Ice-Prevention and De-Icing Capacity of Epoxy Resin Filled with Hybrid Carbon-Nanostructured Forms: Self-Heating by Joule Effect

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Characterization

2.4. Heating Test

2.5. Ice-Prevention and De-Icing Tests

3. Results

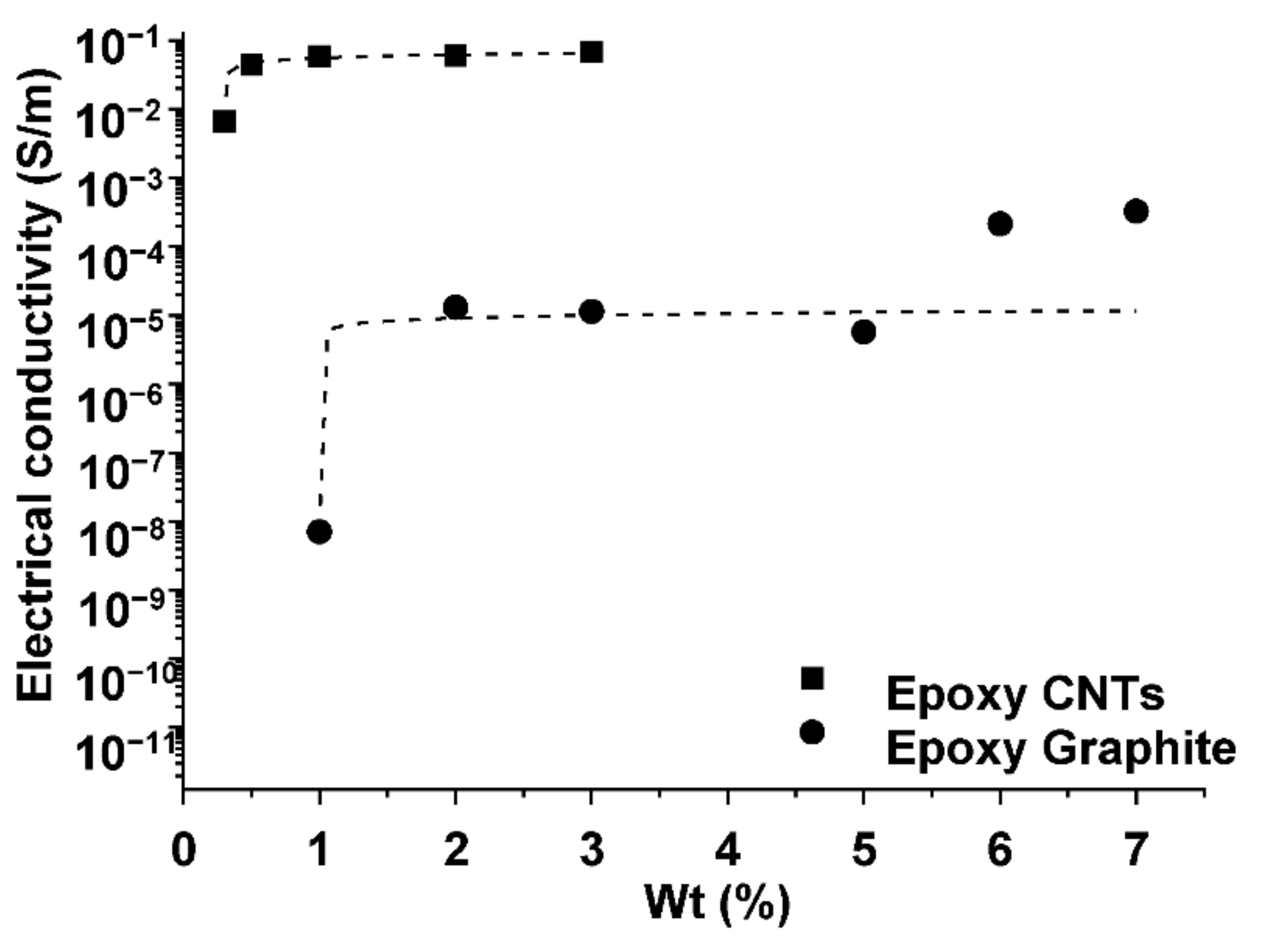

3.1. Study of the Electrical Conductivity of the Epoxy Resin with CNT and Graphite Separately

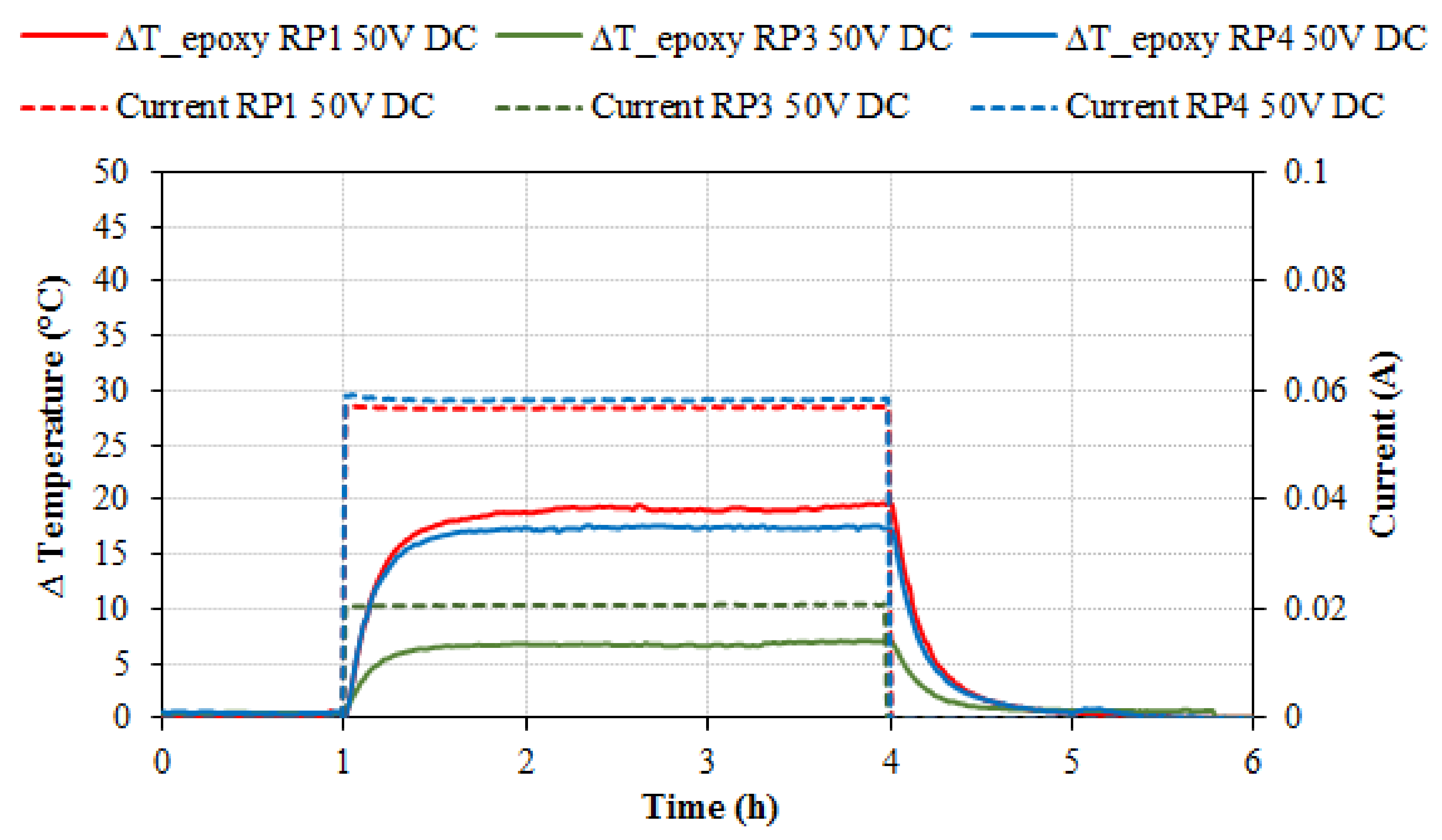

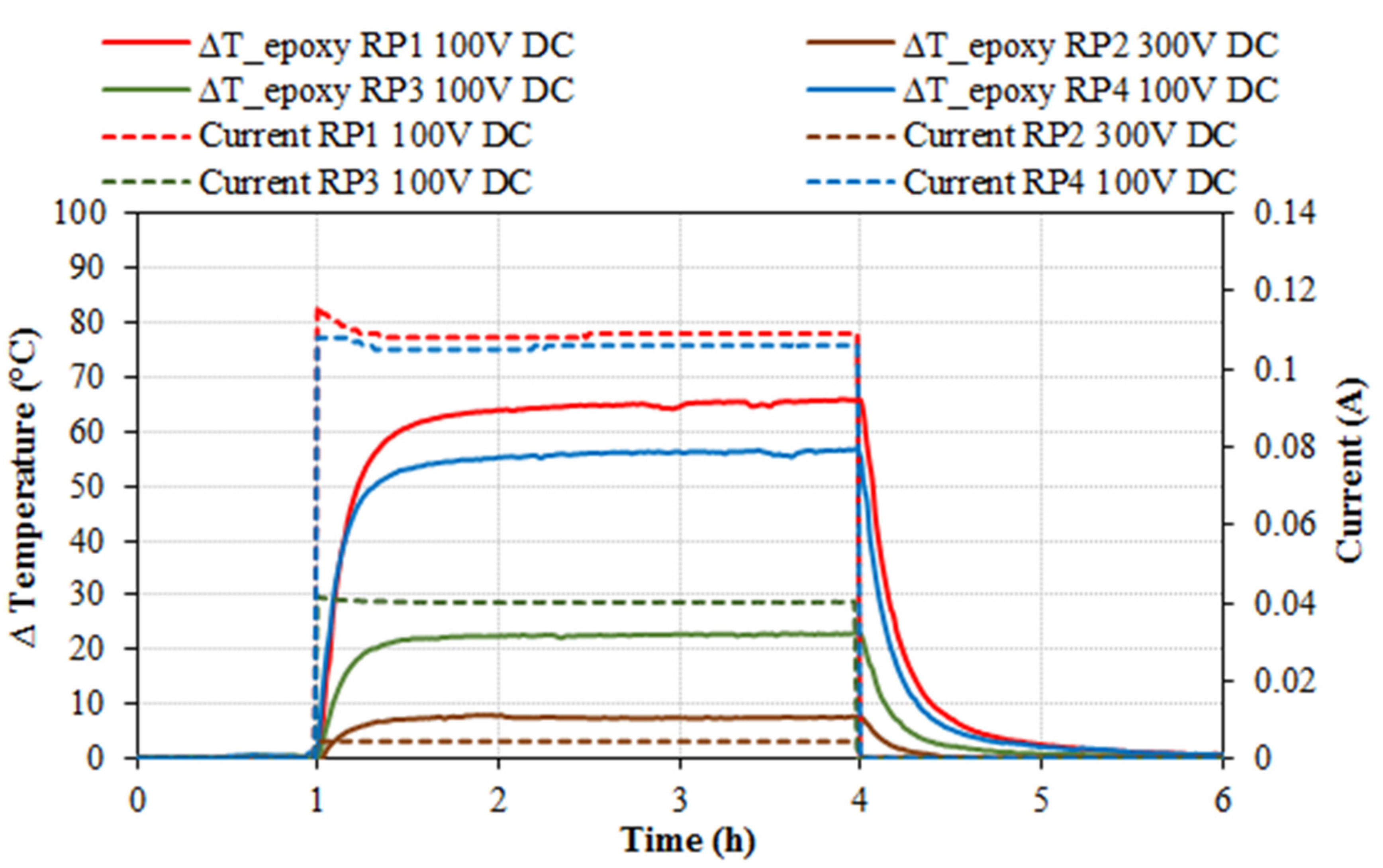

