Large-Area Biocompatible Random Laser for Wearable Applications

Abstract

:1. Introduction

2. Materials and Methods

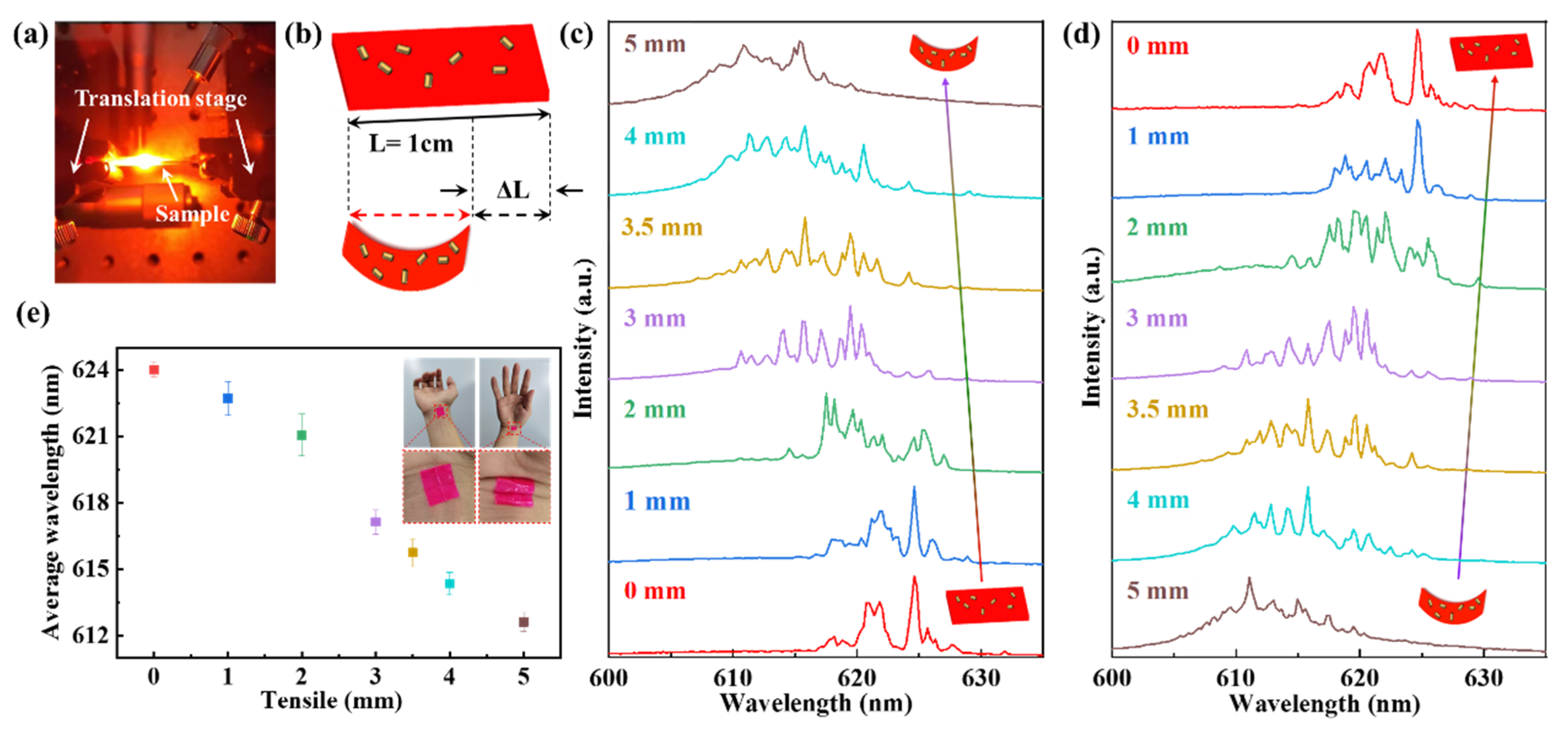

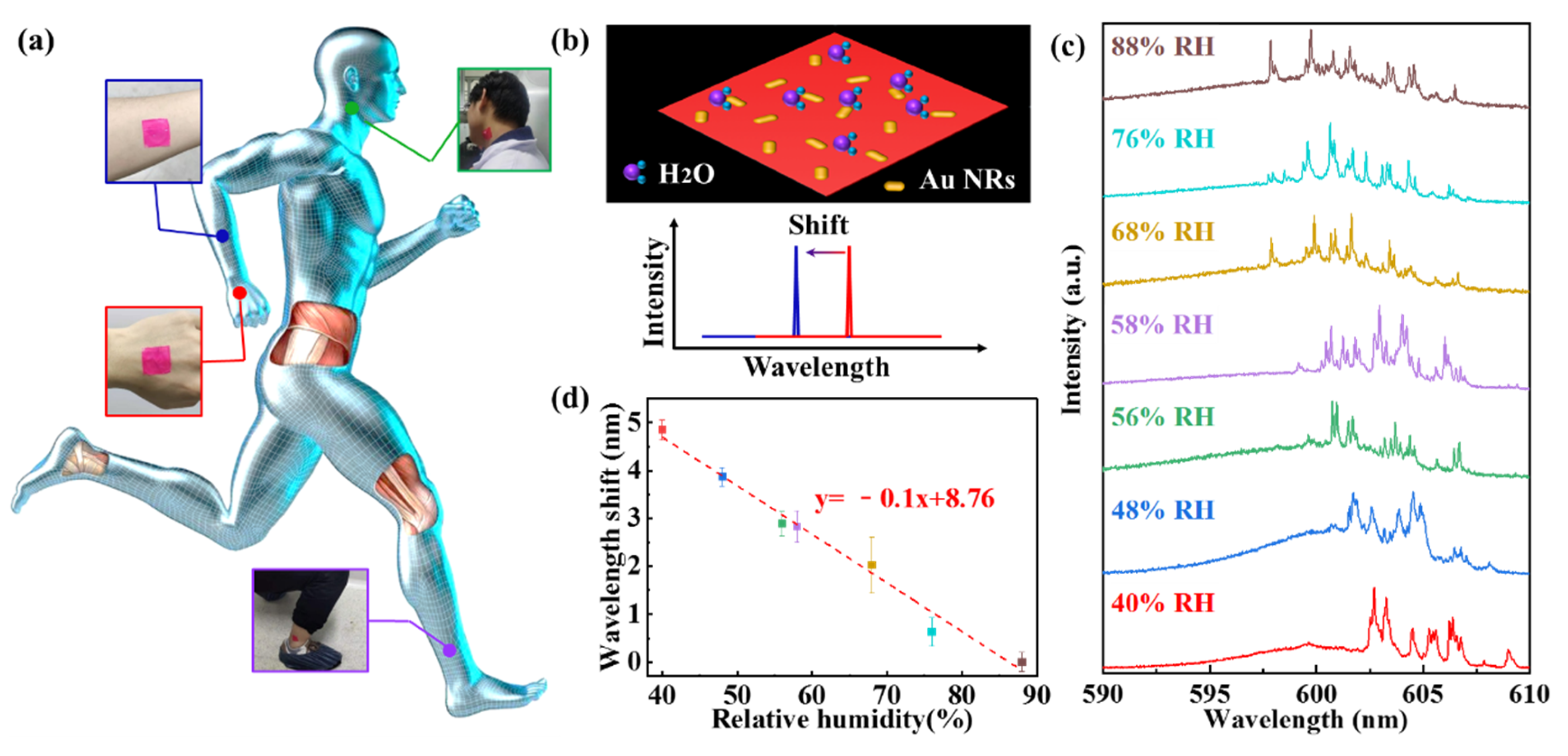

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lawandy, N.; Balachandran, R.; Gomes, A.; Sauvain, E. Laser action in strongly scattering media. Nature 1994, 368, 436–438. [Google Scholar] [CrossRef]

