Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review

Abstract

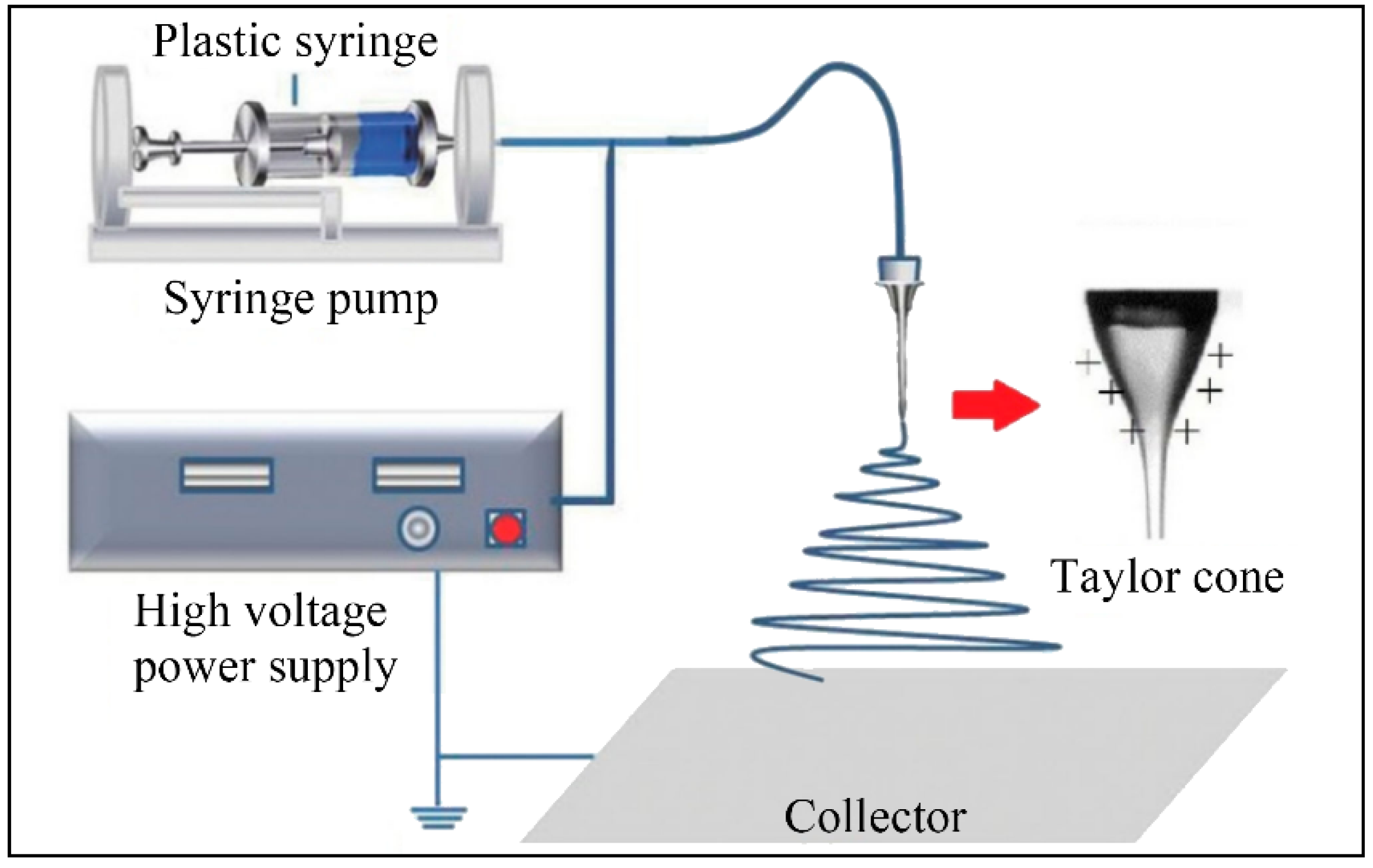

:1. Introduction

2. Advantages of Electrospinning for Reutilizing Polymeric Waste

2.1. Diversity of Electrospinning Materials

2.2. Variety of Modified Electrospinning Techniques

2.3. The Complexity of Electrospinning Structures

3. Typical Polymer Waste and Reutilization via Electrospinning

3.1. PET

3.1.1. Directly Electrospun Recycled PET into Micro/Nanofibers for Different Applications

3.1.2. Recycled PET as a Raw Source of Electrospinning for Mechanism Research

3.1.3. Combine Electrospinning with Other Techniques to Fabricate Functionalized Fibers

3.1.4. Electrospun Recycled PET Incorporated with Additives to Obtain Fibers with Unique Properties

3.2. PS

3.3. PA

3.4. Other Plastic Waste

4. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saleem, J.; Riaz, M.A.; McKay, G. Oil Sorbents from Plastic Wastes and Polymers: A Review. Hazard. Mater. 2018, 341, 424–437. [Google Scholar] [CrossRef] [PubMed]

- Basto, M.N.; Nicastro, K.R.; Tavares, A.I.; McQuaid, C.D.; Casero, M.; Azevedo, F.; Zardi, G.I. Plastic Ingestion in Aquatic Birds in Portugal. Mar. Pollut. Bull. 2019, 138, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Verma, A.; Sharma, B.; Chaudhary, J.; Tamulevicius, S.; Thakur, V.K. Recent Developments in Recycling of Polystyrene Based Plastics. Curr. Opin. Green Sustain. Chem. 2018, 13, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [Green Version]

- Bujak, J.W. Thermal utilization (treatment) of plastic waste. Energy 2015, 90, 1468–1477. [Google Scholar] [CrossRef]

- Pan, D.; Su, F.M.; Liu, C.T.; Guo, Z.H. Research progress for plastic waste management and manufacture of value-added products. Adv. Compos. Hybrid Mater. 2020, 3, 443–461. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Environmental Performance of Bio-based and Biodegradable Plastics: The Road Ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef]

