A Novel Self-Assembly Strategy for the Fabrication of Nano-Hybrid Satellite Materials with Plasmonically Enhanced Catalytic Activity

Abstract

:1. Introduction

2. Results and Discussion

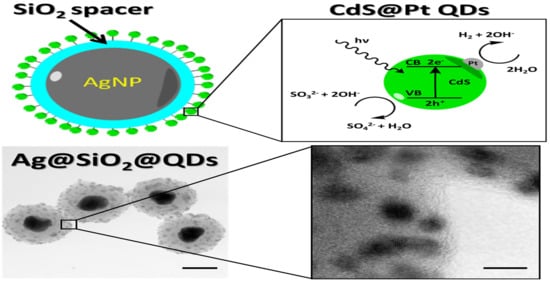

2.1. Fabrication Strategy for the Nano-Hybrid Satellite Materials

2.2. The Photo-Catalytic Unit: CdS QDs Functionalised with Pt Clusters

2.3. Plasmonic Antenna: Quasi-Spherical Silver Nanoparticles Coated with Amino Functionalised SiO2 Spacing Layer (AgNP@SiO2-NH2)

2.4. Nano-Hybrid Satellite Material Combining AgNP@SiO2-NH2 Plasmonic Antenna and Photo-Catalytic CdS@Pt QDs

2.5. Photo-Activated Hydrogen Generation by Nano-Hybrid Satellite Materials

3. Conclusions

4. Materials and Methods

4.1. Chemicals

4.2. Synthesis of Silver Nanoparticles (AgNPs)

4.3. Preparation of AgNP@SiO2-NH2

4.4. Synthesis of Cadmium Sulfide (CdS) Quantum Dots (QDs)

4.5. Preparation of 3-Mercaptopropionic Acid Functionalised CdS QDs

4.6. Photodeposition of Pt islands on CdS QDs

4.7. Fabrication of the Nano-Hybrid Satellite Material

4.8. Ultraviolet-Visible (UV-Vis) Spectrophotometry

4.9. Transmission Electron Microscopy (TEM) of Plasmonic Nanomaterials

4.10. Bright Field Scanning Transmission Electron Microscopy (BF-STEM), Coupled with Energy Disperse Spectroscopy (EDS)

4.11. X-Ray Photoelectron Spectroscopy (XPS)

4.12. Hydrogen Evolution Experiments

4.13. Inductively Coupled Plasma Optical Emission Spectrophotometry (ICP-OES)

4.14. Quantification of AgNP Size and SiO2 Outer Coating Thickness

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lange, J.P. Performance metrics for sustainable catalysis in industry. Nat. Catal. 2021, 4, 186–192. [Google Scholar] [CrossRef]

- Copéret, C. Fuels and energy carriers from single-site catalysts prepared via surface organometallic chemistry. Nat. Energy 2019, 4, 1018–1024. [Google Scholar] [CrossRef]

- Amirav, L.; Alivisatos, A.P. Photocatalytic hydrogen production with tunable nanorod heterostructures. J. Phys. Chem. Lett. 2010, 1, 1051–1054. [Google Scholar] [CrossRef]

- Berr, M.; Vaneski, A.; Susha, A.S.; Rodríguez-Fernández, J.; Döblinger, M.; Jäckel, F.; Rogach, A.L.; Feldmann, J. Colloidal CdS nanorods decorated with subnanometer sized Pt clusters for photocatalytic hydrogen generation. Appl. Phys. Lett. 2010, 97, 93108. [Google Scholar] [CrossRef]

- Aslam, U.; Rao, V.G.; Chavez, S.; Linic, S. Catalytic conversion of solar to chemical energy on plasmonic metal nanostructures. Nat. Catal. 2018, 1, 656–665. [Google Scholar] [CrossRef]

- House, R.A.; Marie, J.-J.; Park, J.; Rees, G.J.; Agrestini, S.; Nag, A.; Garcia-Fernandez, M.; Zhou, K.-J.; Bruce, P.G. Covalency does not suppress O2 formation in 4d and 5d Li-rich O-redox cathodes. Nat. Commun. 2021, 12, 2975. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Chen, M.; Zhao, Z.; Zhang, Z.; Ye, S.; Xu, S.; Wang, H.; Li, H. Bridging the gap between highly active oxygen reduction reaction catalysts and effective catalyst layers for proton exchange membrane fuel cells. Nat. Energy 2021, 6, 475–486. [Google Scholar] [CrossRef]

