidification. Mater. Sci. Eng. A 2021, 800, 140304. [Google Scholar] [CrossRef]

- Glezer, A.M.; Kozlov, E.V.; Koneva, N.A.; Popova, N.A.; Kurzina, I.A. Plastic Deformation of Nanostructured Materials; CISP CRC, Ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A Review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2018, 35, 270–284. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.R.; Zhang, Y.; Xia, Y.; Free, M. Powder metallurgy of titanium—Past, present, and future. Int. Mater. Rev. 2018, 63, 1–53. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Stock, H.R.; Köhler, B.; Bomas, H.; Zoch, H.W. Characteristics of aluminium–scandium alloy thin sheets obtained by physical vapour deposition. Mater. Des. 2010, 31, 76–81. [Google Scholar] [CrossRef]

- Yener, T.; Okumus, S.C.; Zeytin, S. In Situ Formation of Ti-TiAl3 metallic-intermetallic composite by electric current activated sintering method. Acta Phys. Pol. A 2015, 127, 917–920. [Google Scholar] [CrossRef]

- Belgibayeva, A.; Abzaev, Y.; Karakchieva, N.; Erkasov, R.; Sachkov, V.; Kurzina, I. The Structural and phase state of the TiAl system alloyed with rare-earth metals of the controlled composition synthesized by the “Hydride technology”. Metals 2020, 859, 1–17. [Google Scholar]

- Narayanan, R.P.; Kazantzis, N.K.; Emmert, M.H. Process for scandium recovery from Jamaican bauxite residue: A probabilistic economic assessment. Mater. Today-Proc. 2019, 9, 578–586. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Jiang, F.; Huang, J.; Xu, G.; Yin, Z. On the role of Sc or Er micro-alloying in the microstructure evolution of Al-Mg alloy sheets during annealing. Mater. Charact. 2019, 157, 109918. [Google Scholar] [CrossRef]

- Zakharov, V.V. Prospects of Creation of Aluminum Alloys Sparingly Alloyed with Scandium. Met. Sci. Heat Treat. 2018, 60, 172–176. [Google Scholar] [CrossRef]

- Zakharov, V.V. Effect of scandium on the structure and properties of aluminum alloys. Met. Sci. Heat Treat. 2003, 45, 246–253. [Google Scholar] [CrossRef]

- Dorin, T.; Ramajayam, M.; Vahid, A.; Langan, T. Aluminium scandium alloys. In Fundamentals of Aluminium Metallurgy; Woodhead Publishing: New York, NY, USA, 2018; pp. 439–494. [Google Scholar]

- Zuo, X.; Cui, H. Effect of Minor Sc, Zr and Ti Additions on the microstructures and the mechanical properties of pure aluminium. Adv. Mat. Res. 2011, 152, 1071–1078. [Google Scholar]

- Feng, J.; Ye, B.; Zuo, L.; Qi, R.; Wang, Q.; Jiang, H.; Wang, C. Effects of Zr, Ti and Sc additions on the microstructure and mechanical properties of Al-0.4Cu-0.14Si-0.05Mg-0.2Fe alloys. J. Mater. Sci. Technol. 2018, 34, 2316–2324. [Google Scholar] [CrossRef]

- Lathabai, S.; Lloyd, P.G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al–Mg alloy. Acta Mater. 2002, 50, 4275–4292. [Google Scholar] [CrossRef]

- Zhang, W.G.; He, L.J.; Li, P.J.; Ye, Y.C.; Xue, F.E.N.G.; Novikov, L.S. Dynamic response and numerical simulation of Al-Sc and Al-Ti alloys under high-speed impact. Trans. Nonferr. Metal. Soc. 2015, 25, 559–570. [Google Scholar] [CrossRef]

