A Novel Highly Durable Carbon/Silver/Silver Chloride Composite Electrode for High-Definition Transcranial Direct Current Stimulation

Abstract

:1. Introduction

2. Materials and Method

2.1. Chemicals and Materials

2.2. Preparation of C/Ag/AgCl Electrodes

2.3. Optimization of the Preparation of C/Ag/AgCl

2.4. Material Characterization

2.5. Electrochemical Measurements

2.6. Simulated tDCS Measurement

2.7. Preliminary Investigation of Skin Tolerance

3. Results and Discussions

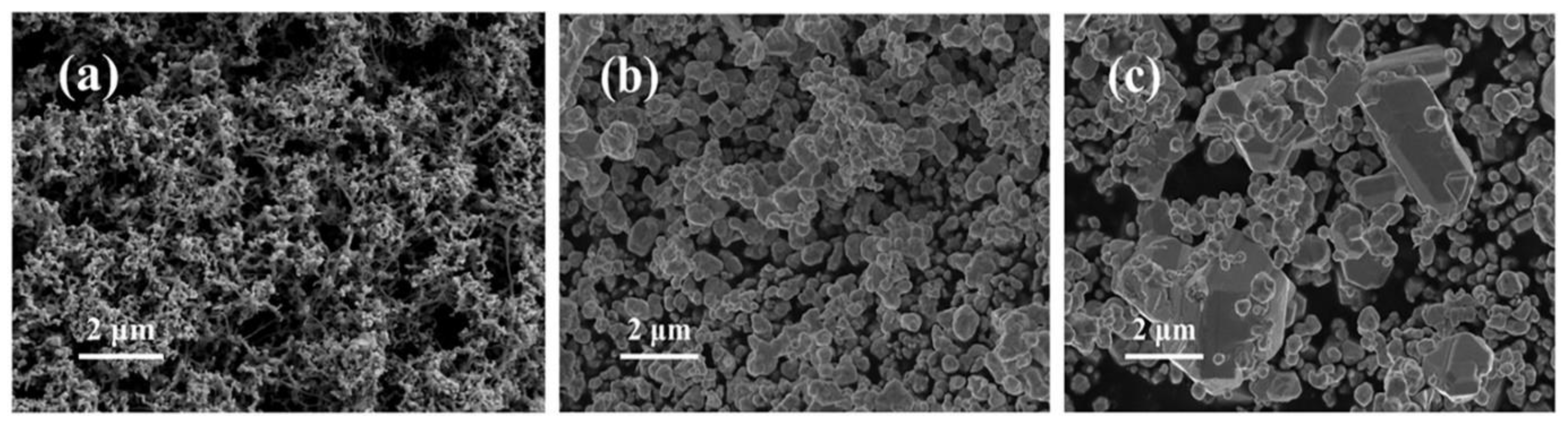

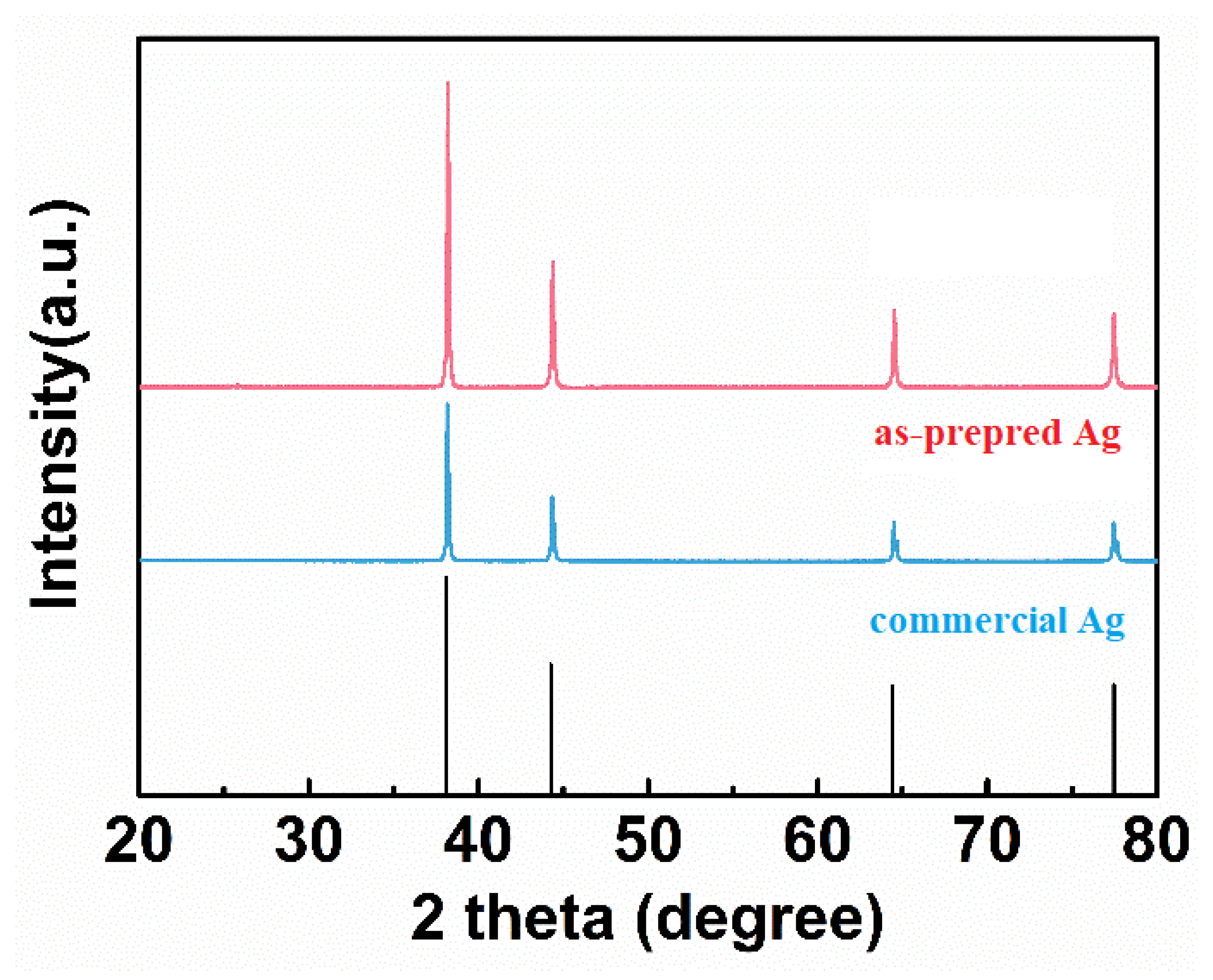

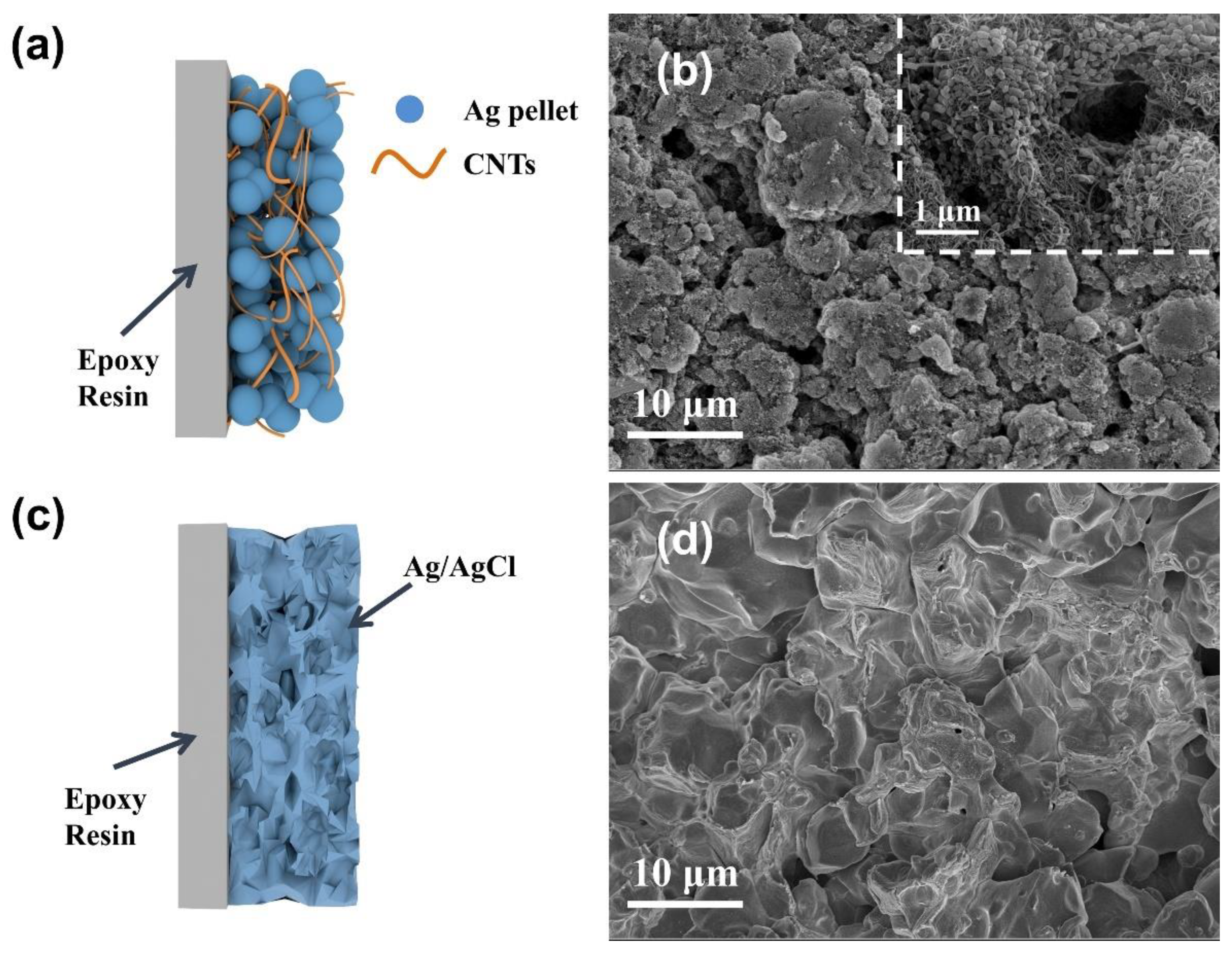

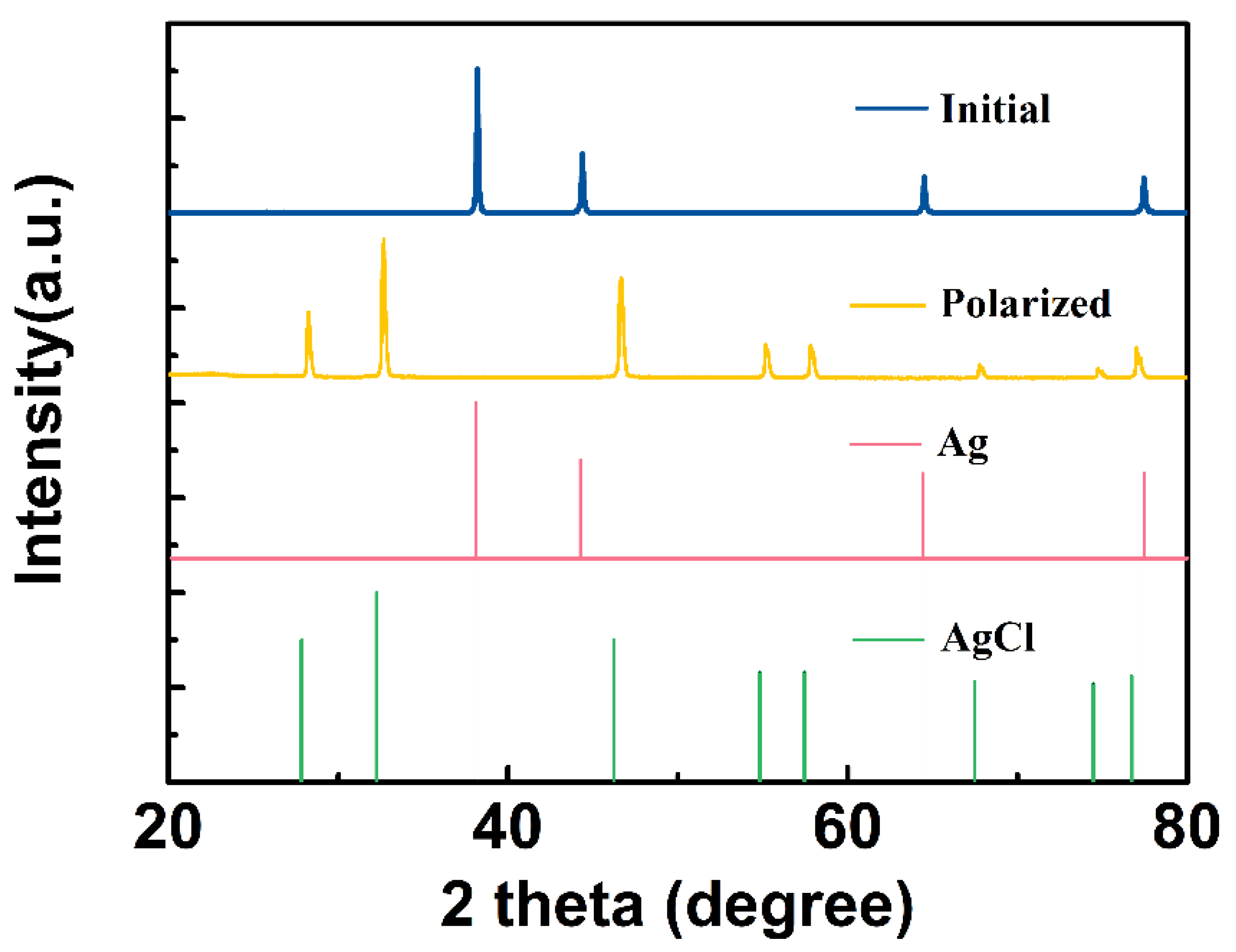

3.1. Physical Characterization of Ag Powders

3.2. Optimization of Preparation of C/Ag/AgCl Electrodes

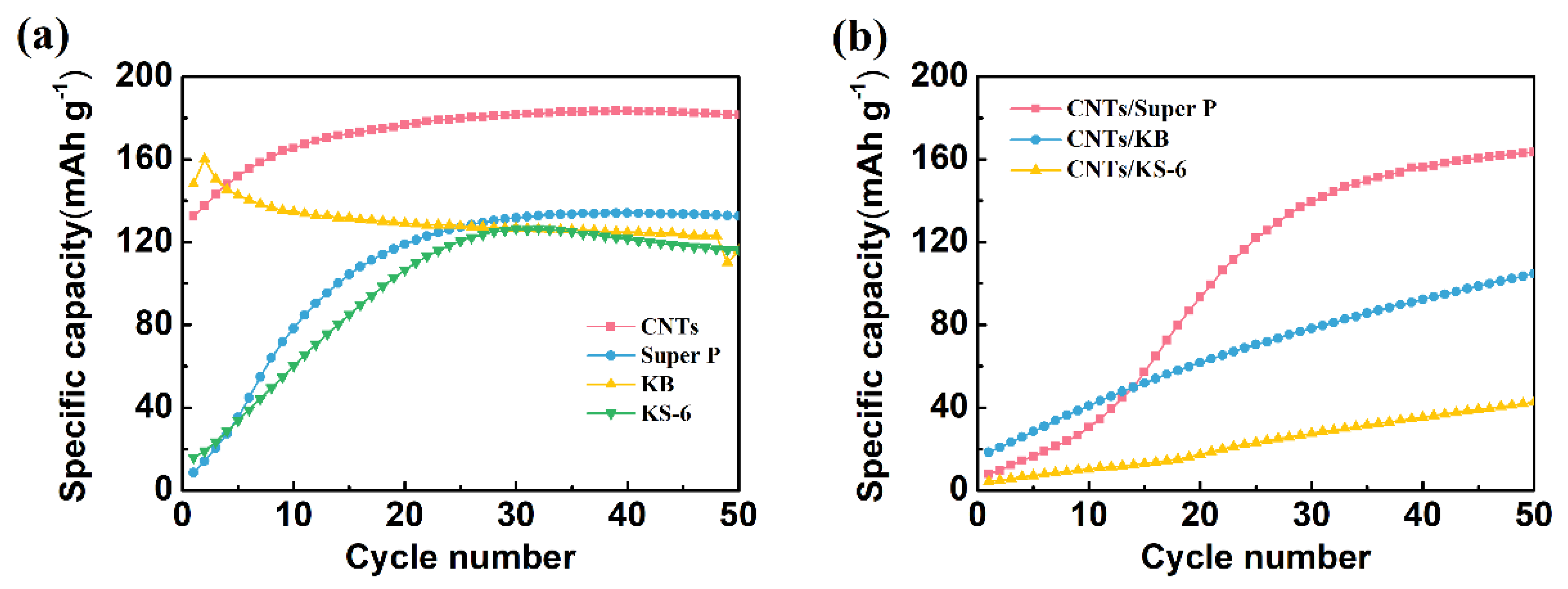

3.2.1. Optimization of Conductive Enhancer

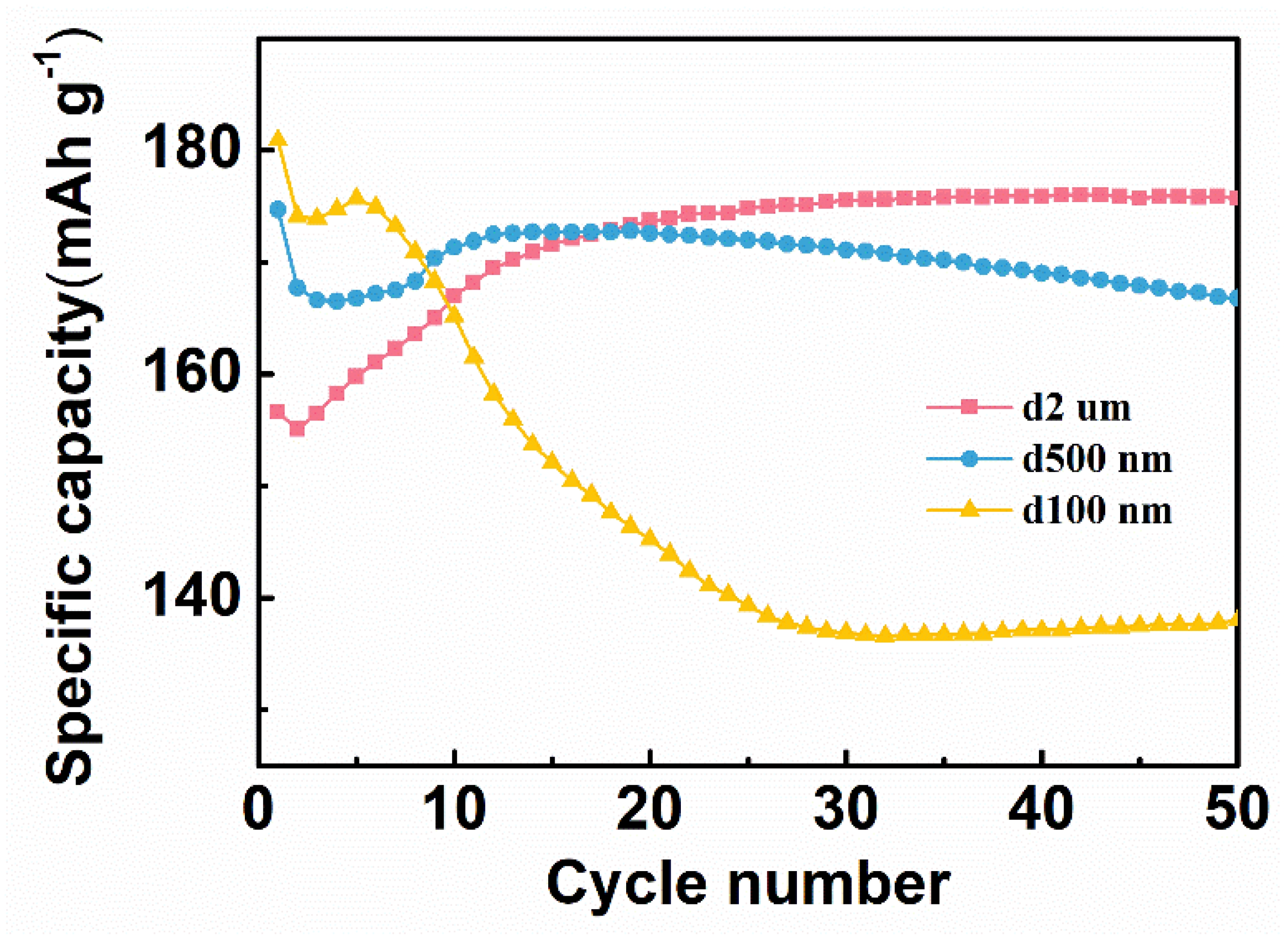

3.2.2. Optimization of Particle Size of Ag Powders

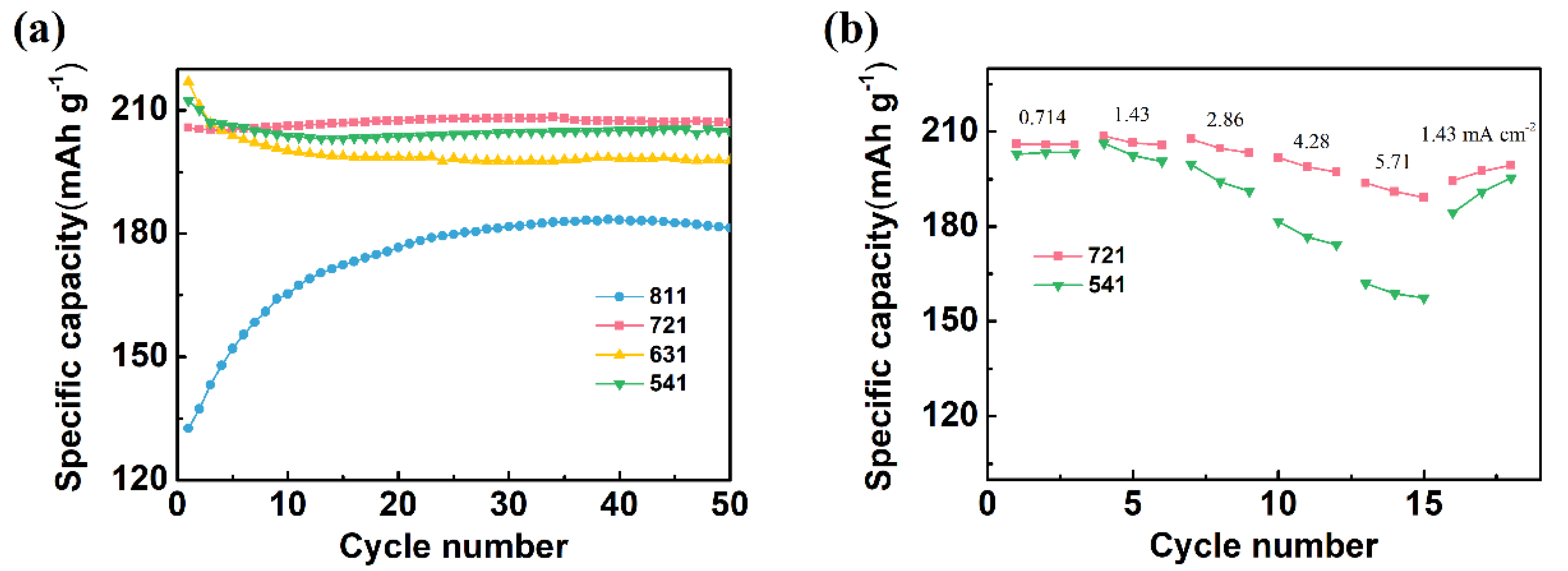

3.2.3. Optimization of C:Ag:PTFE Ratio