3.2. Study of the Heating Function in Epoxy Resin

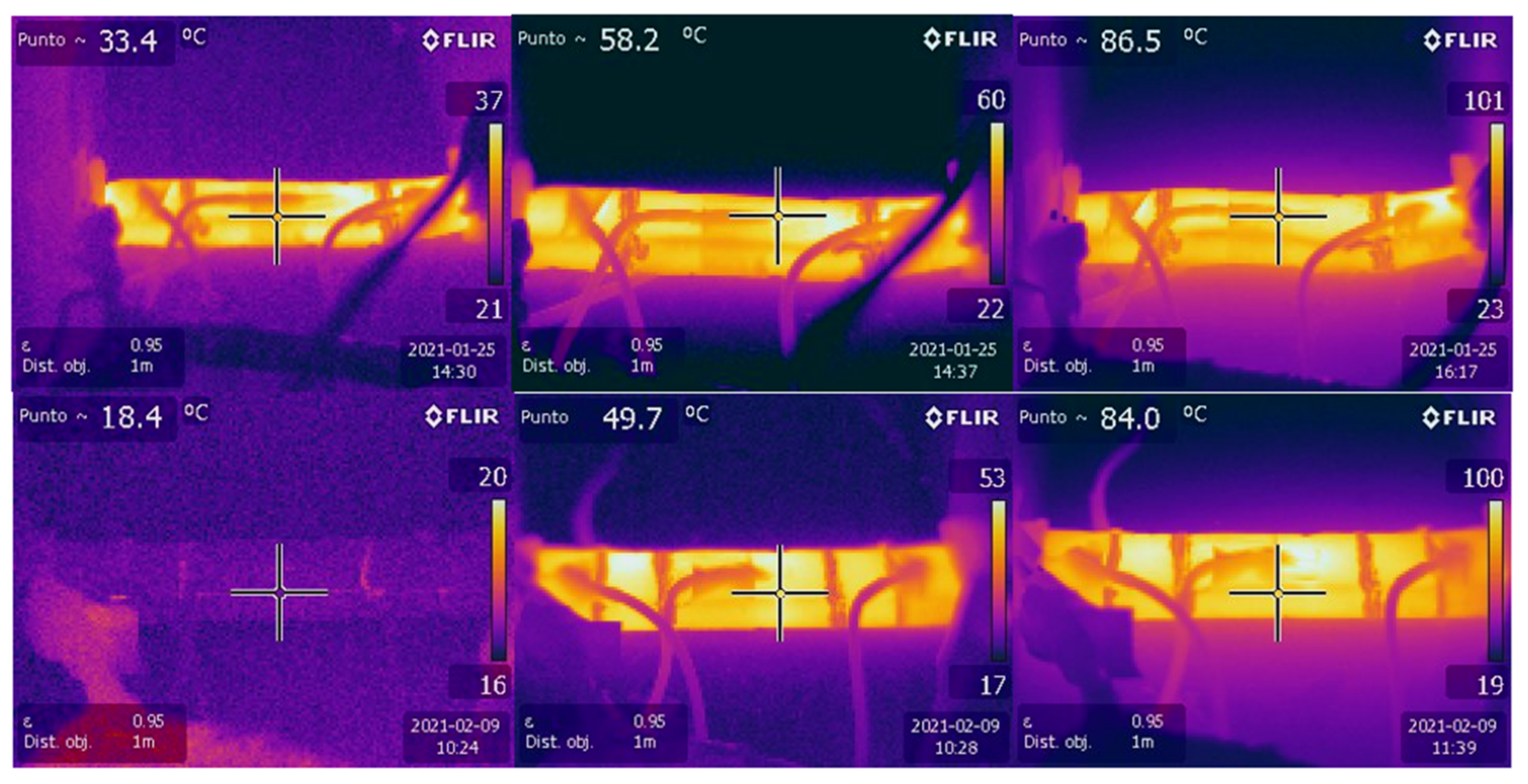

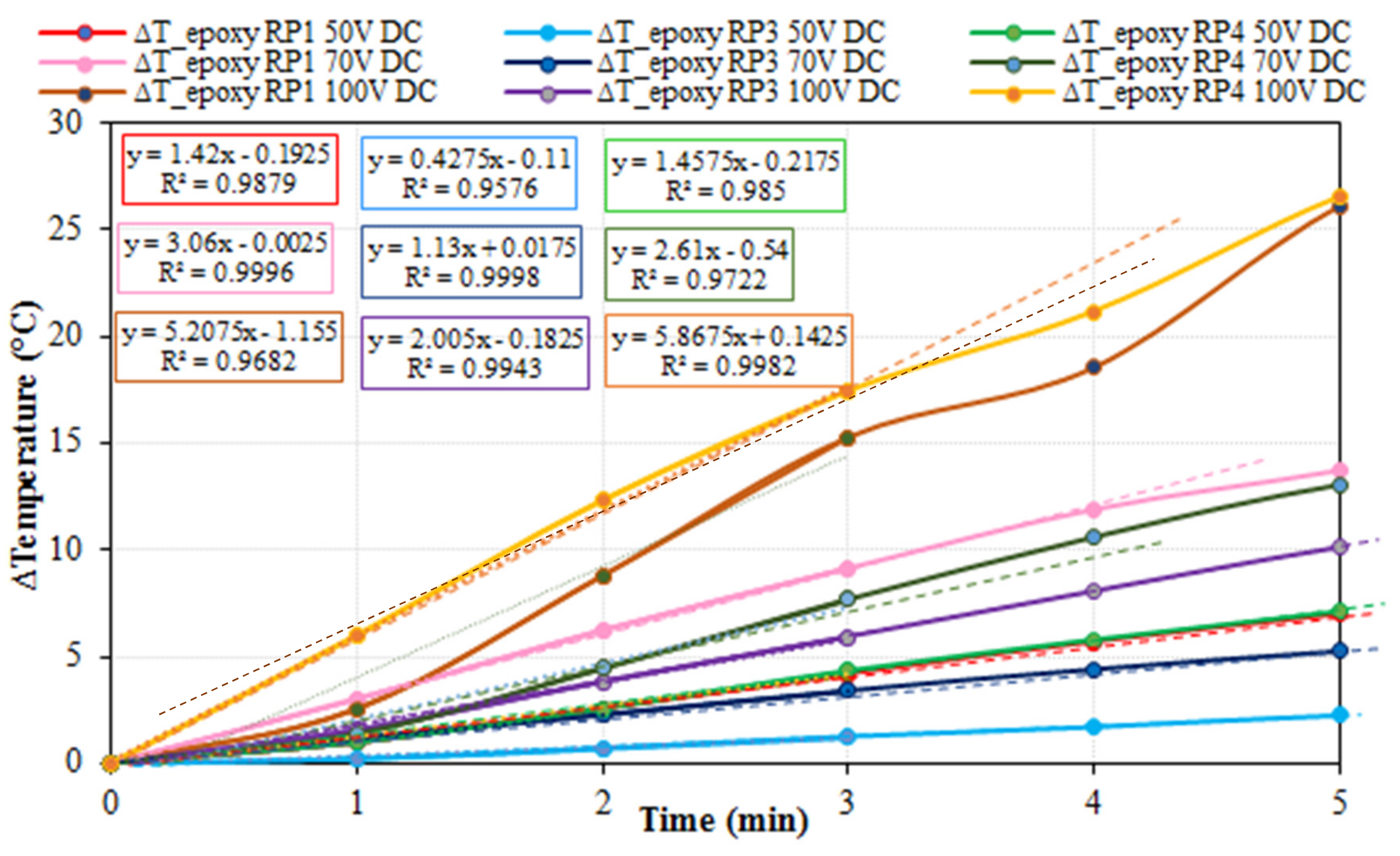

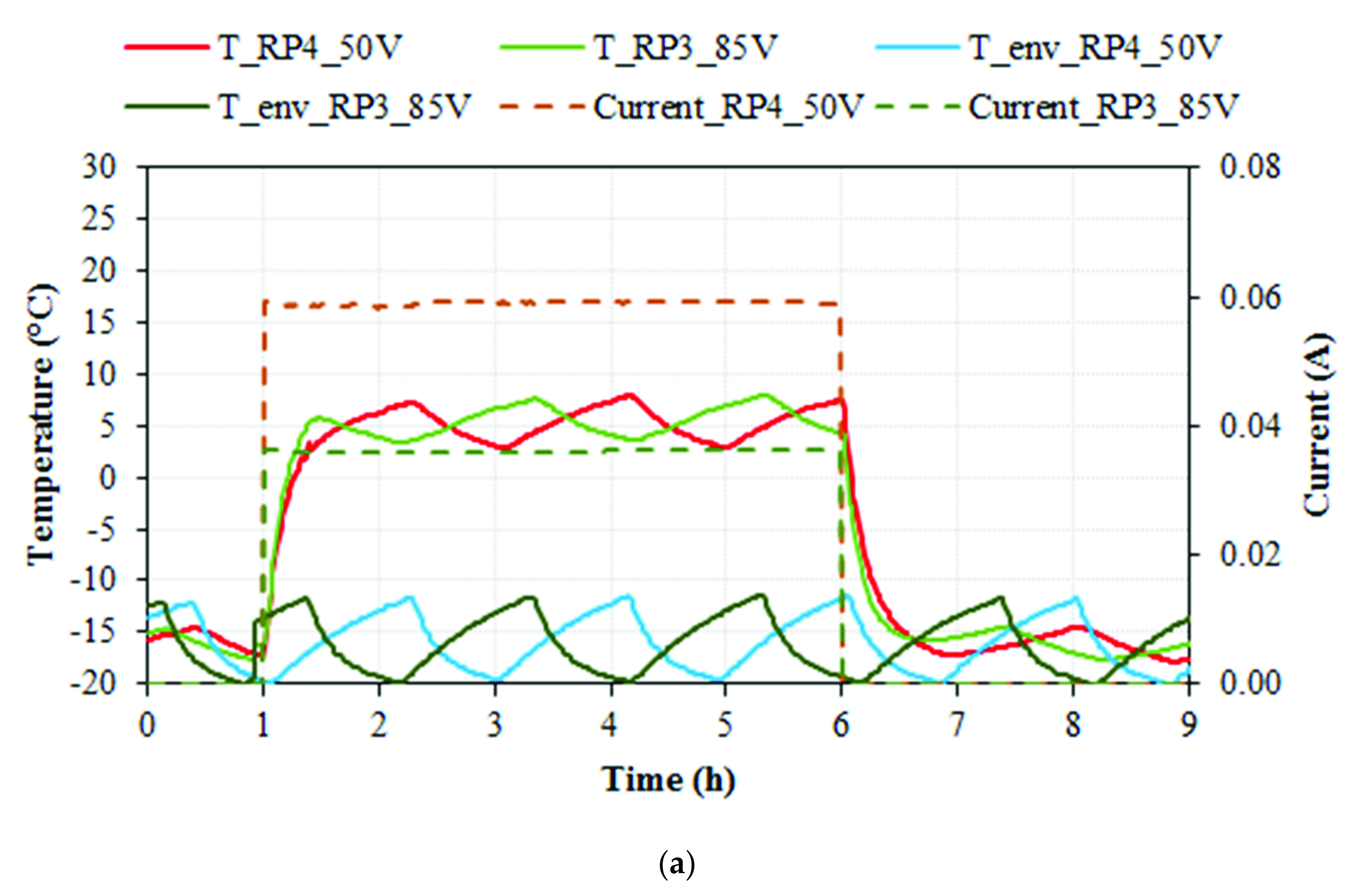

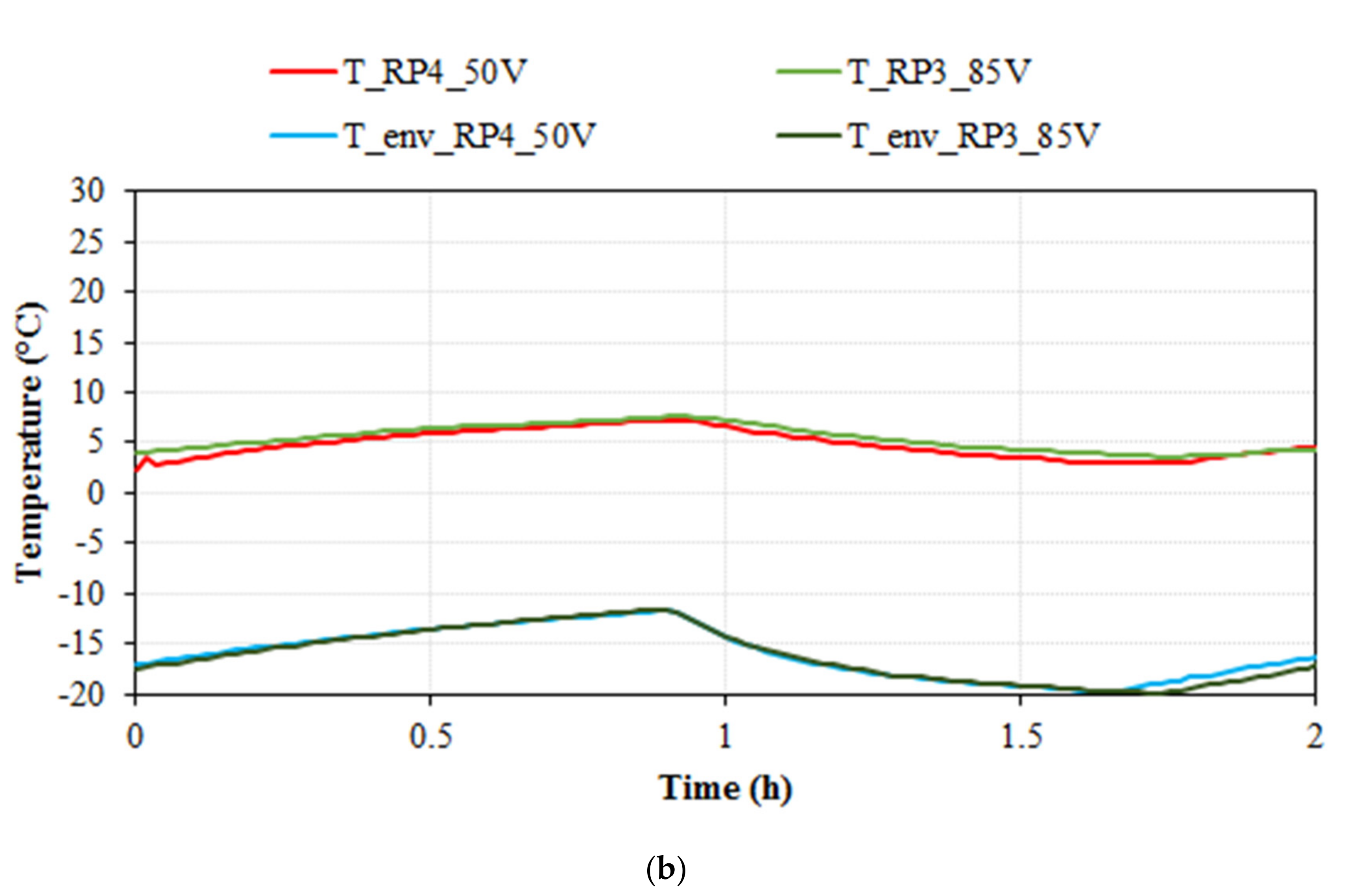

3.3. Study of Ice-Prevention and De-Icing for Epoxy Resin RP4 (1% C100 + 5% ABG1010) and RP3 (0.5% C100 + 5% ABG1010)

4. Conclusions

- RP3 specimens, with the hybrid addition of 0.5% C100 + 5% ABG1010, and RP4 specimens, with the hybrid addition of 1% C100 + 5% ABG1010, significantly increased their temperature