Advancement in Graphene-Based Materials and Their Nacre Inspired Composites for Armour Applications—A Review

Abstract

1. Introduction

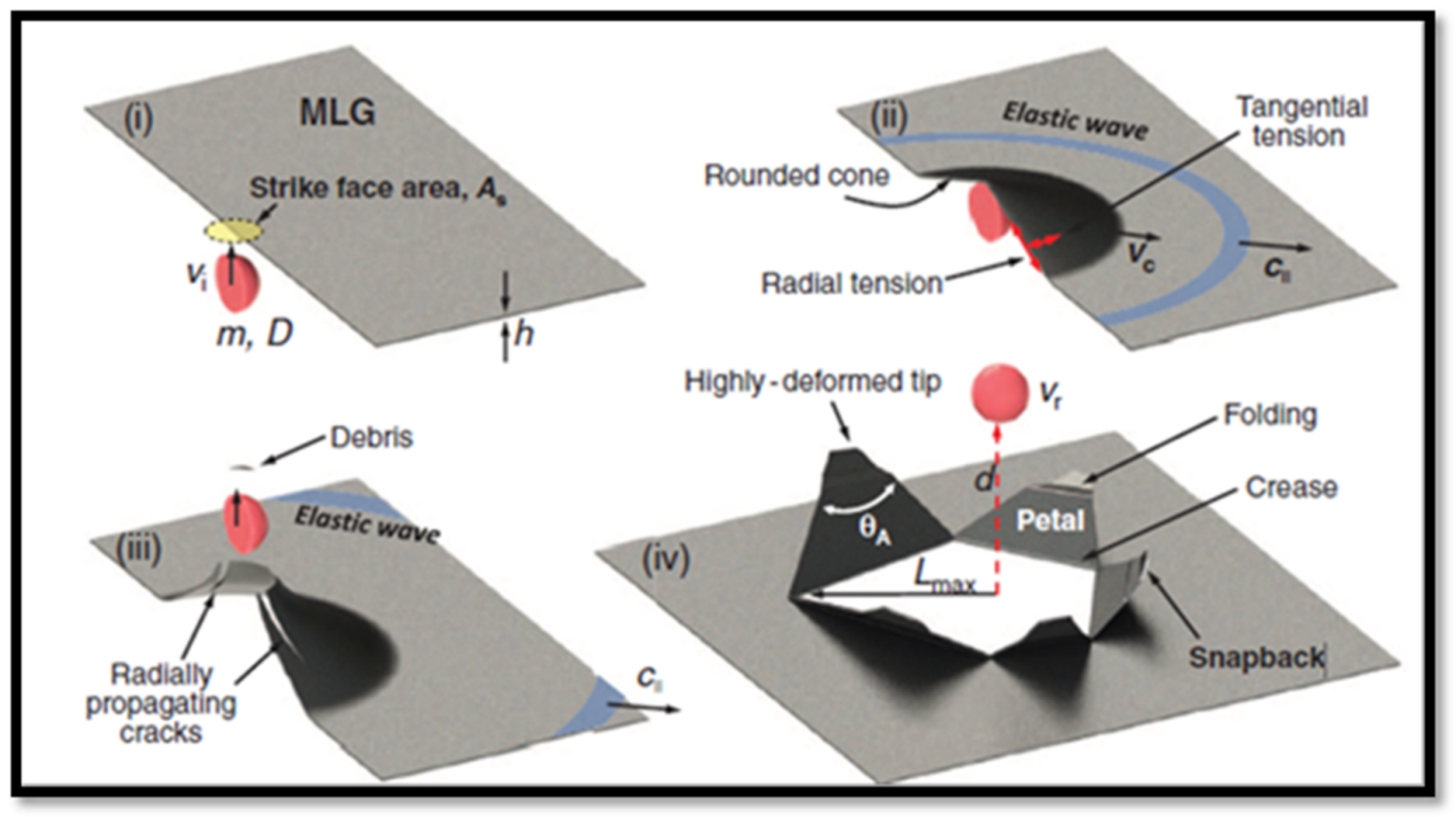

2. Dynamic Mechanical Behaviours of Multilayer Graphene Sheets

3. Predicted Strain Energy Density and Ballistic Limit Velocity of Graphene with Other Armour Materials

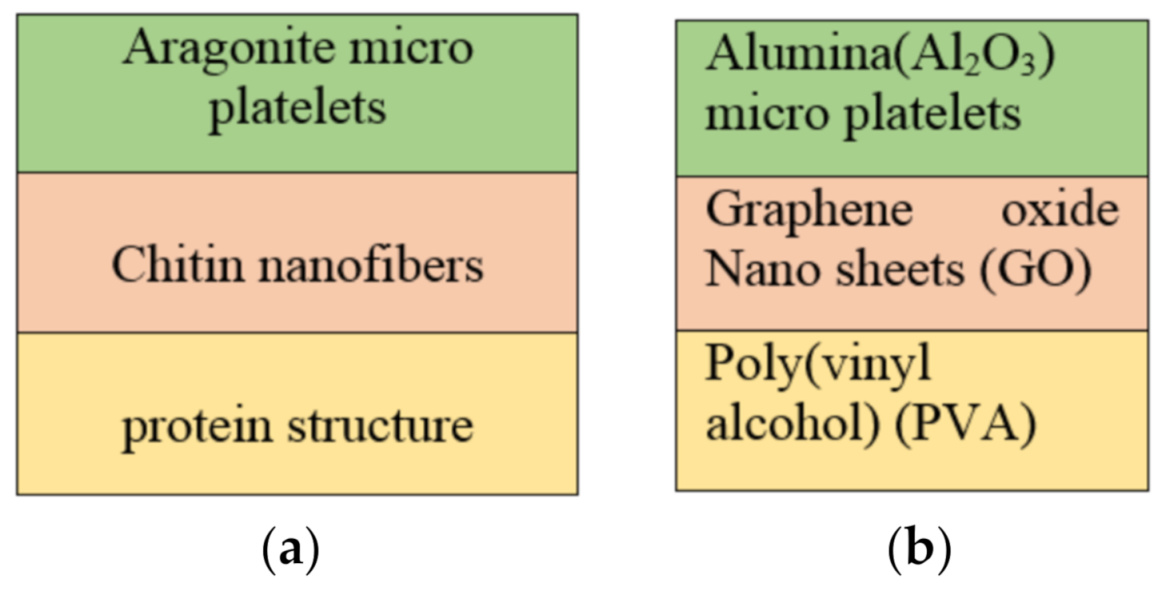

4. Nacre (Natural Armour System)-Like Graphene Structures

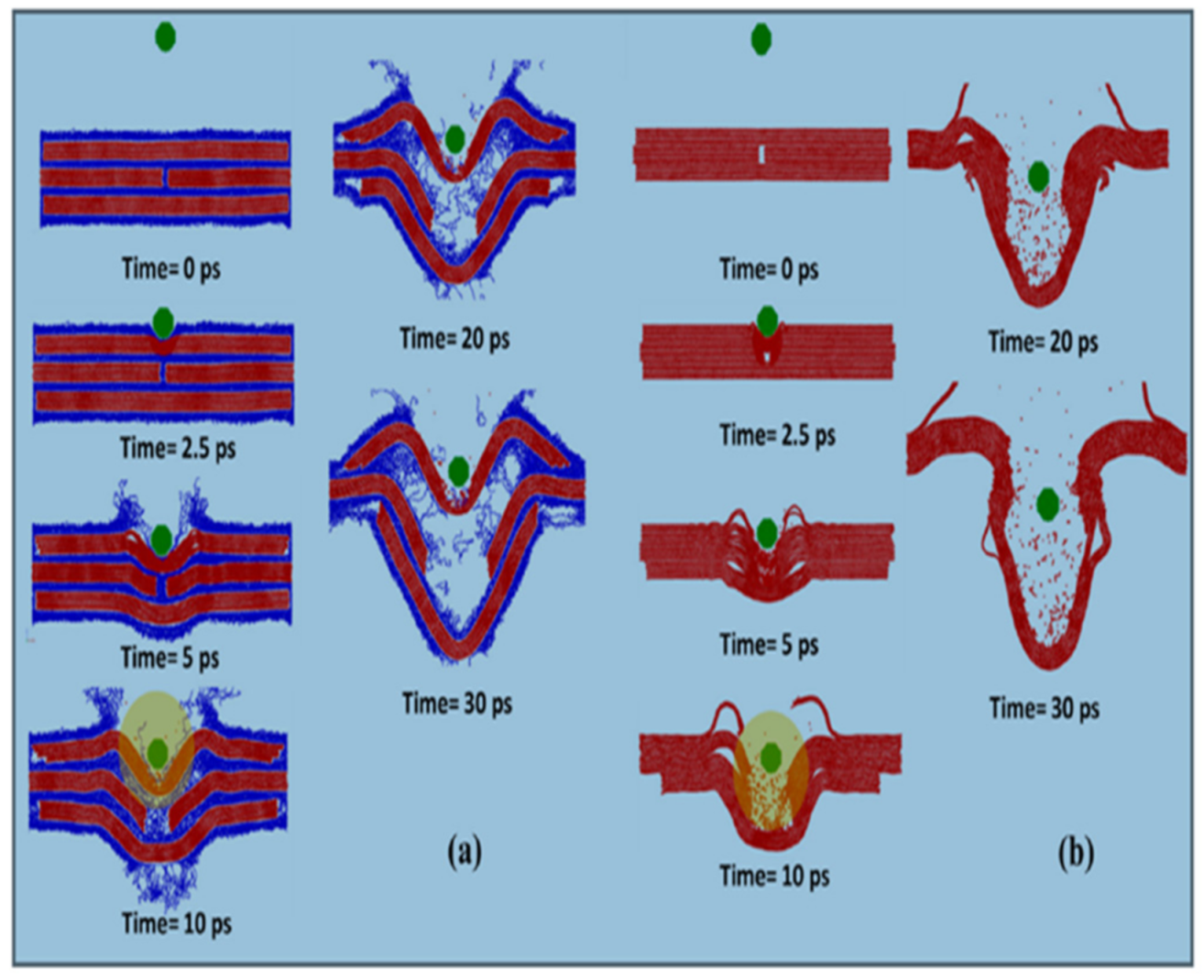

4.1. Molecular Dynamic Simulation of Multi-Layer Graphene Based Polymer Composites

4.2. Nacre-Like Multi-Layer Graphene Based Polymeric Composites

4.3. Nacre-Like Graphene Oxide Paper

4.4. Nacre-Like Multi-Layer Graphene Oxide Based Polymeric Composites

4.5. Artificial Nacre with Alumina/Graphene Oxide/Poly (Vinyl Alcohol)

4.6. Artificial Nacre with MoS2/rGO/TPU

4.7. Artificial Nacre with rGO-DWCNTs-PVA Nanocomposites

4.8. Graphene-Based Bio-Inspired Polymer Nano Composites—Fabrication Techniques

