PVDF HFP_RuO2 Nanocomposite Aerogels Produced by Supercritical Drying for Electrochemical Oxidation of Model Tannery Wastewaters

Abstract

:1. Introduction

2. Materials and Methods

2.1. RuO2 Nanoparticle Synthesis

2.2. Aerogel Preparation Procedure

2.3. Characterizations

2.4. Tannery Wastewater Treatment

3. Results and Discussion

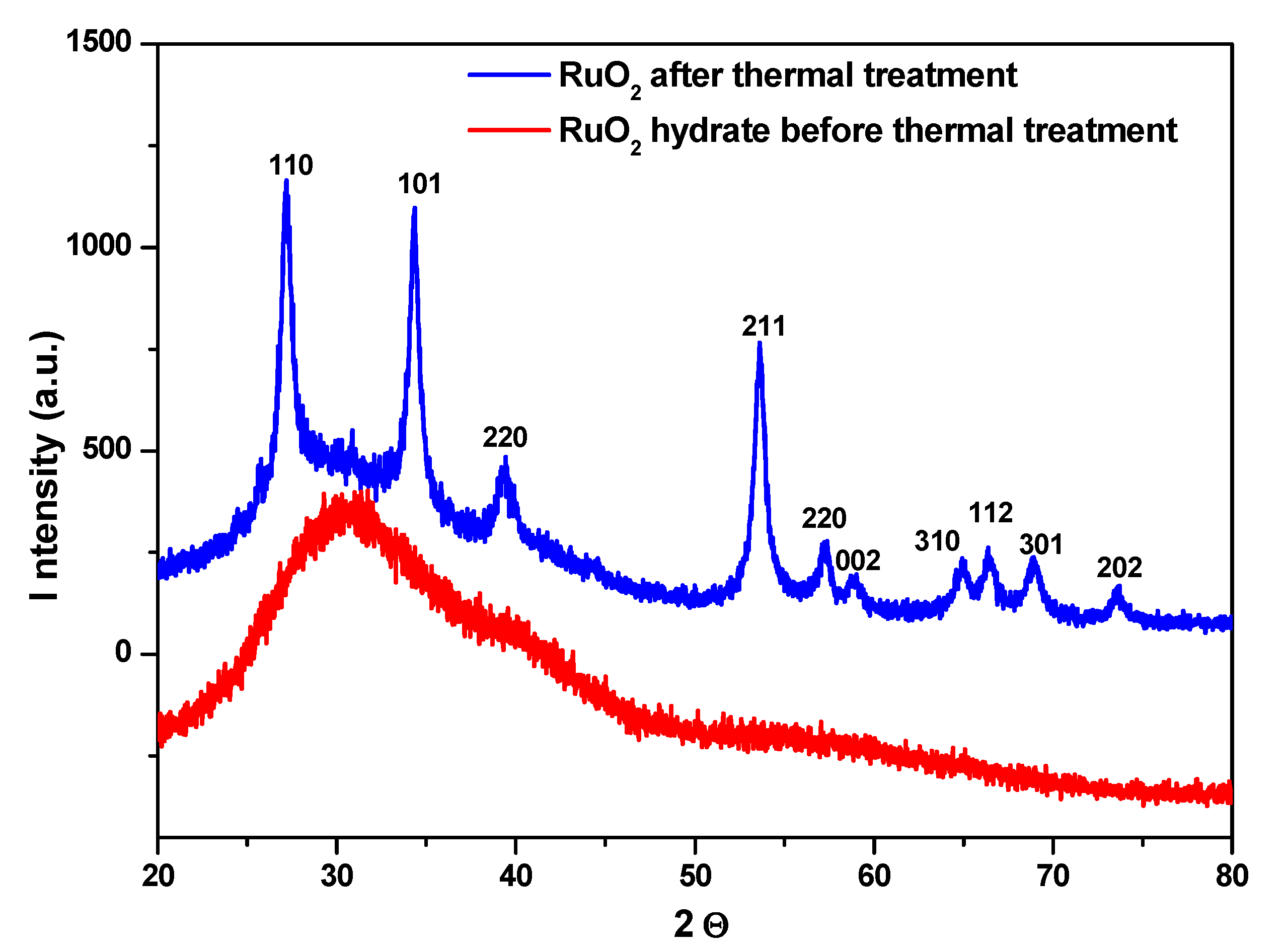