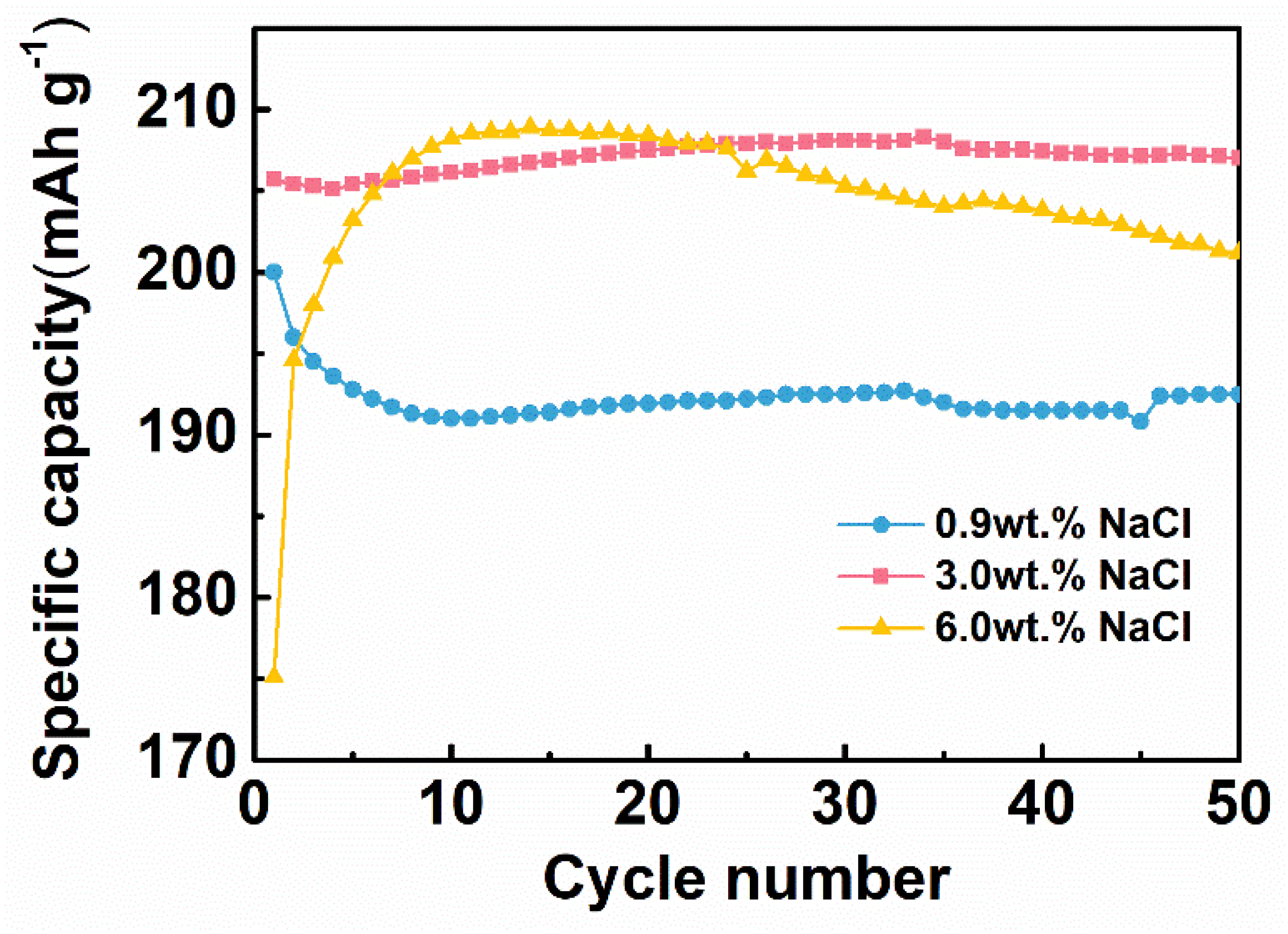

3.2.4. Optimization of Saline Concentration

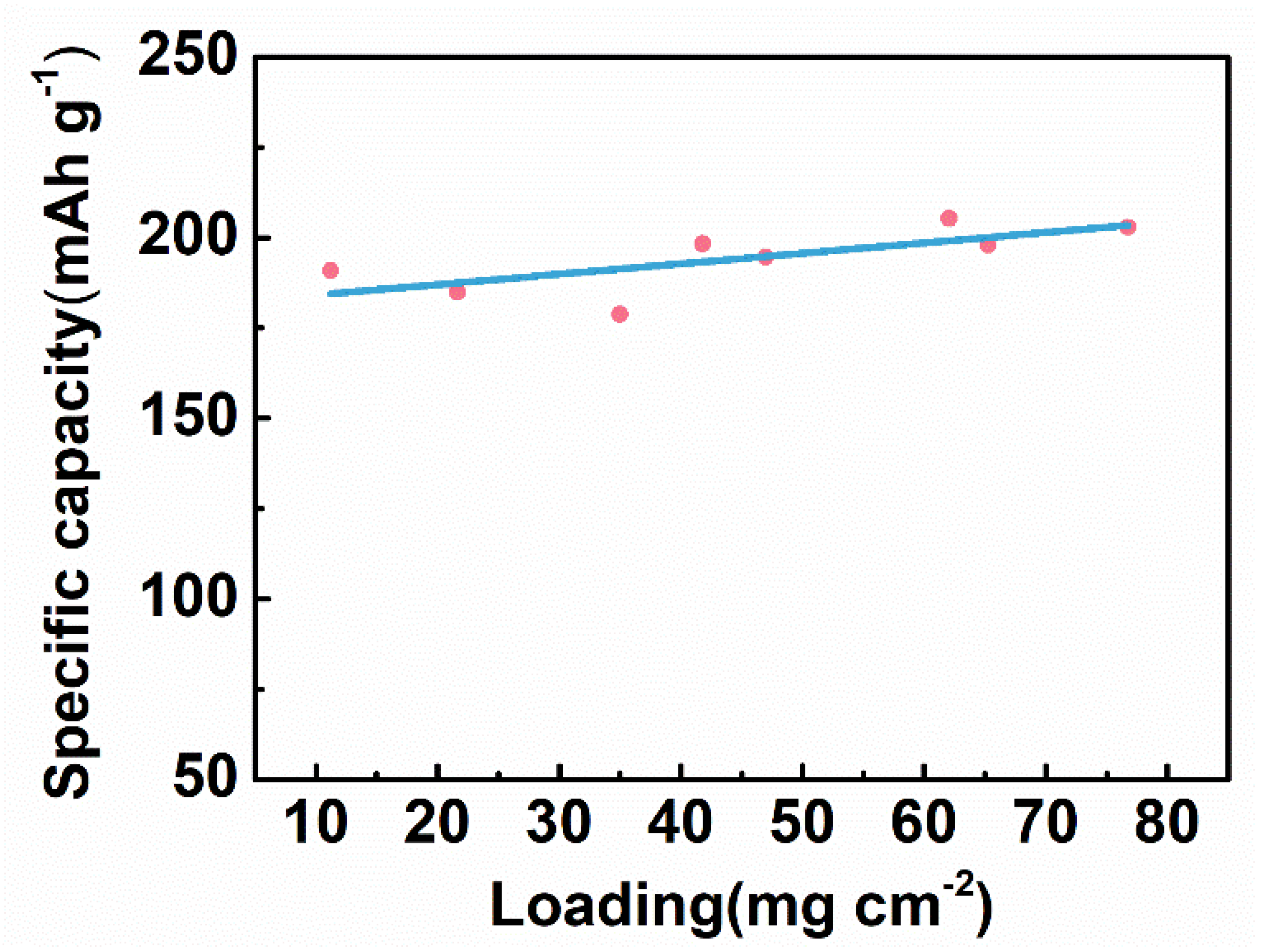

3.2.5. Optimization of Active Substance Loading

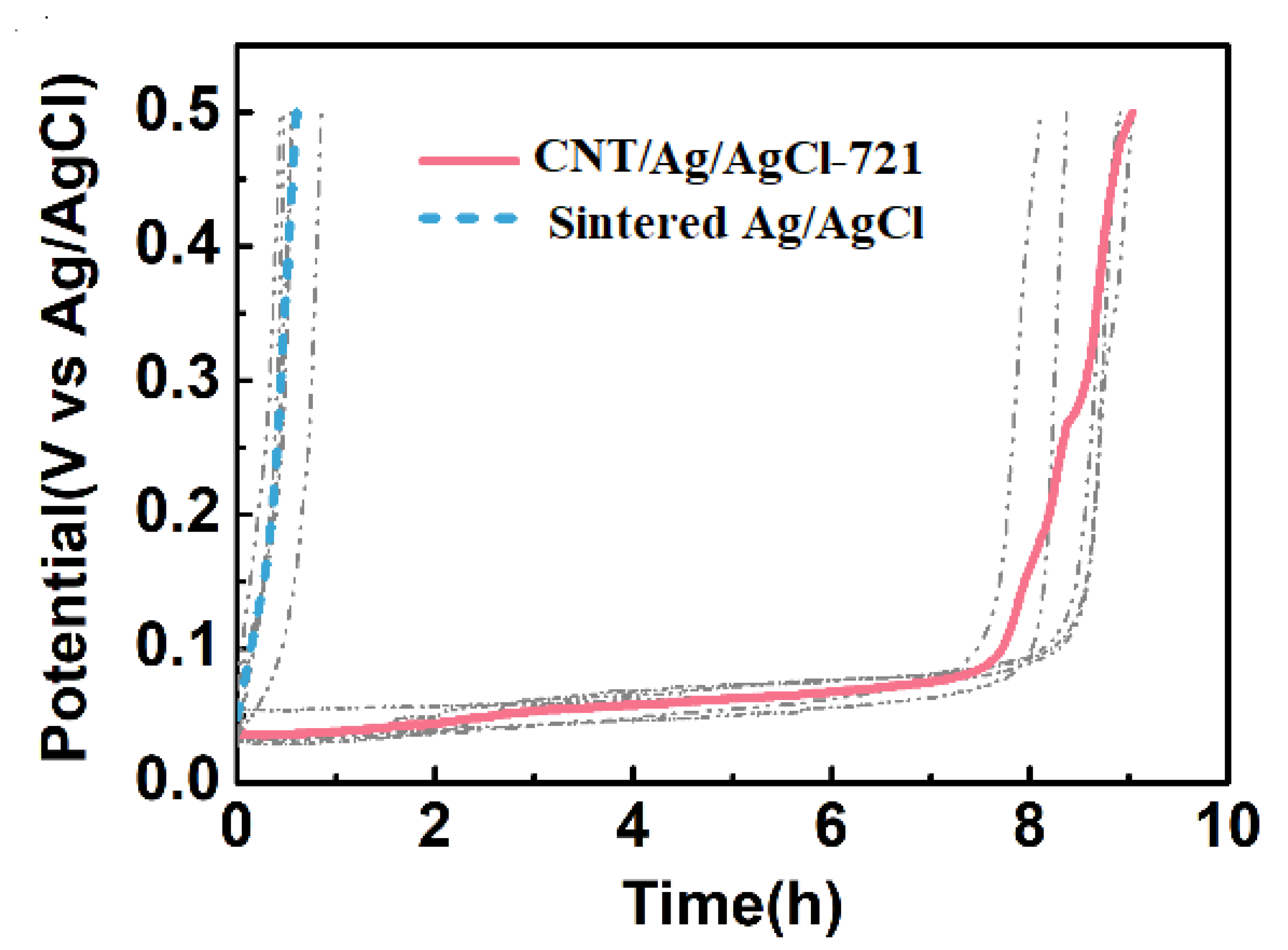

3.3. Constant Current Anodic Polarization

3.4. Simulated tDCS Measurement

3.5. Preliminary Evaluation of Skin Tolerance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liebetanz, D.; Nitsche, M.A.; Tergau, F.; Paulus, W. Pharmacological approach to the mechanisms of transcranial DC-stimulation-induced after-effects of human motor cortex excitability. Brain 2002, 125, 2238–2247. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nitsche, M.A.; Liebetanz, D.; Tergau, F.; Paulus, W. Modulation of cortical excitability by transcranial direct current stimulation. Nervenarzt 2002, 73, 332–335. [Google Scholar] [CrossRef]

- Zhao, H.; Qiao, L.; Fan, D.; Zhang, S.; Turel, O.; Li, Y.; Li, J.; Xue, G.; Chen, A.; He, Q. Modulation of brain activity with noninvasive transcranial direct current stimulation (tDCS): Clinical applications and safety concerns. Front. Psychol. 2017, 8, 00685. [Google Scholar] [CrossRef]