- Zare, Y. Recent Progress on Preparation and Properties of Nanocomposites from Recycled Polymers: A Review. Waste Manag. 2013, 33, 598–604. [Google Scholar] [CrossRef]

- Qasim, S.B.; Zafar, M.S.; Najeeb, S.; Khurshid, Z.; Shah, A.H.; Husain, S.; Rehman, I.U. Electrospinning of Chitosan-Based Solutions for Tissue Engineering and Regenerative Medicine. Int. J. Mol. Sci. 2018, 19, 407. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.T.; Chen, Y.M.; Li, Y.; Zhou, W.; Xu, W.H.; Pang, L.; Fan, X.M.; Jiang, S.H. Electrospun Fibrous Materials and Their Applications for Electromagnetic Interference Shielding: A Review. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106309. [Google Scholar] [CrossRef]

- Xue, J.J.; Wu, T.; Dai, Y.Q.; Xia, Y.N. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Peng, S.J.; Li, L.L.; Hu, Y.X.; Srinivasan, M.; Cheng, F.Y.; Chen, J.; Ramakrishna, S. Fabrication of Spinel One-Dimensional Architectures by Single-Spinneret Electrospinning for Energy Storage Applications. ACS Nano 2015, 9, 1945–1954. [Google Scholar] [CrossRef]

- Dong, Z.X.; Kennedy, S.J.; Wu, Y.Q. Electrospinning Materials for Energy-Related Applications and Devices. J. Power Sources 2011, 196, 4886–4904. [Google Scholar] [CrossRef]

- Ondarçuhu, T.; Joachim, C. Drawing a Single Nanofibre over Hundreds of Microns. Europhys. Lett. 1998, 42, 215. [Google Scholar] [CrossRef]

- Rafii-Tabar, H. Modelling the Nano–scale Phenomena in Condensed Matter Physics via Computer-Based Numerical Simulations. Phys. Rep. 2000, 325, 239–310. [Google Scholar] [CrossRef]

- Liu, G.J.; Ding, J.F.; Qiao, L.J.; Guo, A.; Dymov, B.P.; Gleeson, J.T.; Hashimoto, T.; Saijo, K. Polystyrene-Block-Poly(2-cinnamoylethyl methacrylate) Nanofibers-Preparation, Characterization, and Liquid Crystalline Properties. Chem. Eur. J. 1999, 5, 2740–2749. [Google Scholar] [CrossRef]

- Whitesides, G.M.; Grzybowski, B. Self-Assembly at All Scales. Science 2002, 295, 2418–2421. [Google Scholar] [CrossRef] [Green Version]

- Lim, C.T. Nanofiber Technology: Current Status and Emerging Developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar] [CrossRef]

- Asmatulu, R.; Davluri, S.; Khan, W. Fabrications of CNT Based Nanocomposite Fibers from the Recycled Plastics. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009. [Google Scholar] [CrossRef]

- Isık, T.; Horzum, N.; Demir, M.M.; Muñoz-espí, R.; Crespy, D. A Recycling Route of Plastics Via Electrospinning: From Daily Wastes to Functional Fibers. In Green Electrospinning; Horzum, N., Demir, M.M., Muñoz-Espí, R., Crespy, D., Eds.; De Gruyter: Berlin, Germany, 2019; pp. 239–264. [Google Scholar] [CrossRef]

- Yasin, S.; Bakr, Z.H.; Ali, G.A.M.; Saeed, I. Recycling Nanofibers from Polyethylene Terephthalate Waste Using Electrospinning Technique. In Waste Recycling Technologies for Nanomaterials Manufacturing; Makhlouf, A.S.H., Ali, G.A.M., Eds.; Springer: Cham, Switzerland, 2021; pp. 805–821. ISBN 978-3-030-68031-2. [Google Scholar] [CrossRef]

- Zander, N.E.; Sweetser, D.; Cole, D.P.; Gillan, M. Formation of Nanofibers from Pure and Mixed Waste Streams Using Electrospinning. Ind. Eng. Chem. Res. 2015, 54, 9057–9063. [Google Scholar] [CrossRef]

- Esmaeili, E.; Deymeh, F.; Rounaghi, S.A. Synthesis and Characterization of the Electrospun Fibers Prepared from Waste Polymeric Materials. Int. J. Nano Dimens 2017, 8, 171–181. [Google Scholar] [CrossRef]

- Chen, K.; Chou, W.; Liu, L.; Cui, Y.; Xue, P.; Jia, M. Electrochemical Sensors Fabricated by Electrospinning Technology: An Overview. Sensors 2019, 19, 3676. [Google Scholar] [CrossRef]

- Taylor, G.I. Electrically Driven Jets. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1969, 313, 453–475. [Google Scholar] [CrossRef]

- Ren, L.Y.; Ozisik, R.; Kotha, S.P.; Underhill, P.T. Highly Efficient Fabrication of Polymer Nanofiber Assembly by Centrifugal Jet Spinning: Process and Characterization. Macromolecules 2015, 48, 2593–2602. [Google Scholar] [CrossRef]

- Zheng, G.F.; Jiang, J.X.; Wang, X.; Li, W.W.; Liu, J.; Fu, G.; Lin, L.W. Nanofiber Membranes by Multi-Jet Electrospinning Arranged as Arc-Array with Sheath Gas for Electrodialysis Applications. Mater. Des. 2020, 189, 108504. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, Y.; Li, A.L.; Wei, L.; Wang, L.M.; Qin, X.H.; Yu, J.Y. Mass Production of High-Quality Nanofibers via Constructing Pre-Taylor Cones with High Curvature on Needleless Electrospinning. Mater. Des. 2020, 197, 109247. [Google Scholar] [CrossRef]

- Quan, Z.Z.; Wang, Y.H.; Zu, Y.; Qin, X.H.; Yu, J.Y. A Rotary Spinneret for High Output of Electrospun Fibers with Bimodal Distribution. Eur. Polym. J. 2021, 159, 110707. [Google Scholar] [CrossRef]