- Tong, Y.X.; Fan, X.M.; Shuitcev, A.V.; Chen, F.; Tian, B.; Li, L.; Zheng, Y.F. Effects of Sc addition and aging on microstructure and martensitic transformation of Ni-rich NiTiHfSc high temperature shape memory alloys. J. Alloy. Compd. 2020, 845, 156331. [Google Scholar] [CrossRef]

- Costa, S.; Puga, H.; Barbosa, J.; Pinto, A.M.P. The effect of Sc additions of the microstructure and age hardening behaviour of as cast Al-Sc alloys. Mater. Des. 2012, 42, 347–352. [Google Scholar] [CrossRef] [Green Version]

- Van Dalen, M.E.; Seidman, D.N.; Dunand, D.C. Creep- and coarsening properties of Al–0.06at.% Sc–0.06at.% Ti at 300–450 °C. Acta Mater. 2008, 56, 369–4377. [Google Scholar] [CrossRef]

- Davydov, V.G.; Rostova, T.D.; Zakharov, V.V.; Filatov, Y.A.; Yelagin, V.I. Scientific principles of making an alloying addition of scandium to aluminium alloys. Mat. Sci. Eng. A-Struct. 2000, 280, 30–36. [Google Scholar] [CrossRef]

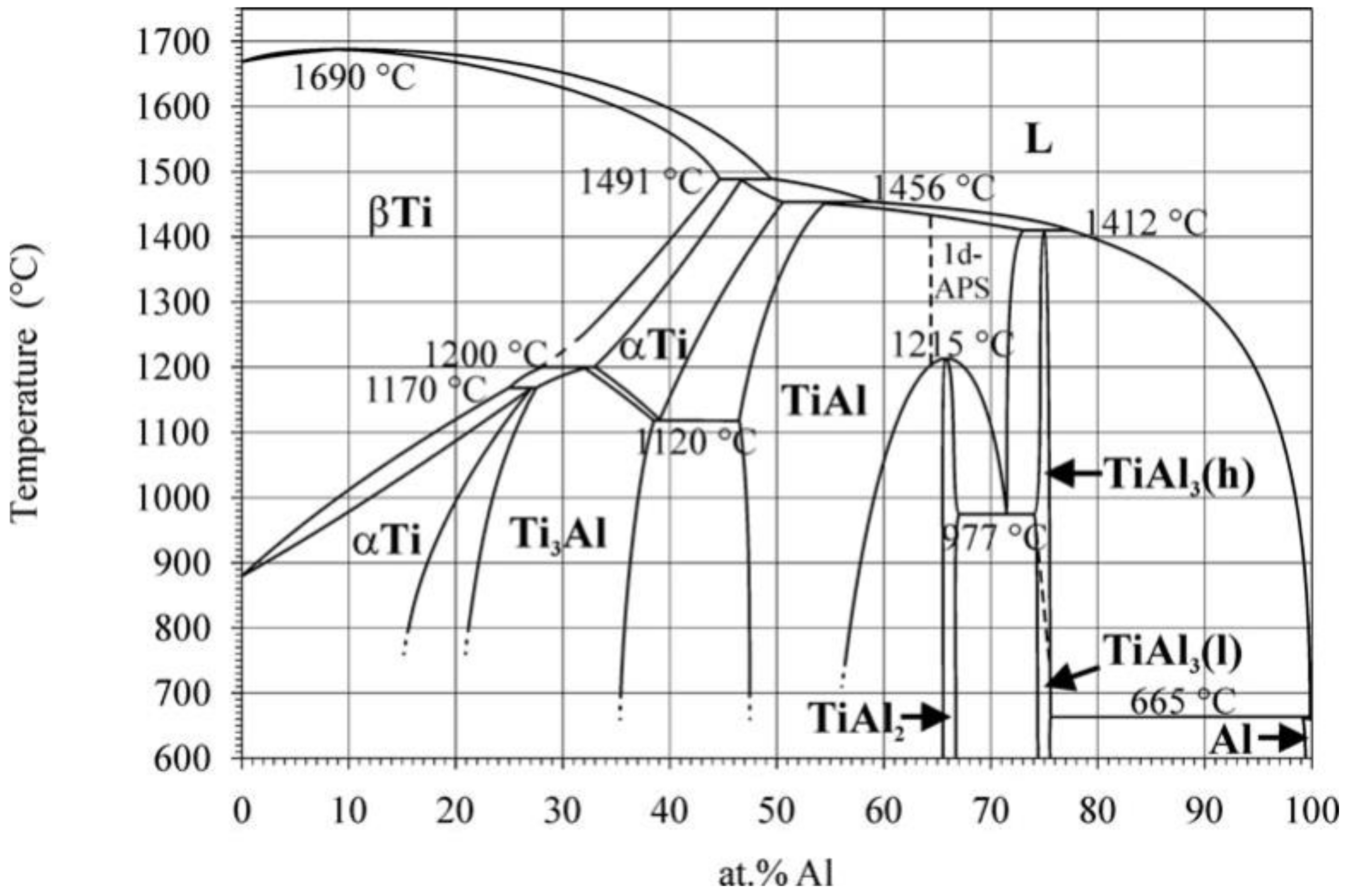

- Schuster, J.C.; Palm, M. Reassessment of the binary Aluminum-Titanium phase diagram. J. Phase Equilib. Diff. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Pecharsky, V.; Zavalij, P. Fundamentals of Powder Diffraction and Structural Characterization of Materials, 2nd ed.; Springer Science+Business Media, LLC: New York, NY, USA, 2005. [Google Scholar]

