Advanced Electron Microscopy of Nanophased Synthetic Polymers and Soft Complexes for Energy and Medicine Applications

Abstract

1. Introduction

2. Comparison of Various Nanostructure Characterization Techniques

2.1. Probes: Tip, Electron, Ion, X-ray, and Neutron

2.2. Connecting Real and Reciprocal Space

2.3. Cryotome, Cryo-Holder, Cryo-Chamber, and Low Dose

3. Sample Preparation Based on Contrast Mechanism

- (1)

- Lower contrast as compared to inorganics;

- (2)

- Abundance of light elements as compared to inorganics;

- (3)

- Polydispersity or nanomorphological variations as compared to proteins;

- (4)

- Large changes induced by electron beams as compared to inorganics.

- Surface- or interface-induced contrast;

- Intrinsic contrast from the increased density of crystalline domains;

- Shadowing with an additional ultrathin coating or epitaxial growth;

- Phase contrast that gives rises to lattice fringes;

- Z contrast by a (high-angle) annular dark-field detector in STEM;

- Inelastic electron scattering (EFTEM contrast) from low-energy plasmon regions and core edges;

- Diffraction contrast using an objective aperture;

- Staining by iodine, a heavy metal, etc.

3.1. Focused Ion Beam (FIB) and Microtome

3.2. Drop Casting, Physical Adsorption, In Situ Sample Growth, and Substrate Selection

3.3. Plunge Freezing

3.4. To Stain or Not to Stain

3.5. Sample Drifting

4. Electron Dose and Spatial Resolution

4.1. Bright Field and High Resolution

- Calibration of the survey, focus, and image mode;

- Search for areas of interest in the survey mode (low magnification, low dose, and low resolution);

- Focus on a neighborhood area near the region of potential interest in the focus mode (at a high magnification equivalent to that of the image mode);

- Go to image mode and allow the system to automatically take images using the designed exposure time;

- Thickness variation, sample drifting, and the misalignment between the survey, focus, and image mode can contribute to a failed attempt. Each new sample may require a new adjustment in imaging parameters.

4.2. Diffraction

- Set a proper camera length. Polymers and organic crystals typically have much larger unit cells than those of ceramics and metals.

- Perform calibration by acquiring a diffraction pattern at the camera length of choice for a sputtered or commercially available gold (or aluminum) film. Align the beam stop so that the pattern is free from the effect of the overly bright central beam. Gold (111) rings should cover a large portion of the pattern to allow features from polymers and organic crystals to show up in detail.

- Angular relations between the SAED pattern and corresponding bright-field image should be understood before acquiring SAED patterns from unknown samples.

- Navigate sample position XY in diffraction mode after Z height adjustment and focusing.

- Observe fading of SAED patterns under the electron beam.

- Capture fading SAED patterns under the electron beam in the context of the electron beam dosage or exposure.

- Real-space imaging at the same location.

5. Chemical Mapping with Monitored Electron Damage

- EELS spectrum calibration at 0 eV with minimal brightness and exposure time.

- Choose either a low-eV plasmon region or core edges.

- Acquire an elastic image for a region of interest as a baseline before EELS scans. Monitor the changes after various EELS scans.

- Spectroscopic measurements with beam damage monitoring.

- Acquire another elastic image for a region of interest as a baseline before EFTEM mapping.

- Use a minimal brightness and exposure time as a starter for EFTEM mapping. Blank the beam, or turn down the brightness right after the mapping to prevent the sample area from receiving an additional electron dosage.

- Monitor the changes in elastic images.

- Contrast improvements by gradually increasing the brightness and exposure time.

- Continued monitoring of real-space images.

- Estimate an optimal brightness and exposure time combination, in order to minimize beam-induced changes and maximize EFTEM contrast.

