Impact of Ar Flow Rates on Micro-Structural Properties of WS2 Thin Film by RF Magnetron Sputtering

Abstract

:1. Introduction

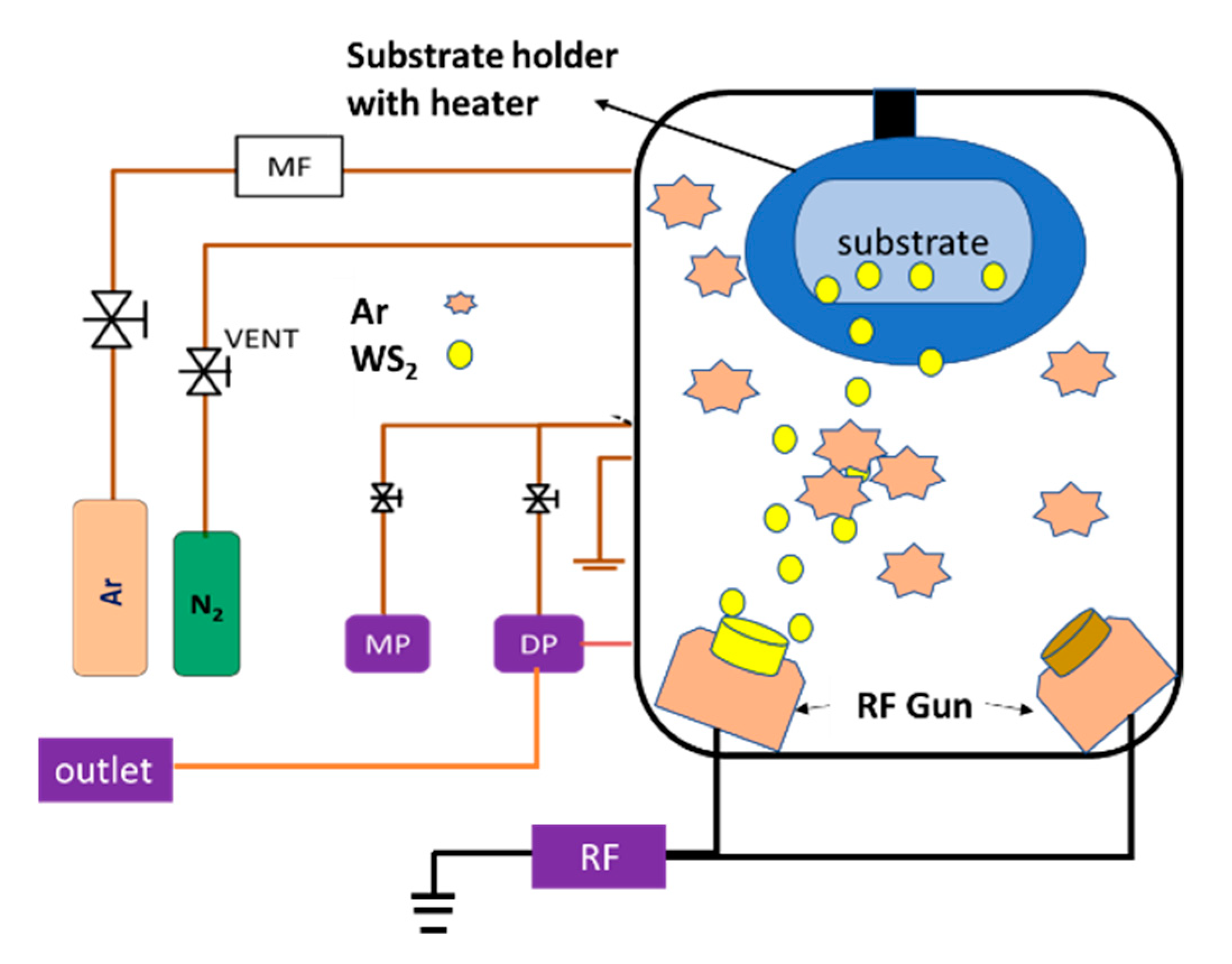

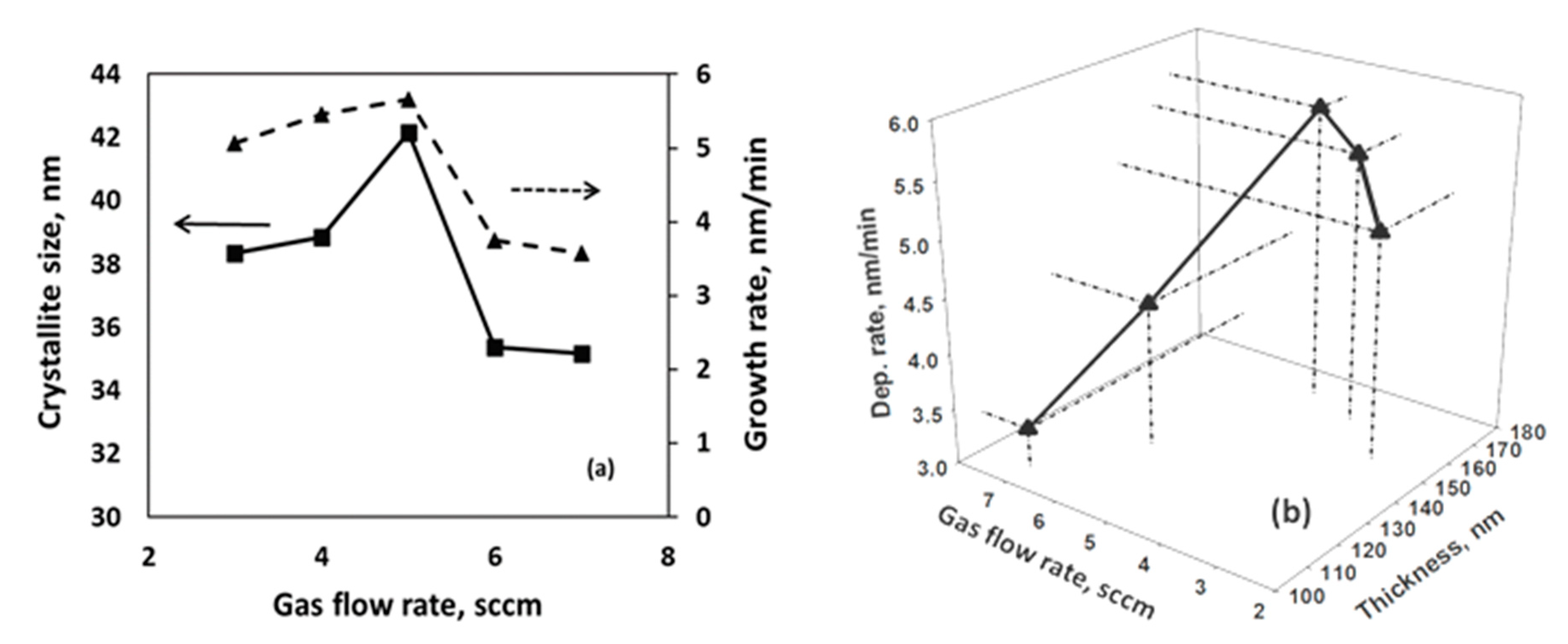

2. Materials and Methods

3. Results and Discussions

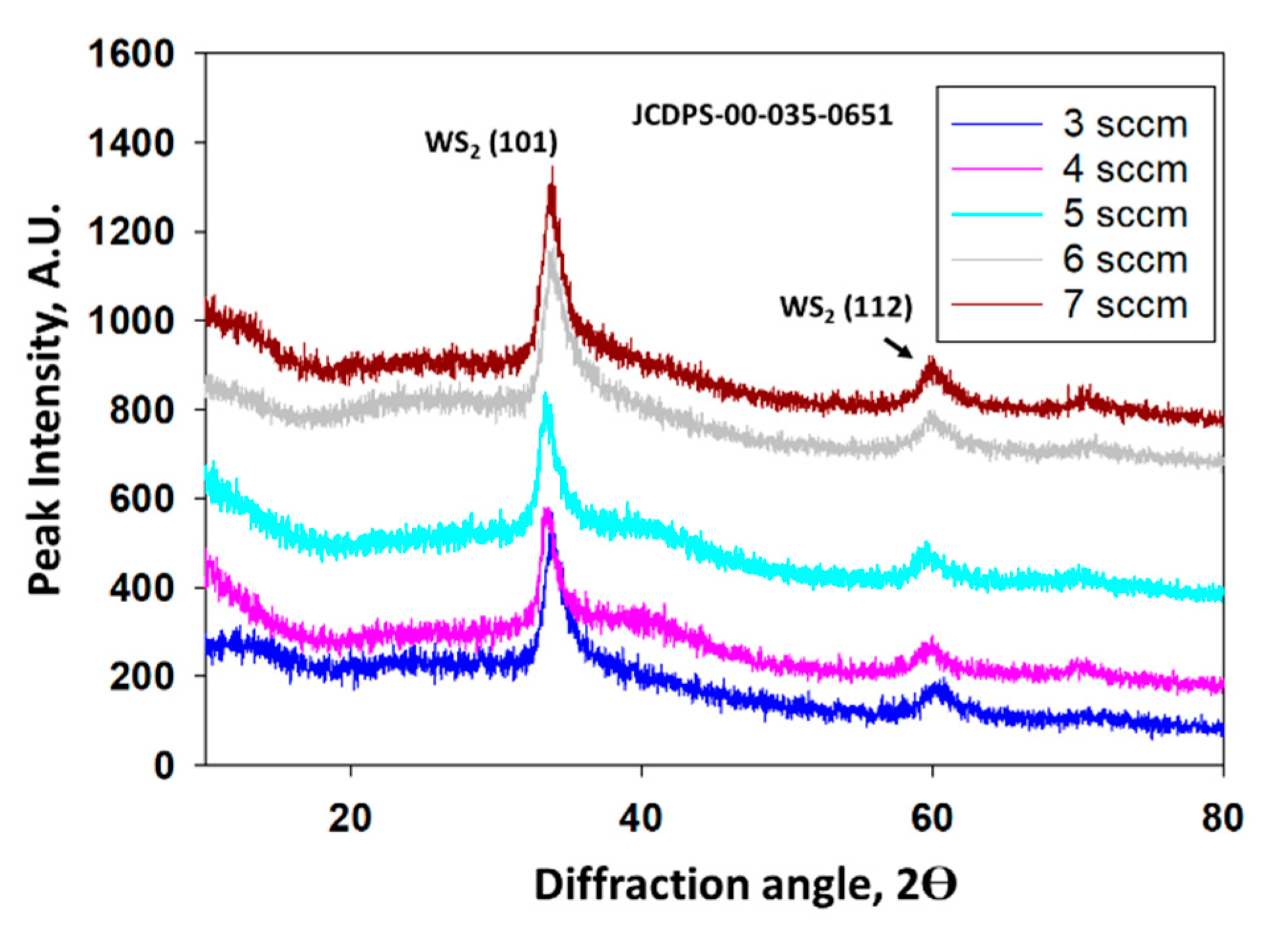

3.1. Structural Analysis from XRD

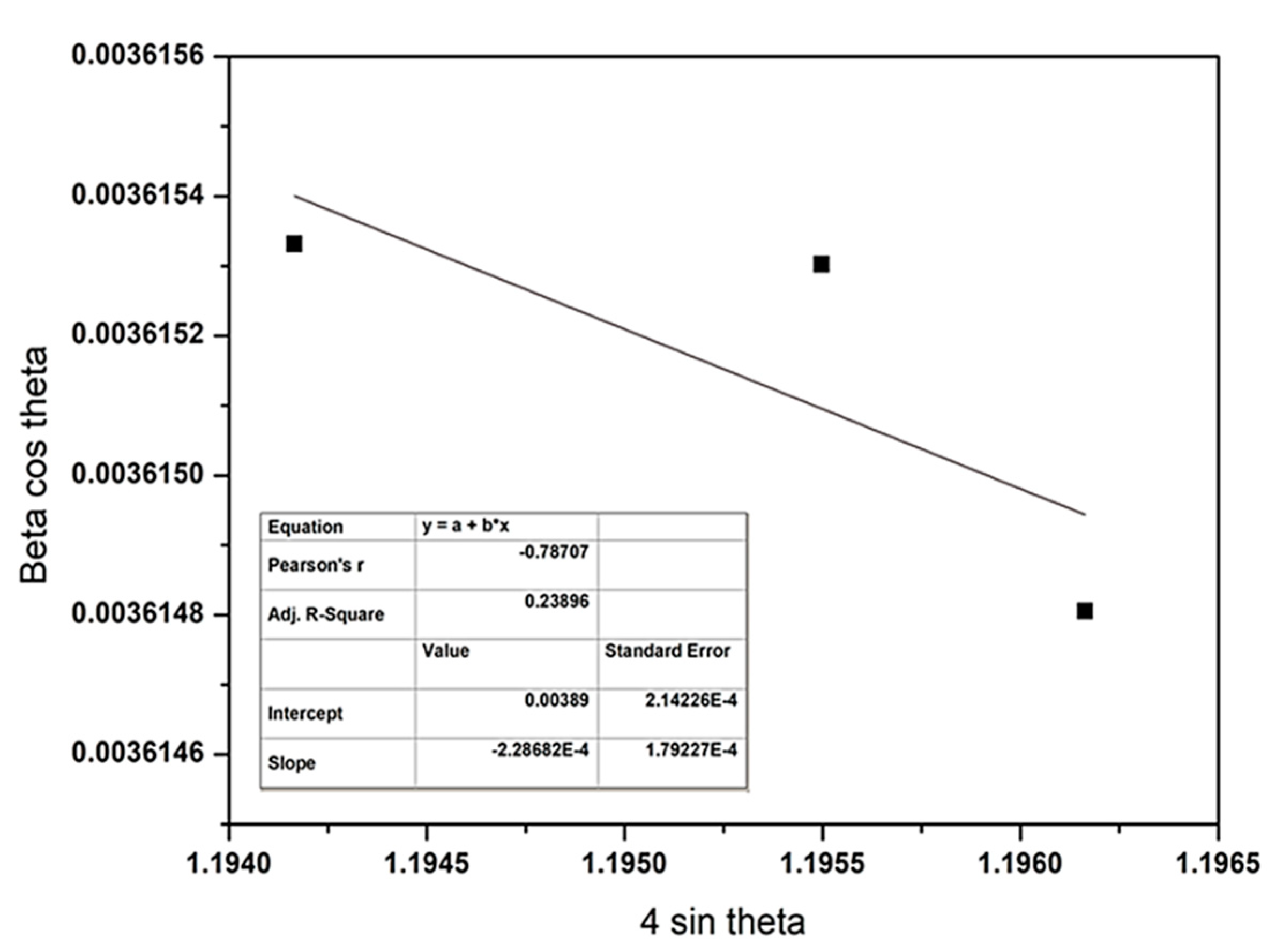

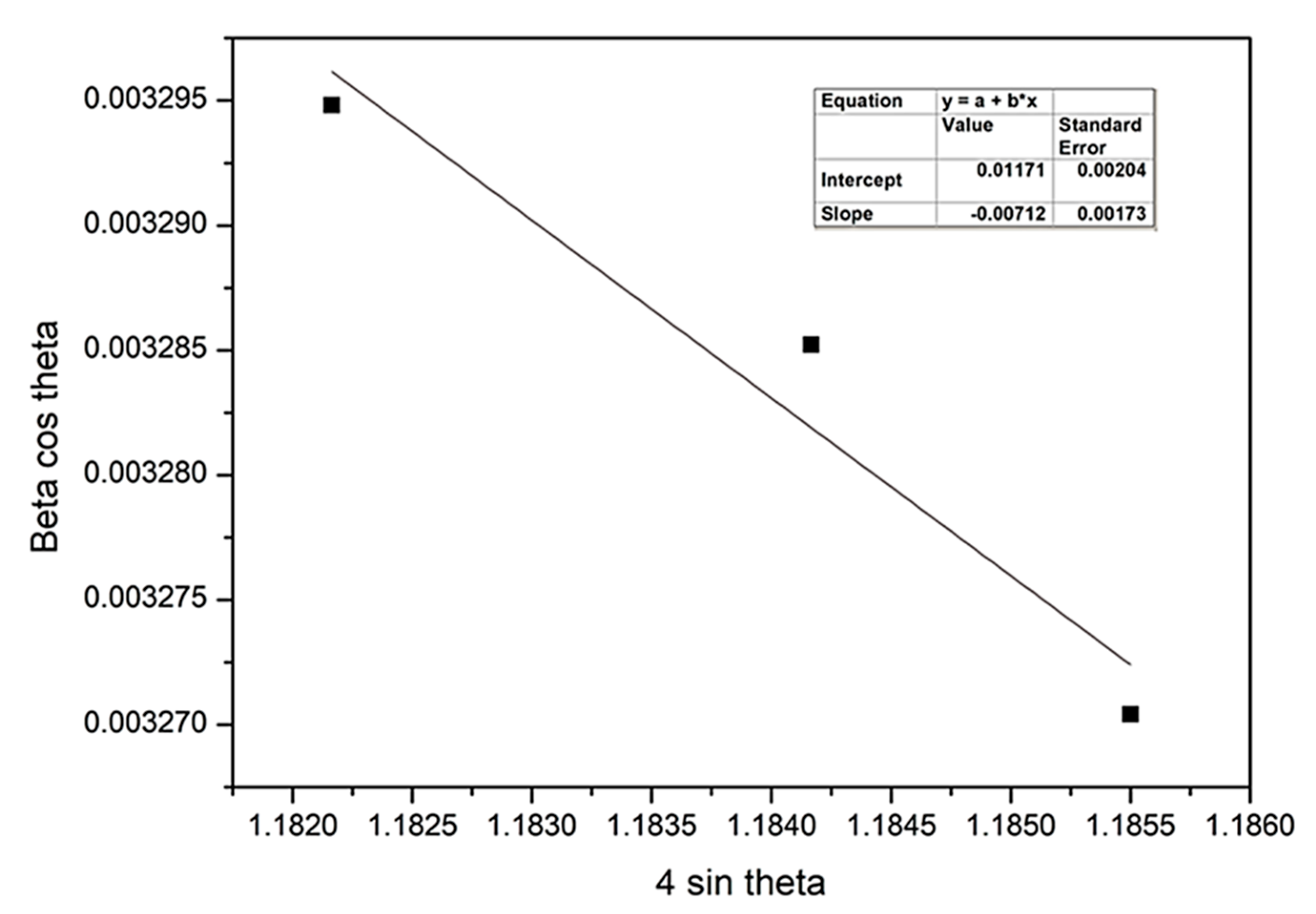

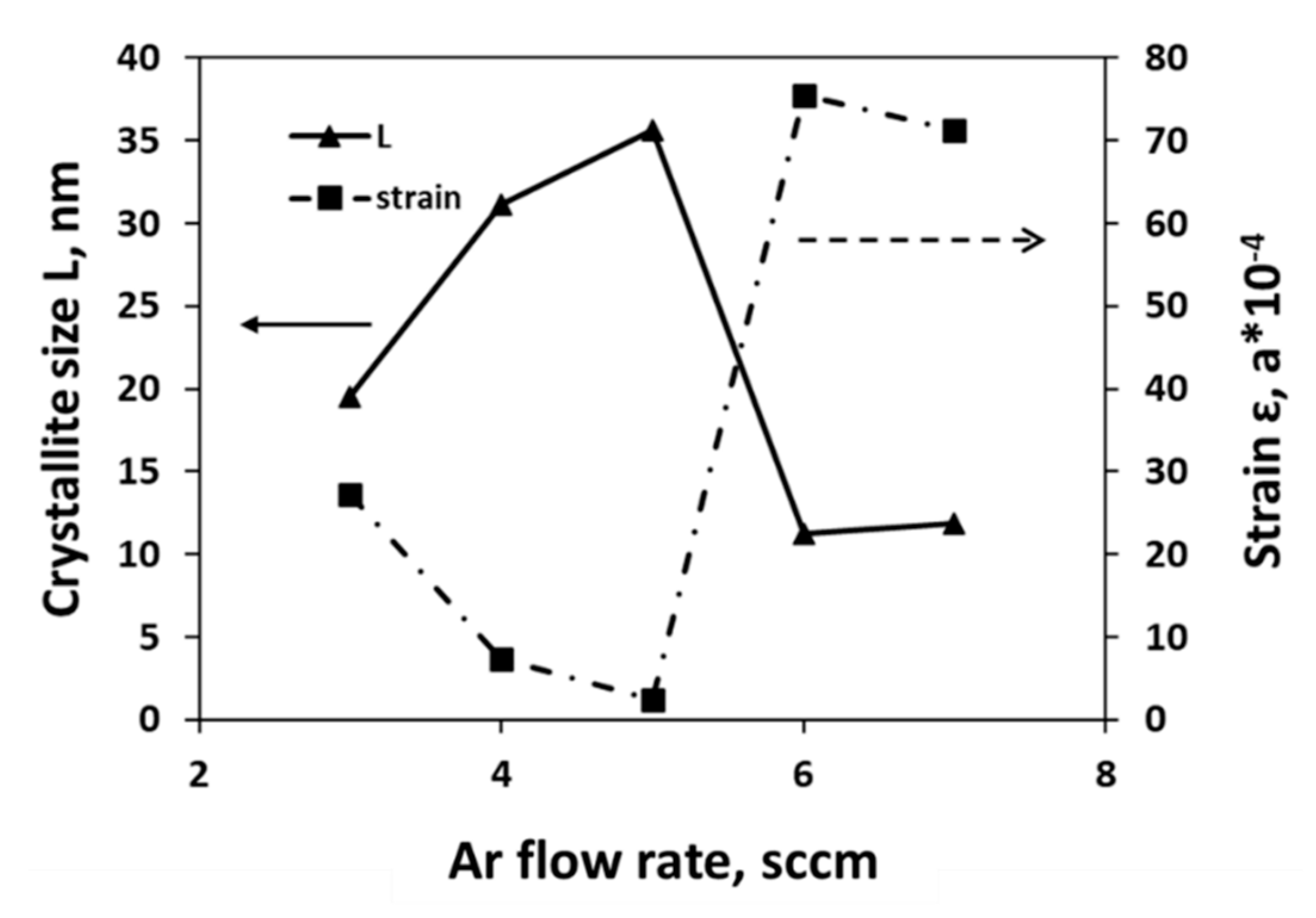

3.2. Williamson–Hall (W-H) Analysis

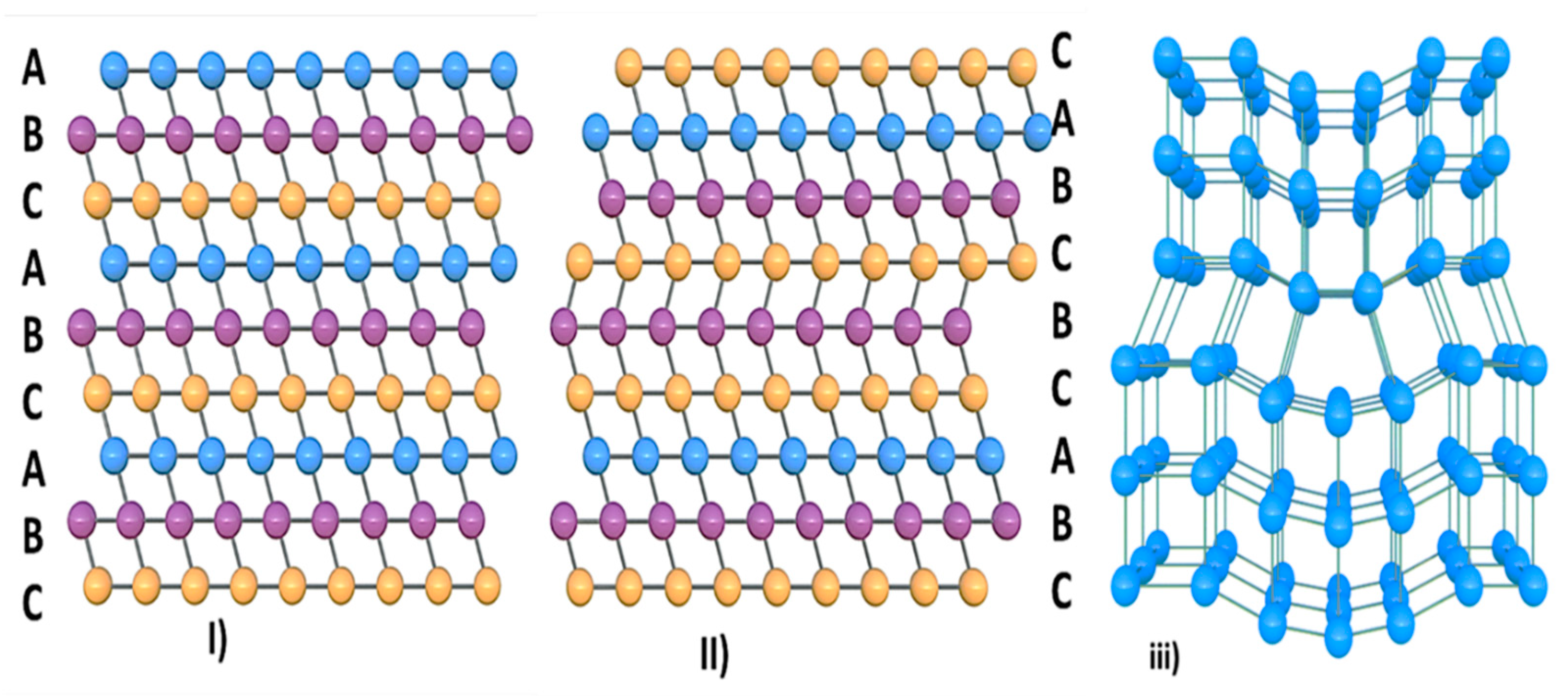

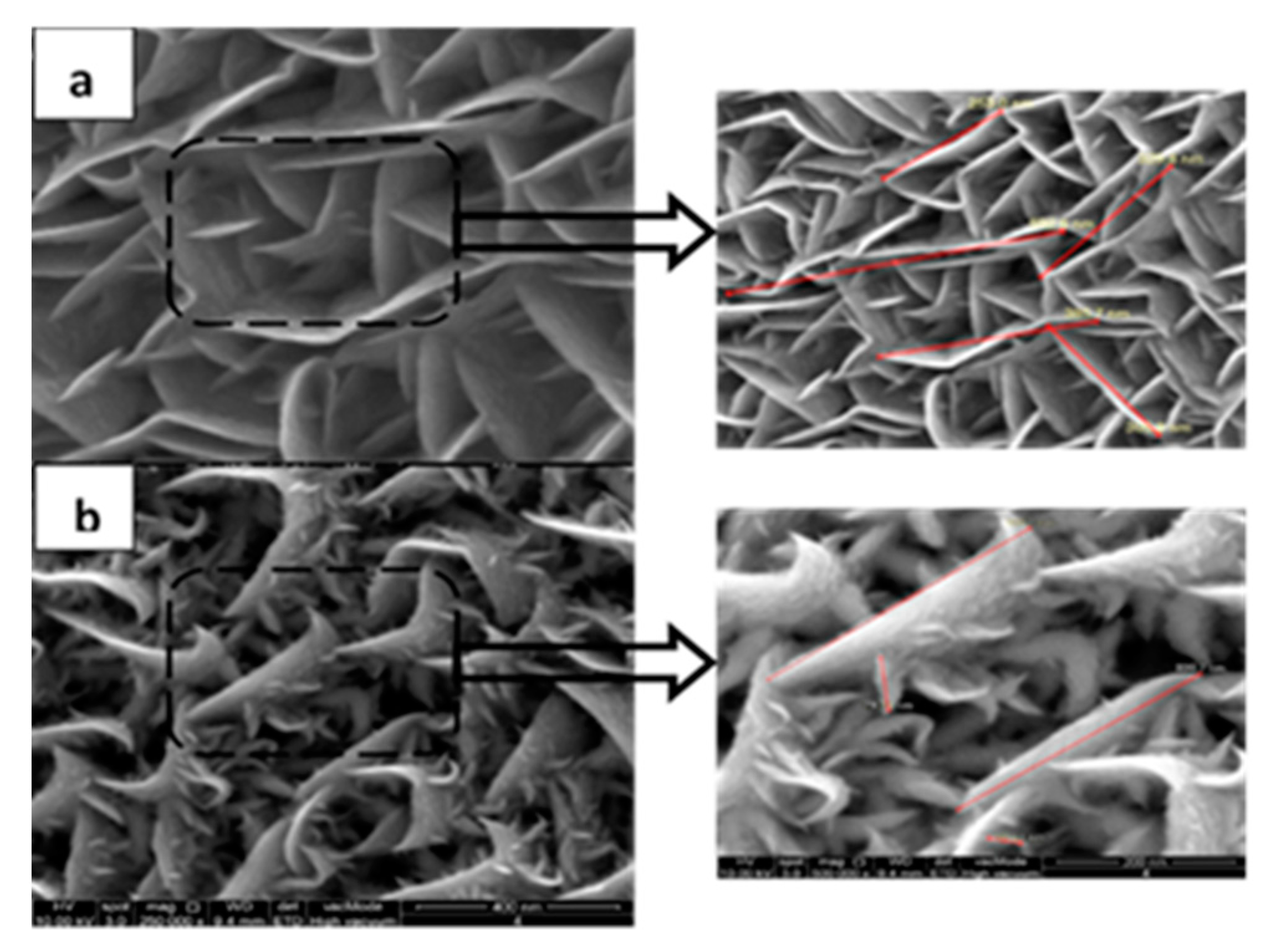