- Toby, B.H. R factors in Rietveld analysis: How good is good enough? Powder. Diffr. 2006, 21, 67–70. [Google Scholar] [CrossRef] [Green Version]

- Young, R.A. The Ritveld Method; Oxford University Press: Oxford, UK, 1996. [Google Scholar]

- Guptaa, R.K.; Panta, B. Titanium aluminides. In Intermetallic Matrix Composites; Mitra, R., Ed.; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Belgibayeva, A.F.; Erkasov, R.S.; Kurzina, I.A.; Karakchieva, N.I.; Sachkov, V.I.; Abzaev, Y.A. Influence of microalloying with scandium on the structure of alloys based on titanium aluminides, Bulletin of the LN Gumilyov Eurasian National University. Chemistry. Geography. Ecol. Ser. 2000, 131, 23–30. [Google Scholar]

- Dettenwanger, F.; Schumann, E.; RuÈhle, M.; Rakowski, J.; Meier, G.H. Microstructural Study of Oxidized –TiAl. Oxid. Met. 1998, 50, 269–307. [Google Scholar] [CrossRef]

- Weinert, K.; Biermann, D.; Bergmann, S. Machining of High Strength Light Weight Alloys for Engine Applications. CIRP Ann. 2007, 56, 105–108. [Google Scholar] [CrossRef]

- Mandal, P.K. Heat Treatment and Friction Stir Processing Effects on Mechanical Properties and Microstructural Evolution of Sc Inoculated Al-Zn-Mg Alloys. Mater. Sci. Metal. Eng. 2017, 4, 16–28. [Google Scholar]