6. Other Low-Dose Techniques and Temporal Resolution

7. Morphological Variations and Hierarchical Structures

8. Case Studies

8.1. Energy Conversion and Optoelectronics

8.1.1. Polymer-Based Solar Cells

8.1.2. Organic Semiconductors

8.1.3. Conjugated (Co)Polymers

8.2. Energy Storage

8.2.1. Meso/Nanoporous Materials and Membranes

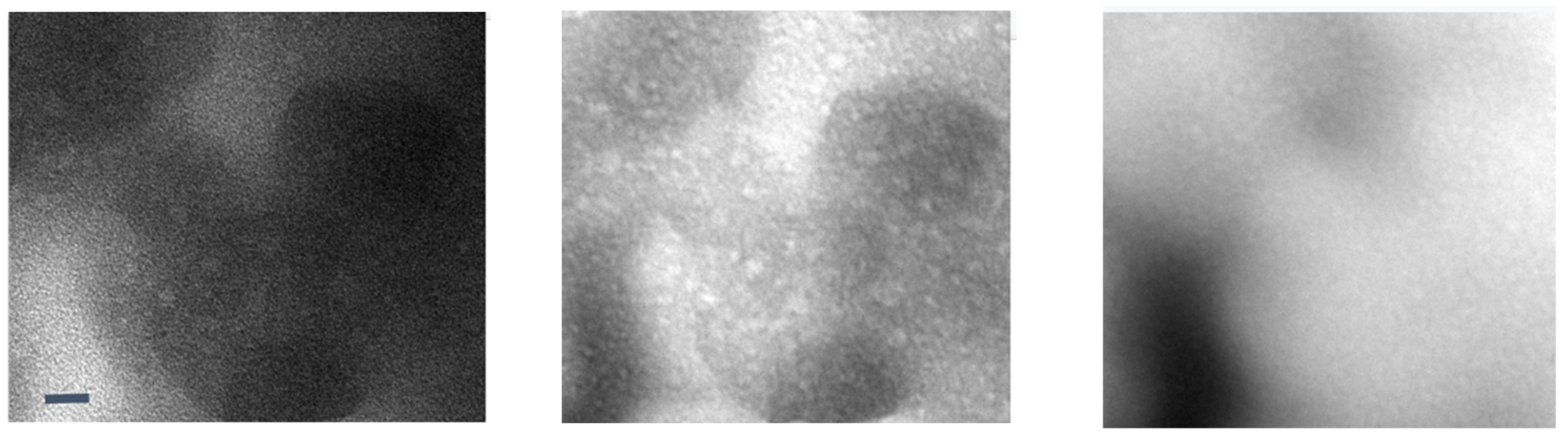

8.2.2. Polymer Electrolyte

8.2.3. Battery Interfaces

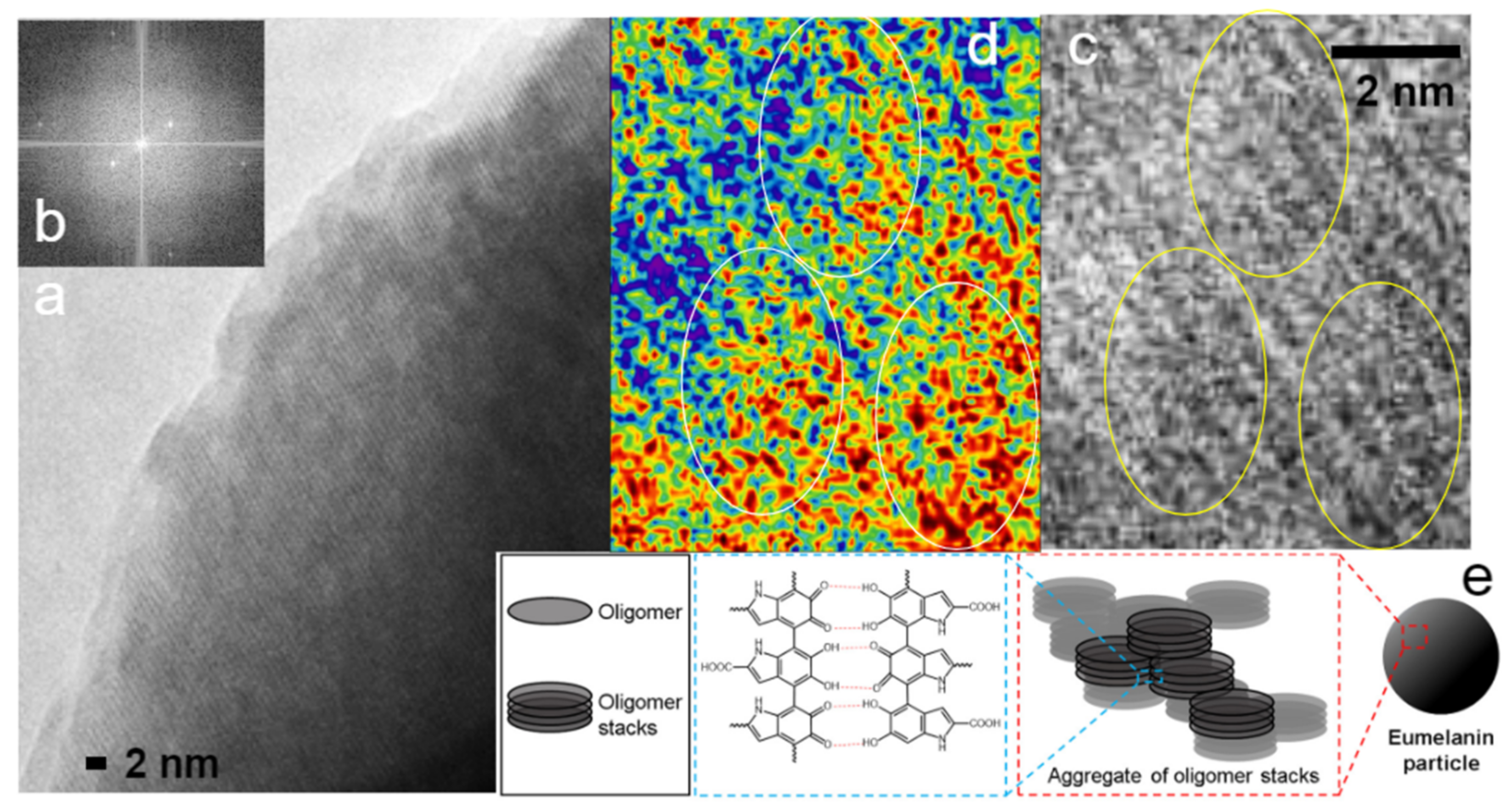

8.3. Medicine

8.3.1. Macromolecular Medicine

8.3.2. Self-Assembly and Kinetics of Block or Graft Copolymers

8.3.3. Self-Assembly and Kinetics of Biomacromolecules

8.3.4. Small Molecule Drugs

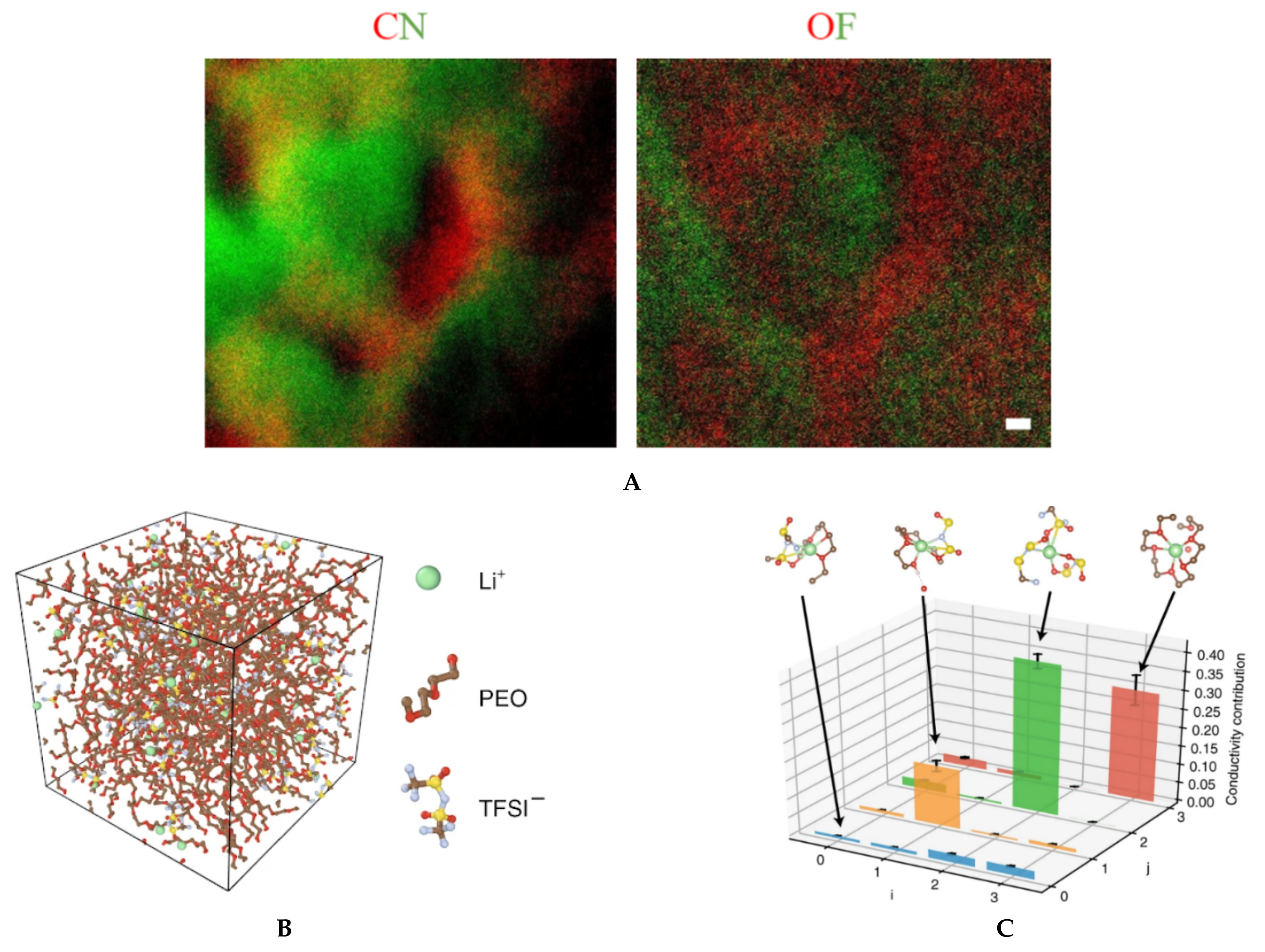

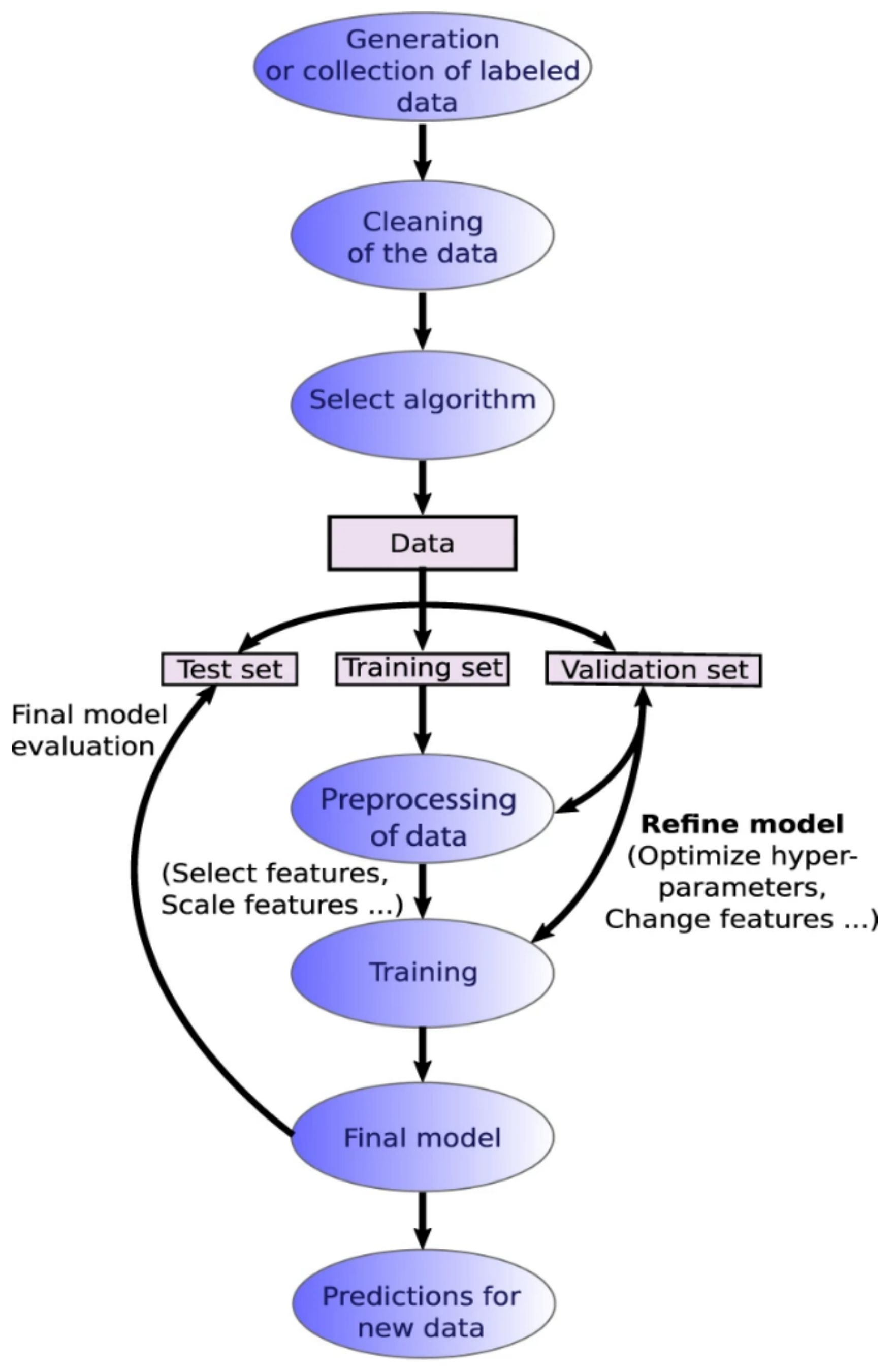

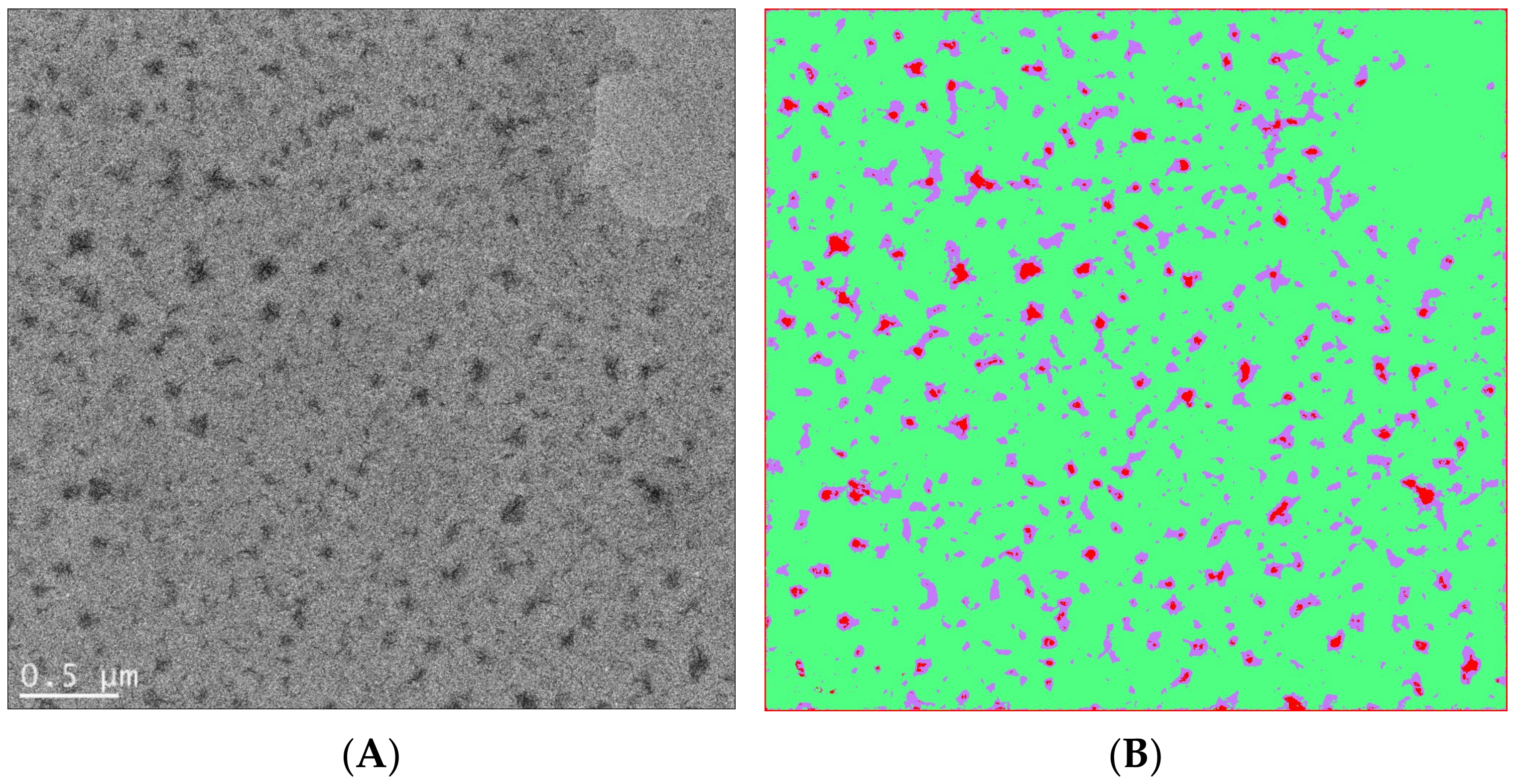

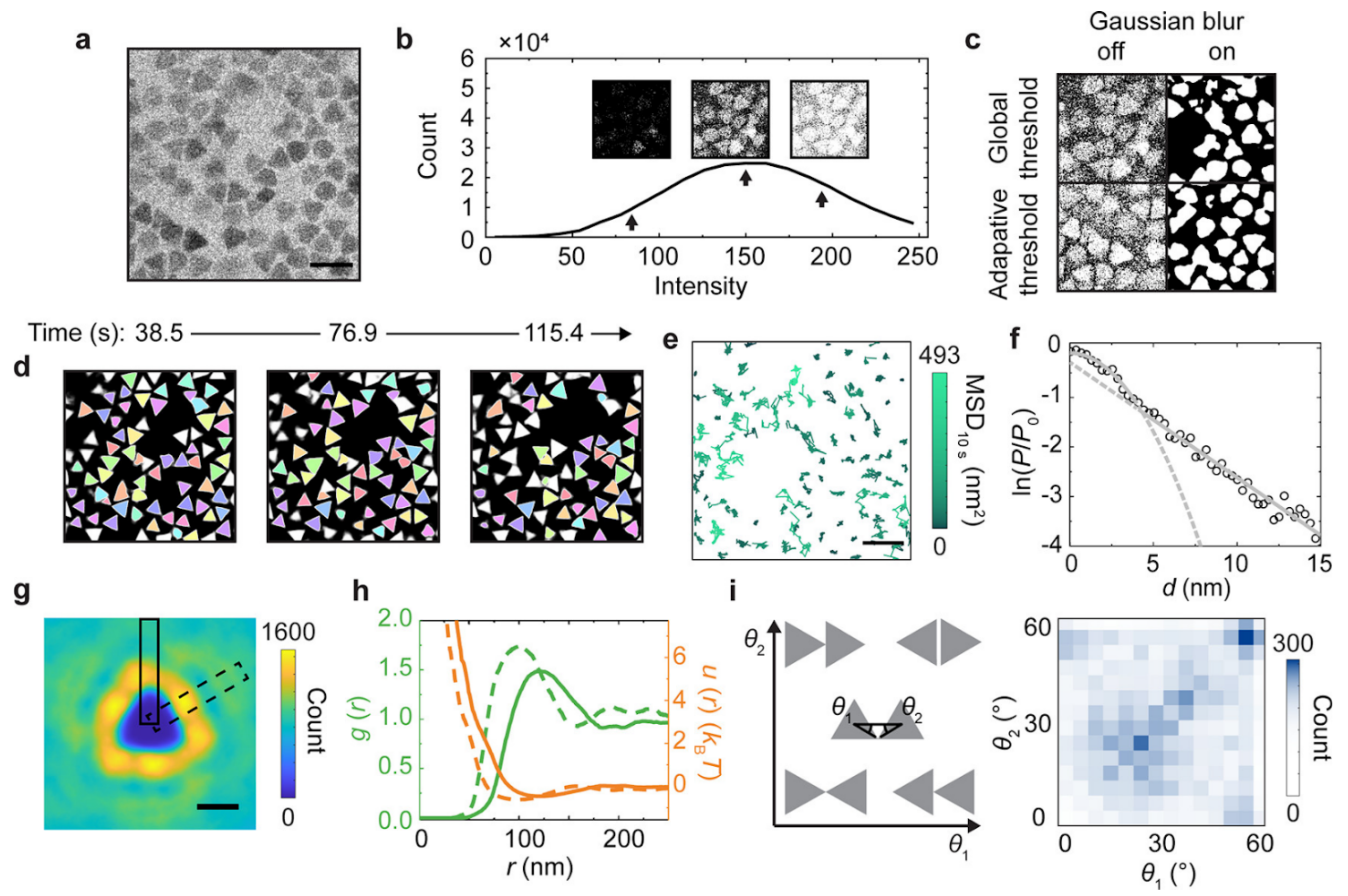

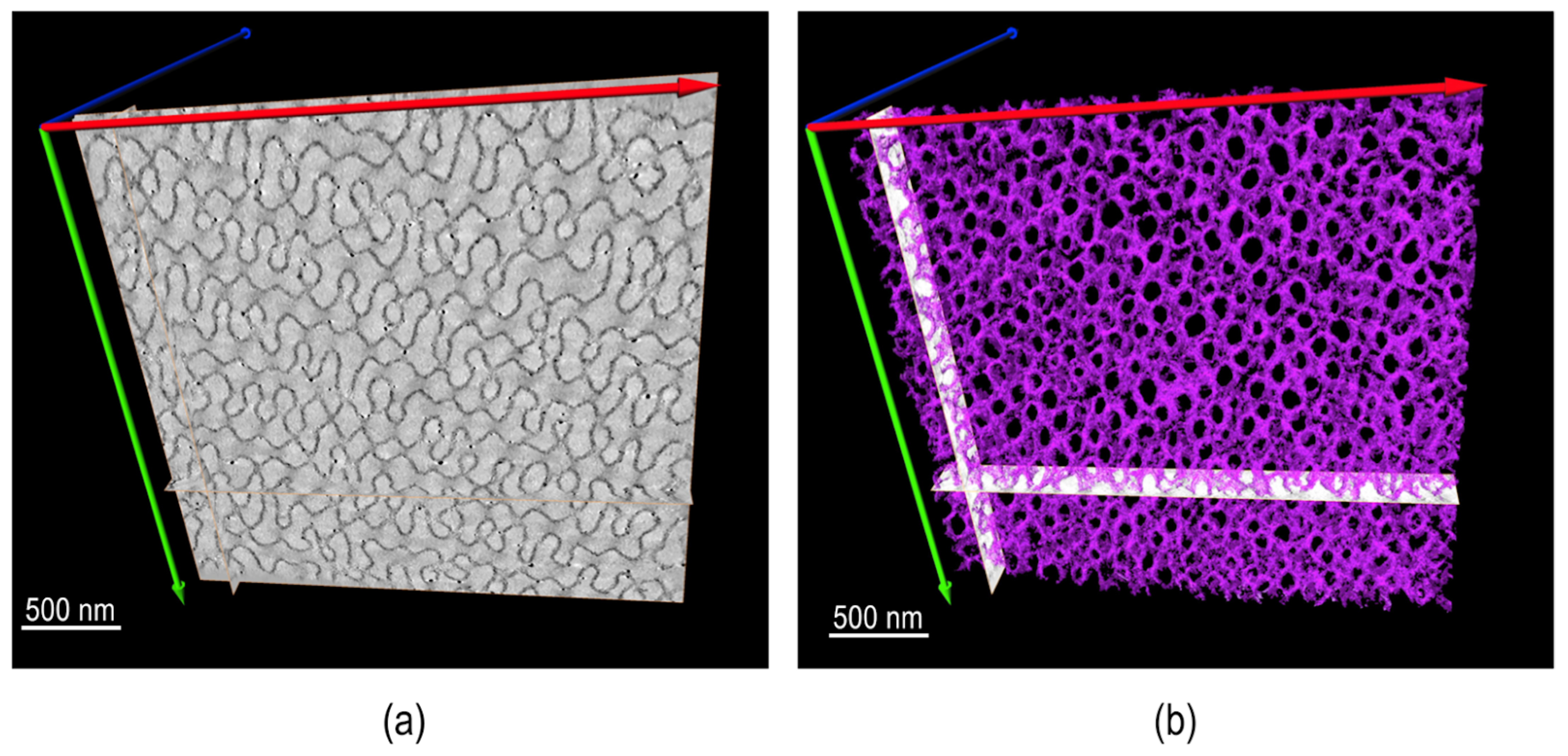

9. AI (Artificial Intelligence) for Soft Nanostructure Analysis

10. Outlook

Funding

Acknowledgments

Conflicts of Interest

References

- Young, R.J.; Lovell, P.A. Introduction to Polymers, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Qiao, Q. Organic Solar Cells: Materials, Devices, Interfaces, and Modeling; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Liechty, W.B.; Kryscio, D.R.; Slaughter, B.V.; Peppas, N.A. Polymers for Drug Delivery Systems. Annu. Rev. Chem. Biomol. Eng. 2010, 1, 149–173. [Google Scholar] [CrossRef]