- Shi, Y.; Ma, Z.-R.; Xiao, Y.-Y.; Yin, Y.-C.; Huang, W.-M.; Huang, Z.-C.; Zheng, Y.-Z.; Mu, F.-Y.; Huang, R.; Shi, G.-Y.; et al. Electronic metal–support interaction modulates single-atom platinum catalysis for hydrogen evolution reaction. Nat. Commun. 2021, 12, 3021. [Google Scholar] [CrossRef]

- Silva, C.G.; Juárez, R.; Marino, T.; Molinari, R.; García, H. Influence of excitation wavelength (UV or visible light) on the photocatalytic activity of titania containing gold nanoparticles for the generation of hydrogen or oxygen from water. J. Am. Chem. Soc. 2011, 133, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Torimoto, T.; Horibe, H.; Kameyama, T.; Okazaki, K.I.; Ikeda, S.; Matsumura, M.; Ishikawa, A.; Ishihara, H. Plasmon-enhanced photocatalytic activity of cadmium sulfide nanoparticle immobilized on silica-coated gold particles. J. Phys. Chem. Lett. 2011, 2, 2057–2062. [Google Scholar] [CrossRef]

- Gan, Z.; Wu, X.; Meng, M.; Zhu, X.; Yang, L.; Chu, P.K. Photothermal contribution to enhanced photocatalytic performance of graphene-based nanocomposites. ACS Nano 2014, 8, 9304–9310. [Google Scholar] [CrossRef] [PubMed]

- Gan, Z.; Chen, Z.; Liu, L.; Zhang, L.; Tu, W.; Liu, Y. Highly Efficient solar-driven photothermal performance in au-carbon core-shell nanospheres. Sol. RRL 2017, 1, 1600032. [Google Scholar] [CrossRef]

- Ma, X.C.; Dai, Y.; Yu, L.; Huang, B.B. Energy transfer in plasmonic photocatalytic composites. Light Sci. Appl. 2016, 5, e16017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hayashido, Y.; Naya, S.; Tada, H. Local electric field-enhanced plasmonic photocatalyst: Formation of Ag cluster-incorporated AgBr nanoparticles on TiO2. J. Phys. Chem. C 2016, 120, 19663–19669. [Google Scholar] [CrossRef]

- Diaz Fernandez, Y.A.; Gschneidtner, T.A.; Wadell, C.; Fornander, L.H.; Lara Avila, S.; Langhammer, C.; Westerlund, F.; Moth-Poulsen, K. The conquest of middle-earth: Combining top-down and bottom-up nanofabrication for constructing nanoparticle based devices. Nanoscale 2014, 6, 14605–14616. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pallavicini, P.; Bassi, B.; Chirico, G.; Collini, M.; Dacarro, G.; Fratini, E.; Grisoli, P.; Patrini, M.; Sironi, L.; Taglietti, A.; et al. Modular approach for bimodal antibacterial surfaces combining photo-switchable activity and sustained biocidal release. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, L.; Xiang, Q.; Liao, Y.; Zhang, H. CdS-Based photocatalysts. Energy Environ. Sci. 2018, 11, 1362. [Google Scholar] [CrossRef]

- Li, W.; Jäckel, F. Size-controlled electron transfer rates determine hydrogen generation efficiency in colloidal Pt-decorated CdS quantum dots. Nanoscale 2018, 10, 16153–16158. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Lee, J.R.; Jäckel, F. Simultaneous optimization of colloidal stability and interfacial charge transfer efficiency in photocatalytic Pt/CdS nanocrystals. ACS Appl. Mater. Interfaces 2016, 8, 29434–29441. [Google Scholar] [CrossRef] [Green Version]

- Yu, W.W.; Qu, L.; Guo, W.; Peng, X. Experimental determination of the extinction coefficient of CdTe, CdSe, and CdS nanocrystals. Chem. Mater. 2003, 15, 2854–2860. [Google Scholar] [CrossRef]

- Veamatahau, A.; Jiang, B.; Seifert, T.; Makuta, S.; Latham, K.; Kanehara, M.; Teranishi, T.; Tachibana, Y. Origin of surface trap states in CdS quantum dots: Relationship between size dependent photoluminescence and sulfur vacancy trap states. Phys. Chem. Chem. Phys. 2015, 17, 2850–2858. [Google Scholar] [CrossRef]