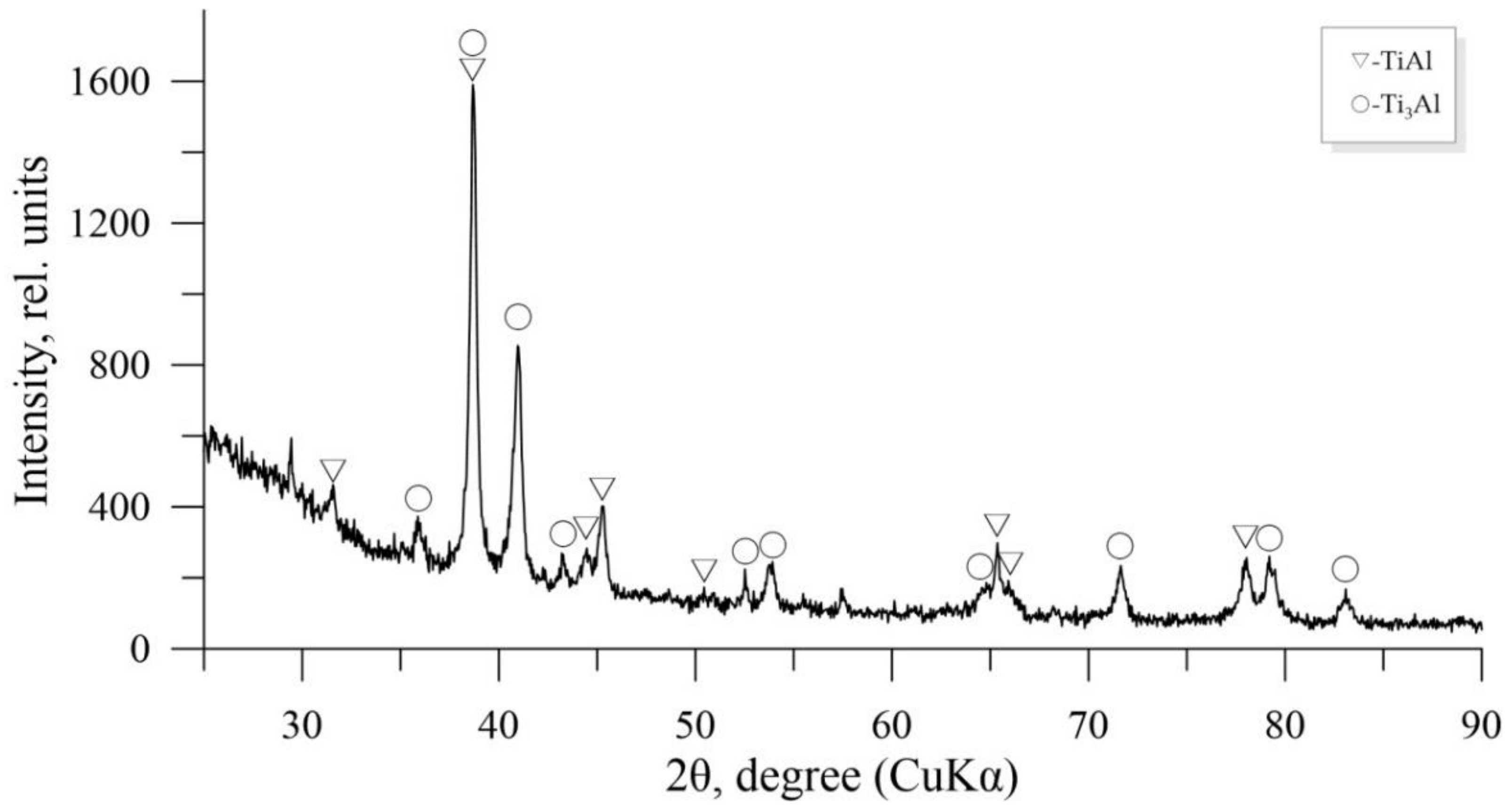

| Phase. | ΔH° (Formation), kJ/mole [33] | Lattice Type | Ti-Al [19] | Ti-Al-Sc [38] |

