Conductive Biomass Films Containing Graphene Oxide and Cationic Cellulose Nanofibers for Electric-Heating Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GO/CCNF Films

2.3. Characterization

2.4. Electric-Heating Performance

3. Results

3.1. Mechanical Properties and Microstructure

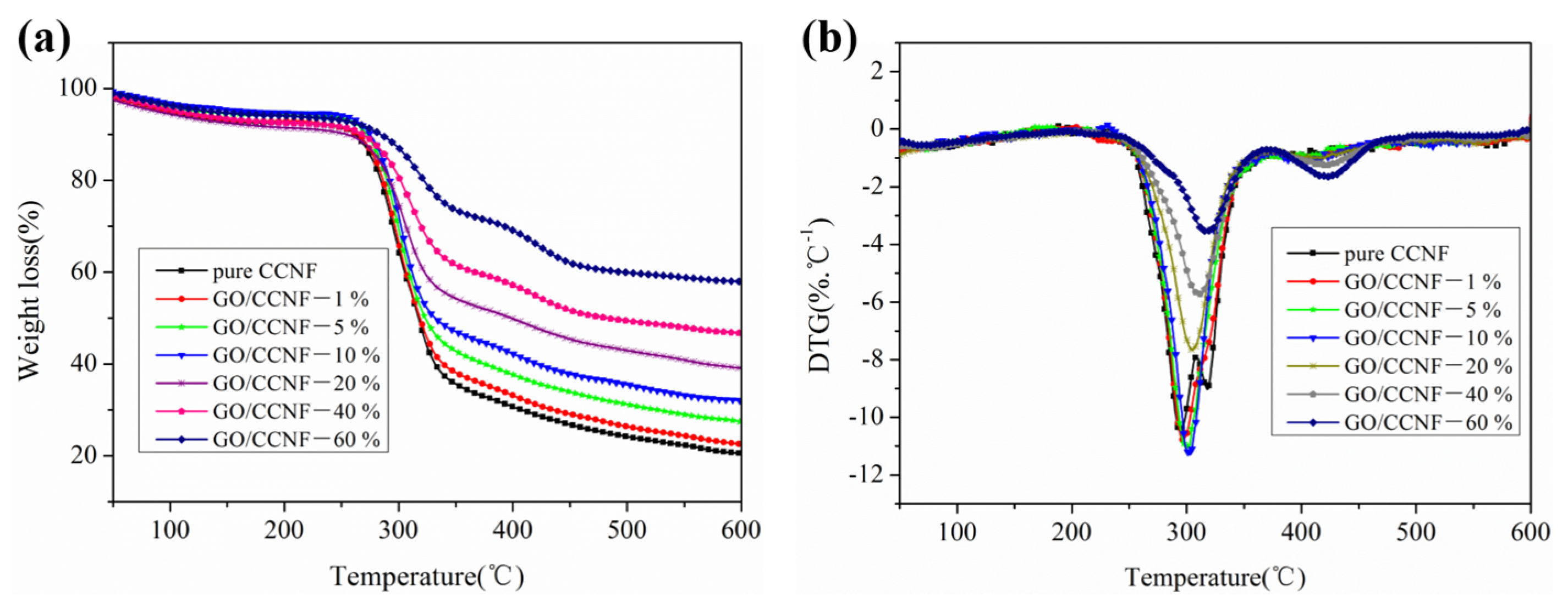

3.2. Thermal Stability

3.3. Electrical Conductivity

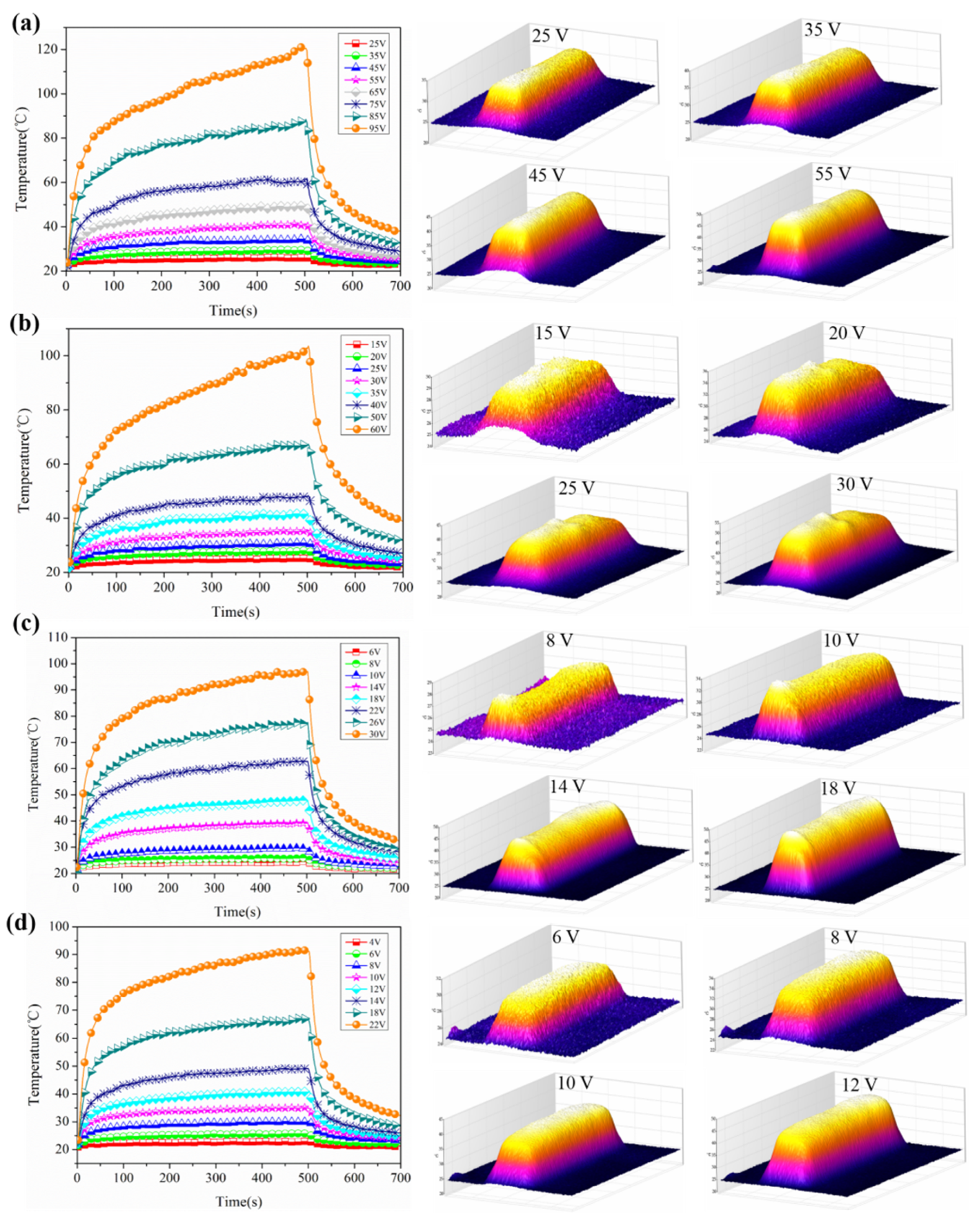

3.4. Electric-Heating Performance

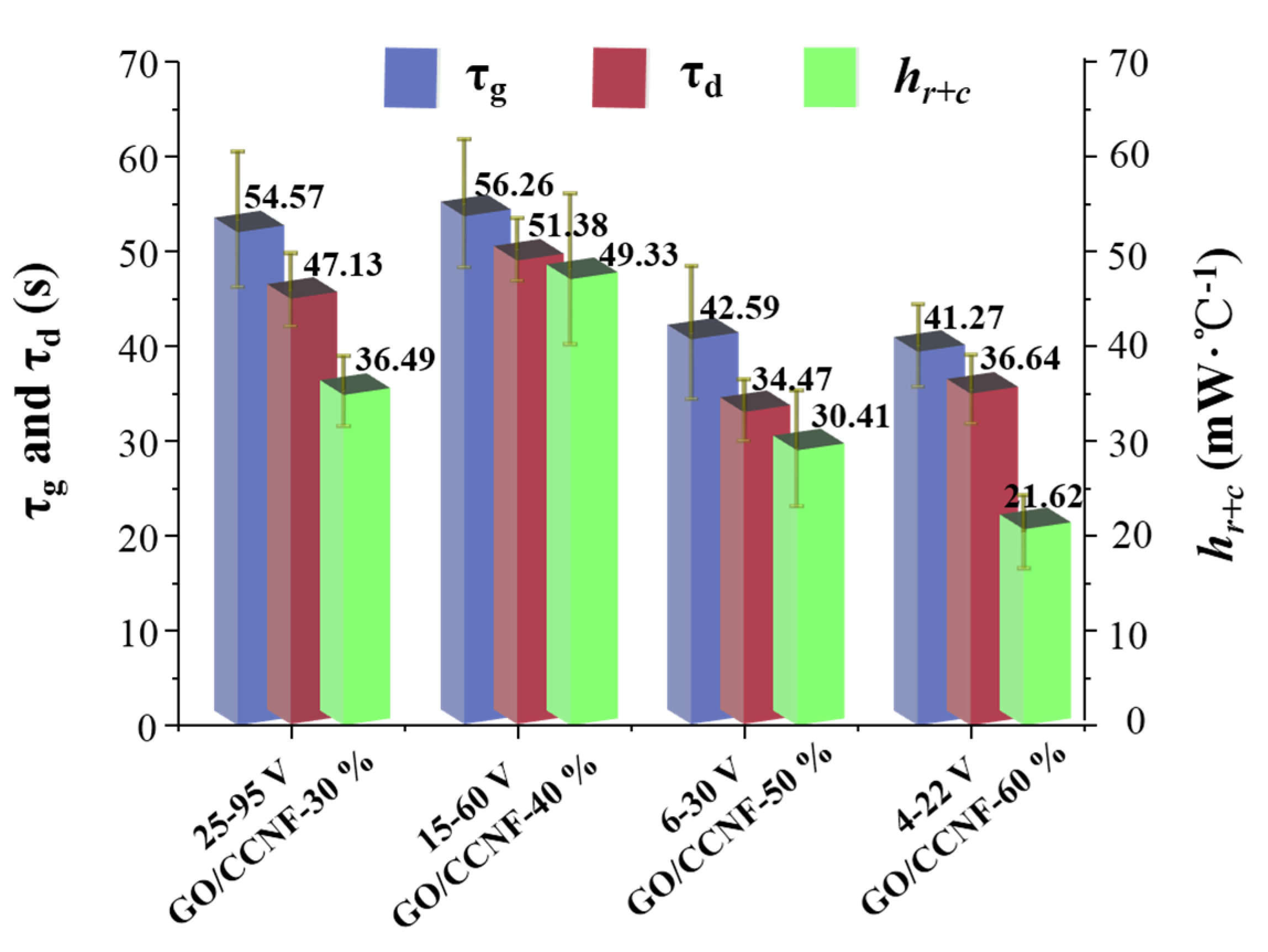

3.5. Electric-Heating Cycle Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, H.B.; Zhu, S.P.; Yang, Y.H.; Huang, W.M.; Leng, J.S.; Du, S.Y. surface grafting of carbon fibers with artificial sil-ver-nanoparticledecorated