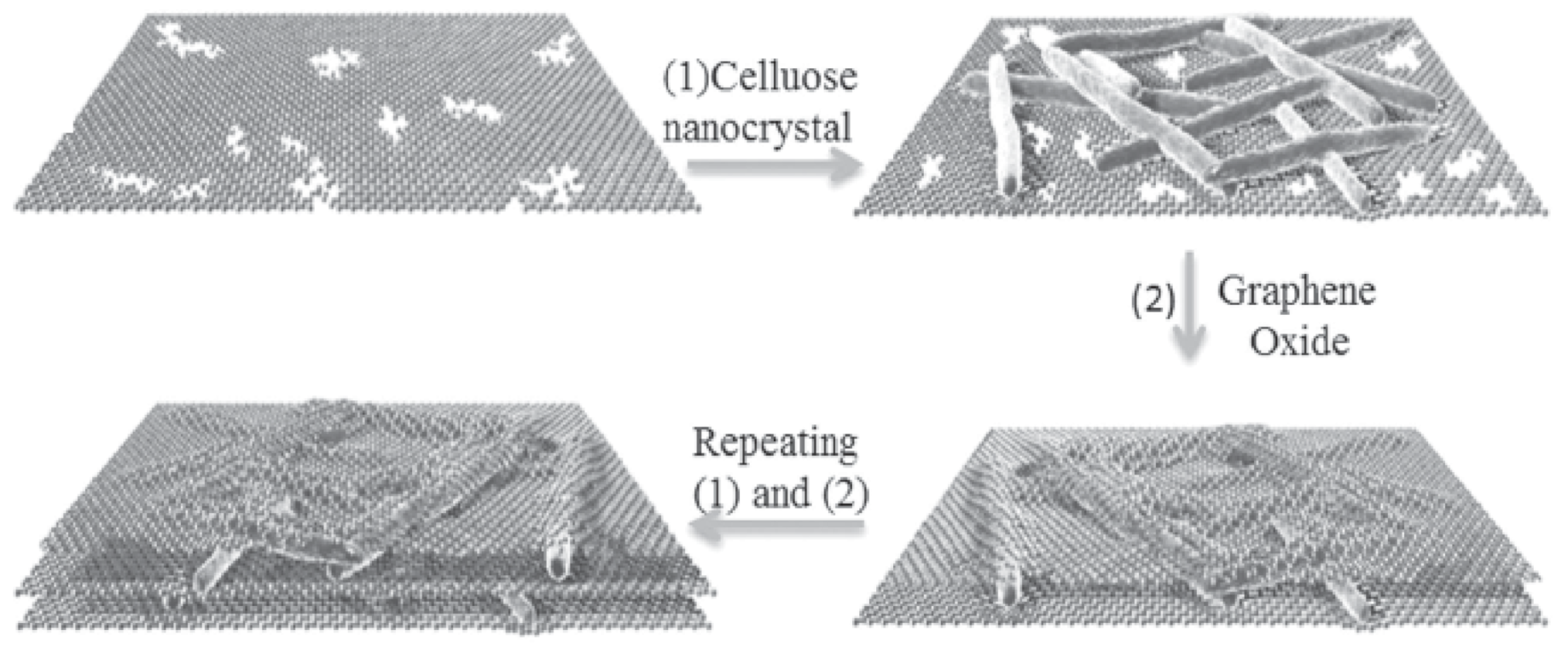

4.8.1. Layer-by-Layer Fabrication Technique

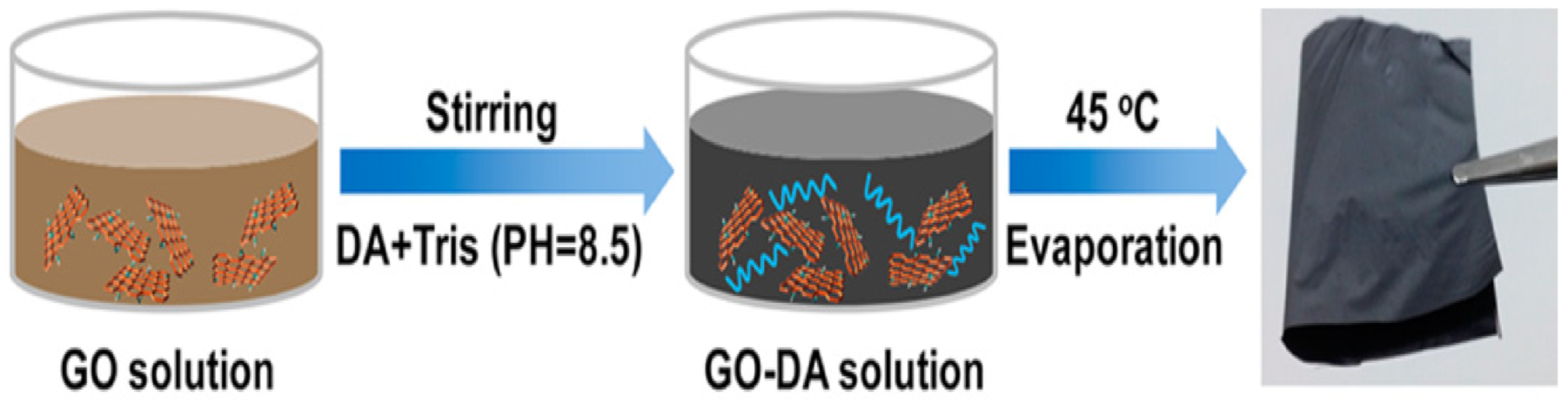

4.8.2. Evaporation

4.8.3. Filtration

4.8.4. Freeze Casting

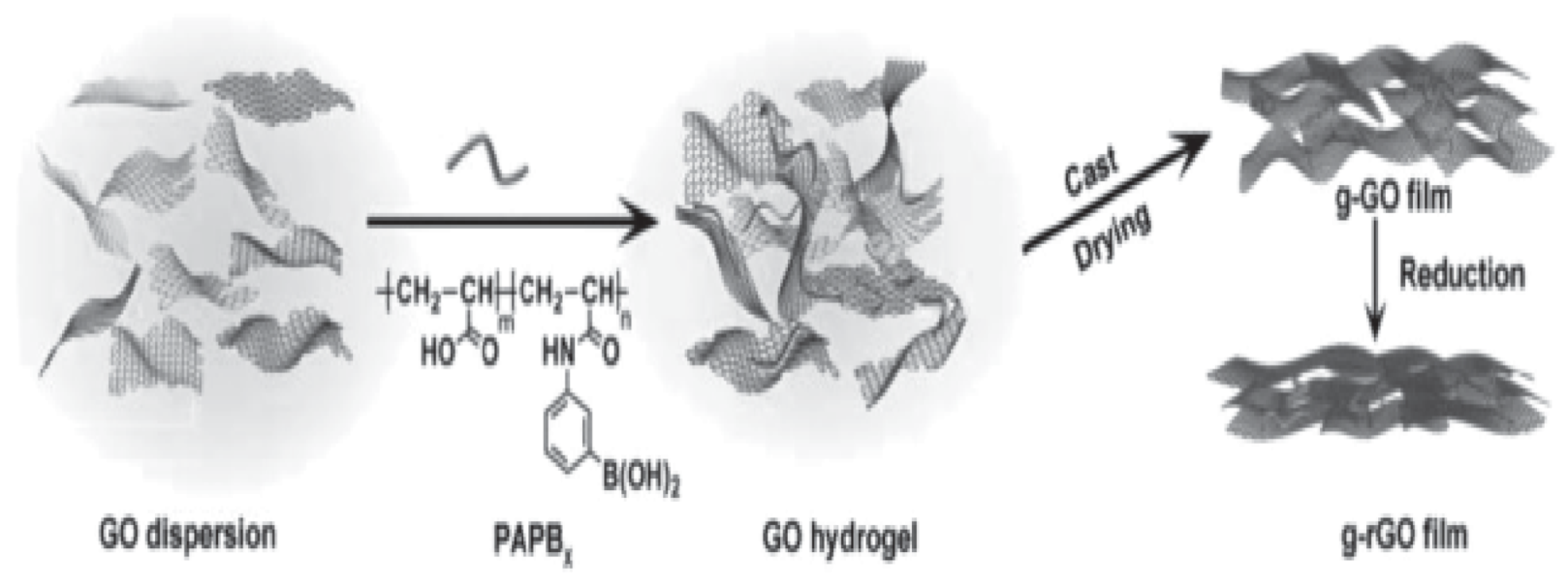

4.8.5. Hydrogel Casting

4.8.6. Electrophoretic Deposition

5. 3D Graphene Materials

6. Effect of Interfacial Interactions

6.1. Non-Covalent Bonding

6.1.1. Hydrogen Bonding

6.1.2. Ionic Bonding

6.1.3. π-π Interaction

6.2. Covalent Bonding

6.2.1. Covalent Bonding through the Linear Molecule in the Polymer

6.2.2. Branched Polymer

6.2.3. 3D Network

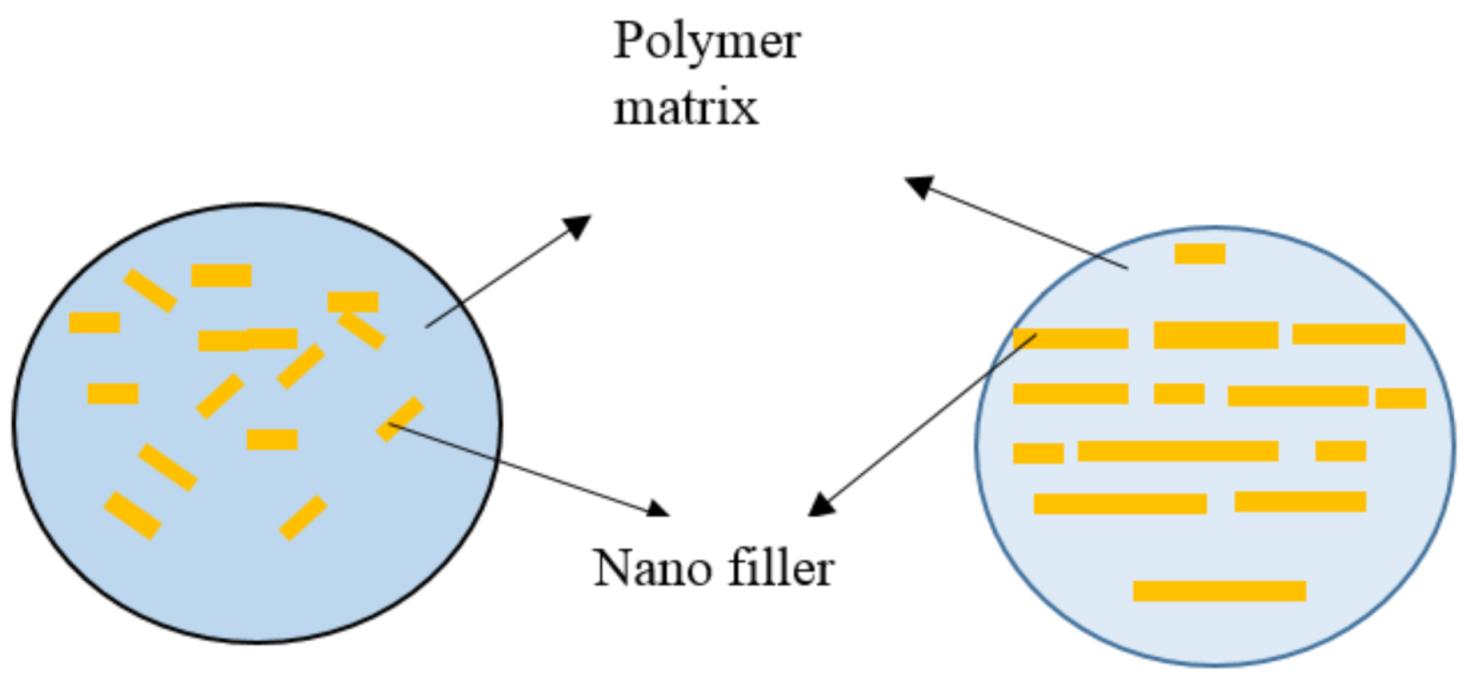

6.3. Conventional and Bioinspired Nano Composite Structure

7. Conclusions and Future Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fogle, J.G. Processing, Structure, and Properties of Nanoparticle Reinforced Nonwoven Sandwich Composites. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 2013. [Google Scholar]