- Aminyan, R.; Bazgir, S. Fabrication and Characterization of Nanofibrous Polyacrylic Acid Superabsorbent Using Gas-Assisted Electrospinning Technique. React. Funct. Polym. 2019, 141, 133–144. [Google Scholar] [CrossRef]

- Kong, X.Z.; Zheng, Y.C.; Wang, Y.P.; Liang, S.Q.; Cao, G.Z.; Pan, A.Q. Necklace-Like Si@ C Nanofibers as Robust Anode Materials for High Performance Lithium Ion Batteries. Sci. Bull. 2019, 64, 261–269. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Shi, X.J.; Zhang, X.X.; Li, L.L. Electrospinning of Polycaprolacton/Chitosan Core-Shell Nanofibers by a Stable Emulsion System. Colloid Surf. A-Physicochem. Eng. Asp. 2019, 583, 123956. [Google Scholar] [CrossRef]

- Gao, J.F.; Song, X.; Huang, X.W.; Wang, L.; Li, B.; Xue, H.G. Facile Preparation of Polymer Microspheres and Fibers with a Hollow Core and Porous Shell for Oil Adsorption and Oil/Water Separation. Appl. Surf. Sci. 2018, 439, 394–404. [Google Scholar] [CrossRef]

- Zhang, D.; Jin, X.Z.; Huang, T.; Zhang, N.; Qi, X.D.; Yang, J.H.; Zhou, Z.W.; Wang, Y. Electrospun Fibrous Membranes with Dual-Scaled Porous Structure: Super Hydrophobicity, Super Lipophilicity, Excellent Water Adhesion, and Anti-Icing for Highly Efficient Oil Adsorption/Separation. ACS Appl. Mater. Interfaces 2019, 11, 5073–5083. [Google Scholar] [CrossRef]

- Cao, X.Y.; Deng, J.P.; Pan, K. Electrospinning Janus Type CoOx/C Nanofibers as Electrocatalysts for Oxygen Reduction Reaction. Adv. Fiber Mater. 2020, 2, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.C.; Taskin, M.B.; Dong, M.D.; Han, X.J.; Besenbacher, F.; Chen, M.L. A Biocompatible Artificial Tendril with a Spontaneous 3D Janus Multi-Helix-Perversion Configuration. Mat. Chem. Front. 2020, 4, 2149–2156. [Google Scholar] [CrossRef]

- Salas, C. 4-Solution electrospinning of nanofibers. In Electrospun Nanofibers; Afshari, M., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 73–108. ISBN 978-0-08-100907-9. [Google Scholar] [CrossRef]

- Larrondo, L.; Manley, R.S.J. Electrostatic Fiber Spinning from Polymer Melts. I. Experimental Observations on Fiber Formation and Properties. J. Polym. Sci Polym. Phys. Ed. 1981, 19, 909–920. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- King, W.E.; Bowlin, G.L. Near-Field Electrospinning and Melt Electrowriting of Biomedical Polymers-Progress and Limitations. Polymers 2021, 13, 1097. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K.; Mohideen, M.M.; Ramakrishna, S. Melt Electrospinning: A Green Method to Produce Superfine Fibers; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-816220-0. [Google Scholar]

- Shin, C. A New Recycling Method for Expanded Polystyrene. Packag. Technol. Sci. 2005, 18, 331–335. [Google Scholar] [CrossRef]

- Opálková Šišková, A.; Pleva, P.; Hrůza, J.; Frajová, J.; Sedlaříková, J.; Peer, P.; Kleinová, A.; Janalíková, M. Reuse of Textile Waste to Production of the Fibrous Antibacterial Membrane with Filtration Potential. Nanomaterials 2022, 12, 50. [Google Scholar] [CrossRef]

- Wang, X.; Niu, H.T.; Lin, T.; Wang, X.G. Needleless Electrospinning of Nanofibers with a Conical Wire Coil. Polym. Eng. Sci. 2009, 49, 1582–1586. [Google Scholar] [CrossRef] [Green Version]

- Lin, T. Needleless Electrospinning: A Practical Way to Mass Production of Nanofibers. J. Text. Sci. Eng. 2012, 2, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Yamashita, Y.; Ko, F.; Tanaka, A.; Miyake, H. Characteristics of Elastomeric Nanofiber Membranes Produced by Electrospinning. J. Text. Eng. 2007, 53, 137–142. [Google Scholar] [CrossRef] [Green Version]

- Varabhas, J.S.; Chase, G.G.; Reneker, D.H. Electrospun Nanofibers from a Porous Hollow Tube. Polymer 2008, 49, 4226–4229. [Google Scholar] [CrossRef]

- Wang, X.F.; Um, I.C.; Fang, D.F.; Okamoto, A.; Hsiao, B.S.; Chu, B. Formation of Water-Resistant Hyaluronic Acid Nanofibers by Blowing-Assisted Electro-Spinning and Non-Toxic Post Treatments. Polymer 2005, 46, 4852–4867. [Google Scholar] [CrossRef]

- Liao, C.C.; Hou, S.S.; Wang, C.C.; Chen, C.Y. Electrospinning Fabrication of Partially Crystalline Bisphenol a Polycarbonate Nanofibers: The Effects of Molecular Motion and Conformation in Solutions. Polymer 2010, 51, 2887–2896. [Google Scholar] [CrossRef]

- Silva, P.M.; Torres-Giner, S.; Vicente, A.A.; Cerqueira, M.A. Management of Operational Parameters and Novel Spinneret Configurations for the Electrohydrodynamic Processing of Functional Polymers. Macromol. Mater. Eng. 2022, 2100858. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.L.; Xia, Y.N. Electrospinning of Polymeric and Ceramic Nanofibers as Uniaxially Aligned Arrays. Nano Lett. 2003, 3, 1167–1171. [Google Scholar] [CrossRef]

- Pan, H.; Li, L.M.; Hu, L.; Cui, X.J. Continuous Aligned Polymer Fibers Produced by a Modified Electrospinning Method. Polymer 2006, 47, 4901–4904. [Google Scholar] [CrossRef]