graphene oxide for high-speed electrical actuation of shape-memory polymers. J. Appl. Polym. Sci. 2015, 132, 41673. [Google Scholar]

- Loeblein, M.; Bolker, A.; Tsang, S.H.; Atar, N.; Saguy, C.U.; Verker, R.; Gouzman, I.; Grossman, E.; Teo, E.H.T. Flexible electronics: 3D graphene–infused polyimide with enhanced electrothermal performance for long–term flexible space applications. Small 2015, 48, 6425–6434. [Google Scholar] [CrossRef]

- Montes, S.; Carrasco, P.M.; Ruiz, V.; Cabanero, G.; Grande, H.J.; Labidi, J.; Odriozola, I. Synergistic reinforcement of poly(vinyl alcohol) nanocomposites with cellulose nanocrystal-stabilized graphene. Compos. Sci. Technol. 2015, 117, 26–31. [Google Scholar] [CrossRef]

- Janas, D.; Koziol, K.K. A review of production methods of carbon nanotube and graphene thin films for electrothermal applications. Nanoscale 2014, 6, 3037–3045. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Xu, Z.; Zhuang, J.; Liu, Z.; Peng, L.; Liu, Y.; Gao, W.; Gao, C. Highly Stretchable Graphene Fibers with Ultrafast Electrothermal Response for Low-Voltage Wearable Heaters. Adv. Electron. Mater. 2017, 3, 1600425. [Google Scholar] [CrossRef]

- Xiao, Z.; Sheng, C.; Xia, Y.; Yu, X.; Liang, C.; Huang, H.; Gan, Y.; Zhang, J.; Zhang, W. Electrical heating behavior of flexible thermoplastic polyurethane/Super-P nanoparticle composite films for advanced wearable heaters. J. Ind. Eng. Chem. 2019, 71, 293–300. [Google Scholar] [CrossRef]