- Muench, S.; Wild, A.; Friebe, C.; Häupler, B.; Janoschka, T.; Schubert, U.S. Polymer-Based Organic Batteries. Chem. Rev. 2016, 116, 9438–9484. [Google Scholar] [CrossRef]

- Ostroverkhova, O. Organic Optoelectronic Materials: Mechanisms and Applications. Chem. Rev. 2016, 116, 13279–13412. [Google Scholar] [CrossRef]

- Libera, M.R.; Egerton, R.F. Advances in the Transmission Electron Microscopy of Polymers. Polym. Rev. 2010, 50, 321–339. [Google Scholar] [CrossRef]

- Martin, D.C.; Thomas, E.L. Experimental High-Resolution Electron Microscopy of Polymers. Polymer 1995, 36, 1743–1759. [Google Scholar] [CrossRef]

- Martin, D.C.; Chen, J.; Yang, J.; Drummy, L.F.; Kübel, C. High Resolution Electron Microscopy of Ordered Polymers and Organic Molecular Crystals: Recent Developments and Future Possibilities. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 1749–1778. [Google Scholar] [CrossRef]

- Kuei, B.; Aplan, M.P.; Litofsky, J.H.; Gomez, E.D. New Opportunities in Transmission Electron Microscopy of Polymers. Mater. Sci. Eng. R Rep. 2020, 139, 100516. [Google Scholar] [CrossRef]

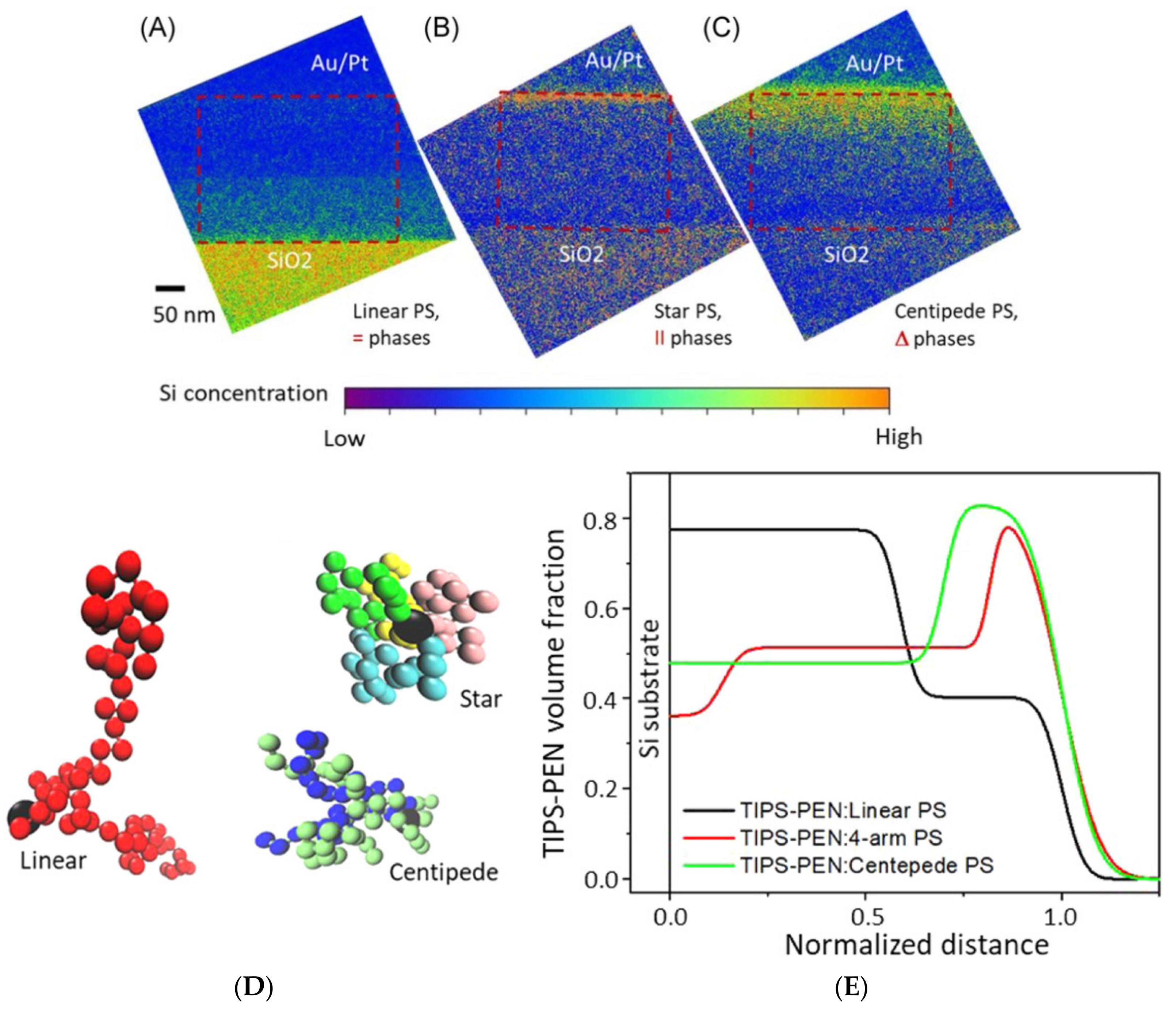

- Chen, J.; Das, S.; Shao, M.; Li, G.; Lian, H.; Qin, J.; James, F.; Browning, J.; Keum, K.; David, U.; et al. Phase segregation mechanisms of small molecule-polymer blends unraveled by varying polymer chain architecture. SmartMat 2021, 1–11. [Google Scholar] [CrossRef]