- Bastús, N.G.; Merkoçi, F.; Piella, J.; Puntes, V. Synthesis of highly monodisperse citrate-stabilized silver nanoparticles of up to 200 nm: Kinetic control and catalytic properties. Chem. Mater. 2014, 26, 2836–2846. [Google Scholar] [CrossRef]

- Lismont, M.; Páez, C.A.; Dreesen, L. A one-step short-time synthesis of Ag@SiO2 core-shell nanoparticles. J. Colloid Interface Sci. 2015, 447, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Carter, J.D.; LaBean, T.H. Coupling strategies for the synthesis of peptide-oligonucleotide conjugates for patterned synthetic biomineralization. J. Nucleic Acids 2011, 2011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sole, R.; Gatto, V.; Conca, S.; Bardella, N.; Morandini, A.; Beghetto, V. Sustainable triazine-based Dehydro-condensation agents for amide synthesis. Molecules 2021, 26, 191. [Google Scholar] [CrossRef]

- Farkaš, P.; Bystrický, S. Efficient activation of carboxyl polysaccharides for the preparation of conjugates. Carbohydr. Polym. 2007, 68, 187–190. [Google Scholar] [CrossRef]

- Li, W.; O’Dowd, G.; Whittles, T.J.; Hesp, D.; Gründer, Y.; Dhanak, V.R.; Jäckel, F. Colloidal dual-band gap cell for photocatalytic hydrogen generation. Nanoscale 2015, 7, 16606–16610. [Google Scholar] [CrossRef] [Green Version]

- Berr, M.J.; Wagner, P.; Fischbach, S.; Vaneski, A.; Schneider, J.; Susha, A.S.; Rogach, A.L.; Jäckel, F.; Feldmann, J. Hole scavenger redox potentials determine quantum efficiency and stability of Pt-decorated CdS nanorods for photocatalytic hydrogen generation. Appl. Phys. Lett. 2012, 100, 223903. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Seung, H.S. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef]

- Fitzgibbon, A.; Pilu, M.; Fisher, R.B. Direct least square fitting of ellipses. IEEE Trans. Pattern Anal. Mach. Intell. 1999, 21, 476–480. [Google Scholar] [CrossRef] [Green Version]

- Wagner, T.; Eglinger, J. Thorstenwagner/ij-ellipsesplit: EllipseSplit 0.6.0 SNAPSHOT. [CrossRef]

- Waskom, M. Seaborn: Statistical data visualization. J. Open Source Softw. 2021, 6, 3021. [Google Scholar] [CrossRef]

| H2 Evolution Sample | Reaction Rate * | Enhancement Factor |

|---|---|---|

| CdS@Pt QDs | 40.4 | 300% |

| Nano-Hybrid Satellite | 120.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morris, G.; Sorzabal-Bellido, I.; Bilton, M.; Dawson, K.; McBride, F.; Raval, R.; Jäckel, F.; Diaz Fernandez, Y.A. A Novel Self-Assembly Strategy for the Fabrication of Nano-Hybrid Satellite Materials with Plasmonically Enhanced Catalytic Activity. Nanomaterials 2021, 11, 1580. https://doi.org/10.3390/nano11061580

Morris G, Sorzabal-Bellido I, Bilton M, Dawson K, McBride F, Raval R, Jäckel F, Diaz Fernandez YA. A Novel Self-Assembly Strategy for the Fabrication of Nano-Hybrid Satellite Materials with Plasmonically Enhanced Catalytic Activity. Nanomaterials. 2021; 11(6):1580. https://doi.org/10.3390/nano11061580

Chicago/Turabian StyleMorris, Gareth, Ioritz Sorzabal-Bellido, Matthew Bilton, Karl Dawson, Fiona McBride, Rasmita Raval, Frank Jäckel, and Yuri A. Diaz Fernandez. 2021. "A Novel Self-Assembly Strategy for the Fabrication of Nano-Hybrid Satellite Materials with Plasmonically Enhanced Catalytic Activity" Nanomaterials 11, no. 6: 1580. https://doi.org/10.3390/nano11061580

APA StyleMorris, G., Sorzabal-Bellido, I., Bilton, M., Dawson, K., McBride, F., Raval, R., Jäckel, F., & Diaz Fernandez, Y. A. (2021). A Novel Self-Assembly Strategy for the Fabrication of Nano-Hybrid Satellite Materials with Plasmonically Enhanced Catalytic Activity. Nanomaterials, 11(6), 1580. https://doi.org/10.3390/nano11061580