1. Introduction

One of the promising directions of solving the global energy crisis, as well as solving the problem of hydrocarbons, is the use of alternative energy sources, including nuclear energy [

1,

2]. The focus of research should be on the new types of nuclear reactors under development [

3,

4], which have great productivity and safety as compared to the previous generation of nuclear reactors. The interest in these power units is due to the possibility of their operation at higher temperatures, which significantly increases the reactors’ efficiency, as well as to the use of new types of uranium fuel with higher burnup rates. Meanwhile, the increase in the coolant temperature, as well as the core operating temperature, requires the use of new types of reactor materials that have high melting temperatures (above 2000 °C), as well as good indicators of resistance to external influences, including mechanical and radiation damage [

5,

6,

7,

8]. There are also additional requirements for these materials used as structural materials, concerning safety and resistance to radiation defects and subsequent effects associated with their accumulation in the damaged layer exposed to irradiation, which can be several tens of microns thick [

9,

10,

11]. The main effects caused by irradiation usually consist in the destruction of crystalline and chemical bonds, as well as disordering, amorphization, or swelling processes [

12,

13,

14,

15]. Most of the effects caused are associated with the formation of point defects and dislocations, which occur as a result of the interaction of incident ions with the crystal structure of the material. At the same time, in most cases, point defects are highly mobile, and can also form more complex defect compounds, the presence of which leads to a deterioration in the properties of the material. A change in the dislocation density, in turn, can have a dual effect: in one case (up to a certain amount of accumulated dislocations), a hardening effect can be observed, in the other case, when the dislocation density is too high, destruction and the formation of microcracks can occur. All these effects are the final stages of interaction between radiation and matter, and also have a cumulative effect, leading to negative consequences.

The degree of radiation damage also depends very strongly on the energy of ionizing radiation and the type of particles that interact with the substance. The most destructive consequences, in terms of destruction and amorphization processes, are two types of radiation damage. These are helium or hydrogen embrittlement due to processes associated with transmutation nuclear reactions under the impact of neutrons or during interaction with coolant, and the destruction of the near-surface layer due to interaction with products or fragments of nuclear fuel fission [

16,

17,

18]. In both cases, the most vulnerable layer is the near-surface layer of structural materials, which is directly exposed to radiation. Although the processes of helium or hydrogen embrittlement are quite clear, since the main mechanisms leading to the destruction of the near-surface layer have been identified, there are still quite a few questions about the effects of nuclear fuel fission fragments [

19,

20].

Firstly, there is no unified theory of defect formation caused by the interaction of heavy charged particles with the structural damage material. Today there are several theoretical and experimental models attempting to describe these processes in various materials that are based on ideas about the energy exchange between the colliding particle and the material structure [

18,

19,

20,

21,

22].

Secondly, there is no consensus on the nature of this energy exchange for various materials, including dielectrics, for which some of the processes associated with post-radiation relaxation processes are impossible due to the dielectric nature of the material [

23,

24].

Thirdly, and no less importantly, there are no precise data on the critical doses of radiation damage leading to complete and irretrievable material degradation. This is due to the fact that for new types of structural materials there are still insufficient experimental data on the nature of radiation damage, which opens up great prospects for research [

20,

21,

22,

23,

24,

25].

The most promising materials for new generation reactors are refractory ceramics based on oxides (MgAl

2O

4, BeO, Al

2O

3, ZrO

2), carbides (WC, TaC, SiC), and nitrides (AlN, BN, Si

3N

4) [

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30]. Interest in them is caused by the possibility of their operation at increased temperatures, as well as in various aggressive environments, as they have high resistance to most types of acids and alkalis. Excellent indices of mechanical strength and wear resistance allow their use as structural materials of the first wall or protective casings for nuclear waste disposal. Among the majority of dielectric ceramics, the three most commonly considered types of ceramics can be highlighted: SiC, AlN, Si

3N

4. As mentioned above, the interest in their use as structural materials is due to a combination of their properties, as well as the results of a number of scientific studies reflecting the relationship between the degree of radiation damage and the degradation resistance of these materials. However, in spite of the sufficient amount of experimental data, there are still a number of unresolved questions that require clarification and refinement. For the most part, this is primarily associated with the establishment of critical doses of damage during irradiation with high-energy particles, as well as with the establishment of the relationship between structural changes induced by irradiation and mechanical and strength properties.