- Liu, P.; Strano, M.S. Toward Ambient Armor: Can New Materials Change Longstanding Concepts of Projectile Protection? Adv. Funct. Mater. 2016, 26, 943–954. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Yusoff, M.Z.M.; Rao, S.; Cantwell, W.J. The Mechanical Properties of Corrugated Core Structures Based on Flax Fibre Composites. Curr. Anal. Chem. 2018, 14, 285–291. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline Cellulose as Reinforcement for Polymeric Matrix Nanocomposites and its Potential Applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Alkbir, M.F.; Sapuan, S.M.; Nuraini, A.A.; Hamouda, A.M.; Ishak, M.R.; Mahdi, E. On the Effects of Geometrical Shapes in Failure Modes in Natural—Conventional Fiber Reinforced Composite Tube: A Review. Curr. Anal. Chem. 2018, 14, 241–248. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Review of Kenaf Reinforced Hybrid Biocomposites: Potential for Defence Applications. Curr. Anal. Chem. 2018, 14, 226–240. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Seaweeds as Renewable Sources for Biopolymers and its Composites: A Review. Curr. Anal. Chem. 2018, 14, 249–267. [Google Scholar] [CrossRef]

- Halimatula, M.; Salit, M.S.; Julkapli, N.; Jawaid, M.; Ishak, M. Starch Cellulosic Bio-composites: A Sustainable and Multifunctional Material for Green Technology. Curr. Anal. Chem. 2017, 13, 1. [Google Scholar] [CrossRef]

- Asim, M.; Saba, N.; Jawaid, M.; Nasir, M.; Pervaiz, M.; Alothman, O.Y. A Review on Phenolic Resin and its Composites. Curr. Anal. Chem. 2018, 14, 185–197. [Google Scholar] [CrossRef]

- Mittal, V. Polymer Nanotubes Nanocomposites: Synthesis, Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Thomas, E.L.; Thomas, E.L. Opportunities in Protection Materials Science and Technology for Future Army Applications. In Ceramic Engineering and Science Proceedings; Wiley: Hoboken, NJ, USA, 2012; pp. 145–148. [Google Scholar]