3.3. Study on Structural Deformation and Defects

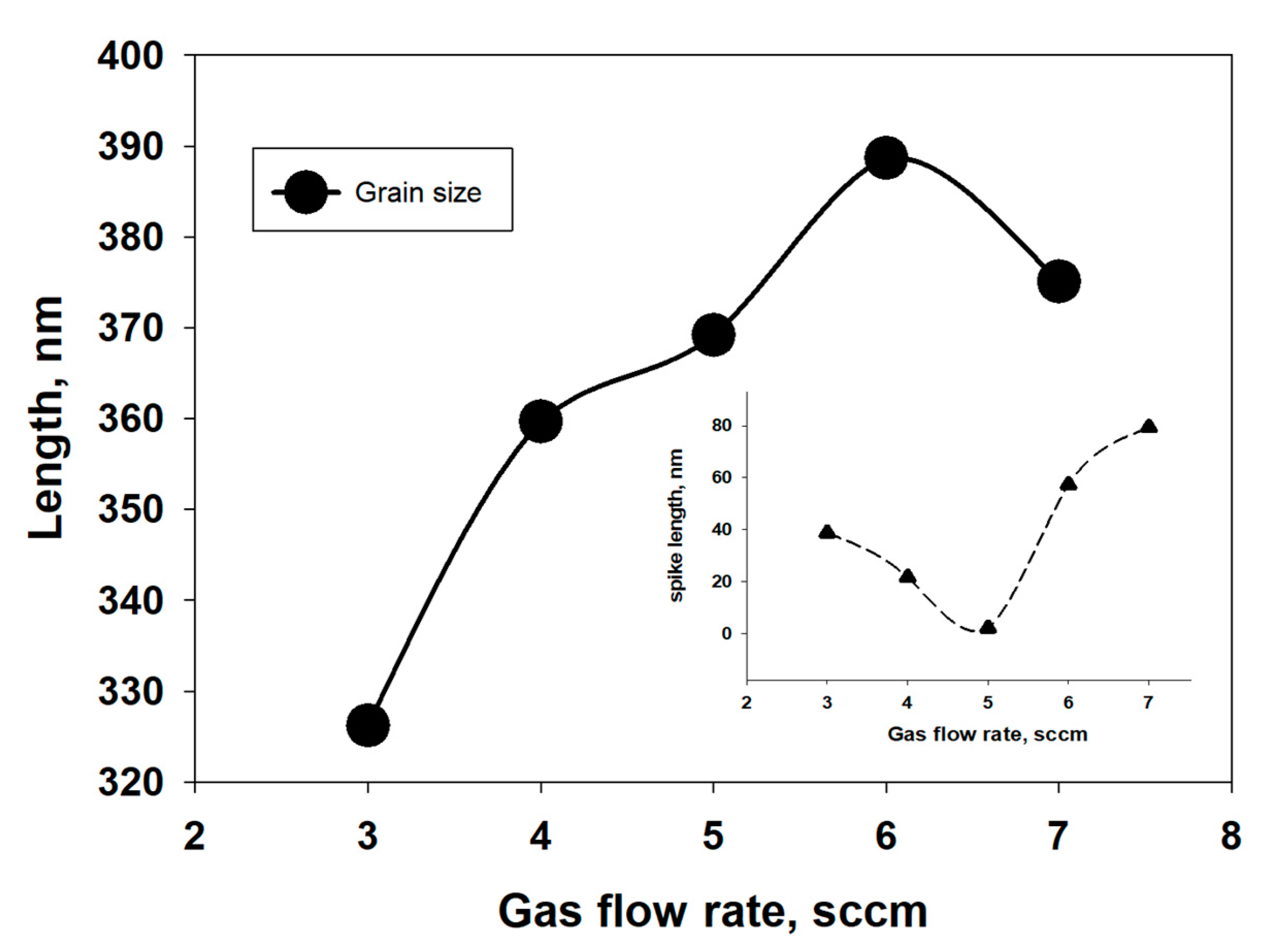

3.4. Morphological Analysis

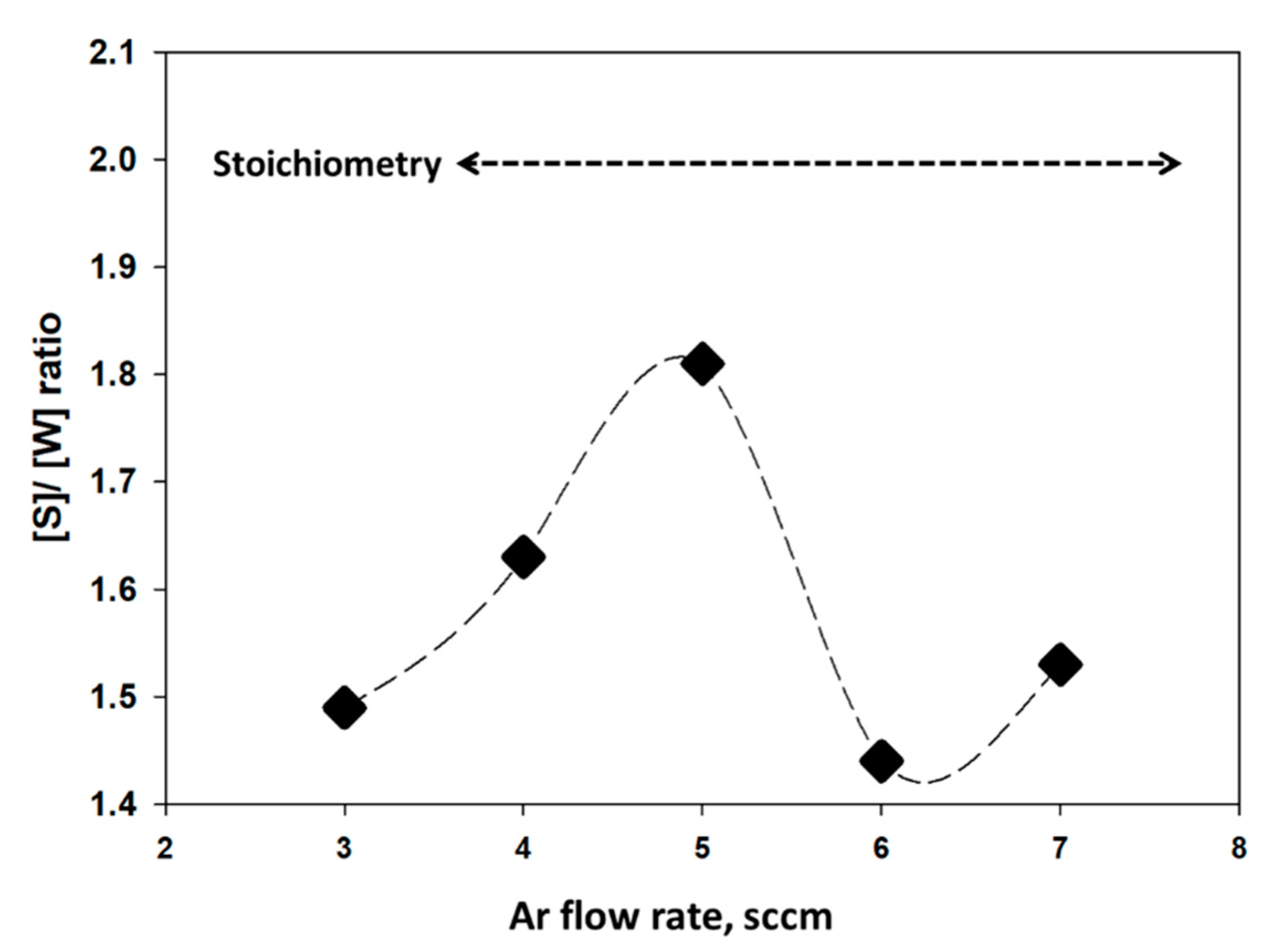

3.5. Compositional Analysis by EDX

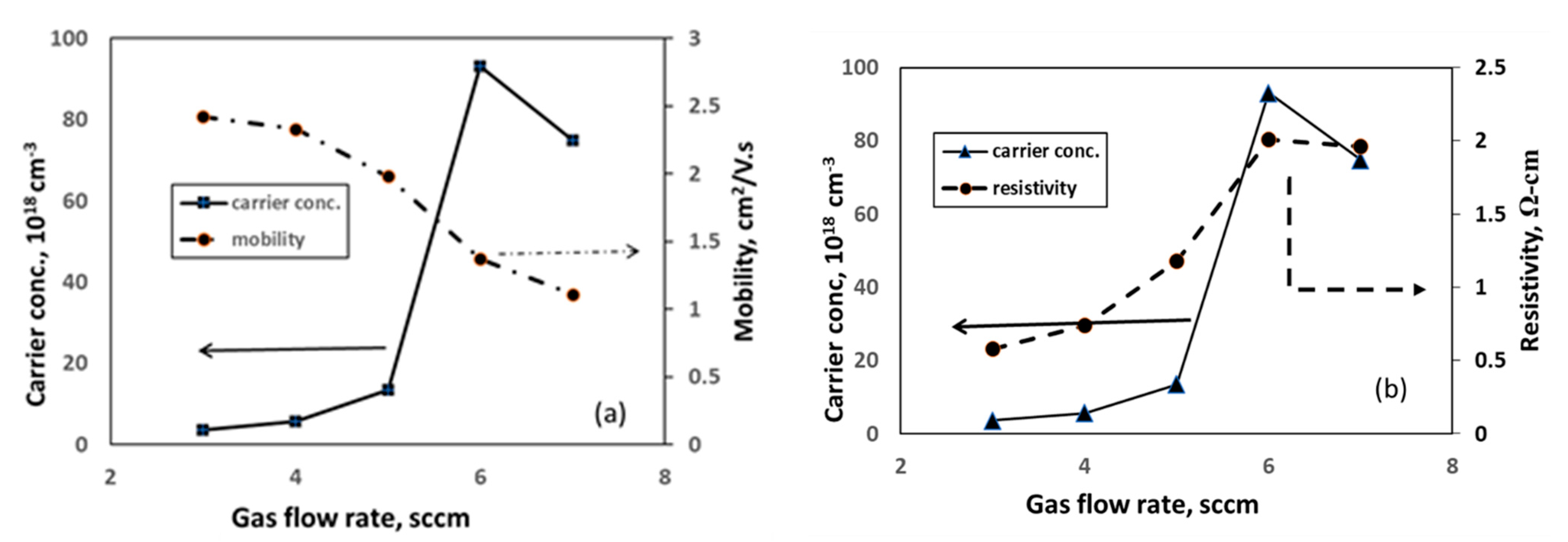

3.6. Electrical Analysis

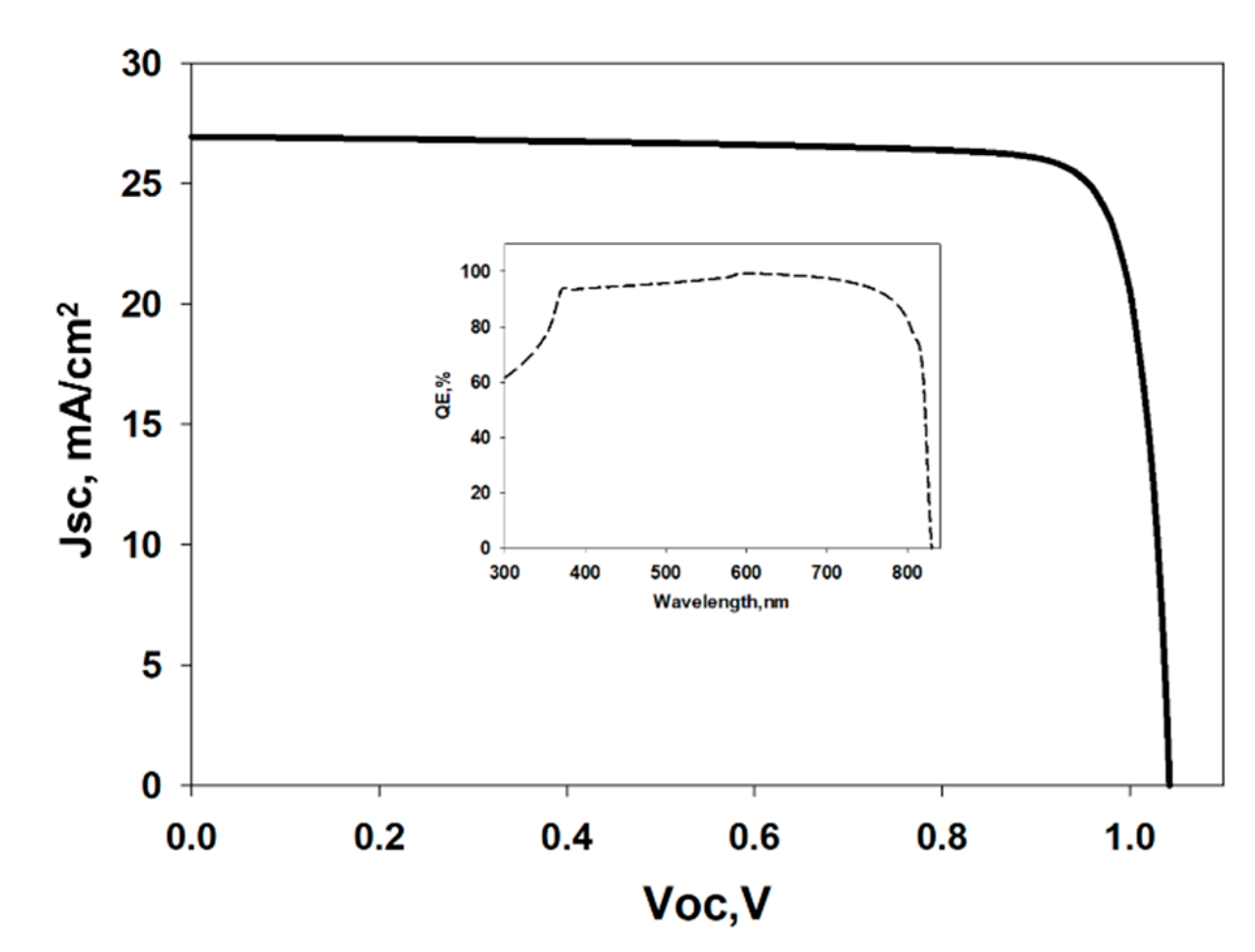

3.7. Evaluation of Solar Cell Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Ar Flow Rate, Sccm | Angle, θ | FWHM, β | Scherrer Method | W-H Method | Dislocation Density δ, 1015 lines/m2 | Crystallite Per Unit Area N, 1015 m−2 | |

|---|---|---|---|---|---|---|---|