by Joule effect with relatively low DC voltages and electrical currents. Although both composites would be feasible for heating applications, the self-heating capacity was more noticeable in the RP4 specimen, with the highest value of electrical conductivity. The highest percentage of CNTs in the formulation of the RP4 specimen compared to that of the RP3 specimen led to the highest self-heating effect.

- RP4 specimens with the same electrical conductivity as RP1 specimens (same CNTs concentration, 1% C100) did not deform at high temperatures (higher than 80 °C) due to the softening of the epoxy resin thanks to the presence of graphite with high thermal conductivity, allowing heat dissipation. RP1 specimens showed severe deformation due to the absence of graphite (no heat dissipation was produced).

- Results have shown that the RP3 and RP4 specimens were able to maintain their temperature above 0 °C in an environmental temperature of −15 °C if a suitable voltage was applied. Therefore, these composites would be feasible for ice-prevention and de-icing applications with a relatively energy low cost (for five hours of testing, the average price was calculated to be 0.94 EUR/m2 for both RP3 and RP4).

- Specimens with the same amount of CNTs showed similar electrical conductivity and similar temperature and energy behavior regardless of the quantity of graphite, indicating that CNTs were the carbon-based material responsible for the electrical conductivity and, consequently, the self-heating capacity by Joule effect.