- Yue, Y.; Qiao, Z.-A.; Fulvio, P.F.; Binder, A.J.; Tian, C.; Chen, J.; Nelson, K.M.; Zhu, X.; Dai, S. Template-Free Synthesis of Hierarchical Porous Metal–Organic Frameworks. J. Am. Chem. Soc. 2013, 135, 9572–9575. [Google Scholar] [CrossRef] [PubMed]

- Tran, C.D.; Ho, H.C.; Keum, J.K.; Chen, J.; Gallego, N.C.; Naskar, A.K. Sustainable Energy-Storage Materials from Lignin–Graphene Nanocomposite-Derived Porous Carbon Film. Energy Technol. 2017, 5, 1927–1935. [Google Scholar] [CrossRef]

- Cai, L.; Chen, J.; Rondinone, A.J.; Wang, S. Injectable and Biodegradable Nanohybrid Polymers with Simultaneously Enhanced Stiffness and Toughness for Bone Repair. Adv. Funct. Mater. 2012, 22, 3181–3190. [Google Scholar] [CrossRef]

- Myung, J.H.; Gajjar, K.A.; Chen, J.; Molokie, R.E.; Hong, S. Differential Detection of Tumor Cells Using a Combination of Cell Rolling, Multivalent Binding, and Multiple Antibodies. Anal. Chem. 2014, 86, 6088–6094. [Google Scholar] [CrossRef] [PubMed]

- Marrocchi, A.; Adriaensens, P.; Bartollini, E.; Barkakaty, B.; Carleer, R.; Chen, J.; Hensley, D.K.; Petrucci, C.; Tassi, M.; Vaccaro, L. Novel Cross-Linked Polystyrenes with Large Space Network as Tailor-Made Catalyst Supports for Sustainable Media. Eur. Polym. J. 2015, 73, 391–401. [Google Scholar] [CrossRef]

- Frost, S.J.; Mawad, D.; Higgins, M.J.; Ruprai, H.; Kuchel, R.; Tilley, R.D.; Myers, S.; Hook, J.M.; Lauto, A. Gecko-Inspired Chitosan Adhesive for Tissue Repair. NPG Asia Mater. 2016, 8, e280. [Google Scholar] [CrossRef]

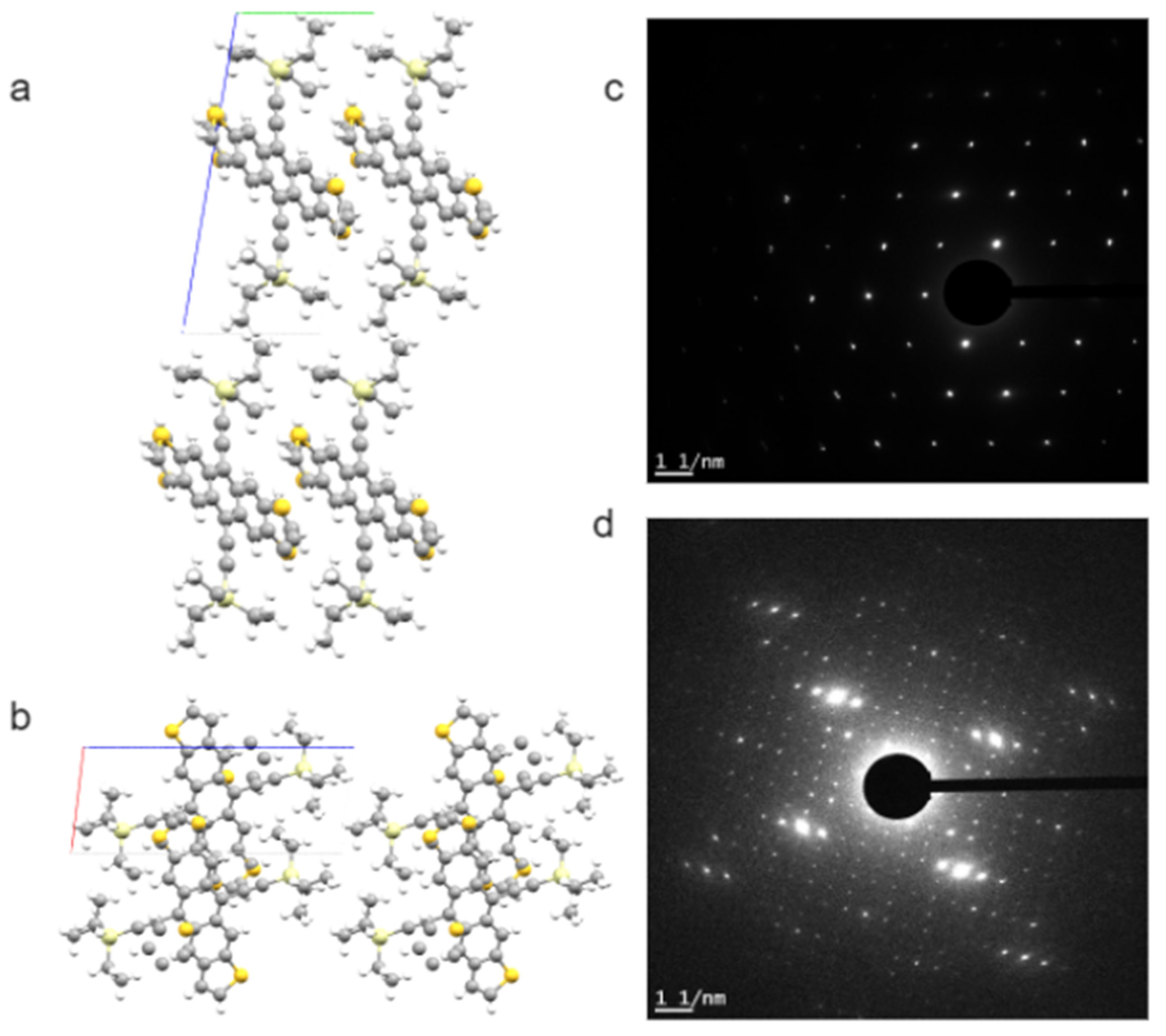

- Chen, J.; Shao, M.; Xiao, K.; He, Z.; Li, D.; Lokitz, B.S.; Hensley, D.K.; Kilbey, S.M.; Anthony, J.E.; Keum, J.K.; et al. Conjugated Polymer-Mediated Polymorphism of a High Performance, Small-Molecule Organic Semiconductor with Tuned Intermolecular Interactions, Enhanced Long-Range Order, and Charge Transport. Chem. Mater. 2013, 25, 4378–4386. [Google Scholar] [CrossRef]

- Creative Commons. Available online: https://creativecommons.org/licenses/by/4.0/ (accessed on 14 September 2021).

- Sakaoku, K.; Kobayashi, K.; Sakaou, K. The Changes of Polymer Crystals Due to Irradiation with Electrons Accelerated at Various Voltages. Bull. Inst. Chem. Res. Kyoto Univ. 1965, 42, 473–493. [Google Scholar]

- Sawyer, L.; Grubb, D.; Meyers, G.F. Polymer Microscopy, 3rd ed.; Springer: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Xiao, Z.; Yuan, Y.; Yang, B.; VanDerslice, J.; Chen, J.; Dyck, O.; Duscher, G.; Huang, J. Universal Formation of Compositionally Graded Bulk Heterojunction for Efficiency Enhancement in Organic Photovoltaics. Adv. Mater. 2014, 26, 3068–3075. [Google Scholar] [CrossRef]

- Wang, W.; Wang, W.; Lu, X.; Bobade, S.; Chen, J.; Kang, N.-G.; Zhang, Q.; Mays, J. Synthesis and Characterization of Comb and Centipede Multigraft Copolymers PnBA-g-PS with High Molecular Weight Using Miniemulsion Polymerization. Macromolecules 2014, 47, 7284–7295. [Google Scholar] [CrossRef]

- Yamashita, S.; Kikkawa, J.; Yanagisawa, K.; Nagai, T.; Ishizuka, K.; Kimoto, K. Atomic number dependence of Z contrast in scanning transmission electron microscopy. Sci. Rep. 2018, 8, 12325. [Google Scholar] [CrossRef]

- Wittmann, J.C.; Lotz, B. Polymer Decoration: The Orientation of Polymer Folds as Revealed by the Crystallization of Polymer Vapors. J. Polym. Sci. Polym. Phys. Ed. 1985, 23, 205–226. [Google Scholar] [CrossRef]

- Kim, S.; Liu, G.; Minor, A.M. FIB Sample Preparation of Polymer Thin Films on Hard Substrates Using the Shadow-FIB Method. Microsc. Today 2009, 17, 20–23. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Huang, W.; Wang, H.; Zhou, W.; Li, Y.; Li, Y.; Xu, J.; Huang, W.; Chiu, W.; et al. Cathode-Electrolyte Interphase in Lithium Batteries Revealed by Cryogenic Electron Microscopy. Matter 2021, 4, 302–312. [Google Scholar] [CrossRef]

- Flannigan, D.J.; Zewail, A.H. 4D Electron Microscopy: Principles and Applications. Acc. Chem. Res. 2012, 45, 1828–1839. [Google Scholar] [CrossRef]

- Lau, J.W.; Schliep, K.B.; Katz, M.B.; Gokhale, V.J.; Gorman, J.J.; Jing, C.; Liu, A.; Zhao, Y.; Montgomery, E.; Choe, H.; et al. Laser-Free GHz Stroboscopic Transmission Electron Microscope: Components, System Integration, and Practical Considerations for Pump–Probe Measurements. Rev. Sci. Instrum. 2020, 91, 021301. [Google Scholar] [CrossRef]

- Crozier, P.A. Vibrational and Valence Aloof Beam EELS: A Potential Tool for Nondestructive Characterization of Nanoparticle Surfaces. Ultramicroscopy 2017, 180, 104–114. [Google Scholar] [CrossRef] [PubMed]

- Egerton, R.F. Scattering Delocalization and Radiation Damage in STEM-EELS. Ultramicroscopy 2017, 180, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Mittelberger, A.; Kramberger, C.; Hofer, C.; Mangler, C.; Meyer, J.C. Automated Image Acquisition for Low-Dose STEM at Atomic Resolution. Microsc. Microanal. Off. J. Microsc. Soc. Am. Microbeam Anal. Soc. Microsc. Soc. Can. 2017, 23, 809–817. [Google Scholar] [CrossRef]

- Hachtel, J.A.; Huang, J.; Popovs, I.; Jansone-Popova, S.; Keum, J.K.; Jakowski, J.; Lovejoy, T.C.; Dellby, N.; Krivanek, O.L.; Idrobo, J.C. Identification of Site-Specific Isotopic Labels by Vibrational Spectroscopy in the Electron Microscope. Science 2019, 363, 525–528. [Google Scholar] [CrossRef] [PubMed]

- Panova, O.; Chen, X.C.; Bustillo, K.C.; Ophus, C.; Bhatt, M.P.; Balsara, N.; Minor, A.M. Orientation Mapping of Semicrystalline Polymers Using Scanning Electron Nanobeam Diffraction. Micron 2016, 88, 30–36. [Google Scholar] [CrossRef]

- Chen, J.; Yu, X.; Hong, K.; Messman, J.M.; Pickel, D.L.; Xiao, K.; Dadmun, M.D.; Mays, J.W.; Rondinone, A.J.; Sumpter, B.G.; et al. Ternary Behavior and Systematic Nanoscale Manipulation of Domain Structures in P3HT/PCBM/P3HT-b-PEO Films. J. Mater. Chem. 2012, 22, 13013–13022. [Google Scholar] [CrossRef]

