Nano-Gradient Materials Prepared by Rotary Swaging

Abstract

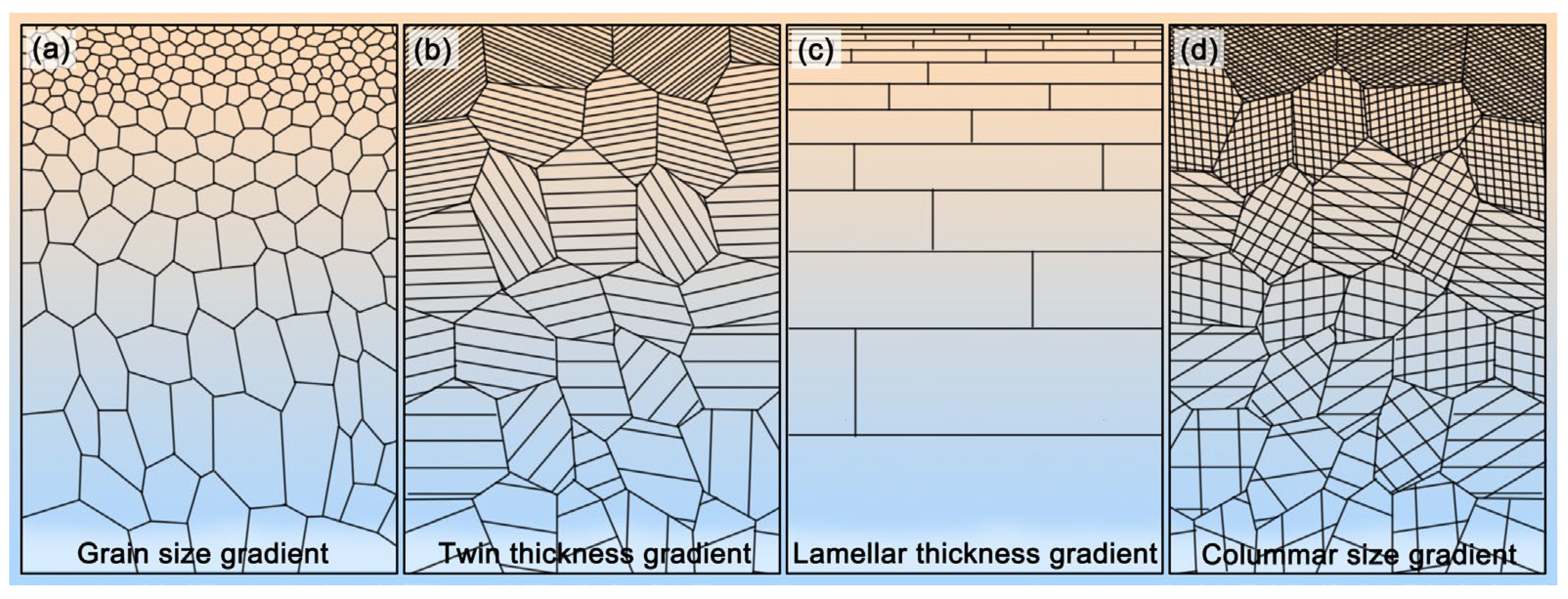

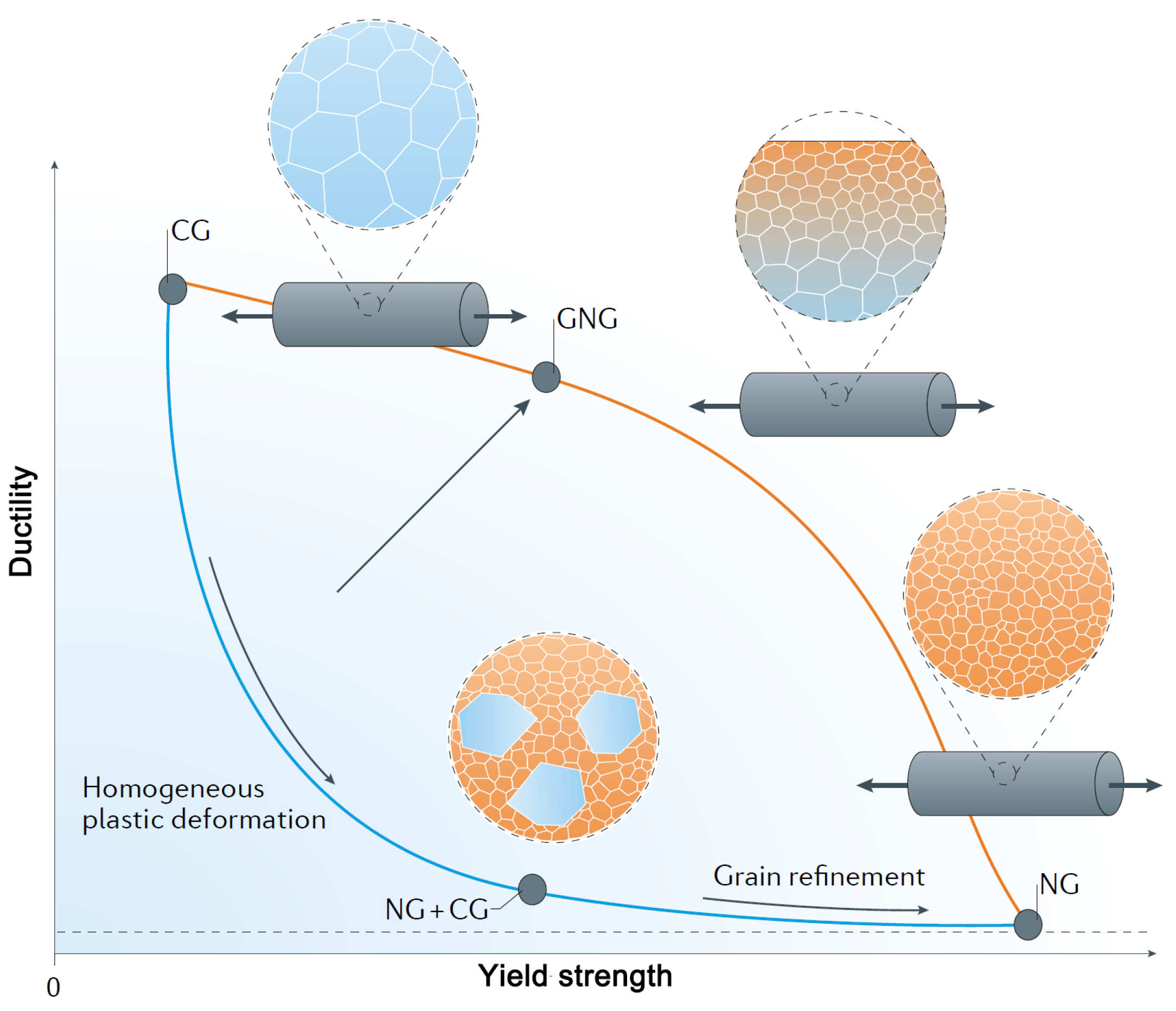

:1. Introduction

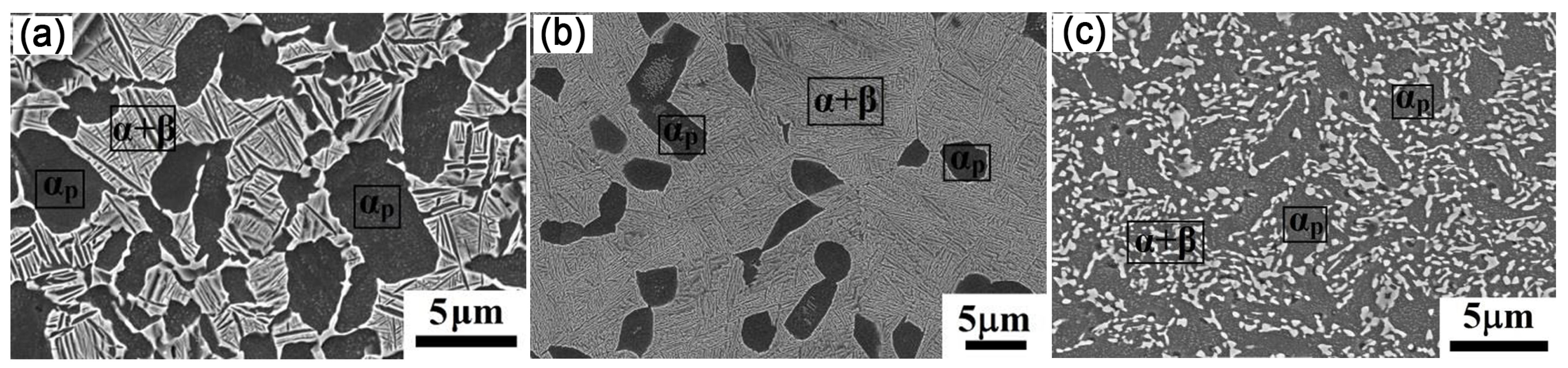

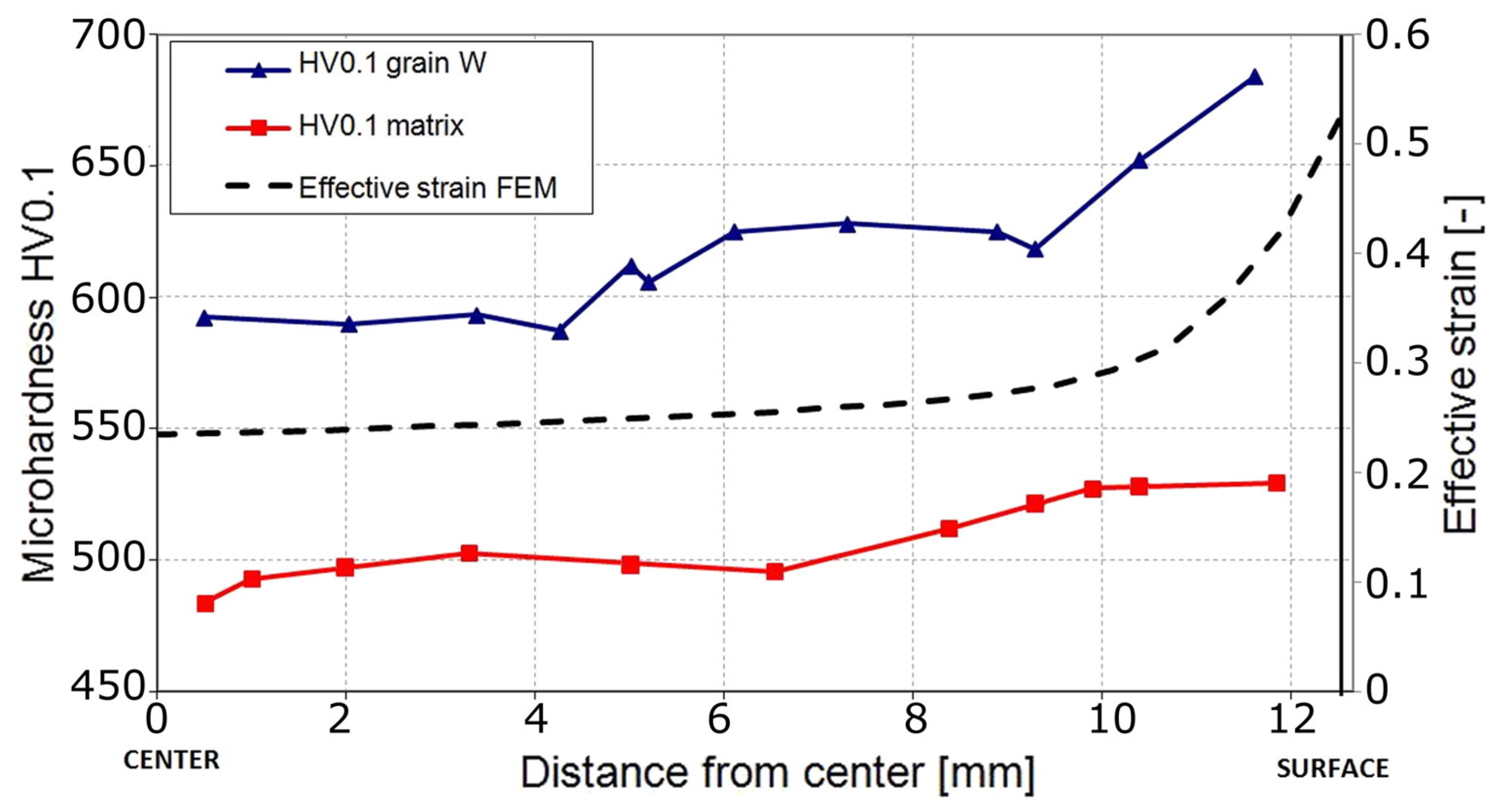

2. Rotary Swaging

2.1. Theory of Rotary Swaging

2.2. Advantages of Rotary Swaging

- Most importantly, RS allows gradient stress to be distributed across the bulk workpiece;

- RS has lower tooling cost and higher efficiency in the metal working industry;

- RS is an efficient way to strengthen hexagonal close-packed (HCP) metals by imposing low strain in each pass;

- Applied cooling and heating modes permit RS at expected temperatures;

- Better surface roughness (less than 1 micrometer) and more precise dimension can be achieved via RS;

- The tandem connection of several RS equipment enables the preparation of extra-long materials.