- Wiersma, D.S. The physics and applications of random lasers. Nat. Phys. 2008, 4, 359–367. [Google Scholar] [CrossRef]

- Bian, Y.X.; Shi, X.Y.; Hu, M.N.; Wang, Z.N. A ring-shaped random laser in momentum space. Nanoscale 2020, 12, 3166. [Google Scholar] [CrossRef]

- Tong, J.H.; Shi, X.Y.; Niu, L.Z.; Zhang, X.; Chen, C.; Han, L.; Zhang, S.; Zhai, T.R. Dual-color plasmonic random lasers for speckle-free imaging. Nanotechnology 2020, 31, 465204. [Google Scholar] [CrossRef]

- Liu, Y.L.; Yang., W.H.; Xiao., S.M.; Zhang., N.; Fan., Y.B.; Qu., G.Y.; Song., Q.H. Surface-emitting perovskite random lasers for speckle-free imaging. ACS Nano 2019, 13, 10653–10661. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.W.; Lu, J.Y.; Hung, B.Y.; Chiesa, M.; Tung, P.H.; Lin, J.H.; Yang, T.C. Random lasers from photonic crystal wings of butterfly and moth for speckle-free imaging. Opt. Express 2021, 29, 2065–2076. [Google Scholar] [CrossRef] [PubMed]

- Ritt, G. Laser safety calculations for imaging sensor. Sensors 2019, 19, 3765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, Y.P.; Zhang, L.; Gao, S.; Lu, P.; Mihailov, S.; Bao, X.Y. Highly sensitive fiber random-grating-based random laser sensor for ultrasound detection. Opt. Lett. 2017, 42, 1353–1356. [Google Scholar] [CrossRef]

- Jayathilaka, W.; Qi, K.; Qin, Y.L.; Chinnappan, A.; Serrano, W.; Baskar., C.; Wang., H.B.; He, J.X.; Cui, S.Z.; Thomas, S.W.; et al. Significance of nanomaterials in wearables: A review on wearable actuators and sensors. Adv. Mater. 2019, 31, 1805921. [Google Scholar] [CrossRef]

- Ta, V.D.; Nguyen, T.T.; Nghiem, T.H.; Tran, H.N.; Le, A.T.; Dao, N.T.; Duong, P.D.; Mai, H.H. Silica based biocompatible random lasers implantable in the skin. Opt. Commun. 2020, 475, 126207. [Google Scholar] [CrossRef]

- Ling, Y.Z.; An, T.; Yap, L.W.; Zhu, B.; Gong, S.; Cheng, W.L. Disruptive, soft, wearable sensors. Adv. Mater. 2020, 32, 1904664. [Google Scholar] [CrossRef] [PubMed]

- Caixeiro, S.; Gaio, M.; Marelli, B.; Omenetto, F.G.; Sapienza, R. Silk-based biocompatible random lasing. Adv. Opt. Mater. 2016, 4, 998–1003. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Ma, Z.; Cao, Z.L.; Pan, L.J.; Shi, Y. Advanced wearable microfluidic sensors for healthcare monitoring. Small 2020, 16, 1903822. [Google Scholar] [CrossRef]

- Ren, K.K.; Wang, J.; Chen, S.Q.; Yang, Q.X.; Tian, J.; Yu, H.C.; Sun, M.F.; Zhu, X.J.; Yue, S.Z.; Sun, Y.; et al. Realization of perovskite-nanowire-based plasmonic lasers capable of mode modulation. Laser Photonics Rev. 2019, 13, 1800306. [Google Scholar] [CrossRef]

- Hayat, A.; Tong, J.H.; Chen, C.; Niu, L.Z.; Aziz, G.; Zhai, T.R.; Zhang, X.P. Multi-wavelength colloidal quantum dots lasers in distributed feedback cavities. Sci. China Inf. Sci. 2020, 63, 182401. [Google Scholar] [CrossRef]