- Tian, M.; Hao, Y.; Qu, L.; Zhu, S.; Zhang, X.; Chen, S. Enhanced electrothermal efficiency of flexible graphene fabric Joule heaters with the aid of graphene oxide. Mater. Lett. 2019, 234, 101–104. [Google Scholar] [CrossRef]

- Huang, K.; Liu, J.; Tan, L.; Zuo, J.; Fu, L. Ultrahigh Temperature Graphene Molecular Heater. Adv. Mater. Interfaces 2018, 5, 1701299. [Google Scholar] [CrossRef]

- Sun, H.; Chen, D.; Ye, C.; Li, X.; Dai, D.; Yuan, Q.; Chee, K.W.; Zhao, P.; Jiang, N.; Lin, C.-T. Large-area self-assembled reduced graphene oxide/electrochemically exfoliated graphene hybrid films for transparent electrothermal heaters. Appl. Surf. Sci. 2018, 435, 809–814. [Google Scholar] [CrossRef]

- Zhang, X.; Li, D.; Liu, K.; Tong, J.; Yi, X.; XuFeng, Z.; Dihui, L.; Kejian, L.; JianFeng, T.; Xiaosu, Y. Flexible graphene-coated carbon fiber veil/polydimethylsiloxane mats as electrothermal materials with rapid responsiveness. Int. J. Lightweight Mater. Manuf. 2019, 2, 241–249. [Google Scholar] [CrossRef]

- Kalita, G.; Wakita, K.; Umeno, M. Low temperature growth of graphene film by microwave assisted surface wave plasma CVD for transparent electrode application. RSC Adv. 2012, 2, 2815–2820. [Google Scholar] [CrossRef]

- Lee, B.-J.; Jeong, G.-H. Fabrication of defrost films using graphenes grown by chemical vapor deposition. Curr. Appl. Phys. 2012, 12, S113–S117. [Google Scholar] [CrossRef]

- Li, C.; Xu, Y.T.; Zhao, B.; Li, C.; Wong, C.P. Flexible grapheme electrothermal films made from electrochemically exfoliated graphite. J. Mater. Sci. 2016, 51, 1043–1051. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, Z.; Xia, Z.; Hu, X.; Kou, L.; Peng, L.; Wei, Y.; Gao, C. Wet-Spun Continuous Graphene Films. Chem. Mater. 2014, 26, 6786–6795. [Google Scholar] [CrossRef]

- Sui, D.; Huang, Y.; Huang, L.; Liang, J.J.; Ma, Y.F.; Chen, Y.S. Flexible and transparent electrothermal film heaters based on graphene mater. Small 2011, 22, 3186–3192. [Google Scholar] [CrossRef]

- Teodoro, K.B.; Migliorini, F.L.; Facure, M.H.; Correa, D.S. Conductive electrospun nanofibers containing cellulose nanowhiskers and reduced graphene oxide for the electrochemical detection of mercury (Ⅱ). Carbohydr. Polym. 2019, 207, 747–754. [Google Scholar] [CrossRef]

- Montes, S.; Etxeberria, A.; Mocholi, V.; Rekondo, A.; Grande, H.; Labidi, J. Effect of combining cellulose nanocrystals and graphene nanoplatelets on the properties of poly(lactic acid) based films. Express Polym. Lett. 2018, 12, 543–555. [Google Scholar] [CrossRef]

- Chen, G.Y.; Chen, T.; Hou, K.; Ma, W.J.; Tebyetekerwa, M.; Cheng, Y.H.; Weng, W.; Zhu, M.F. Robust, hydrophilic graphene/cellulose nanocrystal fiber–based electrode with high capacitive performance and conductivity. Carbon 2018, 127, 218–227. [Google Scholar] [CrossRef]

- Liu, D.; Dong, Y.; Liu, Y.; Ma, N.; Sui, G. Cellulose Nanowhisker (CNW)/Graphene Nanoplatelet (GN) Composite Films with Simultaneously Enhanced Thermal, Electrical and Mechanical Properties. Front. Mater. 2019, 6, 235. [Google Scholar] [CrossRef]

- Lee, T.W.; Jeong, Y.G. Regenerated cellulose/multiwalled carbon nanotube composite films with efficient electric heating performance. Carbohydr. Polym. 2015, 133, 456–463. [Google Scholar] [CrossRef]

- Lee, T.W.; Lee, S.E.; Jeong, Y.G. Carbon nanotube/cellulose papers with high performance in electric heating and electro-magnetic interference shielding. Compos. Sci. Technol. 2016, 131, 77–87. [Google Scholar] [CrossRef]

