Renewable Hydrocarbon Production from Waste Cottonseed Oil Pyrolysis and Catalytic Upgrading of Vapors with Mo-Co and Mo-Ni Catalysts Supported on γ-Al2O3

Abstract

:1. Introduction

2. Materials and Methods

2.1. Catalysts Preparation

2.2. Catalyst Characterization

2.3. Characterization of the Waste Cottonseed Oil

2.4. Non-Catalytic and Catalytic Off-Line Micropyrolysis

2.5. Product Gas Characterization

2.6. Bio-Oil Characterization

2.6.1. Gas Chromatography with Flame Ionization Detector

2.6.2. Gas Chromatography/Mass Spectrometry (GC/MS)

2.6.3. Electrospray-Fourier Transform-Mass Spectrometry (ESI-FT Orbitrap MS)

2.6.4. Acidity Index Determination

2.6.5. Elementary Analysis (CHN)

3. Results

3.1. Catalysts Characterization

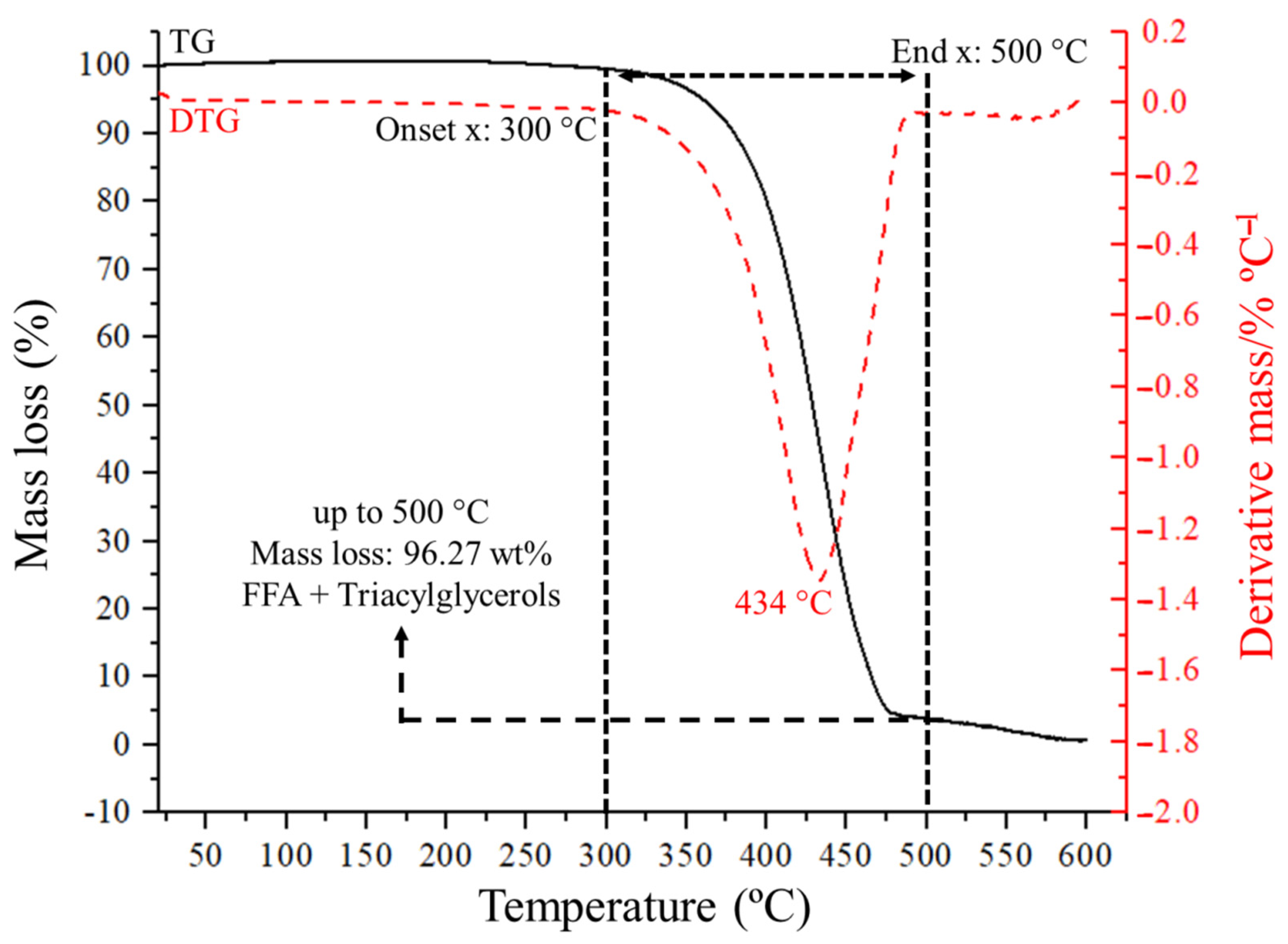

3.2. Characterization of the Waste Cottonseed Oil

3.3. Chemical Characterization of the Bio-Oils

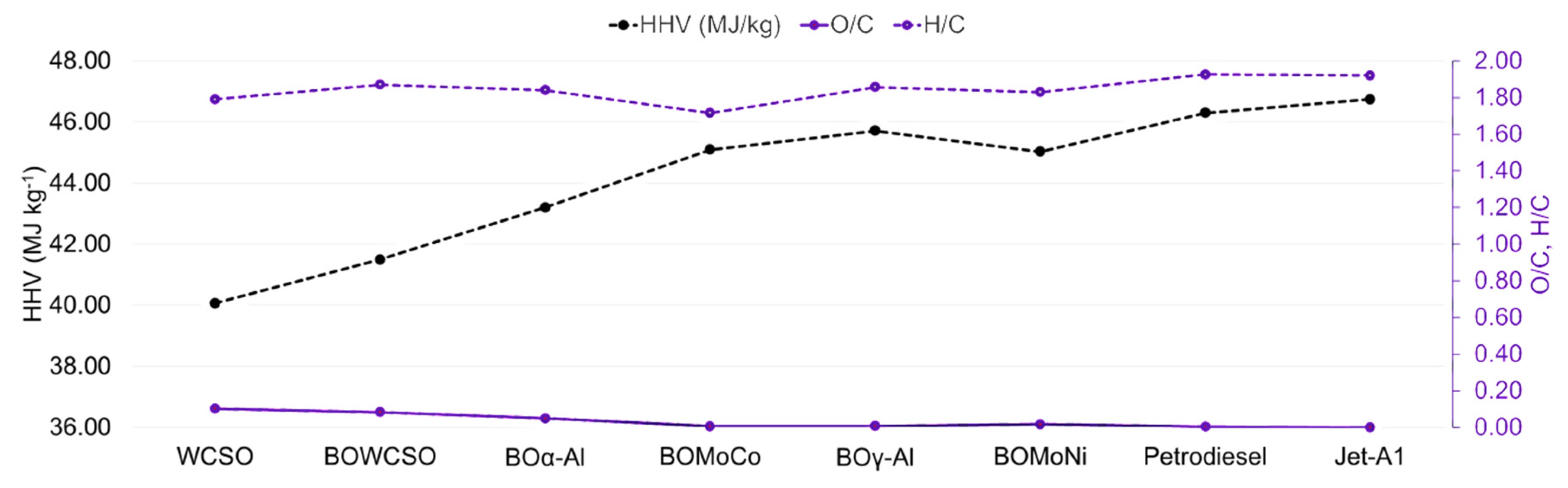

3.3.1. Elemental Analysis (CHN)

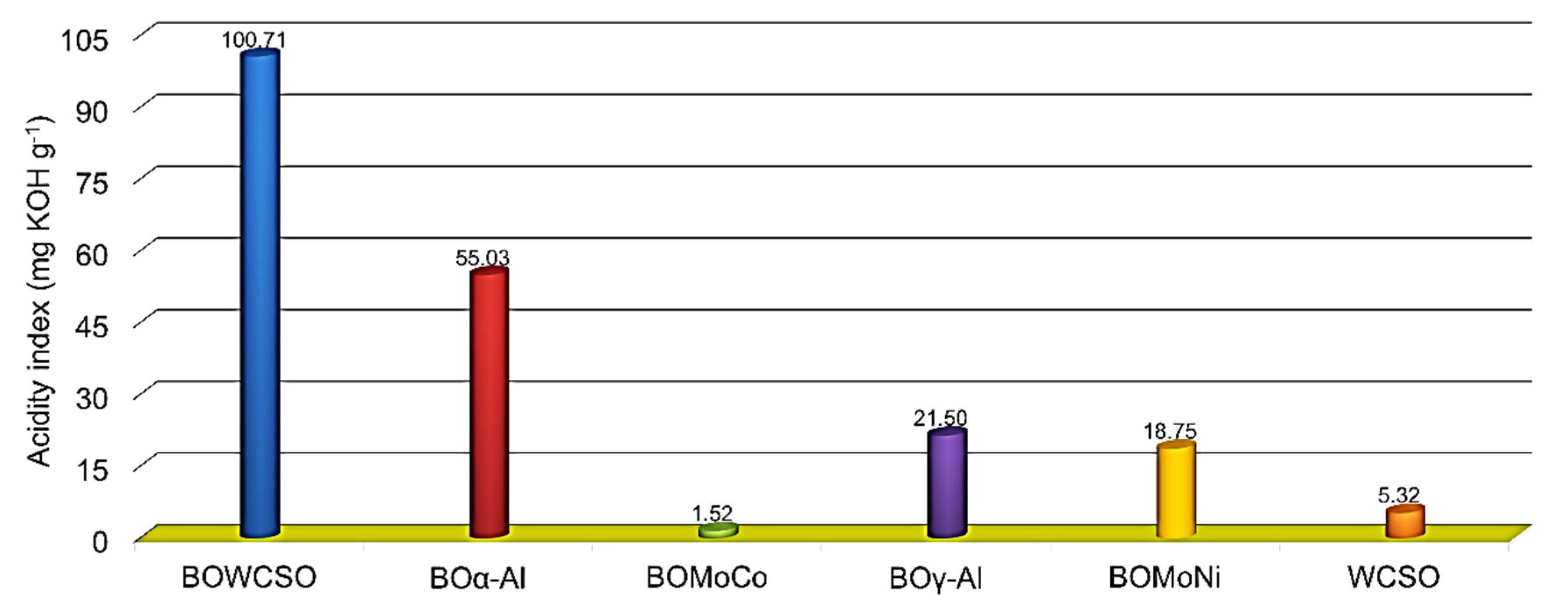

3.3.2. Acidity Index

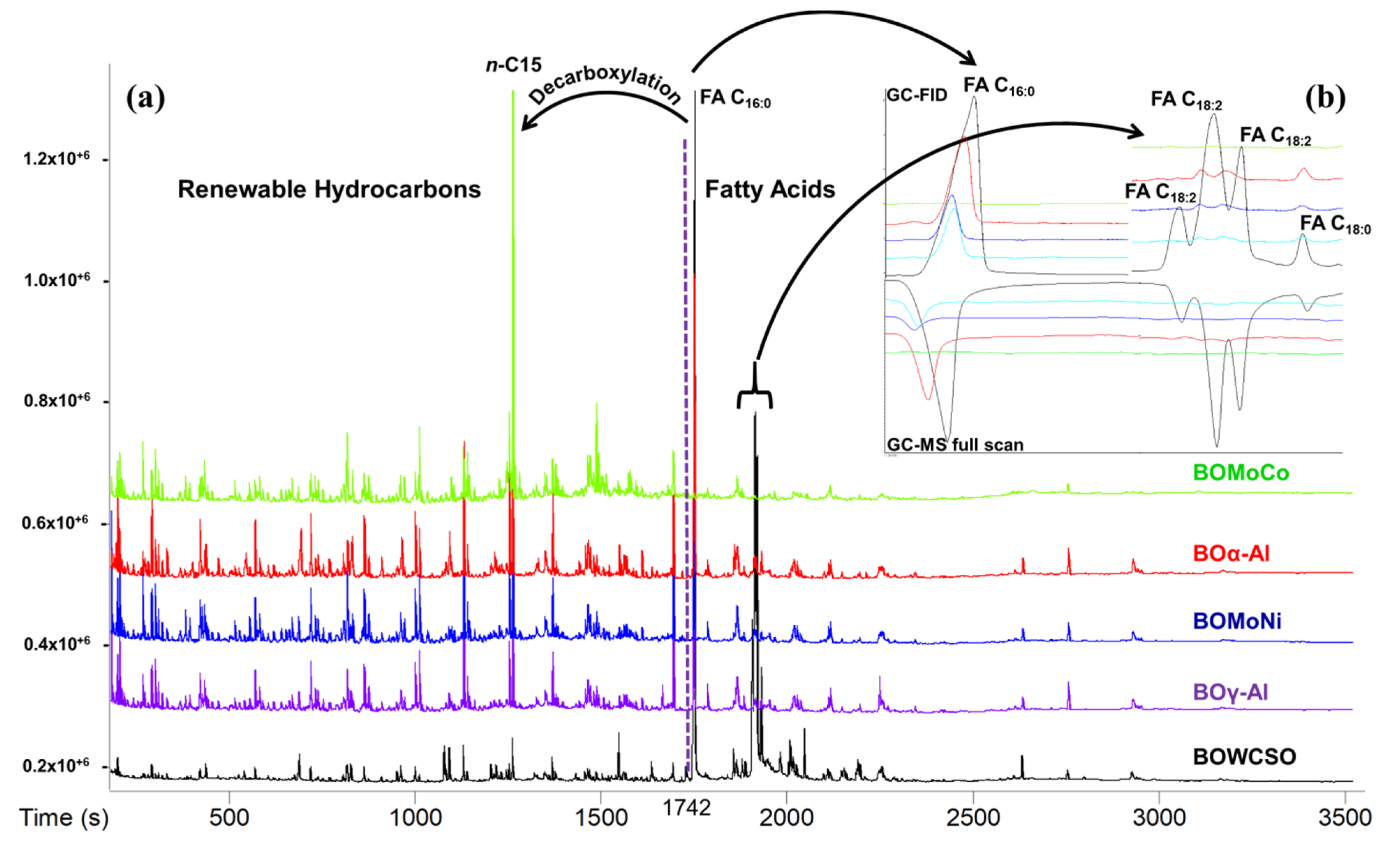

3.3.3. Gas Chromatography/Mass Spectrometry

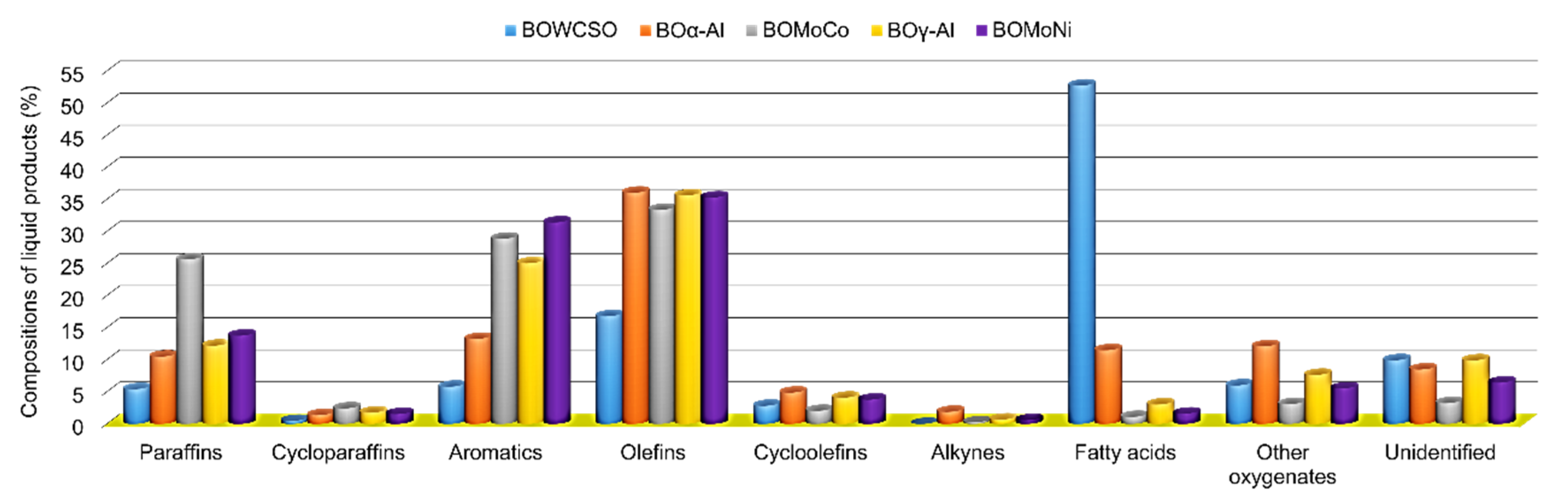

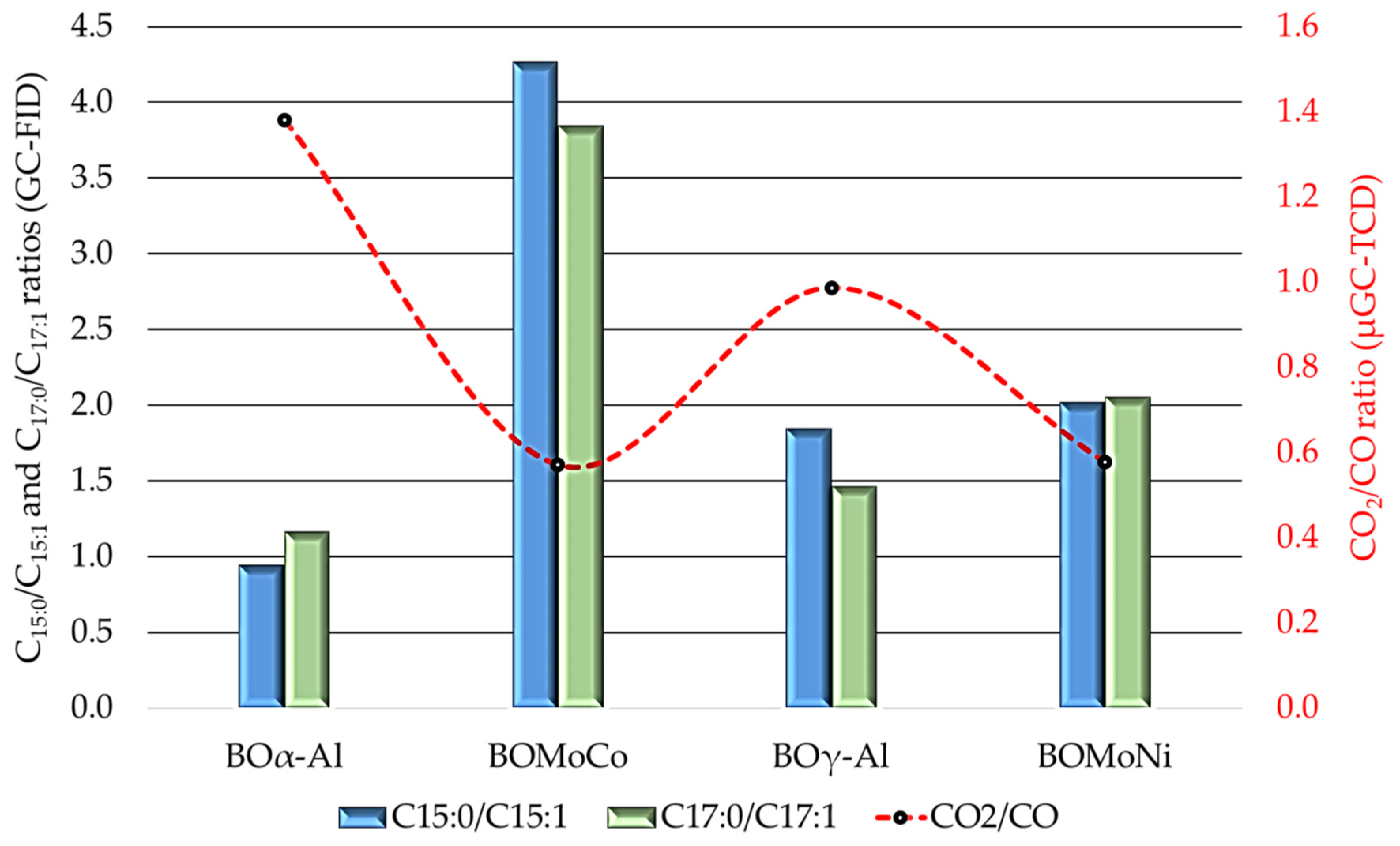

3.3.4. Gas Chromatography with Flame Ionization Detector

