Mesocrystals from Platinum Nanocubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

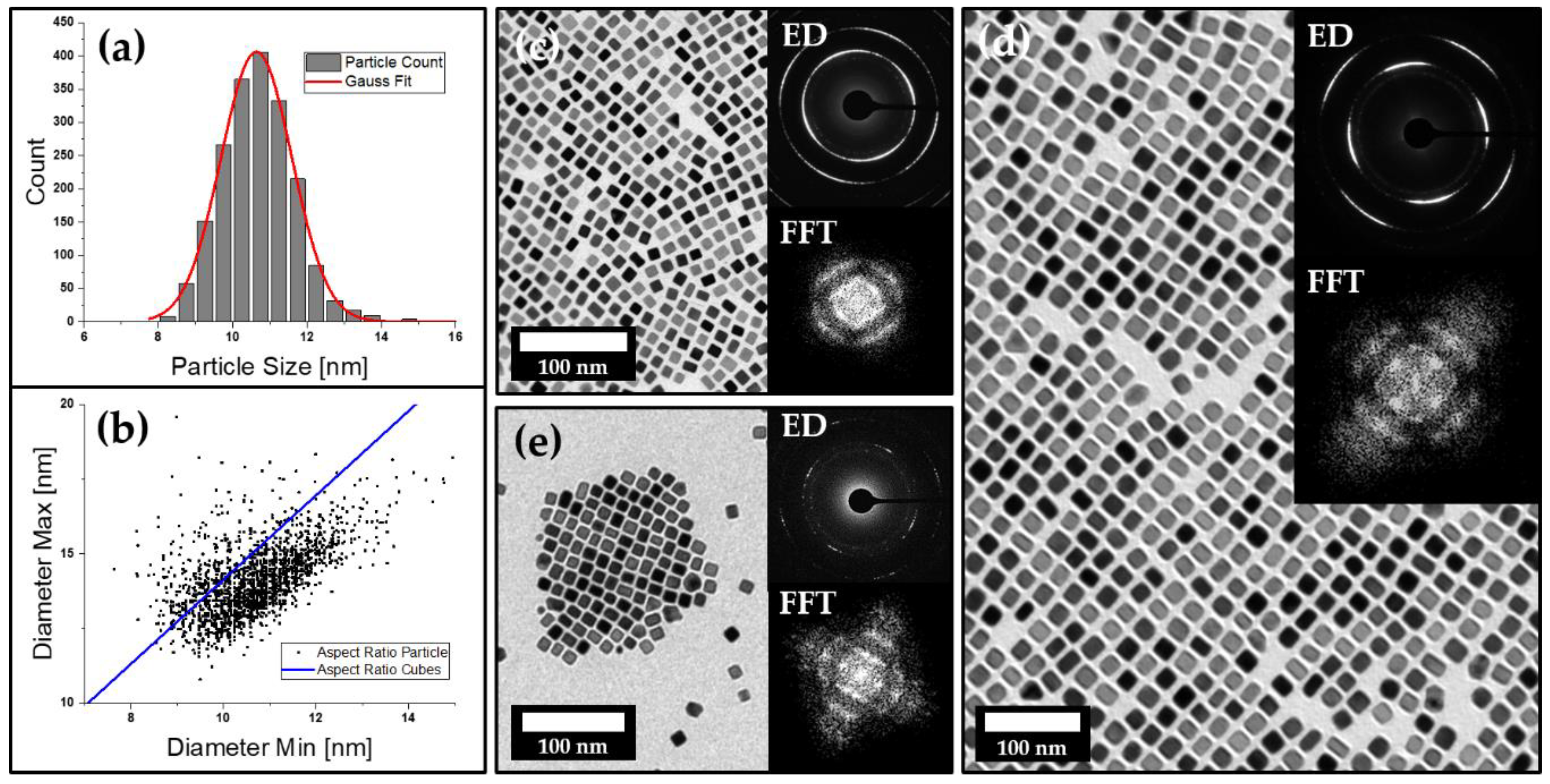

2.2. Platinum Nanocubes

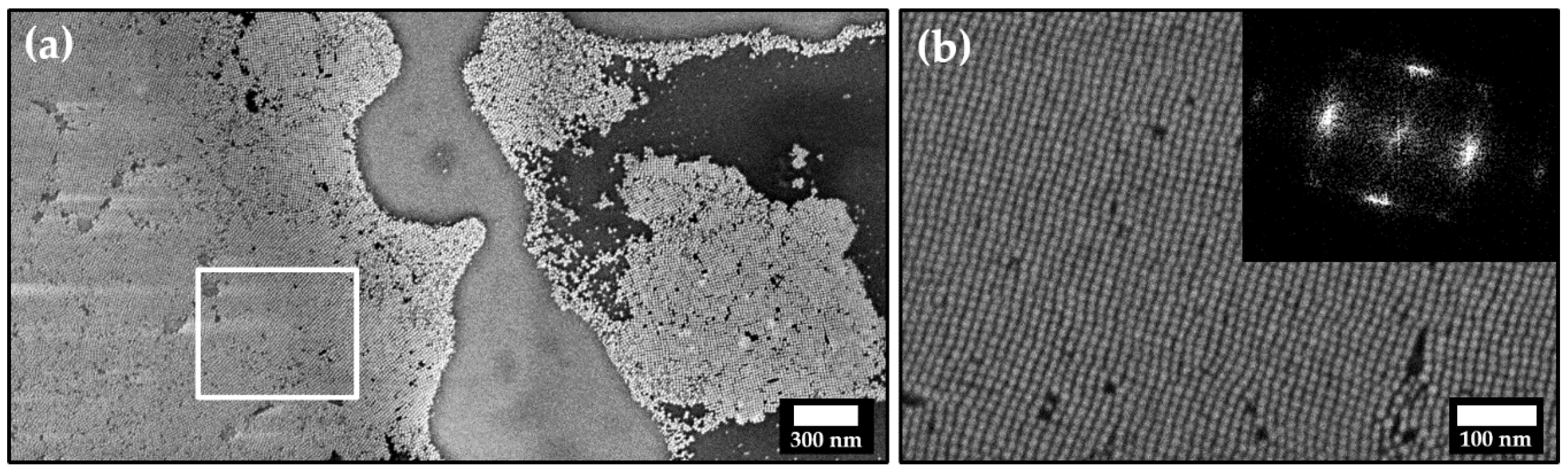

2.3. 2D Self-Assemblies

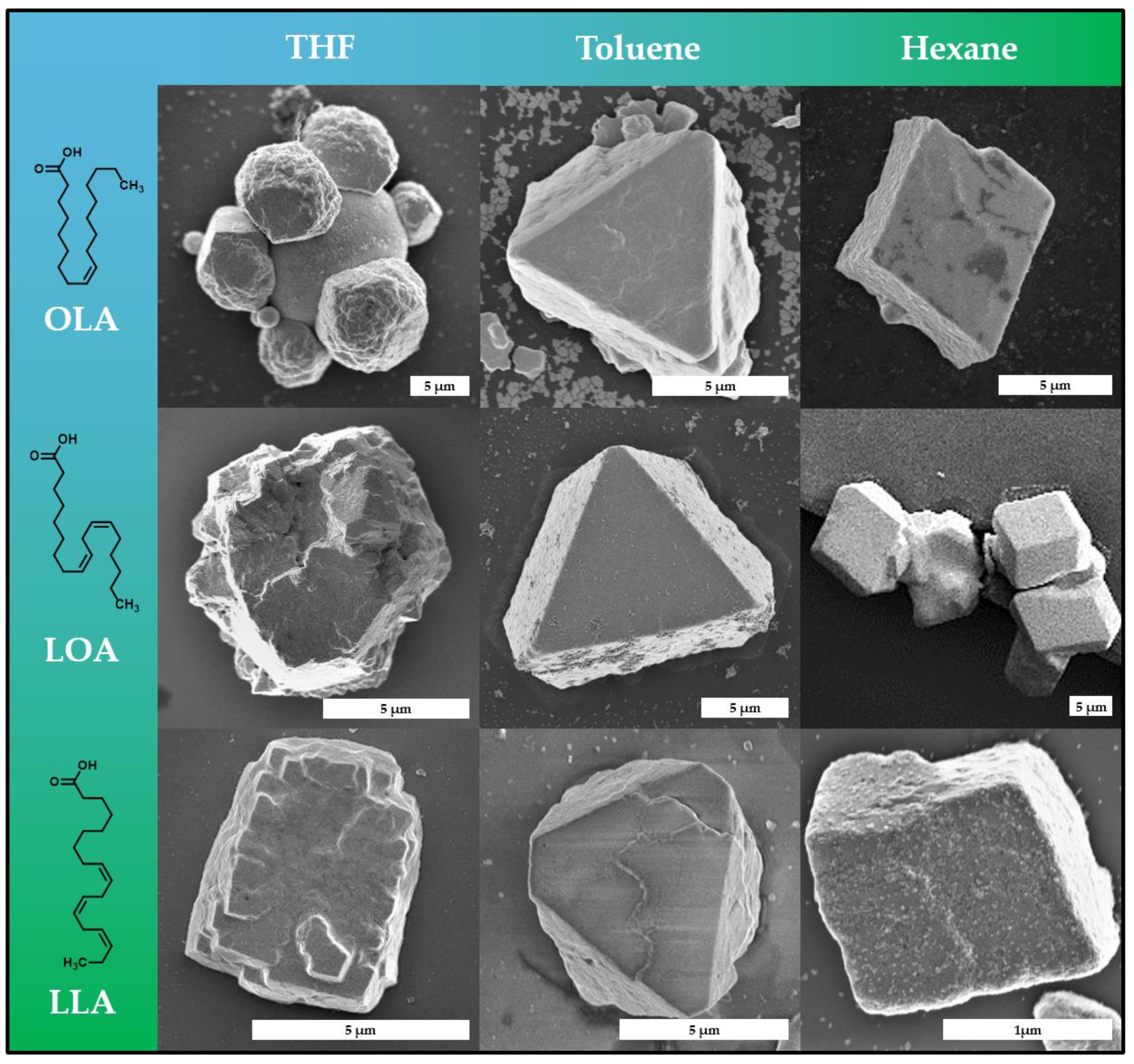

2.4. Mesocrystal Formation

2.5. Analytics

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quan, Z.; Fang, J. Superlattices with non-spherical building blocks. Nano Today 2010, 5, 390–411. [Google Scholar] [CrossRef]

- Vanmaekelbergh, D. Self-assembly of colloidal nanocrystals as route to novel classes of nanostructured materials. Nano Today 2011, 6, 419–437. [Google Scholar] [CrossRef]

- Talapin, D.V. Nanocrystal solids: A modular approach to materials design. MRS Bull. 2012, 37, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; LaMontagne, D.; Lynch, J.; Zhuang, J.; Cao, Y.C. Colloidal superparticles from nanoparticle assembly. Chem. Soc. Rev. 2013, 42, 2804–2823. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Regulacio, M.D.; Han, M.-Y. Self-assembly of colloidal one-dimensional nanocrystals. Chem. Soc. Rev. 2014, 43, 2301–2323. [Google Scholar] [CrossRef]

- Kovalenko, M.V.; Manna, L.; Cabot, A.; Hens, Z.; Talapin, D.V.; Kagan, C.R.; Klimov, V.I.; Rogach, A.L.; Reiss, P.; Milliron, D.J. Prospects of Nanoscience with Nanocrystals; ACS Publications: Washington, DC, USA, 2015. [Google Scholar]

- Cölfen, H.; Antonietti, M. Mesocrystals and Nonclassical Crystallization; Wiley: Chichester, UK; Hoboken, NJ, USA, 2008; 276p. [Google Scholar]

- Cölfen, H.; Antonietti, M. Mesocrystals: Inorganic superstructures made by highly parallel crystallization and controlled alignment. Angew. Chem. Int. Ed. 2005, 44, 5576–5591. [Google Scholar] [CrossRef] [Green Version]

- Jehannin, M.; Rao, A.; Cölfen, H. New horizons of nonclassical crystallization. J. Am. Chem. Soc. 2019, 141, 10120–10136. [Google Scholar] [CrossRef]

- Sturm, E.V.; Colfen, H. Mesocrystals: Past, Presence, Future. Crystals 2017, 7, 207. [Google Scholar] [CrossRef] [Green Version]

- Sturm, E.V.; Cölfen, H. Mesocrystals: Structural and morphogenetic aspects. Chem. Soc. Rev. 2016, 45, 5821–5833. [Google Scholar] [CrossRef] [Green Version]

- Bergström, L.; Sturm, E.V.; Salazar-Alvarez, G.; Cölfen, H. Mesocrystals in biominerals and colloidal arrays. Acc. Chem. Res. 2015, 48, 1391–1402. [Google Scholar] [CrossRef]