- Yang, D.; Lu, B.; Zhao, Y.; Jiang, X. Fabrication of Aligned Fibrous Arrays by Magnetic Electrospinning. Adv. Mater. 2007, 19, 3702–3706. [Google Scholar] [CrossRef]

- Kameoka, J.; Orth, R.; Yang, Y.; Czaplewski, D.; Mathers, R.; Coates, G.W.; Craighead, H.G. A Scanning Tip Electrospinning Source for Deposition of Oriented Nanofibres. Nanotechnology 2003, 14, 1124. [Google Scholar] [CrossRef]

- Sun, D.H.; Chang, C.; Li, S.; Lin, L.W. Near-Field Electrospinning. Nano Lett. 2006, 6, 839–842. [Google Scholar] [CrossRef] [Green Version]

- Brown, T.D.; Brown, T.D.; Hutmacher, D.W. Direct Writing by Way of Melt Electrospinning. Adv. Mater. 2011, 23, 5651. [Google Scholar] [CrossRef]

- Brown, T.D.; Slotosch, A.; Thibaudeau, L.; Taubenberger, A.; Loessner, D.; Vaquette, C.; Dalton, P.D.; Hutmacher, D.W. Design and Fabrication of Tubular Scaffolds via Direct Writing in a Melt Electrospinning Mode. Biointerphases 2012, 7, 13. [Google Scholar] [CrossRef] [Green Version]

- He, X.X.; Zheng, J.; Yu, G.F.; You, M.H.; Yu, M.; Ning, X.; Long, Y.Z. Near-Field Electrospinning: Progress and Applications. J. Phys. Chem. C 2017, 121, 8663–8678. [Google Scholar] [CrossRef]

- Loscertales, I.G.; Barrero, A.; Guerrero, I.; Cortijo, R.; Marquez, M.; Gañán-Calvo, A.M. Micro/Nano Encapsulation Via Electrified Coaxial Liquid Jets. Science 2002, 295, 1695–1698. [Google Scholar] [CrossRef]

- Yarin, A.L. Coaxial Electrospinning and Emulsion Electrospinning of Core-Shell Fibers. Polym. Adv. Technol. 2010, 33, 310–317. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, X.D.; Fu, J.; Huan, C.M.; Qi, S.; Zhan, Y.J.; Zhu, Y.Q.; Xu, G. Novel Smart Textile with Phase Change Materials Encapsulated Core-Sheath Structure Fabricated by Coaxial Electrospinning. Chem. Eng. J. 2018, 355, 532–539. [Google Scholar] [CrossRef]

- Huang, B.Y.; Zhang, Z.X.; Zhao, C.H.; Cairang, L.M.; Bai, J.L.; Zhang, Y.X.; Mu, X.M.; Du, J.W.; Wang, H.; Pan, X.J.; et al. Enhanced Gas-Sensing Performance of Zno@In2o3 Core@Shell Nanofibers Prepared by Coaxial Electrospinning. Sens. Actuator B-Chem. 2018, 255, 2248–2257. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Zeng, L.; Qiao, Z.; Liu, X.; Liu, H.; Zhang, J.; Ding, J. Fabrication of Electrospun Polymer Nanofibers with Diverse Morphologies. Molecules 2019, 24, 834. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.F.; Lu, Y.; Yu, L.; Lou, X.W. Designed Formation of Hollow Particle-Based Nitrogen-Doped Carbon Nanofibers for High-Performance Supercapacitors. Energy Environ. Sci. 2017, 10, 1777–1783. [Google Scholar] [CrossRef]

- Wu, J.; Wang, N.; Wang, L.; Dong, H.; Zhao, Y.; Jiang, L. Electrospun Porous Structure Fibrous Film with High Oil Adsorption Capacity. ACS Appl. Mater. Interfaces 2012, 4, 3207–3212. [Google Scholar] [CrossRef]

- Lin, M.F.; Xiong, J.Q.; Wang, J.X.; Parida, K.; Lee, P.S. Core-Shell Nanofiber Mats for Tactile Pressure Sensor and Nanogenerator Applications. Nano Energy 2018, 44, 248–255. [Google Scholar] [CrossRef]

- Pais, V.; Mota, C.; Bessa, J.; Dias, J.G.; Cunha, F.; Fangueiro, R. Study of the Filtration Performance of Multilayer and Multiscale Fibrous Structures. Materials 2021, 14, 7147. [Google Scholar] [CrossRef]

- Li, R.; Cheng, Z.Q.; Yu, X.B.; Wang, S.; Han, Z.L.; Kang, L.J. Preparation of Antibacterial PCL/PVP-AgNP Janus Nanofibers by Uniaxial Electrospinning. Mater. Lett. 2019, 254, 206–209. [Google Scholar] [CrossRef]

- Strain, I.N.; Wu, Q.; Pourrahimi, A.M.; Hedenqvist, M.S.; Olsson, R.T.; Andersson, R.L. Electrospinning of recycled PET to generate tough mesomorphic fibre membranes for smoke filtration. J. Mater. Chem. A 2015, 3, 1632–1640. [Google Scholar] [CrossRef] [Green Version]

- Šišková, A.O.; Frajová, J.; Nosko, M. Recycling of poly(ethylene terephthalate) by electrospinning to enhanced the filtration efficiency. Mater. Lett. 2020, 278, 128426. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Cruz, F.G.S.; Bretas, R.E.S.; Guerra, V.G.; Aguiar, M.L. A Sustainable Recycling Alternative: Electrospun PET-Membranes for Air Nanofiltration. Polymers 2021, 13, 1166. [Google Scholar] [CrossRef]