- Andres, B.; Dahlström, C.; Blomquist, N.; Norgren, M.; Olin, H. Cellulose binders for electric double-layer capacitor electrodes: The influence of cellulose quality on electrical properties. Mater. Des. 2018, 141, 342–349. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose Nanocrystals/Graphene Hybrids: A Promising New Class of Materials for Advanced Applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Jin, S.; Han, Y.; Li, J.; Chen, H. Improvement in Functional Properties of Soy Protein Isolate-Based Film by Cellulose Nanocrystal–Graphene Artificial Nacre Nanocomposite. Polymers 2017, 9, 321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiong, R.; Hu, K.; Grant, A.M.; Ma, R.; Xu, W.; Lu, C.; Zhang, X.; Tsukruk, V.V. Ultrarobust Transparent Cellulose Nanocrystal-Graphene Membranes with High Electrical Conductivity. Adv. Mater. 2015, 28, 1501–1509. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Ketterle, L.; Järvinen, T.; Lorite, G.S.; Hong, S.; Liimatainen, H. Self-assembly of graphene oxide and cellulose nanocrystals into continuous filament via interfacial nanoparticle complexation. Mater. Des. 2020, 193, 108791. [Google Scholar] [CrossRef]

- Cui, S.; Wei, P.; Li, L. Preparation of poly (propylene carbonate)/graphite nanoplates-spherical nanocrystal cellulose composite with improved glass transition temperature and electrical conductivity. Compos. Sci. Technol. 2018, 168, 63–73. [Google Scholar] [CrossRef]

- Kabiri, R.; Namazi, H. Nanocrystalline cellulose acetate (NCCA)/graphene oxide (GO) nanocomposites with enhanced mechanical properties and barrier against water vapor. Cellulose 2014, 21, 3527–3539. [Google Scholar] [CrossRef]

- Yang, F.; Wu, Y.; Zhang, S.; Zhang, H.; Zhao, S.; Zhang, J.; Fei, B. Mechanical and Thermal Properties of Waterborne Polyurethane Coating Modified through One-Step Cellulose Nanocrystals/Graphene Materials Sols Method. Coatings 2020, 10, 40. [Google Scholar] [CrossRef] [Green Version]

- Jeon, G.W.; Jeong, Y.G. Electric heating films based on m-aramid nanocomposites containing hybrid fillers of graphene and carbon nanotube. J. Mater. Sci. 2013, 48, 4041–4049. [Google Scholar] [CrossRef]

- Tian, S.; He, P.; Chen, L.; Wang, H.; Ding, G.; Xie, X. Electrochemical Fabrication of High Quality Graphene in Mixed Electrolyte for Ultrafast Electrothermal Heater. Chem. Mater. 2017, 29, 6214–6219. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Zhao, H.M.; Yang, Z.; Wang, Q.; Wang, D.Y.; Deng, N.Q.; Yang, Y.; Ren, T.L. Improved electrothermal performance of custom-shaped micro heater based on anisotropic laser-reduced graphene oxide. Appl. Phys. Lett. 2016, 109, 151905. [Google Scholar] [CrossRef]

- Zhao, H.; Tian, M.; Hao, Y.; Qu, L.; Zhu, S.; Chen, S. Fast and facile graphene oxide grafting on hydrophobic polyamide fabric via electrophoretic deposition route. J. Mater. Sci. 2018, 53, 9504–9520. [Google Scholar] [CrossRef]

- Farid, E.T. Joule heating treatments of conductive butyl rubber/ceramic superconductor composites: A new way for improving the stability and reproducibility. Eur. Polym. J. 2001, 3, 565–574. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Wang, H.; Tao, X. Conductive Biomass Films Containing Graphene Oxide and Cationic Cellulose Nanofibers for Electric-Heating Applications. Nanomaterials 2021, 11, 1187. https://doi.org/10.3390/nano11051187

Liang S, Wang H, Tao X. Conductive Biomass Films Containing Graphene Oxide and Cationic Cellulose Nanofibers for Electric-Heating Applications. Nanomaterials. 2021; 11(5):1187. https://doi.org/10.3390/nano11051187

Chicago/Turabian StyleLiang, Shanqing, Huicong Wang, and Xin Tao. 2021. "Conductive Biomass Films Containing Graphene Oxide and Cationic Cellulose Nanofibers for Electric-Heating Applications" Nanomaterials 11, no. 5: 1187. https://doi.org/10.3390/nano11051187