2. Experimental Part

Polycrystalline ceramics AlN, Si3N4, and SiC were chosen as objects for research. According to a priori data, the selected ceramic samples are polycrystalline structures consisting of grains the sizes of which vary within 70–90 nm, which provides a dislocation density in the initial samples of ~1010 1/cm2. Additionally, X-ray phase and energy dispersive analysis showed the absence of any impurities in the composition of ceramics, which excludes the influence of impurity defects on the radiation resistance of ceramics. The choice of objects for research is due to the prospects of their use as structural materials for high-temperature nuclear reactors. At the same time, the choice of nitride ceramics, in particular AlN and Si3N4, was due to their different mechanisms of radiation damage and the consequences of exposure to heavy ions; and the choice of SiC due to the need to compare changes in the strength of nitride ceramics with one of the traditional materials used in nuclear power and has high rates of radiation damage resistance. The differences in the consequences of radiation damage during heavy ion irradiation in AlN and Si3N4 consist in the so-called latent tracks found earlier in Si3N4—discontinuous damaged areas along the trajectory of ions in the material, as well as amorphization of the damaged near-surface layer at doses above 1013 ions/cm2.

The studied samples were irradiated with Kr

15+ and Xe

22+ heavy ions on the DC-60 heavy ion accelerator. Irradiation fluences were 10

12–10

15 ions/cm

2. Irradiation was conducted at 1000 K in order to simulate radiation damage conditions as close as possible to the real influences. The irradiation fluences were chosen due to the simulation possibility of the effects of both the beginning of isolated damaged region formation along the ion trajectory in the material and their overlap, which contributes to the effect of the formation of disordered regions with altered electronic density, as well as structural damage.

Table 1 shows the results of the simulation of the values of energy losses of the incident ions during interaction with electron shells and nuclei for two types of ions and all types of investigated ceramics.

As it is visible from the data presented on the energy losses of incident ions in ceramics, their values are close enough for all the chosen types of ceramics, in view of the proximity of the structural properties of the chosen objects for research, and also the density of materials. Changing the type of irradiation from Kr15+ ions to Xe22+ ions leads to a two-fold increase in energy losses in the interaction with nuclei and one and a half times the interaction with electron shells, while the maximum depth of penetration of ions in the material is increased by less than 10–12%. The total ion penetration depth for the selected types of ions in the materials is 15–16 μm depending on the type of incident ions. In the case of comparison with neutron exposure (during neutron irradiation), the selected fluences and energies of incident ions correspond to atomic displacements of ~0.001–1 dpa, depending on the irradiation fluence. At the same time, it is also necessary to make the clarification that, in contrast to neutron exposure, which affects a great depth (several tens of microns), irradiation with heavy ions is localized in an area not exceeding 15–16 microns, which corresponds to the near-surface layer, which is most susceptible to external mechanical influences.

The determination of strength properties and the dynamics of their changes as a result of radiation damage accumulation was conducted with the application of the indentation method using standard Vickers pyramid at variable load on the indenter. The choice of indenter loading conditions was carried out in order to determine the deformation and reduction in strength properties, along with hardness at different depths. Based on the change in hardness value data compared to the initial values, the degree of softening and destruction of the near-surface layer was determined.

The thermal conductivity properties of the investigated ceramics, as well as the study of thermal conductivity reduction, were carried out using the standard method of determining the longitudinal heat flux, implemented using the KIT-800 unit.

