3.1. Growth Mechanism and Microstructure of the TiO2 Film

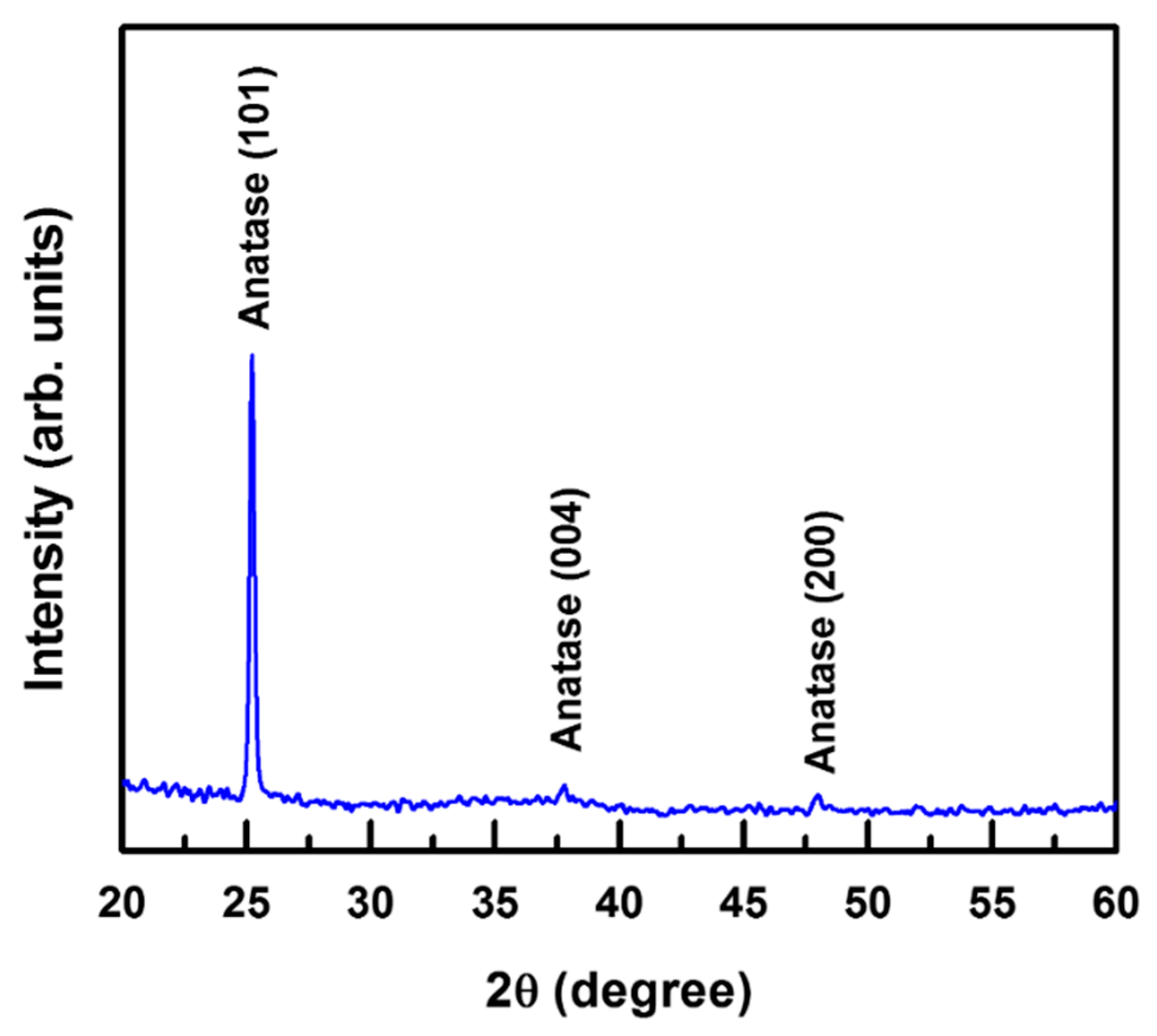

Figure 1 presents the X-ray diffraction (XRD) pattern of a 100 nm thick TiO

2 film deposited on a glass substrate at 100 °C by CAPE using a shielded net (shielded CAPE) between the arc source and substrate. The diffraction peaks could be attributed to the antase-phase TiO

2 (JCPDS card No. 21-1272) and the peaks could be indexed to the (101), (004), and (200) planes. Thus, the XRD analysis indicates that single-phase TiO

2 films can be grown by this method, without any secondary phases. Although the TiO

2 films were grown at a low temperature of 100 °C, the intensive and sharp diffraction peaks indicated good crystallinity of the coatings. This is attributed to the ion-assisted growth arising from the high-ionization arc plasma [

12]. In contrast, the formation of high-crystallinity TiO

2 films through conventional vapor deposition without ion assistance generally requires a growth temperature of >300 °C [

15]. The XRD patterns exhibited a higher intensity of the (101) peak than other peaks, revealing the stronger tendency of the TiO

2 crystallites to grow with a preferred (101) orientation. According to thermodynamics, a TiO

2 structure with (101) orientation is more stable because of its lower surface free energy over that of a structure with (100) orientation [

28]. Thus, the anatase-phase TiO

2 films grew preferably along the [101] axis in the direction perpendicular to the glass substrate.