- Akella, K.; Naik, N.K. Composite Armour—A Review. J. Indian Inst. Sci. 2015, 95, 297–312. [Google Scholar]

- Wan, S.; Li, Y.; Peng, J.; Hu, H.; Cheng, Q.; Jiang, L. Synergistic Toughening of Graphene Oxide–Molybdenum Disulfide–Thermoplastic Polyurethane Ternary Artificial Nacre. ACS Nano 2015, 9, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the Fracture Toughness and the Strength of Epoxy Using Nanomaterials—A Review of the Current Status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef]

- Craig, R.G.; Ostafin, A.E. Carbon Nanotube-Reinforced Fabric, Assembly and Related Methods of Manufacture. Google Patents WO2014197040A3, 26 February 2015. [Google Scholar]

- Brown, M. Hybridized High Strength High Modulus Yarn Intercalated with Graphene Oxide Relationship at High Strain Rate. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2017. [Google Scholar]

- Faridbod, F.; Sanati, A.L. Graphene Quantum Dots in Electrochemical Sensors/Biosensors. Curr. Anal. Chem. 2019, 15, 103–123. [Google Scholar] [CrossRef]

- Lee, G.-H.; Cooper, R.C.; An, S.J.; Lee, S.; Van Der Zande, A.; Petrone, N.; Hammerberg, A.G.; Lee, C.; Crawford, B.; Oliver, W.; et al. High-Strength Chemical-Vapor-Deposited Graphene and Grain Boundaries. Science 2013, 340, 1073–1076. [Google Scholar] [CrossRef]

- Pàmies, P. Defective yet strong. Nat. Mater. 2014, 13, 223. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Wetzel, E.D.; Balu, R.; Beaudet, T.D. A theoretical consideration of the ballistic response of continuous graphene membranes. J. Mech. Phys. Solids 2015, 82, 23–31. [Google Scholar] [CrossRef]

- Robbins, J.; Ding, J.; Gupta, Y. Load spreading and penetration resistance of layered structures—a numerical study. Int. J. Impact Eng. 2004, 30, 593–615. [Google Scholar] [CrossRef]

- Lee, J.-H.; Loya, P.E.; Lou, J.; Thomas, E.L. Dynamic mechanical behavior of multilayer graphene via supersonic projectile penetration. Science 2014, 346, 1092–1096. [Google Scholar] [CrossRef] [PubMed]

- Wan, S.; Hu, H.; Peng, J.; Li, Y.; Fan, Y.; Jiang, L.; Cheng, Q. Nacre-inspired integrated strong and tough reduced graphene oxide–poly(acrylic acid) nanocomposites. Nanoscale 2016, 8, 5649–5656. [Google Scholar] [CrossRef] [PubMed]

- Yoon, K.; Ostadhossein, A.; van Duin, A.C. Atomistic-scale simulations of the chemomechanical behavior of graphene under nanoprojectile impact. Carbon 2016, 99, 58–64. [Google Scholar] [CrossRef]

- Meng, Z.; Singh, A.; Qin, X.; Keten, S. Reduced ballistic limit velocity of graphene membranes due to cone wave reflection. Extreme Mech. Lett. 2017, 15, 70–77. [Google Scholar] [CrossRef]

- Meng, Z.; Han, J.; Qin, X.; Zhang, Y.; Balogun, O.; Keten, S. Spalling-like failure by cylindrical projectiles deteriorates the ballistic performance of multi-layer graphene plates. Carbon 2018, 126, 611–619. [Google Scholar] [CrossRef]

- Sanderson, K. Structure: Artificial armour. Nat. Cell Biol. 2015, 519, S14–S15. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Lieber, C.M. Nanoelectronics from the Bottom Up. Nanosci. Technol. Collect. Rev. Nat. J. 2010, 137–146. [Google Scholar]

- Ramanathan, T.; Abdala, A.A.; Stankovich, S.; Dikin, D.A.; Herreraalonso, M.; Piner, R.D.; Adamson, D.H.; Schniepp, H.C.; Chen, X.; Ruoff, R.S.; et al. Functionalized graphene sheets for polymer nanocomposites. Nat. Nanotechnol. 2008, 3, 327–331. [Google Scholar] [CrossRef]

- Xia, W.; Ruiz, L.; Pugno, N.M.; Keten, S. Critical length scales and strain localization govern the mechanical performance of multi-layer graphene assemblies. Nanoscale 2016, 8, 6456–6462. [Google Scholar] [CrossRef]

- Xia, W.; Song, J.; Meng, Z.; Shao, C.; Keten, S. Designing multi-layer graphene-based assemblies for enhanced toughness in nacre-inspired nanocomposites. Mol. Syst. Des. Eng. 2016, 1, 40–47. [Google Scholar] [CrossRef]

- Liu, N.; Pidaparti, R.; Wang, X. Mechanical Performance of Graphene-Based Artificial Nacres under Impact Loads: A Coarse-Grained Molecular Dynamic Study. Polymers 2017, 9, 134. [Google Scholar] [CrossRef] [PubMed]

- O’Masta, M.; Russell, B.; Deshpande, V. An exploration of the ballistic resistance of multilayer graphene polymer composites. Extreme Mech. Lett. 2017, 11, 49–58. [Google Scholar] [CrossRef]

- Choi, J.-Y.; Yu, H.-C.; Lee, J.; Jeon, J.; Im, J.; Jang, J.; Jin, S.-W.; Kim, K.-K.; Cho, S.; Chung, C.-M. Preparation of Polyimide/Graphene Oxide Nanocomposite and Its Application to Nonvolatile Resistive Memory Device. Polymers 2018, 10, 901. [Google Scholar] [CrossRef] [PubMed]

- Putz, K.W.; Compton, O.C.; Palmeri, M.J.; Nguyen, S.T.; Brinson, L.C. High-Nanofiller-Content Graphene Oxide-Polymer Nanocomposites via Vacuum-Assisted Self-Assembly. Adv. Funct. Mater. 2010, 20, 3322–3329. [Google Scholar] [CrossRef]

- Tan, Z.; Zhang, M.; Li, C.; Yu, S.; Shi, G. A General Route to Robust Nacre-Like Graphene Oxide Films. ACS Appl. Mater. Interfaces 2015, 7, 15010–15016. [Google Scholar] [CrossRef]