3. Gradient Micro-Hardness and Microstructures by Rotary Swaging

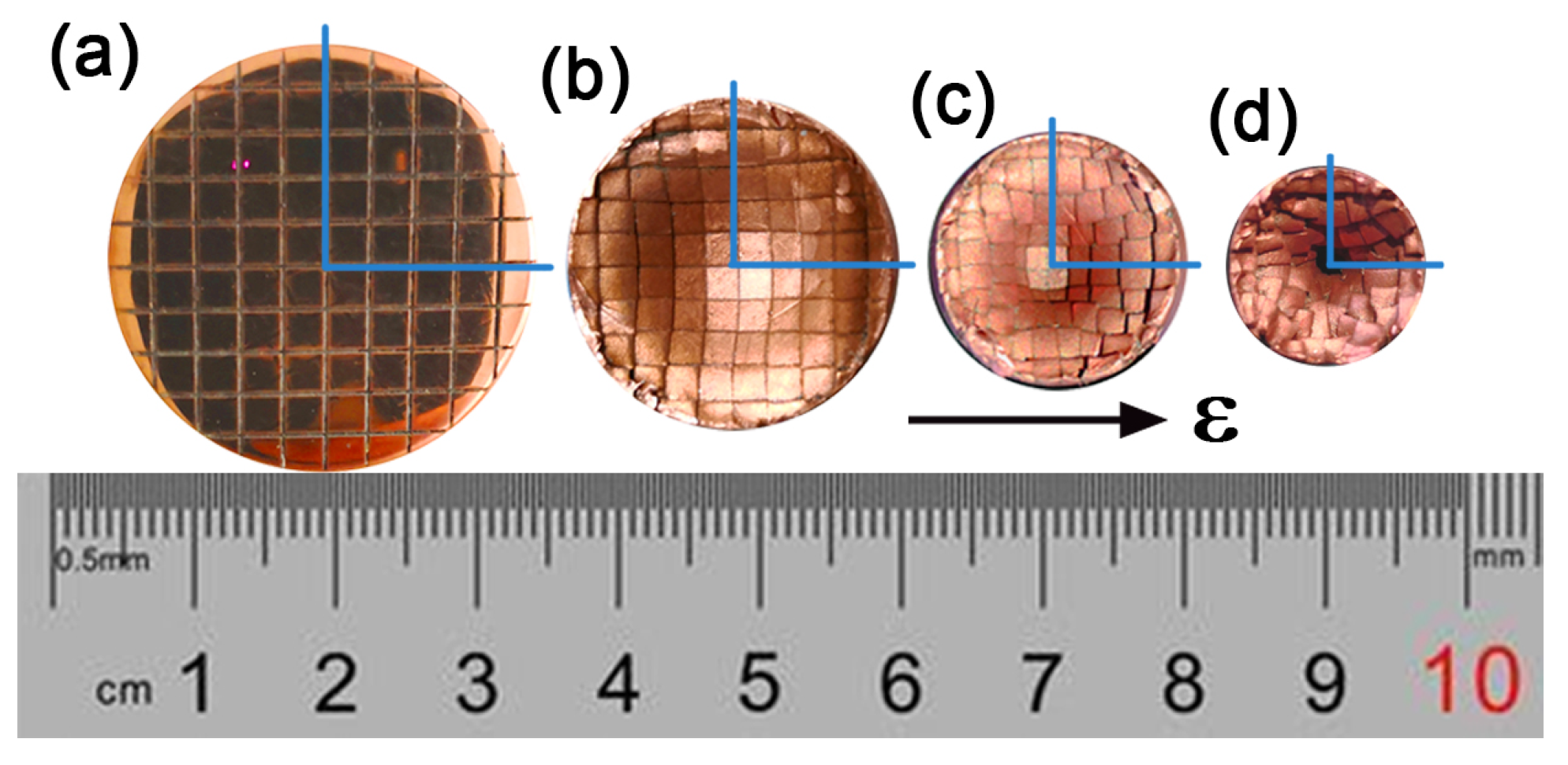

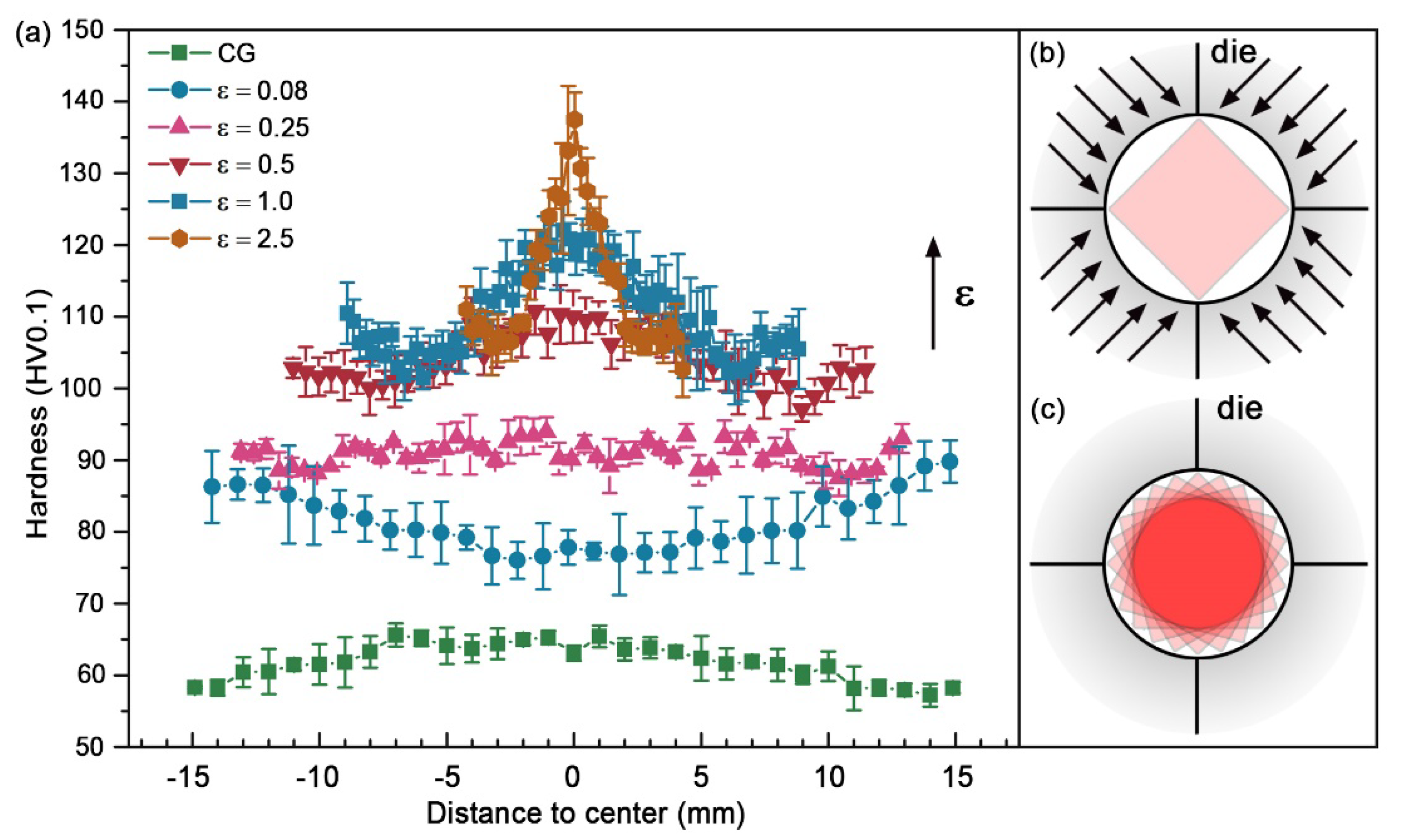

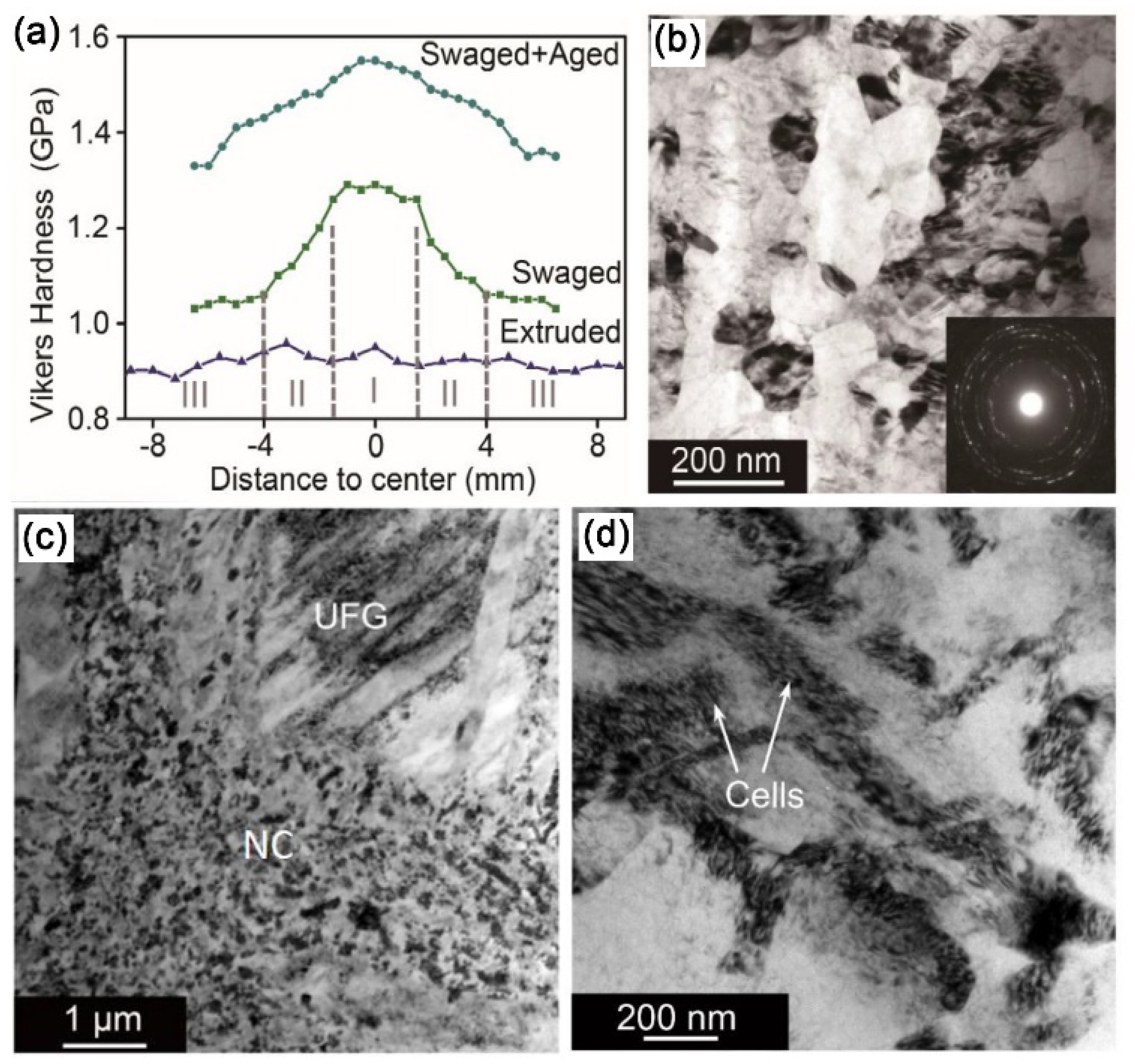

3.1. Rotary Swaged Face-Centered Cubic Metal

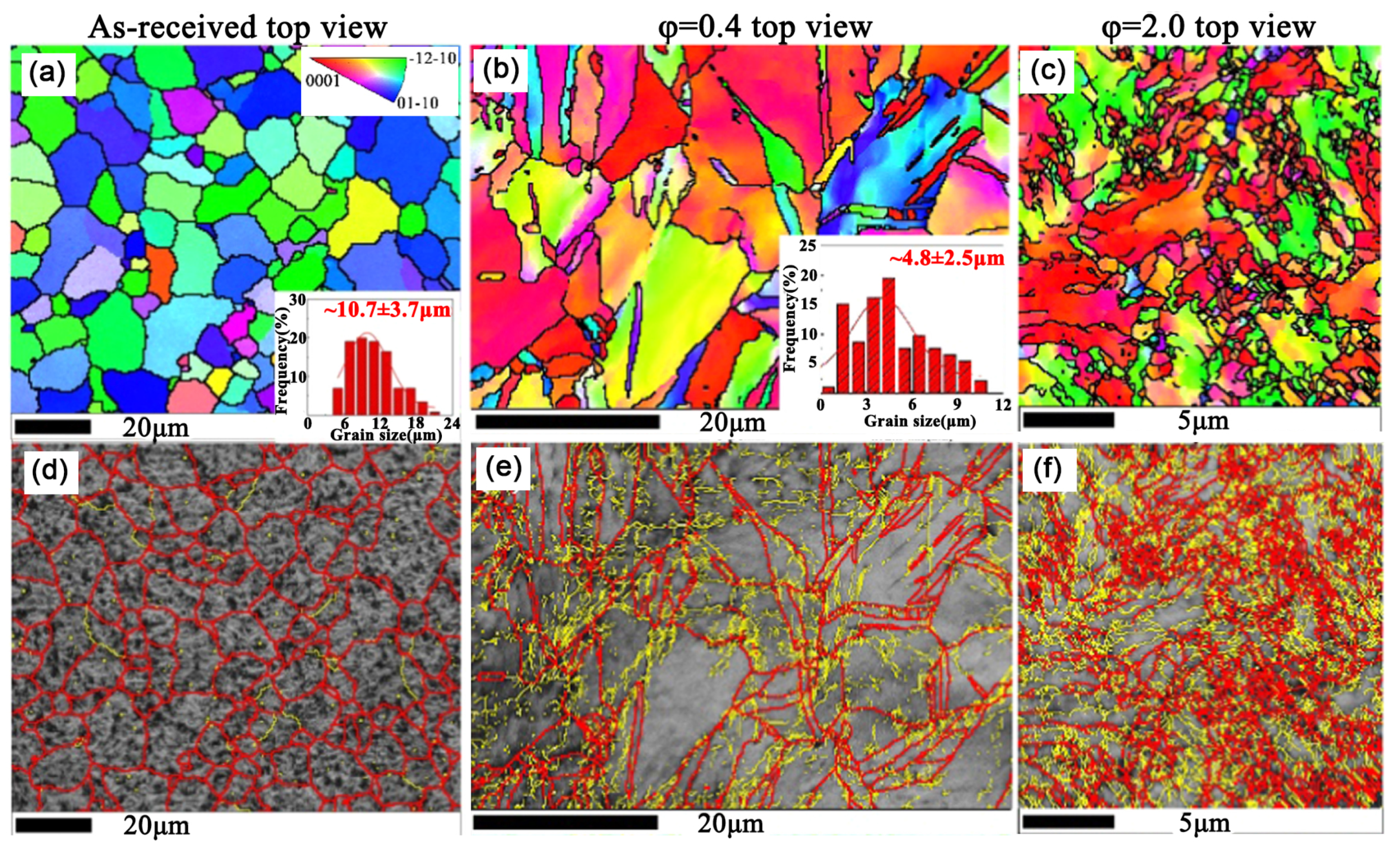

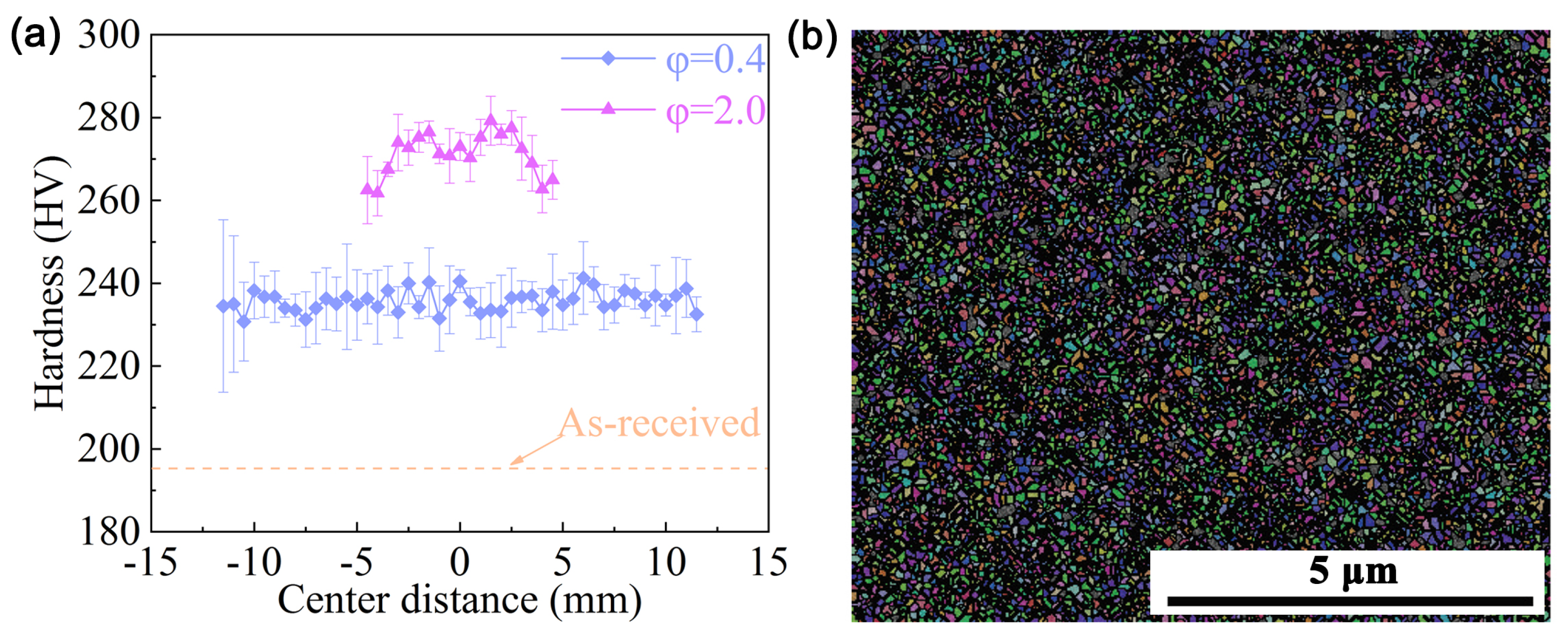

3.2. Rotary Swaged Hexagonal Close-Packed Metals

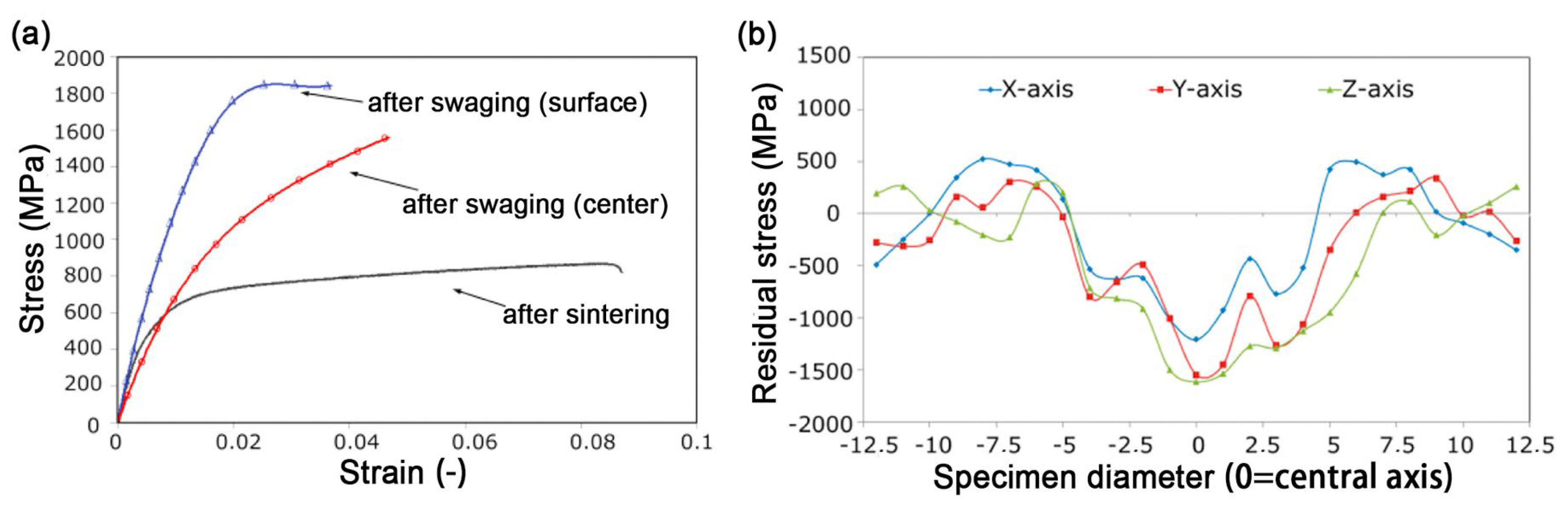

3.3. Rotary Swaged Body Centered Cube Metals

4. Concluding Remarks and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, K.; Lu, J. Surface Nanocrystallization (SNC) of Metallic Materials-Presentation of the Concept behind a New Approach. J. Mater. Sci. Technol. 1999, 15, 193–197. [Google Scholar]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2020, 9, 1–31. [Google Scholar] [CrossRef]

- Lu, K. Gradient nanostructured materials. Acta Metall. Sin. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Yang, M.; Yuan, F.; Chen, L.; Zhu, Y. Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar] [CrossRef] [Green Version]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lu, L.; Li, J.; Zhang, X.; Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Q.; Xiao, L.; Sun, J. Effect of Surface Nanocrystallization on Fatigue Behavior of Pure Titanium. J. Mater. Eng. Perform. 2015, 25, 241–249. [Google Scholar] [CrossRef]

- Villegas, J.C.; Shaw, L.L.; Dai, K.; Yuan, W.; Tian, J.; Liaw, P.K.; Klarstrom, D.L. Enhanced fatigue resistance of a nickel-based hastelloy induced by a surface nanocrystallization and hardening process. Philos. Mag. Lett. 2005, 85, 427–438. [Google Scholar] [CrossRef]