| Crystallite Size L, nm | Crystallite Size L, nm | Strain ε, 10−4 | |||||

| 3 | 16.97 | 0.0233 | 35.3 | 19.5 | 27.3 | 26.29 | 20.46 |

| 4 | 17.14 | 0.0214 | 38.7 | 31.2 | 7.41 | 10.3 | 5.4 |

| 5 | 17.39 | 0.0217 | 44.8 | 35.6 | 2.36 | 0.78 | 3.74 |

| 6 | 17.44 | 0.0196 | 36.6 | 11.2 | 75.5 | 7.92 | 91.4 |

| 7 | 17.22 | 0.0196 | 42.6 | 11.8 | 71.2 | 7.13 | 64.5 |

| Ar Flow Rate, Sccm | Resistivity, Ω-cm | Mobility, cm2/V.s | Carrier Concentration, cm−3 |

|---|---|---|---|

| 3 | 0.58 | 2.42 | 3.58 × 1018 |

| 4 | 0.74 | 2.33 | 5.64 × 1018 |

| 5 | 1.18 | 1.98 | 5.05 × 1019 |

| 6 | 2.01 | 1.37 | 9.31 × 1019 |

| 7 | 1.96 | 1.11 | 7.48 × 1019 |

References

- Novoselov, K.; Jiang, D.; Schedin, F.; Booth, T.; Khotkevich, V.; Morozov, S.V.; Geim, A. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699. [Google Scholar] [CrossRef] [PubMed]

- Chowalla, M.; Shin, H.S.; Eda, G.; Li, L.J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.-Y.; Galli, G.; Wang, F. Emerging Photoluminescence in Monolayer MoS2. Nano Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marks, T.J.; Hersam, M.C. Emerging device applications for semiconducting two-dimensional