Nano-Crystal and Microstructure Formation in Fluoride Photo-Thermo-Refractive Glass Using Chirp-Controlled Ultrafast Laser Bessel Beams

Abstract

1. Introduction

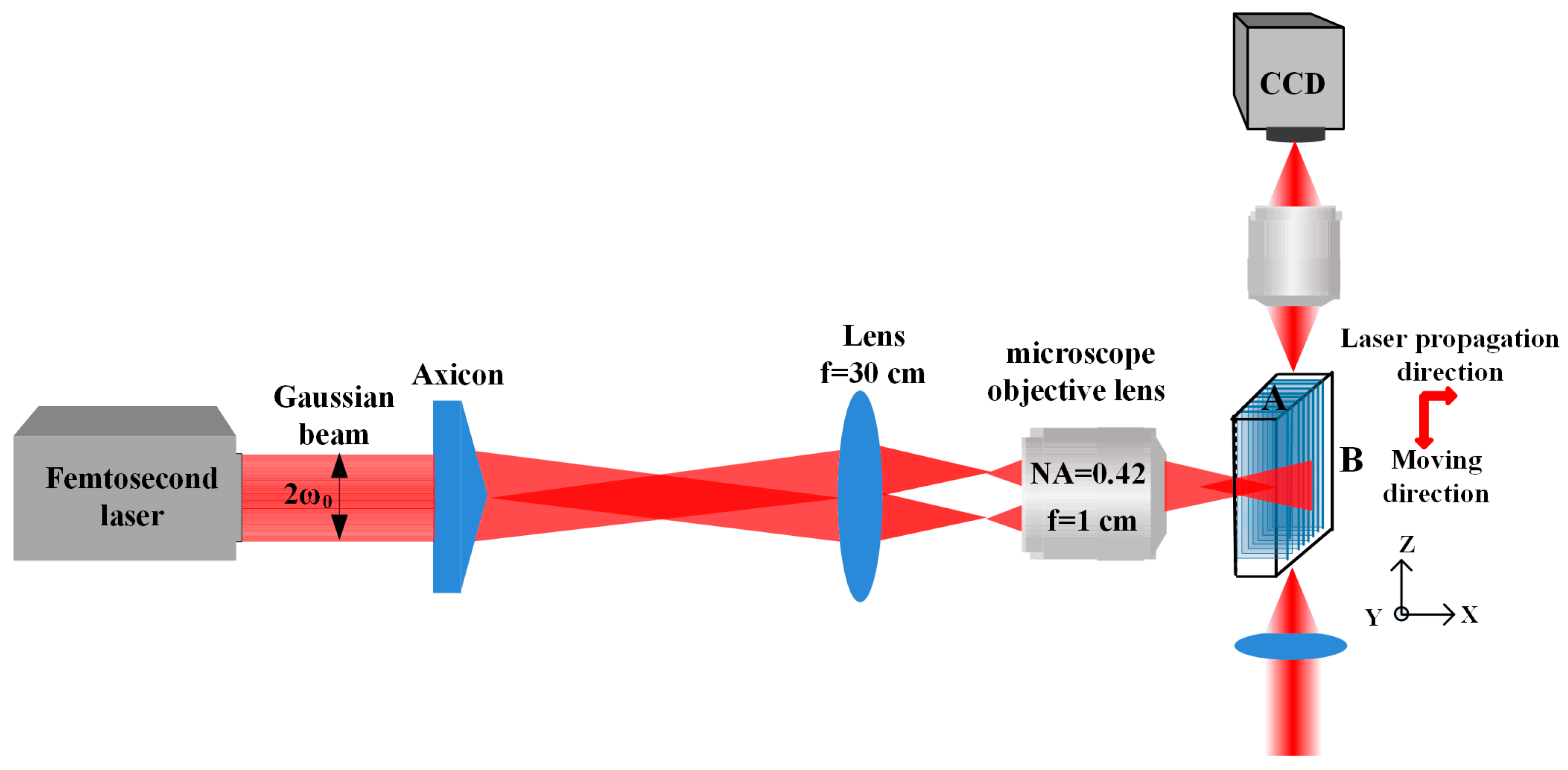

2. Materials and Methods

2.1. Irradiation Process

2.2. Sample Preparation

2.3. Characterization

3. Results