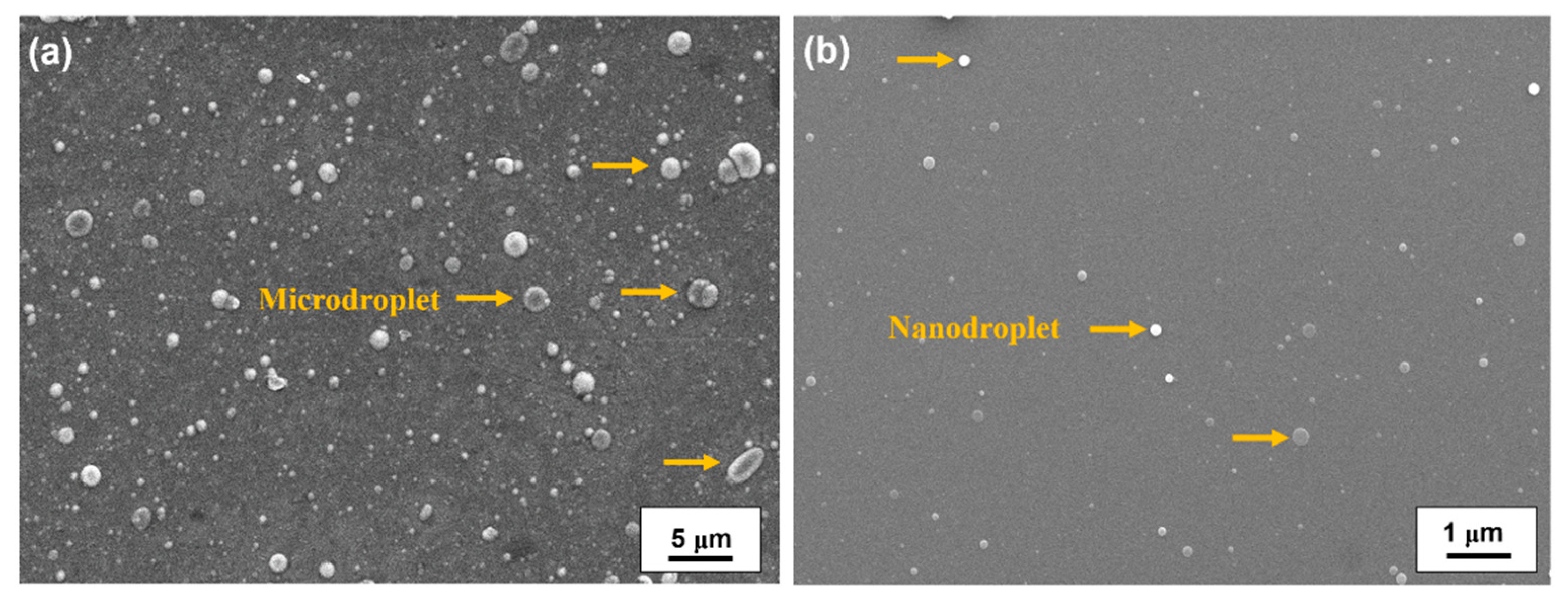

The variations in the surface morphology of the TiO

2 thin films with the different deposition methods were examined by SEM to investigate the Ti microdroplet size distribution.

Figure 2 shows the plane-view SEM images of the TiO

2 thin films deposited by CAPE (a) without and (b) with a shielded net via the reaction of a Ti target with O

2 at the temperature of 100 °C.

Figure 2a shows some Ti microdroplets incorporated into the TiO

2 film deposited by CAPE without a shielded net. The size of the microdroplets was in the range of 0.5 to 4 µm, as indicated by the arrows. As the cathode spots are a center of explosive electron emission on the target surface with an extremely high current density (~10

12 A/m

2), they create high ion kinetic energies (20–200 eV) and multiple charge states for ion-assisted growth [

29]. However, the major disadvantage of this process is the emission of the microdroplets from the target, and their adhesion onto the films during their deposition. Large Ti microdroplets are emitted owing to the interaction between the arc plasma and Ti target at the cathode spots. In general, large microdroplets of sizes ranging up to several micrometers may cause a self-shadowing effect during the thin film growth process, leading to voids or gaps at the film–droplet interfaces [

30]. The deposition of large microdroplets on a growing film results in degraded optical properties of the final film, owing to the opacity of the metal microdroplets and self-shadowing effect. These factors restrict the application of the CAPE process in the preparation of optical coatings. To overcome this issue of the incorporation of opaque metal microdroplets into the films, TiO

2 films are prepared by shielded CAPE via the reaction of a Ti metal target with O

2. The SEM image of the TiO

2 film deposited by shielded CAPE (

Figure 2b) exhibits only a few Ti nanodroplets incorporated in the film, and the size of the droplets is significantly decreased from several micrometers to 50–150 nm, as marked by the arrows in the image. This result indicates that the liquid droplets of Ti emitted from the target were effectively blocked by the shielded net. However, the average growth rate decreased significantly from 8.5 to 1.2 nm/s when the shielded CAPE method was used.