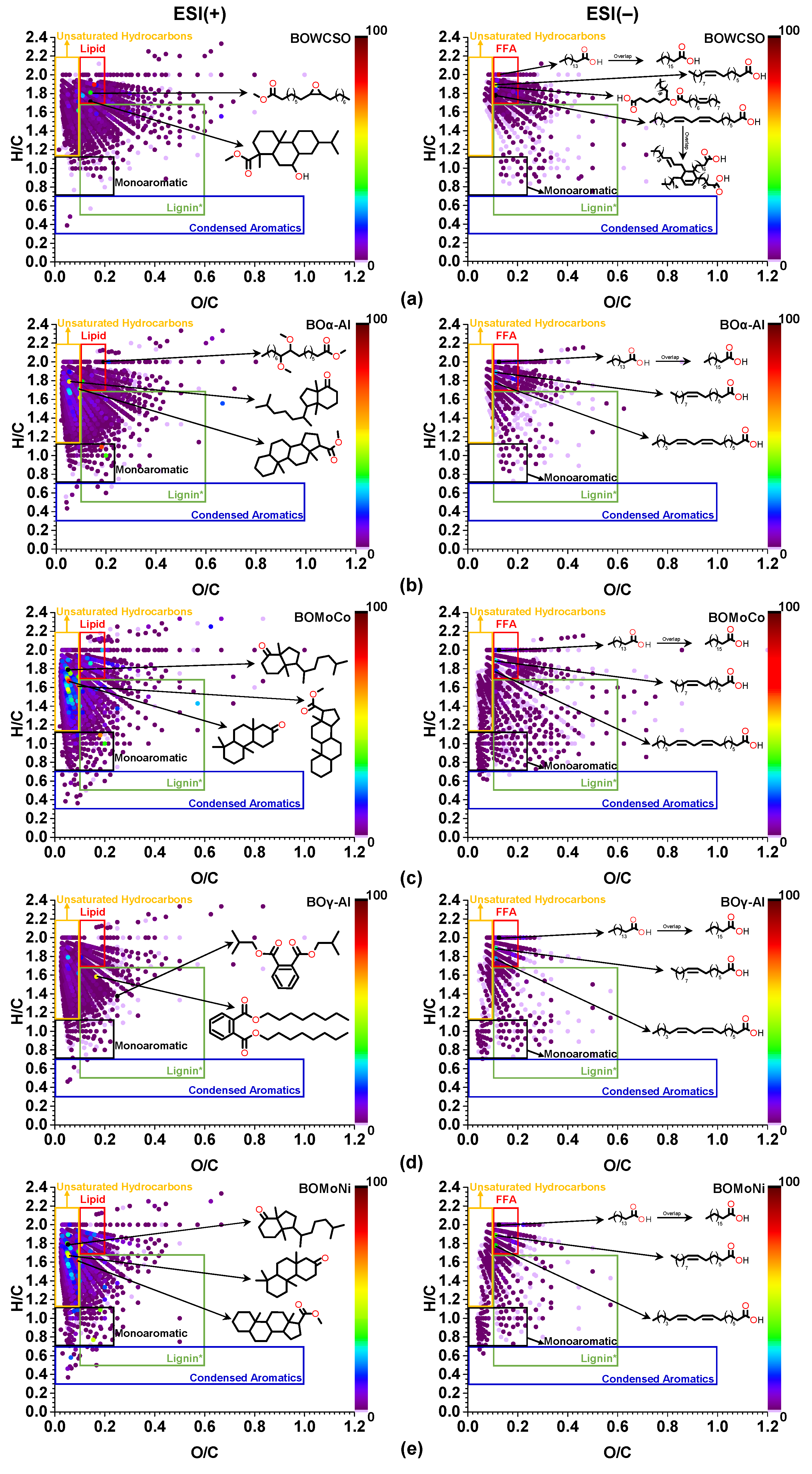

3.4. ESI(±)-FT Orbitrap MS Analysis

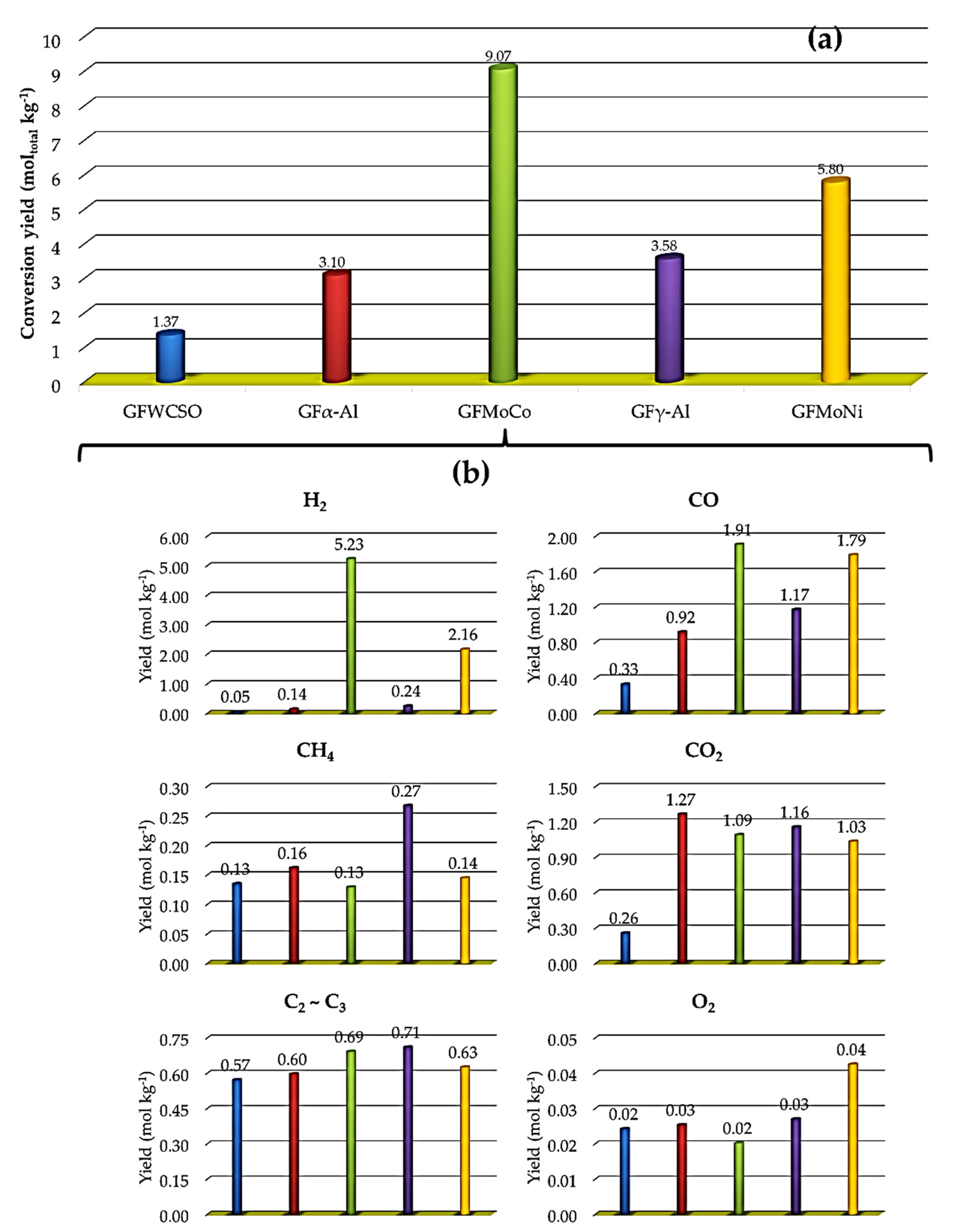

3.5. Chemical Characterization of Pyrolysis Gases

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Civil Aviation Organization (ICAO). Aviation Benefits 2017. Available online: https://www.icao.int/sustainability/Documents/AVIATION-BENEFITS-2017-web.pdf (accessed on 7 October 2020).

- Available online: https://blog.satair.com/2021-aviation-industry-outlook (accessed on 8 June 2021).

- Neuling, U.; Kaltschmitt, M. Conversion routes for production of biokerosene—Status and assessment. Biomass Convers. Biorefinery 2015, 5, 367–385. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Sustainable alternative fuels in aviation. Energy 2017, 140, 1378–1386. [Google Scholar] [CrossRef]

- Chuck, C.J.; Donnelly, J. The compatibility of potential bioderived fuels with Jet A-1 aviation kerosene. Appl. Energy 2014, 118, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Souza, T.G.d.S.; Santos, B.L.P.; Santos, A.M.A.; Souza, A.M.G.P.d.; Correia de Melo, J.; Wisniewski, A. Thermal and catalytic micropyrolysis for conversion of cottonseed oil dregs to produce biokerosene. J. Anal. Appl. Pyrolysis 2018, 129, 21–28. [Google Scholar] [CrossRef]