- Bonfim, D.P.F.; Cruz, F.G.S.; Guerra, V.G.; Aguiar, M.L. Development of Filter Media by Electrospinning for Air Filtration of Nanoparticles from PET Bottles. Membranes 2021, 11, 293. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Sweetser, D. Recycled PET Nanofibers for Water Filtration Applications. Materials 2016, 9, 247. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirjalili, A.; Dong, B.; Pena, P.; Ozkan, C.S.; Ozkan, M. Upcycling of Polyethylene Terephthalate Plastic Waste to Microporous Carbon Structure for Energy Storage. Energy Storage 2020, 2, e201. [Google Scholar] [CrossRef]

- Angelov, R.R.; Georgieva, B.C.; Karashanova, D.B. Films of Recycled Polyethylene Terephthalate, Obtained by Electrospraying, for Paper and Textile Impregnation. In Proceedings of the Scientific Session on Advanced Materials and Technologies, Sofia, Bulgaria, 10–11 October 2016; pp. 156–160. [Google Scholar] [CrossRef]

- Rajabinezhad, H.; Khajavi, R.; Rashidi, A.; Mansouri, N.; Yazdanshenas, M.E. Recycling of Used Bottle Grade Polyethylene Terephthalate to Nanofibers by Melt-Electrospinning Method. Int. J. Environ. Res. 2009, 3, 663–670. [Google Scholar]

- Naksuwan, P.; Komárek, M.; Salačová, J.; Militký, J. The Study of Recycled Poly (Ethylene Terephthalate) Nanofibres from PET Bottle. Appl. Mech. Mater. 2016, 848, 3–6. [Google Scholar] [CrossRef]

- Mehdi, M.; Mahar, F.K.; Qureshi, U.A.; Khatri, M.; Khatri, Z.; Ahmed, F.; Kim, I.S. Preparation of Colored Recycled Polyethylene Terephthalate Nanofibers from Waste Bottles: Physicochemical Studies. Adv. Polym. Technol. 2018, 37, 2820–2827. [Google Scholar] [CrossRef]

- Mahar, F.K.; Mehdi, M.; Qureshi, U.A.; Brohi, K.M.; Zahid, B.; Ahmed, F.; Khatri, Z. Dyeability of Recycled Electrospun Polyethylene Terephthalate (PET) Nanofibers: Kinetics and Thermodynamic Study. J. Mol. Liq. 2018, 248, 911–919. [Google Scholar] [CrossRef]

- Svinterikos, E.; Zuburtikudis, I. Tailor-Made Electrospun Nanofibers of Biowaste Lignin/Recycled Poly(Ethylene Terephthalate). J. Polym. Environ. 2017, 25, 465–478. [Google Scholar] [CrossRef]

- Abbas, J.A.; Said, I.A.; Mohamed, M.A.; Yasin, S.A.; Ali, Z.A.; Ahmed, I.H. Electrospinning of Polyethylene Terephthalate (PET) Nanofibers: Optimization Study Using Taguchi Design of Experiment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 12130. [Google Scholar] [CrossRef]

- Svinterikos, E.; Zuburtikudis, I.; Al-Marzouqi, M. The Nanoscale Dimension Determines the Carbonization Outcome of Electrospun Lignin/Recycled-PET Fibers. Chem. Eng. Sci. 2019, 202, 26–35. [Google Scholar] [CrossRef]

- Svinterikos, E.; Zuburtikudis, I. Carbon Nanofibers from Renewable Bioresources (Lignin) and a Recycled Commodity Polymer [Poly(Ethylene Terephthalate)]. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Khorram, M.; Mousavi, A.; Mehranbod, N. Chromium Removal Using Adsorptive Membranes Composed of Electrospun Plasma-Treated Functionalized Polyethylene Terephthalate (PET) with Chitosan. J. Environ. Chem. Eng. 2017, 5, 2366–2377. [Google Scholar] [CrossRef]

- Doan, H.N.; Vo, P.P.; Hayashi, K.; Kinashi, K.; Sakai, W.; Tsutsumi, N. Recycled PET as a PDMS-Functionalized Electrospun Fibrous Membrane for Oil-Water Separation. J. Environ. Chem. Eng. 2020, 8, 103921. [Google Scholar] [CrossRef]

- Hussain, N.; Mehdi, M.; Yousif, M.; Ali, A.; Ullah, S.; Hussain Siyal, S.; Hussain, T.; Kim, I.S. Synthesis of Highly Conductive Electrospun Recycled Polyethylene Terephthalate Nanofibers Using the Electroless Deposition Method. Nanomaterials 2021, 11, 531. [Google Scholar] [CrossRef] [PubMed]

- Shojaei, B.; Abtahi, M.; Najafi, M. Chemical Recycling of Pet: A Stepping-Stone toward Sustainability. Polym. Adv. Technol. 2020, 31, 2912–2938. [Google Scholar] [CrossRef]

- Li, H.Y.; Bubakir, M.M.; Xia, T.; Zhong, X.F.; Ding, Y.M.; Yang, W.M. Mass production of ultra-fine fibre by melt electrospinning method using umbellate spinneret. Mater. Res. Innov. 2014, 18, 921–925. [Google Scholar] [CrossRef]

- Lyu, C.; Zhao, P.; Xie, J.; Dong, S.; Liu, J.; Rao, C.; Fu, J. Electrospinning of Nanofibrous Membrane and Its Applications in Air Filtration: A Review. Nanomaterials 2021, 11, 1501. [Google Scholar] [CrossRef]

- Gergely, A.; Kántor, J.; Bitay, E.; Biró, D. Electrospinning of Polymer Fibres Using Recycled PET. Acta Mater. Transylvanica 2019, 2, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, K.; Vanegas, P.; Cruzat, C.; Novoa, N.; Arrué, R.; Vanegas, E. Antibacterial and Antifungal Properties of Electrospun Recycled PET Polymeric Fibers Functionalized with Zinc Oxide Nanoparticles. Polymers 2021, 13, 3763. [Google Scholar] [CrossRef]

- Tas, M.; Musa, U.G.; Ahmed, I.; Xu, F.; Smartt, C.; Hou, X.H. Functionalised SiO2 Modified Icephobic Nanocomposite Electrospun Membranes for Outdoor Electromagnetic Shielding Applications. Polymer 2022, 240, 124499. [Google Scholar] [CrossRef]