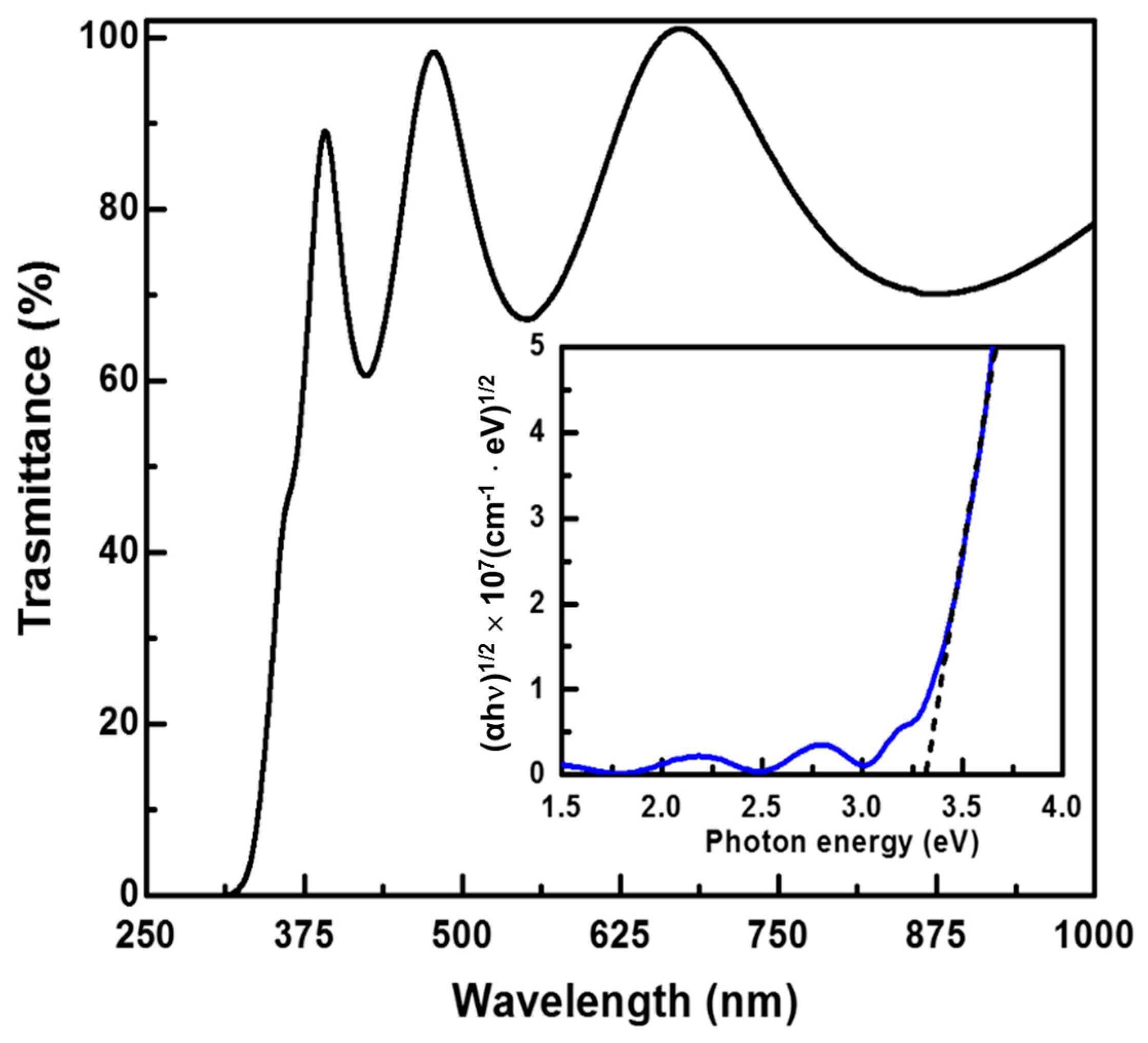

Figure 3 displays the transmittance spectrum of a TiO

2 thin film deposited by shielded CAPE via the reaction of a Ti target with O

2 at the growth temperature of 100 °C. The inset shows the optical band gap of the TiO

2 coating. The series of broad peaks located at 391, 497, and 675 nm is due to light interference owing to the difference in the refractive index between the TiO

2 thin film and glass substrate; it indicates the uniformity of the TiO

2 film thickness. The transmittance spectrum indicates that the TiO

2 films had an average transmittance >83.6% in the visible light range (400–760 nm). The as-deposited TiO

2 films obtained by shielded CAPE showed good visible light transmittance because the arc plasma provided sufficient energy to Ti and O adatoms to reach their equilibrium positions; thus, the undesired absorption due to structural defects is reduced. In contrast, TiO

2 films deposited by the DC-sputtering deposition process require a higher thermal treatment temperature of >300 °C to enhance visible light transmittance, because high-temperature thermal annealing is required to eliminate the defects in the film [

16].

To investigate the UV-shielding properties of the TiO

2 films deposited by shielded CAPE, the indirect band gap of the TiO

2 (E

g,TiO2) film was determined from the absorption spectra using the indirect transition model [

31]:

where

α is the absorption coefficient,

Ai is a constant, and h

ν is the photon energy. The inset of

Figure 3 shows the plot of (

αh

ν)

1/2 versus the photon energy for the TiO

2 film. According to Equation (1), the optical bandgap can be determined by extrapolating the linear region of the plot to the abscissa. The bandgap of the TiO

2 films was thus determined to be ~3.3 eV, which corresponds to the band-to-band transition of anatase-phase TiO

2. This band-to-band transition (absorption edge at ~375 nm) facilitates a strong absorption in the UV range, leading to high UVB- and UVA-shielding properties.

3.2. IRB-Shielding ITO Layers

ITO films have high visible light transparency and good IRB absorption properties owing to the plasmon excitation of the free electrons [

27]. ITO films with a high free carrier concentration are prepared carefully to obtain a higher IRB-shielding rate. RF magnetron sputtering combined with a negatively biased substrate can facilitate intense ion bombardment during the film deposition. A suitable bias voltage can provide sufficient kinetic energy to enable the adatoms to reach the equilibrium position, resulting in a highly crystalline film. Therefore, ITO films were deposited on a glass substrate with an RF bias voltage of −40 V at 150 °C.

Figure 4 shows the XRD patterns of the ITO films with various thicknesses in the range of 200 to 600 nm. All the recorded diffraction peaks could be indexed to the bixbyite structure of ITO (JCPDS card No. 89-4598). Thus, the XRD analysis indicated that the films were formed in the pure ITO phase, without any secondary phases. Despite the relatively low deposition temperature, the sharp diffraction peaks indicate a good crystallinity of the ITO coatings. This is attributed to enhanced ion bombardment resulting from the effect of the substrate bias. In general, the temperature required for the crystallization of amorphous ITO films is ~300 °C [

32]. The ion bombardment provided the adatoms with sufficient energy to move on the growing film surface. Thus, high-crystallinity ITO films could be deposited at a relatively low growth temperature of 150 °C. Furthermore, the intensity ratio of the (400) and (222) diffraction peaks (

I400/

I222) in the XRD patterns increased from 0.32 to 1.03 with an increase in the ITO film thickness from 200 to 600 nm. The

I400/

I222 ratio of the 200 nm thick ITO film was determined to be 0.32, comparable to that of a randomly oriented polycrystalline ITO powder (

I400/

I222 = 0.30) [

27]. The orientation of the initially formed ITO layer was influenced by the amorphous structure of glass substrate; therefore, a random orientation was observed when the film thickness was 200 nm. The

I400/

I222 ratio increases significantly from 0.68 to 1.03 as the thickness was increased from 400 to 600 nm, indicating that the (100) preferred orientation evolved with increasing film thickness.

To further investigate the microstructure of the ITO films deposited by RF sputtering combined with a negatively biased (−40 V) substrate, a representative cross-sectional sample of a 400 nm thick film was analyzed by TEM (

Figure 5). The cross-sectional bright-field (BF) TEM images revealed that the dense columnar structure of ITO film, as shown in

Figure 5a. In addition, the initial growth region near the amorphous glass substrate contained small columnar grains (~40 nm) and the columnar grains gradually coalesced into larger columnar grains (~90 nm) with an increase in the film ITO thickness to 400 nm.

Figure 5b,c show the nano-beam diffraction (NBD) patterns for the regions marked as NBD-I and NBD-II, respectively, in

Figure 5a. The NBD patterns in

Figure 5b,c were recorded along the [001] and [

] zone axes, respectively. The NBD could be indexed to the bixbyite-phase ITO with a lattice parameter of 1.016 nm [

33]. According to the NBD analysis, the columnar ITO grains grow along the [100] direction, perpendicular to the plane of the substrate. Thus, the BF image and NBD patterns indicates that a (100)-textured microstructure had formed in the ITO films at thicknesses greater than 400 nm, consistent with the XRD results. According to Choi et al., ITO films that contain more oxygen vacancies provide sites for ions to migrate under the low oxygen sputtering growth condition [

34]. In addition, the oxygen vacancies are preferentially incorporated into (100) planes than into (111) planes, because the former can accommodate more oxygen vacancies than the latter [

33,

34]. A large number of oxygen vacancy sites could assist ion diffusion owing to the open lattice structure of these sites. From the perspective of kinetics, only grains with the highest growth-rate lattice plane eventually survive [

35]; therefore, the preferred (100) orientation was obtained at a greater film thickness.