- Samy, B.; Kumar, S.; Narayanan, T.S. Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel. Corros. Sci. 2010, 52, 3826–3834. [Google Scholar] [CrossRef]

- Jelliti, S.; Richard, C.; Retraint, D.; Roland, T.; Chemkhi, M.; Demangel, C. Effect of surface nanocrystallization on the corrosion behavior of Ti–6Al–4V titanium alloy. Surf. Coatings Technol. 2013, 224, 82–87. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z.; Li, X.; Lu, K. Lowering coefficient of friction in Cu alloys with stable gradient nanostructures. Sci. Adv. 2016, 2, e1601942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Han, Z.; Li, X.; Lu, K. Friction of stable gradient nano-grained metals. Scr. Mater. 2020, 185, 82–87. [Google Scholar] [CrossRef]

- Chen, X.; Han, Z.; Lu, K. Friction and Wear Reduction in Copper with a Gradient Nano-grained Surface Layer. ACS Appl. Mater. Interfaces 2018, 10, 13829–13838. [Google Scholar] [CrossRef]

- Tao, N.; Wang, Z.; Tong, W.; Sui, M.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Montross, C.S. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Nalla, R.; Altenberger, I.; Noster, U.; Liu, G.; Scholtes, B.; Ritchie, R. On the influence of mechanical surface treatments—deep rolling and laser shock peening—on the fatigue behavior of Ti–6Al–4V at ambient and elevated temperatures. Mater. Sci. Eng. A 2003, 355, 216–230. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, Z.; Xu, J.; Lu, K. Simultaneous enhancement of stress- and strain-controlled fatigue properties in 316L stainless steel with gradient nanostructure. Acta Mater. 2019, 168, 133–142. [Google Scholar] [CrossRef]