- Attia, A.A.M.; Abas, K.M.; Ahmed Nada, A.A.; Shouman, M.A.H.; Šišková, A.O.; Mosnáček, J. Fabrication, Modification, and Characterization of Lignin-Based Electrospun Fibers Derived from Distinctive Biomass Sources. Polymers 2021, 13, 2277. [Google Scholar] [CrossRef]

- Song, J.; Zhao, Q.; Meng, C.; Meng, J.M.; Chen, Z.D.; Li, J.S. Hierarchical Porous Recycled PET Nanofibers for High-Efficiency Aerosols and Virus Capturing. ACS Appl. Mater. Interfaces 2021, 13, 49380–49389. [Google Scholar] [CrossRef] [PubMed]

- Kakoria, A.; Chandel, S.S.; Sinha-Ray, S. Novel Supersonically Solution Blown Nanofibers from Waste PET Bottle for Pm0.1-2 Filtration: From Waste to Pollution Mitigation. Polymer 2021, 234, 124260. [Google Scholar] [CrossRef]

- Shi, H.T.H.; Naguib, H.E. Highly Flexible Binder-Free Core-Shell Nanofibrous Electrode for Lightweight Electrochemical Energy Storage Using Recycled Water Bottles. Nanotechnology 2016, 27, 325402. [Google Scholar] [CrossRef] [PubMed]

- Santos, R.P.O.; Rodrigues, B.V.M.; Ramires, E.C.; Ruvolo, A.C.; Frollini, E. Bio-Based Materials from the Electrospinning of Lignocellulosic Sisal Fibers and Recycled PET. Ind. Crops Prod. 2015, 72, 69–76. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Orozco-Carmona, V.M.; Alvarado-Beltran, C.G.; Almaral-Sanchez, J.L.; Sepulveda-Guzman, S.; Jasso-Ramos, L.E.; Castro-Beltran, A. Synthesis of Recycled Poly(ethylene terephthalate)/Polyacrylonitrile/Styrene Composite Nanofibers by Electrospinning and Their Mechanical Properties Evaluation. J. Polym. Environ. 2019, 27, 659–669. [Google Scholar] [CrossRef]

- Totito, T.C.; Laatikainen, K.; Pereao, O.; Bode-Aluko, C.; Petrik, L. Adsorptive Recovery of Cu2+ from Aqueous Solution by Polyethylene Terephthalate Nanofibres Modified with 2-(Aminomethyl)Pyridine. Appl. Sci. 2021, 11, 11912. [Google Scholar] [CrossRef]

- Xu, G.R.; An, X.C.; Das, R.; Xu, K.; Xing, Y.L.; Hu, Y.X. Application of Electrospun Nanofibrous Amphiphobic Membrane Using Low-Cost Poly (Ethylene Terephthalate) for Robust Membrane Distillation. J. Water Process. Eng. 2020, 36, 101351. [Google Scholar] [CrossRef]

- Roy, S.; Maji, P.K.; Goh, K.L. Sustainable Design of Flexible 3D Aerogel from Waste PET Bottle for Wastewater Treatment to Energy Harvesting Device. Chem. Eng. J. 2021, 413, 127409. [Google Scholar] [CrossRef]

- Baggio, A.; Doan, H.N.; Vo, P.P.; Kinashi, K.; Sakai, W.; Tsutsumi, N.; Fuse, Y.; Sangermano, M. Chitosan-Functionalized Recycled Polyethylene Terephthalate Nanofibrous Membrane for Sustainable On-Demand Oil-Water Separation. Glob. Chall. 2021, 5, 2000107. [Google Scholar] [CrossRef]

- Opálková Šišková, A.; Mosnáčková, K.; Hrůza, J.; Frajová, J.; Opálek, A.; Bučková, M.; Kozics, K.; Peer, P.; Eckstein Andicsová, A. Electrospun Poly(ethylene Terephthalate)/Silk Fibroin Composite for Filtration Application. Polymers 2021, 13, 2499. [Google Scholar] [CrossRef]

- Mohammadkhani, F.; Montazer, M.; Latifi, M. Microwave Absorption Characterization and Wettability of Magnetic Nano Iron Oxide/Recycled PET Nanofibers Web. J. Text. Inst. 2019, 110, 989–999. [Google Scholar] [CrossRef]

- Abbaszadeh, A.; Ravandi, S.A.H.; Valipouri, A.; Alirezazadeh, A. Investigating the Wicking Behavior of Micro/Nanofibrous Core-Sheath PET-PAN Yarn Modified by Dimethyl 5-Sodium Sulfoisophthalate. J. Appl. Polym. Sci. 2019, 136, 48185. [Google Scholar] [CrossRef]

- Ho, B.T.; Roberts, T.K.; Lucas, S. An Overview on Biodegradation of Polystyrene and Modified Polystyrene: The Microbial Approach. Crit. Rev. Biotechnol. 2018, 38, 308–320. [Google Scholar] [CrossRef] [PubMed]

- Raza, Z.A.; Abid, S.; Banat, I.M. Polyhydroxyalkanoates: Characteristics, Production, Recent Developments and Applications. Int. Biodeterior. Biodegrad. 2018, 126, 45–56. [Google Scholar] [CrossRef]

- Graca, B.; Bełdowska, M.; Wrzesień, P.; Zgrundo, A. Styrofoam Debris as a Potential Carrier of Mercury within Ecosystems. Environ. Sci. Pollut. Res. 2014, 21, 2263–2271. [Google Scholar] [CrossRef] [Green Version]

- Alayande, S.O.; Dare, E.O.; Akinlabi, A.K.; Ajao, J.A.; Pelemo, D.A.; Fasasi, A.Y.; Osinkolu, G.A. Recycling of Expanded Polystyrene via Electrospinning Technique. Niger. J. Mater. Sci. 2012, 3, 71–75. [Google Scholar]