- Staples, M.D.; Malina, R.; Suresh, P.; Hileman, J.I.; Barrett, S.R.H. Aviation CO2 emissions reductions from the use of alternative jet fuels. Energy Policy 2018, 114, 342–354. [Google Scholar] [CrossRef]

- International Air Transport Association (IATA). Annual Review 2018. Available online: https://www.iata.org/contentassets/c81222d96c9a4e0bb4ff6ced0126f0bb/iata-annual-review-2018.pdf (accessed on 7 October 2020).

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.-H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in utilisation of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Ranucci, C.R.; Alves, H.J.; Monteiro, M.R.; Kugelmeier, C.L.; Bariccatti, R.A.; Rodrigues de Oliveira, C.; Antônio da Silva, E. Potential alternative aviation fuel from jatropha (Jatropha curcas L.), babassu (Orbignya phalerata) and palm kernel (Elaeis guineensis) as blends with Jet-A1 kerosene. J. Clean. Prod. 2018, 185, 860–869. [Google Scholar] [CrossRef]

- Neves, R.C.; Klein, B.C.; da Silva, R.J.; Rezende, M.C.A.F.; Funke, A.; Olivarez-Gómez, E.; Bonomi, A.; Maciel-Filho, R. A vision on biomass-to-liquids (BTL) thermochemical routes in integrated sugarcane biorefineries for biojet fuel production. Renew. Sustain. Energy Rev. 2020, 119, 109607. [Google Scholar] [CrossRef]