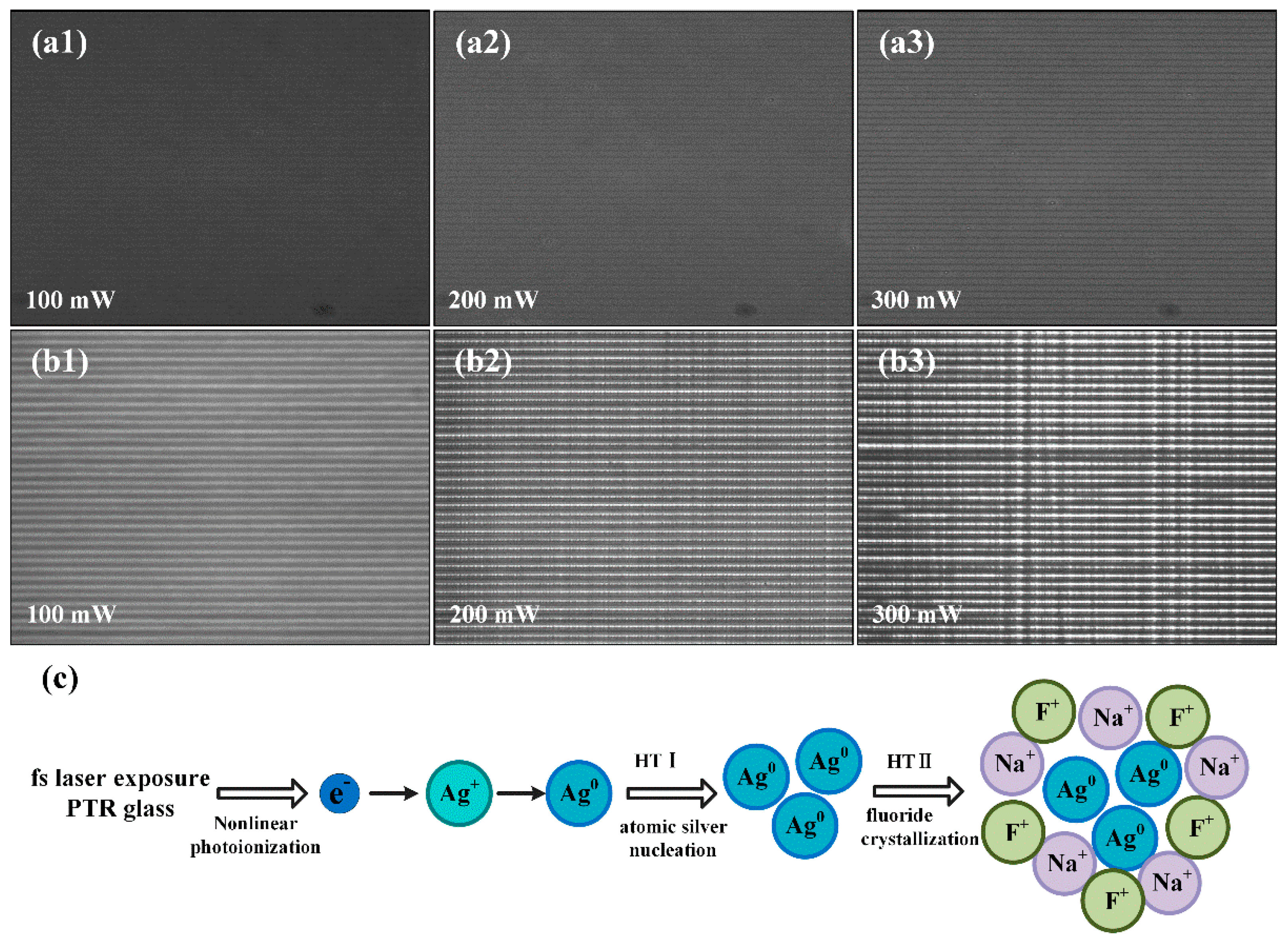

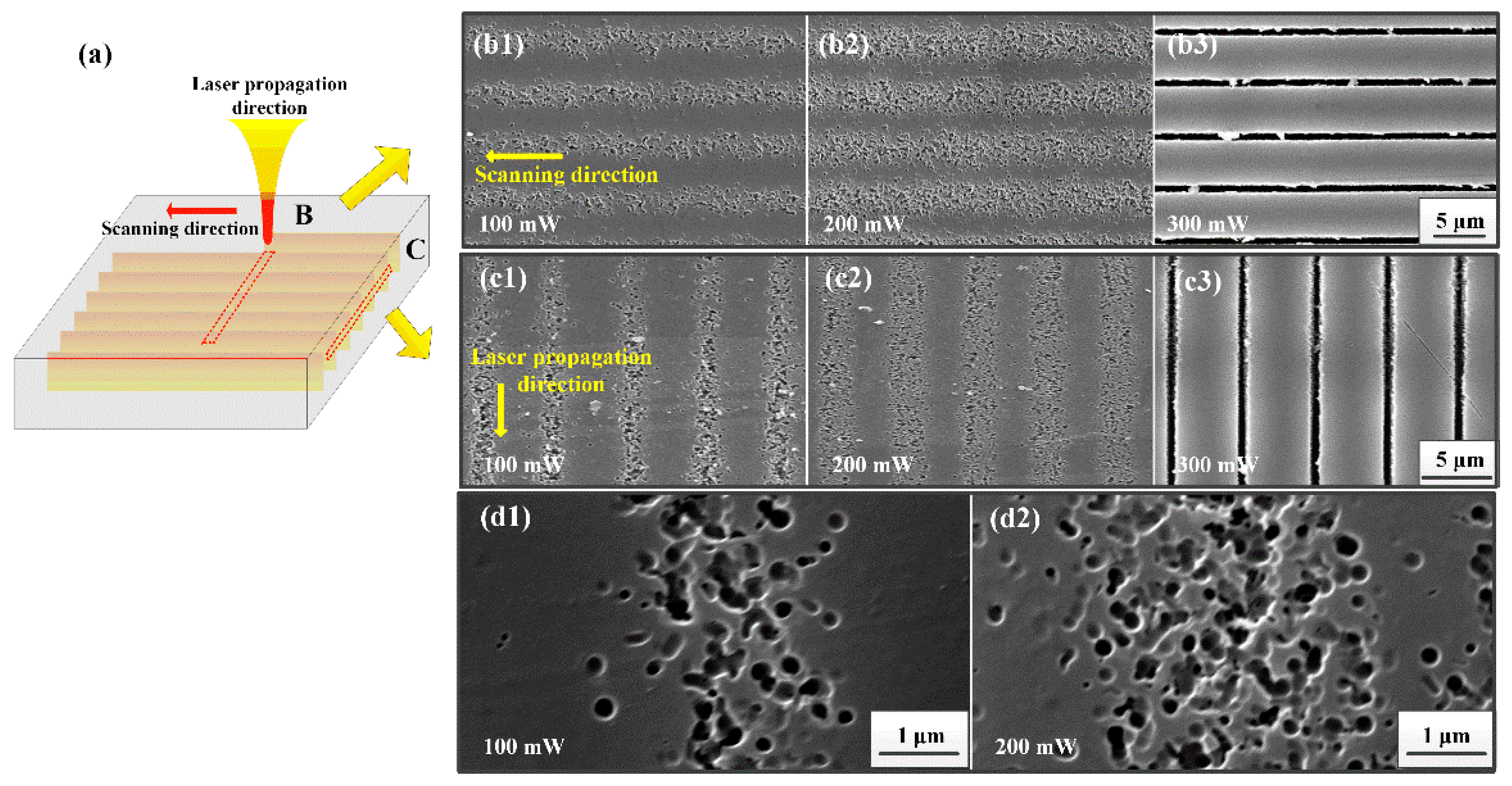

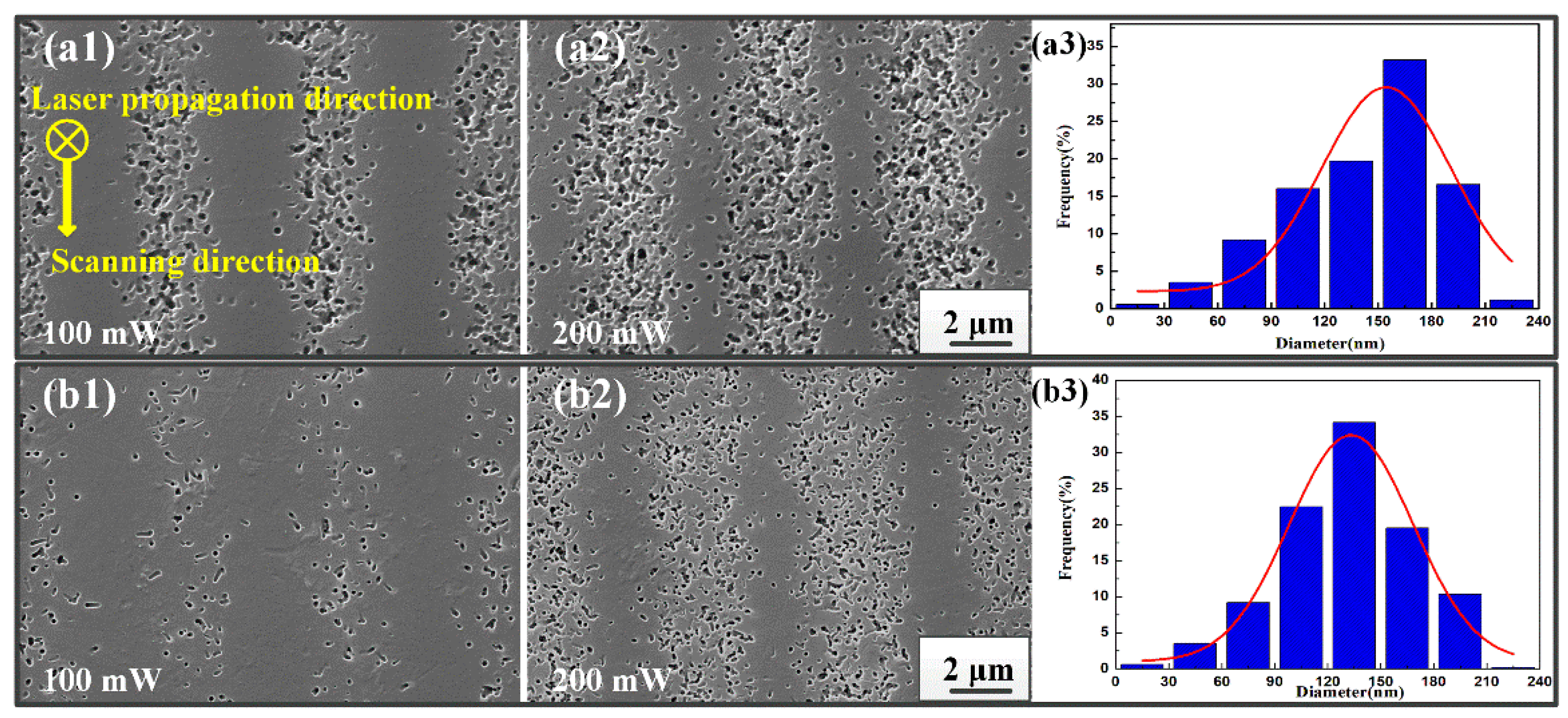

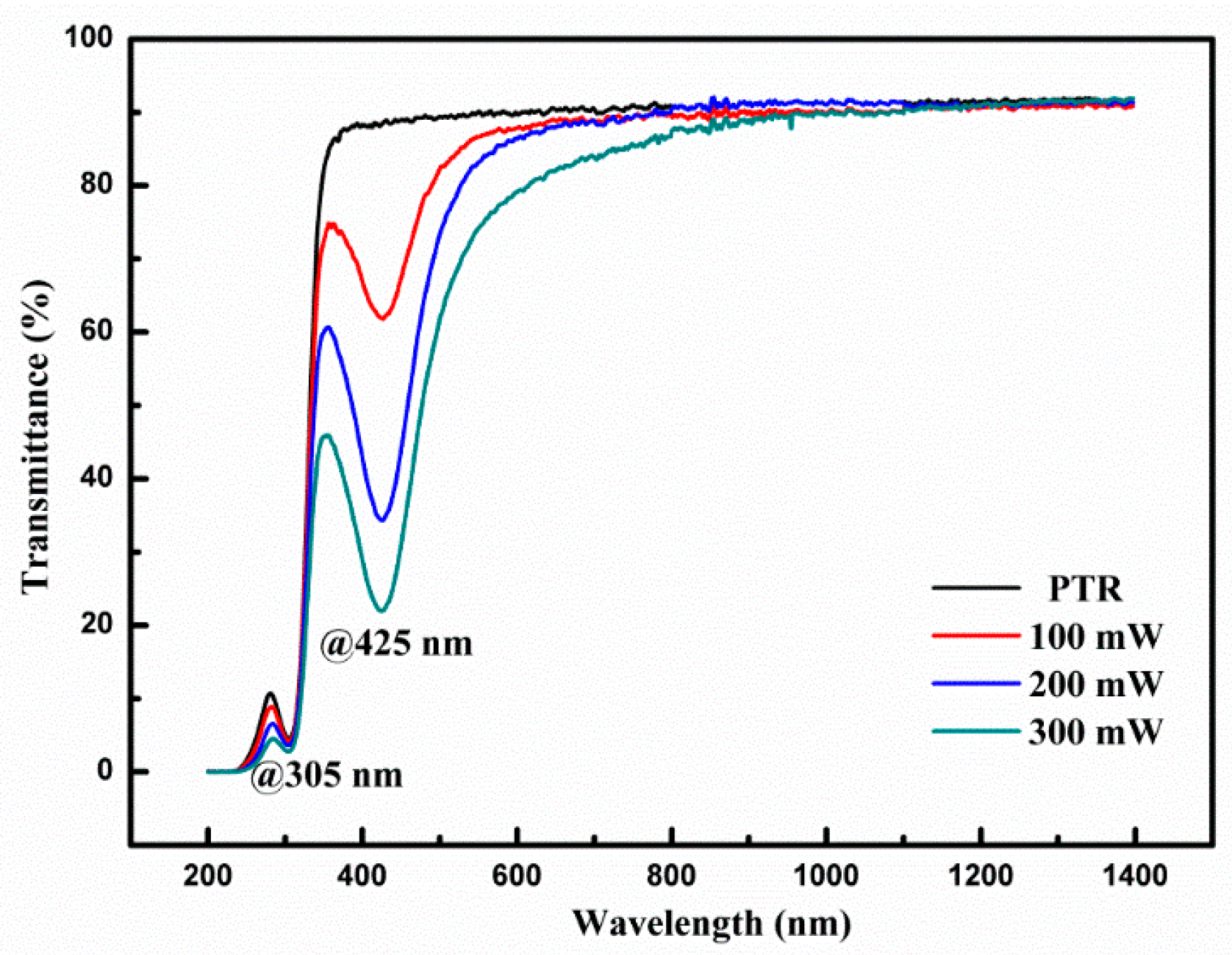

3.1. Microstructure of PTR Glass under Various Writing Power

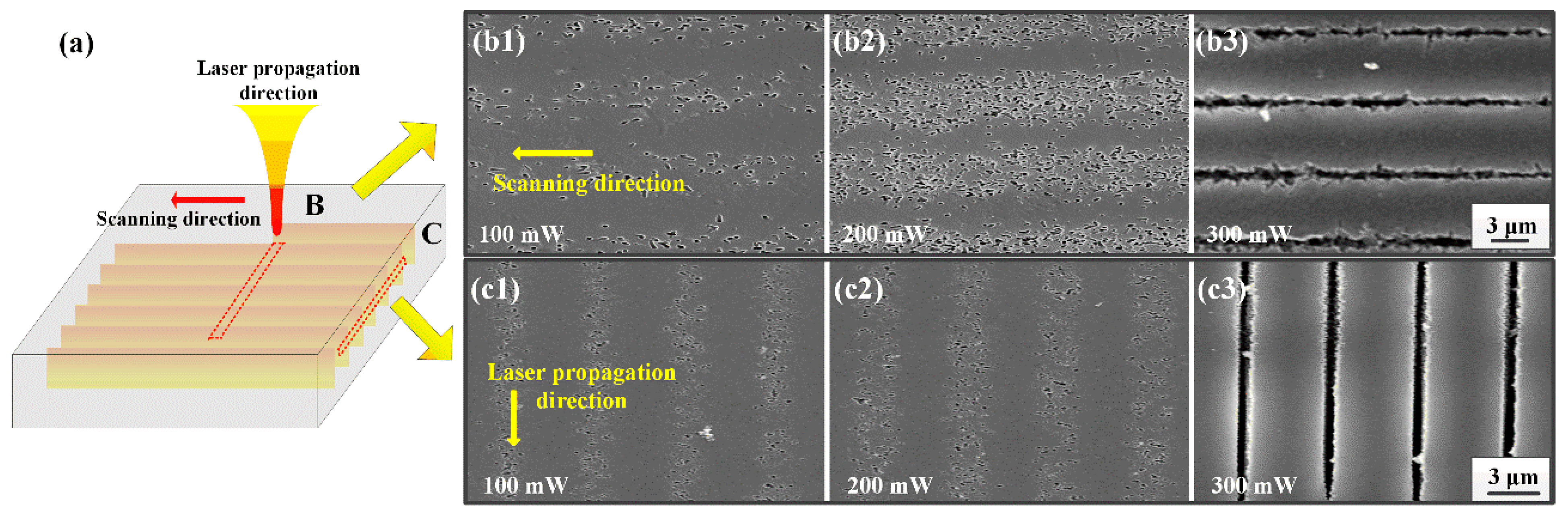

3.2. Nanostructure of PTR Glass under Various Pulse Durations

