Single-Step Fabrication of Longtail Glasswing Butterfly-Inspired Omnidirectional Antireflective Structures

Abstract

:1. Introduction

2. Materials and Methods

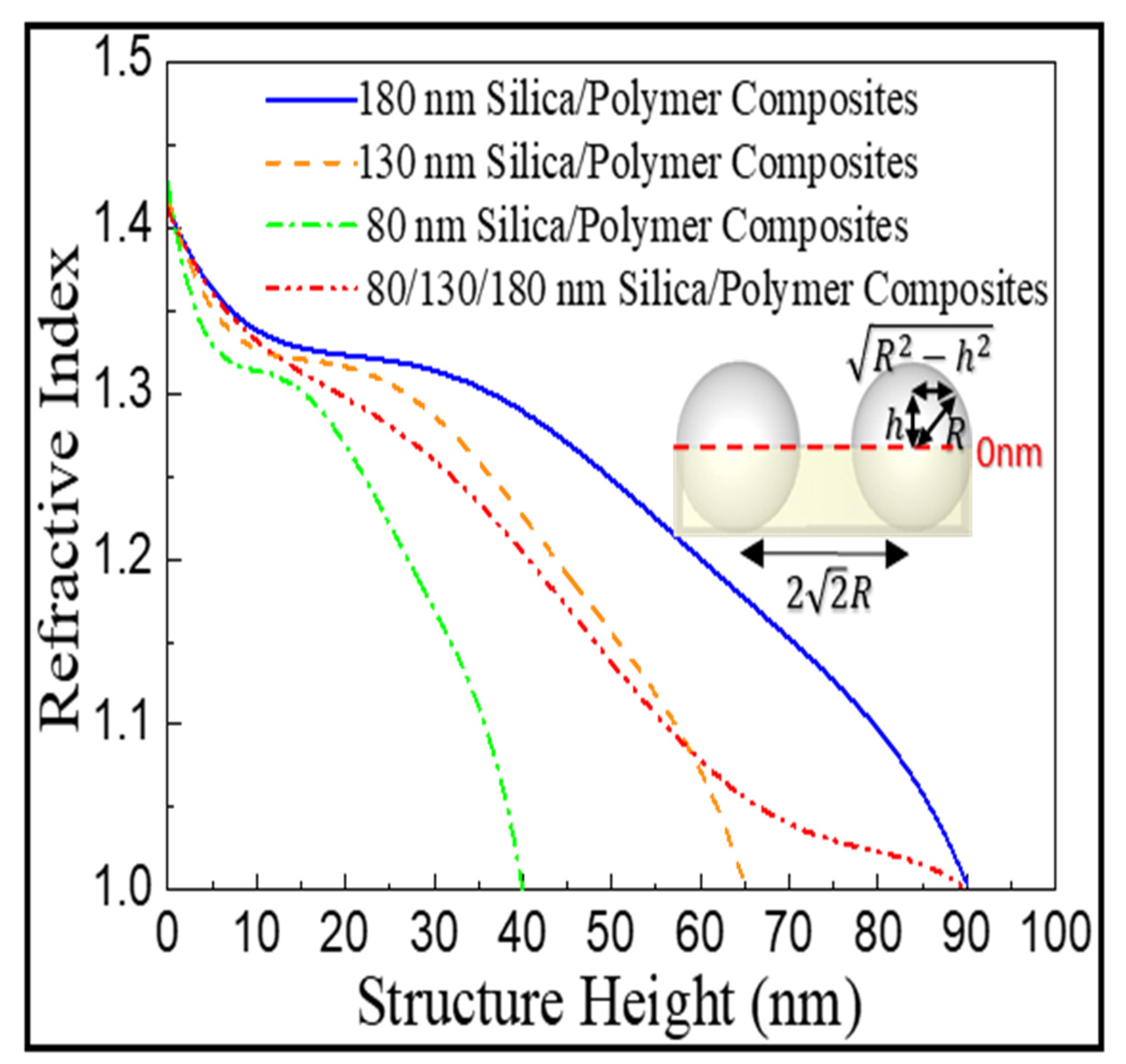

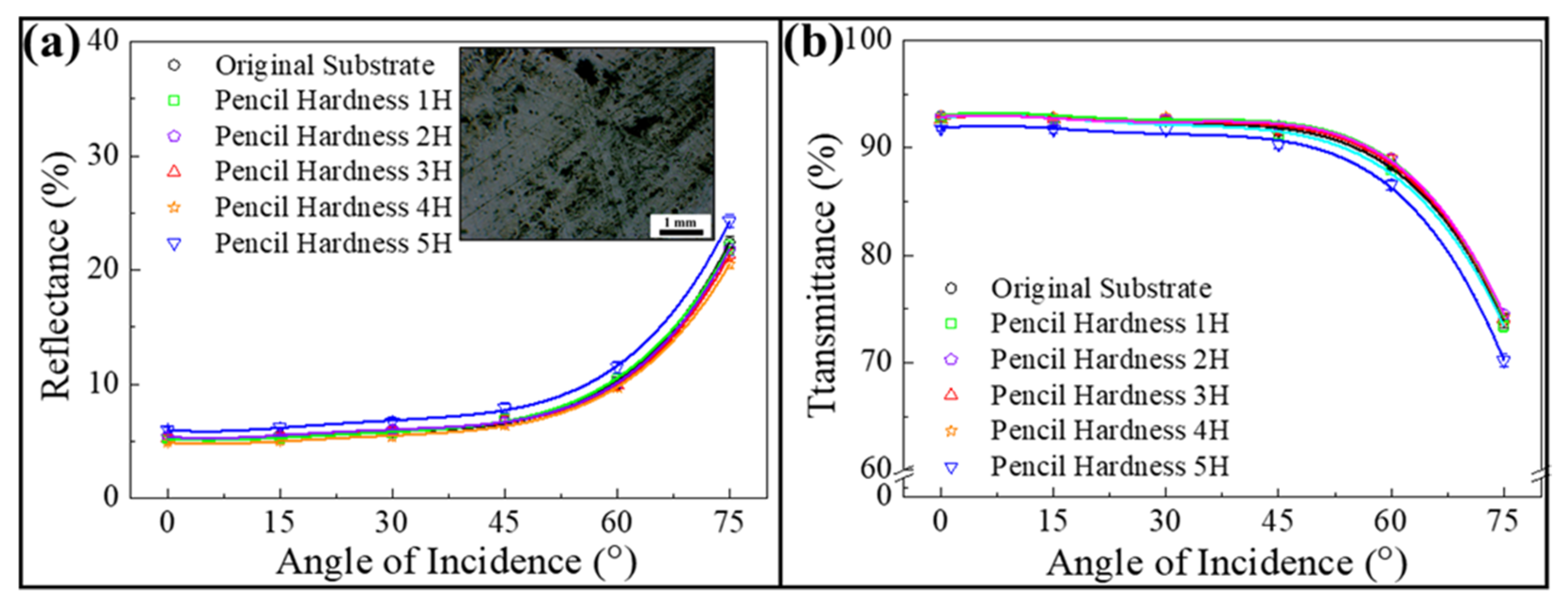

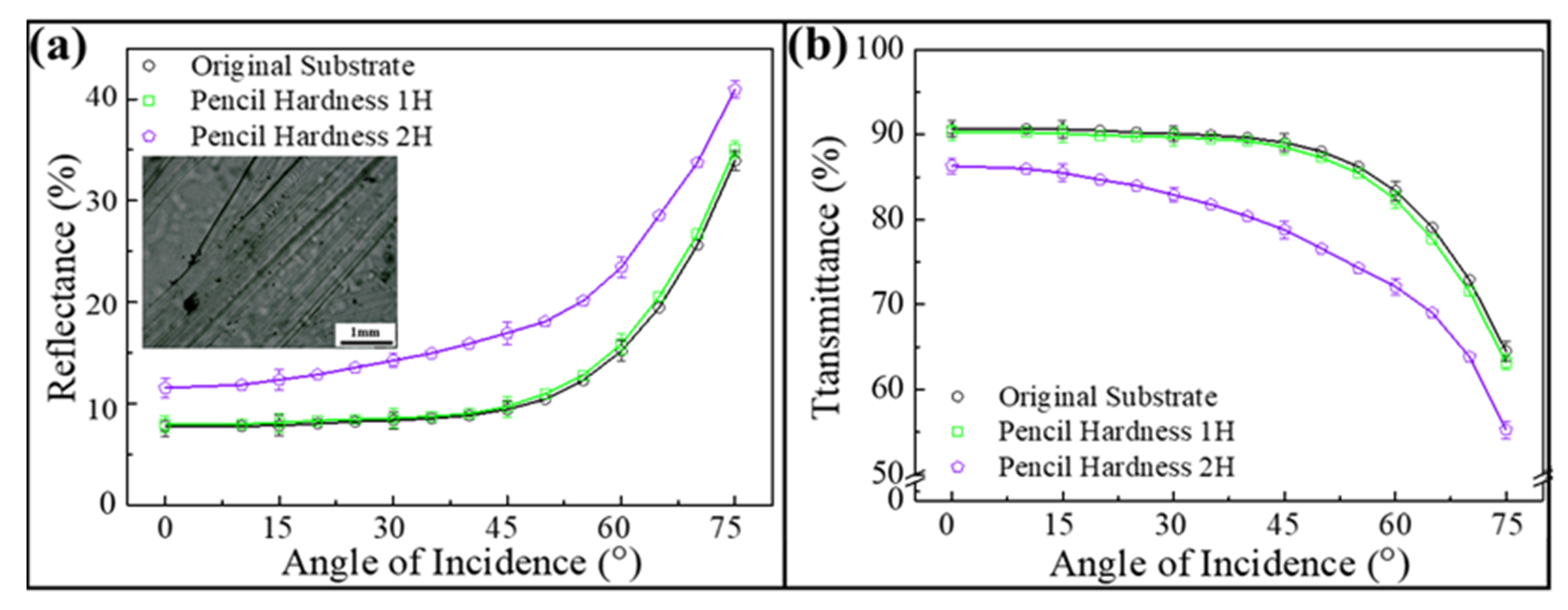

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yoo, G.Y.; Nurrosyid, N.; Lee, S.; Jeong, Y.; Yoon, I.; Kim, C.; Kim, W.; Jang, S.Y.; Do, Y.R. Newly Developed Broadband Antireflective Nanostructures by Coating a Low-Index MgF2 Film onto a SiO2 Moth-Eye Nanopattern. ACS Appl. Mater. Interfaces 2020, 12, 10626–10636. [Google Scholar] [CrossRef] [PubMed]

- Yu, N.F.; Genevet, P.; Kats, M.A.; Aieta, F.; Tetienne, J.P.; Capasso, F.; Gaburro, Z. Light Propagation with Phase Discontinuities: Generalized Laws of Reflection and Refraction. Science 2011, 334, 333–337. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.Y.; Zou, H.J.; Su, M.Y.; Tang, L.W.; Wang, C.F.; Chen, S.Q.; Su, C.L.; Li, Y. All-Dielectric Metasurface-Based Beam Splitter with Arbitrary Splitting Ratio. Nanomaterials 2021, 11, 1137. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.N.; Yang, S. Responsive Smart Windows from Nanoparticle-Polymer Composites. Adv. Funct. Mater. 2020, 30, 1902597. [Google Scholar] [CrossRef]

- Lan, J.; Yang, Y.; Hu, S. Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate. Nanomaterials 2021, 11, 3313. [Google Scholar] [CrossRef]

- Meng, Z.P.; Huang, B.T.; Wu, S.L.; Li, L.; Zhang, S.F. Bio-Inspired Transparent Structural Color Film and Its Application in Biomimetic Camouflage. Nanoscale 2019, 11, 13377–13384. [Google Scholar] [CrossRef]

- Khan, S.B.; Zhang, Z.J.; Lee, S.L. Single Component: Bilayer TiO2 as a Durable Antireflective Coating. J. Alloy. Compd. 2020, 834, 155137. [Google Scholar] [CrossRef]

- Chen, N.; Lee, Y.M. Anion Exchange Polyelectrolytes for Membranes and Ionomers. Prog. Polym. Sci. 2021, 113, 101345. [Google Scholar] [CrossRef]

- Yang, J.M.; Zhu, X.W.; Yu, Q.; Zhou, G.L.; Li, Q.D.; Wang, C.T.; Hua, Y.J.; She, Y.B.; Xu, H.; Li, H.M. Plasma-Induced Defect Engineering: Boosted the Reverse Water Gas Shift Reaction Performance with Electron Trap. J. Colloid Interface Sci. 2020, 580, 814–821. [Google Scholar] [CrossRef]

- Kweon, O.Y.; Samanta, S.K.; Won, Y.; Yoo, J.H.; Oh, J.H. Stretchable and Self-Healable Conductive Hydrogels for Wearable Multimodal Touch Sensors with Thermoresponsive Behavior. ACS Appl. Mater. Interfaces 2019, 11, 26134–26143. [Google Scholar] [CrossRef]

- Ding, H.L.; Liu, D.L.; Li, B.; Ze, W.; Niu, S.C.; Xu, C.H.; Han, Z.W.; Ren, L.Q. Broader-Band and Flexible Antireflective Films with the Window-Like Structures Inspired by the Backside of Butterfly Wing Scales. ACS Appl. Mater. Interfaces 2021, 13, 19450–19459. [Google Scholar] [CrossRef] [PubMed]