- Lee, K.; Lee, M.-E.; Kim, J.-K.; Shin, B.; Choi, M. Single-step hydroconversion of triglycerides into biojet fuel using CO-tolerant PtRe catalyst supported on USY. J. Catal. 2019, 379, 180–190. [Google Scholar] [CrossRef]

- Wang, W.-C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Xin, Z.; He, Q.; Corscadden, K.; Niu, H. An overview on performance characteristics of bio-jet fuels. Fuel 2019, 237, 916–936. [Google Scholar] [CrossRef]

- Prussi, M.; O’Connell, A.; Lonza, L. Analysis of current aviation biofuel technical production potential in EU28. Biomass Bioenergy 2019, 130, 105371. [Google Scholar] [CrossRef]

- Tomasek, S.; Varga, Z.; Hancsók, J. Production of jet fuel from cracked fractions of waste polypropylene and polyethylene. Fuel Process. Technol. 2020, 197, 106197. [Google Scholar] [CrossRef]

- Khan, S.; Kay Lup, A.N.; Qureshi, K.M.; Abnisa, F.; Wan Daud, W.M.A.; Patah, M.F.A. A review on deoxygenation of triglycerides for jet fuel range hydrocarbons. J. Anal. Appl. Pyrolysis 2019, 140, 1–24. [Google Scholar] [CrossRef]