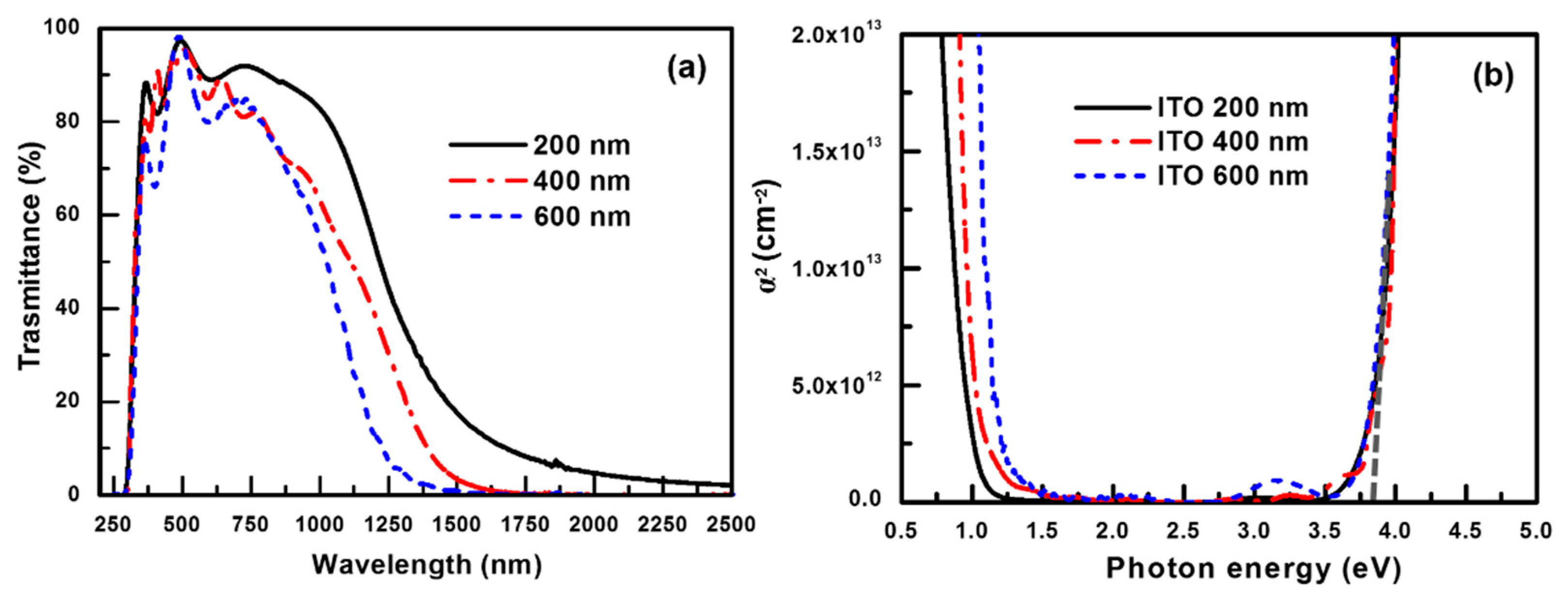

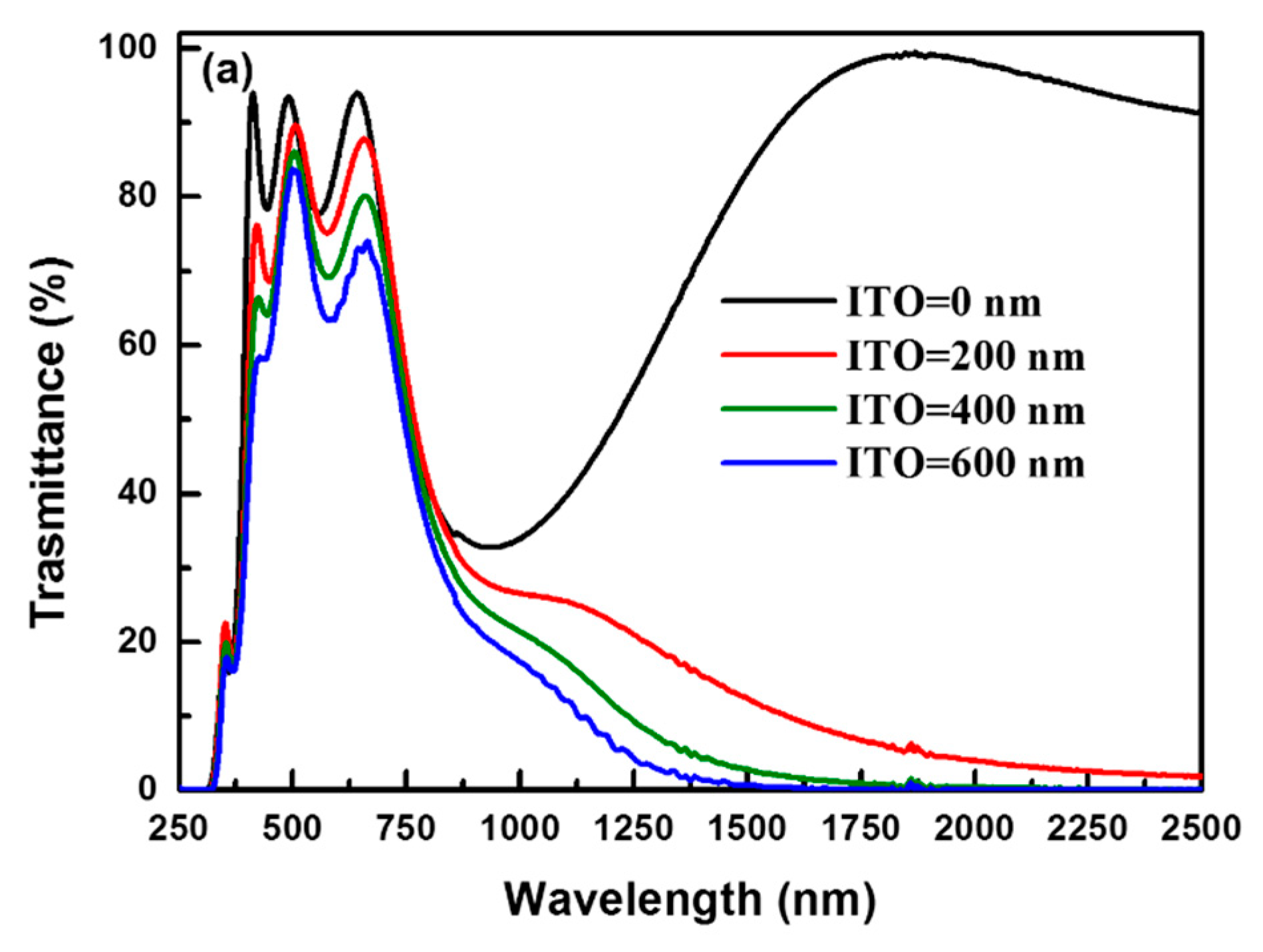

Figure 6a shows the transmittance spectra of the ITO coatings grown to different thicknesses (200 to 600 nm). The optical properties, including the average transmittance from UVB to UVA (

TUVB~UVA), average visible light transmittance (

TVIS), average IRA transmittance (

TIRA), and average IRB transmittance (

TIRB) were calculated from the transmittance spectra. The electrical and optical properties, including the carrier density, Hall mobility, and resistivity, and the

TUVB~UVA,

TVIS,

TIRA, and

TIRB values of the ITO films with different thicknesses (200–600 nm) are summarized in

Table 1. As the film thickness increased from 200 to 600 nm, the Hall mobility increased from 25.9 to 31.8 cm

2/V s. The carrier density also increased with the film thickness from 9.1 × 10

20 to 1.12 × 10

21 cm

−3. Thus, the best conductivity was obtained at the thickness of 600 nm. The changes in the electrical properties can be rationalized based on the microstructure, crystalline defects and effective donor density. The electrons encountered fewer scattering events during their transport, leading to higher mobility. The mobility increased continuously with an increase in the film thickness from 200 to 600 nm, owing to the decrease in the number of scattering centers due to the reduction in the crystalline defects with increasing crystallite size. The crystallite size and crystallinity of the ITO films increase with an increase in the film thickness from 200 to 600 nm, resulting in the increase in mobility with increasing film thickness.

The high carrier concentration of the high-crystallinity ITO film indicated that the In

3+ ions were replaced by a Sn

4+ donors, resulting in the donation of free electrons. Further, the incorporated oxygen vacancies can behave as double donors and the trapped electrons are easily thermally activated to the conduction band [

33]. In contrast, grain boundaries and lattice distortion lead to large recombination centers owing to localized states related to the nearby dangling bonds, which could act as undesirable electron-trapping state [

36,

37]. The carrier concentration increases from 9.1 × 10

20 to 1.1 × 10

21 cm

−3 with increasing thickness from 200 nm to 600 nm. The film with 600 nm thickness has the highest election density, which originates from the increase in the effective dopant concentration due to the improved crystallinity and the decrease in the number of trapping sites arising from crystalline defects. In addition, the ITO films with the preferred (100) orientation at the thickness of >400 nm can incorporate a higher number of oxygen vacancies, leading to higher carrier density.

Figure 6b shows the square of the absorption coefficient versus the photon energy for ITO films of different film thicknesses. The bandgaps of the ITO films can be obtained based on the Moss method [

38]. The optical bandgap of the ITO films (E