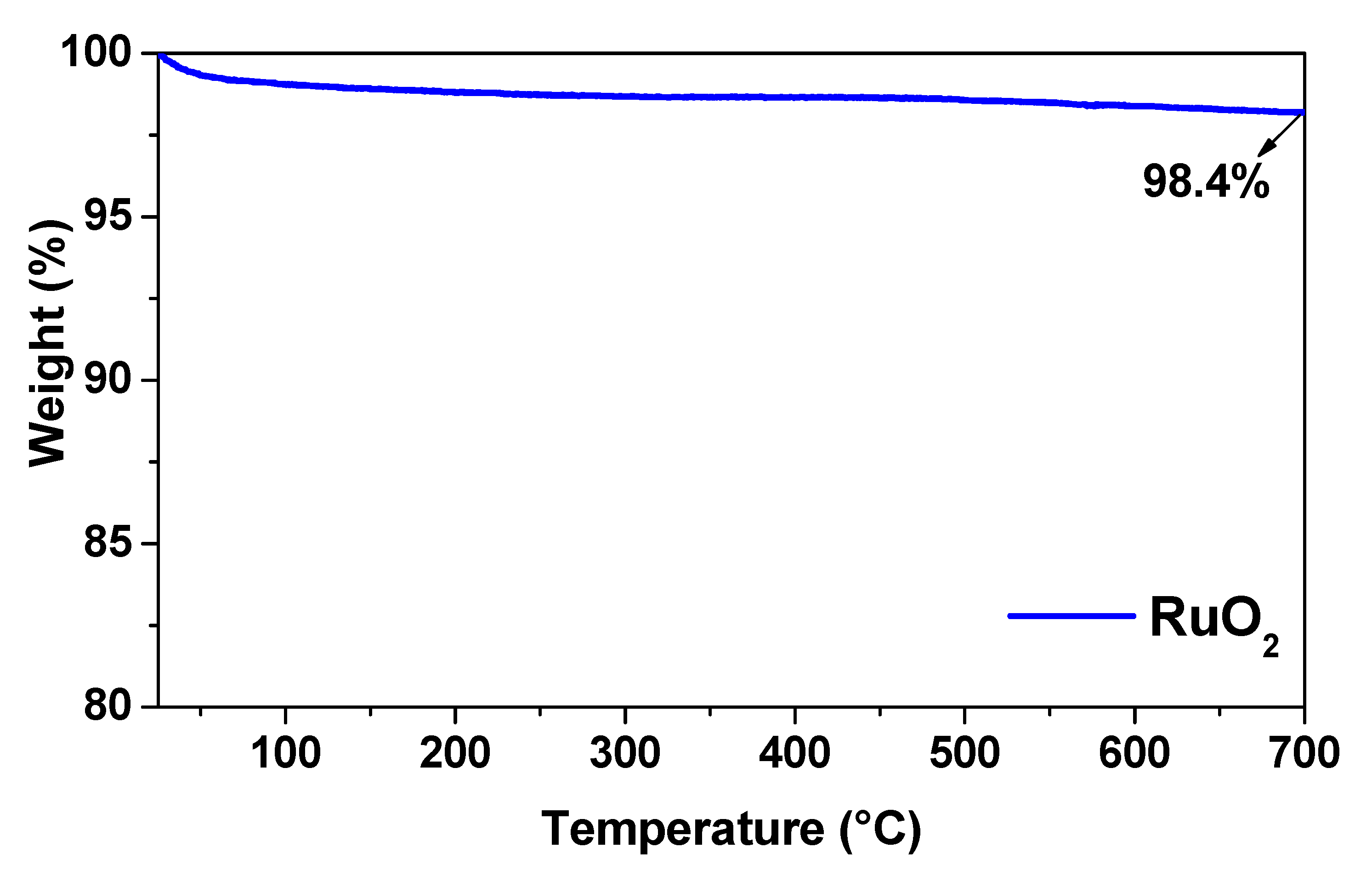

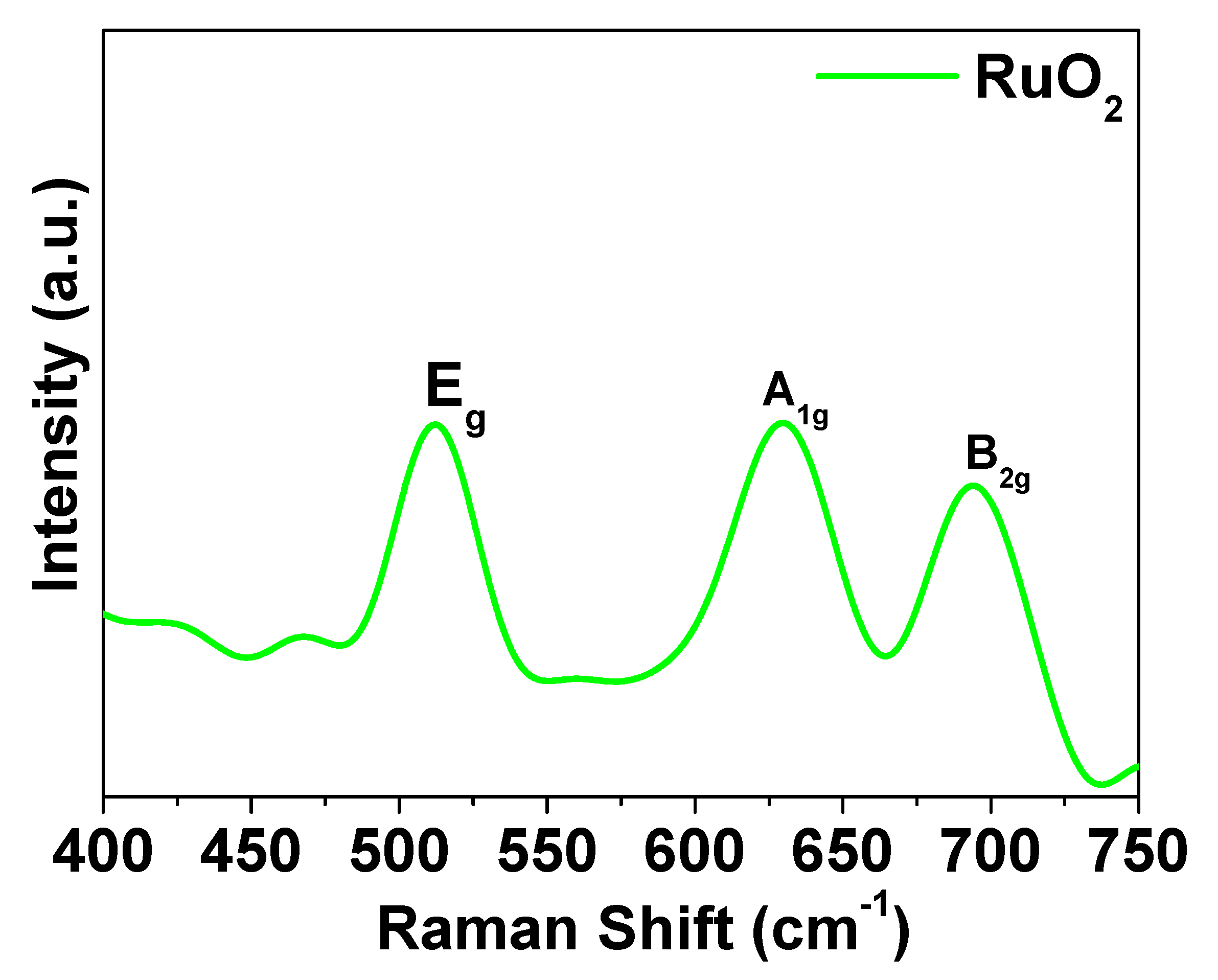

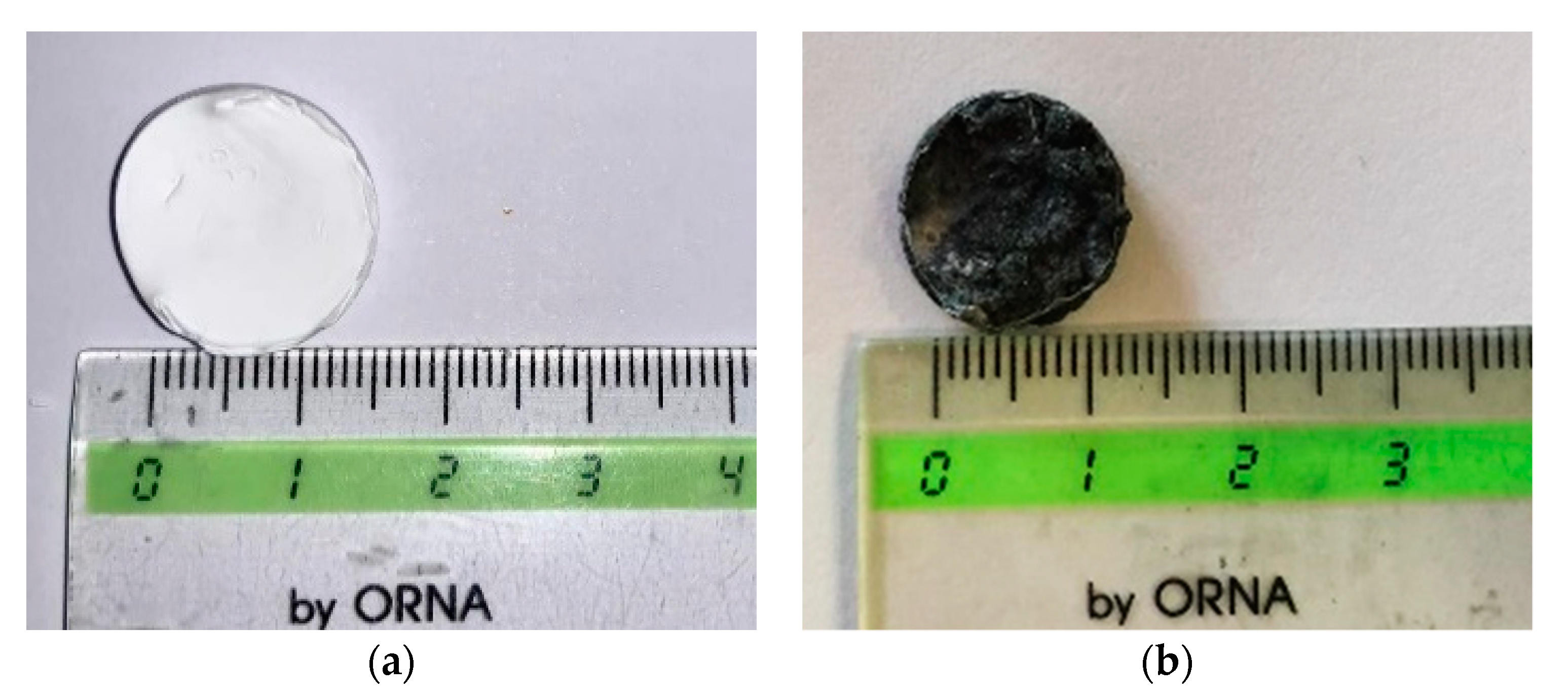

3.1. RuO2 Nanoparticle Characterization

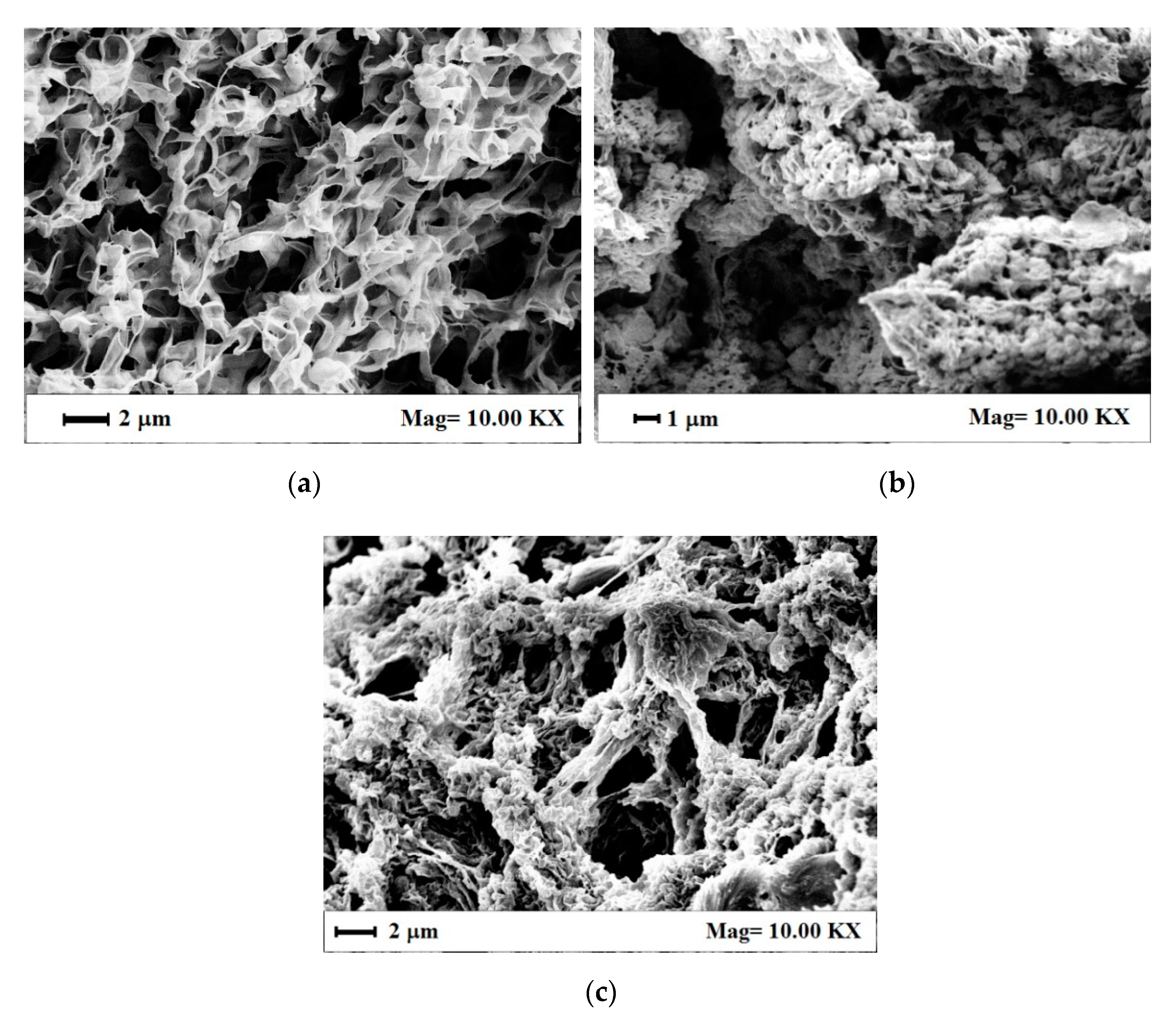