- Wang, J.; Qiao, J.; Wang, J.; Zhu, Y.; Jiang, L. Bioinspired Hierarchical Alumina–Graphene Oxide–Poly(vinyl alcohol) Artificial Nacre with Optimized Strength and Toughness. ACS Appl. Mater. Interfaces 2015, 7, 9281–9286. [Google Scholar] [CrossRef]

- Bertolazzi, S.; Brivio, J.; Kis, A. Stretching and Breaking of Ultrathin MoS2. ACS Nano 2011, 5, 9703–9709. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Wu, M.; Jiang, L.; Cheng, Q. Integrated ternary artificial nacre via synergistic toughening of reduced graphene oxide/double-walled carbon nanotubes/poly(vinyl alcohol). Mater. Res. Express 2016, 3, 075002. [Google Scholar] [CrossRef]

- Prasad, K.E.; Das, B.; Maitra, U.; Ramamurty, U.; Rao, C.N.R. Extraordinary synergy in the mechanical properties of polymer matrix composites reinforced with 2 nanocarbons. Proc. Natl. Acad. Sci. USA 2009, 106, 13186–13189. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Cui, W.; Zhang, Q.; Cao, A.; Jiang, L.; Cheng, Q. Integrated Ternary Bioinspired Nanocomposites via Synergistic Toughening of Reduced Graphene Oxide and Double-Walled Carbon Nanotubes. ACS Nano 2015, 9, 11568–11573. [Google Scholar] [CrossRef]

- Huang, C.; Cheng, Q. Learning from nacre: Constructing polymer nanocomposites. Compos. Sci. Technol. 2017, 150, 141–166. [Google Scholar] [CrossRef]

- Cheng, Q.; Jiang, L.; Tang, Z. Bioinspired Layered Materials with Superior Mechanical Performance. Accounts Chem. Res. 2014, 47, 1256–1266. [Google Scholar] [CrossRef]

- Richardson, J.J.; Björnmalm, M.; Caruso, F. Technology-Driven Layer-by-Layer Assembly of Nanofilms. Science 2015, 348, aaa2491. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Q.; Lin, L.; Chen, L.; Jiang, L. Understanding the relationship of performance with nanofiller content in the biomimetic layered nanocomposites. Nanoscale 2013, 5, 6356–6362. [Google Scholar] [CrossRef]

- Wang, J.; Lin, L.; Cheng, Q.; Jiang, L. A Strong Bio-Inspired Layered PNIPAM-Clay Nanocomposite Hydrogel. Angew. Chem. Int. Ed. 2012, 51, 4676–4680. [Google Scholar] [CrossRef] [PubMed]

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, Bio-Inspired Hybrid Materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef] [PubMed]

- Long, B.; Wang, C.-A.; Lin, W.; Huang, Y.; Sun, J. Polyacrylamide-clay nacre-like nanocomposites prepared by electrophoretic deposition. Compos. Sci. Technol. 2007, 67, 2770–2774. [Google Scholar] [CrossRef]

- Wan, S.; Peng, J.; Jiang, L.; Cheng, Q. Bioinspired Graphene-Based Nanocomposites and Their Application in Flexible Energy Devices. Adv. Mater. 2016, 28, 7862–7898. [Google Scholar] [CrossRef] [PubMed]

- Decher, G.; Hong, J.; Schmitt, J. Buildup of ultrathin multilayer films by a self-assembly process: III. Consecutively alternating adsorption of anionic and cationic polyelectrolytes on charged surfaces. Thin Solid Films 1992, 210-211, 831–835. [Google Scholar] [CrossRef]

- Xiong, R.; Hu, K.; Grant, A.M.; Ma, R.; Xu, W.; Lu, C.; Zhang, X.; Tsukruk, V.V. Ultrarobust Transparent Cellulose Nanocrystal-Graphene Membranes with High Electrical Conductivity. Adv. Mater. 2015, 28, 1501–1509. [Google Scholar] [CrossRef]

- Cui, W.; Li, M.; Liu, J.; Wang, B.; Zhang, C.; Jiang, L.; Cheng, Q. A Strong Integrated Strength and Toughness Artificial Nacre Based on Dopamine Cross-Linked Graphene Oxide. ACS Nano 2014, 8, 9511–9517. [Google Scholar] [CrossRef]

- Zeng, G.; Gao, J.; Chen, S.; Chen, H.; Wang, Z.; Zhang, X. Combining Hydrogen-Bonding Complexation in Solution and Hydrogen-Bonding-Directed Layer-by-Layer Assembly for the Controlled Loading of a Small Organic Molecule into Multilayer Films. Langmuir 2007, 23, 11631–11636. [Google Scholar] [CrossRef]

- Malho, J.-M.; Laaksonen, P.; Walther, A.; Ikkala, O.; Linder, M.B. Facile Method for Stiff, Tough, and Strong Nanocomposites by Direct Exfoliation of Multilayered Graphene into Native Nanocellulose Matrix. Biomacromolecules 2012, 13, 1093–1099. [Google Scholar] [CrossRef] [PubMed]

- Macchetta, A.; Turner, I.; Bowen, C. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method. Acta Biomater. 2009, 5, 1319–1327. [Google Scholar] [CrossRef] [PubMed]

- Deville, S.; Saiz, E.; Nalla, R.K.; Tomsia, A.P. Freezing as a Path to Build Complex Composites. Science 2006, 311, 515–518. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, L.; Han, J.; Jiang, Z. Freeze casting of aqueous alumina slurries with glycerol for porous ceramics. Ceram. Int. 2010, 36, 617–621. [Google Scholar] [CrossRef]

- Bai, H.; Li, C.; Wang, X.; Shi, G. On the Gelation of Graphene Oxide. J. Phys. Chem. C 2011, 115, 5545–5551. [Google Scholar] [CrossRef]

- Bai, H.; Chen, Y.; Delattre, B.; Tomsia, A.P.; Ritchie, R.O. Bioinspired large-scale aligned porous materials assembled with dual temperature gradients. Sci. Adv. 2015, 1, e1500849. [Google Scholar] [CrossRef]

- Xiong, Z.; Liao, C.; Han, W.; Wang, X. Mechanically Tough Large-Area Hierarchical Porous Graphene Films for High-Performance Flexible Supercapacitor Applications. Adv. Mater. 2015, 27, 4469–4475. [Google Scholar] [CrossRef]