3. Results and Discussion

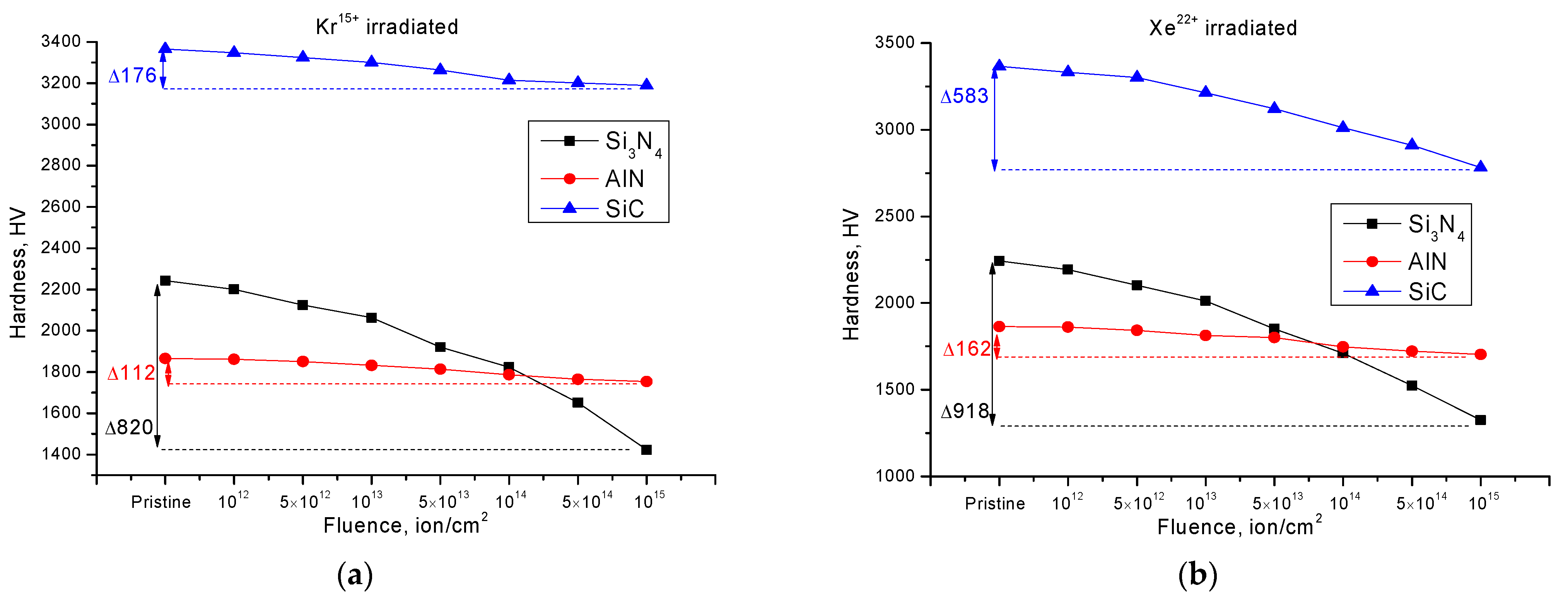

Figure 1 shows the results of changes in the hardness value of the surface-damaged layer of ceramics depending on the irradiation fluence and the type of incident ions. The general appearance of changes in hardness values can be characterized by two different stages for all types of ceramics depending on the irradiation fluence. The first stage is characterized by insignificant changes of hardness parameters and softening degree (decrease in hardness parameters) for AlN and SiC ceramics of not more than 0.2–2% for a fluence range of 10

12–5 × 10

13 ions/cm

2. It should be noted that for Si

3N

4 ceramics in this range of fluences, the change in hardness values was from 3 to 7–10% depending on the type of incident ions. The second stage of change in strength characteristics is typical for irradiation fluences above 5 × 10

13 ions/cm

2 and is characterized by a stronger change in hardness values, as well as an increase in the degree of softening. Such a behavior of the strength properties of ceramics at irradiation fluences of 5 × 10

13 ion/cm

2 ions may be due to the fact that with an increase in the irradiation fluence, there is an overlap of defect regions formed during the passage of ions through the material, which at lower fluences remain isolated from each other, which also does not make it possible to increase the probability of the formation of complex defects or dislocation loops. However, for Si

3N

4 ceramics the change in strength at these fluences of irradiation is more pronounced than for AlN and SiC ceramics.

It is also worth noting that for Si3N4 ceramics irradiation with Kr15+ and Xe22+ ions leads to almost the same decrease in hardness depending on the fluence, and the difference at high irradiation fluences of 1014–1015 ions/cm2 is not more than 3–5%. In the case of AlN ceramics, the hardness degradation at irradiation fluences of 1014–1015 ions/cm2 for both types of ions is approximately the same, while for SiC ceramics, changing the irradiation type leads to a threefold decrease in hardness at high irradiation fluences. These changes of hardness depending on the change in the type of incident ions indicates the different nature of structural changes caused by irradiation in the damaged layer, which leads to different mechanisms of damage and their influence on the resistance of ceramics to degradation.

The softening degree of the damaged surface as a result of irradiation was calculated on the basis of the obtained data on the change in hardness values. This value was calculated using Formula (1):

where

H0 is the hardness value in the initial state;

Hirr is the hardness value in the irradiated state. This value is normalized to 100% in order to show the degradation of strength properties of ceramics depending on the irradiation fluence. The calculation results are presented in

Figure 2.