- Kalogiannis, K.G.; Stefanidis, S.D.; Karakoulia, S.A.; Triantafyllidis, K.S.; Yiannoulakis, H.; Michailof, C.; Lappas, A.A. First pilot scale study of basic vs acidic catalysts in biomass pyrolysis: Deoxygenation mechanisms and catalyst deactivation. Appl. Catal. B Environ. 2018, 238, 346–357. [Google Scholar] [CrossRef]

- Sousa, F.P.; Silva, L.N.; de Rezende, D.B.; de Oliveira, L.C.A.; Pasa, V.M.D. Simultaneous deoxygenation, cracking and isomerization of palm kernel oil and palm olein over beta zeolite to produce biogasoline, green diesel and biojet-fuel. Fuel 2018, 223, 149–156. [Google Scholar] [CrossRef]

- Veriansyah, B.; Han, J.Y.; Kim, S.K.; Hong, S.-A.; Kim, Y.J.; Lim, J.S.; Shu, Y.-W.; Oh, S.-G.; Kim, J. Production of renewable diesel by hydroprocessing of soybean oil: Effect of catalysts. Fuel 2012, 94, 578–585. [Google Scholar] [CrossRef]

- Li, F.; Srivatsa, S.C.; Bhattacharya, S. A review on catalytic pyrolysis of microalgae to high-quality bio-oil with low oxygeneous and nitrogenous compounds. Renew. Sustain. Energy Rev. 2019, 108, 481–497. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A.; Meletidis, G. Effectiveness of CoMo and NiMo catalysts on co-hydroprocessing of heavy atmospheric gas oil–waste cooking oil mixtures. Fuel 2014, 125, 129–136. [Google Scholar] [CrossRef]