- Lei, Z.H.; Sun, C.X.; Pei, P.; Wang, S.F.; Li, D.D.; Zhang, X.; Zhang, F. Stable, Wavelength-Tunable Fluorescent Dyes in the NIR-II Region for In Vivo High-Contrast Bioimaging and Multiplexed Biosensing. Angew. Chem. Int. Edit. 2019, 58, 8166–8171. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Bae, C.; Lee, J.; Lee, S.; Oh, S.H.; Kim, J.; Park, G.S.; Jung, H.S.; Shin, H. Fabrication of a Stable New Polymorph Gold Nanowire with Sixfold Rotational Symmetry. Adv. Mater. 2018, 30, 1706261. [Google Scholar] [CrossRef] [PubMed]

- Askar, K.; Gu, Z.X.; Leverant, C.J.; Wang, J.M.; Kim, C.; Jiang, B.; Jiang, P. Self-Assembled Nanoparticle Antireflection Coatings on Geometrically Complex Optical Surfaces. Opt. Lett. 2018, 43, 5238–5241. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective Coatings: A Critical, In-Depth Review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Shanmugam, N.; Pugazhendhi, R.; Elavarasan, R.M.; Kasiviswanathan, P.; Das, N. Anti-Reflective Coating Materials: A Holistic Review from PV Perspective. Energies 2020, 13, 2631. [Google Scholar] [CrossRef]

- Min, W.L.; Jiang, B.; Jiang, P. Bioinspired Self-Cleaning Antireflection Coatings. Adv. Mater. 2008, 20, 3914. [Google Scholar] [CrossRef]

- Gruzd, A.; Tokarev, A.; Tokarev, I.; Kuksenkov, D.; Minko, S. All-Nanoparticle Monolayer Broadband Antireflective and Self-Cleaning Transparent Glass Coatings. ACS Appl. Mater. Interfaces 2021, 13, 6767–6777. [Google Scholar] [CrossRef]

- Qdemat, A.; Kentzinger, E.; Buitenhuis, J.; Rucker, U.; Ganeva, M.; Bruckel, T. Self Assembled Monolayer of Silica Nanoparticles with Improved Order by Drop Casting. RSC Adv. 2020, 10, 18339–18347. [Google Scholar] [CrossRef]

- Yabu, H. Fabrication of Honeycomb Films by the Breath Figure Technique and Their Applications. Sci. Technol. Adv. Mater. 2018, 19, 802–822. [Google Scholar] [CrossRef] [Green Version]

- Preger, C.; Josefsson, M.; Westerstrom, R.; Messing, M.E. Bottom-Up Field-Directed Self-Assembly of Magnetic Nanoparticles into Ordered Nano and Macrostructures. Nanotechnology 2021, 32, 195603. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.C.; Wang, S.S.; Chen, Z.; Sun, Y.Y.; Gao, Z.F.; Zhang, H.; Zhang, J. Electric-Field-Assisted Growth of Vertical Graphene Arrays and the Application in Thermal Interface Materials. Adv. Funct. Mater. 2020, 30, 2003302. [Google Scholar] [CrossRef]

- Hu, Y.L.; Yuan, H.W.; Liu, S.L.; Ni, J.C.; Lao, Z.X.; Xin, C.; Pan, D.; Zhang, Y.Y.; Zhu, W.L.; Li, J.W.; et al. Chiral Assemblies of Laser-Printed Micropillars Directed by Asymmetrical Capillary Force. Adv. Mater. 2020, 32, 8. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.Y.; Yan, H.; Liu, Z.Q.; Wang, Z.C.; Gao, H.N.; Zhang, Z.J.; Wang, B.L.; Xu, N.; Zhang, S.Q.; Liu, X.J.; et al. Langmuir-Blodgett Self-Assembly of Ultrathin Graphene Quantum Dot Films with Modulated Optical Properties. Nanoscale 2018, 10, 19612–19620. [Google Scholar] [CrossRef]

- Chen, L.L.; Song, Z.Y. Simultaneous Realizations of Absorber and Transparent Conducting Metal in a Single Metamaterial. Opt. Express 2020, 28, 6565–6571. [Google Scholar] [CrossRef]

- Xie, S.P.; Wan, X.J.; Yang, B.; Zhang, W.; Wei, X.X.; Zhuang, S.L. Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures. Nanomaterials 2019, 9, 747. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.C.; Zhou, L.; Zhang, G.Q.; Liu, G.J.; Fan, Q.G.; Shao, J.Z. Study on the Effects of the Characteristics of Textile Substrates on the Photonic Crystal Films and the Related Structural Colors. Surf. Coat. Technol. 2017, 319, 267–276. [Google Scholar] [CrossRef]