The general type of change in the value of the degree of softening and destruction of the damaged layer of ceramics has a different trend depending not only on the type of irradiated ceramics, but also on the type of incident ions. At the same time, at low irradiation fluences, a small change in the softening degree is observed, which may be due to the fact that the formation of point defects isolated from each other is observed in the structure, which also does not allow them to form complex defects. Thus, for Si3N4 ceramics the damaged layer destruction has the same tendency for both types of irradiated ions, which at the maximum fluences of irradiation becomes more than 35%, indicating a strong destruction of material and its embrittlement.

For AlN ceramics the change in resistance to softening is much less than for Si3N4 ceramics and is not more than 5% when irradiated with Kr15+ ions and not more than 7–10% when irradiated with Xe22+ ions. Meanwhile, at high irradiation fluences of 1014–1015 ions/cm2 for both types of ions, a change in the degradation trend is observed, with its growth decreasing with increasing fluence. Such behavior may be due to the effect of the accumulation of radiation damage and changes in dislocation density, which leads to the effect of radiation hardening and increases resistance to embrittlement and degradation.

For SiC ceramics the change in the degree of softening for different types of ions has a different character. Thus, for samples irradiated with Kr

15+ ions the change in softening resistance is comparable with the results for AlN ceramics; at high irradiation fluences of 5 × 10

15–10

15 ions/cm

2, SiC ceramics have greater resistance to degradation. However, when irradiated with Xe

22+ ions, the trend of change in the resistance to softening is close to the results for Si

3N

4 ceramics, but the degradation value is much less and at the maximum irradiation fluence was not more than 20%. Such a change in the character of resistance to degradation from irradiation by Xe

22+ ions in SiC ceramics can be explained by the fact that some of the chemical bonds, Si-Si, Si-C, and C-C, are destroyed due to the large energy losses of the incident ions, thereby creating the additional chemical disorder in the ceramic’s structure whose presence leads to the degradation of the damaged layer. However, at low irradiation fluences, as well as due to high-temperature irradiation, some of the structural deformations in SiC ceramics can be stabilized or annealed by enhancing the dynamic annealing of defects [

31].

Let us consider in more detail the processes and mechanisms which can influence changes in the strength properties of ceramics under irradiation. More intensive reductions in the strength characteristics for Si

3N

4 ceramics at irradiation fluences higher than 5 × 10

13 ion/cm

2 can be caused by the amorphization processes of the damaged near-surface layer. More about the amorphization processes and increases in the degree of structural disorder in Si

3N

4 ceramics under irradiation by heavy ions of Xe and Bi was reported in [

32,

33,

34]. The authors, using Raman spectroscopy, showed that the so-called amorphization of the near-surface layer occurs when the fluence exceeds 10

13 ions/cm

2 depending on the type of incident ions. Herewith, the authors established visible changes in the near-surface damaged layer throughout the depth of ion penetration into the material. The authors attribute this behavior of the damaged layer, as well as the amorphization of Si

3N

4 ceramics, to the effect of overlapping defect regions, the radius of which is estimated to be no more than 2 nm, which at fluences above 10

13 ions/cm

2 leads to the appearance of the effect of overlapping defect regions.

In turn, the amorphization processes so evident for Si

3N

4 ceramics were not experimentally detected for AlN and SiC ceramics. It is also worth noting that for Si

3N

4 ceramics, intermittent latent tracks were found earlier in [

32,

33,

34], the presence of which the authors attribute to the energy losses of the incident ions, as well as the destruction of chemical and crystalline bonds. However, it should be noted that the density of the detected tracks is much less than the irradiation fluence, which indicates that the latent discontinuous tracks are formed by a more complex mechanism in Si

3N

4 ceramics than similar structural elements in dielectric polymers. It is also worth noting that the observed effects of the amorphization of the damaged layer are observed throughout the irradiated volume of the material. This fact indicates that the greatest contribution to the processes leading to the destruction and subsequent amorphization is made by electron losses of incident ions, and therefore with a change in the electron density and its anisotropic change along the trajectory of the ions in the irradiated material. In this case, unlike metals, in which the change in the electron density distribution as a result of external influences has a reversible nature, such processes are difficult for dielectric materials. It is also worth noting that for the selected types of ions the electronic losses are approximately equal, but the degradation processes leading to a change in strength characteristics at high fluences of irradiation have a different trend, as well as different degrees of degradation and softening.