- Fang, J.; Ding, B.; Gleiter, H. Mesocrystals: Syntheses in metals and applications. Chem. Soc. Rev. 2011, 40, 5347–5360. [Google Scholar] [CrossRef] [PubMed]

- Imai, H.; Matsumoto, R.; Takasaki, M.; Tsukiyama, K.; Sawano, K.; Nakagawa, Y. Evaporation-driven manipulation of nanoscale brickwork structures for the design of 1D, 2D, and 3D microarrays of rectangular building blocks. Crystengcomm 2019, 21, 6905–6914. [Google Scholar] [CrossRef]

- Sawano, K.; Tsukiyama, K.; Shimizu, M.; Takasaki, M.; Oaki, Y.; Yamamoto, T.; Einaga, Y.; Jenewein, C.; Cölfen, H.; Kaiju, H. Enhancement of coercivity of self-assembled stacking of ferrimagnetic and antiferromagnetic nanocubes. Nanoscale 2020, 12, 7792–7796. [Google Scholar] [CrossRef]

- Tachikawa, T.; Majima, T. Metal oxide mesocrystals with tailored structures and properties for energy conversion and storage applications. NPG Asia Mater. 2014, 6, e100. [Google Scholar] [CrossRef]

- Uchaker, E.; Cao, G. Mesocrystals as electrode materials for lithium-ion batteries. Nano Today 2014, 9, 499–524. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, W.; Wang, Y.; Li, L.; Yao, F.; Miao, L.; Zhao, W.; Kong, X.; Feng, Q.; Hu, D. Formation mechanisms and electrical properties of perovskite mesocrystals. Ceram. Int. 2020, 47, 1479–1512. [Google Scholar] [CrossRef]

- Zhang, P.; Tachikawa, T.; Fujitsuka, M.; Majima, T. The development of functional mesocrystals for energy harvesting, storage, and conversion. Chem. A Eur. J. 2018, 24, 6295–6307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pileni, M. Self organization of inorganic nanocrystals: Unexpected chemical and physical properties. J. Colloid Interface Sci. 2012, 388, 1–8. [Google Scholar] [CrossRef]

- Crisp, R.W.; Pach, G.F.; Kurley, J.M.; France, R.M.; Reese, M.O.; Nanayakkara, S.U.; MacLeod, B.A.; Talapin, D.V.; Beard, M.C.; Luther, J.M. Tandem solar cells from solution-processed CdTe and PbS quantum dots using a ZnTe–ZnO tunnel junction. Nano Lett. 2017, 17, 1020–1027. [Google Scholar] [CrossRef]

- Kagan, C.R.; Lifshitz, E.; Sargent, E.H.; Talapin, D.V. Building devices from colloidal quantum dots. Science 2016, 353, 885. [Google Scholar] [CrossRef]

- Boles, M.A.; Engel, M.; Talapin, D.V. Self-assembly of colloidal nanocrystals: From intricate structures to functional materials. Chem. Rev. 2016, 116, 11220–11289. [Google Scholar] [CrossRef]

- Henzie, J.; Grünwald, M.; Widmer-Cooper, A.; Geissler, P.L.; Yang, P. Self-assembly of uniform polyhedral silver nanocrystals into densest packings and exotic superlattices. Nat. Mater. 2012, 11, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Petres, J.J.; Dezelic, G.; Tezak, B. Monodisperse Sols of Barium Sulfate.3. Electron-Microscopic Study of Internal Structure of Particles. Croat. Chem. Acta 1969, 41, 183. [Google Scholar]

- Hsu, W.P.; Ronnquist, L.; Matijevic, E. Preparation and Properties of Monodispersed Colloidal Particles of Lanthanide Compounds. 2. Cerium(Iv). Langmuir 1988, 4, 31–37. [Google Scholar] [CrossRef]

- Gross, B.; Philipp, S.; Josten, E.; Leliaert, J.; Wetterskog, E.; Bergström, L.; Poggio, M. Magnetic anisotropy of individual maghemite mesocrystals. Phys. Rev. B 2021, 103, 014402. [Google Scholar] [CrossRef]

- Niederberger, M.; Cölfen, H. Oriented attachment and mesocrystals: Non-classical crystallization mechanisms based on nanoparticle assembly. Phys. Chem. Chem. Phys. 2006, 8, 3271–3287. [Google Scholar] [CrossRef]