- Mishra, R.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Deng, S.; Godfrey, A.; Liu, W.; Hansen, N. A gradient nanostructure generated in pure copper by platen friction sliding deformation. Scr. Mater. 2016, 117, 41–45. [Google Scholar] [CrossRef] [Green Version]

- Kitahara, H.; Yada, T.; Tsushida, M.; Ando, S. Microstructure and Evaluation of Wire-brushed Mg Sheets. Procedia Eng. 2011, 10, 2737–2742. [Google Scholar] [CrossRef] [Green Version]

- Dai, K.; Shaw, L. Analysis of fatigue resistance improvements via surface severe plastic deformation. Int. J. Fatigue 2008, 30, 1398–1408. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, Y.; Nie, J.; Zhou, H.; Li, Y. Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening. Materials 2018, 11, 366. [Google Scholar] [CrossRef] [Green Version]

- Umemoto, M. Nanocrystallization of Steels by Severe Plastic Deformation. Mater. Trans. 2003, 44, 1900–1911. [Google Scholar] [CrossRef] [Green Version]

- Umemoto, M.; Todaka, Y.; Tsuchiya, K. Formation of Nanocrystalline Structure in Steels by Air Blast Shot Peening. Mater. Trans. 2003, 44, 1488–1493. [Google Scholar] [CrossRef] [Green Version]

- Abramov, V.; Abramov, O.; Sommer, F.; Gradov, O.; Smirnov, O. Surface hardening of metals by ultrasonically accelerated small metal balls. Ultrasonics 1998, 36, 1013–1019. [Google Scholar] [CrossRef]