It is also worth noting that the investigated samples were irradiated at a temperature of 1000 K, the choice of which is due to the possibility of modeling the effects of radiation damage comparable to the real conditions of operation of materials in high-temperature nuclear reactors. It is well known that during high-temperature irradiation, at low fluences, the effect of the formation of point defects can be leveled by the effect of the thermal annealing of defects associated with changes in the vibrational modes of atoms in the lattice nodes. The change in the thermal vibrational modes of the atoms in the crystal lattice, in some cases, can play a dual role.

On the one hand, as was shown in [

35], an increase in irradiation temperature above 773 K leads to a decrease in radiation damage in ceramics, and in the case of irradiation at 1223 K irradiation does not carry visible structural damage, according to X-ray diffraction data. As a result, some of the point defects formed when ions pass through the material can be annealed; this leads to a decrease in the degree of radiation damage in the material. However, this proposal is not quite consistent with the observed effects of strength reduction in Si

3N

4 ceramics, for which the strength reduction effect has a fairly pronounced trend throughout the studied range of irradiation fluences. This effect can be explained by the fact that Si

3N

4 ceramics are more susceptible to the influence of electronic interactions leading to degradation and amorphization than AlN and SiC ceramics, which are more resistant to the influence of electronic interactions and the consequences caused by them. The higher resistance to the influence of electron losses of incident ions for AlN and SiC ceramics is expressed in the absence of experimental data confirming the presence of latent tracks in these materials during irradiation with heavy ions.

On the other hand, high-temperature irradiation, at high fluences, can lead to an increase in the size of point defects, as well as the formation of dislocation loops and complex defects, which can also affect the strength properties of ceramics. For example, it was shown in [

36] that an increase in the irradiation temperature leads to an increase in the defect density at high irradiation doses, as well as to the formation of complex defects, while for samples irradiated at room temperature, the defect density remains virtually unchanged at high irradiation fluences. The formation of complex defects, as well as dislocation loops, can lead to a disordered structure and thereby reduce the resistance to the formation of microcracks under mechanical action.

Another important characteristic of ceramics, which affects the definition of their application as well as the efficiency of their use as structural materials, is their thermal-physical properties. When these ceramics are used as first wall materials or inert matrices, their heat-transfer properties play an important role. The destruction of material as a result of the accumulation of radiation damage can lead to additional barriers to heat transfer, thereby reducing the heat removal from the core or creating local areas of overheating, which can have a negative impact on the performance of the entire reactor unit. In this connection, the investigated samples were tested before and after irradiation for the preservation of thermal conductivity parameters, as well as for the determination of the influence of degradation processes caused by irradiation on heat exchange and heat losses of irradiated ceramics.