- Gautam, R.; Vinu, R. Non-catalytic fast pyrolysis and catalytic fast pyrolysis of Nannochloropsis oculata using Co-Mo/γ-Al2O3 catalyst for valuable chemicals. Algal Res. 2018, 34, 12–24. [Google Scholar] [CrossRef]

- Krobkrong, N.; Itthibenchapong, V.; Khongpracha, P.; Faungnawakij, K. Deoxygenation of oleic acid under an inert atmosphere using molybdenum oxide-based catalysts. Energy Convers. Manag. 2018, 167, 1–8. [Google Scholar] [CrossRef]

- Shim, J.-O.; Jeong, D.-W.; Jang, W.-J.; Jeon, K.-W.; Kim, S.-H.; Jeon, B.-H.; Roh, H.-S.; Na, J.-G.; Oh, Y.-K.; Han, S.S.; et al. Optimization of unsupported CoMo catalysts for decarboxylation of oleic acid. Catal. Commun. 2015, 67, 16–20. [Google Scholar] [CrossRef]

- Souza Macedo, L.; Oliveira, R.R.; van Haasterecht, T.; Teixeira da Silva, V.; Bitter, H. Influence of synthesis method on molybdenum carbide crystal structure and catalytic performance in stearic acid hydrodeoxygenation. Appl. Catal. B Environ. 2019, 241, 81–88. [Google Scholar] [CrossRef]

- Olcese, R.; Carré, V.; Aubriet, F.; Dufour, A. Selectivity of Bio-oils Catalytic Hydrotreatment Assessed by Petroleomic and GC*GC/MS-FID Analysis. Energy Fuels 2013, 27, 2135–2145. [Google Scholar] [CrossRef]

- Michailof, C.M.; Kalogiannis, K.G.; Sfetsas, T.; Patiaka, D.T.; Lappas, A.A. Advanced analytical techniques for bio-oil characterization. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 614–639. [Google Scholar] [CrossRef]

- Jiang, S.-F.; Sheng, G.-P.; Jiang, H. Advances in the Characterization Methods of Biomass Pyrolysis Products. ACS Sustainable Chem. Eng. 2019, 7, 12639–12655. [Google Scholar] [CrossRef]

- Staš, M.; Chudoba, J.; Kubička, D.; Blažek, J.; Pospíšil, M. Petroleomic Characterization of Pyrolysis Bio-oils: A Review. Energy Fuels 2017, 31, 10283–10299. [Google Scholar] [CrossRef]

- Staš, M.; Chudoba, J.; Auersvald, M.; Kubička, D.; Conrad, S.; Schulzke, T.; Pospíšil, M. Application of orbitrap mass spectrometry for analysis of model bio-oil compounds and fast pyrolysis bio-oils from different biomass sources. J. Anal. Appl. Pyrolysis 2017, 124, 230–238. [Google Scholar] [CrossRef]

- Nunes, V.O.; Silva, R.V.S.; Romeiro, G.A.; Azevedo, D.A. The speciation of the organic compounds of slow pyrolysis bio-oils from Brazilian tropical seed cake fruits using high-resolution techniques: GCxGC-TOFMS and ESI(±)-Orbitrap HRMS. Microchem. J. 2020, 153, 104514. [Google Scholar] [CrossRef]

- Santos, J.M.; dos Santos, L.O.; Silva, F.F.; Eberlin, M.N.; Wisniewski, A. Comprehensive Characterization of Second-Generation Biofuel from Invasive Freshwater Plants by FT-ICR MS. BioEnergy Res. 2015, 8, 1938–1945. [Google Scholar] [CrossRef]

- Xu, Z.-X.; Liu, P.; Xu, G.-S.; Liu, Q.; He, Z.-X.; Wang, Q. Bio-fuel oil characteristic from catalytic cracking of hydrogenated palm oil. Energy 2017, 133, 666–675. [Google Scholar] [CrossRef]

- Benés, M.; Bilbao, R.; Santos, J.M.; Alves Melo, J.; Wisniewski, A.; Fonts, I. Hydrodeoxygenation of Lignocellulosic Fast Pyrolysis Bio-Oil: Characterization of the Products and Effect of the Catalyst Loading Ratio. Energy Fuels 2019, 33, 4272–4286. [Google Scholar] [CrossRef]

- Kubátová, A.; Luo, Y.; Šťávová, J.; Sadrameli, S.M.; Aulich, T.; Kozliak, E.; Seames, W. New path in the thermal cracking of triacylglycerols (canola and soybean oil). Fuel 2011, 90, 2598–2608. [Google Scholar] [CrossRef]

- Li, L.; Coppola, E.; Rine, J.; Miller, J.L.; Walker, D. Catalytic Hydrothermal Conversion of Triglycerides to Non-ester Biofuels. Energy Fuels 2010, 24, 1305–1315. [Google Scholar] [CrossRef]

- Moreira, R.; Moral, A.; Bimbela, F.; Portugal, A.; Ferreira, A.; Sanchez, J.L.; Gandía, L.M. Syngas production via catalytic oxidative steam reforming of glycerol using a Co/Al coprecipitated catalyst and different bed fillers. Fuel Process. Technol. 2019, 189, 120–133. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Malet, P.; Caballero, A. The selection of experimental conditions in temperature-programmed reduction experiments. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1988, 84, 2369–2375. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). D1762-84—Chemical Analysis of Wood Charcoal; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- American Society for Testing and Materials (ASTM). D664—Total Acid Number (TAN); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Ranga, C.; Lødeng, R.; Alexiadis, V.I.; Rajkhowa, T.; Bjørkan, H.; Chytil, S.; Svenum, I.H.; Walmsley, J.; Detavernier, C.; Poelman, H.; et al. Effect of composition and preparation of supported MoO3 catalysts for anisole hydrodeoxygenation. Chem. Eng. J. 2018, 335, 120–132. [Google Scholar] [CrossRef]

- Al-Hammadi, S.A.; Al-Amer, A.M.; Saleh, T.A. Alumina-carbon nanofiber composite as a support for MoCo catalysts in hydrodesulfurization reactions. Chem. Eng. J. 2018, 345, 242–251. [Google Scholar] [CrossRef]

- Molina, R.; Poncelet, G. α-Alumina-Supported Nickel Catalysts Prepared from Nickel Acetylacetonate: A TPR Study. J. Catal. 1998, 173, 257–267. [Google Scholar] [CrossRef]

- Moral, A.; Reyero, I.; Llorca, J.; Bimbela, F.; Gandía, L.M. Partial oxidation of methane to syngas using Co/Mg and Co/Mg-Al oxide supported catalysts. Catal. Today 2019, 333, 259–267. [Google Scholar] [CrossRef]

- Wiggers, V.R.; Wisniewski, A.; Madureira, L.A.S.; Barros, A.A.C.; Meier, H.F. Biofuels from waste fish oil pyrolysis: Continuous production in a pilot plant. Fuel 2009, 88, 2135–2141. [Google Scholar] [CrossRef]