- Shin, C.; Chase, G.G. Nanofibers from Recycle Waste Expanded Polystyrene Using Natural Solvent. Polym. Bull. 2005, 55, 209–215. [Google Scholar] [CrossRef]

- Shin, C.; Chase, G.G.; Reneker, D.H. Recycled Expanded Polystyrene Nanofibers Applied in Filter Media. Colloid Surf. A Physicochem. Eng. Asp. 2005, 262, 211–215. [Google Scholar] [CrossRef]

- Shin, C. Filtration Application from Recycled Expanded Polystyrene. J. Colloid Interfaces Sci. 2006, 302, 267–271. [Google Scholar] [CrossRef]

- Shin, C.; Chase, G.G. Separation of Liquid Drops from Air by Glass Fiber Filters Augmented with Polystyrene Nanofibers. J. Dispers. Sci. Technol. 2006, 27, 5–9. [Google Scholar] [CrossRef]

- Zulfi, A.; Munir, M.M.; Hapidin, D.A.; Rajak, A.; Edikresnha, D.; Iskandar, F.; Khairurrijal, K. Air Filtration Media from Electrospun Waste High-Impact Polystyrene Fiber Membrane. Mater. Res. Express 2018, 5, 35049. [Google Scholar] [CrossRef]

- Rajak, A.; Hapidin, D.A.; Iskandar, F.; Munir, M.M.; Khairurrijal, K. Controlled Morphology of Electrospun Nanofibers from Waste Expanded Polystyrene for Aerosol Filtration. Nanotechnology 2019, 30, 425602. [Google Scholar] [CrossRef] [PubMed]

- Rajak, A.; Hapidin, D.A.; Iskandar, F.; Munir, M.M.; Khairurrijal, K. Electrospun Nanofiber from Various Source of Expanded Polystyrene (EPS) Waste and Their Characterization as Potential Air Filter Media. Waste Manag. 2020, 103, 76–86. [Google Scholar] [CrossRef] [PubMed]

- Isik, T.; Demir, M.M. Medical Waste Treatment via Waste Electrospinning of PS. Fiber. Polym. 2018, 19, 767–774. [Google Scholar] [CrossRef]

- Isik, T.; Demir, M.M. Tailored Electrospun Fibers from Waste Polystyrene for High Oil Adsorption. Sustain. Mater. Technol. 2019, 18, e00084. [Google Scholar] [CrossRef]

- Munir, M.M.; Nuryantini, A.Y.; Iskandar; Suciati, T.; Khairurrijal, K. Mass Production of Stacked Styrofoam Nanofibers Using a Multinozzle and Drum Collector Electrospinning System. Adv. Mater. Res. 2014, 896, 20–23. [Google Scholar] [CrossRef]

- Rajak, A.; Munir, M.M.; Abdullah, M.; Khairurrijal, K. Photocatalytic Activities of Electrospun TiO2/Styrofoam Composite Nanofiber Membrane in Degradation of Waste Water. Mater. Sci. Forum 2015, 827, 7–12. [Google Scholar] [CrossRef]

- Uddin, M.N.; Desai, F.J.; Subeshan, B.; Rahman, M.M.; Asmatulu, E. Sustainable Atmospheric Fog Water Generator through Superhydrophobic Electrospun Nanocomposite Fibers of Recycled Expanded Polystyrene Foams. Surf. Interfaces 2021, 25, 425602. [Google Scholar] [CrossRef]

- Uddin, M.N. Electrospun Nanocomposite Fibers of Recycled Polystyrene Foams: An Efficient Atmospheric Fog Water Generator. In Proceedings of the 16th Annual Symposium on Graduate Research and Scholarly Projects, Wichita, KS, USA, 1 May 2020; p. 64. [Google Scholar]

- Khan, W.S.; Asmatulu, R.; Davuluri, S.; Dandin, V.K. Improving the Economic Values of the Recycled Plastics Using Nanotechnology Associated Studies. J. Mater. Sci. Technol. 2014, 30, 854–859. [Google Scholar] [CrossRef] [Green Version]

- Jalal, N.M.; Jabur, A.R.; Hamza, M.S.; Allami, S. Sulfonated Electrospun Polystyrene as Cation Exchange Membranes for Fuel Cells. Energy Rep. 2020, 6, 287–298. [Google Scholar] [CrossRef]

- Žagar, E.; Češarek, U.; Drinčić, A.; Sitar, S.; Shlyapnikov, I.M.; Pahovnik, D. Quantitative Determination of PA6 and/or PA66 Content in Polyamide-Containing Wastes. ACS Sustain. Chem. Eng. 2020, 8, 11818–11826. [Google Scholar] [CrossRef]

- Ulrich, T.; Arenas, J.P. Sound Absorption of Sustainable Polymer Nanofibrous Thin Membranes Bonded to a Bulk Porous Material. Sustainability 2020, 12, 2361. [Google Scholar] [CrossRef] [Green Version]

- Hwang, T.I.; Kim, J.I.; Lee, J.; Moon, J.Y.; Lee, J.C.; Joshi, M.K.; Park, C.H.; Kim, C.S. In Situ Biological Transmutation of Catalytic Lactic Acid Waste into Calcium Lactate in a Readily Processable Three-Dimensional Fibrillar Structure for Bone Tissue Engineering. ACS Appl. Mater. Interfaces 2020, 12, 18197–18210. [Google Scholar] [CrossRef] [PubMed]

- Zulfi, A.; Hapidin, D.A.; Munir, M.M.; Iskandar, F.; Khairurrijal, K. The Synthesis of Nanofiber Membranes from Acrylonitrile Butadiene Styrene (ABS) Waste Using Electrospinning for Use as Air Filtration Media. RSC Adv. 2019, 9, 30741–30751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zulfi, A.; Rezeki, Y.A.; Edikresnha, D.; Munir, M.M.; Khairurrijal, K. Synthesis of Fibers and Particles from Polyvinyl Chloride (PVC) Waste Using Electrospinning. IOP Conf. Ser. Mater. Sci. Eng. 2018, 367, 12014. [Google Scholar] [CrossRef] [Green Version]