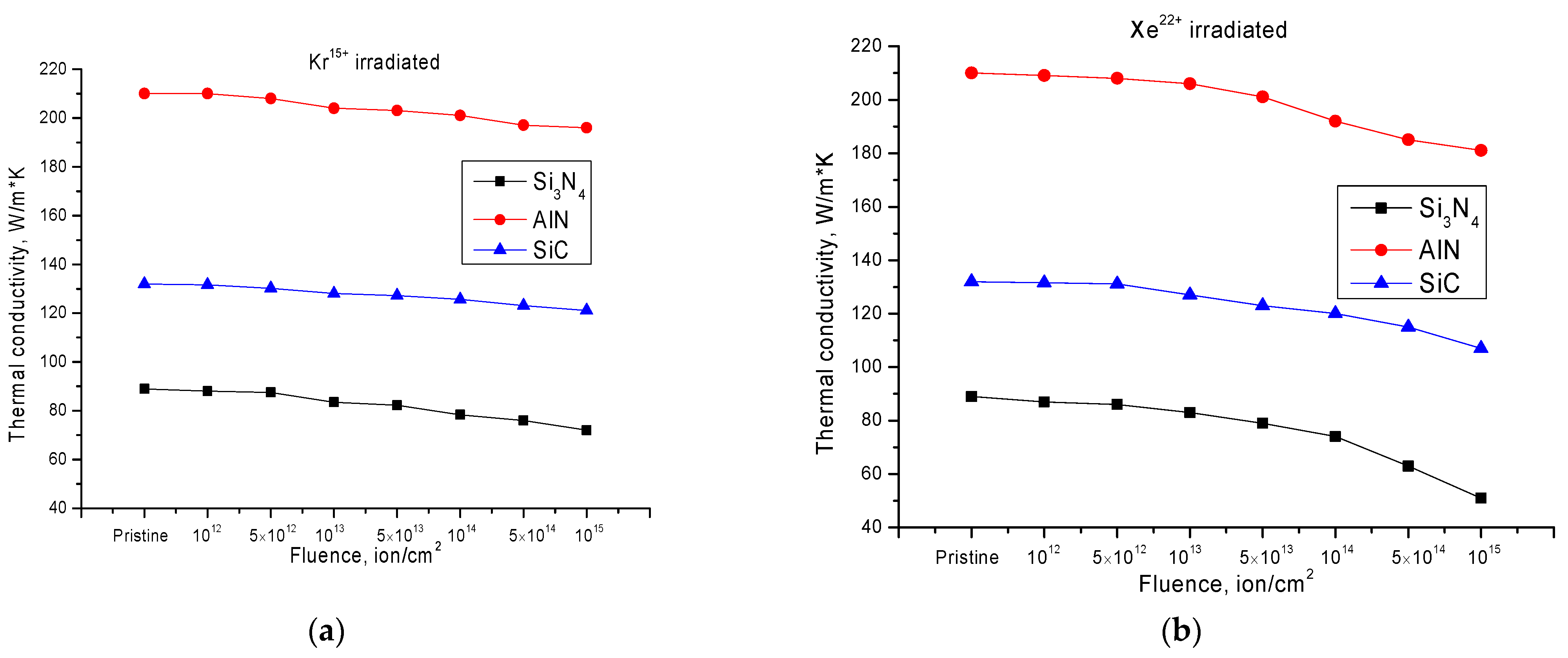

The results of changes in the value of the thermal conductivity coefficient depending on the fluence of the flying ions are shown in

Figure 3. The measurements were made in the range of 100 to 800 °C in order to determine the stability of the thermal conductivity coefficient as a function of temperature.

Figure 3 shows the data of the average value of the thermal conductivity coefficient.

The general view of changes in the value of the thermal conductivity coefficient for samples irradiated with Kr

15+ ions indicates that the selected ceramics are sufficiently resistant to changes in thermal physical properties as a result of radiation damage. At small fluences of irradiation 10

12–10

13 ions/cm

2, the change in thermal conductivity is practically not observed, and insignificant fluctuations of thermal conductivity coefficient value can be explained by a measurement error which amounted to no more than 1–2%. This lack of change in thermal conductivity at low irradiation fluences can be explained by the effects of the dynamic annealing of formed point defects during high-temperature irradiation, as well as by the isolation of defect regions formed along the trajectory of the ions in the material. An increase in the irradiation fluence, and hence an increase in the probability of overlapping defect regions, leads to a decrease in the annihilation effect of point defects in the structure due to changes in the value of thermal vibrations of the crystal lattice, which leads to a decrease in thermal conductivity due to changes in the defect concentration in the damaged layer. Additionally, the small changes in the thermal conductivity of irradiated ceramics as compared to data from the literature [

27,

28] are due to the fact that the samples were irradiated at 1000 K, which contributes to the partial annealing of simple defects, such as vacancies, embedded atoms, or dislocations, which have a strong effect on the thermal conductivity of materials.

At the same time, the greatest changes in the reduction in the thermal conductivity coefficient during irradiation with Kr15+ ions are observed for Si3N4 ceramics, the decrease in thermal conductivity for which at high fluences of irradiation was 15–20% in comparison with the initial values. However, for AlN and SiC the change in thermal conductivity at irradiation fluences of 1014–1015 ions/cm2 was not more than 6–8% in comparison with the initial values. This behavior of the thermal-physical properties for the selected types of ceramics has a correlation with the change in strength properties, which indicates that the deformation effect caused by irradiation also affects the thermal physical properties of the ceramics. However, for Si3N4 ceramics, the degradation of strength properties is much greater than the change in thermal physical properties, which indicates that the thermal physical properties are greatly affected by electronic ion losses and, consequently, by the change in electronic density in the irradiated layer. This is also evidenced by the results of changes in the thermal conductivity of ceramics under irradiation with Xe22+ ions, for which the decrease in thermal physical parameters is more significant than under irradiation with Kr15+ ions.