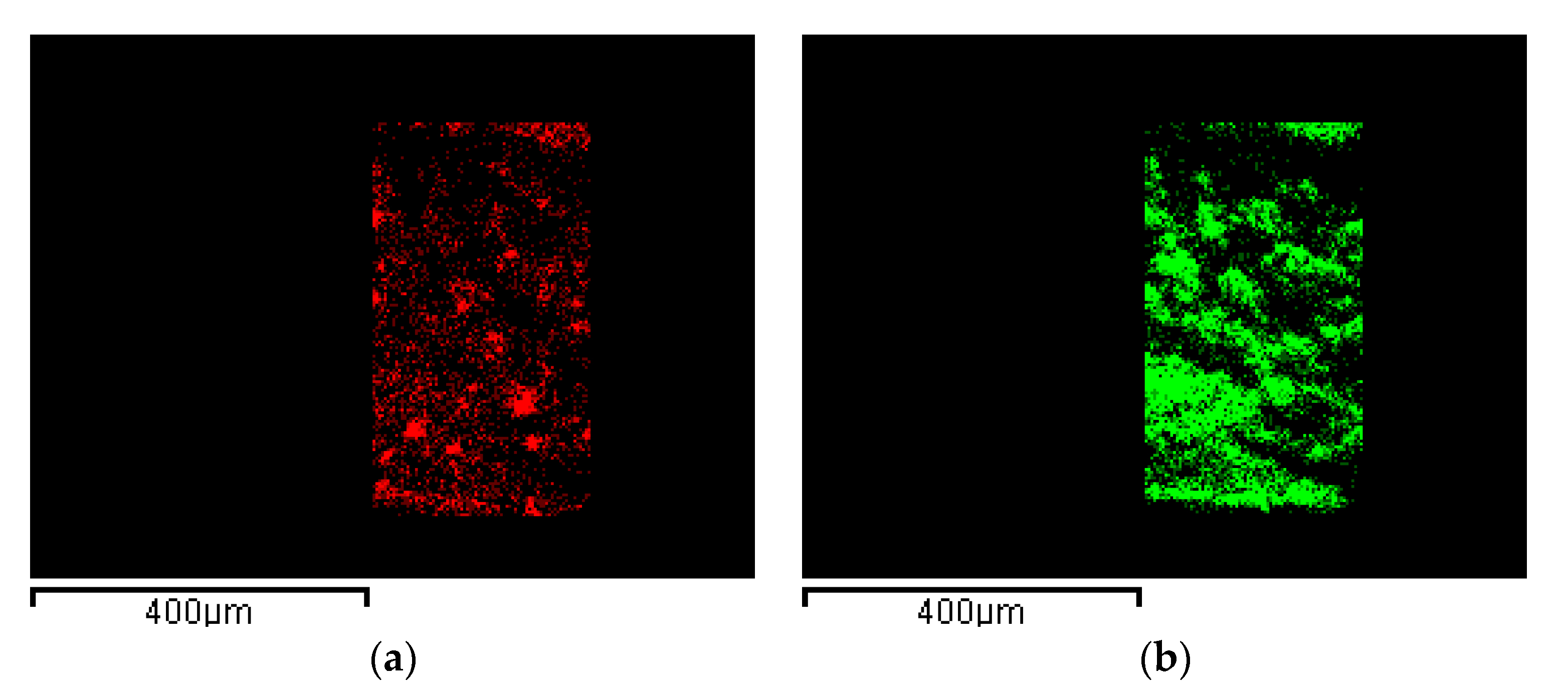

3.2. Nanocomposite Aerogel Characterization

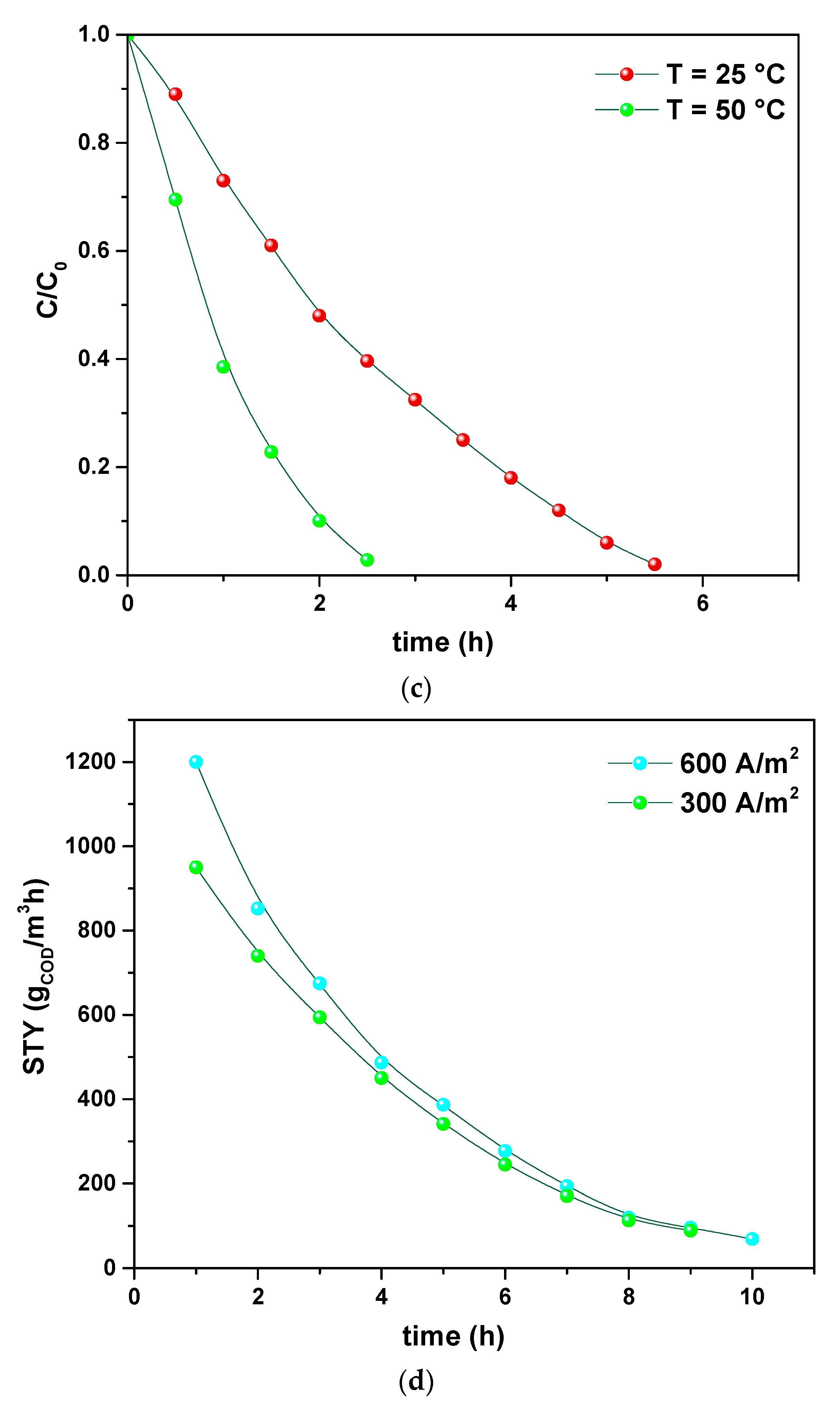

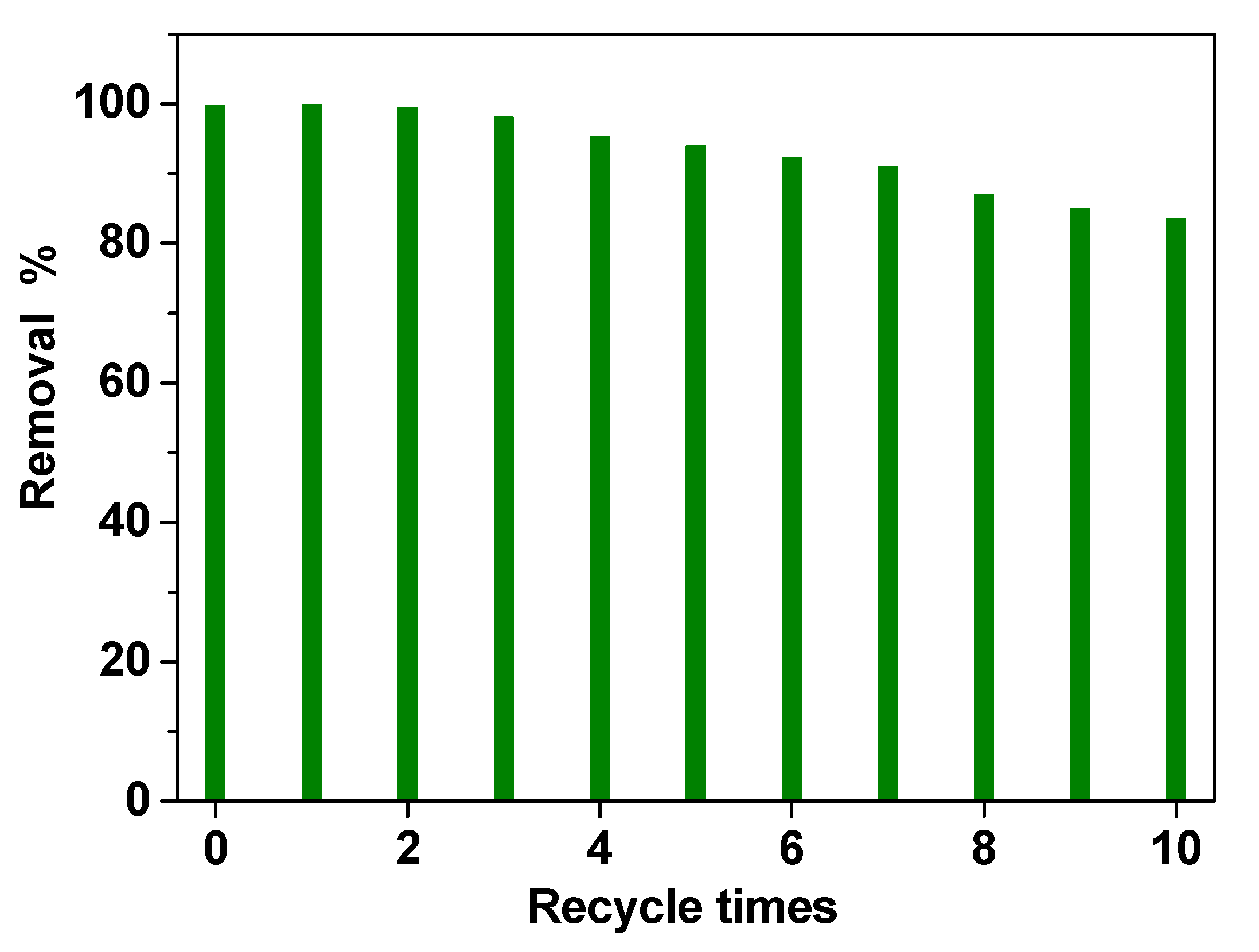

3.3. Electrochemical Oxidation of Model Tannery Wastewaters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Chen, G. Electrochemical technologies in wastewater treatment. Sep. Purif. Technol. 2004, 38, 11–41. [Google Scholar] [CrossRef]

- Brillas, E.; Martínez-Huitle, C.A. Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods. Appl. Catal. B 2015, 166–167, 603–643. [Google Scholar] [CrossRef]