3.3. Microstructure with Various HT Times

3.4. Crystallographic Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Borrelli, N.F. Photosensitive Glass and Glass-Ceramics; CRC Press: Boca Raton, FL, USA, 2016; pp. 41–60. [Google Scholar]

- Dubrovin, V.D.; Ignatiev, A.I.; Nikonorov, N.V. Chloride photo-thermo-refractive glasses. Opt. Mat. Express 2016, 6, 1701–1713. [Google Scholar] [CrossRef]

- Stookey, S.D.; Beall, G.H.; Pierson, J.E. Full-color photosensitive glass. J. Appl. Phys. 1978, 49, 5114–5123. [Google Scholar] [CrossRef]

- Glebov, A.L.; Mokhun, O.; Rapaport, A.; Vergnole, S.; Smirnov, V.; Glebov, L.B. Volume Bragg gratings as ultra-narrow and multiband optical filters. Proceedings 2012, 8428, 84280C. [Google Scholar]

- Nikonorov, N.; Ivanov, S.; Dubrovin, V.; Ignatiev, A.; Nikolay, N.; Sergey, I.; Victor, D.; Alexander, I. New Photo-Thermo-Refractive Glasses for Holographic Optical Elements: Properties and Applications; IntechOpen: London, UK, 2017; Chapter 19. [Google Scholar]

- Nikonorov, N.; Aseev, V. Holographic optical elements and devices based on polyfunctional photo-thermo-refractive glass. Proceedings 2009, 7506, 75060K. [Google Scholar]

- Efimov, O.M.; Glebov, L.B.; Smirnov, V.I. High-frequency Bragg gratings in a photo thermo refractive glass. Opt. Lett. 2000, 25, 1693–1695. [Google Scholar] [CrossRef] [PubMed]