- Kiernan, M.C.; Bostock, H. Effects of membrane polarization and ischaemia on the excitability properties of human motor axons. Brain 2000, 123, 2542–2551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- VanHaerents, S.; Chang, B.S.; Rotenberg, A.; Pascual-Leone, A.; Shafi, M.M. Noninvasive Brain Stimulation in Epilepsy. J. Clin. Neurophysiol. 2020, 37, 118–130. [Google Scholar] [CrossRef] [PubMed]

- Auvichayapat, N.; Rotenberg, A.; Gersner, R.; Ngodklang, S.; Tiamkao, S.; Tassaneeyakul, W.; Auvichayapat, P. Transcranial Direct Current Stimulation for Treatment of Refractory Childhood Focal Epilepsy. Brain Stimul. 2013, 6, 696–700. [Google Scholar] [CrossRef] [PubMed]

- Han, C.-L.; Hu, W.; Stead, M.; Zhang, T.; Zhang, J.-G.; Worrell, G.A.; Meng, F.-G. Electrical stimulation of hippocampus for the treatment of refractory temporal lobe epilepsy. Brain Res. Bull. 2014, 109, 13–21. [Google Scholar] [CrossRef]

- Morrell, M.J. Responsive cortical stimulation for the treatment of medically intractable partial epilepsy. Neurology 2011, 77, 1295–1304. [Google Scholar] [CrossRef]

- Moffa, A.H.; Martin, D.; Alonzo, A.; Bennabi, D.; Blumberger, D.M.; Benseñor, I.M.; Daskalakis, Z.; Fregni, F.; Haffen, E.; Lisanby, S.H.; et al. Efficacy and acceptability of transcranial direct current stimulation (tDCS) for major depressive disorder: An individual patient data meta-analysis. Prog. NeuroPsychopharmacol. Biol. Psychiatry 2020, 99, 109836. [Google Scholar] [CrossRef]

- Bares, M.; Brunovsky, M.; Stopkova, P.; Hejzlar, M.; Novak, T. Transcranial Direct-Current Stimulation (tDCS) Versus Venlafaxine ER in The Treatment of Depression: A Randomized, Double-Blind, Single-Center Study with Open-Label, Follow-Up. Neuropsychiatr. Dis. Treat. 2019, 15, 3003–3014. [Google Scholar] [CrossRef] [Green Version]