- Khatiwada, D.; Venkatesan, S.; Chen, Q.; Chen, J.; Adhikari, N.; Dubey, A.; Mitul, A.F.; Mohammed, L.; Qiao, Q. Improved Performance by Morphology Control via Fullerenes in PBDT-TBT-AlkoBT Based Organic Solar Cells. J. Mater. Chem. A 2015, 3, 15307–15313. [Google Scholar] [CrossRef]

- Venkatesan, S.; Chen, J.; Ngo, E.C.; Dubey, A.; Khatiwada, D.; Zhang, C.; Qiao, Q. Critical Role of Domain Crystallinity, Domain Purity and Domain Interface Sharpness for Reduced Bimolecular Recombination in Polymer Solar Cells. Nano Energy 2015, 12, 457–467. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, S.-T.; Sonar, P.; Ma, X.; Chen, J.; Zheng, Z.; Roy, V.A.L. Reversible Conversion of Dominant Polarity in Ambipolar Polymer/Graphene Oxide Hybrids. Sci. Rep. 2015, 5, 9446. [Google Scholar] [CrossRef]

- Shewmon, N.T.; Watkins, D.L.; Galindo, J.F.; Zerdan, R.B.; Chen, J.; Keum, J.; Roitberg, A.E.; Xue, J.; Castellano, R.K. Enhancement in Organic Photovoltaic Efficiency through the Synergistic Interplay of Molecular Donor Hydrogen Bonding and π-Stacking. Adv. Funct. Mater. 2015, 25, 5166–5177. [Google Scholar] [CrossRef]

- Chen, W.; Xu, T.; He, F.; Wang, W.; Wang, C.; Strzalka, J.; Liu, Y.; Wen, J.; Miller, D.J.; Chen, J.; et al. Hierarchical Nanomorphologies Promote Exciton Dissociation in Polymer/Fullerene Bulk Heterojunction Solar Cells. Nano Lett. 2011, 11, 3707–3713. [Google Scholar] [CrossRef] [PubMed]

- Hegde, R.; Henry, N.; Whittle, B.; Zang, H.; Hu, B.; Chen, J.; Xiao, K.; Dadmun, M. The Impact of Controlled Solvent Exposure on the Morphology, Structure and Function of Bulk Heterojunction Solar Cells. Sol. Energy Mater. Sol. Cells 2012, 107, 112–124. [Google Scholar] [CrossRef]

- Chen, H.; Chen, J.; Yin, W.; Yu, X.; Shao, M.; Xiao, K.; Hong, K.; Pickel, D.L.; Kochemba, W.M.; Ii, S.M.K.; et al. Correlation of Polymeric Compatibilizer Structure to Its Impact on the Morphology and Function of P3HT:PCBM Bulk Heterojunctions. J. Mater. Chem. A 2013, 1, 5309–5319. [Google Scholar] [CrossRef]

- Sun, Z.; Xiao, K.; Keum, J.K.; Yu, X.; Hong, K.; Browning, J.; Ivanov, I.N.; Chen, J.; Alonzo, J.; Li, D.; et al. PS-b-P3HT Copolymers as P3HT/PCBM Interfacial Compatibilizers for High Efficiency Photovoltaics. Adv. Mater. 2011, 23, 5529–5535. [Google Scholar] [CrossRef]

- He, Z.; Liu, F.; Wang, C.; Chen, J.; He, L.; Nordlund, D.; Wu, H.P.; Russell, T.; Cao, Y. Simultaneous Spin-Coating and Solvent Annealing: Manipulating the Active Layer Morphology to a Power Conversion Efficiency of 9.6% in Polymer Solar Cells. Mater. Horiz. 2015, 2, 592–597. [Google Scholar] [CrossRef]

- Das, S.; Keum, J.K.; Browning, J.F.; Gu, G.; Yang, B.; Dyck, O.; Do, C.; Chen, W.; Chen, J.; Ivanov, I.N.; et al. Correlating High Power Conversion Efficiency of PTB7:PC71BM Inverted Organic Solar Cells with Nanoscale Structures. Nanoscale 2015, 7, 15576–15583. [Google Scholar] [CrossRef]

- Chen, H.; Hsiao, Y.-C.; Chen, J.; Hu, B.; Dadmun, M. Distinguishing the Importance of Fullerene Phase Separation from Polymer Ordering in the Performance of Low Band Gap Polymer:Bis-Fullerene Heterojunctions. Adv. Funct. Mater. 2014, 24, 7284–7290. [Google Scholar] [CrossRef]

- Shao, M.; Keum, J.K.; Kumar, R.; Chen, J.; Browning, J.F.; Das, S.; Chen, W.; Hou, J.; Do, C.; Littrell, K.C.; et al. Understanding How Processing Additives Tune the Nanoscale Morphology of High Efficiency Organic Photovoltaic Blends: From Casting Solution to Spun-Cast Thin Film. Adv. Funct. Mater. 2014, 24, 6647–6657. [Google Scholar] [CrossRef]

- Chen, J. TEM of Nanostructured Organic and Hybrid Materials for Photovoltaic and Battery Applications. Microsc. Microanal. 2014, 20, 626–627. [Google Scholar] [CrossRef]

- Shao, M.; Keum, J.; Chen, J.; He, Y.; Chen, W.; Browning, J.F.; Jakowski, J.; Sumpter, B.G.; Ivanov, I.N.; Ma, Y.-Z.; et al. The Isotopic Effects of Deuteration on Optoelectronic Properties of Conducting Polymers. Nat. Commun. 2014, 5, 3180. [Google Scholar] [CrossRef] [PubMed]

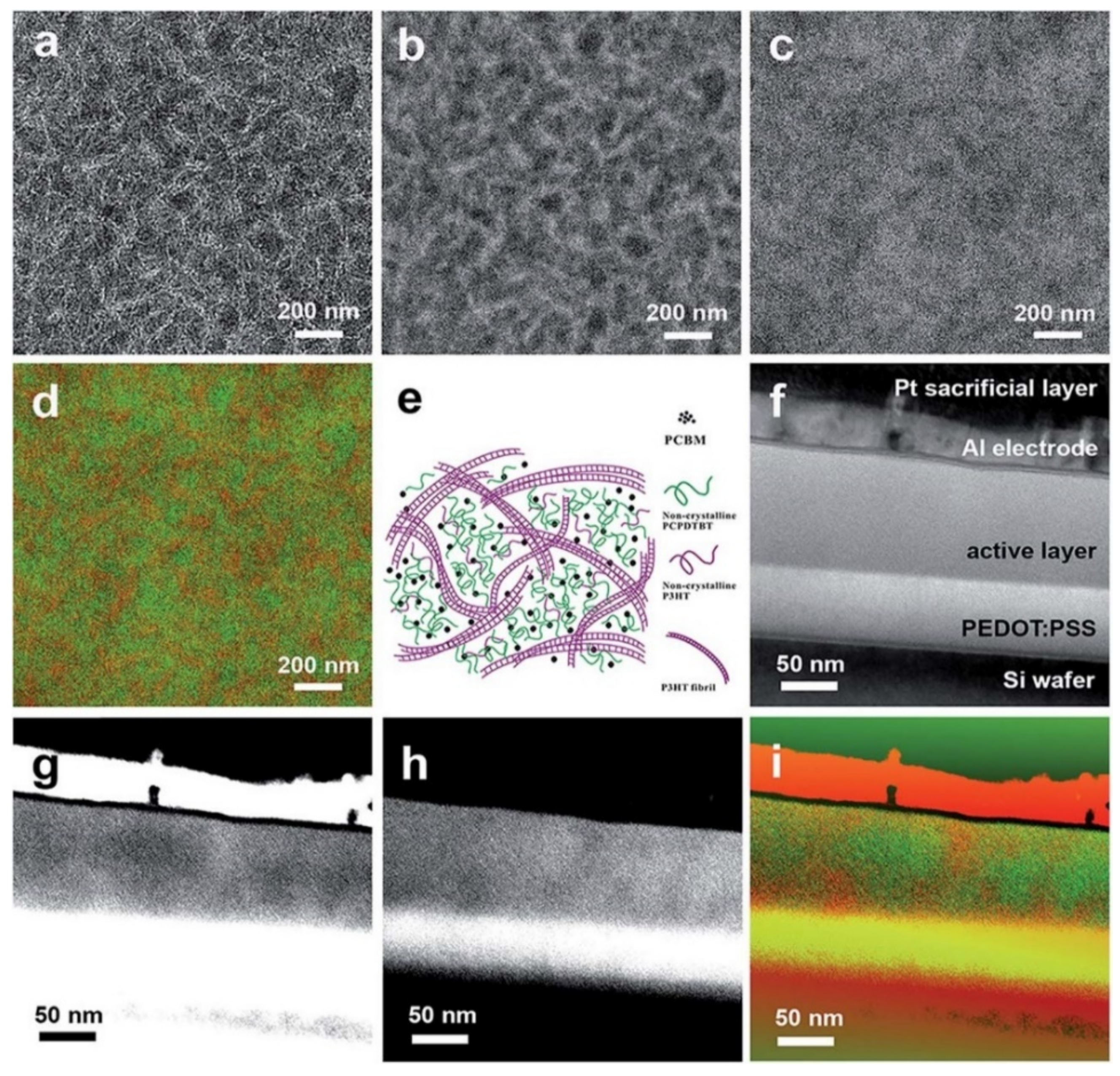

- Gu, Y.; Wang, C.; Liu, F.; Chen, J.; Dyck, O.E.; Duscher, G.; Russell, T.P. Guided Crystallization of P3HT in Ternary Blend Solar Cell Based on P3HT:PCPDTBT:PCBM. Energy Environ. Sci. 2014, 7, 3782–3790. [Google Scholar] [CrossRef]

- Venkatesan, S.; Adhikari, N.; Chen, J.; Ngo, E.C.; Dubey, A.; Galipeau, D.W.; Qiao, Q. Interplay of Nanoscale Domain Purity and Size on Charge Transport and Recombination Dynamics in Polymer Solar Cells. Nanoscale 2013, 6, 1011–1019. [Google Scholar] [CrossRef] [PubMed]

- Ajuria, J.; Chavhan, S.; Tena-Zaera, R.; Chen, J.; Rondinone, A.J.; Sonar, P.; Dodabalapur, A.; Pacios, R. Nanomorphology Influence on the Light Conversion Mechanisms in Highly Efficient Diketopyrrolopyrrole Based Organic Solar Cells. Org. Electron. 2013, 14, 326–334. [Google Scholar] [CrossRef]

- Pfannmöller, M.; Heidari, H.; Nanson, L.; Lozman, O.R.; Chrapa, M.; Offermans, T.; Nisato, G.; Bals, S. Quantitative Tomography of Organic Photovoltaic Blends at the Nanoscale. Nano Lett. 2015, 15, 6634–6642. [Google Scholar] [CrossRef]

- Chen, J.; Alonzo, J.; Yu, X.; Hong, K.; Messman, J.M.; Ivanov, I.; Lavrik, N.V.; Banerjee, M.; Rathore, R.; Sun, Z.; et al. Grafting Density Effects, Optoelectrical Properties and Nano-Patterning of Poly(Para-Phenylene) Brushes. J. Mater. Chem. A 2013, 1, 13426–13432. [Google Scholar] [CrossRef]