- Xu, J.; Long, F.; Jiang, J.; Li, F.; Zhai, Q.; Wang, F.; Liu, P.; Li, J. Integrated catalytic conversion of waste triglycerides to liquid hydrocarbons for aviation biofuels. J. Clean. Prod. 2019, 222, 784–792. [Google Scholar] [CrossRef]

- Hoffmann, J.F.; Vaitilingom, G.; Henry, J.F.; Chirtoc, M.; Olives, R.; Goetz, V.; Py, X. Temperature dependence of thermophysical and rheological properties of seven vegetable oils in view of their use as heat transfer fluids in concentrated solar plants. Sol. Energy Mater. Sol. Cells 2018, 178, 129–138. [Google Scholar] [CrossRef]

- Nogueira, R.L.; Soares, J.B.; Soares, S.d.A. Rheological evaluation of cotton seed oil fatty amides as a rejuvenating agent for RAP oxidized asphalts. Constr. Build. Mater. 2019, 223, 1145–1153. [Google Scholar] [CrossRef]

- Fassinou, W.F.; Steene, L.V.d.; Toure, S.; Martin, E. What correlation is appropriate to evaluate biodiesels and vegetable oils higher heating value (HHV)? Fuel 2011, 90, 3398–3403. [Google Scholar] [CrossRef]

- Fassinou, W.F. Higher heating value (HHV) of vegetable oils, fats and biodiesels evaluation based on their pure fatty acids’ HHV. Energy 2012, 45, 798–805. [Google Scholar] [CrossRef]

- Fassinou, W.F.; Sako, A.; Fofana, A.; Koua, K.B.; Toure, S. Fatty acids composition as a means to estimate the high heating value (HHV) of vegetable oils and biodiesel fuels. Energy 2010, 35, 4949–4954. [Google Scholar] [CrossRef]

- Ling, T.-R.; Chang, J.-S.; Chiou, Y.-J.; Chern, J.-M.; Chou, T.-C. Characterization of high acid value waste cottonseed oil by temperature programmed pyrolysis in a batch reactor. J. Anal. Appl. Pyrolysis 2016, 120, 222–230. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Serqueira, D.S.; Portela, F.M.; Assunção, R.M.N.; Munoz, R.A.A.; Terrones, M.G.H. Preparation and characterization of methylic and ethylic biodiesel from cottonseed oil and effect of tert-butylhydroquinone on its oxidative stability. Fuel 2012, 97, 658–661. [Google Scholar] [CrossRef] [Green Version]

- Yıldız, A.; Goldfarb, J.L.; Ceylan, S. Sustainable hydrocarbon fuels via “one-pot” catalytic deoxygenation of waste cooking oil using inexpensive, unsupported metal oxide catalysts. Fuel 2020, 263, 116750. [Google Scholar] [CrossRef]

- Daho, T.; Vaitilingom, G.; Sanogo, O. Optimization of the combustion of blends of domestic fuel oil and cottonseed oil in a non-modified domestic boiler. Fuel 2009, 88, 1261–1268. [Google Scholar] [CrossRef]

- Lloyd, W.G.; Davenport, D.A. Applying Thermodynamics to Fossil Fuels Heats of combustion from elemental compositions. J. Chem. Educ. 1980, 57, 56–60. [Google Scholar] [CrossRef]

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A review on novel processes of biodiesel production from waste cooking oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Shirazi, Y.; Viamajala, S.; Varanasi, S. High-yield production of fuel- and oleochemical-precursors from triacylglycerols in a novel continuous-flow pyrolysis reactor. Appl. Energy 2016, 179, 755–764. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Li, L.; Yu, S.; Liu, S.; Yu, H.; Wu, Q.; Ragauskas, A.J. Catalytic conversion of waste cooking oils for the production of liquid hydrocarbon biofuels using in-situ coating metal oxide on SBA-15 as heterogeneous catalyst. J. Anal. Appl. Pyrolysis 2019, 138, 137–144. [Google Scholar] [CrossRef]

- Trabelsi, A.B.H.; Zaafouri, K.; Baghdadi, W.; Naoui, S.; Ouerghi, A. Second generation biofuels production from waste cooking oil via pyrolysis process. Renew. Energy 2018, 126, 888–896. [Google Scholar] [CrossRef]

- Moreira, J.d.B.D.; Bastos de Rezende, D.; Pasa, V.M.D. Deoxygenation of Macauba acid oil over Co-based catalyst supported on activated biochar from Macauba endocarp: A potential and sustainable route for green diesel and biokerosene production. Fuel 2020, 269, 117253. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M. Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression-ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Convers. Manag. 2020, 205, 112355. [Google Scholar] [CrossRef]

- Maher, K.D.; Bressler, D.C. Pyrolysis of triglyceride materials for the production of renewable fuels and chemicals. Bioresour. Technol. 2007, 98, 2351–2368. [Google Scholar] [CrossRef]

- Wang, Y.; Ke, L.; Peng, Y.; Yang, Q.; Du, Z.; Dai, L.; Zhou, N.; Liu, Y.; Fu, G.; Ruan, R.; et al. Characteristics of the catalytic fast pyrolysis of vegetable oil soapstock for hydrocarbon-rich fuel. Energy Convers. Manag. 2020, 213, 112860. [Google Scholar] [CrossRef]

- Horáček, J.; Tišler, Z.; Rubáš, V.; Kubička, D. HDO catalysts for triglycerides conversion into pyrolysis and isomerization feedstock. Fuel 2014, 121, 57–64. [Google Scholar] [CrossRef]

- Wisniewski, A.; Wiggers, V.R.; Simionatto, E.L.; Meier, H.F.; Barros, A.A.C.; Madureira, L.A.S. Biofuels from waste fish oil pyrolysis: Chemical composition. Fuel 2010, 89, 563–568. [Google Scholar] [CrossRef]

- Srifa, A.; Faungnawakij, K.; Itthibenchapong, V.; Assabumrungrat, S. Roles of monometallic catalysts in hydrodeoxygenation of palm oil to green diesel. Chem. Eng. J. 2015, 278, 249–258. [Google Scholar] [CrossRef]

- Ng, T.T.; Li, S.; Ng, C.C.A.; So, P.K.; Wong, T.F.; Li, Z.Y.; Chan, S.T.; Yao, Z.P. Establishment of a spectral database for classification of edible oils using matrix-assisted laser desorption/ionization mass spectrometry. Food Chem. 2018, 252, 335–342. [Google Scholar] [CrossRef]

- Kubátová, A.; Št’ávová, J.; Seames, W.S.; Luo, Y.; Sadrameli, S.M.; Linnen, M.J.; Baglayeva, G.V.; Smoliakova, I.P.; Kozliak, E.I. Triacylglyceride Thermal Cracking: Pathways to Cyclic Hydrocarbons. Energy Fuels 2012, 26, 672–685. [Google Scholar] [CrossRef]