g,ITO) can be determined from the absorption coefficient of the films using the relationship for parabolic direct bands [

27]:

where

α is absorption coefficient, A is a constant, and h

ν is the photon energy. According to Equation (2), the interpolation of the linear part of the

α2 versus h

ν plot onto the h axis yields the band gap of the ITO films [

27]. The E

g,ITO value determined by this method is ~3.75 eV (absorption edge is located at ~330 nm); thus, ITO films cannot completely block the UVA radiation (wavelength: 320–400 nm). Therefore, the

TUVB~UVA value decreased only marginally from 52.9 to 48.1% owing to the band-to-band absorption of ITO. Moreover, ITO films have a high transmittance of >85% in the visible light range; however, the

TVIS value decreased slightly from 90.9 to 85.2% with increasing film thickness, as shown in

Table 2. The visible light transmittance decreased with increasing ITO thickness owing to the broad absorption range of the ITO film, which may be attributed to the s

2 → sp bonding transition of Sn

2+ [

33]. It has been suggested that the formation mechanism of Sn

2+ ions involves the charge neutralization; therefore, Sn

2+ ion were formed to the compensation of the local positive charge at Sn

4+ in ITO films [

33].

Further, the transmittance edge in the NIR region decreased from 1500 to 1250 nm with increasing thickness of the ITO film. The TIRA value decreased rapidly from 66.7 to 38.2%, and the IRB radiation was effectively blocked (i.e.,

TIRB < 1%) at the ITO thickness of >400 nm, as shown in

Table 1. The transmittance in the IRB region decreased rapidly, because the plasmon resonance absorption was enhanced by the increased free electron density of the TCO film [

24,

25]. The plasmon resonance frequency (

ωp) is given by

ωp = (4

πNe

2/

εom∗)

1/2, where

N is the density of free electrons,

e is the elementary charge,

εo is the permittivity of free space, and

m∗ is the electron effective mass [

24,

25]. According to the Drude model, the absorption spectrum of plasmons can be described as follows [

39]:

where

α is the absorption coefficient and

ω is frequency. The absorption coefficient decreases with increasing frequency and it becomes zero for

ω >

ωp. The carrier concentration of the ITO film increased form 9.1 × 10

20 to 1.12 × 10

21 cm

−3 with an increase in the film thickness from 200 to 600 nm; therefore, the

ωp value shift to high energy when the increase in ITO thickness, as shown in

Figure 6b. Despite the good IRB-shielding properties, the cost of indium becomes too prohibitive due to the scarcity of indium. To address the indium-scarcity issues, significant effort has been devoted for development of ITO-alternative materials with high infrared shielding properties, such as gallium-doped ZnO films [

25], conductive metal oxides (CMO) plasmonic nanostructures [

40], CMO nanocrystals [

41], and degenerately doped semiconductor nanocrystals [

42].