- It is feasible to model the self-heating of carbon-based epoxy resins in order to validate the mechanism of heating. An increment of +17 °C was obtained for RP4, with a fixed voltage of 50 V.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Guadagno, L.; de Vivo, B.; di Bartolomeo, A.; Sorrentino, A.; Tucci, V.; Vertuccio, L.; Vittoria, V. Effect of functionalization on the thermo-mechanical and electrical behavior of multi-wall carbon nanotube/epoxy composites. Carbon 2011, 49, 1919–1930. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vertuccio, L.; Mauro, M.; Guerra, G.; Lafdi, K.; de Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V. Optimization of graphene-based materials outperforming host epoxy matrices. RSC Adv. 2015, 5, 36969. [Google Scholar] [CrossRef] [Green Version]

- Kong, L.; Chen, W. Carbon Nanotube and Graphene-based Bioinspired Electrochemical Actuators. Adv. Mater. 2014, 26, 1025–1043. [Google Scholar] [CrossRef] [PubMed]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, I.A.; Shaffer, M.S.P.; Windle, A.H. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- el Assami, Y.; Habti, M.D.; Raman, V. Stiffening offshore composite wind-blades bonding joints by carbon nanotubes reinforced resin—A new concept. J. Struct. Integr. Maint. 2020, 5, 87–103. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications. Polymers 2019, 11, 903. [Google Scholar] [CrossRef] [Green Version]

- Munir, A. Microwave Radar Absorbing Properties of Multiwalled Carbon Nanotubes Polymer Composites: A Review. Adv. Polym. Technol. 2017, 36, 362–370. [Google Scholar] [CrossRef]

- Vertuccio, L.; Foglia, F.; Pantani, R.; Romero-Sánchez, M.D.; Calderón, B.; Guadagno, L. Carbon nanotubes and expanded graphite based bulk nanocomposites for de-icing applications. Compos. Part B Eng. 2021, 207, 108583. [Google Scholar] [CrossRef]

- Jang, B.Z. Advanced Polymer Composites: Principles and Applications; OH 44073-0; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Kim, J.-K.; Mai, Y.-W.; Mai, Y.-W. Engineered Interfaces in Fiber Reinforced Composites; Elsevier Science Ltd: Oxford, UK, 1998. [Google Scholar]

- Mäder, E. Study of fibre surface treatments for control of interphase properties in composites. Compos. Sci. Technol. 1997, 57, 1077–1088. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Lamberti, P.; Zarrelli, M.; Russo, S.; Iannuzzo, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part B Eng. 2018, 147, 42–46. [Google Scholar] [CrossRef]

- Vertuccio, L.; Vittoria, V.; Guadagno, L.; de Santis, F. Strain and damage monitoring in carbon-nanotube-based composite under cyclic strain. Compos. Part A Appl. Sci. Manuf. 2015, 71, 9–16. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Muhammad, B. Aerospace Application of Polymer Nanocomposite with Carbon Nanotube, Graphite, Graphene Oxide, and Nanoclay. Polym. Plast. Technol. Eng. 2017, 56, 1438–1456. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Wang, C.; Sun, Q.; Zhao, L.; Jia, J.; Yao, L.; Peng, Z. Mechanical and dielectric strength of laminated epoxy dielectric graded materials. Polymers 2020, 12, 622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Waenawae, W.; Pumkrachang, S.; Zainudin, S.; Vongsetskul, T.; Osotchan, T. Curing Mechanism Study for Dual Cure of Epoxy Adhesive by Differential Scanning Calorimetry. Mater. Sci. Forum 2016, 864, 3–7. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. Epoxy resin based hybrid polymer composites. In Hybrid Polymer Composite Materials: Properties and Characterisation; Thakur, V.K., Thakur, M.K., Pappu, A., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 57–82. [Google Scholar]

- Samankan, S.; Ayatollahi, M.R.; Shadlou, S. Mechanical and Electrical Properties of Multiwalled Carbon Nanotube Nanocomposites with Different Resin Matrices. Phys. Mesomech. 2021, 24, 219–224. [Google Scholar] [CrossRef]

- Pujar, N.V.; Nanjundaradhya, N.V.; Sharma, R.S. Effect of graphene oxide nano filler on dynamic behaviour of GFRP composites. AIP Conf. Proc. 2018, 1943. [Google Scholar] [CrossRef]

- Fouda, H.; Guo, L. The Mechanical Properties of CF / Epoxy Resin Composite with Adding Different Types of CNTs. Int. J. Eng. Res. Technol. (IJERT) 2017, 6, 311–315. [Google Scholar]

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy nanocomposites reinforced with functionalized carbon nanotubes. Polymers 2020, 12, 816. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Liang, M.; Yao, Z.; Su, L.; Zhang, J.; Li, P.; Sun, C.; Jiang, H. Self-sensing behavior and mechanical properties of carbon nanotubes/epoxy resin composite for asphalt pavement strain monitoring. Constr. Build. Mater. 2020, 257, 119404. [Google Scholar] [CrossRef]

- Cataldo, A.; Biagetti, G.; Mencarelli, D.; Micciulla, F.; Crippa, P.; Turchetti, C.; Pierantoni, L.; Bellucci, S. Modeling and Electrochemical Characterization of Electrodes Based on Epoxy Composite with Functionalized Nanocarbon Fillers at High Concentration. Nanomaterials 2020, 10, 850. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Hawkins, S.C.; Falzon, B.G. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs. Carbon 2018, 136, 130–138. [Google Scholar] [CrossRef] [Green Version]

- Shioya, M.; Kuroyanagi, Y.; Ryu, M.; Morikawa, J. Analysis of the adhesive properties of carbon nanotube- and graphene oxide nanoribbon-dispersed aliphatic epoxy resins based on the Maxwell model. Int. J. Adhes. Adhes. 2018, 84, 27–36. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Verdejo, R.; Khayet, M.; de Zarate, J.M.O.; Essalhi, M.; Lopez-Manchado, M.A. Thermal conductivity of carbon nanotubes and graphene in epoxy nanofluids and nanocomposites. Nanoscale Res. Lett. 2011, 6, 610. [Google Scholar] [CrossRef] [Green Version]