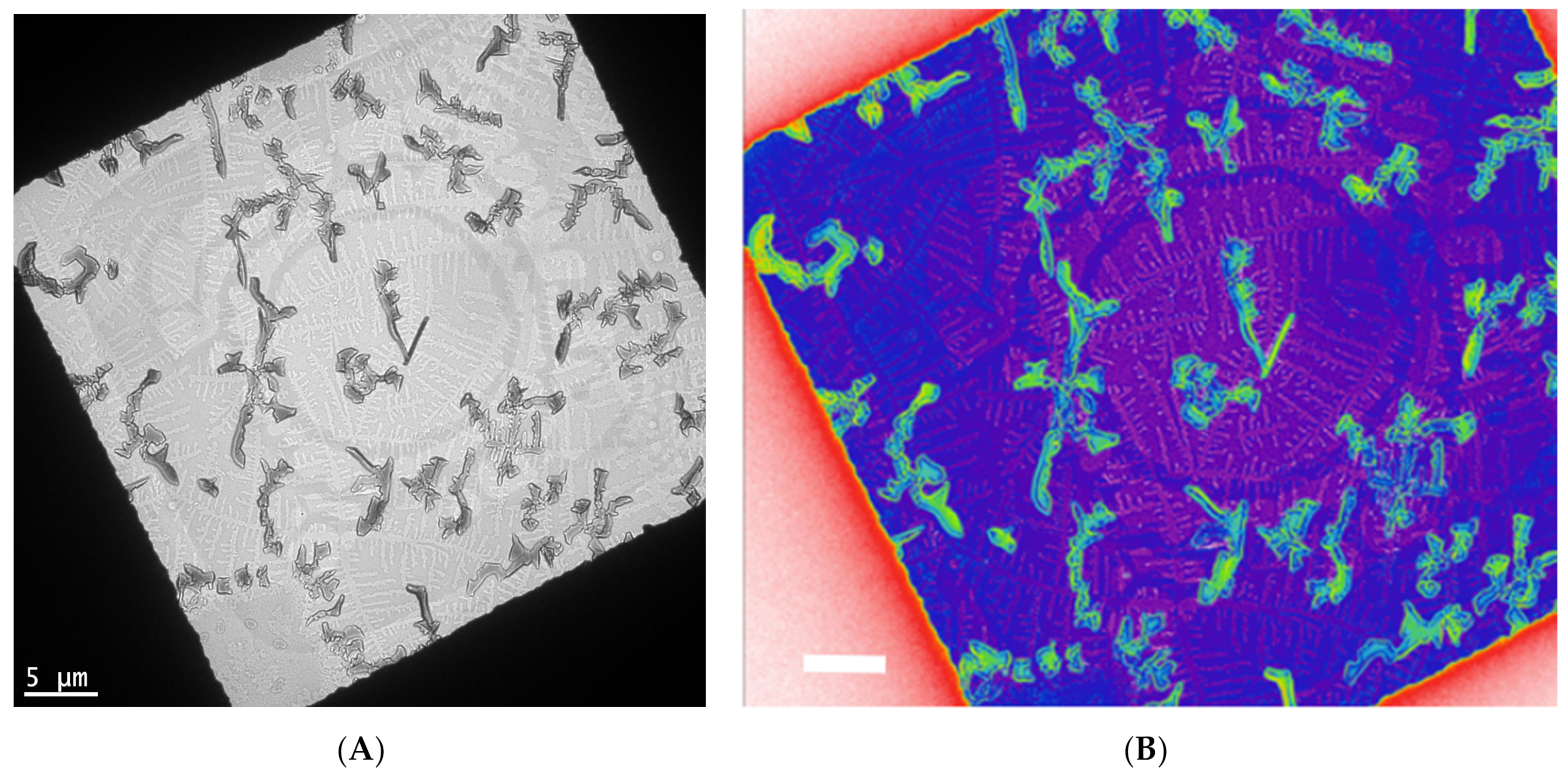

- Hunter, S.; Chen, J.; Anthopoulos, T.D. Microstructural Control of Charge Transport in Organic Blend Thin-Film Transistors. Adv. Funct. Mater. 2014, 24, 5969–5976. [Google Scholar] [CrossRef]

- Yu, X.; Xiao, K.; Chen, J.; Lavrik, N.V.; Hong, K.; Sumpter, B.G.; Geohegan, D.B. High-Performance Field-Effect Transistors Based on Polystyrene-b-Poly(3-Hexylthiophene) Diblock Copolymers. ACS Nano 2011, 5, 3559–3567. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Chen, J.; Li, D. Polymer Additive Controlled Morphology for High Performance Organic Thin Film Transistors. Soft Matter 2019, 15, 5790–5803. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Zhang, Z.; Bi, S.; Asare-Yeboah, K.; Chen, J. Ultra-Low Misorientation Angle in Small-Molecule Semiconductor/Polyethylene Oxide Blends for Organic Thin Film Transistors. J. Polym. Res. 2020, 27, 75. [Google Scholar] [CrossRef]

- He, Z.; Chen, J.; Li, D. Review Article: Crystal Alignment for High Performance Organic Electronics Devices. J. Vac. Sci. Technol. A 2019, 37, 040801. [Google Scholar] [CrossRef]

- Mei, Y.; Fogel, D.; Chen, J.; Ward, J.W.; Payne, M.M.; Anthony, J.E.; Jurchescu, O.D. Interface Engineering to Enhance Charge Injection and Transport in Solution-Deposited Organic Transistors. Org. Electron. 2017, 50, 100–105. [Google Scholar] [CrossRef]

- Ahn, S.; Carrillo, J.-M.Y.; Keum, J.K.; Chen, J.; Uhrig, D.; Lokitz, B.S.; Sumpter, B.G.; Kilbey, S.M. Nanoporous Poly(3-Hexylthiophene) Thin Film Structures from Self-Organization of a Tunable Molecular Bottlebrush Scaffold. Nanoscale 2017, 9, 7071–7080. [Google Scholar] [CrossRef]

- Goetz, K.P.; Tsutsumi, J.; Pookpanratana, S.; Chen, J.; Corbin, N.S.; Behera, R.K.; Coropceanu, V.; Richter, C.A.; Hacker, C.A.; Hasegawa, T.; et al. Polymorphism in the 1:1 Charge-Transfer Complex DBTTF–TCNQ and Its Effects on Optical and Electronic Properties. Adv. Electron. Mater. 2016, 2, 1600203. [Google Scholar] [CrossRef]

- Sonar, P.; Zhuo, J.-M.; Zhao, L.-H.; Lim, K.-M.; Chen, J.; Rondinone, A.J.; Singh, S.P.; Chua, L.-L.; Ho, P.K.H.; Dodabalapur, A. Furan Substituted Diketopyrrolopyrrole and Thienylenevinylene Based Low Band Gap Copolymer for High Mobility Organic Thin Film Transistors. J. Mater. Chem. 2012, 22, 17284–17292. [Google Scholar] [CrossRef]

- Chen, J.; Chee Keong, T.; Shtein, M.; Martin, D.C.; Anthony, J. Controlled solution deposition and systematic study of charge-transport anisotropy in single crystal and single-crystal textured TIPS pentacene thin films. Org. Electron. 2009, 10, 696–703. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S.; Chen, J.; Li, D. Conjugated Polymer Controlled Morphology and Charge Transport of Small-Molecule Organic Semiconductors. Sci. Rep. 2020, 10, 4344. [Google Scholar] [CrossRef]

- He, Z.; Zhang, Z.; Bi, S.; Asare-Yeboah, K.; Chen, J.; Li, D. A Facile and Novel Route to Improve TIPS Pentacene Based Organic Thin Film Transistor Performance with Elastomer. Synth. Met. 2020, 262, 116337. [Google Scholar] [CrossRef]

- Bi, S.; He, Z.; Chen, J.; Li, D. Solution-Grown Small-Molecule Organic Semiconductor with Enhanced Crystal Alignment and Areal Coverage for Organic Thin Film Transistors. AIP Adv. 2015, 5, 077170. [Google Scholar] [CrossRef]

- He, Z.; Shaik, S.; Bi, S.; Chen, J.; Li, D. Air-Stable Solution-Processed n-Channel Organic Thin Film Transistors with Polymer-Enhanced Morphology. Appl. Phys. Lett. 2015, 106, 183301. [Google Scholar] [CrossRef]

- He, Z.; Chen, J.; Keum, J.K.; Szulczewski, G.; Li, D. Improving Performance of TIPS Pentacene-Based Organic Thin Film Transistors with Small-Molecule Additives. Org. Electron. 2014, 15, 150–155. [Google Scholar] [CrossRef]

- Yuan, Y.; Giri, G.; Ayzner, A.L.; Zoombelt, A.P.; Mannsfeld, S.C.B.; Chen, J.; Nordlund, D.; Toney, M.F.; Huang, J.; Bao, Z. Ultra-High Mobility Transparent Organic Thin Film Transistors Grown by an off-Centre Spin-Coating Method. Nat. Commun. 2014, 5, 3005. [Google Scholar] [CrossRef]

- He, Z.; Li, D.; Hensley, D.K.; Rondinone, A.J.; Chen, J. Switching Phase Separation Mode by Varying the Hydrophobicity of Polymer Additives in Solution-Processed Semiconducting Small-Molecule/Polymer Blends. Appl. Phys. Lett. 2013, 103, 113301. [Google Scholar] [CrossRef]

- Ahn, S.; Pickel, D.L.; Kochemba, W.M.; Chen, J.; Uhrig, D.; Hinestrosa, J.P.; Carrillo, J.-M.; Shao, M.; Do, C.; Messman, J.M.; et al. Poly(3-Hexylthiophene) Molecular Bottlebrushes via Ring-Opening Metathesis Polymerization: Macromolecular Architecture Enhanced Aggregation. ACS Macro Lett. 2013, 2, 761–765. [Google Scholar] [CrossRef]

- Alonzo, J.; Kochemba, W.M.; Pickel, D.L.; Ramanathan, M.; Sun, Z.; Li, D.; Chen, J.; Sumpter, B.G.; Heller, W.T.; Ii, S.M.K. Assembly and Organization of Poly(3-Hexylthiophene) Brushes and Their Potential Use as Novel Anode Buffer Layers for Organic Photovoltaics. Nanoscale 2013, 5, 9357–9364. [Google Scholar] [CrossRef]

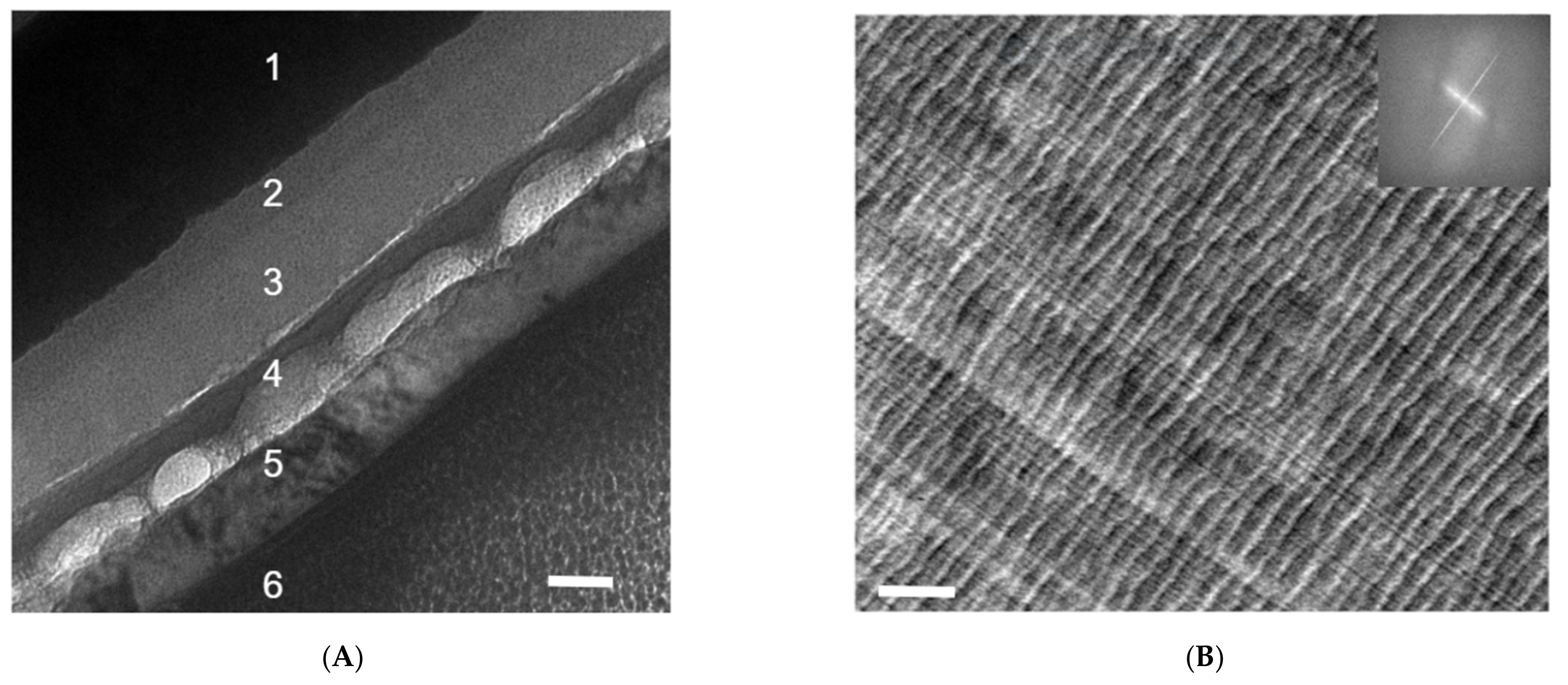

- Chen, J.; Shao, M.; Xiao, K.J.; Rondinone, A.; Loo, Y.-L.; Kent, C.P.R.; Sumpter, G.B.; Li, D.; Keum, K.J.; Diemer, J.P.; et al. Solvent-Type-Dependent Polymorphism and Charge Transport in a Long Fused-Ring Organic Semiconductor. Nanoscale 2014, 6, 449–456. [Google Scholar] [CrossRef]