- Orrù, G.; Conversano, C.; Hitchcott, P.K.; Gemignani, A. Motor stroke recovery after tDCS: A systematic review. Rev. Neurosci. 2020, 31, 201–218. [Google Scholar] [CrossRef] [PubMed]

- Shibata, T.; Urata, A.; Kawahara, K.; Furuya, K.; Ishikuro, K.; Hattori, N.; Kuroda, S. Therapeutic Effects of Diagonal-Transcranial Direct Current Stimulation on Functional Recovery in Acute Stroke: A Pilot Study. J. Stroke Cerebrovasc. Dis. 2020, 29, 105107. [Google Scholar] [CrossRef]

- da Silva, R.d.F.; Batistuzzo, M.C.; Shavitt, R.G.; Miguel, E.C.; Stern, E.; Mezger, E.; Padberg, F.; D’Urso, G.; Brunoni, A.R. Transcranial direct current stimulation in obsessive-compulsive disorder: An update in electric field modeling and investigations for optimal electrode montage. Expert Rev. Neurother. 2019, 19, 1025–1035. [Google Scholar] [CrossRef]

- Horiba, M.; Ueki, Y.; Nojima, I.; Shimizu, Y.; Sahashi, K.; Itamoto, S.; Suzuki, A.; Yamada, G.; Matsukawa, N.; Wada, I. Impaired Motor Skill Acquisition Using Mirror Visual Feedback Improved by Transcranial Direct Current Stimulation (tDCS) in Patients with Parkinson’s Disease. Front. Neurosci. 2019, 13, 602. [Google Scholar] [CrossRef]

- Bystad, M.; Rasmussen, I.D.; Grønli, O.; Aslaksen, P. Can 8 months of daily tDCS application slow the cognitive decline in Alzheimer’s disease? A case study. Neurocase 2017, 23, 146–148. [Google Scholar] [CrossRef]

- Castillo-Saavedra, L.; Gebodh, N.; Bikson, M.; Diaz-Cruz, C.; Brandao, R.; Coutinho, L.; Truong, D.; Datta, A.; Shani-Hershkovich, R.; Weiss, M.; et al. Clinically Effective Treatment of Fibromyalgia Pain with High-Definition Transcranial Direct Current Stimulation: Phase II Open-Label Dose Optimization. J. Pain 2016, 17, 14–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- DaSilva, A.F.; Truong, D.Q.; DosSantos, M.; Toback, R.L.; Datta, A.; Bikson, M. State-of-art neuroanatomical target analysis of high-definition and conventional tDCS montages used for migraine and pain control. Front. Neuroanat. 2015, 9, 89. [Google Scholar] [CrossRef] [Green Version]