- Ma, G.-Z.; Xu, B.-S.; Wang, H.-D.; Si, H.-J. Effects of surface nanocrystallization pretreatment on low-temperature ion sulfurization behavior of 1Cr18Ni9Ti stainless steel. Appl. Surf. Sci. 2010, 257, 1204–1210. [Google Scholar] [CrossRef]

- Dai, K.; Villegas, J.; Shaw, L. An analytical model of the surface roughness of an aluminum alloy treated with a surface nanocrystallization and hardening process. Scr. Mater. 2005, 52, 259–263. [Google Scholar] [CrossRef]

- Liu, G.; Wang, S.; Lou, X.; Lu, J.; Lu, K. Low carbon steel with nanostructured surface layer induced by high-energy shot peening. Scr. Mater. 2001, 44, 1791–1795. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Tao, N.; Liu, G.; Lu, J.; Lu, K. Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 2006, 54, 5281–5291. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, H.; Lu, K. Formation of nano-laminated structure in nickel by means of surface mechanical grinding treatment. Acta Mater. 2015, 96, 24–36. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Zhang, Q.; Zhao, Y.; Zhu, Y. Gradient Structured Copper by Rotationally Accelerated Shot Peening. J. Mater. Sci. Technol. 2016, 33, 758–761. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, W.; Yang, M.; Li, Y.; Zhang, H.; Zhang, H.; Zhang, W. Microstructure and Texture of Thin-Walled Ti-6Al-4V Alloy Seamless Tubing Manufactured by Cold-Rotary Swaging. JOM 2021, 73, 1786–1794. [Google Scholar] [CrossRef]