- Li, C.; Shi, G. Functional Gels Based on Chemically Modified Graphenes. Adv. Mater. 2014, 26, 3992–4012. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Huang, L.; Chen, J.; Li, C.; Shi, G. Ultratough, Ultrastrong, and Highly Conductive Graphene Films with Arbitrary Sizes. Adv. Mater. 2014, 26, 7588–7592. [Google Scholar] [CrossRef]

- Lin, T.-H.; Huang, W.-H.; Jun, I.-K.; Jiang, P. Bioinspired Assembly of Colloidal Nanoplatelets by Electric Field. Chem. Mater. 2009, 21, 2039–2044. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, X.; Garakani, M.A.; Lin, X.; Wu, Y.; Liu, X.; Sun, X.; Kim, J.-K. Graphene Aerogel/Epoxy Composites with Exceptional Anisotropic Structure and Properties. ACS Appl. Mater. Interfaces 2015, 7, 5538–5549. [Google Scholar] [CrossRef]

- Niebel, T.P.; Carnelli, D.; Binelli, M.R.; Libanori, R.; Studart, A.R. Hierarchically roughened microplatelets enhance the strength and ductility of nacre-inspired composites. J. Mech. Behav. Biomed. Mater. 2016, 60, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Sainsbury, T.; Gnaniah, S.; Spencer, S.J.; Mignuzzi, S.; Belsey, N.A.; Paton, K.R.; Satti, A. Extreme mechanical reinforcement in graphene oxide based thin-film nanocomposites via covalently tailored nanofiller matrix compatibilization. Carbon 2017, 114, 367–376. [Google Scholar] [CrossRef]

- Li, Y.-Q.; Yu, T.; Yang, T.-Y.; Zheng, L.-X.; Liao, K. Bio-Inspired Nacre-like Composite Films Based on Graphene with Superior Mechanical, Electrical, and Biocompatible Properties. Adv. Mater. 2012, 24, 3426–3431. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Lee, K.-S.; Bozoklu, G.; Cai, W.; Nguyen, S.T.; Ruoff, R.S. Graphene Oxide Papers Modified by Divalent Ions—Enhancing Mechanical Properties via Chemical Cross-Linking. ACS Nano 2008, 2, 572–578. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, Y.; Tang, S.; Feng, W. Preparation of a Graphene Oxide–Phthalocyanine Hybrid through Strong Π–Π Interactions. Carbon 2010, 48, 211–216. [Google Scholar] [CrossRef]

- An, Z.; Compton, O.C.; Putz, K.W.; Brinson, L.C.; Nguyen, S.T. Bio-Inspired Borate Cross-Linking in Ultra-Stiff Graphene Oxide Thin Films. Adv. Mater. 2011, 23, 3842–3846. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Liu, L.-Q.; Zu, S.-Z.; Peng, K.; Zhou, D.; Han, B.-H.; Zhang, Z. The Effect of Interlayer Adhesion on the Mechanical Behaviors of Macroscopic Graphene Oxide Papers. ACS Nano 2011, 5, 2134–2141. [Google Scholar] [CrossRef]

- Cheng, Q.; Wu, M.; Li, M.; Jiang, L.; Tang, Z. Ultratough Artificial Nacre Based on Conjugated Cross-linked Graphene Oxide. Angew. Chem. 2013, 52, 3750–3755. [Google Scholar] [CrossRef]

- Hu, X.; Xu, Z.; Liu, Z.; Gao, C. Liquid crystal self-templating approach to ultrastrong and tough biomimic composites. Sci. Rep. 2013, 3, 2374. [Google Scholar] [CrossRef]

- Ming, P.; Zhang, Y.; Bao, J.; Liu, G.; Li, Z.; Jiang, L.; Cheng, Q. Bioinspired highly electrically conductive graphene–epoxy layered composites. RSC Adv. 2015, 5, 22283–22288. [Google Scholar] [CrossRef]

- Ni, H.; Xu, F.; Tomsia, A.P.; Saiz, E.; Jiang, L.; Cheng, Q. Robust Bioinspired Graphene Film Via Π–Π Cross-Linking. ACS Appl. Mater. Interfaces 2017, 9, 24987–24992. [Google Scholar] [CrossRef] [PubMed]

- Shahzadi, K.; Zhang, X.; Mohsin, I.; Ge, X.; Jiang, Y.; Peng, H.; Liu, H.; Li, H.; Mu, X. Reduced Graphene Oxide/Alumina, A Good Accelerant for Cellulose-Based Artificial Nacre with Excellent Mechanical, Barrier, and Conductive Properties. ACS Nano 2017, 11, 5717–5725. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liang, Z.; Liu, T.; Wang, B.; Zhang, C. Effective amino-functionalization of carbon nanotubes for reinforcing epoxy polymer composites. Nanotechnology 2006, 17, 1551–1557. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer Nanocomposites—A Comparison between Carbon Nanotubes, Graphene, and Clay as Nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef]

- Nosrati, H.; Sarraf-Mamoory, R.; Le, D.Q.S.; Bünger, C.E. Enhanced fracture toughness of three dimensional graphene- hydroxyapatite nanocomposites by employing the Taguchi method. Compos. Part B Eng. 2020, 190, 107928. [Google Scholar] [CrossRef]

- Cho, B.-G.; Joshi, S.R.; Lee, J.; Park, Y.-B.; Kim, G.-H. Direct growth of thermally reduced graphene oxide on carbon fiber for enhanced mechanical strength. Compos. Part B Eng. 2020, 193, 108010. [Google Scholar] [CrossRef]

- Bera, M.; Prabhakar, A.; Maji, P.K. Nanotailoring of thermoplastic polyurethane by amine functionalized graphene oxide: Effect of different amine modifier on final properties. Compos. Part B Eng. 2020, 195, 108075. [Google Scholar] [CrossRef]