- Xu, Z.-X.; Cheng, J.-H.; Song, H.; Wang, Q.; He, Z.-X.; Li, B.; Duan, P.-G.; Hu, X. Production of bio-fuel from plant oil asphalt via pyrolysis. J. Energy Inst. 2020, 93, 1763–1772. [Google Scholar] [CrossRef]

- Kim, S.; Kramer, R.W.; Hatcher, P.G. Graphical Method for Analysis of Ultrahigh-Resolution Broadband Mass Spectra of Natural Organic Matter, the Van Krevelen Diagram. Anal. Chem. 2003, 75, 5336–5344. [Google Scholar] [CrossRef] [PubMed]

- Kujawinski, E.B.; Behn, M.D. Automated Analysis of Electrospray Ionization Fourier Transform Ion Cyclotron Resonance Mass Spectra of Natural Organic Matter. Anal. Chem. 2006, 78, 4363–4373. [Google Scholar] [CrossRef]

- Ohno, T.; He, Z.; Sleighter, R.L.; Honeycutt, C.W.; Hatcher, P.G. Ultrahigh Resolution Mass Spectrometry and Indicator Species Analysis to Identify Marker Components of Soil- and Plant Biomass-Derived Organic Matter Fractions. Environ. Sci. Technol. 2010, 44, 8594–8600. [Google Scholar] [CrossRef]

- He, Z.; Guo, M.; Sleighter, R.L.; Zhang, H.; Chanel, F.; Hatcher, P.G. Characterization of defatted cottonseed meal-derived pyrolysis bio-oil by ultrahigh resolution electrospray ionization Fourier transform ion cyclotron resonance mass spectrometry. J. Anal. Appl. Pyrolysis 2018, 136, 96–106. [Google Scholar] [CrossRef]

- Xu, L.; Cheng, J.-H.; Liu, P.; Wang, Q.; Xu, Z.-X.; Liu, Q.; Shen, J.-Y.; Wang, L.-J. Production of bio-fuel oil from pyrolysis of plant acidified oil. Renew. Energy 2019, 130, 910–919. [Google Scholar] [CrossRef]

- Nanda, S.; Rana, R.; Hunter, H.N.; Fang, Z.; Dalai, A.K.; Kozinski, J.A. Hydrothermal catalytic processing of waste cooking oil for hydrogen-rich syngas production. Chem. Eng. Sci. 2019, 195, 935–945. [Google Scholar] [CrossRef]

| Sample | BET Surface Area (m2 g−1) | % Mo (wt.%) | % Co (wt.%) | % Ni (wt.%) |

|---|---|---|---|---|

| Mo-Co/γ-Al2O3 | 127 ± 6 | 8.9 ± 0.4 | 1.8 ± 0.1 | - |

| Mo-Ni/γ-Al2O3 | 234 ± 7 | 5.0 ± 0.2 | - | 0.3 ± 0.1 |

| γ-Al2O3 | 251 ± 4 | - | - | - |

| α-Al2O3 | 3 ± 1 | - | - | - |

| Property | Reported Value | Reference | This Work |

|---|---|---|---|

| Density (kg m−3) a | 911.5 | [49] | 917.2 |

| Moisture (wt.%) a | 0.02 | [50] | 0.47 |

| Ash (wt.%) a | 0.0 | [51] | 0.19 |

| Higher heating value (HHV, MJ kg−1) a | 39.4 | [52,53] | 40.1 |

| Acidity index (mg KOH g−1) b | 10.6 | [6] | 5.3 |

| Samples | Elemental Composition (wt.%) * | Oxygen Removal Efficiency (%) | ||||

|---|---|---|---|---|---|---|

| C | H | N | O a | |||

| Raw material | WCSO | 77.69 ± 0.13 | 11.59 ± 0.30 | 0.08 ± 0.01 | 10.64 ± 0.43 | – |

| Non catalytic bio-oil | BOWCSO | 78.97 ± 0.15 | 12.31 ± 0.09 | 0.00 | 8.72 ± 0.12 | 18.0 |

| Catalytic bio-oils | BOα-Al | 82.05 ± 0.50 | 12.59 ± 0.13 | 0.01 ± 0.01 | 5.35 ± 0.63 | 49.7 |

| BOMoCo | 86.81 ± 0.42 | 12.41 ± 0.05 | 0.01 ± 0.01 | 0.77 ± 0.43 | 92.8 | |

| BOγ-Al | 85.81 ± 0.63 | 13.28 ± 0.11 | 0.03 ± 0.03 | 0.88 ± 0.71 | 91.8 | |

| BOMoNi | 85.11 ± 0.54 | 12.98 ± 0.06 | 0.00 | 1.92 ± 0.60 | 82.0 | |

| Reference material | Petrodiesel | 85.72 ± 0.17 | 13.76 ± 0.23 | 0.00 | 0.53 ± 0.06 | – |

| Jet-A1 | 86.64 ± 0.12 | 13.86 ± 0.35 | 0.00 | 0.00 | – | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melo, J.A.; de Sá, M.S.; Moral, A.; Bimbela, F.; Gandía, L.M.; Wisniewski, A., Jr. Renewable Hydrocarbon Production from Waste Cottonseed Oil Pyrolysis and Catalytic Upgrading of Vapors with Mo-Co and Mo-Ni Catalysts Supported on γ-Al2O3. Nanomaterials 2021, 11, 1659. https://doi.org/10.3390/nano11071659

Melo JA, de Sá MS, Moral A, Bimbela F, Gandía LM, Wisniewski A Jr. Renewable Hydrocarbon Production from Waste Cottonseed Oil Pyrolysis and Catalytic Upgrading of Vapors with Mo-Co and Mo-Ni Catalysts Supported on γ-Al2O3. Nanomaterials. 2021; 11(7):1659. https://doi.org/10.3390/nano11071659

Chicago/Turabian StyleMelo, Josué Alves, Mirele Santana de Sá, Ainara Moral, Fernando Bimbela, Luis M. Gandía, and Alberto Wisniewski, Jr. 2021. "Renewable Hydrocarbon Production from Waste Cottonseed Oil Pyrolysis and Catalytic Upgrading of Vapors with Mo-Co and Mo-Ni Catalysts Supported on γ-Al2O3" Nanomaterials 11, no. 7: 1659. https://doi.org/10.3390/nano11071659

APA StyleMelo, J. A., de Sá, M. S., Moral, A., Bimbela, F., Gandía, L. M., & Wisniewski, A., Jr. (2021). Renewable Hydrocarbon Production from Waste Cottonseed Oil Pyrolysis and Catalytic Upgrading of Vapors with Mo-Co and Mo-Ni Catalysts Supported on γ-Al2O3. Nanomaterials, 11(7), 1659. https://doi.org/10.3390/nano11071659