- Ortmann-Ishkina, S.; Charni, D.; Herrmann, M.; Liu, Y.; Epp, J.; Schenck, C.; Kuhfuss, B. Development of residual stresses by infeed rotary swaging of steel tubes. Arch. Appl. Mech. 2021, 1–11. [Google Scholar] [CrossRef]

- Trojanová, Z.; Drozd, Z.; Halmešová, K.; Džugan, J.; Škraban, T.; Minárik, P.; Németh, G.; Lukáč, P. Strain Hardening in an AZ31 Alloy Submitted to Rotary Swaging. Materials 2020, 14, 157. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, X.; Nie, J.; Wei, K.; Mao, Q.; Lu, F.; Zhao, Y. Achieving ultra-strong Magnesium–lithium alloys by low-strain rotary swaging. Mater. Res. Lett. 2021, 9, 255–262. [Google Scholar] [CrossRef]

- Meng, A.; Chen, X.; Nie, J.; Gu, L.; Mao, Q.; Zhao, Y. Microstructure evolution and mechanical properties of commercial pure titanium subjected to rotary swaging. J. Alloys Compd. 2020, 859, 158222. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Dohnalík, D.; Macháčková, A.; Šofer, M. Cold rotary swaging of a tungsten heavy alloy: Numerical and experimental investigations. Int. J. Refract. Met. Hard Mater. 2016, 61, 264–272. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Hervoches, C.; Macháčková, A. Study of structure and residual stresses in cold rotary swaged tungsten heavy alloy. Mater. Sci. Eng. A 2017, 704, 25–31. [Google Scholar] [CrossRef]

- Singh, G.; Kalita, B.; Narayanan, K.V.; Arora, U.; Mahapatra, M.; Jayaganthan, R. Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging. Metals 2020, 10, 1281. [Google Scholar] [CrossRef]

- Ishkina, S.; Kuhfuss, B.; Schenck, C. Grain Size Modification by Micro Rotary Swaging. Key Eng. Mater. 2015, 651–653, 627–632. [Google Scholar] [CrossRef]

- Piwek, V.; Kuhfuss, B.; Moumi, E.; Hork, M. Light weight design of rotary swaged components and optimization of the swaging process. Int. J. Mater. Form. 2010, 3, 845–848. [Google Scholar] [CrossRef]

- Jang, J.H.; Joo, B.D.; Mun, S.M.; Moon, Y.H. Shell Body Nose Forming by Rotary Swaging Process. Adv. Mater. Res. 2011, 213, 221–225. [Google Scholar] [CrossRef]

- Vinogradov, A.; Vasilev, E.; Kopylov, V.I.; Linderov, M.; Brilevesky, A.; Merson, D. High Performance Fine-Grained Biodegradable Mg-Zn-Ca Alloys Processed by Severe Plastic Deformation. Metals 2019, 9, 186. [Google Scholar] [CrossRef] [Green Version]

- Gan, W.; Huang, Y.; Wang, R.; Wang, G.; Srinivasan, A.; Brokmeier, H.-G.; Schell, N.; Kainer, K.; Hort, N. Microstructures and mechanical properties of pure Mg processed by rotary swaging. Mater. Des. 2014, 63, 83–88. [Google Scholar] [CrossRef] [Green Version]

- Wan, Y.; Tang, B.; Gao, Y.; Tang, L.; Sha, G.; Zhang, B.; Liang, N.; Liu, C.; Jiang, S.; Chen, Z.; et al. Bulk nanocrystalline high-strength magnesium alloys prepared via rotary swaging. Acta Mater. 2020, 200, 274–286. [Google Scholar] [CrossRef]

- Modina, I.M.; Polyakov, A.V.; Dyakonov, G.; Yakovleva, T.V.; Raab, A.G.; Semenova, I.P. Peculiarities of microstructure and mechanical behavior of VT8M-1 alloy processed by rotary swaging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012056. [Google Scholar] [CrossRef]

- Martynenko, N.S.; Luk’Yanova, E.A.; Morozov, M.M.; Yusupov, V.S.; Dobatkin, S.V.; Estrin, Y.Z. A Study of the Structure, Mechanical Properties and Corrosion Resistance of Magnesium Alloy WE43 After Rotary Swaging. Met. Sci. Heat Treat. 2018, 60, 253–258. [Google Scholar] [CrossRef]

- Yang, Y.; Nie, J.; Mao, Q.; Zhao, Y. Improving the combination of electrical conductivity and tensile strength of Al 1070 by rotary swaging deformation. Results Phys. 2019, 13, 102236. [Google Scholar] [CrossRef]

- Alkhazraji, H.; El-Danaf, E.; Wollmann, M.; Wagner, L. Enhanced Fatigue Strength of Commercially Pure Ti Processed by Rotary Swaging. Adv. Mater. Sci. Eng. 2015, 2015, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Abdulstaar, M.A.; Mhaede, M.; Wollmann, M.; Wagner, L. Fatigue behaviour of commercially pure aluminium processed by rotary swaging. J. Mater. Sci. 2013, 49, 1138–1143. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Huang, A.; Gao, L.; Li, Y.; Huang, C. Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment. Materials 2018, 11, 2261. [Google Scholar] [CrossRef] [Green Version]

- Gholami, M.; Mhaede, M.; Pastorek, F.; Altenberger, I.; Hadzima, B.; Wollmann, M.; Wagner, L. Corrosion Behavior and Mechanical Properties of Ultrafine-Grained Pure Copper with Potential as a Biomaterial. Adv. Eng. Mater. 2015, 18, 615–623. [Google Scholar] [CrossRef]

- AAhmed, A.A.; Mhaede, M.; Wollmann, M.; Wagner, L. Effect of surface and bulk plastic deformations on the corrosion resistance and corrosion fatigue performance of AISI 316L. Surf. Coat. Technol. 2014, 259, 448–455. [Google Scholar] [CrossRef]

- Abdulstaar, M.; Mhaede, M.; Wagner, L.; Wollmann, M. Corrosion behaviour of Al 1050 severely deformed by rotary swaging. Mater. Des. 2014, 57, 325–329. [Google Scholar] [CrossRef]

- Bösing, I.; Herrmann, M.; Bobrov, I.; Thöming, J.; Kuhfuss, B.; Epp, J.; Baune, M. The influence of microstructure deformation on the corrosion resistance of cold formed stainless steel. MATEC Web Conf. 2018, 190, 04002. [Google Scholar] [CrossRef]

- Mao, Q.; Zhang, Y.; Guo, Y.; Zhao, Y. Enhanced electrical conductivity and mechanical properties in thermally stable fine-grained copper wire. Commun. Mater. 2021, 2, 1–9. [Google Scholar] [CrossRef]

- Mao, Q.; Zhang, Y.; Liu, J.; Zhao, Y. Breaking Material Property Trade-offs via Macrodesign of Microstructure. Nano Lett. 2021, 21, 3191–3197. [Google Scholar] [CrossRef] [PubMed]