- Li, S.T.; Wang, L.; Zhai, T.R.; Chen, L.; Wang, M.; Wang, Y.Y.; Tong, F.; Wang, Y.L.; Zhang, X.P. Plasmonic random lasing in polymer fiber. Opt. Express 2016, 24, 12748. [Google Scholar] [CrossRef] [PubMed]

- Gummalure, V.S.; Nair, R.V.; Krishnan, S.R.; Vijayan, C. Femtosecond laser-pumped plasmonically enhanced near-infrared random laser based on engineered scatterers. Opt. Lett. 2017, 42, 5002. [Google Scholar] [CrossRef]

- Lang, X.; Jia, P.; Chen, Y.; Qin, L.; Liang, L.; Chen, C.; Wang, Y.; Shan, X.; Ning, Y.; Wang, L. Advances in narrow linewidth diode lasers. Sci. China Inf. Sci. 2019, 62, 061401. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.L.; Zhai, T.R. Distributed feedback organic lasing in photonic crystals. Front. Optoelectron. 2020, 13, 18–34. [Google Scholar] [CrossRef]

- Munkhbat, B.; Ziegler, J.; Pöhl, H.; Wörister, C.; Sivun, D.; Scharber, M.C.; Klar, T.A.; Hrelescu, C. Hybrid multilayered plasmonic nanostars for coherent random lasing. J. Phys. Chem. C. 2016, 120, 23707–23715. [Google Scholar] [CrossRef]

- He, D.S.; Bao, W.Y.; Long, L.; Zhang, P.; Jiang, M.H.; Zhang, D.K. Random lasing from dye-Ag nanoparticles in polymer films: Improved lasing performance by localized surface plasmon resonance. Opt. Laser Technol. 2017, 91, 193–196. [Google Scholar] [CrossRef]

- Ma, B.; Zou, W. Demonstration of a distributed feedback laser diode working as a graded-potential-signaling photonic neuron and its application to neuromorphic information processing. Sci. China Inf. Sci. 2020, 63, 160408. [Google Scholar] [CrossRef]

- Fukushima, M.; Yanagi, H.; Hayashi, S.; Taniguchi, Y. Distributed feedback lasing from dye-doped glass films using photopatterned gold nanoparticles. J. Appl. Phys. 2005, 97, 106104. [Google Scholar] [CrossRef]

- Stehr, J.; Crewett, J.; Schindler, F.; Sperling, R.; Plessen, G.; Lemmer, U.; Lupton, J.; Klar, T.; Feldmann, J.; Holleitner, A.; et al. A low threshold polymer laser based on metallic nanoparticle gratings. Adv. Mater. 2003, 15, 1726–1729. [Google Scholar] [CrossRef]

- Keshmarzi, E.; Tait, R.; Berini, P. Single-mode surface plasmon distributed feedback lasers. Nanoscale 2018, 10, 5914. [Google Scholar] [CrossRef] [PubMed]

- Tian, T.R.; Zhang, X.L.; Fang, H.H.; Liu, Y.F.; Jin, Y.; Wang, J.P.; Fu, Y.G. Lowered threshold of polymer distributed feedback laser by hybridizing waveguide and surface-plasmon polariton modes. Opt. Laser Technol. 2013, 45, 246–249. [Google Scholar] [CrossRef]

- Ning, S.Y.; Wu, Z.X.; Dong, H.; Ma, L.; Jiao, B.; Ding, L.; Ding, L.P.; Zhang, F.H. The enhanced random lasing from dye-doped polymer films with different-sized silver nanoparticles. Org. Electron. 2016, 30, 165–170. [Google Scholar] [CrossRef]

- Ye, L.H.; Zhao, C.; Feng, Y.Y.; Gu, B.; Cui, Y.P.; Lu, Y.Q. Study on the polarization of random lasers from dye-doped nematic liquid crystals. Nanoscale Res. Lett. 2017, 12, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zheng, P.P.; Tang, H.B.; Liu, B.T.; Kasani, S.J.; Huang, L.; Wu, N.Q. Origin of strong and narrow localized surface plasmon resonance of copper nanocubes. Nano Res. 2019, 12, 63–68. [Google Scholar] [CrossRef]