- Lumeau, J.; Glebov, L.B. Mechanisms and kinetics of short pulse laser-induced destruction of silver-containing nanoparticles in multicomponent silicate photothermo-refractive glass. Appl. Opt. 2014, 53, 7362–7368. [Google Scholar] [CrossRef] [PubMed]

- Glebov, L.; Smirnov, V.; Rotari, E.; Cohanoschi, I.; Glebova, L.; Smolski, O.; Lumeau, J.; Lantigua, C.; Glebov, A. Volume-chirped Bragg gratings: Monolithic components for stretching and compression of ultrashort laser pulses. Opt. Eng. 2014, 53, 051514. [Google Scholar] [CrossRef]

- Fokin, V.M.; Souza, G.P.; Zanotto, E.D.; Lumeau, J.; Glebova, L.; Glebov, L.B. Sodium Fluoride Solubility and Crystallization in Photo-Thermo-Refractive Glass. J. Am. Ceram. Soc. 2010, 93, 716–721. [Google Scholar] [CrossRef]

- Lumeau, J.; Chamma, K.; Glebova, L.; Glebov, L.B. X-ray diffraction study of NaF nano-crystals in photo-thermo-refractive glass. J. Non-Cryst. Solids 2014, 405, 188–195. [Google Scholar] [CrossRef]

- Lumeau, J.; Glebova, L.; Souza, G.P.; Zanotto, E.D.; Glebov, L.B. Effect of cooling on the optical properties and crystallization of UV-exposed photo-thermo-refractive glass. J. Non-Cryst. Solids 2008, 354, 4730–4736. [Google Scholar] [CrossRef]

- Meany, T.; Gräfe, M.; Heilmann, R.; Perez-Leija, A.; Gross, S.; Steel, M.J.; Withford, M.J.; Szameit, A. Laser written circuits for quantum photonics. Laser Photonics Rev. 2015, 9, 363–384. [Google Scholar] [CrossRef]

- Minoshima, K.; Kowalevicz, A.M.; Hartl, I.; Ippen, E.P.; Fujimoto, J.G. Photonic device fabrication in glass by use of nonlinear materials processing with a femtosecond laser oscillator. Opt. Lett. 2001, 26, 1516–1518. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, L.A.; Grenier, J.R.; Aitchison, J.S.; Herman, P.R. Fiber optic stress-independent helical torsion sensor. Opt. Lett. 2015, 40, 657–660. [Google Scholar] [CrossRef]

- Cheng, Y.; Sugioka, K.; Midorikawa, K. Microfluidic laser embedded in glass by three-dimensional femtosecond laser microprocessing. Opt. Lett. 2004, 29, 2007–2009. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, B.; Wang, L.; Qiu, J.; Dai, Y.; Ma, H. Femtosecond laser induced coordination transformation and migration of ions in sodium borate glasses. Appl. Phys. Lett. 2008, 92, 121113. [Google Scholar] [CrossRef]

- Braun, A.; Korn, G.; Liu, X.; Du, D.; Squier, J.; Mourou, G. Self-channeling of high-peak-power femtosecond laser pulses in air. Opt. Lett. 1995, 20, 73–75. [Google Scholar] [CrossRef] [PubMed]

- Couairon, A.; Mysyrowicz, A. Femtosecond filamentation in transparent media. Phys. Rep. 2007, 441, 47–189. [Google Scholar] [CrossRef]

- Polesana, P.; Franco, M.; Couairon, A.; Faccio, D.; Trapani, P.D. Filamentation in Kerr media from pulsed Bessel beams. Phys. Rev. A 2008, 77, 043814-1–043814-11. [Google Scholar] [CrossRef]

- Durnin, J.; Miceli, M.J., Jr.; Eberly, J.H. Diffraction-free beams. Phys. Rev. Lett. 1987, 58, 1499–1501. [Google Scholar] [CrossRef] [PubMed]

- Bhuyan, M.K.; Somayaji, M.; Mermillod-Blondin, A.; Bourquard, F.; Colombier, J.P.; Stoian, R. Ultrafast laser nanostructuring in bulk silica, a slow microexplosion. Optica 2017, 4, 951–958. [Google Scholar] [CrossRef]