- Kim, J.-C.; Oh, S.-I.; Kang, W.; Yoo, H.-Y.; Lee, J.; Kim, D.-W. Superior anodic oxidation in tailored Sb-doped SnO2/RuO2 composite nanofibers for electrochemical water treatment. J. Catal. 2019, 374, 118–126. [Google Scholar] [CrossRef]

- Cheng, Q.; Cui, Z.Y.; Li, J.B.; Qin, S.H.; Yan, F.; Li, J.X. Preparation and performance of polymer electrolyte based on poly(vinylidene fluoride)/polysulfone blend membrane via thermally induced phase separation process for lithium ion battery. J. Power Sources 2014, 266, 401–413. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, F.; Zhang, L.; Zhang, T.; Huang, Y.; Chen, Y. A high-performance all-solid-state supercapacitor with graphene-doped carbon material electrodes and a graphene oxide-doped ion gel electrolyte. Carbon 2014, 72, 381–386. [Google Scholar] [CrossRef]

- Costa, C.M.; Rodrigues, L.C.; Sencadas, V.; Silva, M.M.; Rocha, J.G.; Lanceros-Méndez, S. Effect of degree of porosity on the properties of poly(vinylidene fluoride–trifluorethylene) for Li-ion battery separators. J. Membr. Sci. 2012, 407–408, 193–201. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, Z.P.; Wang, D.; Zhang, B.; Yang, S.; Wang, H.F.; Hu, P.; Zhao, H.J.; Yang, H.G. Highly electrocatalytic activity of RuO2 nanocrystals for triiodide reduction in dye-sensitized solar cells. Small 2014, 10, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Panizza, M.; Cerisola, G. Electrochemical oxidation of 2-naphthol with in situ electrogenerated active chlorine. Electrochim. Acta 2003, 48, 1515–1519. [Google Scholar] [CrossRef]

- Trasatti, S. Electrocatalysis: Understanding the success of DSA. Electrochim. Acta 2000, 45, 2377–2385. [Google Scholar] [CrossRef]

- Sarno, M.; Baldino, L.; Scudieri, C.; Cardea, S.; Reverchon, E. A one-step SC-CO2 assisted technique to produce compact PVDF-HFP MoS2 supercapacitor device. J. Phys. Chem. Solids 2020, 136, 109132. [Google Scholar] [CrossRef]

- Vlyssides, A.G.; Israilides, C.J. Detoxification of tannery waste liquors with an electrolysis system. Environ. Pollut. 1997, 97, 147–152. [Google Scholar] [CrossRef]

- Jochimsen, J.C.; Schenk, H.; Jekel, M.R.; Hegemann, W. Combined oxidative and biological treatment for separated streams of tannery wastewater. Wat. Sci. Tech. 1997, 36, 209–216. [Google Scholar] [CrossRef]

- Di Iaconi, C.; Ricco, G.; Tanzarella, C.; Tomei, M.C. Chemical oxidation combined with biological oxidation in removal of biorefractory compounds. Annali di Chimica 1998, 88, 849–858. [Google Scholar]

- Chowdhury, M.; Mostafa, M.G.; Biswas, T.K.; Saha, A.K. Treatment of leather industrial effluents by filtration and coagulation processes. Water. Resour. Ind. 2013, 3, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Huitle, C.A.; Ferro, S. Electrochemical oxidation of organic pollutants for the wastewater treatment: Direct and indirect processes. Chem. Soc. Rev. 2006, 35, 1324–1340. [Google Scholar] [CrossRef] [PubMed]

- Bai, H.; He, P.; Chen, J.; Liu, K.; Lei, H.; Zhang, X.; Dong, F.; Li, H. Electrocatalytic degradation of bromocresol green wastewater on Ti/SnO2-RuO2 electrode. Water Sci. Technol. 2017, 75, 220–227. [Google Scholar] [CrossRef] [PubMed]

- Fajardo, A.S.; Seca, H.F.; Martins, R.C.; Corceiro, V.N.; Freitas, I.F.; Quinta-Ferreira, M.E.; Quinta-Ferreira, R.M. Electrochemical oxidation of phenolic wastewaters using a batch-stirred reactor with NaCl electrolyte and Ti/RuO2 anodes. J. Electroanal. Chem. 2017, 785, 180–189. [Google Scholar] [CrossRef]

- Kaur, P.; Kushwaha, J.P.; Sangal, V.K. Evaluation and disposability study of actual textile wastewater treatment by electro-oxidation method using Ti/RuO2 anode. Process Saf. Environ. Prot. 2017, 3, 13–22. [Google Scholar] [CrossRef]

- Chauhan, R.; Srivastava, V.C. Electrochemical denitrification of highly contaminated actual nitrate wastewater by Ti/RuO2 anode and iron cathode. Chem. Eng. J. 2020, 386, 122065. [Google Scholar] [CrossRef]

- Baldino, L.; Cardea, S.; Reverchon, E. Natural aerogels production by supercritical gel drying. Chem. Eng. Trans. 2015, 43, 739–744. [Google Scholar]

- Cardea, S.; Baldino, L.; Reverchon, E. Comparative study of PVDF-HFP-curcumin porous structures produced by supercritical assisted processes. J. Supercrit. Fluids 2018, 133, 270–277. [Google Scholar] [CrossRef]