transition metal dichalcogenides. ACS Nano 2014, 8, 1102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmidt, H.; Giustiniano, F.; Eda, G. Electronic transport properties of transition metal dichalcogenide field-effect devices: Surface and interface effects. Chem. Soc. Rev. 2015, 44, 7715–7736. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Yakobson, B.I. An open canvas-2D materials with defects, disorder, and functionality. Acc. Chem. Res. 2015, 48, 73. [Google Scholar] [CrossRef] [PubMed]

- Najmaei, S.; Yuan, J.; Zhang, J.; Ajayan, P.; Lou, J. Synthesis and Defect Investigation of Two-Dimensional Molybdenum Disulfide Atomic Layers. Acc. Chem. Res. 2014, 48, 31–40. [Google Scholar] [CrossRef]

- Zatko, V.; Galbiati, M.; Dubois, S.M.-M.; Och, M.; Palczynski, P.; Mattevi, C.; Brus, P.; Bezencenet, O.; Martin, M.-B.; Servet, B.; et al. Band-Structure Spin-Filtering in Vertical Spin Valves Based on Chemical Vapor Deposited WS2. ACS Nano 2019, 13, 14468–14476. [Google Scholar] [CrossRef] [Green Version]

- Dickinson, R.G.; Pauling, L. The crystal structure of molybdenite. J. Am. Chem. Soc. 1923, 45, 1466–1471. [Google Scholar] [CrossRef]