- Erdélyi, M.; Horváth, Z.L.; Szabó, G.; Bor, Z.; Tittel, F.K.; Cavallaro, J.R.; Smayling, M.C. Generation of diffraction-free beams for applications in optical microlithography. J. Vac. Sci. Technol. B 1997, 15, 287–292. [Google Scholar] [CrossRef][Green Version]

- Zhang, G.D.; Stoian, R.; Zhao, W.; Cheng, G.H. Femtosecond laser Bessel beam welding of transparent to non-transparent materials with large focal-position tolerant zone. Opt. Express 2018, 26, 917–926. [Google Scholar] [CrossRef]

- Sawaki, D.; Fujii, E.; Amako, J. Microstructuring transparent materials by use of nondiffracting ultrashort pulse beams generated by diffractive optics. J. Opt. Soc. Am. B 2003, 20, 2562–2568. [Google Scholar]

- Zhang, Y.J.; Zhang, G.D.; Chen, C.L.; Stoian, R.; Cheng, G.H. Transmission volume phase holographic gratings in photo-thermo-refractive glass written with femtosecond laser Bessel beams. Opt. Mat. Express 2016, 6, 3491–3499. [Google Scholar] [CrossRef]

- Marcinkevicius, A.; Juodkazis, S.; Watanabe, M.; Miwa, M.; Misawa, S.M.H.; Nishii, J. Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt. Lett. 2001, 26, 277–279. [Google Scholar] [CrossRef] [PubMed]

- Bhuyan, M.K.; Velpula, P.K.; Colombier, J.P.; Olivier, T.; Faure, N.; Stoian, R. Single-shot high aspect ratio bulk nanostructuring of fused silica using chirp-controlled ultrafast laser Bessel beams. Appl. Phys. Lett. 2014, 104, 021107. [Google Scholar] [CrossRef]

- Siiman, L.A.; Lumeau, J.; Glebov, L.B. Nonlinear photosensitivity of photo-thermo-refractive glass by high intensity laser irradiation. J. Non-Cryst. Solids 2008, 354, 4070–4074. [Google Scholar] [CrossRef]

- Lumeau, J.; Zanotto, E.D. A review of the photo-thermal mechanism and crystallization of photo-thermo-refractive (PTR) glass. Int. Mater. Rev. 2016, 62, 1264132. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Zhang, Y.; Xie, X.; Li, W. Photochemical response triggered by ultrashort laser Gaussian-Bessel beams in photo-thermo-refractive glass. Opt. Express 2020, 28, 31093. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, X.; Zhang, G.; Stoian, R.; Cheng, G. Nano-Crystal and Microstructure Formation in Fluoride Photo-Thermo-Refractive Glass Using Chirp-Controlled Ultrafast Laser Bessel Beams. Nanomaterials 2021, 11, 1432. https://doi.org/10.3390/nano11061432

Zhang Y, Wang X, Zhang G, Stoian R, Cheng G. Nano-Crystal and Microstructure Formation in Fluoride Photo-Thermo-Refractive Glass Using Chirp-Controlled Ultrafast Laser Bessel Beams. Nanomaterials. 2021; 11(6):1432. https://doi.org/10.3390/nano11061432

Chicago/Turabian StyleZhang, Yunjie, Xu Wang, Guodong Zhang, Razvan Stoian, and Guanghua Cheng. 2021. "Nano-Crystal and Microstructure Formation in Fluoride Photo-Thermo-Refractive Glass Using Chirp-Controlled Ultrafast Laser Bessel Beams" Nanomaterials 11, no. 6: 1432. https://doi.org/10.3390/nano11061432

APA StyleZhang, Y., Wang, X., Zhang, G., Stoian, R., & Cheng, G. (2021). Nano-Crystal and Microstructure Formation in Fluoride Photo-Thermo-Refractive Glass Using Chirp-Controlled Ultrafast Laser Bessel Beams. Nanomaterials, 11(6), 1432. https://doi.org/10.3390/nano11061432