3.3. TiO2/SiO2 IRA-Shielding Multilayers

The IRB radiation is almost completely absorbed by an ITO film at the thickness of >400 nm. However, as the IR radiation absorption edge of the ITO film is limited to ~1300 nm, the IRA light is not completely shielded by a single ITO layer because of its limited free carrier density. Therefore, to develop a coating with optimal IRA-shielding abilities, a series of TiO

2/SiO

2 multilayer films with different stacking structure was designed. NIR-reflecting multilayer coatings composed of the high-refractive-index TiO

2 and low-refractive-index SiO

2 films were deposited on glass substrates using the shielded CAPE and RF sputtering deposition processes, respectively. As the IRA waves undergo constructive interference, the thickness of a TiO

2/SiO

2 alternating multilayer is set to be equal to the quarter of the IRA wavelength [

43]. The thickness (

t) values of the individual TiO

2 and SiO

2 films determined using the relationship

t =

λB/4

n [

43], where n is the refractive index (TiO

2: 2.25, SiO

2:1.45) and

λB is the Bragg wavelength. TiO

2(SiO

2/TiO

2)

x stacked multilayers with TiO

2/SiO

2 pairs (

x) equal to 1–3 are designed to fulfill a Bragg wavelength (

λB) of ~950 nm. According to a quarter of the Bragg wavelength relationship (

t =

λB/4

n), the thickness of each oxide layer was 163.8 and 105.6 nm for SiO

2 and TiO

2, respectively.

Figure 7 shows the transmittance spectra of the coatings with various structures that fulfill a Bragg wavelength of 950 nm, viz., (I) TiO

2(SiO

2/TiO

2), (II) TiO

2(SiO

2/TiO

2)

2, and (III) TiO

2(SiO

2/TiO

2)

3.

Table 2 lists the average

TVIS,

TIRA, and

TIRB values of the SiO

2/TiO

2 multilayers, viz., structures (I), (II), and (III). The

TVIS (i.e., the transmittance in the visible light region) decreases from 81.6 to 72.7% with an increase in the number of pairs (x) in the order of (I) > (II) > (III). The

TIRA significantly decreases from 45.1 to 38.2% with an increase in the number of TiO

2/SiO

2 pairs from 1 to 3, which attributes to the increase in the number of reflections, and the constructive interference of the multiply reflected waves originating from the structure with an increased number of TiO

2/SiO

2 pairs [

43]. The TiO

2/SiO

2 multilayer shielded the IRA light; however, the transmittance spectra of the optical structures denoted as (I), (II), and (III) indicated high transmittances (>88.8%) in the IRB region (as shown in

Table 2). The band width of a TiO

2/SiO

2 multilayer depends on the difference in the refractive index of its constituent materials; a greater difference results in a greater IRA-shielding band width, while an increase in the number of pairs may narrow the band width. The TiO

2(SiO

2/TiO

2)

3 multilayer (design III) exhibited the best IRA-shielding abilities; however, its band width was only ~420 nm in the IRA wavelength range of 760–1200 nm, as indicated in

Figure 7. Therefore, the NIR radiation was not completely shielded by the single-Bragg wavelength TiO

2(SiO

2/TiO

2)

x multilayer owing to the constrained difference between the refractive indices of the constituent layers.

To study the effects of the microstructure on the optical properties of the TiO

2/SiO

2 IRA-shielding multilayer films, representative cross-sectional specimens prepared by the FIB method for a TiO

2/SiO

2 multilayer with design (III) was analyzed by TEM.

Figure 8a shows a BF TEM image of a SiO

2/TiO

2 multilayer with design (III) deposited on a glass substrate. The BF image clearly shows that the SiO

2 and TiO

2 layer are dense and uniform. The interfaces of the multilayers are sharp, indicating that the inter-diffusion of atoms across the SiO

2/TiO

2 interfaces is not significant owing to the low growth temperature. In order to identify the phase and investigate the orientation of the TiO

2 grains,

Figure 8b shows a magnified BF TEM image for the square region marked as 1 in

Figure 8a, and the corresponding selected-area diffraction pattern (SADP) of the TiO

2 film is shown in the inset of

Figure 8b, as indicated for region 2 in

Figure 8b. The SADP was recorded along the [

] zone axis and the SADP could be indexed to the anatase-phase TiO

2 with the lattice parameters of a = 0.3785 nm and c = 0.9513 nm [

8]. The SADP of the film deposited on amorphous SiO

2 showed (101) preferred orientation, indicating that the TiO

2 crystallites grow along the [101] axis. The magnified BF TEM image and SADP unequivocally demonstrate that a highly crystalline TiO

2 film was obtained by the shielded CAPE process at a low growth temperature. Therefore, the TiO

2 films with high visible-light transparency and high refractive index (2.25) were obtained.

In general, the deposition temperature required to form highly crystalline TiO

2 films is greater than 400 °C [

15]. This is attributed to the ion-assisted growth resulting from the high-density plasma of CAPE. Previously, the kinetics of the crystallization of amorphous TiO

2 to the anatase phase has been studied by differential scanning calorimetry, and the activation energy of crystallization has been determined to be 202.4 kJ/mol (~2.1 eV/atom) [

44]. In the arc plasma, each ion has kinetic and potential energies, which contribute to the energy delivered to adatoms on the growing film, a process referred to as atomic scale heating (ASH) [

45]. The ionization energy of multiple charged ions contributes predominantly to the potential energy in the CAPE process, and the ionization energy is in the range of several electron volts to hundreds of electron volts depending on the charge state of the ion [

45]; note that this ionization energy is much higher than that of the thermal evaporation or magnetron sputtering techniques [

12]. The activation energies for the surface diffusion of the adatoms of Ti and O on the TiO

2 surface are typically ~0.5 eV [

46] and ~2 eV [

47], respectively. These activation energies for the surface diffusion of the adatoms on growing films are smaller than those provided by the ASH in the cathodic arc plasma; this results in enhanced surface mobility during the deposition process.

Figure 8c shows a high-resolution (HR) TEM image of the square region marked as HR in

Figure 8c.

Figure 8d shows a two-dimensional inverse fast Fourier transform (2D IFFT) image corresponding to

Figure 8c. The 2D IFFT image indicates the planes of the anatase TiO

2 (101) planes (viewed edge on) with an interplanar spacing of 0.35 nm, suggesting that ideal (line- and planar-defect-free) TiO

2 crystallites were grown in the [101] direction. Moreover, the (101) lattice plane grew perpendicular to the film growth direction, leading to a (101)-textured microstructure. As the (101) plane of TiO

2 is thermodynamically stable because of its lower surface free energy than those of other planes [

28], the adatoms on the (101) crystalline plane diffuse faster, resulting in the growth of grains with (101) orientation. These results are consistent with the XRD results of the TiO

2 films.