- De Yoreo, J.J.; Gilbert, P.U.; Sommerdijk, N.A.; Penn, R.L.; Whitelam, S.; Joester, D.; Zhang, H.; Rimer, J.D.; Navrotsky, A.; Banfield, J.F. Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science 2015, 349, aaa6760. [Google Scholar] [CrossRef]

- Wetterskog, E.; Agthe, M.; Mayence, A.; Grins, J.; Wang, D.; Rana, S.; Ahniyaz, A.; Salazar-Alvarez, G.; Bergstrom, L. Precise control over shape and size of iron oxide nanocrystals suitable for assembly into ordered particle arrays. Sci. Technol. Adv. Mater. 2014, 15, 055010. [Google Scholar] [CrossRef] [PubMed]

- Brunner, J.; Baburin, I.A.; Sturm, S.; Kvashnina, K.; Rossberg, A.; Pietsch, T.; Andreev, S.; Sturm, E.; Cölfen, H. Self-Assembled Magnetite Mesocrystalline Films: Toward Structural Evolution from 2D to 3D Superlattices. Adv. Mater. Interfaces 2017, 4, 1600431. [Google Scholar] [CrossRef] [Green Version]

- Brunner, J.J.; Krumova, M.; Cölfen, H.; Sturm, E.V. Magnetic field-assisted assembly of iron oxide mesocrystals: A matter of nanoparticle shape and magnetic anisotropy. Beilstein J. Nanotechnol. 2019, 10, 894–900. [Google Scholar] [CrossRef] [Green Version]

- Agthe, M.; Plivelic, T.S.; Labrador, A.; Bergstrom, L.; Salazar-Alvarez, G. Following in real time the two-step assembly of nanoparticles into mesocrystals in levitating drops. Nano Lett. 2016, 16, 6838–6843. [Google Scholar] [CrossRef]

- Kapuscinski, M.; Agthe, M.; Lv, Z.-P.; Liu, Y.; Segad, M.; Bergström, L. Temporal Evolution of Superlattice Contraction and Defect-Induced Strain Anisotropy in Mesocrystals during Nanocube Self-Assembly. ACS Nano 2020, 14, 5337–5347. [Google Scholar] [CrossRef]

- Bratlie, K.M.; Lee, H.; Komvopoulos, K.; Yang, P.; Somorjai, G.A. Platinum nanoparticle shape effects on benzene hydrogenation selectivity. Nano Lett. 2007, 7, 3097–3101. [Google Scholar] [CrossRef]

- Peng, K.-Q.; Wang, X.; Wu, X.-L.; Lee, S.-T. Platinum nanoparticle decorated silicon nanowires for efficient solar energy conversion. Nano Lett. 2009, 9, 3704–3709. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, J.Y. A General Strategy for Preparation of Pt 3d-Transition Metal (Co, Fe, Ni) Nanocubes. J. Am. Chem Soc. 2009, 131, 18543–18547. [Google Scholar] [CrossRef]

- Li, R.; Bian, K.; Wang, Y.; Xu, H.; Hollingsworth, J.A.; Hanrath, T.; Fang, J.; Wang, Z. An obtuse rhombohedral superlattice assembled by Pt nanocubes. Nano Lett. 2015, 15, 6254–6260. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, R.; Yamazaki, H.; Takasaki, M.; Oaki, Y.; Sato, T.; Imai, H. Nanoscale Mosaic Works: Tetragonal Lattices of Iso-Oriented Heterogeneous Nanocubes. Langmuir 2018, 34, 4031–4035. [Google Scholar] [CrossRef] [PubMed]

- Brunner, J.J. Iron Oxide Mesocrystals Dissertation; Universität Konstanz: Konstanz, Germany, 2019; Available online: http://nbn-resolving.de/urn:nbn:de:bsz:352-2-1ere0iqqzixbm4 (accessed on 12 June 2019).