|---|---|---|---|---|

| Proportion, % | Proportion, % | |||

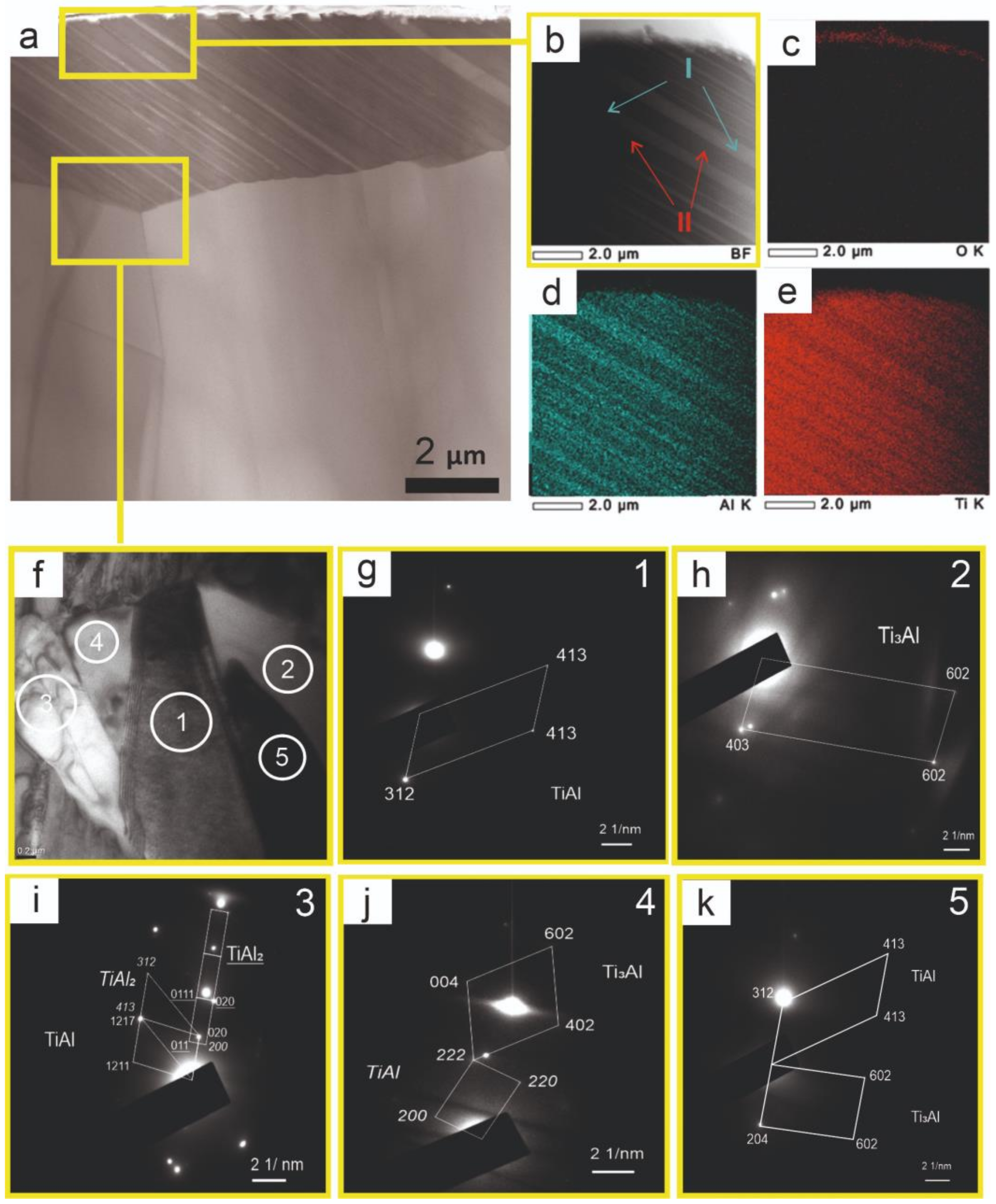

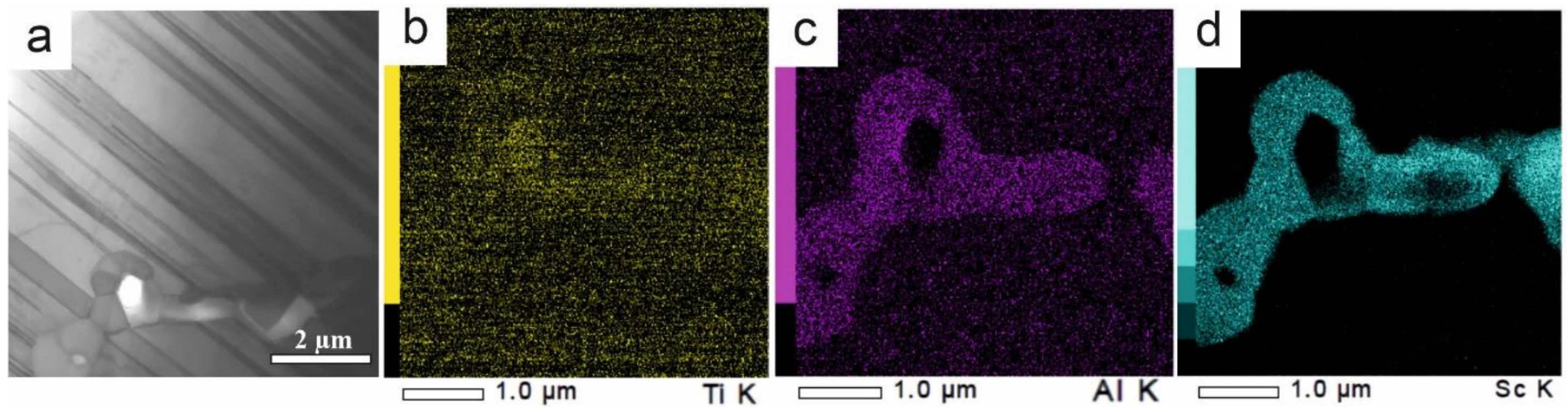

| TiAl | −40.0 ± 1.0 | P4/mmm | 31 | 42 |

| Ti3Al | −20.3 ± 1.9 | P63/mmc | 19 | 26 |

| Ti1.5Al2.5 | - | Pmmm | 3 | 11 |

| Ti2Al5 | - | P4/mmm | 3 | 4 |

| Ti5Al11 | - | I4/mmm | 8 | 4 |

| TiAl2 | −38.6 ± 2.6 | Cmmm | 9 | 3 |

| (TiAl2)1.33 | - | P4/mmm | 2 | - |

| Al | - | Fm-3m | 1 | 2 |

| α-Ti | −9.5 ± 1.0 | Im-3m | 19 | 6 |

| β-Ti | - | Im-3m | 2 | 2 |

| Total | 100 | 100 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karakchieva, N.; Lepakova, O.; Abzaev, Y.; Sachkov, V.; Kurzina, I. The Influence of Scandium on the Composition and Structure of the Ti-Al Alloy Obtained by “Hydride Technology”. Nanomaterials 2021, 11, 918. https://doi.org/10.3390/nano11040918

Karakchieva N, Lepakova O, Abzaev Y, Sachkov V, Kurzina I. The Influence of Scandium on the Composition and Structure of the Ti-Al Alloy Obtained by “Hydride Technology”. Nanomaterials. 2021; 11(4):918. https://doi.org/10.3390/nano11040918

Chicago/Turabian StyleKarakchieva, Natalia, Olga Lepakova, Yuri Abzaev, Victor Sachkov, and Irina Kurzina. 2021. "The Influence of Scandium on the Composition and Structure of the Ti-Al Alloy Obtained by “Hydride Technology”" Nanomaterials 11, no. 4: 918. https://doi.org/10.3390/nano11040918

APA StyleKarakchieva, N., Lepakova, O., Abzaev, Y., Sachkov, V., & Kurzina, I. (2021). The Influence of Scandium on the Composition and Structure of the Ti-Al Alloy Obtained by “Hydride Technology”. Nanomaterials, 11(4), 918. https://doi.org/10.3390/nano11040918