- Park, J.C.; Kim, J.C.; Park, S.; Kim, D.W. Efficient Waste Polyvinyl(butyral) and Cellulose Composite Enabled Carbon Nanofibers for Oxygen Reduction Reaction and Water Remediation. Appl. Surf. Sci. 2020, 510, 145505. [Google Scholar] [CrossRef]

| Management | Advantages | Disadvantages | Ref. |

|---|---|---|---|

| Landfill | Convenience | Occupies large space/ Difficult to decompose | [4] |

| Incineration | Recovery of thermal energy/ Reduction in the weight and volume of waste | Harmful to the environment | [5] |

| Mechanical pulverization (Physical recycling) | Reused as materials compounded with additives | Remanufactured products with worse properties | [6] |

| Microbial decomposition | Reduces secondary pollution | Needs special conditions Releases methane gas | [7,8] |

| Thermal decomposition (Chemical recycling) | Low pollution/ High utilization rate/ High value of products | Relatively complicated | [6,9] |

| Physical and chemical modification reuse | Recycled products with good properties and values/ Less secondary pollution | Needs high-level techniques and high costs | [6] |

| Mechanical recycling | Economical/ Environmental | Difficult to recycle complex and contaminated polymer waste/Intense energy consumption | [9,10] |

| Products | Origin Waste Source | Performance Discussion (Indicator) | Application | Ref. |

|---|---|---|---|---|

| PET, PS, PC nanofibers | Water bottles, styrofoam, Compact discs (CDs) | Elastic moduli: 15 to 60 MPa/ High water filtration efficiency (over 99%) of 1 μm particles | Ultra/micro filtration | [25] |

| Tough mesomorphic fiber membranes | Coca Cola bottles (500 mL) | Fiber diameters: 0.4 to 4.3 μm/ High strength (62.5 MPa), modulus (1.39 GPa), toughness (65.5 MJ m−3)/ High absorption capacity of smoke residuals (43 × its own weight) | Smoke filtration | [72] |

| PET nanofibrous membranes | Beverage bottles | Fiber diameters: 95 ± 37 nm/ High filtering efficiency (more than 98% for particles over 120 nm) | Filtration media in face mask | [73] |

| PET membranes | PET bottles | Fiber diameters: 1.29 μm/ High mechanical resistance (4 MPa)/ High collection efficiency (98.4%) and low-pressure drop (212 Pa) | Air filters | [74] |

| PET fibers | Clear soda packaging | Mean fiber diameter: 3.25 to 0.65 μm/ Mechanical strength: 3.2 to 4.5 MPa/ High filtration efficiency (up to 99%) | Air/gas filtration | [75] |

| PET membranes | Plastic water bottles | Fiber diameters: 100 nm/ High filtration efficiency (more than 99% of particles as small as 500 nm/6 log reductions for Gram-negative and Gram-positive bacteria) | Water filtration | [76] |

| Electrochemical active microporous carbon structure | Used PET bottles | The medium combines double-layer and redox reaction pseudocapacitance characteristics. | Energy storage | [77] |

| PET films on paper and textile materials | Used mineral water bottles | The impregnated with PET do not absorb water droplets. | Waterproof materials | [78] |

| PET nanofibers | Used grade PET bottles, PET granule | Minimum fiber diameters: 61 to 93 nm (Produced by melt-electrospinning) | - | [79] |

| PET nanofibers | Clear PET bottles | Fiber diameters: 45 to 65 μm | - | [80] |

| Colored PET nanofibers | Recycled PET bottles | Good colorfastness/ Good mechanical strength | Advanced colorful applications | [81] |

| PET nanofiber mats | Recycled PET bottles | Good colorfastness/ Good mechanical strength/ Low processing temperature/ Minimum dyeing time | Advanced apparel applications | [82] |

| PET/lignin nanofibers | Waste water bottles | Average fiber diameter: 191 ± 60 nm | Separators/ filters | [83] |

| Sooth uniform PET nanofibers | Waste PET materials | Minimum average fiber diameter: 105.03 ± 36.79 nm | - | [84] |

| Lignin/recycled PET fibrous mats | Waste water bottles | Average fiber diameter: 80 to 781 nm | - | [85] |

| Carbon nanofibers | Used PET water bottles | Average fiber diameter: 191 ± 60 nm/ The C content of the nanofibers: 94.3% | Advanced separation | [86] |

| Adsorptive membranes | PET bottle waste | Cr(VI) removal capacity (5.54 mg/50 mg)/ Reusability (93.7% adsorption effectiveness after five cycles) | Removal of hexavalent chromium from water | [87] |

| PDMS functionalized PET fibrous membranes | Recycled PET pellets | Superoleophilic properties (oil contact angle of 0°)/ Anti-water-fouling properties/ High flux (~20,000 L m−2 h−1)/ High separation efficiency (>98%) | Oil/water separation | [88] |

| Conductive PET nanofibers | Water bottles | Average fiber diameter of copper-coated r-PET nanofibers (700 nm)/ Low electrical resistance (0.1 Ω)/ Flexible/ Good mechanical strength | Wearable electronics/ Flexible sensors/Energy storage | [89] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Peng, Y.; Deng, Y.; Ye, F.; Zhang, C.; Hu, X.; Liu, Y.; Zhang, D. Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review. Nanomaterials 2022, 12, 1663. https://doi.org/10.3390/nano12101663

Li X, Peng Y, Deng Y, Ye F, Zhang C, Hu X, Liu Y, Zhang D. Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review. Nanomaterials. 2022; 12(10):1663. https://doi.org/10.3390/nano12101663

Chicago/Turabian StyleLi, Xiuhong, Yujie Peng, Yichen Deng, Fangping Ye, Chupeng Zhang, Xinyu Hu, Yong Liu, and Daode Zhang. 2022. "Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review" Nanomaterials 12, no. 10: 1663. https://doi.org/10.3390/nano12101663