- Nejad, S.M.; Srivastava, R.; Bellussi, F.M.; Thielemann, H.C.; Asinari, P.; Fasano, M. Nanoscale thermal properties of carbon nanotubes/epoxy composites by atomistic simulations. Int. J. Therm. Sci. 2021, 159, 106588. [Google Scholar] [CrossRef]

- Giraud, L.; Tourrette, A.; Flahaut, E. Carbon nanomaterials-based polymer-matrix nanocomposites for antimicrobial applications: A review. Carbon 2021, 182, 463–483. [Google Scholar] [CrossRef]

- Shen, W.; Feng, L.; Liu, X.; Luo, H.; Liu, Z.; Tong, P.; Zhang, W. Multiwall carbon nanotubes-reinforced epoxy hybrid coatings with high electrical conductivity and corrosion resistance prepared via electrostatic spraying. Prog. Org. Coatings 2016, 90, 139–146. [Google Scholar] [CrossRef]

- Li, J.; Chen, P.; Wang, Y.; Wang, G. Corrosion resistance of surface texturing epoxy resin coatings reinforced with fly ash cenospheres and multiwalled carbon nanotubes. Prog. Org. Coatings 2021, 158, 106388. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Guadagno, L.; Vertuccio, L. Damage Monitoring of Structural Resins Loaded with Carbon Fillers: Experimental and Theoretical Study. Nanomaterials 2020, 10, 434. [Google Scholar] [CrossRef] [Green Version]

- Guadagno, L.; Foglia, F.; Pantani, R.; Romero-Sanchez, M.D.; Calderón, B.; Vertuccio, L. Low-Voltage Icing Protection Film for Automotive and Aeronautical Industries. Nanomaterials 2020, 10, 1343. [Google Scholar] [CrossRef]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets - Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

- al Mahmud, H.; Gbaguidi, A.; Namilae, S.; Kim, D. Synergy effect in hybrid nanocomposites based on carbon nanotubes and graphene nanoplatelets. Nanotechnology 2020, 31, 255704. [Google Scholar] [CrossRef]

- Lee, C.; Jug, L.; Meng, E. High strain biocompatible polydimethylsiloxane-based conductive graphene and multiwalled carbon nanotube nanocomposite strain sensors. Appl. Phys. Lett. 2013, 102, 183511. [Google Scholar] [CrossRef] [Green Version]

- Luo, S.; Liu, T. SWCNT/graphite nanoplatelet hybrid thin films for self-temperature- compensated, highly sensitive, and extensible piezoresistive sensors. Adv. Mater. 2013, 25, 5650–5657. [Google Scholar] [CrossRef] [PubMed]

- Maiti, S.; Khatua, B.B. Graphene nanoplate and multiwall carbon nanotube–embedded polycarbonate hybrid composites: High electromagnetic interference shielding with low percolation threshold. Polym. Compos. 2016, 37, 2058–2069. [Google Scholar] [CrossRef]

- Redondo, O.; Prolongo, S.G.; Campo, M.; Sbarufatti, C.; Giglio, M. Anti-icing and de-icing coatings based Joule’s heating of graphene nanoplatelets. Compos. Sci. Technol. 2018, 164, 65–73. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Moriche, R.; del Rosario, G.; Jiménez-Suárez, A.; Prolongo, M.G.; Ureña, A. Joule effect self-heating of epoxy composites reinforced with graphitic nanofillers. J. Polym. Res. 2016, 23. [Google Scholar] [CrossRef] [Green Version]

- Singh, N.P.; Gupta, V.K.; Singh, A.P. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer 2019, 180, 121724. [Google Scholar] [CrossRef]

- Moosa, A.; Ramazani, A.; Nabil, M. Mechanical and Electrical Properties of Graphene Nanoplates and Carbon-Nanotubes Hybrid Epoxy Nanocomposites. Am. J. Mater. Sci. 2016, 6, 157–165. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Sun, X.; Bekyarova, E.; Itkis, M.E.; Haddon, R. Enhanced Thermal Conductivity in a Hybrid Graphite Nanoplatelet - Carbon Nanotube Filler for Epoxy Composites. Adv. Mater. 2008, 20, 4740–4744. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.H.; Schlagenhauf, L.; Nüesch, F.A.; Chu, B.T.T. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Farcas, C.; Galao, O.; Navarro, R.; Zornoza, E.; Baeza, F.J.; del Moral, B.; Pla, R.; Garcés, P. Heating and de-icing function in conductive concrete and cement paste with the hybrid addition of carbon nanotubes and graphite products. Smart Mater. Struct. 2021, 30, 045010. [Google Scholar] [CrossRef]

- Gomis, J.; Galao, O.; Gomis, V.; Zornoza, E.; Garcés, P. Self-heating and deicing conductive cement. Experimental study and modeling. Constr. Build. Mater. 2015, 75, 442–449. [Google Scholar] [CrossRef]