- Wyckoff, R.G.W. Crystal Structures; Interscience Publishers: New York, NY, USA, 1963; Volume 1. [Google Scholar]

- Starnberg, H.I.; Brauer, H.E.; Hughes, H.P. Electron Spectroscopies Applied to Low-Dimensional Materials; Springer: Berlin/Heidelberg, Germany, 2001; Volume 41. [Google Scholar]

- Tenne, R.; Margulis, L.; Genut, M.; Hodes, G. Polyhedral and cylindrical structures of tungsten disulphide. Nat. Cell Biol. 1992, 360, 444–446. [Google Scholar] [CrossRef]

- Lorchat, E.; Froehlicher, G.; Berciaud, S. Splitting of Interlayer Shear Modes and Photon Energy Dependent Anisotropic Raman Response in N-Layer ReSe2 and ReS2. ACS Nano 2016, 10, 2752–2760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashimoto, A.; Suenaga, K.; Gloter, A.; Urita, K.; Iijima, S. Direct evidence for atomic defects in graphene layers. Nat. Cell Biol. 2004, 430, 870–873. [Google Scholar] [CrossRef] [PubMed]

- Terrones, H.; Lv, R.; Terrones, M.; Dresselhaus, M.S. The role of defects and doping in 2D graphene sheets and 1D nanoribbons. Rep. Prog. Phys. 2012, 75, 062501. [Google Scholar] [CrossRef]

- Zhao, P. Understanding and Engineering Surface and Edge Defects of Transition Metal Dichalcogenides; Technical Report No. UCB/EECS-2018-157; EECS Department, University of California: Berkeley, CA, USA, 2018. [Google Scholar]

- Hanif, U.; Bernabé, M.; Luis, M.; Sánchez, R. Effect of defects on the performance of some photovoltaic solar cells: An introduction to research methods to engineering students. In Proceedings of the 44th SEFI Conference, Tampere, Finland, 12–15 September 2016. [Google Scholar]

- Rafiq, M.K.S.B.; Amin, N.; Alharbi, H.F.; Luqman, M.; Ayob, A.; Alharthi, Y.S.; Alharthi, N.H.; Bais, B.; Akhtaruzzaman, M. WS2: A New Window Layer Material for Solar Cell Application. Sci. Rep. 2020, 10, 771. [Google Scholar] [CrossRef] [PubMed]

- Al-Mansoori, M.; Al-Shaibani, S.; Al-Jaeedi, A.; Lee, J.; Choi, D.; Hasoon, F.S. Effects of gas flow rate on the structure and elemental composition of tin oxide thin films deposited by RF sputtering. AIP Adv. 2017, 7, 125105. [Google Scholar] [CrossRef]

- Vijaya, G.; Muralidhar, S.M.; Krupashankara, M.S.; Kulkarni, R.S. Effect of Argon Gas Flow Rate on the Optical and Mechanical Properties of Sputtered Tungsten Thin Film Coatings. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012075. [Google Scholar] [CrossRef] [Green Version]

- Rafiq, M.K.S.B.; Ayoba, A.; Baisa, B.; Akhtaruzzamanb, M.; Aminc, N. Investigating the Impact of Growth Temperature on WS2 Thin Film. J. Kejuruter. 2020, 3, 23–28. [Google Scholar]

- Ahmadipour, M.; Arjmand, M.; Ain, M.F.; Ahmad, Z.A.; Pung, S.-Y. Effect of Ar:N2 flow rate on morphology, optical and electrical properties of CCTO thin films deposited by RF magnetron sputtering. Ceram. Int. 2019, 45, 15077–15081. [Google Scholar] [CrossRef]

- Kumar, M.; Mishra, S.; Mitra, R. Effect of Ar:N2 ratio on structure and properties of Ni-TiN nanocomposite thin films pro-cessed by reactive RF/DC magnetron sputtering. Surf. Coat. Technol. 2013, 228, 100–114. [Google Scholar] [CrossRef]

- Sundberg, J.; Lindblad, R.; Gorgoi, M.; Rensmo, H.; Jansson, U.; Lindblad, A. Understanding the effects of sputter damage in W–S thin films by HAXPES. Appl. Surf. Sci. 2014, 305, 2014. [Google Scholar] [CrossRef] [Green Version]

- Tian, H.; Feng, L.P.; Liu, Z.T. Effect of N2/Ar flow ratio on the structural and electrical properties of SrHfON thin films pre-pared by magnetron sputtering. Vacuum 2014, 109, 139–143. [Google Scholar] [CrossRef]

- Vijayakumar, A.; Todi, R.M.; Sundaram, K.B. Effect of N2/Ar Gas Mixture Composition on the Chemistry of SiCBN Thin Films Prepared by RF Reactive Sputtering. J. Electrochem. Soc. 2007, 154, H271–H274. [Google Scholar] [CrossRef]

- Jiang, P.-C.; Chen, J.S.; Lin, Y.K. Structural and electrical characteristics of W–N thin films prepared by reactive rf sputtering. J. Vac. Sci. Technol. A 2003, 21, 616–622. [Google Scholar] [CrossRef]

- Cheng, Y.; Zheng, Y.F. Effect of N2/Ar gas flow ratio on the deposition of TiN/Ti coatings on NiTi shape memory alloy by PIIID. Mater. Lett. 2006, 60, 2243–2247. [Google Scholar] [CrossRef]

- Wicher, B.; Chodun, R.; Nowakowska-Langier, K.; Trzcinski, M.; Skowroński, L.; Okrasa, S.; Minikayev, R.; Naparty, M.K.; Zdunek, K. Chemical and structural characterization of tungsten nitride (WNx) thin films synthesized via Gas Injection Mag-netron Sputtering technique. Vacuum 2019, 165, 266–273. [Google Scholar] [CrossRef]

- Nossa, A.; Cavaleiro, A. Chemical and physical characterization of C(N)-doped W–S sputtered films. J. Mater. Res. 2004, 19, 2356–2365. [Google Scholar] [CrossRef]

- Panich, N.; Wangyao, P.; Hannongbua, S.; Sricharoenchai, P.; Sun, Y. Effect of argon-nitrogen mixing gas during magnetron sputtering on titanium interlayer deposition with Tib2 coatings on high speed steel. Rev. Adv. Mater. Sci. 2007, 16, 80–85. [Google Scholar]

- Guruvenket, S.; Rao, G.M. Bias induced structural changes in tungsten nitride films deposited by unbalanced magnetron sputtering. Mater. Sci. Eng. B 2004, 106, 172–176. [Google Scholar] [CrossRef]

- Addonizio, M.L.; Castaldo, A.; Antonaia, A.; Gambale, E.; Iemmo, L. Influence of process parameters on properties of reactively sputtered tungsten nitride thin films. J. Vac. Sci. Technol. A 2012, 30, 31506. [Google Scholar] [CrossRef]

- Wilson, J.; Yoffe, A. The transition metal dichalcogenides discussion and interpretation of the observed optical, electrical and structural properties. Adv. Phys. 1969, 18, 193. [Google Scholar] [CrossRef]

- Lin, Z.; Carvalho, B.R.; Kahn, E.; Lv, R.; Rao, R.; Terrones, H.; Pimenta, M.A.; Terrones, M. Defect engineering of two-dimensional transition metal dichalcogenides. 2D Mater. 2016, 3, 022002. [Google Scholar] [CrossRef]

- Tsay, C.-Y.; Cheng, H.-C.; Tung, Y.-T.; Tuan, W.-H.; Lin, C.-K. Effect of Sn-doped on microstructural and optical properties of ZnO thin films deposited by sol–gel method. Thin Solid Film 2008, 517, 1032–1036. [Google Scholar] [CrossRef]

- Islam, M.A.; Hossain, M.; Aliyu, M.; Karim, M.; Razykov, T.; Sopian, K.; Amin, N. Effect of CdCl2 treatment on structural and electronic property of CdTe thin films deposited by magnetron sputtering. Thin Solid Film 2013, 546, 367–374. [Google Scholar] [CrossRef]