- Narasimhan, V.; Siddique, R.H.; Lee, J.O.; Kumar, S.; Ndjamen, B.; Du, J.; Hong, N.; Sretavan, D.; Choo, H. Multifunctional Biophotonic Nanostructures Inspired by the Longtail Glasswing Butterfly for Medical Devices. Nat. Nanotechnol. 2018, 13, 512. [Google Scholar] [CrossRef] [Green Version]

- Siddique, R.H.; Gomard, G.; Holscher, H. The Role of Random Nanostructures for the Omnidirectional Anti-Reflection Properties of the Glasswing Butterfly. Nat. Commun. 2015, 6, 8. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled Growth of Monodisperse Silica Spheres in the Micron Size Range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Mehla, S.; Kandjani, A.; Coyle, V.; Harrison, C.J.; Low, M.X.; Kaner, R.B.; Sabri, Y.; Bhargava, S.K. Gold Sunflower Microelectrode Arrays with Dendritic Nanostructures on the Lateral Surfaces for Antireflection and Surface-Enhanced Raman Scattering. ACS Appl. Nano Mater. 2022, 5, 18. [Google Scholar] [CrossRef]

- Hsieh, A.H.; Corti, D.S.; Franses, E.I. Rayleigh and Rayleigh-Debye-Gans Light Scattering Intensities and Spetroturbidimetry of Dispersions of Unilamellar Vesicles and Multilamellar Liposomes. J. Colloid Interface Sci. 2020, 578, 471–483. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Sengupta, M.; Habte, A.; Andreas, A. The “Fresnel Equations” for Diffuse Radiation on Inclined Photovoltaic Surfaces (FEDIS). Renew. Sust. Energ. Rev. 2022, 161, 13. [Google Scholar] [CrossRef]

- Meng, X.; Wang, Y.; Wang, H.; Zhong, J.; Chen, R. Preparation of Hydrophobic and Abrasion-Resistant Silica Antireflective Coatings by Using a Cationic Surfactant to Regulate Surface Morphologies. Sol. Energy 2014, 101, 283–290. [Google Scholar] [CrossRef]

- Zhi, J.; Zhang, L.-Z. Durable Superhydrophobic Surface with Highly Antireflective and Self-Cleaning Properties for the Glass Covers of Solar Cells. Appl. Surf. Sci. 2018, 454, 239–248. [Google Scholar] [CrossRef]

- Bender, D.N.; Zhang, K.K.; Wang, J.D.; Liu, G.J. Hard yet Flexible Transparent Omniphobic GPOSS Coatings Modified with Perfluorinated Agents. ACS Appl. Mater. Interfaces 2021, 13, 10467–10479. [Google Scholar] [CrossRef]

- Chi, F.; Liu, D.; Wu, H.; Lei, J. Mechanically Robust and Self-Cleaning Antireflection Coatings from Nanoscale Binding of Hydrophobic Silica Nanoparticles. Sol. Energy Mater. Sol. Cells 2019, 200, 109939. [Google Scholar] [CrossRef]

- Hossain, M.I.; Aissa, B.; Samara, A.; Mansour, S.A.; Broussillou, C.A.; Benito, V.B. Hydrophilic Antireflection and Antidust Silica Coatings. ACS Omega 2021, 6, 5276–5286. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, C.-J.; Tsai, H.-P.; Chen, J.-Y.; Wu, M.-X.; Chen, Y.-J.; Lin, K.-Y.; Yang, H.-T. Single-Step Fabrication of Longtail Glasswing Butterfly-Inspired Omnidirectional Antireflective Structures. Nanomaterials 2022, 12, 1856. https://doi.org/10.3390/nano12111856

Lai C-J, Tsai H-P, Chen J-Y, Wu M-X, Chen Y-J, Lin K-Y, Yang H-T. Single-Step Fabrication of Longtail Glasswing Butterfly-Inspired Omnidirectional Antireflective Structures. Nanomaterials. 2022; 12(11):1856. https://doi.org/10.3390/nano12111856

Chicago/Turabian StyleLai, Chung-Jui, Hui-Ping Tsai, Ju-Yu Chen, Mei-Xuan Wu, You-Jie Chen, Kun-Yi Lin, and Hong-Ta Yang. 2022. "Single-Step Fabrication of Longtail Glasswing Butterfly-Inspired Omnidirectional Antireflective Structures" Nanomaterials 12, no. 11: 1856. https://doi.org/10.3390/nano12111856

_Lin.png)