- Baldino, L.; Cardea, S.; Reverchon, E. Biodegradable membranes loaded with curcumin to be used as engineered independent devices in active packaging. J. Taiwan Inst. Chem. Eng. 2017, 71, 518–526. [Google Scholar] [CrossRef]

- Sarno, M.; Baldino, L.; Scudieri, C.; Cardea, S.; Ciambelli, P.; Reverchon, E. SC-CO2-assisted process for a high energy density aerogel supercapacitor: The effect of GO loading. Nanotechnology 2017, 28, 204001. [Google Scholar] [CrossRef] [PubMed]

- Bi, R.-R.; Wu, X.-L.; Cao, F.-F.; Jiang, L.-Y.; Guo, Y.-G.; Wan, L.-J. Highly dispersed RuO2 nanoparticles on carbon nanotubes: Facile synthesis and enhanced supercapacitance performance. J. Phys. Chem. C 2010, 114, 2448–2451. [Google Scholar] [CrossRef]

- Audichon, T.; Napporn, T.W.; Canaff, C.; Morais, C.; Comminges, C.; Kokoh, K.B. IrO2 coated on RuO2 as efficient and stable electroactive nanocatalysts for electrochemical water splitting. J. Phys. Chem. C 2016, 120, 2562–2573. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, B.; Huang, X.; Chen, S.; Wang, G. Honeycomb-like porous gel polymer electrolyte membrane for lithium ion batteries with enhanced safety. Sci. Rep. 2014, 4, 6007. [Google Scholar] [CrossRef] [PubMed]

- Goodridge, F.; Scott, K. Electrochemical Process Engineering; Plenum Press: New York, NY, USA, 1995. [Google Scholar]

- Devadas, A.; Baranton, S.; Napporn, T.W.; Coutanceau, C. Tailoring of RuO2 nanoparticles by microwave assisted “Instant method” for energy storage applications. J. Power Sources 2011, 196, 4044–4053. [Google Scholar] [CrossRef]

- Kim, H.; Popov, B.N. Characterization of hydrous ruthenium oxide/carbon nanocomposite supercapacitors prepared by a colloidal method. J. Power Sources 2002, 104, 52–61. [Google Scholar] [CrossRef]

- Khorasani-Motlagh, M.; Noroozifar, M.; Yousefi, M. A simple new method to synthesize nanocrystalline ruthenium dioxide in the presence of octanoic acid as organic surfactant. Int. J. Nanosci. Nanotechnol. 2011, 7, 167–172. [Google Scholar]

- Aravindan, V.; Vickraman, P.; Sivashanmugam, A.; Thirunakaran, R.; Gopukumar, S. LiFAP-based PVdF–HFP microporous membranes by phase-inversion technique with Li/LiFePO4 cell. Appl. Phys. A 2009, 97, 811–820. [Google Scholar] [CrossRef]

- Bonfatti, F.; Ferro, S.; Lavezzo, F.; Malacarne, M.; Lodi, G.; De Battisti, A. Electrochemical incineration of glucose as a model organic substrate. II. Role of active chlorine mediation. J. Electrochem. Soc. 2000, 147, 592. [Google Scholar] [CrossRef]

- Do, J.S.; Yeh, W.C. In situ degradation of formaldehyde with electrogenerated hypochlorite ion. J. Appl. Electrochem. 1995, 25, 483. [Google Scholar] [CrossRef]

- Garcia-Segura, S.; Ocon, J.D.; Chong, M.N. Electrochemical oxidation remediation of real wastewater effluents—A review. Process Saf. Environ. Prot. 2018, 113, 48–67. [Google Scholar] [CrossRef]

- Panizza, M.; Bocca, C.; Cerisola, G. Electrochemical treatment of wastewater containing polyaromatic organic pollutants. Water Res. 2000, 34, 2601–2605. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarno, M.; Scudieri, C.; Ponticorvo, E.; Baldino, L.; Cardea, S.; Reverchon, E. PVDF HFP_RuO2 Nanocomposite Aerogels Produced by Supercritical Drying for Electrochemical Oxidation of Model Tannery Wastewaters. Nanomaterials 2021, 11, 1436. https://doi.org/10.3390/nano11061436

Sarno M, Scudieri C, Ponticorvo E, Baldino L, Cardea S, Reverchon E. PVDF HFP_RuO2 Nanocomposite Aerogels Produced by Supercritical Drying for Electrochemical Oxidation of Model Tannery Wastewaters. Nanomaterials. 2021; 11(6):1436. https://doi.org/10.3390/nano11061436

Chicago/Turabian StyleSarno, Maria, Carmela Scudieri, Eleonora Ponticorvo, Lucia Baldino, Stefano Cardea, and Ernesto Reverchon. 2021. "PVDF HFP_RuO2 Nanocomposite Aerogels Produced by Supercritical Drying for Electrochemical Oxidation of Model Tannery Wastewaters" Nanomaterials 11, no. 6: 1436. https://doi.org/10.3390/nano11061436

APA StyleSarno, M., Scudieri, C., Ponticorvo, E., Baldino, L., Cardea, S., & Reverchon, E. (2021). PVDF HFP_RuO2 Nanocomposite Aerogels Produced by Supercritical Drying for Electrochemical Oxidation of Model Tannery Wastewaters. Nanomaterials, 11(6), 1436. https://doi.org/10.3390/nano11061436