- Kuk-Youn, J.; Simone, D.; Martin, C.F.; Zhou, K.C.; Jia, X.; Yu, J.; Warren, S.W. Unraveling the molecular nature of melanin changes in metastatic cancer. J. Biomed. Opt. 2019, 24, 051414. [Google Scholar] [CrossRef]

- Qiao, Z.-A.; Chai, S.-H.; Nelson, K.; Bi, Z.; Chen, J.; Mahurin, S.M.; Zhu, X.; Dai, S. Polymeric Molecular Sieve Membranes via in Situ Cross-Linking of Non-Porous Polymer Membrane Templates. Nat. Commun. 2014, 5, 3705. [Google Scholar] [CrossRef]

- Yue, Y.; Mayes, R.T.; Kim, J.; Fulvio, P.F.; Sun, X.-G.; Tsouris, C.; Chen, J.; Brown, S.; Dai, S. Seawater Uranium Sorbents: Preparation from a Mesoporous Copolymer Initiator by Atom-Transfer Radical Polymerization. Angew. Chem. 2013, 125, 13700–13704. [Google Scholar] [CrossRef]

- Zhang, J.; Chai, S.-H.; Qiao, Z.-A.; Mahurin, S.M.; Chen, J.; Fang, Y.; Wan, S.; Nelson, K.; Zhang, P.; Dai, S. Porous Liquids: A Promising Class of Media for Gas Separation. Angew. Chem. 2015, 127, 946–950. [Google Scholar] [CrossRef]

- Bi, S.; Sun, C.-N.; Zawodzinski, T.A.; Ren, F.; Keum, J.K.; Ahn, S.-K.; Li, D.; Chen, J. Reciprocated Suppression of Polymer Crystallization toward Improved Solid Polymer Electrolytes: Higher Ion Conductivity and Tunable Mechanical Properties. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1450–1457. [Google Scholar] [CrossRef]

- Sun, C.-N.; Zawodzinski, T.A.; Tenhaeff, W.E.; Ren, F.; Keum, J.K.; Bi, S.; Li, D.; Ahn, S.-K.; Hong, K.; Rondinone, A.J.; et al. Nanostructure Enhanced Ionic Transport in Fullerene Reinforced Solid Polymer Electrolytes. Phys. Chem. Chem. Phys. 2015, 17, 8266–8275. [Google Scholar] [CrossRef]

- Xie, T.; France-Lanord, A.; Wang, Y.; Shao-Horn, Y.; Grossman, J.C. Graph dynamical networks for unsupervised learning of atomic scale dynamics in materials. Nat. Commun. 2019, 10, 2667. [Google Scholar] [CrossRef]

- Zachman, M.J.; Tu, Z.; Choudhury, S.; Archer, L.A.; Kourkoutis, L.F. Cryo-STEM Mapping of Solid–Liquid Interfaces and Dendrites in Lithium-Metal Batteries. Nature 2018, 560, 345–349. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Pei, A.; Yan, K.; Sun, Y.; Wu, C.-L.; Joubert, L.-M.; Chin, R.; Koh, A.L.; Yu, Y.; et al. Atomic Structure of Sensitive Battery Materials and Interfaces Revealed by Cryo–Electron Microscopy. Science 2017, 358, 506–510. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, M.; Alvarado, J.; Wang, S.; Sina, M.; Lu, B.; Bouwer, J.; Xu, W.; Xiao, J.; Zhang, J.-G.; et al. New Insights on the Structure of Electrochemically Deposited Lithium Metal and Its Solid Electrolyte Interphases via Cryogenic TEM. Nano Lett. 2017, 17, 7606–7612. [Google Scholar] [CrossRef]

- Misichronis, K.; Chen, J.; Imel, A.; Kumar, R.; Thostenson, J.; Hong, K.; Dadmun, M.; Sumpter, B.G.; Kennemur, J.G.; Hadjichristidis, N.; et al. Investigations on the Phase Diagram and Interaction Parameter of Poly(Styrene- b-1,3-Cyclohexadiene) Copolymers. Macromolecules 2017, 50, 2354–2363. [Google Scholar] [CrossRef]

- Wang, X.; Chen, J.; Hong, K.; Mays, J.W. Well-Defined Polyisoprene-b-Poly(Acrylic Acid)/Polystyrene-b-Polyisoprene-b-Poly(Acrylic Acid) Block Copolymers: Synthesis and Their Self-Assembled Hierarchical Structures in Aqueous Media. ACS Macro Lett. 2012, 1, 743–747. [Google Scholar] [CrossRef]

- Worthington, P.; Langhans, S.; Pochan, D. β-Hairpin Peptide Hydrogels for Package Delivery. Adv. Drug Deliv. Rev. 2017, 110–111, 127–136. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-U.; Smart, T.P.; Guo, L.; Epps, T.H., 3rd; Zhang, D. Synthesis and Characterization of Amphiphilic Cyclic Diblock Copolypeptoids from N-Heterocyclic Carbene-Mediated Zwitterionic Polymerization of N-Substituted N-Carboxyanhydride. Macromolecules 2011, 44, 9574–9585. [Google Scholar] [CrossRef] [PubMed]

- Scheutz, G.M.; Touve, M.A.; Carlini, A.S.; Garrison, J.B.; Gnanasekaran, K.; Sumerlin, B.S.; Gianneschi, N.C. Probing Thermoresponsive Polymerization-Induced Self-Assembly with Variable-Temperature Liquid-Cell Transmission Electron Microscopy. Matter 2021, 4, 722–736. [Google Scholar] [CrossRef]

- Dong, M.; Wessels, M.G.; Lee, J.Y.; Su, L.; Wang, H.; Letteri, R.A.; Song, Y.; Lin, Y.-N.; Chen, Y.; Li, R.; et al. Experiments and Simulations of Complex Sugar-Based Coil−Brush Block Polymer Nanoassemblies in Aqueous Solution. ACS Nano 2019, 13, 5147–5162. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.V.; Polzer, F.; Haider, M.J.; Tian, Y.; Villegas, J.A.; Kiick, K.L.; Pochan, D.J.; Saven, J.G. Computationally Designed Peptides for Self-Assembly of Nanostructured Lattices. Sci. Adv. 2016, 2, e1600307. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, K.; Wang, X.; Zhang, F.; Zhu, J.; Mays, J.W.; Wooley, K.L.; Pochan, D.J. Multigeometry Nanoparticles: Hybrid Vesicle/Cylinder Nanoparticles Constructed with Block Copolymer Solution Assembly and Kinetic Control. Macromolecules 2015, 48, 5621–5631. [Google Scholar] [CrossRef]

- Dyer, C.; Driva, P.; Sides, S.W.; Sumpter, B.G.; Mays, J.W.; Chen, J.; Kumar, R.; Goswami, M.; Dadmun, M.D. Effect of Macromolecular Architecture on the Morphology of Polystyrene–Polyisoprene Block Copolymers. Macromolecules 2013, 46, 2023–2031. [Google Scholar] [CrossRef]

- Ni, B.; Huang, M.; Chen, Z.; Chen, Y.; Hsu, C.-H.; Li, Y.; Pochan, D.; Zhang, W.-B.; Cheng, S.Z.D.; Dong, X.-H. Pathway toward Large Two-Dimensional Hexagonally Patterned Colloidal Nanosheets in Solution. J. Am. Chem. Soc. 2015, 137, 1392–1395. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Sun, H.-J.; Hughes, A.D.; Moussodia, R.-O.; Bertin, A.; Chen, Y.; Pochan, D.J.; Heiney, P.A.; Klein, M.L.; Percec, V. Self-Assembly of Amphiphilic Janus Dendrimers into Uniform Onion-like Dendrimersomes with Predictable Size and Number of Bilayers. Proc. Natl. Acad. Sci. USA 2014, 111, 9058–9063. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Xu, C.; Liu, Y.; Liu, Z.; Wall, J.S.; Zuo, X.; Lian, T.; Salaita, K.; Ni, C.; Pochan, D.; et al. Structurally Defined Nanoscale Sheets from Self-Assembly of Collagen-Mimetic Peptides. J. Am. Chem. Soc. 2014, 136, 4300–4308. [Google Scholar] [CrossRef]

- Lee, C.-U.; Lu, L.; Chen, J.; Garno, J.C.; Zhang, D. Crystallization-Driven Thermoreversible Gelation of Coil-Crystalline Cyclic and Linear Diblock Copolypeptoids. ACS Macro Lett. 2013, 2, 436–440. [Google Scholar] [CrossRef]

- S’ari, M.; Koniuch, N.; Brydson, R.; Hondow, N.; Brown, A. High-Resolution Imaging of Organic Pharmaceutical Crystals by Transmission Electron Microscopy and Scanning Moiré Fringes. J. Microsc. 2020, 279, 197–206. [Google Scholar] [CrossRef]

- Woollam, G.R.; Das, P.P.; Mugnaioli, E.; Andrusenko, I.; Galanis, A.S.; van de Streek, J.; Nicolopoulos, S.; Gemmi, M.; Wagner, T. Structural Analysis of Metastable Pharmaceutical Loratadine Form II, by 3D Electron Diffraction and DFT+D Energy Minimisation. CrystEngComm 2020, 22, 7490–7499. [Google Scholar] [CrossRef]

- Brázda, P.; Palatinus, L.; Babor, M. Electron Diffraction Determines Molecular Absolute Configuration in a Pharmaceutical Nanocrystal. Science 2019, 364, 667–669. [Google Scholar] [CrossRef]

- Das, P.P.; Mugnaioli, E.; Nicolopoulos, S.; Tossi, C.; Gemmi, M.; Galanis, A.; Borodi, G.; Pop, M.M. Crystal Structures of Two Important Pharmaceuticals Solved by 3D Precession Electron Diffraction Tomography. Org. Process Res. Dev. 2018, 22, 1365–1372. [Google Scholar] [CrossRef]

- Van der Walt, S. Scientific Python: A Mature Computational Ecosystem for Microscopy. Microsc. Microanal. 2019, 25, 132–133. [Google Scholar] [CrossRef][Green Version]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Sebastian Seung, H. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef] [PubMed]

- Barkley, S.; Dimiduk, T.G.; Fung, J.; Kaz, D.M.; Manoharan, V.N.; McGorty, R.; Perry, R.W.; Wang, A. Holographic Microscopy With Python and HoloPy. Comput. Sci. Eng. 2020, 22, 72–82. [Google Scholar] [CrossRef]