- Huang, A.; Wang, Y.; Wang, M.; Song, L.; Li, Y.; Gao, L.; Huang, C.; Zhu, Y. Optimizing the strength, ductility and electrical conductivity of a Cu-Cr-Zr alloy by rotary swaging and aging treatment. Mater. Sci. Eng. A 2019, 746, 211–216. [Google Scholar] [CrossRef]

- Hupalo, M.F.; Padilha, A.F.; Sandim, H.; Kliauga, A. Cold Swaging, Recovery and Recrystallization of Oligocrystalline INCOLOY MA 956-Part I: Deformed State. ISIJ Int. 2004, 44, 1894–1901. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Y.; Zhou, H.; Chen, X.; Liu, Y.; Xiao, L.; Huan, X.; Zhao, Y.; Zhu, Y. Mechanical Properties and Microstructures of Commercial-Purity Aluminum Processed by Rotational Accelerated Shot Peening Plus Cold Rolling. Adv. Eng. Mater. 2019, 22. [Google Scholar] [CrossRef]

- Sun, H.; Ding, Z.; Zhang, D.; Zhou, H.; Li, S.; Lavernia, E.J.; Zhu, Y.; Liu, W. Predicting the formation of dislocations in magnesium alloys from multiple stacking fault energies. Materialia 2019, 7, 100352. [Google Scholar] [CrossRef]

- Luo, X.; Feng, Z.; Yu, T.; Luo, J.; Huang, T.; Wu, G.; Hansen, N.; Huang, X. Transitions in mechanical behavior and in deformation mechanisms enhance the strength and ductility of Mg-3Gd. Acta Mater. 2019, 183, 398–407. [Google Scholar] [CrossRef]

- Liu, B.-Y.; Liu, F.; Yang, N.; Zhai, X.-B.; Zhang, L.; Yang, Y.; Li, B.; Li, J.; Ma, E.; Nie, J.-F.; et al. Large plasticity in magnesium mediated by pyramidal dislocations. Science 2019, 365, 73–75. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.; Wan, Y.; Jiang, S.; Chen, Z.; Zhao, Y. Grain Refinement Mechanisms in Gradient Nanostructured AZ31B Mg Alloy Prepared via Rotary Swaging. Met. Mater. Trans. A 2021, 52, 4053–4065. [Google Scholar] [CrossRef]

- Minárik, P.; Zemkova, M.; Král, R.; Mhaede, M.; Wagner, L.; Hadzima, B. Effect of Microstructure on the Corrosion Resistance of the AE42 Magnesium Alloy Processed by Rotary Swaging. Acta Phys. Pol. A 2015, 128, 805–808. [Google Scholar] [CrossRef]

- Baptista, C.; Schneider, S.; Taddei, E.; Da Silva, H. Fatigue behavior of arc melted Ti–13Nb–13Zr alloy. Int. J. Fatigue 2004, 26, 967–973. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, W.; Li, Y.; Yang, M.; Zhang, H.; Zhang, W. Effect of annealing temperature on texture and residual stress of Ti-6Al-4V alloy seamless tubing processed by cold rotary swaging. Vacuum 2020, 177, 109399. [Google Scholar] [CrossRef]

- Palán, J.; Procházka, R.; Džugan, J.; Nacházel, J.; Duchek, M.; Németh, G.; Máthis, K.; Minárik, P.; Horváth, K. Comprehensive Evaluation of the Properties of Ultrafine to Nanocrystalline Grade 2 Titanium Wires. Materials 2018, 11, 2522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geetha, M.; Singh, A.; Asokamani, R.; Gogia, A. Ti based biomaterials, the ultimate choice for orthopaedic implants —A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Stotskiy, A.G.; Yakovleva, T.V.; Modina, I.; Polyakov, A.V.; Ramazanov, I.A.; Semenova, I.P. Mechanical behavior at elevated temperatures of the ultrafine-grained titanium alloy VT8M-1 processed by rotary swaging. IOP Conf. Ser. Mater. Sci. Eng. 2019, 672. [Google Scholar] [CrossRef] [Green Version]

- Macháčková, A.; Krátká, L.; Petrmichl, R.; Kunčická, L.; Kocich, R. Affecting Structure Characteristics of Rotary Swaged Tungsten Heavy Alloy Via Variable Deformation Temperature. Materials 2019, 12, 4200. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Tan, H.; Lin, N.; Li, Z.; He, Y. The influences of La doping method on the microstructure and mechanical properties of Mo alloys. Int. J. Refract. Met. Hard Mater. 2015, 51, 301–308. [Google Scholar] [CrossRef]

- Durlu, N.; Çalişkan, N.K. Effect of swaging on microstructure and tensile properties of W–Ni–Fe alloys. Int. J. Refract. Met. Hard Mater. 2014, 42, 126–131. [Google Scholar] [CrossRef]

- Estrin, Y.; Martynenko, N.; Lukyanova, E.; Serebryany, V.; Gorshenkov, M.; Morozov, M.; Yusupov, V.; Dobatkin, S. Effect of Rotary Swaging on Microstructure, Texture, and Mechanical Properties of a Mg-Al-Zn Alloy. Adv. Eng. Mater. 2019, 22. [Google Scholar] [CrossRef]

| Fabrication Method | Gradient Distribution in Feature Size (from Top to Interior) | Depth of Nano-Grains | Depth of Gradient | Refs. |

|---|---|---|---|---|

| SMAT | Tens of nanometers to ~10 μm | ~20 μm | ~300 μm | [9,17,33] |

| SMGT | Several nanometers to ~10 μm | ~75 μm | ~300 μm | [9,34] |

| LSP | Tens of nanometers to ~100 nm | ~50 μm | <1 mm | [9,19] |

| RASP | Tens of nanometers to ~10 μm | <50 μm | ~2 mm | [26,35] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Q.; Chen, X.; Li, J.; Zhao, Y. Nano-Gradient Materials Prepared by Rotary Swaging. Nanomaterials 2021, 11, 2223. https://doi.org/10.3390/nano11092223

Mao Q, Chen X, Li J, Zhao Y. Nano-Gradient Materials Prepared by Rotary Swaging. Nanomaterials. 2021; 11(9):2223. https://doi.org/10.3390/nano11092223

Chicago/Turabian StyleMao, Qingzhong, Xiang Chen, Jiansheng Li, and Yonghao Zhao. 2021. "Nano-Gradient Materials Prepared by Rotary Swaging" Nanomaterials 11, no. 9: 2223. https://doi.org/10.3390/nano11092223

APA StyleMao, Q., Chen, X., Li, J., & Zhao, Y. (2021). Nano-Gradient Materials Prepared by Rotary Swaging. Nanomaterials, 11(9), 2223. https://doi.org/10.3390/nano11092223