| Property | Epoxy Resin | Hardener |

|---|---|---|

| Mix ratio (parts by weight) | 100 | 100 |

| Initial viscosity at 25 °C (cP) | 617 | 80 |

| Density (g/cm3) | 1.16 | 1.19 |

| Mixed density (g/cm3) | 1.17 | |

| Property | Value |

|---|---|

| Outer diameter (nm) | 10–15 |

| Mean length (mm) | 1 |

| Mean nº of walls | 5–15 |

| C content (%) | >90 |

| Apparent density (kg/m3) | 50–150 |

| Mean agglomerate size (mm) | 200–500 |

| Aspect ratio | >>>100 |

| Fe content (%) | 4–7 |

| Property | Value |

|---|---|

| Loss of ignition (%) | 99.9 |

| Ash (%) | 0.01 |

| Moisture (%) | <0.1 |

| True density (g/cm3) | 2.25 |

| Scott volume (g/cm3) | 0.043 |

| Surface area (m2/g) | 22 |

| Sulfur (%) | 0.1 |

| Size distribution (µm) | D10 3.3 |

| D50 9.8 | |

| D90 40.2 |

| Nomenclature | wt.% CNTs | wt.% Graphite | Specimen Type |

| RP1 | 1 | - | Parallelepipedal |

| RP2 | 0.25 | 5 | Parallelepipedal |

| RP3 | 0.5 | 5 | Parallelepipedal |

| RP4 | 1 | 5 | Parallelepipedal |

| EC1 | 0.3 | Disk | |

| EC2 | 0.5 | Disk | |

| EC3 | 1 | Disk | |

| EC4 | 2 | Disk | |

| EC5 | 3 | Disk | |

| EC6 | 1 | Disk | |

| EC7 | 2 | Disk | |

| EC8 | 3 | Disk | |

| EC9 | 5 | Disk | |

| EC10 | 6 | Disk | |

| EC11 | 7 | Disk |

| Heating | ||||||||

|---|---|---|---|---|---|---|---|---|

| Type | Resistivity (Ω·cm) | Voltage (V) DC | Current (A) | ΔT (°C) | Average Power (W/m2) | Consumed Energy (kW·h) | Cost (EUR) | Average Energy Consumption (kW·h/m2) |

| RP1 1%C100 | 192 | 50 | 0.057 | 19.7 | 247.1 | 8.46·10−3 | 1.27·10−3 | 0.737 |

| 194 | 70 | 0.079 | 35.5 | 480.0 | 16.4·10−3 | 2.47·10−3 | 1.432 | |

| 201 | 100 | 0.109 | 66.0 | 948.5 | 32.5·10−3 | 4.87·10−3 | 2.830 | |

| RP2 0.25% C100 + 5%ABG1010 | 14231 | 250 | 0.004 | 6.5 | 78.1 | 2.8·10−3 | 0.42·10−3 | 0.233 |

| 14147 | 300 | 0.005 | 7.9 | 113.2 | 4.0·10−3 | 0.60·10−3 | 0.338 | |

| RP3 0.5% C100 + 5%ABG1010 | 510 | 50 | 0.021 | 7.1 | 85.7 | 3.1·10−3 | 0.46·10−3 | 0.254 |

| 515 | 70 | 0.029 | 13.1 | 166.5 | 5.2·10−3 | 0.78·10−3 | 0.427 | |

| 525 | 100 | 0.040 | 23.2 | 333.0 | 12.0·10−3 | 1.80·10−3 | 0.988 | |

| RP4 1% C100 + 5%ABG1010 | 184 | 50 | 0.058 | 17.6 | 247.6 | 8.7·10−3 | 1.30·10−3 | 0.739 |

| 184 | 70 | 0.078 | 31.9 | 462.8 | 16.1·10−3 | 2.42·10−3 | 1.373 | |

| 184 | 100 | 0.106 | 56.8 | 902.4 | 31.7·10−3 | 4.75·10−3 | 2.692 | |

| Type | Electrical Resistivity (Ω·cm) at 50 V (Excepting RP2 at 300 V) | Thermal Conductivity (W/m·K) |

|---|---|---|

| RP1 1%C100 | 192 | 0.224 |

| RP2 0.25% C100 + 5% ABG1010 | 14,147 | 0.351 |

| RP3 0.5% C100 + 5% ABG1010 | 510 | 0.370 |

| RP4 1% C100 + 5% ABG1010 | 184 | 0.391 |

| Type | Resistivity (Ω·cm) | Voltage (V) DC | ΔT (°C) | T (°C) | Average Power (W/m2) | Consumed Energy (kW·h) | Average Consumption (kW·h/m2) | |

|---|---|---|---|---|---|---|---|---|

| Ice-prevention | RP3 0.5% C100 + 5% ABG1010 | 501 | 85 | 21 | 4.8 | 252 | 1.53·10−2 | 1.260 |

| De-icing | 497 | 85 | 21.4 | 5.5 | 253 | 1.53·10−2 | 1.263 | |

| Ice-prevention | RP4 1% C100 + 5% ABG1010 | 182 | 50 | 21.2 | 6.2 | 250 | 1.47·10−2 | 1.249 |

| De-icing | 181 | 50 | 21.3 | 5.4 | 251 | 1.48·10−2 | 1.255 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farcas, C.; Galao, O.; Vertuccio, L.; Guadagno, L.; Romero-Sánchez, M.D.; Rodríguez-Pastor, I.; Garcés, P. Ice-Prevention and De-Icing Capacity of Epoxy Resin Filled with Hybrid Carbon-Nanostructured Forms: Self-Heating by Joule Effect. Nanomaterials 2021, 11, 2427. https://doi.org/10.3390/nano11092427

Farcas C, Galao O, Vertuccio L, Guadagno L, Romero-Sánchez MD, Rodríguez-Pastor I, Garcés P. Ice-Prevention and De-Icing Capacity of Epoxy Resin Filled with Hybrid Carbon-Nanostructured Forms: Self-Heating by Joule Effect. Nanomaterials. 2021; 11(9):2427. https://doi.org/10.3390/nano11092427

Chicago/Turabian StyleFarcas, Catalina, Oscar Galao, Luigi Vertuccio, Liberata Guadagno, M. Dolores Romero-Sánchez, Iluminada Rodríguez-Pastor, and Pedro Garcés. 2021. "Ice-Prevention and De-Icing Capacity of Epoxy Resin Filled with Hybrid Carbon-Nanostructured Forms: Self-Heating by Joule Effect" Nanomaterials 11, no. 9: 2427. https://doi.org/10.3390/nano11092427

APA StyleFarcas, C., Galao, O., Vertuccio, L., Guadagno, L., Romero-Sánchez, M. D., Rodríguez-Pastor, I., & Garcés, P. (2021). Ice-Prevention and De-Icing Capacity of Epoxy Resin Filled with Hybrid Carbon-Nanostructured Forms: Self-Heating by Joule Effect. Nanomaterials, 11(9), 2427. https://doi.org/10.3390/nano11092427