- Somnath, S.; Smith, C.R.; Laanait, N.; Vasudevan, R.K.; Ievlev, A.; Belianinov, A.; Lupini, A.R.; Shankar, M.; Kalinin, S.V.; Jesse, S. USID and Pycroscopy—Open Frameworks for Storing and Analyzing Spectroscopic and Imaging Data. arXiv 2019, arXiv:190309515. [Google Scholar]

- Salvaire, F. High-Content Digital Microscopy with Python. arXiv 2014, arXiv:14046385. [Google Scholar]

- Wei, J.; Chu, X.; Sun, X.Y.; Xu, K.; Deng, H.X.; Chen, J.; Wei, Z.; Lei, M. Machine learning in materials science. InfoMat 2019, 1, 338–358. [Google Scholar] [CrossRef]

- Schmidt, J.; Marques, M.R.G.; Botti, S.; Marques, M.A.L. Recent advances and applications of machine learning in solid-state materials science. NPJ Comput. Mater. 2019, 5, 83. [Google Scholar] [CrossRef]

- He, Q.; Chen, J.; Keffer, D.J.; Joy, D.C. Electron Beam Induced Radiation Damage in the Catalyst Layer of a Proton Exchange Membrane Fuel Cell. Scanning 2014, 36, 338–346. [Google Scholar] [CrossRef] [PubMed]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional networks for biomedical image segmentation. In Medical Image Computing and Computer-Assisted Intervention-MICCAI 2015; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2015; pp. 234–241. [Google Scholar]

- Yao, L.; Ou, Z.; Luo, B.; Xu, C.; Chen, Q. Machine Learning to Reveal Nanoparticle Dynamics from Liquid-Phase TEM Videos. ACS Cent. Sci. 2020, 6, 1421–1430. [Google Scholar] [CrossRef] [PubMed]

- Kaufmann, K.; Zhu, C.; Rosengarten, A.S.; Maryanovsky, D.; Harrington, T.J.; Marin, E.; Vecchio, K.S. Crystal Symmetry Determination in Electron Diffraction Using Machine Learning. Science 2020, 367, 564–568. [Google Scholar] [CrossRef] [PubMed]

- Hiroshi, J.; Richard, J.S. Transmission electron microtomography in polymer research. Polymer 2009, 50, 1067–1087. [Google Scholar] [CrossRef]

- Alvarez, J.; Saudino, G.; Musteata, V.; Madhavan, P.; Genovese, A.; Behzad, A.R.; Sougrat, R.; Boi, C.; Peinemann, K.-V.; Nunes, S.P. 3D Analysis of Ordered Porous Polymeric Particles using Complementary Electron Microscopy Methods. Sci. Rep. 2019, 9, 13987. [Google Scholar] [CrossRef]

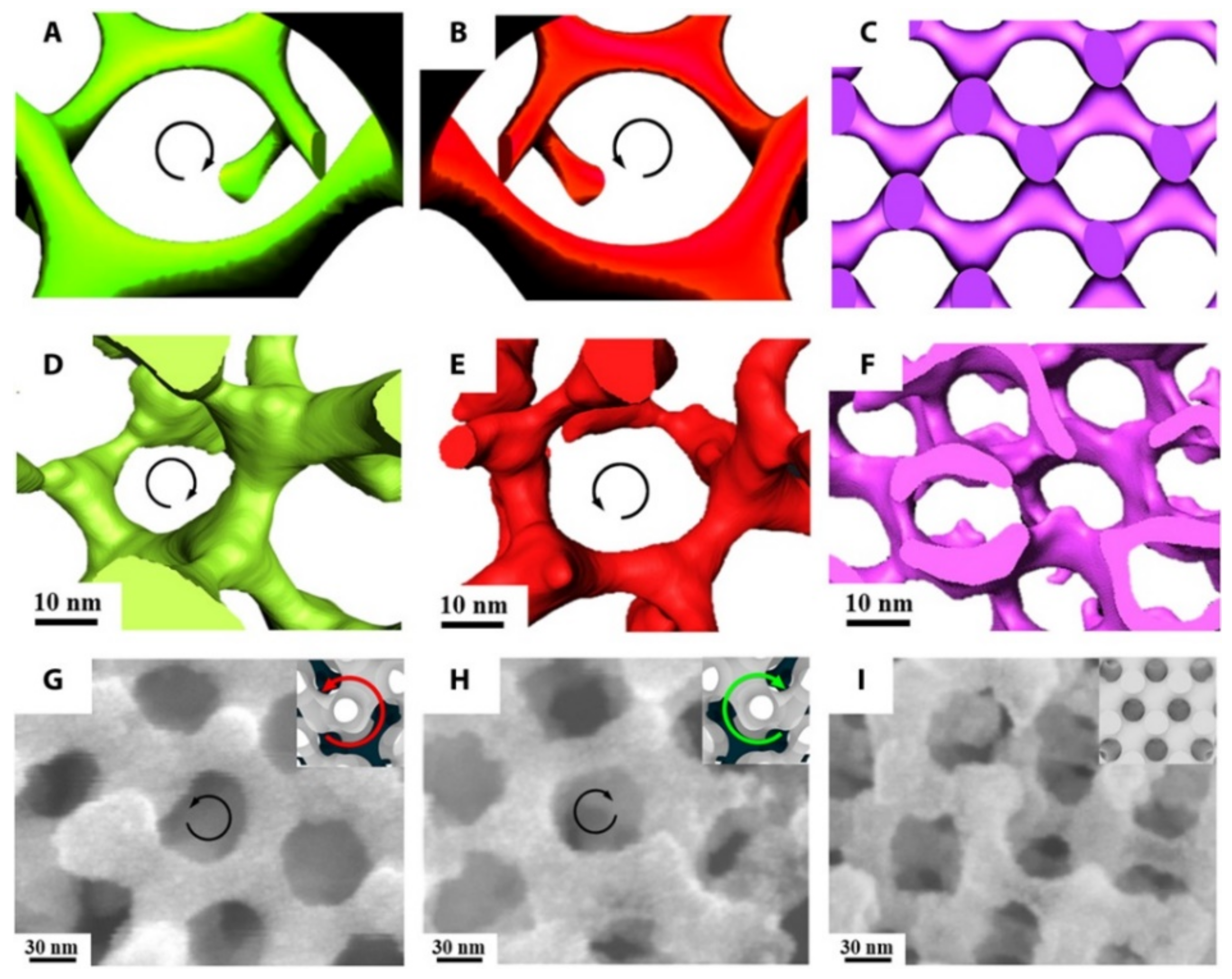

- Wang, H.-F.; Chiu, P.-T.; Yang, C.-Y.; Xie, Z.-H.; Hung, Y.-C.; Lee, J.-Y.; Tsai, J.-C.; Ishan, P.; Hiroshi, J.; Edwin, L. Thomas and Rong-Ming Ho,* Networks with controlled chirality via self-assembly of chiral triblock terpolymers. Sci. Adv. 2020, 6, eabc3644. [Google Scholar] [CrossRef]

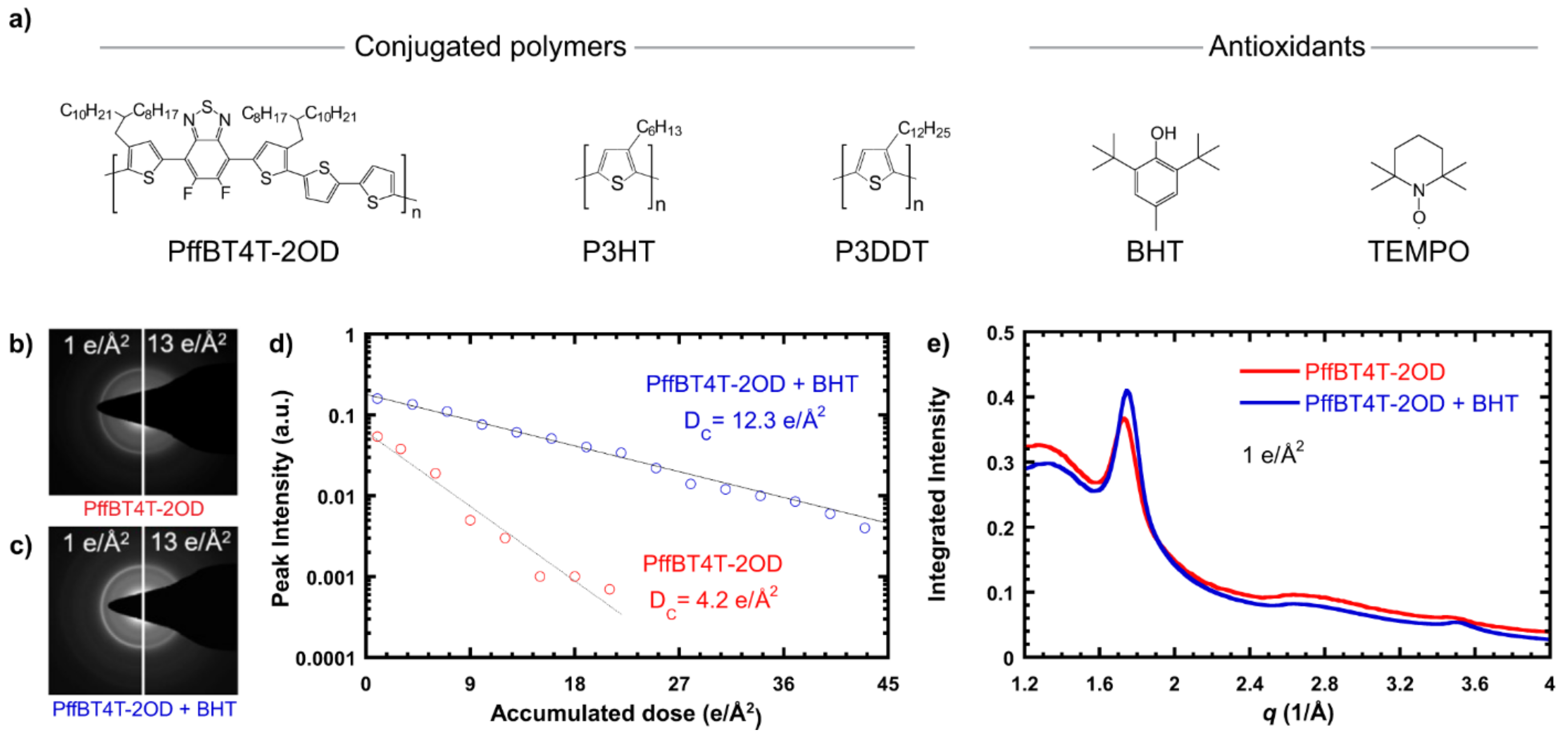

- Kuei, B.; Gomez, E.D. Pushing the limits of high-resolution polymer microscopy using antioxidants. Nat. Commun. 2021, 12, 153. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J. Advanced Electron Microscopy of Nanophased Synthetic Polymers and Soft Complexes for Energy and Medicine Applications. Nanomaterials 2021, 11, 2405. https://doi.org/10.3390/nano11092405

Chen J. Advanced Electron Microscopy of Nanophased Synthetic Polymers and Soft Complexes for Energy and Medicine Applications. Nanomaterials. 2021; 11(9):2405. https://doi.org/10.3390/nano11092405

Chicago/Turabian StyleChen, Jihua. 2021. "Advanced Electron Microscopy of Nanophased Synthetic Polymers and Soft Complexes for Energy and Medicine Applications" Nanomaterials 11, no. 9: 2405. https://doi.org/10.3390/nano11092405

APA StyleChen, J. (2021). Advanced Electron Microscopy of Nanophased Synthetic Polymers and Soft Complexes for Energy and Medicine Applications. Nanomaterials, 11(9), 2405. https://doi.org/10.3390/nano11092405