- Ghazlan, A.; Ngo, T.; Tan, P.; Xie, Y.M.; Tran, P.; Donough, M. Inspiration from Nature’s body armours—A review of biological and bioinspired composites. Compos. Part B Eng. 2020, 205, 108513. [Google Scholar] [CrossRef]

| Material | Strain Energy Density (J/g) | V50/V50 Kevlar |

|---|---|---|

| Kevlar129 | 38.7 | 1.00 |

| Dyneema SK-76 | 48.1 | 1.13 |

| Carbon fibre | 26.8 | 0.99 |

| CNT yarn | 121 | 1.97 |

| Aluminium alloy5083 | 9.5 | 0.76 |

| Titanium alloyTi-6-4 | 29.4 | 1.10 |

| Graphene | 8350 | 11.6 |

| Sl.No | Fabrication Technique | Merits | Limitations |

|---|---|---|---|

| 1. | Layer by layer | Layered structure can be controlled precisely | Time consuming process. |

| 2. | Evaporation | The evaporation procedure is quiet easy. | Precise control of the structure is difficult |

| 3. | Filtration | Simple operating procedure. | Scaling up is a tedious and time consuming process |

| 4. | Freeze casting | Suitable to fabricate bulk materials | Consumes more energy |

| 5. | Hydrogel casting | Economical technique. | Controlling the layered structure is difficult. |

| 6. | Electrophoretic deposition | Precise control of the structure | Fabrication of thick film is very difficult. |

| Material | Fabrication Techniques | Energy Absorption | Ballistic Limit | Stress (Tensile Strength) | Toughness | Ref. | |

|---|---|---|---|---|---|---|---|

| Type of Graphene | Polymer | ||||||

| Multilayer graphene | - | Overlapping | 3 MJ | - | 50 MPa | 7 × 103 MJ/m3 | [32] |

| Multilayer graphene | Poly vinyl alcohol | liquid exfoliation | - | 15 m/s | 50 MPa | - | [35] |

| Graphene oxide paper | - | Flow-directed assembly of individual graphene oxide sheets | - | - | 130 MPa | - | [36] |

| Graphene oxide | Poly Vinyl alcohol or hydrophobic poly(methyl methacrylate) | Filtration | - | - | 102.9 MPa | - | [37] |

| Graphene oxide | Water soluble | Gel film Transformation (GFT) | - | - | 200 MPa | 8.98 ± 0.73 MJ/m3 (varies with different materials) | [38] |

| Graphene oxide | Poly vinyl alcohol | Layer by Layer | - | - | 143 ± 13 MPa | 9.2 ± 2.7 MJ/m3 | [39] |

| Graphene oxide | Poly vinyl alcohol | Evaporation | - | - | 240.4 ± 30.8 MPa | 2.0 ± 0.5 MJ/m3 | [43] |

| Graphene oxide | Al2O3 platelets and chitosan | Hydrogen bonding | - | - | 152 MPa (varies on linkages) | 75 MJ/m3 (varies on linkages) | [45] |

| Graphene | Poly vinyl alcohol | Layer-by-Layer | - | - | 219 ± 19 MPa | - | [47] |

| Bioinspired Graphene | Bio polymer | Hydrogel Casting | - | - | 382 MPa (varies while increase in bio polymers) | 7.5 MJ/m3 | [51] |

| Layer-by-Layer | - | - | 300 MPa (varies while increase in bio polymers) | 75 MJ/m3 (varies with GO sheets) | |||

| Filtration | - | - | 133 MPa (varies while increase in bio polymers) | - | |||

| Evaporation | - | - | - | - | |||

| Graphene oxide | Fibre-based biopolymers and polymer nano composites. | Drop-casting or vacuum-assisted filtration | - | - | 400 MPa (varies by linkages) | 3.9 ± 0.5 MJ/m3 (varies on polymers) | [53] |

| Graphene oxide | Poly vinyl alcohol | Layer by Layer | 91.2 ± 1.6 MPa (varies by linkages) | 1.4 ± 0.1 MJ/m3 (varies on different sheet linkages) | [55] | ||

| Multilayered Graphene | Polypeptide | Filtration | 6000 J | - | 351 MPa (maximum) | - | [56] |

| Graphene oxide | Poly acrylic acid | Vacuum-assisted filtration | - | - | 179.03 ± 4.55 MPa (Depends on humidity varies) | 6.04 ± 0.49 MJ/m3 (Depends on humidity varies) | [25] |

| Graphene oxide | Bio inspired nano composite | Evaporation | - | - | 374.1 ± 22.8 MPa (2.6 times increased than original) | 9.2 ± 0.8 MJ/m3 (3.3 times increased than original) | [43] |

| Graphene oxide | Poly crystalline rings | Hydrogel casting | - | - | 1.91 ± 0.08 MPa | - | [62] |

| Chemically modified graphene | Hydrophilic polymer | Hydrogel casting | - | - | - | - | [63] |

| Graphene oxide | poly (acrylic acid-co-acrylamidophenylboronic acid) | Gel Film Transformation technique | - | - | 382 ± 12 MPa | 7.50 ± 0.4 MJ/m3 | [64] |

| 3D Graphene | hydroxyapatite | Hydrothermal method | - | - | 2.8 MPa·m0.5 | [82] | |

| Thermally reduced grapheme oxide | Natural polymer | Compression moulding | - | - | 3.5 GPa | - | [83] |

| Graphene oxide | Polyurethane | In-situ polymerization | 40.2 ± 1.8 MPa (varies with linkages) | 192.9 ± 4.7 MJ/m3 (varies with linkages) | [84] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naveen, J.; Jawaid, M.; Goh, K.L.; Reddy, D.M.; Muthukumar, C.; Loganathan, T.M.; Reshwanth, K.N.G.L. Advancement in Graphene-Based Materials and Their Nacre Inspired Composites for Armour Applications—A Review. Nanomaterials 2021, 11, 1239. https://doi.org/10.3390/nano11051239

Naveen J, Jawaid M, Goh KL, Reddy DM, Muthukumar C, Loganathan TM, Reshwanth KNGL. Advancement in Graphene-Based Materials and Their Nacre Inspired Composites for Armour Applications—A Review. Nanomaterials. 2021; 11(5):1239. https://doi.org/10.3390/nano11051239

Chicago/Turabian StyleNaveen, Jesuarockiam, Mohammad Jawaid, Kheng Lim Goh, Degalhal Mallikarjuna Reddy, Chandrasekar Muthukumar, Tamil Moli Loganathan, and Koduri Naga Ganapathy Lakshmi Reshwanth. 2021. "Advancement in Graphene-Based Materials and Their Nacre Inspired Composites for Armour Applications—A Review" Nanomaterials 11, no. 5: 1239. https://doi.org/10.3390/nano11051239

APA StyleNaveen, J., Jawaid, M., Goh, K. L., Reddy, D. M., Muthukumar, C., Loganathan, T. M., & Reshwanth, K. N. G. L. (2021). Advancement in Graphene-Based Materials and Their Nacre Inspired Composites for Armour Applications—A Review. Nanomaterials, 11(5), 1239. https://doi.org/10.3390/nano11051239