- Stokes, A.R.; Wilson, A.J.C. The diffraction of X rays by distorted crystal aggregates—I. Proc. Phys. Soc. 1944, 56, 174. [Google Scholar] [CrossRef]

- Balzar, D. X-Ray Diffraction Line Broadening: Modeling and Applications to High-Tc Superconductors. J. Res. Natl. Inst. Stand. Technol. 1993, 98, 321–353. [Google Scholar] [CrossRef] [PubMed]

- Pijush, C.D.; Sarkar, S.; Das, R. X-ray diffraction study of the elastic properties of jagged spherical CdS nano-crystals. Mater. Sci. Pol. 2020, 38, 271–278. [Google Scholar]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef]

- Beyerlein, K.R.; Snyder, R.L.; Li, M.; Scardi, P. Application of the Debye function to systems of crystallites. Philos. Mag. 2010, 3891–3905. [Google Scholar] [CrossRef]

- Kariper, İ.A. Structural, optical and porosity properties of CdI2 thin film. J. Mater. Res. Technol. 2016, 5, 77–83. [Google Scholar] [CrossRef] [Green Version]

- Rawat, R.S.; Arun, P.; Vedeshwar, A.G.; Lee, P.; Lee, S. Effect of energetic ion irradiation on CdI2 films. J. Appl. Phys. 2004, 95, 7725–7730. [Google Scholar] [CrossRef] [Green Version]

- Kariper, İ.A. Synthesis and characterization of cerium sulfide thin film. Prog. Nat. Sci. 2014, 24, 663–670. [Google Scholar] [CrossRef] [Green Version]

- Munna, F.; Chelvanathan, P.; Sobayel, K.; Nurhafiza, K.; Sarkar, D.; Nour, M.; Sindi, H.; Rawa, M.; Sopian, K.; Amin, N.; et al. Effect of zinc doping on the optoelectronic properties of cadmium sulphide (CdS) thin films deposited by chemical bath deposition by utilising an alternative sulphur precursor. Optik 2020, 218, 165197. [Google Scholar] [CrossRef]

- Kastl, C.; Koch, R.J.; Chen, C.T.; Eichhorn, J.; Ulstrup, S.; Bostwick, A.; Jozwiak, C.; Kuykendall, T.R.; Borys, N.J.; Toma, F.M.; et al. Effects of Defects on Band Structure and Excitons in WS2 Revealed by Nanoscale Photoemission Spectroscopy. ACS Nano 2019, 13, 1284–1291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Regula, M.; Ballif, C.; Moser, J.; Lévy, F. Structural, chemical, and electrical characterisation of reactively sputtered WSx thin films. Thin Solid Film 1996, 280, 67–75. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, K.S.; Sobayel, K.; Enam, T.; Ali, A.M.; Zaman, M.; Akhtaruzzaman, M.; Amin, N. Fabrication of high efficiency sputtered CdS: O/CdTe thin film solar cells from window/absorber layer growth optimization in magnetron sputtering. Sol. Energy Mater. 2017, 172, 384–393. [Google Scholar] [CrossRef]

- Moser, J.; Lévy, F. Random stacking in MoS2−x sputtered thin films. Thin Solid Film 1994, 240, 56–59. [Google Scholar] [CrossRef]

- Tseng, K.-S.; Lo, Y.-L. Effect of sputtering parameters on optical and electrical properties of ITO films on PET substrates. Appl. Surf. Sci. 2013, 285, 157–166. [Google Scholar] [CrossRef]

- Jung, Y.S. Spectroscopic ellipsometry studies on the optical constants of indium tin oxide films deposited under various sputtering conditions. Thin Solid Film 2004, 467, 36–42. [Google Scholar] [CrossRef]

- Liu, Z.; Suenaga, K.; Wang, Z.; Shi, Z.; Okunishi, E.; Iijima, S. Identification of active atomic defects in a monolayered tungsten disulphide nanoribbon. Nat. Commun. 2011, 2, 213. [Google Scholar] [CrossRef]

- Komsa, H.-P.; Kurasch, S.; Lehtinen, O.; Kaiser, U.; Krasheninnikov, A.V. From point to extended defects in two-dimensional MoS2: Evolution of atomic structure under electron irradiation. Phys. Rev. B 2013, 88, 035301. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Hu, T.; Li, R.; Zhou, J.; Dong, J. Stabilities and electronic properties of monolayer MoS2 with one or two sulfur line vacancy defects. Phys. Chem. Chem. Phys. 2014, 17, 3813–3819. [Google Scholar] [CrossRef] [PubMed]

- Rogozin, A.I.; Vinnichenko, M.V.; Kolitsch, A.; Moller, W. Effect of deposition parameters on properties of ITO films prepared by reactive middle frequency pulsed dual magnetron sputtering. J. Vac. Sci. Technol. 2004, 22, 349–355. [Google Scholar] [CrossRef]

- Shin, D.-H.; Kim, Y.-H.; Han, J.-W.; Moon, K.-M.; Murakami, R.-I. Effect of process parameters on electrical, optical properties of IZO films produced by inclination opposite target type DC magnetron sputtering. Trans. Nonferrous Met. Soc. China 2009, 19, 997–1000. [Google Scholar] [CrossRef]

- Dominguez, J.E.; Fu, L.; Pan, X.Q. Effect of crystal defects on the electrical properties in epitaxial tin dioxide thin films. Appl. Phys. Lett. 2002, 81, 5168–5170. [Google Scholar] [CrossRef]

- Cheng, L.-C.; Wu, M.-R.; Huang, C.-Y.; Juang, T.-K.; Liu, P.-L.; Horng, R.H. Effect of Defects on the Properties of ZnGa2O4 Thin-Film Transistors. ACS Appl. Electron. Mater. 2019, 1, 253–259. [Google Scholar] [CrossRef]

- Scharpf, J.; Denisenko, A.; Pietzka, C.; Kohn, E. Effect of surface defects by RF oxygen plasma on the electrical properties of thin boron-doped diamond layers in electrolyte. Diam. Relat. Mater. 2011, 20, 1250–1254. [Google Scholar] [CrossRef]

| Parameters | WS2 Fabrication Process |

|---|---|

| Preheat temperature Preheat time Growth temperature | 100 °C 15 min 100 °C |

| RF power Ar gas flow | 50 W 3, 4, 5, 6, 7 sccm |

| Base pressure | 10−6 Torr |

| Operating pressure | 1.3~1.8 Pa |

| Deposition time | 30 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhtaruzzaman, M.; Shahiduzzaman, M.; Amin, N.; Muhammad, G.; Islam, M.A.; Rafiq, K.S.B.; Sopian, K. Impact of Ar Flow Rates on Micro-Structural Properties of WS2 Thin Film by RF Magnetron Sputtering. Nanomaterials 2021, 11, 1635. https://doi.org/10.3390/nano11071635

Akhtaruzzaman M, Shahiduzzaman M, Amin N, Muhammad G, Islam MA, Rafiq KSB, Sopian K. Impact of Ar Flow Rates on Micro-Structural Properties of WS2 Thin Film by RF Magnetron Sputtering. Nanomaterials. 2021; 11(7):1635. https://doi.org/10.3390/nano11071635

Chicago/Turabian StyleAkhtaruzzaman, Md., Md. Shahiduzzaman, Nowshad Amin, Ghulam Muhammad, Mohammad Aminul Islam, Khan Sobayel Bin Rafiq, and Kamaruzzaman Sopian. 2021. "Impact of Ar Flow Rates on Micro-Structural Properties of WS2 Thin Film by RF Magnetron Sputtering" Nanomaterials 11, no. 7: 1635. https://doi.org/10.3390/nano11071635

APA StyleAkhtaruzzaman, M., Shahiduzzaman, M., Amin, N., Muhammad, G., Islam, M. A., Rafiq, K. S. B., & Sopian, K. (2021). Impact of Ar Flow Rates on Micro-Structural Properties of WS2 Thin Film by RF Magnetron Sputtering. Nanomaterials, 11(7), 1635. https://doi.org/10.3390/nano11071635