- Long, L.; He, D.S.; Bao, W.Y.; Feng, M.L.; Zhang, P.; Zhang, D.K.; Chen, S.J. Localized surface plasmon resonance improved lasing performance of Ag nanoparticles/organic dye random laser. J. Alloy. Compd. 2017, 693, 876–881. [Google Scholar] [CrossRef]

- Noginov, M.A.; Zhu, G.; Belgrave, A.M.; Bakker, R.; Shalaev, V.M.; Narimanov, E.E.; Stout, S.; Herz, E.; Suteewong, T.; Wiesner, U. Demonstration of a spaser-based nanolaser. Nature 2009, 460, 1110–1112. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.R.; Zhang, X.P.; Pang, Z.G.; Su, X.Q.; Liu, H.M.; Feng, S.F.; Wang, L. Random laser based on waveguided plasmonic gain channels. Nano. Lett. 2011, 11, 4295–4298. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.H.; Feng, Y.Y.; Cheng, Z.X.; Wang, C.L.; Lu, C.G.; Lu, Y.Q.; Cui, Y.P. Coherent random lasing from dye aggregates in polydimethylsiloxane thin films. ACS Appl. Mater. Interfaces 2017, 9, 27232–27238. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.J.; Zhang, Q.; Miao, B.; Fu, Q.; Zou, G.; Chen, Y.; Luo, Y.; Zhang, D.; Wang, P.; Ming, H. Coherent random fiber laser based on nanoparticles scattering in the extremely weakly scattering regime. Phys. Rev. Lett. 2012, 109, 253901. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Liu, Y.X.; Zhong, D.L.; Nikzad, S.; Liu, S.H.; Yu, Z.; Liu, D.Y.; Wu, H.C.; Zhu, C.X.; Li, J.X.; et al. Monolithic optical microlithography of high-density elastic circuits. Science 2021, 373, 88–94. [Google Scholar] [CrossRef]

- Hu, M.N.; Bian, Y.X.; Shen, H.H.; Wang, Z.N. A humidity-tailored film random laser. Org. Electron. 2020, 86, 105923. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Zhai, T.R.; Shi, X.Y.; Tong, J.H.; Wang, X.L.; Deng, J.X. Multifunctional sensing based on an ultrathin transferrable microring laser. ACS Appl. Mater. Interfaces 2021, 13, 19324–19331. [Google Scholar] [CrossRef]

- Desimoni, E.; Brunetti, B. About estimating the limit of detection by the signal to noise approach. Pharm. Anal. Acta 2015, 6, 1000355. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, K.; Guo, D.; Ma, X.; Xu, Z.; Hayat, A.; Li, S.; Zhai, T. Large-Area Biocompatible Random Laser for Wearable Applications. Nanomaterials 2021, 11, 1809. https://doi.org/10.3390/nano11071809

Ge K, Guo D, Ma X, Xu Z, Hayat A, Li S, Zhai T. Large-Area Biocompatible Random Laser for Wearable Applications. Nanomaterials. 2021; 11(7):1809. https://doi.org/10.3390/nano11071809

Chicago/Turabian StyleGe, Kun, Dan Guo, Xiaojie Ma, Zhiyang Xu, Anwer Hayat, Songtao Li, and Tianrui Zhai. 2021. "Large-Area Biocompatible Random Laser for Wearable Applications" Nanomaterials 11, no. 7: 1809. https://doi.org/10.3390/nano11071809

APA StyleGe, K., Guo, D., Ma, X., Xu, Z., Hayat, A., Li, S., & Zhai, T. (2021). Large-Area Biocompatible Random Laser for Wearable Applications. Nanomaterials, 11(7), 1809. https://doi.org/10.3390/nano11071809