- Khedr, E.M.; Gamal, N.F.E.; El-Fetoh, N.A.; Khalifa, H.; Ahmed, E.M.; Ali, A.M.; Noaman, M.; El-Baki, A.A.; Karim, A.A. A double-blind randomized clinical trial on the efficacy of cortical direct current stimulation for the treatment of Alzheimer’s disease. Front. Aging Neurosci. 2014, 6, 275. [Google Scholar] [CrossRef] [PubMed]

- Sheltraw, D.J.; Inglis, B.; Labruna, L.; Ivry, R. Comparing the electric fields of transcranial electric and magnetic perturbation. J. Neural Eng. 2021, 18, 046067. [Google Scholar] [CrossRef]

- Antal, A.; Alekseichuk, I.; Bikson, M.; Brockmöller, J.; Brunoni, A.R.; Chen, R.; Cohen, L.; Dowthwaite, G.; Ellrich, J.; Flöel, A.; et al. Low intensity transcranial electric stimulation: Safety, ethical, legal regulatory and application guidelines. Clin. Neurophysiol. 2017, 128, 1774–1809. [Google Scholar] [CrossRef] [Green Version]

- Bikson, M.; Grossman, P.; Thomas, C.; Zannou, A.L.; Jiang, J.; Adnan, T.; Mourdoukoutas, A.P.; Kronberg, G.; Truong, D.; Boggio, P.; et al. Safety of Transcranial Direct Current Stimulation: Evidence Based Update 2016. Brain Stimul. 2016, 9, 641–661. [Google Scholar] [CrossRef] [Green Version]

- Aparício, L.V.; Guarienti, F.; Razza, L.B.; Carvalho, A.F.; Fregni, F.; Brunoni, A.R. A Systematic Review on the Acceptability and Tolerability of Transcranial Direct Current Stimulation Treatment in Neuropsychiatry Trials. Brain Stimul. 2016, 9, 671–681. [Google Scholar] [CrossRef]

- Woods, A.; Antal, A.; Bikson, M.; Boggio, P.; Brunoni, A.R.; Celnik, P.; Cohen, L.; Fregni, F.; Herrmann, C.; Kappenman, E.; et al. A technical guide to tDCS, and related non-invasive brain stimulation tools. Clin. Neurophysiol. 2016, 127, 1031–1048. [Google Scholar] [CrossRef] [Green Version]

- Charvet, L.E.; Shaw, M.T.; Bikson, M.; Woods, A.J.; Knotkova, H. Supervised transcranial direct current stimulation (tDCS) at home: A guide for clinical research and practice. Brain Stimul. 2020, 13, 686–693. [Google Scholar] [CrossRef] [Green Version]

- Shaw, M.; Pilloni, G.; Charvet, L. Delivering Transcranial Direct Current Stimulation Away from Clinic: Remotely Supervised tDCS. Mil. Med. 2020, 185, 319–325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pilloni, G.; Shaw, M.; Feinberg, C.; Clayton, A.; Palmeri, M.; Datta, A.; Charvet, L.E. Long term at-home treatment with transcranial direct current stimulation (tDCS) improves symptoms of cerebellar ataxia: A case report. J. NeuroEng. Rehabil. 2019, 16, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clayton, A.M.; Howard, J.; Dobbs, B.; Shaw, M.T.; Charvet, L.E. Remotely supervised transcranial direct current stimulation after ECT improves mood and cognition in a patient with multiple sclerosis: A case study. J. ECT 2018, 34, e15. [Google Scholar] [CrossRef] [PubMed]

- Masina, F.; Arcara, G.; Galletti, E.; Cinque, I.; Gamberini, L.; Mapelli, D. Neurophysiological and behavioural effects of conventional and high definition tDCS. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef] [PubMed]

- DaSilva, A.F.; Volz, M.S.; Bikson, M.; Fregni, F. Electrode Positioning and Montage in Transcranial Direct Current Stimulation. J. Vis. Exp. 2011, 51, e2744. [Google Scholar] [CrossRef] [Green Version]

- Solomons, C.D.; Shanmugasundaram, V. Transcranial direct current stimulation: A review of electrode characteristics and materials. Med. Eng. Phys. 2020, 85, 63–74. [Google Scholar] [CrossRef]

- Villamar, M.F.; Volz, M.S.; Bikson, M.; Datta, A.; DaSilva, A.F.; Fregni, F. Technique and considerations in the use of 4 × 1 ring high-definition transcranial direct current stimulation (HD-tDCS). J. Vis. Exp. 2013, 77, e50309. [Google Scholar] [CrossRef]

- Merrill, D.R.; Bikson, M.; Jefferys, J.G.R. Electrical stimulation of excitable tissue: Design of efficacious and safe protocols. J. Neurosci. Methods 2005, 141, 171–198. [Google Scholar] [CrossRef]

- Pellegrini, M.; Zoghi, M.; Jaberzadeh, S. The effects of transcranial direct current stimulation on corticospinal and cortico-cortical excitability and response variability: Conventional versus high-definition montages. Neurosci. Res. 2021, 166, 12–25. [Google Scholar] [CrossRef]

- To, W.T.; Hart, J.; De Ridder, D.; Vanneste, S. Considering the influence of stimulation parameters on the effect of conventional and high-definition transcranial direct current stimulation. Expert Rev. Med. Devices 2016, 13, 391–404. [Google Scholar] [CrossRef]

- Kuo, H.-I.; Bikson, M.; Datta, A.; Minhas, P.; Paulus, W.; Kuo, M.-F.; Nitsche, M.A. Comparing Cortical Plasticity Induced by Conventional and High-Definition 4 × 1 Ring tDCS: A Neurophysiological Study. Brain Stimul. 2013, 6, 644–648. [Google Scholar] [CrossRef] [PubMed]

- Edwards, D.; Cortes, M.; Datta, A.; Minhas, P.; Wassermann, E.M.; Bikson, M. Physiological and modeling evidence for focal transcranial electrical brain stimulation in humans: A basis for high-definition tDCS. NeuroImage 2013, 74, 266–275. [Google Scholar] [CrossRef] [Green Version]

- Caparelli-Daquer, E.; Zimmermann, T.J.; Mooshagian, E.; Parra, L.C.; Rice, J.K.; Datta, A.; Bikson, M.; Wassermann, E.M. A pilot study on effects of 4 × 1 High-Definition tDCS on motor cortex excitability. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012; pp. 735–738. [Google Scholar]