3.4. UV/NIR-Shielding Double-Sided Coatings

To obtain a better UV-shielding rate and wide-range NIR-shielding ability of the coatings; thus, UV/NIR-shielding double-sided coatings were fabricated. These double-sided UV/NIR coatings consist of quarter-wave stacks of SiO

2/TiO

2 multilayers and ITO films with different thicknesses (200–600 nm) on different side of glass.

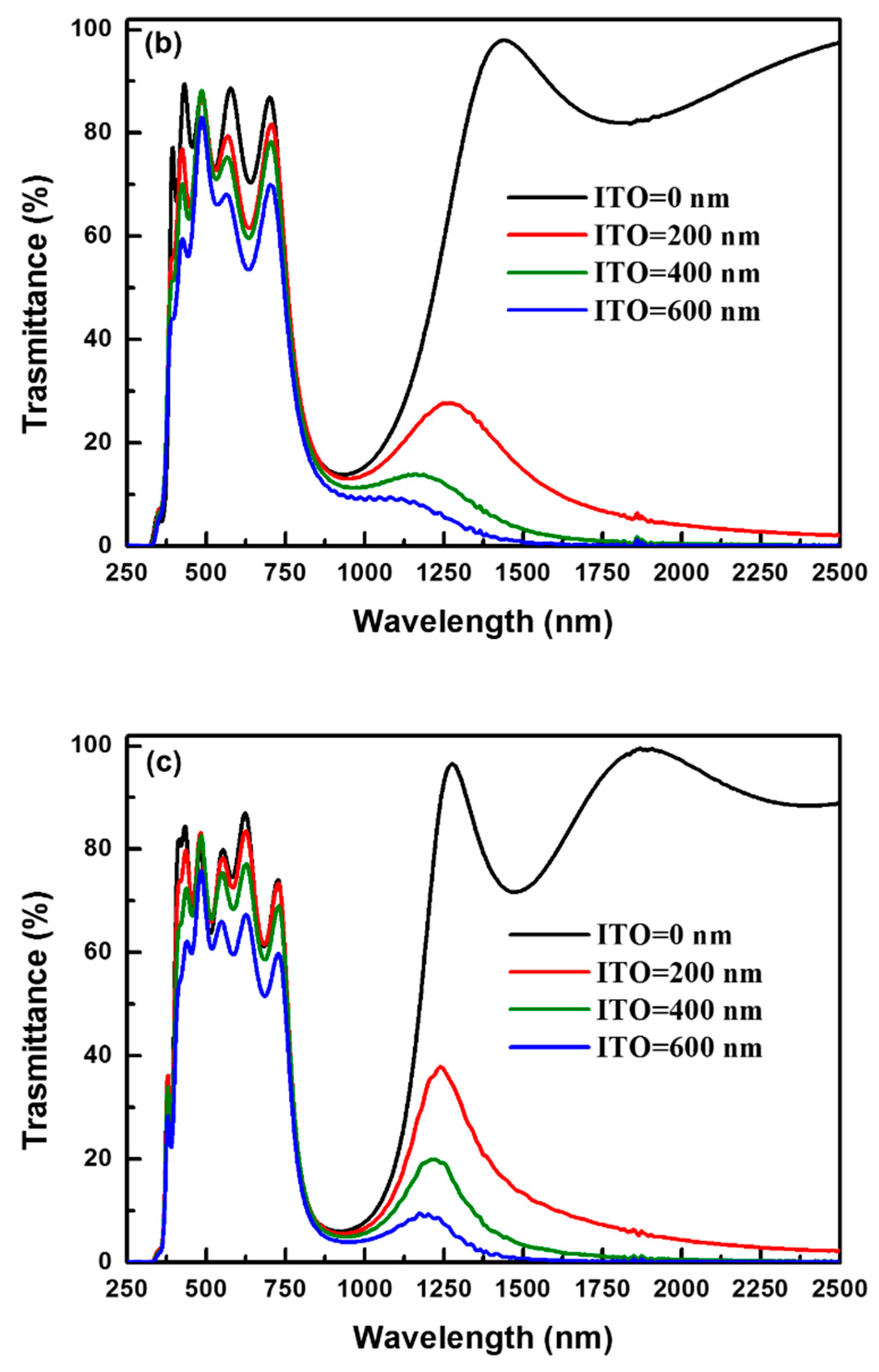

Figure 9 shows the transmittance spectra of the different optical structures, viz., (I) TiO

2(SiO

2/TiO

2), (II) TiO

2(SiO

2/TiO

2)

2, and (III) TiO

2(SiO

2/TiO

2)

3 with different ITO film thicknesses (0–600 nm).

Table 3 summarizes the key parameters used in the evaluation of the performance and characteristics of the different designs with various ITO film thicknesses in the range of 0 to 600 nm. That is, the average UV transmittance in the range of UVB to UVA (

TUVB~UVA), average visible light transmittance (

TVIS), average IRA transmittance (

TIRA), average IRB transmittance (

TIRB), average NIR (wavelength: 760–2500 nm) transmittance (

TNIR), UVB to UVA-shielding rate (

SUVB~UVA = 100% −

TUVB~UVA), NIR-shielding rate (

SNIR = 100% −

TNIR), figure of merit (

SUVB~UVA ×

TVIS ×

SNIR), and transparent thermal insulation index (

K) of the SiO

2/TiO

2 multilayers of designs (I), (II), and (III) are compared. In the evaluation of a coating, the UV-shielding properties in the UVB to UVA range, visible light transmittance, and NIR-shielding ability should be taken into consideration; therefore, the product of

SUVB~

UVA,

TVIS, and

SNIR (

SUVB~

UVA ×

TVIS ×

SNIR) is defined as the figure of merit (FOM). A larger FOM value indicates both a better transparency in visible light and a better UV/NIR-shielding performance. The

TUVB~UVA value not only decreased with increasing in the number of SiO

2/TiO

2 pairs, but also with an increase in the ITO film thickness. The enhancement of the UV-shielding properties is due to the band-to-band absorptions of the anatase TiO

2 and ITO films. Therefore, the TiO

2(SiO

2/TiO

2)

3 multilayer coating with different ITO film thicknesses (0–600 nm) exhibited

SUVB~UVA values of >90%.