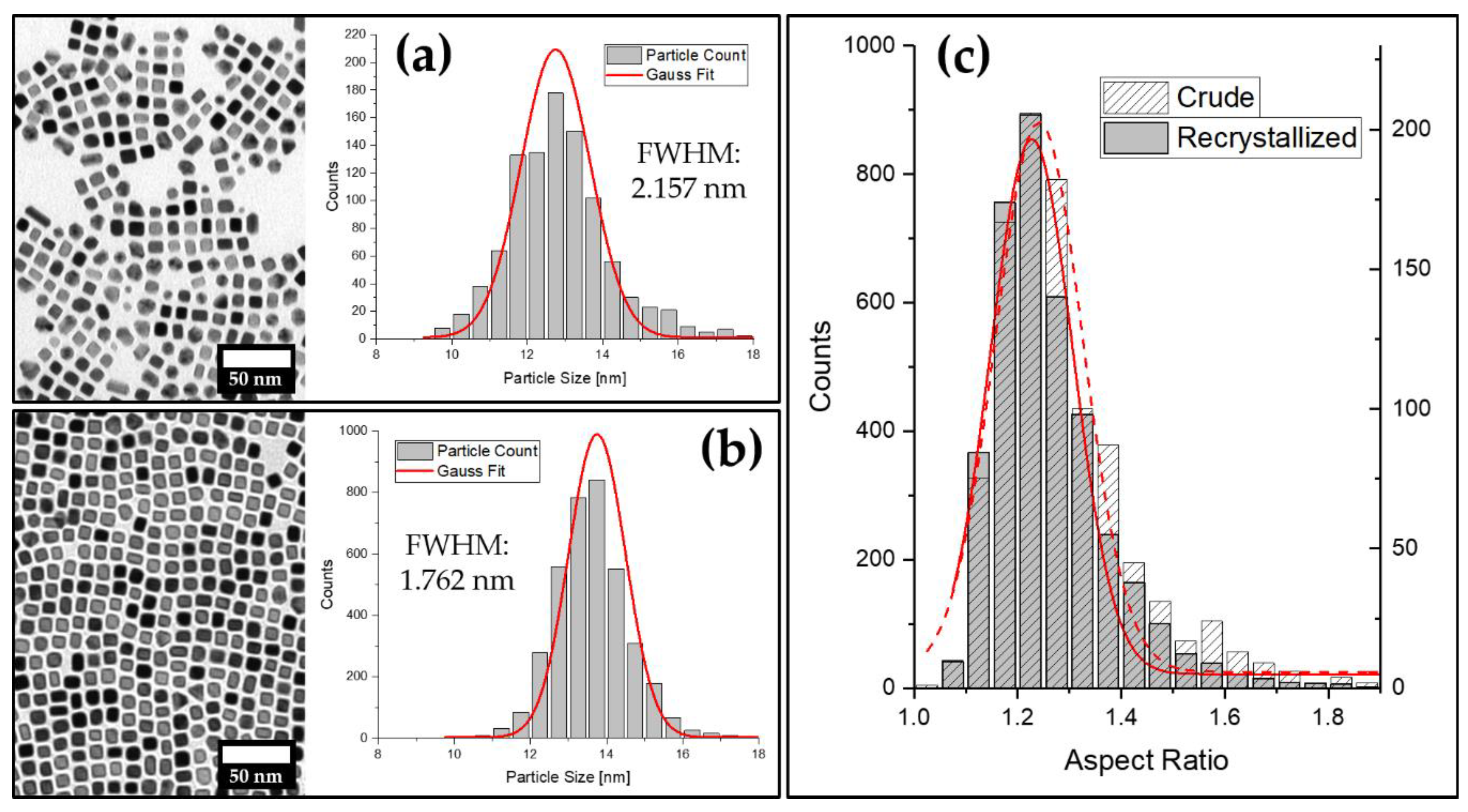

- Brunner, J.; Maier, B.; Rosenberg, R.; Sturm, S.; Cölfen, H.; Sturm, E.V. Nonclassical recrystallization. Chem. Eur. J. 2020, 26, 15242–15248. [Google Scholar] [CrossRef] [PubMed]

| Dispersion Solvent | Crystallization Time | Predominant Crystal Shape |

|---|---|---|

| tetrahydrofuran | 1 day | polycrystalline |

| toluene | 7–14 days | trigonal truncated pyramid |

| hexane | 14–28 days | rhombohedral |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jenewein, C.; Cölfen, H. Mesocrystals from Platinum Nanocubes. Nanomaterials 2021, 11, 2122. https://doi.org/10.3390/nano11082122

Jenewein C, Cölfen H. Mesocrystals from Platinum Nanocubes. Nanomaterials. 2021; 11(8):2122. https://doi.org/10.3390/nano11082122

Chicago/Turabian StyleJenewein, Christian, and Helmut Cölfen. 2021. "Mesocrystals from Platinum Nanocubes" Nanomaterials 11, no. 8: 2122. https://doi.org/10.3390/nano11082122