- Datta, A.; Bansal, V.; Diaz, J.; Patel, J.; Reato, D.; Bikson, M. Gyri-precise head model of transcranial direct current stimulation: Improved spatial focality using a ring electrode versus conventional rectangular pad. Brain Stimul. 2009, 2, 201–207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Villamar, M.F.; Wivatvongvana, P.; Patumanond, J.; Bikson, M.; Truong, D.Q.; Datta, A.; Fregni, F. Focal modulation of the primary motor cortex in fibromyalgia using 4 × 1-ring high-definition transcranial direct current stimulation (HD-tDCS): Immediate and delayed analgesic effects of cathodal and anodal stimulation. J. Pain 2013, 14, 371–383. [Google Scholar] [CrossRef]

- Tallgren, P.; Vanhatalo, S.; Kaila, K.; Voipio, J. Evaluation of commercially available electrodes and gels for recording of slow EEG potentials. Clin. Neurophysiol. 2005, 116, 799–806. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wu, J.; Xia, Y.; Wu, Y.; Tian, Y.; Liu, J.; Chen, D.; He, Q. Towards emerging EEG applications: A novel printable flexible Ag/AgCl dry electrode array for robust recording EEG signals at forehead sites. J. Neural Eng. 2020, 17, 026001. [Google Scholar] [CrossRef]

- Li, G.-L.; Wu, J.-T.; Xia, Y.-H.; He, Q.-G.; Jin, H.-G. Review of semi-dry electrodes for EEG recording. J. Neural Eng. 2020, 17, 051004. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Li, M.; Duan, Y.Y. Towards real-life EEG applications: Novel superporous hydrogel-based semi-dry EEG electrodes enabling automatically charge-discharge electrolyte. J. Neural Eng. 2021, 18, 046016. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Duan, Y.Y. Towards conductive-gel-free electrodes: Understanding the wet electrode, semi-dry electrode and dry electrode-skin interface impedance using electrochemical impedance spectroscopy fitting. Sens Actuators B Chem. 2018, 277, 250–260. [Google Scholar] [CrossRef]

- Minhas, P.; Bansal, V.; Patel, J.; Ho, J.S.; Diaz, J.; Datta, A.; Bikson, M. Electrodes for high-definition transcutaneous DC stimulation for applications in drug delivery and electrotherapy, including tDCS. J. Neurosci. Methods 2010, 190, 188–197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Langenbach, B.P.; Savic, B.; Baumgartner, T.; Knoch, D. Repeated anodal HD-tDCS stimulation might render silver chloride electrodes unreliable. Brain Stimul. 2020, 13, 525–526. [Google Scholar] [CrossRef]

- Hampstead, B.M.; Ehmann, M.; Rahman-Filipiak, A. Reliable use of silver chloride HD-tDCS electrodes. Brain Stimul. 2020, 13, 1005–1007. [Google Scholar] [CrossRef] [PubMed]

- Nitsche, M.A.; Liebetanz, D.; Lang, N.; Antal, A.; Tergau, F.; Paulus, W. Safety criteria for transcranial direct current stimulation (tDCS) in humans. Clin. Neurophysiol. 2003, 114, 2220–2222. [Google Scholar] [CrossRef]

- Gandiga, P.C.; Hummel, F.C.; Cohen, L.G. Transcranial DC stimulation (tDCS): A tool for double-blind sham-controlled clinical studies in brain stimulation. Clin. Neurophysiol. 2006, 117, 845–850. [Google Scholar] [CrossRef]

- Chhatbar, P.Y.; Chen, R.; Deardorff, R.; Dellenbach, B.; Kautz, S.A.; George, M.S.; Feng, W. Safety and tolerability of transcranial direct current stimulation to stroke patients—A phase I current escalation study. Brain Stimul. 2017, 10, 553–559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poreisz, C.; Boros, K.; Antal, A.; Paulus, W. Safety aspects of transcranial direct current stimulation concerning healthy subjects and patients. Brain Res. Bull. 2007, 72, 208–214. [Google Scholar] [CrossRef]

- Maldonado, T.; Bernard, J.A. The polarity-specific nature of single-session high-definition transcranial direct current stimulation to the cerebellum and prefrontal cortex on motor and non-motor task performance. Cerebellum 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Jog, M.S.; Kim, E.; Anderson, C.; Kubicki, A.; Kayathi, R.; Jann, K.; Yan, L.; Leaver, A.; Hellemann, G.; Iacoboni, M.; et al. In-vivo imaging of targeting and modulation of depression-relevant circuitry by transcranial direct current stimulation: A randomized clinical trial. Transl. Psychiatry 2021, 11, 138. [Google Scholar] [CrossRef] [PubMed]

- Sasia, B.; Cacciamani, L. High-definition transcranial direct current stimulation of the lateral occipital cortex influences figure-ground perception. Neuropsychologia 2021, 155, 107792. [Google Scholar] [CrossRef] [PubMed]

| Optimized Parameters | Conductive Enhancer | Particle Size of Ag | Ag:C:PTFE Ratio | Saline Concentration | Active Substance Loading |

|---|---|---|---|---|---|

| Conductive enhancer | CNTs, KB, Super P, KS-6 | Commercial 2.0 μm | 8:1:1 | 3.0 wt.% | 39 mg cm−2 |

| Particle size of Ag | CNTs | 0.1, 0.5 and commercial 2.0 μm | 8:1:1 | 3.0 wt.% | 39 mg cm−2 |

| Ag:C:PTFE ratio | CNTs | Commercial 2.0 μm | 8:1:1,7:2:1, 6:3:1, 5:4:1 | 3.0 wt.% | 39 mg cm−2 |

| Saline concentration | CNTs | Commercial 2.0 μm | 7:2:1 | 0.9, 3.0 and 6.0 wt.% | 39 mg cm−2 |

| Active substance loading | CNTs | Commercial 2.0 μm | 7:2:1 | 3.0 wt.% | 10~80 mg cm−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, G.; Cao, Y.; Duan, Y.Y. A Novel Highly Durable Carbon/Silver/Silver Chloride Composite Electrode for High-Definition Transcranial Direct Current Stimulation. Nanomaterials 2021, 11, 1962. https://doi.org/10.3390/nano11081962

Li L, Li G, Cao Y, Duan YY. A Novel Highly Durable Carbon/Silver/Silver Chloride Composite Electrode for High-Definition Transcranial Direct Current Stimulation. Nanomaterials. 2021; 11(8):1962. https://doi.org/10.3390/nano11081962

Chicago/Turabian StyleLi, Lingjun, Guangli Li, Yuliang Cao, and Yvonne Yanwen Duan. 2021. "A Novel Highly Durable Carbon/Silver/Silver Chloride Composite Electrode for High-Definition Transcranial Direct Current Stimulation" Nanomaterials 11, no. 8: 1962. https://doi.org/10.3390/nano11081962

APA StyleLi, L., Li, G., Cao, Y., & Duan, Y. Y. (2021). A Novel Highly Durable Carbon/Silver/Silver Chloride Composite Electrode for High-Definition Transcranial Direct Current Stimulation. Nanomaterials, 11(8), 1962. https://doi.org/10.3390/nano11081962