The

TVIS values of all the optical designs decreased with the increase in the ITO film thickness from 0 to 600 nm. This decrease in the visible light absorption may be attributed to the s

2 → sp bonding transition of Sn

2+ [

33]. The

SNIR of the UV/NIR-shielding films increased with increasing ITO film thickness. The IRB radiation was almost completely shielded (i.e.,

TIRB ≤ 1%) at the ITO film thickness of >400 nm. This is because ITO has high-density free carriers, resulting in plasmon resonance absorption in the IR range. Therefore, the ITO thickness should be restricted to achieve a balance between the transparency in visible light and NIR- and UV-shielding rate. All the structures with an ITO thickness of 400 nm showed a high NIR-shielding rate (

SNIR > 92%) and a high

TVIS value (>68%). The three types of the optical designs combined with the 400 nm ITO film yielded a higher FOM (

SUVB~UVA ×

TVIS ×

SNIR) of >0.58, which indicates their better transparency and UV/NIR-shielding properties over other UV/NIR-shielding coatings with ITO film thicknesses of 200 and 600 nm. Among the metal-free double-side shielding coatings, 400 nm thick ITO films combined with TiO

2(SiO

2/TiO

2)

3 multilayers with the optical structure of (III) yielded the highest figure of merit (0.60) the corresponding average visible light transmittance is 68.1%, near-infrared shielding rate is 94.8%, and UVB to UVA-range shielding rate is 92.7%.

To compare the transparent thermal insulation performance of the transparent UV/NIR-shielding films with recent studies of transparent IR-sheading materials, the transparent thermal insulation index was used. The transparent thermal insulation index (

K) is defined as the ratio of the average visible light transmittance (

TVIS) to the average NIR transmittance (

TNIR) [

48,

49], expressed as follows:

A higher

K value implies better performance and the

K values of the different coatings in this work are listed in

Table 3. In general, the typical

K values for Cs

xWO

3-based films with excellent transparent thermal insulation performance are in the range of 7–9 [

48,

49].

Table 3 summarizes the

K values of the UV/NIR-shielding coatings prepared in this study. The

K values of our UV/NIR-shielding coatings not only increased with the increase in the ITO film thickness from 0 to 600 nm, but also with an increase in the number of SiO

2/TiO

2 pairs. The high-performance transparent thermal insulation coatings of different optical structures with a

K value of >9.43 could be obtained using an ITO film thickness of >400 nm. Among the prepared oxide-based shielding coatings, 600 nm thick ITO films combined with the TiO

2(SiO

2/TiO

2)

3 multilayers (optical design (III)) yielded the highest

K value (20.98), which is better than those of the Pt-doped Cs

xWO

3 nanorods (

K = 8.79) [

48] and two-dimensional nano-Cs

xWO

3 films (

K = 7.1) [

49]. According to the

K value analysis, it can be concluded that the UV/NIR-shielding coatings developed in this study have excellent thermal insulation performance, and can be prepared at a low deposition temperature of <150 °C. The excellent transparent thermal insulation performance of the UV/NIR-shielding coatings along with high visible transparency and NIR-shielding performance renders them suitable to be applied as energy-saving window coatings in buildings and automobiles.

3.5. Effects of UVB/IR Radiations on Human Skin Cells (Human Dermal Fibroblasts)

Photoaging is the most crucial factor on causing skin aging damage. The light-induced ROS generation elicits inflammatory cytokines releasing, DNA modification and oxidative damage. Previous study has revealed that UVB-induced skin is damaged by the excess of ROS generation in human dermal fibroblasts [

50]. NIR radiation induced cellular senescence in human keratinocyte, which resulted in premature skin aging [

51]. Moreover, the IR radiation reduces the amount of the endogenous antioxidant enzyme catalase and superoxide dismutase, leading to the deterioration of the antioxidant defense capability against oxidative stress [

52]. The effect of the UVB or IR or UVB/IR radiation on the ROS generation was therefore examined. Human dermal fibroblast cell line CCD-966SK cells were exposed to UVB or IR or UVB/IR, and intracellular ROS levels were determined DCF fluorescence using flow cytometry. As shown in

Figure 10a, a 2.48-fold increase in the ROS generation was noted when the human dermal fibroblasts were exposed to UVB radiation. No significant change in the ROS generation was observed with IR-irradiated cells. The mean intensity following the H

2DCFDA staining was significantly higher in the UVB/IR-irradiated cells than in the UVB-irradiated cells, consistent with increased ROS generation in the UVB/IR-irradiated cells (4.22-fold increase), suggesting that the increased production of ROS in the UVB/IR-exposed human fibroblasts is related to the IR irradiation-induced decrease in the antioxidant defense capability of the skin. Previous studies have revealed that increased oxidative stress in the skin leads to inflammatory responses, which involve the production of various inflammatory cytokines such as TNF-

α and IL-6 [

53]. Real-time PCR analyses revealed that the amounts of TNF-

α mRNA and IL-6 mRNA expressed in the UVB/IR-irradiated cells are higher than that in the UVB- or IR-irradiated cells (

Figure 10b), suggesting that the oxidative stress causes the increase in the expression of the inflammatory cytokines, TNF-

α and IL-6.

The metal-free UV/NIR-shielding coatings were also evaluated for their ability to protect human skin cells from UVB/IR through ROS generation and inflammatory cytokine (TNF-

α and IL-6) mRNA up-regulation in human dermal fibroblasts. We selected the structure with the highest figure of merit and K value, TiO

2(SiO

2/TiO

2)

3 multilayers combined with the 600 nm ITO film, to study the influence of the UVB/IR-shielding coating on the dermal fibroblasts. As shown in

Figure 10a, the ROS generation of the fibroblasts protected by the UV/NIR-shielding film was lower than that of the unshielded UVB/IR-exposed fibroblasts. This result suggested that the UV/NIR-shielding film significantly decreased the UV/IR transmittance, thereby decreasing the deleterious effects of the UVB/IR radiation through ROS generation. Moreover, these cells displayed TNF-

α and IL-6 mRNA up-regulation after a 24 h exposure to UV/IR irradiation. However, when protected with the UV and NIR-shielding film, they exhibited reduced expression of the UVB/IR-induced inflammatory cytokines (

Figure 10b). These data demonstrate that the metal-free UV/NIR-shielding coatings effectively suppressed the UVB/IR-induced ROS generation and inflammatory responses in a human dermal fibroblast cell line. Thus, this work provides practical applications of metal-free high-performance UV/NIR-shielding coatings for human skin protection.